Introduction: Navigating the Global Market for leather or fabric

In the dynamic landscape of global sourcing, making informed choices about leather or fabric can be a daunting challenge for B2B buyers. Whether you are sourcing high-quality upholstery for hospitality projects or selecting durable materials for manufacturing, understanding the nuances between leather and fabric is essential for successful procurement. This guide serves as a comprehensive resource, delving into various types of leather and fabric, their applications across industries, and the critical factors to consider when vetting suppliers.

By exploring aspects such as cost comparisons, durability, maintenance requirements, and aesthetic appeal, this guide empowers international B2B buyers from regions like Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil, to make strategic purchasing decisions. In an era where quality and sustainability are paramount, understanding the strengths and limitations of each material will not only enhance product offerings but also align with market demands and consumer preferences.

Equipped with actionable insights, this guide aims to streamline your sourcing process, ensuring you select the right materials that meet both your operational needs and budget constraints. Navigate the complexities of the leather and fabric markets with confidence, and discover how to leverage these materials to enhance your business’s competitive edge.

Table Of Contents

- Top 4 Leather Or Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather or fabric

- Understanding leather or fabric Types and Variations

- Key Industrial Applications of leather or fabric

- 3 Common User Pain Points for ‘leather or fabric’ & Their Solutions

- Strategic Material Selection Guide for leather or fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for leather or fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather or fabric’

- Comprehensive Cost and Pricing Analysis for leather or fabric Sourcing

- Alternatives Analysis: Comparing leather or fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for leather or fabric

- Navigating Market Dynamics and Sourcing Trends in the leather or fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather or fabric

- Strategic Sourcing Conclusion and Outlook for leather or fabric

- Important Disclaimer & Terms of Use

Understanding leather or fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains the natural grain and imperfections of the hide | High-end furniture, luxury automotive | Pros: Durable, ages beautifully. Cons: Expensive, sensitive to stains. |

| Top Grain Leather | Sanded and refinished for a smoother finish | Upholstered furniture, handbags, wallets | Pros: Good balance of quality and cost. Cons: Less durable than full grain. |

| Faux Leather | Synthetic material designed to mimic leather | Budget furniture, fashion accessories | Pros: Cost-effective, easy to clean. Cons: Less durable, may not age well. |

| Cotton Canvas | Durable, woven fabric available in various weights | Outdoor furniture, bags, and tents | Pros: Breathable, versatile. Cons: Prone to staining, requires regular maintenance. |

| Polyester Blend | Synthetic fibers mixed with natural fibers for durability | Upholstery, activewear, and home textiles | Pros: Stain-resistant, affordable. Cons: Can lack the aesthetic appeal of natural fabrics. |

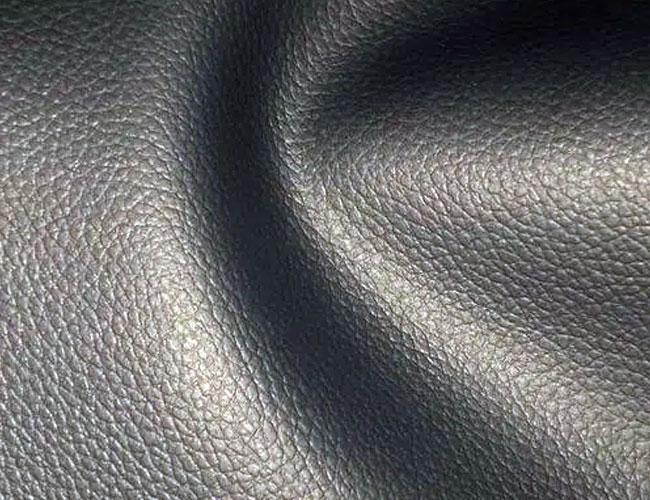

What Are the Characteristics of Full Grain Leather?

Full grain leather is the highest quality leather available, characterized by its natural grain and the absence of artificial finishes. This type of leather retains the hide’s natural texture, which can include scars and imperfections. It is highly sought after in B2B applications for luxury furniture and automotive interiors, as it offers exceptional durability and develops a rich patina over time. Buyers should consider the higher cost and the need for careful maintenance to prevent staining, but the long-term investment often pays off in terms of longevity and visual appeal.

How Does Top Grain Leather Compare to Full Grain?

Top grain leather is slightly less durable than full grain as it is sanded to remove imperfections, resulting in a smoother surface. This type is popular for upholstered furniture, handbags, and wallets due to its refined look and feel. While it offers a good balance between quality and price, buyers must be aware that it may not age as beautifully as full grain leather. It is essential for B2B buyers to evaluate their target market’s preferences for quality versus cost when considering top grain options.

What Makes Faux Leather a Viable Option?

Faux leather, made from synthetic materials, is designed to mimic the look and feel of real leather at a fraction of the cost. It is commonly used in budget-friendly furniture and fashion accessories. The primary advantages include ease of cleaning and maintenance, making it an attractive option for high-traffic environments. However, it typically lacks the durability and aging characteristics of genuine leather. B2B buyers should assess the target demographic’s expectations for quality and sustainability when selecting faux leather products.

Illustrative image related to leather or fabric

Why Choose Cotton Canvas for Outdoor Applications?

Cotton canvas is a durable, breathable fabric known for its versatility. It is often used in outdoor furniture, bags, and tents due to its robust nature and ability to withstand the elements. While cotton canvas is generally affordable, it does require regular maintenance to avoid staining and fading. B2B buyers should consider the specific use case and environment when selecting cotton canvas, ensuring it meets durability and aesthetic needs for outdoor applications.

How Do Polyester Blends Enhance Fabric Durability?

Polyester blends combine synthetic fibers with natural materials to create a durable and stain-resistant fabric suitable for upholstery, activewear, and home textiles. This blend provides an affordable option without sacrificing too much on quality. However, polyester may not offer the same aesthetic appeal as natural fabrics, which could be a consideration for buyers focused on high-end markets. When sourcing polyester blends, B2B buyers should evaluate the target audience’s preferences for texture and appearance alongside functionality.

Key Industrial Applications of leather or fabric

| Industry/Sector | Specific Application of leather or fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for seats and interiors | Enhances comfort and aesthetics, increases vehicle value | Material durability, compliance with safety standards |

| Fashion and Apparel | Clothing and accessories | Offers style and customization, appeals to consumer preferences | Sustainable sourcing, trend alignment, fabric quality |

| Furniture Manufacturing | Sofas, chairs, and upholstery | Provides durability and luxury, enhances product appeal | Cost, quality of materials, design versatility |

| Home Textiles | Curtains, cushions, and bedding | Improves aesthetics and comfort, broadens product range | Color options, fabric care requirements, market trends |

| Industrial Applications | Protective gear and workwear | Ensures safety and durability, meets industry standards | Compliance with safety regulations, material strength |

How is Leather or Fabric Used in the Automotive Industry?

In the automotive sector, leather and fabric are extensively used for upholstery in seats and interiors, significantly enhancing the comfort and aesthetic appeal of vehicles. High-quality leather provides a luxurious feel and is often associated with premium vehicles, thereby increasing resale value. Buyers from regions like Africa and South America should consider sourcing materials that comply with local safety standards and ensure durability against environmental factors, such as heat and humidity.

What Role Does Leather or Fabric Play in Fashion and Apparel?

Leather and fabric are fundamental in the fashion industry, utilized for a wide range of clothing and accessories. These materials allow for high levels of customization and can cater to various consumer preferences, from casual wear to high-end fashion. International B2B buyers need to focus on sustainable sourcing practices and the quality of the fabric to align with current market trends, especially in Europe, where eco-consciousness is rising.

Why are Leather and Fabric Essential in Furniture Manufacturing?

In furniture manufacturing, leather and fabric are crucial for producing sofas, chairs, and other upholstered items. The durability and luxury associated with leather can set a brand apart in a competitive market, while fabric offers versatility in design and color. Buyers should prioritize sourcing high-quality materials that align with the desired aesthetic and can withstand wear and tear, particularly in high-traffic areas.

How Does Leather or Fabric Enhance Home Textiles?

Leather and fabric are widely used in home textiles, including curtains, cushions, and bedding, to improve the aesthetics and comfort of living spaces. The vast array of colors and patterns available allows businesses to cater to diverse consumer tastes. For buyers, understanding fabric care requirements and current market trends is essential to ensure product longevity and customer satisfaction, particularly in European markets where design trends can shift rapidly.

What are the Industrial Applications of Leather or Fabric in Protective Gear?

In industrial applications, leather and fabric are vital for manufacturing protective gear and workwear, ensuring safety and durability in hazardous environments. These materials are designed to meet stringent industry standards, providing workers with the necessary protection against various risks. B2B buyers need to focus on compliance with safety regulations and the strength of materials used to guarantee the effectiveness of the protective gear, especially in regions with stringent labor laws.

3 Common User Pain Points for ‘leather or fabric’ & Their Solutions

Scenario 1: Navigating Cost vs. Quality in Leather and Fabric Purchases

The Problem: Many B2B buyers face the challenge of balancing cost and quality when sourcing leather or fabric materials. In regions like Africa and South America, where budget constraints are common, buyers often opt for lower-priced options that may not meet quality standards. This can lead to dissatisfaction, increased returns, and ultimately harm a business’s reputation. Additionally, the lack of clarity regarding the long-term durability of cheaper materials can create anxiety about future costs related to maintenance and replacements.

The Solution: To address this issue, B2B buyers should conduct thorough market research to understand the price ranges associated with different grades of leather and fabric. Engaging with reputable suppliers who provide transparent information about their materials is crucial. Buyers should request samples to assess quality firsthand and consider investing in higher-quality materials that may have a higher initial cost but offer better durability and lower long-term maintenance costs. Establishing relationships with suppliers that offer warranties can also provide peace of mind, ensuring that the investment is protected against premature wear and tear.

Scenario 2: Dealing with Maintenance Challenges of Leather and Fabric

The Problem: B2B buyers often struggle with the upkeep of leather and fabric products, particularly in high-traffic environments such as hotels or offices. For instance, leather may require regular conditioning to prevent cracking, while fabric can be prone to staining and allergens. This maintenance can be time-consuming and costly, leading to frustration among business owners who must balance operational efficiency with aesthetic appeal.

Illustrative image related to leather or fabric

The Solution: To mitigate maintenance challenges, buyers should prioritize sourcing materials that come with built-in protective features, such as stain-resistant finishes for fabrics or treated leathers that resist scratches. Establishing a clear maintenance protocol is essential; this could include regular cleaning schedules and utilizing appropriate cleaning products recommended by the manufacturer. Furthermore, investing in training staff on proper care techniques will ensure that both leather and fabric items remain in optimal condition, reducing the likelihood of costly repairs or replacements.

Scenario 3: Ensuring Style Versatility with Leather and Fabric Options

The Problem: B2B buyers often encounter difficulties when trying to find leather or fabric options that match their specific design needs. In diverse markets across Europe and the Middle East, buyers may struggle to find materials that align with varying cultural aesthetics or contemporary design trends. This challenge can result in missed opportunities for creating cohesive and appealing environments, impacting customer satisfaction and brand perception.

The Solution: To overcome this hurdle, buyers should consider collaborating with design consultants or interior decorators who specialize in understanding local market preferences and trends. Conducting surveys or focus groups can provide insights into desired styles and colors. Additionally, suppliers that offer a wide range of customizable options—such as color palettes, textures, and patterns—can significantly enhance the ability to create tailored solutions. By leveraging these resources, B2B buyers can ensure that their leather and fabric selections not only meet functional requirements but also resonate with the intended audience’s aesthetic preferences.

Strategic Material Selection Guide for leather or fabric

What Are the Key Properties of Common Leather and Fabric Materials?

When selecting materials for leather or fabric applications, understanding the properties and implications of each option is crucial for B2B buyers. Below, we analyze four common materials: genuine leather, faux leather, cotton fabric, and polyester fabric. Each material has distinct characteristics that influence its performance, cost, and suitability for various applications.

Genuine Leather: What Are Its Key Properties and Suitability?

Genuine leather is prized for its durability and aesthetic appeal. It is naturally breathable, which helps in maintaining a comfortable temperature, and it ages beautifully, developing a unique patina over time. However, genuine leather is sensitive to scratches and can be costly to maintain.

Pros:

– High durability and lifespan when properly cared for.

– Offers a luxurious appearance and feel, making it suitable for high-end markets.

– Hypoallergenic properties, reducing allergens in environments.

Cons:

– Higher cost compared to synthetic alternatives.

– Requires regular conditioning to prevent drying and cracking.

– Vulnerable to scratches and stains, necessitating careful use in family or pet-heavy environments.

For international buyers, understanding compliance with local standards, such as ASTM for leather quality, is essential. Regions like Africa and South America may have varying preferences for leather types based on cultural significance and climate.

Faux Leather: How Does It Compare to Genuine Leather?

Faux leather, often made from polyurethane or PVC, mimics the appearance of genuine leather but is generally more affordable. It is easier to clean and maintain, making it appealing for commercial applications.

Pros:

– Cost-effective alternative to genuine leather.

– Resistant to stains and easier to clean, ideal for high-traffic areas.

– Available in a wide range of colors and textures.

Illustrative image related to leather or fabric

Cons:

– Less durable than genuine leather and may not age as well.

– Can emit volatile organic compounds (VOCs), raising health concerns.

– Lacks the luxurious feel of genuine leather, which may be a drawback in upscale markets.

International buyers should consider environmental regulations regarding synthetic materials, especially in Europe, where compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is critical.

Cotton Fabric: What Advantages Does It Offer?

Cotton fabric is a natural fiber known for its comfort, breathability, and versatility. It is widely used in various applications, from upholstery to clothing. Cotton can be treated to enhance its durability and stain resistance.

Pros:

– Soft and comfortable, making it suitable for residential applications.

– Highly customizable in terms of color and pattern.

– Generally more affordable than leather options.

Illustrative image related to leather or fabric

Cons:

– Less durable than leather, prone to wear and tear over time.

– Can absorb moisture and stains, requiring regular cleaning.

– Susceptible to fading in direct sunlight.

For B2B buyers in regions like Africa and South America, cotton’s agricultural availability can lower costs, but buyers must also consider local market preferences for fabric types and patterns.

Polyester Fabric: What Are Its Key Characteristics?

Polyester fabric is a synthetic alternative that offers excellent durability and stain resistance. It is often blended with other fibers to enhance its properties and is commonly used in both commercial and residential applications.

Pros:

– Highly durable and resistant to wrinkles, mildew, and fading.

– Easy to clean and maintain, making it suitable for various environments.

– Cost-effective, often less expensive than cotton or leather.

Cons:

– Less breathable than natural fibers, which can affect comfort in warm climates.

– May not have the same aesthetic appeal as natural materials.

– Environmental concerns regarding the production of synthetic fibers.

International buyers should be aware of the environmental impact of polyester and consider compliance with sustainability standards, especially in European markets.

Summary Table of Material Selection for Leather or Fabric

| Material | Typical Use Case for leather or fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end furniture and accessories | Luxurious appearance and durability | High maintenance and cost | High |

| Faux Leather | Budget furniture and automotive seats | Easy to clean and maintain | Less durable than genuine leather | Med |

| Cotton Fabric | Upholstery and clothing | Soft, comfortable, and customizable | Prone to stains and wear | Low |

| Polyester Fabric | Commercial upholstery and garments | Durable and stain-resistant | Less breathable and aesthetic appeal | Low |

This table encapsulates the essential insights for B2B buyers, aiding them in making informed decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for leather or fabric

What Are the Main Stages of Leather and Fabric Manufacturing?

The manufacturing processes for leather and fabric involve several critical stages, each designed to ensure that the final product meets quality standards and consumer expectations. Understanding these stages is essential for B2B buyers who want to source reliable and durable materials.

Material Preparation: What Goes into Leather and Fabric?

-

Leather Preparation: The journey of leather begins with the selection of hides, which are typically sourced from cattle, goats, or sheep. After selection, the hides undergo a curing process to prevent decay, which can involve salting or drying. Once cured, they are soaked in water and subjected to a series of treatments, including dehairing and fleshing, to remove unwanted materials. This stage is crucial, as the quality of the raw hide directly impacts the final product.

-

Fabric Preparation: Fabric manufacturing often starts with the selection of fibers, which can be natural (like cotton or wool) or synthetic (like polyester or nylon). The fibers are spun into yarns, which are then woven or knitted into fabric. Pre-treatment processes, such as bleaching or dyeing, may also occur at this stage to enhance the fabric’s aesthetic qualities.

How Are Leather and Fabric Formed into Finished Products?

Forming Techniques: What Methods Are Commonly Used?

-

Leather Forming: Leather can be cut, stamped, or molded into various shapes and sizes. Techniques such as die-cutting are frequently used to achieve precise shapes for items like upholstery, garments, and accessories. Heat and pressure may also be applied to create textured finishes or embossed patterns.

-

Fabric Forming: The forming of fabric into finished products typically involves cutting and sewing. Advanced techniques, such as laser cutting, can create intricate designs while minimizing fabric waste. Additionally, methods like digital printing allow for high-quality imagery directly on the fabric, catering to diverse design needs.

What Steps Are Involved in the Assembly of Leather and Fabric Products?

Assembly Process: How Are Products Constructed?

The assembly stage integrates the components produced during forming. For leather products, skilled artisans may hand-stitch or machine-stitch pieces together, ensuring durability and aesthetic appeal. The assembly of fabric products often involves sewing, where seams are reinforced for strength, especially in high-wear areas.

Quality control checkpoints are crucial during assembly to ensure alignment, stitching integrity, and overall craftsmanship. This stage significantly influences the longevity and performance of the final product.

What Are the Finishing Techniques Applied to Leather and Fabric?

Finishing Processes: How Is the Final Touch Achieved?

-

Leather Finishing: After assembly, leather products often undergo finishing processes, including dyeing, conditioning, and applying protective coatings. These finishes not only enhance the visual appeal but also improve durability and resistance to environmental factors.

-

Fabric Finishing: Fabric finishing may involve treatments such as water repellency, flame retardancy, or anti-static coatings. These processes are essential for improving the fabric’s functionality and ensuring it meets specific industry requirements, particularly for sectors such as automotive or upholstery.

What Quality Assurance Standards Should B2B Buyers Consider?

International Standards: Which Certifications Are Relevant?

For B2B buyers, understanding quality assurance is critical. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Additionally, industry-specific standards like CE marking for products sold in Europe or API standards for certain industrial applications may also be relevant.

How Are Quality Control Checkpoints Established in Leather and Fabric Manufacturing?

QC Checkpoints: What Are the Key Stages?

Quality control is integrated into various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival. Buyers should verify that suppliers have robust IQC processes to ensure only high-quality materials are used.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves monitoring production to identify defects early. Regular audits and process checks can help maintain product standards.

-

Final Quality Control (FQC): Before products are shipped, FQC ensures that they meet all specifications and standards. This final check is crucial for B2B buyers, as it affects customer satisfaction and return rates.

What Testing Methods Are Commonly Used in Leather and Fabric Quality Control?

Common Testing Methods: How Are Products Evaluated?

Various testing methods are employed to evaluate the quality of leather and fabric products:

-

Physical Testing: This includes tests for tensile strength, abrasion resistance, and colorfastness. These metrics are essential for assessing how well the product will perform under normal use.

-

Chemical Testing: This may involve checking for harmful substances, especially important for textiles used in children’s products. Compliance with regulations like REACH in the EU can help assure buyers of safety.

How Can B2B Buyers Verify Supplier Quality Control?

Verification Strategies: What Should Buyers Look For?

B2B buyers can employ several strategies to verify supplier quality control:

-

Audits: Regular audits of suppliers can help ensure compliance with quality standards. Buyers should request audit reports and findings to assess supplier reliability.

-

Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of manufacturing practices and product quality. These inspections can occur at various stages of production.

-

Documentation: Requesting quality control documentation, including test reports and certifications, is essential. This documentation should be transparent and readily available from suppliers.

What Are the QC and Certification Nuances for International Buyers?

International Considerations: What Should Buyers Be Aware Of?

For buyers from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Different countries may have specific requirements for imports, and compliance with these can affect market access. Buyers should ensure that their suppliers are familiar with these nuances and can provide products that meet the necessary certifications.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for leather and fabric can empower B2B buyers to make informed decisions. By focusing on quality at every stage—from material preparation to final inspection—buyers can secure products that meet their standards and satisfy their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather or fabric’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of leather or fabric materials. As the market evolves, understanding the nuances of these materials, supplier capabilities, and regional considerations is crucial for making informed purchasing decisions. This checklist will help streamline your sourcing process, ensuring you acquire the best materials for your needs.

Step 1: Define Your Technical Specifications

Clearly outline your product requirements. Before reaching out to suppliers, it’s essential to specify the type of leather or fabric you need, including texture, durability, and aesthetic qualities. Consider factors such as the intended use, end-user preferences, and any specific industry standards that must be met.

- Material Type: Specify whether you need genuine leather, synthetic leather, or specific fabric types (e.g., cotton, polyester).

- Durability Requirements: Identify the expected lifespan and wear resistance needed for your products.

Step 2: Research Market Trends

Stay updated on industry trends and innovations. Understanding current market demands can significantly impact your sourcing decisions. Look for emerging trends in materials, such as eco-friendly options or advancements in manufacturing techniques that could provide a competitive edge.

- Sustainability: Consider sourcing from suppliers who offer sustainable or recycled materials.

- Consumer Preferences: Analyze what styles and functionalities are gaining popularity in your target markets.

Step 3: Evaluate Potential Suppliers

Conduct thorough assessments of potential suppliers. A supplier’s reliability can affect your business operations directly. Look beyond their website and request detailed company profiles, customer references, and case studies from similar industries.

Illustrative image related to leather or fabric

- Experience and Reputation: Check how long the supplier has been in business and their reputation within the industry.

- Production Capabilities: Ensure they can meet your volume requirements and lead times.

Step 4: Request Material Samples

Obtain samples of the materials you are considering. Evaluating physical samples allows you to assess quality firsthand. This step is critical to ensure the material meets your specifications and quality standards before making a bulk purchase.

- Quality Assessment: Check for consistency in color, texture, and finish.

- Durability Tests: Consider conducting tests on the samples to evaluate their resistance to wear, stains, and environmental factors.

Step 5: Verify Compliance and Certifications

Ensure suppliers adhere to industry standards and regulations. Compliance with local and international regulations is crucial, especially for industries like automotive or textiles. Verify that your suppliers have the necessary certifications.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance standards.

- Environmental Compliance: Confirm adherence to environmental regulations, especially if sourcing from regions with strict sustainability laws.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms. Once you have selected a potential supplier, it’s essential to discuss pricing, payment terms, and delivery schedules. Clear agreements can help prevent misunderstandings later on.

- Pricing Structure: Understand how pricing varies based on order volume and material type.

- Delivery Timelines: Confirm the expected delivery dates and any penalties for delays.

Step 7: Establish a Quality Control Process

Implement a robust quality control system. Once you start receiving materials, it’s vital to have a quality control process in place to ensure that the materials meet your specifications consistently.

Illustrative image related to leather or fabric

- Inspection Protocols: Define how and when inspections will occur, whether upon arrival or during production.

- Feedback Mechanism: Create a system for providing feedback to suppliers to address any issues promptly and maintain a high standard of quality.

This comprehensive checklist serves as a foundation for B2B buyers to navigate the complexities of sourcing leather and fabric materials effectively. By following these steps, you can ensure a successful procurement process that aligns with your business goals.

Comprehensive Cost and Pricing Analysis for leather or fabric Sourcing

What Are the Key Cost Components in Leather and Fabric Sourcing?

When sourcing leather or fabric for B2B applications, understanding the cost structure is crucial for making informed decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of leather or fabric significantly influences the cost. High-quality leather, such as full-grain or top-grain, typically costs more than synthetic options or lower-grade leather. Similarly, premium fabrics (e.g., organic cotton or high-thread-count textiles) can be pricier than standard options.

-

Labor: Labor costs can vary widely based on the region and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing, but this can sometimes affect quality. Skilled labor is often required for leather craftsmanship, making it a significant factor in overall costs.

-

Manufacturing Overhead: This includes costs related to facilities, equipment, utilities, and administrative expenses. Efficient production processes and advanced technologies can reduce overhead costs, thus impacting pricing.

-

Tooling: The investment in specialized tools and equipment for cutting, sewing, or finishing materials can add to the upfront costs. Custom tooling for unique designs or specifications can increase costs but may be necessary for differentiation in the market.

-

Quality Control (QC): Ensuring the quality of leather or fabric involves rigorous testing and inspection, which incurs additional costs. However, high QC standards can enhance product value and customer satisfaction, justifying the expense.

-

Logistics: Transportation costs, including shipping and handling, significantly influence the final price. International buyers must consider potential tariffs, customs fees, and the choice of shipping methods, which can vary based on urgency and destination.

-

Margin: Suppliers typically add a profit margin to cover costs and ensure profitability. Understanding the industry standard margins for leather and fabric can help buyers assess if they are receiving a fair price.

How Do Price Influencers Affect Leather and Fabric Sourcing?

Several factors can influence the pricing of leather and fabric, particularly for international B2B buyers:

Illustrative image related to leather or fabric

-

Volume/MOQ: Minimum Order Quantities (MOQs) often dictate pricing. Larger orders may lead to bulk discounts, reducing the per-unit cost.

-

Specifications and Customization: Custom designs or specifications can increase costs due to additional labor and material requirements. Buyers should weigh the benefits of customization against the increased expense.

-

Material Quality and Certifications: The presence of certifications (e.g., eco-friendly, fair trade) can influence both cost and buyer perception. High-quality materials often justify a higher price point.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge more due to their track record, while newer suppliers may offer competitive rates to gain market share.

-

Incoterms: The terms of sale (Incoterms) determine who is responsible for shipping costs, insurance, and duties. Understanding these terms can help buyers avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Leather and Fabric?

To maximize cost-efficiency, international B2B buyers should consider the following strategies:

-

Negotiation: Always engage in negotiations. Suppliers may have flexibility in pricing, especially for large orders or long-term contracts. Establishing a good relationship can lead to better terms.

-

Total Cost of Ownership (TCO): Consider not just the upfront cost but the TCO, which includes maintenance, durability, and potential resale value. Investing in higher-quality materials may reduce long-term costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, geopolitical factors, and local market conditions that can impact pricing. Establishing contracts in stable currencies can help mitigate risks.

-

Research and Compare: Conduct thorough market research and compare multiple suppliers to ensure competitive pricing. Look for reviews and testimonials to gauge reliability and quality.

Disclaimer for Indicative Prices

Prices for leather and fabric can vary significantly based on the factors mentioned above. The figures provided in this analysis are indicative and should not be considered fixed. Buyers are encouraged to obtain specific quotes based on their unique requirements and to engage in thorough discussions with potential suppliers.

Alternatives Analysis: Comparing leather or fabric With Other Solutions

In the competitive landscape of furniture materials, B2B buyers often face the challenge of choosing between leather or fabric options. However, there are alternative solutions that can provide similar aesthetic and functional benefits. This section explores these alternatives, allowing businesses to make informed decisions based on their specific requirements.

| Comparison Aspect | Leather or Fabric | Synthetic Leather | Natural Fiber Textiles |

|---|---|---|---|

| Performance | Durable, stylish, can withstand wear over time | High durability, resistant to stains and spills | Comfort and breathability, varies in durability |

| Cost | Generally higher price point, especially for leather | Typically lower cost than genuine leather | Mid-range to high, depending on fiber quality |

| Ease of Implementation | Requires careful selection and maintenance | Easy to clean and install | Installation may require special care |

| Maintenance | Needs regular conditioning and can show scratches | Low maintenance, easy to wipe clean | Requires regular cleaning, may fade over time |

| Best Use Case | Upscale settings, luxury markets | Commercial use, high-traffic areas | Eco-friendly initiatives, sustainable design projects |

What Are the Advantages of Synthetic Leather as an Alternative?

Synthetic leather, also known as faux leather or vegan leather, is a popular alternative that mimics the look and feel of genuine leather. It offers high durability and is often resistant to stains and spills, making it an ideal choice for high-traffic areas such as offices or public spaces. The lower cost compared to genuine leather makes it accessible for budget-conscious businesses. However, synthetic materials can lack the luxurious feel and longevity of genuine leather, and may not age as gracefully.

Illustrative image related to leather or fabric

How Do Natural Fiber Textiles Compare to Leather or Fabric?

Natural fiber textiles, such as cotton, linen, or wool, present an eco-friendly alternative to leather and synthetic options. These materials are known for their comfort and breathability, making them suitable for residential settings and environments where temperature regulation is crucial. While they can provide a unique aesthetic and are often biodegradable, natural fibers may require more maintenance to keep them looking their best. They can also be susceptible to fading and wear, particularly in high-traffic areas.

Conclusion: How Can B2B Buyers Select the Right Solution for Their Needs?

Choosing between leather, fabric, and alternative materials requires a careful assessment of various factors, including performance, cost, and maintenance. B2B buyers should consider the specific needs of their target market, the intended use of the furniture, and the overall design aesthetics they aim to achieve. By evaluating these aspects and understanding the pros and cons of each material, businesses can make informed decisions that align with their operational goals and customer preferences.

Essential Technical Properties and Trade Terminology for leather or fabric

What Are the Key Technical Properties of Leather and Fabric?

When selecting leather or fabric for B2B applications, understanding the essential technical properties is crucial for ensuring product quality and performance. Here are several critical specifications to consider:

1. Material Grade

Material grade refers to the quality classification of leather or fabric. For leather, grades can range from full-grain (the highest quality) to corrected grain, which may have imperfections corrected through sanding and finishing. For fabrics, grades vary based on fiber content and weave tightness. Understanding material grade is essential for B2B buyers as it directly impacts durability, aesthetics, and maintenance requirements, influencing customer satisfaction and return on investment.

2. Tolerance

Tolerance indicates the allowable variation in dimensions or properties during manufacturing. For leather, this could relate to thickness, while for fabric, it may refer to color consistency or weave density. High tolerance levels ensure that products maintain a uniform appearance and performance, which is vital for large-scale production. Buyers must consider tolerance to avoid discrepancies that could lead to product recalls or customer dissatisfaction.

3. Abrasion Resistance

Abrasion resistance measures how well a material can withstand wear and tear from friction. This property is particularly important in high-traffic environments or products like upholstery and clothing. Fabrics and leathers with high abrasion resistance will last longer, reducing replacement costs and improving customer loyalty. B2B buyers should prioritize this property when sourcing materials for durability.

4. Fire Retardancy

Fire retardancy refers to a material’s ability to resist ignition and slow the spread of flames. In many industries, including automotive and furniture, compliance with fire safety regulations is essential. Materials that meet fire retardant standards can prevent costly accidents and liabilities, making this a critical specification for B2B buyers in sectors where safety is paramount.

5. Water Resistance

Water resistance indicates how well a material can repel water or moisture. This is particularly relevant for fabrics and leathers used in outdoor applications or environments prone to spills. Understanding water resistance levels helps buyers select materials suitable for specific uses, ensuring longevity and maintaining product integrity.

What Are the Common Trade Terms Used in Leather and Fabric Industries?

Familiarity with industry jargon can streamline communication and negotiations in B2B transactions. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that are used in another company’s final product. In the leather and fabric industry, OEMs often supply specialized materials for brand-name manufacturers. Understanding OEM relationships can help buyers secure quality inputs and foster collaborations.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B buyers as it influences inventory management and cash flow. Knowing the MOQ helps in budgeting and planning for large-scale purchases, ensuring that companies do not overextend their resources.

Illustrative image related to leather or fabric

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically outlines specific requirements, including material specifications and delivery timelines. For B2B buyers, issuing an RFQ is a strategic move to compare pricing and terms from various suppliers, ensuring the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, reducing the risk of misunderstandings. B2B buyers must understand Incoterms to navigate global trade efficiently and mitigate potential legal issues.

5. Lead Time

Lead time is the time taken from placing an order to receiving the goods. It is a critical consideration for inventory management and production planning. Understanding lead times allows B2B buyers to manage their supply chain effectively, ensuring they have the materials needed when required.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ultimately enhancing their procurement strategy and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the leather or fabric Sector

What Are the Key Market Dynamics and Trends in the Leather or Fabric Sector?

The global leather and fabric market is witnessing a transformative phase, driven by evolving consumer preferences, technological advancements, and regional sourcing strategies. In regions like Africa and South America, the demand for sustainable and ethically sourced materials is surging, as consumers become more aware of environmental impacts. This trend is complemented by the rise of e-commerce platforms, which facilitate international trade and allow buyers to access a diverse range of products with ease.

Emerging technologies, such as digital supply chain management and AI-driven analytics, are reshaping sourcing practices. International B2B buyers can leverage these technologies to enhance transparency, optimize inventory management, and reduce lead times. Moreover, the integration of augmented reality (AR) in fabric selection processes is revolutionizing how buyers assess materials before procurement, particularly in the fashion and interior design sectors.

The market is also responding to the growing influence of the circular economy, promoting the recycling and upcycling of materials. This shift is especially pertinent in Europe, where regulatory frameworks are increasingly supportive of sustainable practices. Buyers from regions like the Middle East are also beginning to embrace these changes, seeking partnerships with suppliers who prioritize sustainability and innovation in their offerings.

Illustrative image related to leather or fabric

How Important Is Sustainability and Ethical Sourcing in the Leather or Fabric Sector?

Sustainability and ethical sourcing have become critical focal points in the leather and fabric industries, reflecting a broader societal shift towards environmental responsibility. The environmental impact of traditional leather tanning processes and fabric production is significant, contributing to pollution and resource depletion. Consequently, B2B buyers are prioritizing suppliers that adhere to sustainable practices, such as using eco-friendly dyes, reducing water usage, and implementing waste management strategies.

Ethical supply chains are equally crucial, as consumers and businesses increasingly demand transparency in sourcing practices. Certifications such as Global Organic Textile Standard (GOTS) for fabrics and Leather Working Group (LWG) for leather offer assurance to buyers regarding the environmental and social compliance of their suppliers. These certifications not only enhance brand reputation but also open doors to new markets that value sustainability.

Furthermore, the adoption of biodegradable and recycled materials is gaining traction. For instance, innovative alternatives such as mushroom leather and recycled polyester are emerging, providing eco-conscious options for manufacturers and designers alike. By aligning with these trends, international buyers can position themselves favorably in a competitive market while contributing to a more sustainable future.

Illustrative image related to leather or fabric

What Is the Historical Context Behind the Current Trends in Leather and Fabric Sourcing?

The leather and fabric industries have a rich history that has evolved significantly over the centuries. Initially, leather was primarily sourced from animal hides, a practice that dates back to prehistoric times. As civilizations advanced, so did the techniques for tanning and fabric production, leading to the establishment of trade routes that connected various regions.

In the 20th century, the industrial revolution brought about mass production, making leather and fabric more accessible but often at the expense of environmental and ethical considerations. The late 20th and early 21st centuries marked a turning point, as awareness of environmental issues grew, prompting a demand for sustainable practices and materials.

Today, the legacy of these historical practices informs contemporary sourcing strategies. International B2B buyers are now tasked with navigating a complex landscape where tradition meets innovation, requiring them to balance quality, sustainability, and ethical considerations in their procurement decisions. This historical context underscores the importance of adapting to current market dynamics while honoring the past.

Frequently Asked Questions (FAQs) for B2B Buyers of leather or fabric

-

How do I choose between leather and fabric for my business needs?

Choosing between leather and fabric involves evaluating your target market and the intended use of the products. Leather offers durability and a premium appearance, making it suitable for high-end markets, while fabric provides a wider range of colors and patterns, appealing to budget-conscious consumers. Consider factors such as comfort, maintenance, and the specific needs of your clientele. Conduct market research to understand preferences in your region, and assess the longevity and care requirements of each material in relation to your business model. -

What are the most important quality indicators for sourcing leather or fabric?

When sourcing leather or fabric, key quality indicators include material grade, weave density, and finish type. For leather, look for full-grain or top-grain varieties, as they offer superior durability and aesthetic appeal. For fabric, consider the fiber content—natural fibers like cotton and wool tend to be more breathable and comfortable than synthetic options. Additionally, check for certifications like OEKO-TEX for safety and environmental standards, and request samples to evaluate texture and durability firsthand. -

What is the minimum order quantity (MOQ) I should expect when sourcing leather or fabric?

MOQs can vary significantly depending on the supplier and the type of material. Generally, for leather, MOQs can range from 50 to 500 square meters, while fabric may have lower MOQs, often starting at 100 meters. It is advisable to negotiate with suppliers to find a balance that meets your inventory needs without overcommitting financially. Be mindful that lower MOQs may come at a higher price per unit, impacting overall cost-effectiveness. -

How can I ensure the supplier I choose is reliable and reputable?

To vet suppliers effectively, start by checking their business credentials, including registration and industry certifications. Request references from previous clients and review their track record in terms of delivery timelines and product quality. Conduct site visits if possible, or utilize third-party inspection services to assess their manufacturing processes. Additionally, consider engaging with trade organizations or industry fairs to connect with reputable suppliers known for their reliability and quality. -

What payment terms are typical in international trade for leather and fabric?

Payment terms can vary widely, but common practices include letters of credit, advance payments, or payment upon delivery. For new relationships, suppliers may request a partial upfront payment (30-50%) with the balance due upon shipment or receipt. Always clarify payment methods, currency, and any potential fees associated with international transactions. Protect your interests by drafting a clear contract that outlines payment schedules, penalties for late payments, and conditions for dispute resolution. -

What logistics considerations should I take into account when importing leather or fabric?

Logistics plays a crucial role in the successful importation of leather or fabric. Key considerations include shipping methods (air vs. sea), customs regulations, and potential tariffs. Work with a freight forwarder who understands the intricacies of your destination country’s import laws. Ensure that you have all necessary documentation, including invoices, packing lists, and certificates of origin. Additionally, factor in lead times for shipping and customs clearance to avoid delays in your supply chain. -

How can I customize leather or fabric products for my brand?

Customization options vary by supplier but often include choices in color, pattern, and texture. Discuss specific design requirements with your supplier, such as branding elements like logos or unique finishes. Some suppliers may offer digital mock-ups or prototypes before full production, allowing you to visualize the final product. Be clear about your branding strategy and ensure that the customization aligns with your market positioning and customer expectations. -

What quality assurance measures should I implement when sourcing leather or fabric?

Implementing quality assurance (QA) measures is essential for maintaining product consistency. Establish clear quality standards and communicate these to your suppliers. Conduct regular inspections during production and before shipment to identify any defects. Consider third-party QA services for impartial evaluations. Additionally, develop a return policy for defective items to safeguard your business interests and maintain strong supplier relationships. Regularly review and adjust your QA protocols based on feedback and market trends.

Top 4 Leather Or Fabric Manufacturers & Suppliers List

1. The Spruce – Fabric vs. Leather Sofas

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: The article discusses the benefits and drawbacks of fabric and leather sofas, highlighting key considerations such as durability, care requirements, appearance, comfort, and cost. Fabric sofas are generally more comfortable, available in a wider range of colors and patterns, and often more affordable than leather. However, they can sag, stain, and require regular cleaning. Leather sofas offer eleg…

2. Reddit – Leather vs. Fabric Sofas: Key Drawbacks

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Drawbacks of leather over fabric sofa include: 1. Leather can feel cold on bare skin and sticky when getting up, making it uncomfortable in warmer climates. 2. Leather is more expensive than fabric, making it costlier to replace or recover. 3. Pets, such as cats, can damage leather easily. 4. Fashion and needs may change, leading to a desire to replace leather furniture sooner than it wears out. 5…

3. Article – Leather vs. Fabric Furniture

Domain: article.com

Registered: 1995 (30 years)

Introduction: Leather vs. Fabric Furniture: Choosing a sofa material involves considering lifestyle, budget, and maintenance. Quality materials are crucial for durability. Fabric options include linen, cotton, and wool, with blends offering breathability and easy maintenance. High-quality fabric sofas should withstand at least 25,000 Martindale rubs; Article sofas can withstand up to 100,000 rubs. Leather optio…

4. StayHomeBody – Leather vs Fabric Sofas Guide

Domain: stayhomebody.com

Registered: 2022 (3 years)

Introduction: Leather vs Fabric Sofas Comparison Guide:

**Fabric Sofas:**

– **Comfort:** Immediately soft and warm.

– **Durability:** Durable with high-quality material; stain-resistant options available.

– **Maintenance:** Needs regular cleaning.

– **Allergies:** Can collect dust and pet hair; needs frequent vacuuming.

– **Climate Response:** Consistent comfort in any temperature; no sticking in he…

Strategic Sourcing Conclusion and Outlook for leather or fabric

What Are the Key Takeaways for B2B Buyers in Sourcing Leather or Fabric?

In the competitive landscape of leather and fabric sourcing, understanding the unique benefits and challenges of each material is crucial for international B2B buyers. Leather offers durability and a timeless aesthetic, making it suitable for high-end applications, while fabric provides versatility and comfort at a more accessible price point. Buyers should prioritize quality and suitability for their target market, considering factors such as durability, care requirements, and design preferences.

How Can Strategic Sourcing Enhance Your Supply Chain?

Strategic sourcing enables businesses to establish long-term relationships with suppliers, ensuring consistency in quality and pricing. By leveraging market insights and understanding regional trends, buyers can optimize their sourcing strategies to meet local demands effectively. This proactive approach not only mitigates risks but also enhances competitive advantage in diverse markets, including Africa, South America, the Middle East, and Europe.

Illustrative image related to leather or fabric

What Is the Future Outlook for Leather and Fabric Sourcing?

As consumer preferences evolve, the demand for sustainable and ethically sourced materials is set to rise. Buyers should stay ahead of these trends by seeking suppliers committed to environmentally friendly practices. Embrace innovation and adaptability in your sourcing strategies to capitalize on emerging opportunities. Connect with reliable partners today to ensure your business remains at the forefront of the leather and fabric industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to leather or fabric

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.