Introduction: Navigating the Global Market for swede leather

In the intricate world of leather sourcing, finding high-quality swede leather can be a daunting challenge for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. With the growing demand for sustainable and ethically sourced materials, navigating this market requires a keen understanding of the diverse offerings, from luxurious Italian swede to more economical options. This guide aims to demystify the complexities associated with sourcing swede leather, addressing critical aspects such as types, applications, supplier vetting processes, and cost considerations.

By providing a comprehensive overview, this resource empowers buyers to make informed purchasing decisions that align with their business needs and market demands. Whether you are looking to procure swede leather for high-end fashion products, durable upholstery, or innovative footwear designs, understanding the nuances of the market is essential. The insights contained within this guide will not only streamline your sourcing process but also enhance your ability to negotiate with suppliers, ensuring you secure the best materials at competitive prices. As we delve deeper into the world of swede leather, you will gain the tools necessary to navigate this global market effectively, ultimately positioning your business for success.

Table Of Contents

- Top 7 Swede Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for swede leather

- Understanding swede leather Types and Variations

- Key Industrial Applications of swede leather

- 3 Common User Pain Points for ‘swede leather’ & Their Solutions

- Strategic Material Selection Guide for swede leather

- In-depth Look: Manufacturing Processes and Quality Assurance for swede leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘swede leather’

- Comprehensive Cost and Pricing Analysis for swede leather Sourcing

- Alternatives Analysis: Comparing swede leather With Other Solutions

- Essential Technical Properties and Trade Terminology for swede leather

- Navigating Market Dynamics and Sourcing Trends in the swede leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of swede leather

- Strategic Sourcing Conclusion and Outlook for swede leather

- Important Disclaimer & Terms of Use

Understanding swede leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Italian Suede | Soft, silky texture, vibrant colors, premium aniline dyes | Luxury fashion, accessories, upholstery | Pros: High quality, aesthetic appeal. Cons: Higher cost, may require special care. |

| Nubuck | Velvety surface, sanded from the outer side of the hide | Footwear, jackets, furniture upholstery | Pros: Durable, water-resistant. Cons: Can stain easily, requires maintenance. |

| Pigmented Suede | Coated with pigment for color uniformity, durable finish | Mass-market fashion, bags, casual wear | Pros: Cost-effective, easy to clean. Cons: Less luxurious feel than natural suede. |

| Deerskin Suede | Unique softness, natural elasticity, lightweight | High-end garments, gloves, specialty items | Pros: Exceptional comfort, flexible. Cons: Limited availability, higher price point. |

| Calfskin Suede | Fine grain, soft texture, often used for luxury items | Premium bags, wallets, high-fashion apparel | Pros: Soft yet durable, ideal for luxury brands. Cons: More expensive, sensitive to moisture. |

What are the Characteristics of Italian Suede?

Italian suede is renowned for its luxurious feel and vibrant color options, making it a preferred choice for high-end fashion and accessories. Tanned with premium aniline dyes, it offers a rich, even color throughout the hide. B2B buyers should consider the quality assurance that comes with sourcing from reputable Italian tanneries, ensuring a product that meets luxury standards. However, the higher price point and the need for careful maintenance to preserve its quality are important factors to weigh.

How Does Nubuck Differ from Other Types of Suede?

Nubuck is distinguished by its velvety surface, achieved by sanding the outer side of the hide. This process not only enhances its aesthetic appeal but also contributes to its durability, making it suitable for a variety of applications, including footwear and jackets. For B2B buyers, the water-resistant properties of nubuck can be a selling point, especially in regions with varied climates. However, it is essential to advise customers about potential staining and the need for appropriate care products.

What Advantages Does Pigmented Suede Offer?

Pigmented suede is created by applying a coating of pigment to achieve color uniformity and enhance durability. This variation is particularly popular in mass-market fashion and casual wear, appealing to budget-conscious buyers. B2B companies can leverage its cost-effectiveness and ease of cleaning as key selling points. However, it is crucial to communicate that pigmented suede may lack the luxurious feel of natural suede, which could impact customer satisfaction in premium markets.

Why Choose Deerskin Suede for Specialty Products?

Deerskin suede is celebrated for its unique softness and natural elasticity, making it ideal for high-end garments and specialty items like gloves. This type of suede is lightweight and comfortable, appealing to consumers looking for luxury without sacrificing functionality. B2B buyers should consider the limited availability and higher price point of deerskin suede, which may affect inventory decisions. However, its exceptional comfort can justify the investment for premium product lines.

What Makes Calfskin Suede a Preferred Choice for Luxury Brands?

Calfskin suede is characterized by its fine grain and soft texture, often used in premium bags and high-fashion apparel. Its combination of softness and durability makes it a favorite among luxury brands. B2B buyers should recognize that while calfskin suede commands a higher price, its appeal in the luxury market can lead to higher profit margins. Additionally, awareness of its sensitivity to moisture and the need for proper care is crucial for maintaining product quality.

Key Industrial Applications of swede leather

| Industry/Sector | Specific Application of swede leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Suede jackets and accessories | Provides a soft, luxurious feel that enhances product appeal | Sourcing from reputable tanneries to ensure consistent quality and color |

| Footwear | Casual shoes and boots | Offers comfort and a unique aesthetic, appealing to fashion-forward consumers | Ensure availability of various colors and finishes to meet market trends |

| Upholstery & Interiors | Soft furnishings and decorative upholstery | Adds a touch of elegance and warmth to interior designs | Consider durability and maintenance requirements for long-lasting use |

| Automotive | Interior trims and seating | Enhances luxury feel while providing comfort to passengers | Focus on sourcing durable suede that meets automotive safety standards |

| Leather Goods | Bags, wallets, and belts | Combines style with functionality, appealing to diverse markets | Evaluate weight, thickness, and finish to ensure versatility in products |

How is Suede Leather Used in Fashion and Apparel?

In the fashion industry, suede leather is primarily used for crafting jackets and accessories. Its soft texture and rich appearance cater to consumers looking for stylish yet comfortable apparel. International B2B buyers must consider sourcing from established tanneries that offer consistent quality, as variations in texture and color can impact the final product’s appeal. Additionally, buyers should be aware of the latest fashion trends to ensure their products resonate with target markets, particularly in regions like Europe and South America, where fashion sensibilities differ.

What Role Does Suede Play in Footwear Manufacturing?

Suede leather is widely used in the footwear industry for making casual shoes and boots. Its unique texture provides a level of comfort that synthetic materials often fail to replicate. For B2B buyers, it is essential to source suede that not only meets aesthetic demands but also aligns with consumer preferences for durability and ease of maintenance. Buyers should also consider the environmental impact of their sourcing practices, as sustainability is increasingly becoming a key factor in consumer purchasing decisions across Africa and the Middle East.

Why is Suede Important for Upholstery and Interior Design?

In the upholstery sector, suede leather is favored for its ability to add a luxurious touch to soft furnishings and decorative upholstery. It enhances the aesthetic appeal of sofas and cushions, making them desirable for high-end interior designs. B2B buyers in this industry should prioritize sourcing suede that meets durability standards, as well as ease of cleaning, to ensure long-lasting customer satisfaction. Understanding regional preferences for colors and textures can also help businesses tailor their offerings to specific markets, such as in Nigeria or Brazil.

How is Suede Used in the Automotive Industry?

Suede leather plays a significant role in the automotive sector, particularly for interior trims and seating. It elevates the luxury feel of vehicles while providing comfort to passengers. B2B buyers should focus on sourcing high-quality suede that complies with automotive safety standards and is resistant to wear and tear. Additionally, understanding the specific requirements for different vehicle models can aid in effective sourcing, especially for international markets where preferences for interior finishes may vary.

What are the Applications of Suede in Leather Goods?

In the realm of leather goods, suede is commonly used for crafting bags, wallets, and belts. It combines style with functionality, appealing to a wide range of consumers. For international B2B buyers, key considerations include the weight, thickness, and finish of the suede to ensure versatility across different product lines. Additionally, staying informed about market trends and consumer preferences can help businesses make strategic sourcing decisions that align with demand in various regions, from Europe to South America.

3 Common User Pain Points for ‘swede leather’ & Their Solutions

Scenario 1: Sourcing Quality Suede Leather for Production Needs

The Problem: B2B buyers often struggle with identifying reliable suppliers of high-quality suede leather. The market is flooded with options, but many suppliers do not meet the specific quality standards required for luxury goods. For instance, a company in Nigeria looking to produce premium handbags may find that the suede they receive is subpar, leading to increased return rates and damaged brand reputation. This inconsistency can create significant financial losses and operational disruptions.

The Solution: To ensure the procurement of quality suede leather, buyers should establish relationships with reputable tanneries known for their craftsmanship. Researching and requesting samples from suppliers can help assess the texture, color consistency, and durability of the suede. Additionally, buyers should inquire about the tanning processes used, as premium aniline dyes and thorough finishing techniques are critical for producing high-quality suede. Building long-term partnerships with trusted suppliers in regions renowned for leather production, such as Italy or France, can also provide more reliable sourcing options. Lastly, implementing a robust quality control process upon receiving materials can prevent issues before they impact production.

Illustrative image related to swede leather

Scenario 2: Addressing Suede Leather’s Care and Maintenance Challenges

The Problem: Suede leather, while aesthetically appealing, presents unique maintenance challenges that can deter buyers from investing in it. For instance, a company in Brazil producing suede footwear may encounter issues with stains and water damage, which can lead to dissatisfied customers and high rates of returns. The delicate nature of suede requires specific care techniques that many manufacturers are unfamiliar with, resulting in products that quickly deteriorate.

The Solution: Educating manufacturers on proper suede care is essential. Providing them with detailed care instructions and recommending specialized cleaning products can help maintain the integrity of suede items. Businesses should consider including care kits with their products, which may consist of brushes, protective sprays, and stain removers specifically designed for suede. Training employees on the best practices for cleaning and maintaining suede can also empower them to handle customer inquiries effectively. Additionally, creating informative content such as videos or guides can enhance customer knowledge and satisfaction, ultimately leading to a stronger brand reputation.

Scenario 3: Navigating Design Limitations with Suede Leather

The Problem: Designers often face challenges when incorporating suede leather into their products due to its unique characteristics. For example, a clothing brand in the Middle East may want to create a line of suede jackets but finds that the material’s softness limits its structural integrity, leading to garments that do not hold their shape. This can be particularly problematic for items requiring a tailored fit, where durability is essential.

Illustrative image related to swede leather

The Solution: To effectively utilize suede in design, buyers should explore innovative methods of construction that enhance the material’s strength. Combining suede with other textiles or using strategic layering techniques can provide the necessary structure while maintaining the desired aesthetic. Additionally, understanding the weight and thickness of various suede hides can help designers select the right material for specific applications. Collaborating with experienced pattern makers who specialize in leather can also lead to designs that maximize the benefits of suede while minimizing its limitations. By embracing creativity and technical expertise, companies can produce unique, high-quality suede products that resonate with their target market.

Strategic Material Selection Guide for swede leather

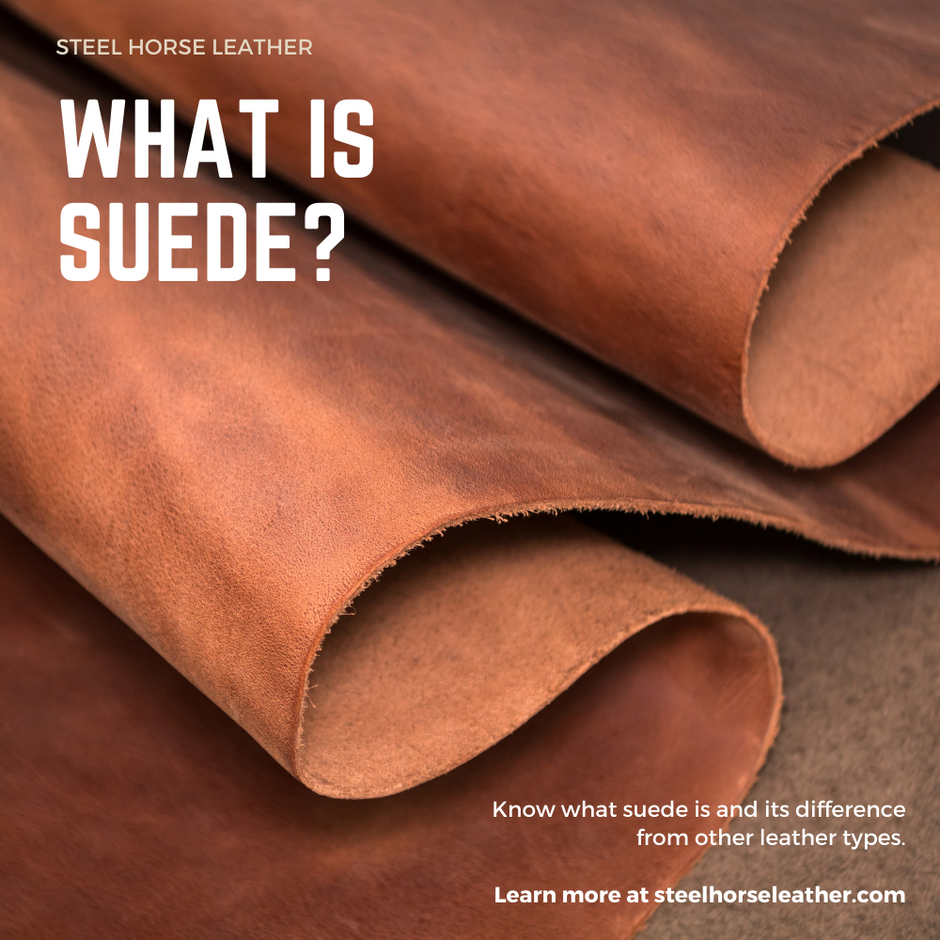

What Are the Key Materials Used in Swede Leather Production?

Swede leather, known for its soft texture and luxurious feel, is typically derived from various animal hides. Each material offers unique properties and considerations that can significantly affect product performance and suitability for specific applications. Here, we analyze four common materials used in the production of swede leather, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Cowhide in Swede Leather?

Cowhide is the most prevalent material used for swede leather due to its availability and versatility. It possesses a strong fiber structure that provides good durability and resistance to wear. The temperature and pressure ratings are generally favorable, making cowhide suitable for various applications, including upholstery and fashion accessories.

Pros: Cowhide is relatively cost-effective and easy to source. Its robust nature makes it ideal for products that require longevity, such as bags and jackets.

Cons: While durable, cowhide can be heavier than other materials, which may not be suitable for lightweight applications. Additionally, it may require more complex manufacturing processes to achieve the desired finish.

Impact on Application: Cowhide swede leather is compatible with dyeing and finishing processes, allowing for a wide range of colors and textures. However, buyers should consider the environmental impact of tanning processes.

How Does Sheepskin Compare as a Material for Swede Leather?

Sheepskin is another popular choice for swede leather, known for its softness and lightweight characteristics. It offers a unique texture that enhances comfort, making it ideal for clothing and accessories.

Pros: The softness of sheepskin provides a luxurious feel, making it suitable for high-end fashion items. It is also lighter than cowhide, which can be advantageous for certain applications.

Cons: Sheepskin is less durable than cowhide and may not withstand heavy wear and tear. It is also generally more expensive, which could affect pricing strategies for B2B buyers.

Impact on Application: Sheepskin swede leather is often used in garments and soft furnishings. Buyers should be aware of the need for more careful maintenance to prolong the lifespan of products made from this material.

Illustrative image related to swede leather

What Advantages Do Goatskin and Calfskin Offer in Swede Leather?

Goatskin and calfskin are premium materials that provide unique benefits for swede leather applications. Goatskin is known for its flexibility and strength, while calfskin is prized for its fine grain and softness.

Pros: Both materials offer a high-quality finish and are well-suited for luxury items. Goatskin is particularly resistant to stretching, making it ideal for products that require a snug fit, such as gloves and shoes.

Cons: The cost of goatskin and calfskin is generally higher than cowhide, which may limit their use in budget-sensitive markets. Additionally, the sourcing of these materials can be more complex due to lower availability.

Impact on Application: Goatskin and calfskin swede leather are often used in high-end fashion and accessories. B2B buyers should consider compliance with international standards, as these materials may be subject to stricter regulations regarding sourcing and treatment.

Illustrative image related to swede leather

What Should International B2B Buyers Consider When Selecting Swede Leather Materials?

When sourcing swede leather, international buyers, particularly from Africa, South America, the Middle East, and Europe, should consider compliance with local and international standards such as ASTM, DIN, and JIS. Preferences for sustainability and ethical sourcing are increasingly important in these regions. Additionally, understanding the specific market demands and cultural preferences can aid in making informed decisions about material selection.

| Material | Typical Use Case for swede leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Bags, jackets, upholstery | Durable and cost-effective | Heavier and complex manufacturing | Medium |

| Sheepskin | Clothing, soft furnishings | Luxurious feel and lightweight | Less durable and higher cost | High |

| Goatskin | Gloves, shoes | Flexible and resistant to stretching | Higher cost and complex sourcing | High |

| Calfskin | Luxury fashion items | Fine grain and softness | Limited availability and higher cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for swede leather

What Are the Key Stages in the Manufacturing Process of Swede Leather?

The manufacturing of swede leather involves several critical stages that ensure the final product meets the desired quality and aesthetic standards. Understanding these stages is essential for B2B buyers looking to source high-quality suede for their products.

Material Preparation: How Is Suede Leather Initially Processed?

The manufacturing process begins with the selection and preparation of raw hides, typically sourced from cattle. The hides are first cleaned and treated to remove any impurities. This stage is crucial as it sets the foundation for the leather’s quality.

After cleaning, the hides undergo tanning, which is the process of converting raw animal hides into leather. For swede leather, chrome tanning is commonly used due to its efficiency and ability to produce soft, supple leather. The tanning process can take several weeks, during which the hides are soaked in tanning solutions.

Illustrative image related to swede leather

Once tanned, the hides are split to separate the grain layer from the flesh side, which is the part used to create suede. The flesh side is then subjected to a sanding process to create the characteristic soft, napped finish of suede.

What Techniques Are Used in Forming and Assembling Suede Leather Products?

After material preparation, the next step involves forming and assembling the suede into various products. This stage includes cutting the leather into required shapes and sizes, which is often done using precision cutting tools to minimize waste.

Sewing techniques play a significant role in assembling suede products. Industrial sewing machines equipped with specialized needles and threads are used to stitch pieces together. The choice of thread is crucial, as it must complement the softness of the suede while providing durability.

Illustrative image related to swede leather

Additionally, edge finishing techniques, such as burnishing or painting, may be applied to enhance the product’s aesthetic appeal and prevent fraying. This attention to detail is vital for B2B buyers seeking high-quality suede products that meet their branding standards.

How Is the Finishing Process Conducted for Swede Leather?

The finishing process is where the suede leather truly comes to life. This stage involves applying various treatments and finishes to enhance the leather’s appearance and performance.

Common finishing techniques include dyeing, which can be done using aniline dyes that penetrate deeply into the leather, ensuring a rich color that lasts. After dyeing, the suede is often brushed to lift the nap and create a velvety texture.

Water and stain repellents may also be applied during this stage to enhance the leather’s durability and functionality. The final finishing touches include quality checks to ensure that the suede meets specified standards before it is packaged for distribution.

What Quality Assurance Measures Are Essential for Swede Leather?

Quality assurance is a critical component of the manufacturing process for swede leather. B2B buyers should look for suppliers that adhere to international standards, such as ISO 9001, which outlines requirements for a quality management system.

How Are Quality Control Checkpoints Structured?

Quality control in the manufacturing of suede leather typically includes several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials as they arrive. Buyers should verify that the hides meet their quality specifications and are free from defects.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that the processes adhere to established standards. This can include checking the consistency of tanning and the quality of cuts.

-

Final Quality Control (FQC): Before products are shipped, a final inspection is performed to assess the overall quality of the finished suede. This includes checking for defects, color consistency, and adherence to customer specifications.

What Testing Methods Are Commonly Used for Swede Leather?

Various testing methods are employed to assess the quality and durability of suede leather. Common tests include:

- Abrasion Resistance Testing: Evaluates how well the leather withstands wear and tear, which is crucial for products like bags and footwear.

- Water Resistance Testing: Determines the leather’s ability to repel water, ensuring that it meets the functional requirements of the end product.

- Color Fastness Testing: Checks how well the color holds up against light and washing, which is essential for maintaining the product’s appearance over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying supplier quality control practices is essential to ensure consistent product quality. Here are several methods to achieve this:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s processes, equipment, and quality control measures firsthand. This is particularly important for international buyers who may not be familiar with local practices.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can provide insights into their testing methods, results, and adherence to international standards.

-

Third-Party Inspections: Engaging a third-party inspection service can offer an unbiased assessment of the manufacturing process and final products, ensuring that they meet the required specifications.

What Are the Nuances of Quality Certification for International Buyers?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality certification:

Illustrative image related to swede leather

-

Regional Standards: Different regions may have varying standards for leather quality. Buyers should familiarize themselves with local regulations and certifications that may be required for their target markets.

-

Cultural Considerations: Understanding cultural preferences regarding leather quality and aesthetics can also influence purchasing decisions. For example, certain markets may prioritize specific textures or colors.

-

Supply Chain Transparency: Buyers should seek suppliers that maintain transparent supply chains, as this not only fosters trust but also ensures compliance with ethical sourcing practices.

By understanding the manufacturing processes and quality assurance measures involved in swede leather production, B2B buyers can make informed decisions that align with their business needs and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘swede leather’

To assist B2B buyers in successfully procuring swede leather, this practical sourcing guide provides a step-by-step checklist to ensure a thorough and effective purchasing process. Swede leather, known for its unique texture and aesthetic appeal, is increasingly popular across various industries, including fashion, upholstery, and accessories. This guide outlines essential steps to help you make informed decisions and secure quality materials.

Step 1: Define Your Technical Specifications

Establishing clear specifications for the swede leather you need is vital. Consider factors such as thickness, color, finish, and intended application. For instance, if you require leather for high-end fashion items, focus on premium grades with a soft, velvety touch. Documenting these requirements will streamline communication with potential suppliers.

Step 2: Research and Identify Reliable Suppliers

Conduct comprehensive research to identify suppliers who specialize in swede leather. Look for companies with a strong reputation in the industry and positive reviews from previous clients. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers. This foundational step is critical to ensuring you partner with reputable sources.

Step 3: Evaluate Potential Suppliers

Before making any commitments, vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. It’s crucial to assess their production capabilities, quality control processes, and experience in supplying swede leather. This evaluation helps mitigate risks associated with quality and delivery.

Step 4: Request Samples for Quality Assessment

Always request samples of the swede leather before placing a bulk order. This allows you to evaluate the texture, color accuracy, and overall quality firsthand. Pay attention to details such as softness, durability, and how well the leather meets your specifications. Testing samples can save you from costly mistakes down the line.

Step 5: Verify Compliance with Industry Standards

Ensure that the suppliers comply with relevant industry standards and certifications. This may include environmental regulations, ethical sourcing practices, and quality certifications such as ISO. Verify that the swede leather is tanned using safe and sustainable processes, as this is increasingly important to consumers and businesses alike.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clearly outline your expectations and ensure that all terms are documented in a contract. This step is crucial to prevent misunderstandings and ensure a smooth transaction.

Illustrative image related to swede leather

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics of transporting the swede leather from the supplier to your location. Assess shipping options, potential tariffs, and lead times. Establishing a clear logistics plan will help avoid delays and ensure that your supply chain remains efficient.

By following this checklist, B2B buyers can navigate the complexities of sourcing swede leather, ensuring they secure high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for swede leather Sourcing

What Are the Key Cost Components in Swede Leather Sourcing?

When sourcing swede leather, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of the raw hides used significantly affects the price. High-quality hides, such as those sourced from reputable tanneries in Italy or France, will command a higher price. Additionally, suede is derived from the flesh side of the hide, and the thickness and texture can influence costs.

-

Labor: Skilled labor is required to process and finish swede leather. Tanning, dyeing, and finishing processes involve specialized knowledge and craftsmanship, which can vary by region and impact overall labor costs.

-

Manufacturing Overhead: This includes the costs associated with running a production facility, such as utilities, maintenance, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Tooling: The costs associated with the tools and machinery necessary for cutting, shaping, and finishing the leather can also add to the overall expenses. Advanced tooling can enhance productivity but may require a higher initial investment.

-

Quality Control (QC): Ensuring that the leather meets specific quality standards incurs additional costs. This can include testing for durability, color consistency, and texture, which are critical for maintaining customer satisfaction.

-

Logistics: Shipping and handling costs can vary significantly based on the origin of the leather and the destination market. International logistics can introduce complexities and expenses related to customs, duties, and transportation.

-

Margin: Suppliers will typically include a profit margin in their pricing. This can vary depending on market conditions, competition, and the uniqueness of the product offered.

What Factors Influence Pricing for Swede Leather?

Several factors can influence the pricing of swede leather:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts, while smaller orders may incur higher per-unit costs. Negotiating favorable terms based on anticipated future orders can lead to cost savings.

-

Specifications and Customization: Customized products or specific color requests can increase costs. Buyers should be clear about their needs to avoid unexpected charges.

-

Materials and Quality Certifications: The presence of certifications (e.g., eco-friendly tanning processes) can add value but also increase the price. Buyers should consider the long-term benefits of sourcing certified materials.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their assurance of quality and timely delivery.

-

Incoterms: The chosen Incoterms can significantly impact the total landed cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift responsibilities and costs between the buyer and seller.

What Are Effective Tips for Negotiating Swede Leather Prices?

B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider the following tips when negotiating prices for swede leather:

Illustrative image related to swede leather

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with sourcing, including maintenance, potential waste, and resale value. A lower upfront cost might lead to higher overall expenses.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often result in preferential treatment and lower costs.

-

Leverage Market Knowledge: Stay informed about market trends, pricing fluctuations, and competitor offerings. This knowledge can empower buyers during negotiations.

-

Be Open to Flexibility: If a supplier cannot meet a desired price, consider negotiating other aspects of the deal, such as payment terms or delivery schedules, which can provide value without altering the price.

-

Request Samples: Before committing to large orders, request samples to assess quality. This can help avoid costly mistakes and ensure the product meets expectations.

What Should B2B Buyers Keep in Mind About Pricing Nuances?

Pricing for swede leather can vary widely based on regional market conditions and supplier capabilities. International buyers should be mindful of currency fluctuations and economic factors in both the supplier’s and buyer’s countries. Understanding local market dynamics will facilitate more informed purchasing decisions and potentially uncover more cost-effective sourcing options.

Disclaimer: Prices for swede leather can fluctuate based on market conditions and specific buyer requirements. Always seek updated quotes and confirm pricing with suppliers.

Alternatives Analysis: Comparing swede leather With Other Solutions

In the competitive landscape of leather products, B2B buyers often seek alternatives to swede leather that can meet their specific needs in terms of performance, cost, and usability. Understanding the strengths and weaknesses of various materials can empower buyers to make informed decisions that align with their business objectives.

| Comparison Aspect | Swede Leather | Full Grain Leather | Synthetic Leather |

|---|---|---|---|

| Performance | Soft texture, less durable | Highly durable, retains shape | Varies widely, generally less durable than leather |

| Cost | Moderate price | Higher price | Lower price, budget-friendly |

| Ease of Implementation | Requires special care | Easy to work with | Simple to manufacture |

| Maintenance | Needs regular cleaning and care | Durable, less frequent maintenance | Low maintenance, easy to clean |

| Best Use Case | Casual wear, upholstery | High-end fashion, durable goods | Budget-friendly products, fashion replicas |

What are the Advantages and Disadvantages of Full Grain Leather Compared to Swede Leather?

Full grain leather is renowned for its durability and ability to age beautifully. It is made from the top layer of the hide, retaining its natural grain and strength. This makes it ideal for products requiring structural integrity, such as high-end handbags and jackets. However, it comes at a higher price point, which may not be feasible for every business. While full grain leather requires minimal maintenance, it can be less forgiving in terms of scratches and blemishes compared to the soft texture of swede leather.

How Does Synthetic Leather Stack Up Against Swede Leather?

Synthetic leather offers a budget-friendly alternative to swede leather, often appealing to businesses looking to reduce costs. It is available in a wide variety of textures and colors, making it highly versatile for fashion and upholstery applications. Moreover, synthetic options are generally easier to clean and maintain. However, they may lack the luxurious feel and breathability of genuine leather. Durability can also vary significantly between synthetic products, making it essential for buyers to vet their suppliers carefully.

Illustrative image related to swede leather

Conclusion: How Can B2B Buyers Choose the Right Leather Solution?

Selecting the right leather solution involves assessing the specific needs of your products and your target market. For businesses focused on high-end, durable items, full grain leather may be the optimal choice despite its higher cost. Alternatively, if budget constraints are a priority, synthetic leather can provide a viable solution, especially for fashion-forward products. Swede leather serves well in casual applications, offering a unique texture and softness. Ultimately, understanding the trade-offs between these options will enable B2B buyers to choose the most appropriate material that aligns with their brand and customer expectations.

Essential Technical Properties and Trade Terminology for swede leather

What Are the Key Technical Properties of Swede Leather?

Swede leather, known for its soft texture and versatility, is an excellent choice for various applications in the fashion and furniture industries. Understanding its technical properties is essential for B2B buyers to ensure they are making informed purchasing decisions. Below are some critical specifications associated with swede leather:

-

Material Grade

Material grade refers to the quality classification of the leather, which can impact its appearance, durability, and cost. Swede leather is typically categorized into different grades based on the quality of the raw hide and the tanning process. Higher-grade swede leather offers superior softness and resistance to wear, making it ideal for high-end products like luxury bags and jackets. -

Thickness

The thickness of swede leather is measured in millimeters (mm) and can significantly influence its application. Standard thickness for swede leather ranges from 0.8mm to 1.5mm. Thicker swede is often used for footwear and upholstery, providing durability, while thinner swede is favored for fashion accessories and garments where flexibility is crucial. -

Tanning Process

The tanning process determines the leather’s final characteristics, such as softness, color retention, and resistance to moisture. Swede leather is commonly produced using chrome or vegetable tanning methods. Buyers should consider the tanning process, as it affects not only the leather’s appearance but also its environmental impact and longevity. -

Colorfastness

This property indicates how well the color of the leather withstands exposure to light and moisture. High colorfastness is vital for swede leather used in products that will see regular use, such as upholstery and clothing. A rating scale (usually A to E) is often applied, with A being the highest level of colorfastness. -

Abrasion Resistance

Abrasion resistance measures how well the leather can withstand surface wear from friction. This is particularly important for items like shoes and bags, which experience frequent contact with other surfaces. A high abrasion resistance rating ensures that the swede leather will maintain its appearance and structural integrity over time. -

Softness

Softness is a subjective but critical characteristic, especially in consumer-facing products. Swede leather is prized for its soft, velvety feel, which enhances comfort and aesthetic appeal. Buyers should assess the softness of the leather, as it directly influences the end-user experience.

What Are Common Trade Terms in the Swede Leather Industry?

Understanding industry jargon is crucial for B2B transactions. Here are some common terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of swede leather, an OEM might manufacture leather goods for a brand without branding their own name on the product. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For swede leather, this often means buyers must purchase a certain amount of hide or finished products, which can influence inventory and cash flow considerations. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers. For swede leather, an RFQ helps buyers understand costs, lead times, and availability of different grades and colors. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Understanding terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is essential for B2B buyers of swede leather, as they dictate who bears the risk and cost at various stages of shipping. -

Lead Time

Lead time is the time taken from placing an order to delivery. In the swede leather industry, lead times can vary significantly based on factors such as production capacity, shipping routes, and seasonal demands. Buyers should account for lead time in their planning to avoid stock shortages. -

Sample Approval

This term refers to the process of reviewing and approving a sample of swede leather before full production begins. Sample approval is critical for ensuring that the quality and specifications meet the buyer’s requirements, helping to mitigate risks associated with bulk orders.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing swede leather, ultimately leading to better product outcomes and business success.

Navigating Market Dynamics and Sourcing Trends in the swede leather Sector

What Are the Key Trends Shaping the Swede Leather Market for International Buyers?

The global market for swede leather is experiencing significant transformations, driven by evolving consumer preferences and technological advancements. A noteworthy trend is the increasing demand for high-quality, versatile materials that cater to both fashion and functional applications. This has led to a surge in the popularity of suede, especially in the production of accessories, footwear, and upholstery. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The rise of e-commerce and digital sourcing platforms has also facilitated easier access to suppliers, enabling buyers to explore a wider array of options without geographical limitations.

Moreover, sustainability is emerging as a key consideration. Buyers are increasingly seeking suppliers who can demonstrate eco-friendly practices, such as vegetable tanning and the use of natural dyes. In addition, advancements in automation and digital tools are streamlining the sourcing process, allowing for better inventory management and supply chain transparency. For example, the integration of blockchain technology is enhancing traceability, enabling buyers to verify the origins of their materials, which is particularly relevant in markets with stringent regulations.

How Does Sustainability Influence Sourcing Decisions in the Swede Leather Sector?

Sustainability is no longer a niche concern but a central pillar for many B2B buyers in the swede leather sector. The environmental impact of leather production is significant, with traditional methods often involving harmful chemicals and extensive water usage. Consequently, there is a growing emphasis on ethical sourcing and sustainable practices among suppliers. Buyers are increasingly prioritizing partnerships with tanneries that utilize eco-friendly processes, such as vegetable tanning, which minimizes chemical use and enhances the leather’s natural characteristics.

Furthermore, certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential for suppliers to demonstrate their commitment to sustainable practices. These certifications not only provide assurance regarding the environmental impact of the materials but also appeal to a growing segment of consumers who prioritize sustainability in their purchasing decisions. As international buyers seek to align with these values, sourcing from certified suppliers can enhance brand reputation and customer loyalty.

What Is the Historical Context of Swede Leather in the Global Market?

The history of swede leather can be traced back to the Scandinavian regions, where it was traditionally made from the underside of animal hides, particularly lamb and goat skins. Its unique texture and soft feel quickly gained popularity, leading to its widespread use in fashion and upholstery. Over the years, advancements in tanning processes have improved the quality and durability of suede, making it a sought-after material in various industries, including automotive and luxury goods.

As markets evolved, so did the production methods, with a shift towards more sustainable practices becoming evident in recent decades. This evolution reflects a growing awareness of environmental issues and consumer demand for ethically sourced materials. For B2B buyers today, understanding this history is vital, as it informs not only the quality and characteristics of swede leather but also the ethical considerations that are increasingly influencing purchasing decisions in the global marketplace.

Illustrative image related to swede leather

Frequently Asked Questions (FAQs) for B2B Buyers of swede leather

-

How do I choose the right supplier for swede leather?

Choosing the right supplier for swede leather involves thorough vetting. Start by assessing the supplier’s reputation through online reviews and industry references. Request samples to evaluate the quality of the suede, looking for consistent texture and color. Verify certifications related to ethical sourcing and tanning processes, especially if you’re importing into regions with strict regulations. Establish communication to gauge responsiveness and willingness to address your specific needs, including customization options and order flexibility. -

What is the best way to ensure quality when sourcing swede leather?

To ensure quality when sourcing swede leather, implement a comprehensive quality assurance (QA) process. This includes requesting detailed specifications on the tanning and finishing processes. Ask for third-party quality certifications and conduct regular quality checks on shipments. Establish clear communication with your supplier about your standards and expectations, and consider visiting their facilities if possible. Additionally, consider using an independent quality control service for large orders to verify that the leather meets your requirements before it reaches your facility. -

What are the common customization options available for swede leather?

Customization options for swede leather can vary widely among suppliers. Common options include color selection, thickness adjustments, and surface finishes such as embossing or debossing. Some suppliers may offer the ability to print logos or designs directly onto the leather. Discuss your specific needs with potential suppliers to understand their capabilities and any minimum order quantities (MOQs) associated with custom projects. Always request samples of customized products to assess quality before placing a large order. -

What is the typical minimum order quantity (MOQ) for swede leather?

Minimum order quantities (MOQs) for swede leather can vary significantly based on the supplier and the customization options requested. Generally, MOQs range from 50 to 500 square feet for standard colors and finishes. For custom orders or unique colors, MOQs may increase. It’s advisable to clarify MOQs upfront during supplier negotiations to avoid any surprises later in the order process. If your needs are smaller, consider partnering with suppliers who are willing to accommodate lower MOQs, particularly for prototypes or smaller projects. -

What payment terms should I expect when sourcing swede leather internationally?

Payment terms when sourcing swede leather can vary by supplier and region. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may offer net 30, 60, or 90 days, particularly for established relationships. Always negotiate terms that suit your cash flow needs and establish clear agreements on payment methods, such as wire transfers or letters of credit. It’s crucial to ensure that the payment terms align with your procurement and financial strategy. -

What logistics considerations should I keep in mind when importing swede leather?

When importing swede leather, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose between air or sea freight based on your urgency and budget. Familiarize yourself with import duties and taxes specific to your country, as these can significantly impact overall costs. Partnering with a reliable freight forwarder can streamline the import process and help navigate customs clearance. Additionally, ensure that your supplier is aware of your logistics needs and can accommodate any specific shipping requirements. -

How can I assess the environmental impact of sourcing swede leather?

To assess the environmental impact of sourcing swede leather, inquire about the supplier’s tanning processes and chemical usage. Look for suppliers who utilize environmentally friendly methods, such as vegetable tanning or low-impact dyes. Check for certifications like the Leather Working Group (LWG) rating, which indicates sustainable practices. Additionally, consider the supplier’s sourcing of raw materials, aiming for those that practice ethical animal husbandry and waste management. Engaging with suppliers on their sustainability initiatives can also provide insights into their overall environmental impact. -

What are the key differences between swede leather and other types of leather?

Swede leather differs from other types of leather primarily in texture and durability. Made from the inner layer of animal hides, suede has a soft, fuzzy surface that offers a unique aesthetic and feel, making it ideal for casual applications like bags and jackets. In contrast, traditional leather (such as full-grain or top-grain) has a smoother surface and is generally more durable and resistant to wear. Understanding these differences can help you choose the right type of leather for your specific product needs, ensuring that you align your material choice with the intended use and target market.

Top 7 Swede Leather Manufacturers & Suppliers List

1. Leather Hide Store – Premium Suede Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Suede leather offered in a variety of colors and sizes. Tanned with premium aniline dyes that penetrate the entire leather. Each piece is finished through a fine sanding process for an even surface and velvety touch. Suede is single-sided, with only the top side fully buffed and polished. Available colors include Fuchsia, Pink, Bordo, Mahogany, Cinnamon, Vineyard Brown, Dark Taupe, Midnight Marble…

2. Buffalo Jackson – Suede Leather Goods

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Suede is made from the inner side of leather, known as the flesh side, featuring a soft, textured surface with a noticeable nap. Leather comes from the outer side of the hide, having a smooth, polished surface with a sheen. Suede has a matte finish and a soft, fuzzy hand feel, while leather feels smoother and may be more rigid. Leather is generally more durable and resistant to wear and tear compa…

3. RM Leather Supply – Quality Leather Goods

Domain: rmleathersupply.com

Registered: 2014 (11 years)

Introduction: This company, RM Leather Supply – Quality Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Noble Shoe – Suede Leather Essentials

Domain: thenobleshoe.com

Registered: 2019 (6 years)

Introduction: Suede Leather is stylish, elegant, and contemporary, making it suitable for casual wear. It is easy to maintain with a suede brush and shampoo, and a protector can be used for extra care. There are two main types of suede: Full-Grain Suede, which is more expensive and water-resistant, and Split-Suede. Suede works well with various shoe types, including sneakers, boots, and oxfords, and can be worn…

5. Tandy Leather – Suede Leather Products

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Suede Leather Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Manuel Dreesmann – Suede Leather Bags & Accessories

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: Suede Leather – A Complete Guide! Worldwide Free Shipping Over 100€. Featured products include the Fiona Bag (Tote Bag with Zipper), the Croissant Bag, and the Saka Bag (Bestseller). Small Leather Goods such as wallets, card & coin holders, key wallets, and eyewear travel items are available. Device sleeves for MacBooks and iPads are customizable. Accessories include belts and leather bracelets.

7. Billy Tannery – Parkland Deer Range

Domain: billytannery.co.uk

Registered: 2016 (9 years)

Introduction: Parkland Deer range includes classic desert boots, multifunctional tote bags, and premium leather aprons. All products are made in England and feature a high-quality, rich dark brown finish.

Strategic Sourcing Conclusion and Outlook for swede leather

In the ever-evolving landscape of leather sourcing, swede leather offers unique opportunities for international B2B buyers. Its distinct texture, versatility, and aesthetic appeal make it a favored choice across various sectors, from fashion to upholstery. Understanding the differences between suede and traditional leather is crucial; while suede may not boast the same durability as full-grain leather, its softness and casual charm cater to a specific market segment that values comfort and style.

Strategic sourcing of swede leather involves identifying reliable suppliers and ensuring consistent quality, which can significantly enhance product offerings. Buyers from regions like Africa, South America, the Middle East, and Europe should prioritize partnerships with tanneries known for their craftsmanship and ethical practices. This not only aligns with global sustainability trends but also meets the increasing consumer demand for responsibly sourced materials.

Looking ahead, the market for swede leather is poised for growth, driven by innovative applications and a shift towards more casual, lifestyle-oriented products. Engage with suppliers today to secure a competitive edge in this dynamic market, positioning your business to meet future demand with confidence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to swede leather

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.