Introduction: Navigating the Global Market for embossed leather fabric

In the ever-evolving global marketplace, sourcing high-quality embossed leather fabric presents unique challenges for international B2B buyers. With diverse applications ranging from luxury upholstery to fashion accessories, the demand for this specialized material is on the rise. However, navigating the myriad options can be daunting, particularly for buyers in regions like Africa, South America, the Middle East, and Europe, including Brazil and Nigeria. This guide aims to demystify the process of acquiring embossed leather fabric, providing actionable insights to streamline your purchasing journey.

Throughout this comprehensive resource, we will explore various types of embossed leather, from classic floral designs to modern geometric patterns, highlighting their unique applications in industries such as furniture, fashion, and automotive. We will also delve into essential considerations for vetting suppliers, ensuring that you partner with reputable manufacturers who can meet your quality standards and delivery timelines. Furthermore, we will provide an overview of pricing structures, helping you to understand the cost implications and budget effectively.

By equipping B2B buyers with the knowledge and tools necessary to make informed decisions, this guide empowers you to confidently navigate the global market for embossed leather fabric. Whether you are seeking to enhance your product offerings or simply wish to stay ahead of industry trends, our insights will pave the way for successful sourcing and procurement strategies.

Table Of Contents

- Top 4 Embossed Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for embossed leather fabric

- Understanding embossed leather fabric Types and Variations

- Key Industrial Applications of embossed leather fabric

- 3 Common User Pain Points for ’embossed leather fabric’ & Their Solutions

- Strategic Material Selection Guide for embossed leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for embossed leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ’embossed leather fabric’

- Comprehensive Cost and Pricing Analysis for embossed leather fabric Sourcing

- Alternatives Analysis: Comparing embossed leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for embossed leather fabric

- Navigating Market Dynamics and Sourcing Trends in the embossed leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of embossed leather fabric

- Strategic Sourcing Conclusion and Outlook for embossed leather fabric

- Important Disclaimer & Terms of Use

Understanding embossed leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Western Embossed Leather | Features rustic, Southwestern designs; often includes motifs like longhorns and floral patterns. | Upholstery for furniture, bags, and accessories. | Pros: Unique aesthetics; strong demand in niche markets. Cons: Limited versatility for modern decor styles. |

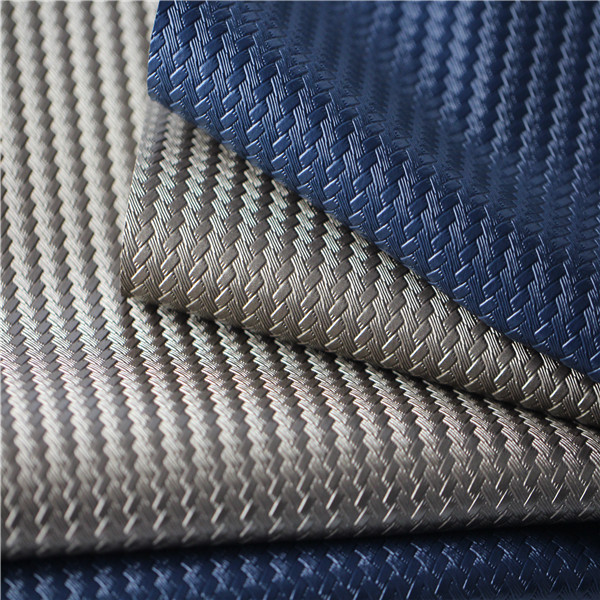

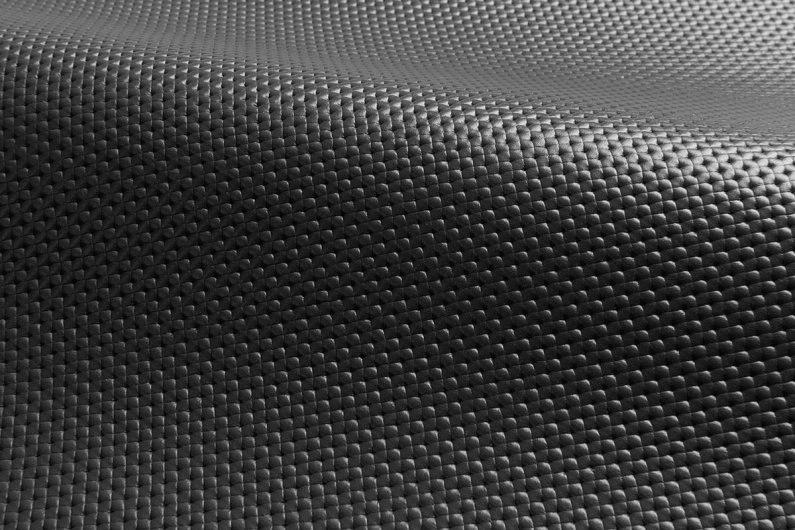

| Geometric Embossed Leather | Characterized by repeating patterns and textures; offers a contemporary look. | Modern furniture, automotive interiors, and fashion accessories. | Pros: Versatile for various applications; appeals to contemporary designers. Cons: May require careful matching with other design elements. |

| Floral Embossed Leather | Displays intricate floral patterns; often used in luxury products. | High-end furniture, handbags, and decorative items. | Pros: Adds elegance and sophistication; strong appeal in luxury markets. Cons: Higher cost may deter budget-conscious buyers. |

| Metallic Embossed Leather | Features metallic finishes; creates a striking visual effect. | Fashion, upholstery, and promotional products. | Pros: Eye-catching; enhances brand visibility. Cons: May not suit all design preferences; potential for scratches. |

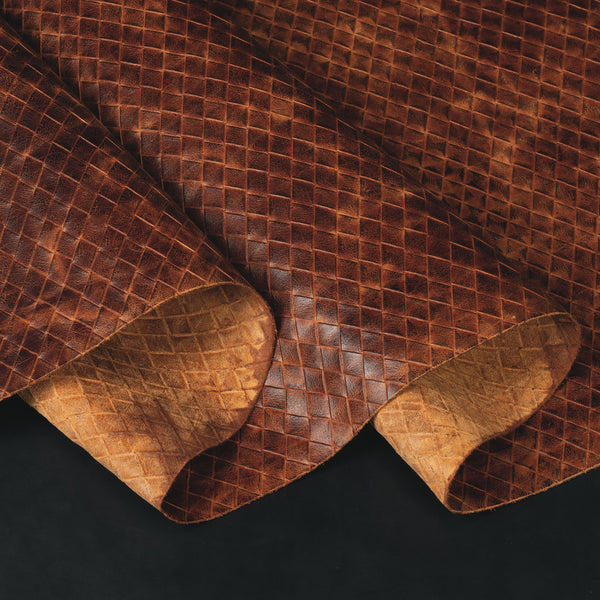

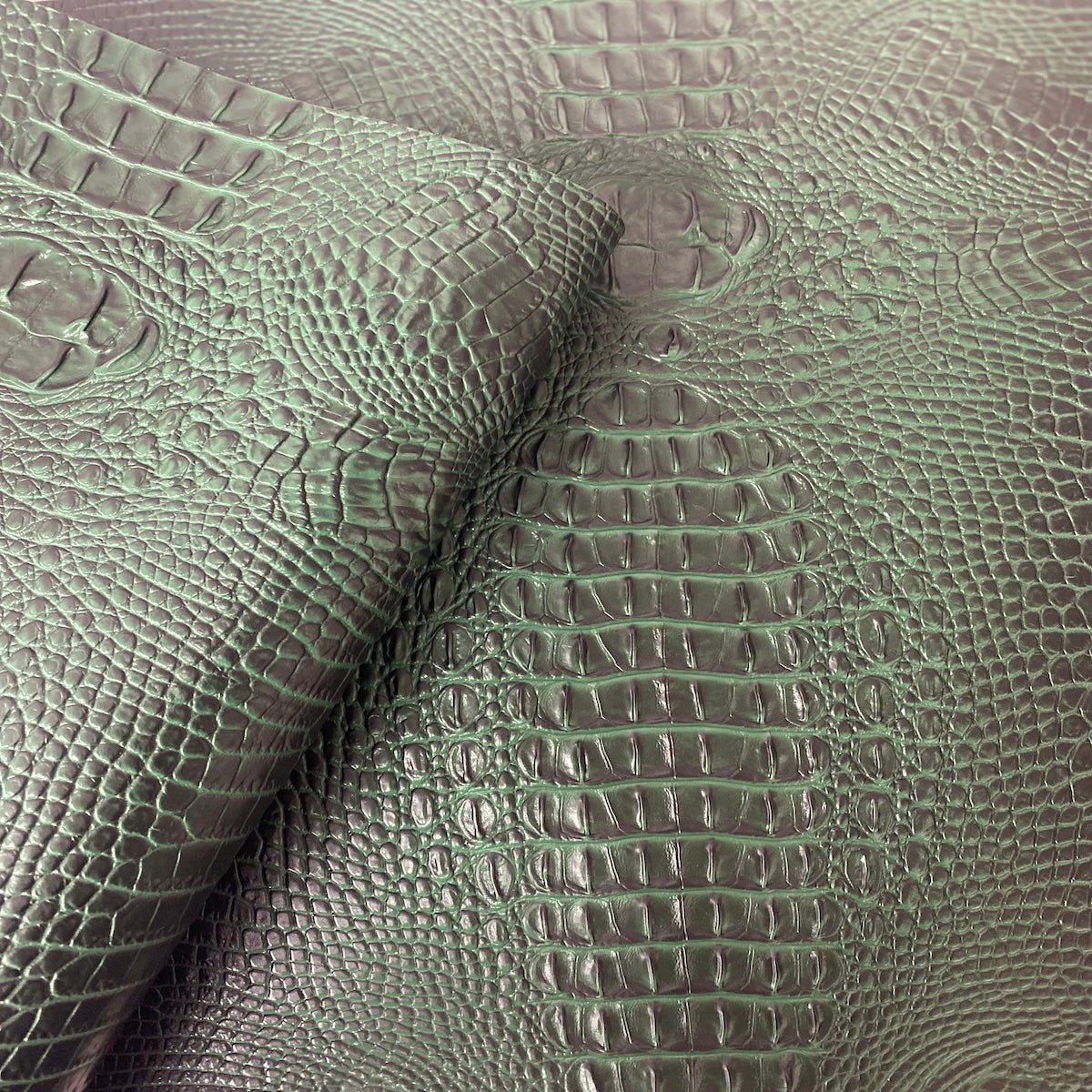

| Exotic Embossed Leather | Mimics the appearance of exotic animal skins; often used for upscale products. | Luxury items, high-end fashion, and bespoke furniture. | Pros: High perceived value; attracts affluent clientele. Cons: Ethical considerations and higher price point. |

What Are the Key Characteristics of Western Embossed Leather?

Western embossed leather is distinguished by its rustic and Southwestern designs, often featuring motifs such as longhorns, floral patterns, and tribal elements. This type is primarily used in upholstery for furniture, bags, and accessories, appealing to markets that value traditional craftsmanship. Buyers should consider the target demographic’s aesthetic preferences, as this style is particularly popular in regions with a strong Western culture. Additionally, while it offers unique aesthetics, its limited versatility may pose challenges in modern decor contexts.

How Does Geometric Embossed Leather Stand Out?

Geometric embossed leather showcases repeating patterns and textures, providing a contemporary look that fits well in modern design applications. Its versatility makes it suitable for various sectors, including furniture, automotive interiors, and fashion accessories. B2B buyers should assess the compatibility of geometric designs with existing product lines and customer preferences. While this type of leather can enhance a product’s appeal, it requires careful matching with other design elements to achieve a cohesive look.

Why Choose Floral Embossed Leather for Luxury Products?

Floral embossed leather is known for its intricate and elegant floral patterns, making it a popular choice for high-end products like luxury furniture, handbags, and decorative items. This type of leather adds sophistication and can significantly elevate the perceived value of a product. B2B buyers in the luxury market should consider the higher costs associated with floral embossed leather, as well as its appeal to affluent clientele. While it offers a distinctive look, careful selection is necessary to ensure it aligns with brand identity and customer expectations.

What Benefits Does Metallic Embossed Leather Offer?

Metallic embossed leather features striking finishes that create a visually impactful effect, making it ideal for fashion, upholstery, and promotional products. This type of leather enhances brand visibility and attracts attention, which can be particularly advantageous in competitive markets. B2B buyers should evaluate the target audience’s design preferences, as metallic finishes may not suit every style. Although it offers eye-catching appeal, buyers must also consider potential drawbacks, such as susceptibility to scratches, which could affect the product’s longevity.

How Does Exotic Embossed Leather Appeal to Upscale Markets?

Exotic embossed leather mimics the appearance of rare animal skins, providing a high perceived value that attracts affluent clientele. This type of leather is commonly used in luxury items, bespoke furniture, and high-end fashion. B2B buyers should be aware of ethical considerations surrounding exotic materials, as well as the higher price point associated with these products. While exotic embossed leather can enhance product exclusivity, it is essential to ensure that the sourcing aligns with brand values and customer expectations.

Key Industrial Applications of embossed leather fabric

| Industry/Sector | Specific Application of embossed leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Enhances aesthetic appeal and durability of furniture | Quality of leather, embossing patterns, and customization options |

| Automotive | Interior detailing (seats, dashboards) | Provides luxury feel and improved durability | Compliance with automotive standards, color matching, and texture consistency |

| Fashion and Accessories | Handbags, wallets, and belts | Adds uniqueness and branding opportunities | Availability of trending designs, material sourcing, and production timelines |

| Interior Design | Wall coverings and decorative elements | Elevates interior aesthetics and adds texture | Custom design capabilities, fire safety standards, and environmental certifications |

| Home Decor | Decorative items (cushions, throws, and curtains) | Differentiates product offerings in a competitive market | Sourcing from reliable suppliers, variety of colors and patterns, and cost-effectiveness |

How is Embossed Leather Fabric Used in Furniture Manufacturing?

In the furniture manufacturing sector, embossed leather fabric is predominantly used for upholstery on sofas, chairs, and other seating options. The textured surface enhances the aesthetic appeal, making furniture items more attractive to consumers. Additionally, embossed leather is known for its durability, which addresses issues of wear and tear in high-traffic areas. Buyers in this sector should consider the quality of leather, available embossing patterns, and the ability to customize designs to align with market trends, particularly in regions like Africa and South America, where local tastes may vary.

What Role Does Embossed Leather Play in the Automotive Industry?

The automotive industry utilizes embossed leather fabric for interior detailing, including seats and dashboards. This material not only provides a luxurious look and feel but also enhances the durability of car interiors, which is crucial for maintaining vehicle value. International buyers, especially from the Middle East and Europe, need to ensure compliance with automotive standards, such as fire resistance and wear resistance. Additionally, consistency in color and texture is vital for maintaining brand identity across various models.

How is Embossed Leather Fabric Integrated into Fashion and Accessories?

In the fashion and accessories industry, embossed leather is favored for products like handbags, wallets, and belts. The unique textures and patterns allow brands to differentiate their offerings and create a distinctive identity. For B2B buyers, sourcing embossed leather involves looking for trending designs and ensuring that the materials can be produced at scale without compromising quality. Moreover, understanding regional preferences, such as color and pattern choices in markets like Nigeria and Brazil, can significantly impact sales.

What are the Applications of Embossed Leather in Interior Design?

Embossed leather fabric finds extensive use in interior design, particularly for wall coverings and decorative elements. The rich textures add depth and sophistication to residential and commercial spaces. Buyers in this sector must consider custom design capabilities to meet specific project requirements, as well as adherence to fire safety standards, especially in public spaces. Environmental certifications may also be a concern for buyers in Europe, aligning with the growing demand for sustainable materials.

How is Embossed Leather Used in Home Decor Products?

In the home decor sector, embossed leather is utilized for decorative items such as cushions, throws, and curtains. This fabric not only enhances the visual appeal of a space but also provides tactile interest. For businesses sourcing these products, it is essential to work with reliable suppliers who can offer a variety of colors and patterns while ensuring cost-effectiveness. Understanding the local market demand in regions like South America can guide effective product development and marketing strategies.

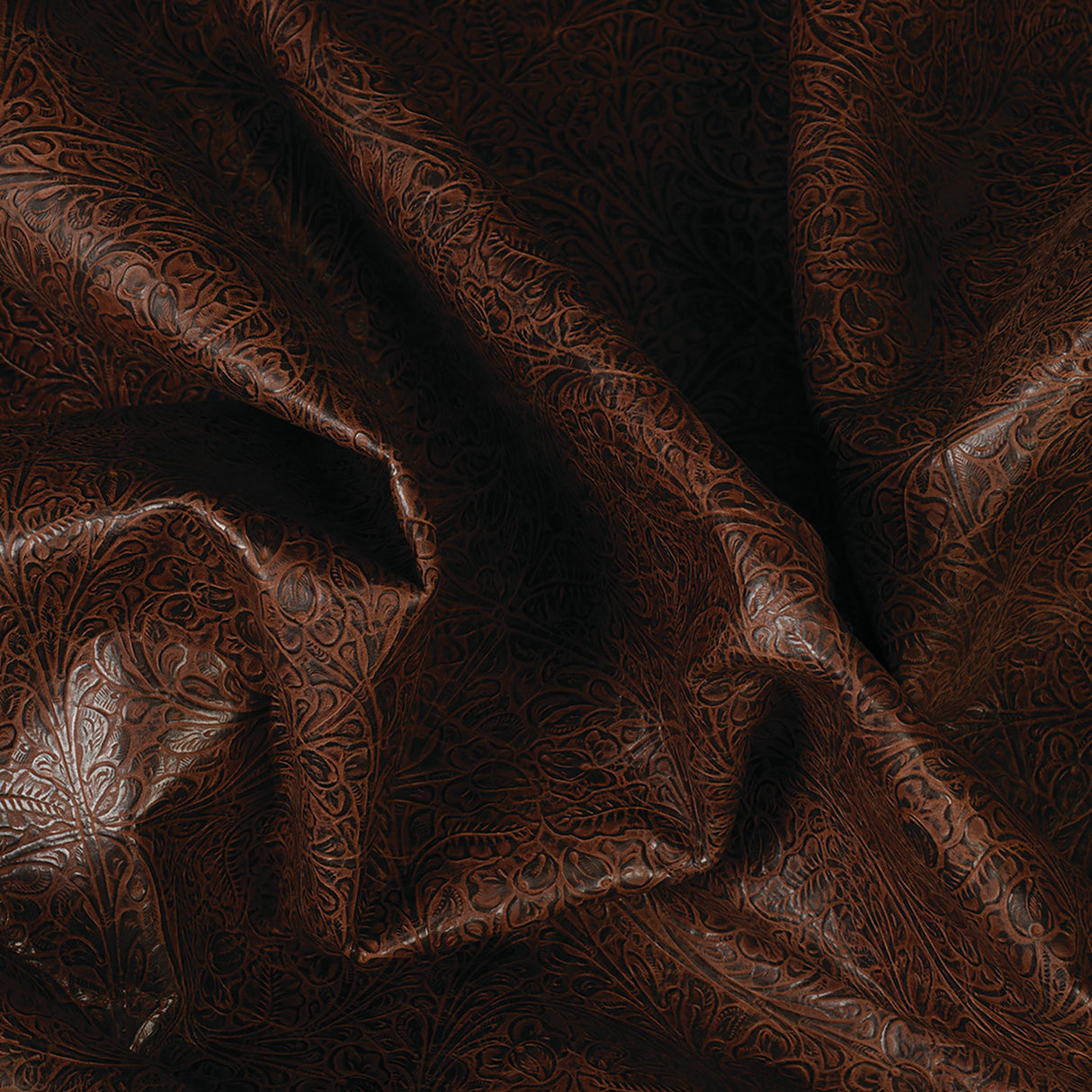

Illustrative image related to embossed leather fabric

3 Common User Pain Points for ’embossed leather fabric’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: B2B buyers often struggle with the inconsistency in the quality of embossed leather fabric sourced from different suppliers. Variability in texture, color, and durability can lead to complications in production, resulting in increased waste and customer dissatisfaction. For instance, a manufacturer in Nigeria may receive a shipment of embossed leather that appears to differ significantly in quality from previous orders, causing delays in their production timeline and potential loss of business.

The Solution: To ensure consistent quality, B2B buyers should establish long-term relationships with a select group of reputable suppliers known for their quality control processes. Before making a bulk purchase, request samples of the embossed leather fabric to evaluate its quality firsthand. It’s also beneficial to create detailed specifications outlining the desired characteristics of the leather, such as thickness, embossing patterns, and colorfastness. By doing so, buyers can communicate their needs clearly and avoid misunderstandings. Additionally, utilizing third-party testing services to validate the quality of the leather can further safeguard against inconsistencies.

Scenario 2: Challenges in Customization and Design

The Problem: Another common pain point for B2B buyers is the difficulty in obtaining customized embossed leather designs that meet specific project requirements. For example, a furniture manufacturer in Brazil may want a unique embossed pattern that reflects local cultural aesthetics, but many suppliers offer limited design options, leaving buyers frustrated and unable to differentiate their products in a competitive market.

The Solution: To address this challenge, B2B buyers should prioritize suppliers who offer custom embossing services. When contacting potential vendors, inquire about their capabilities in creating bespoke designs and the minimum order quantities required for custom embossing. Providing detailed design specifications, including sketches or digital mock-ups, can help streamline the customization process. Furthermore, working closely with suppliers during the design phase can ensure that the final product aligns with the buyer’s vision. Establishing a collaborative relationship with a supplier who understands the importance of cultural relevance in design can lead to innovative and marketable products.

Scenario 3: Uncertainty in Pricing and Order Minimums

The Problem: B2B buyers frequently face confusion regarding pricing structures and minimum order quantities when sourcing embossed leather fabric. A buyer in the Middle East might find that different suppliers have varying pricing models, which complicates budgeting for projects. Moreover, high minimum order requirements can restrict smaller manufacturers from accessing the materials they need, leading to missed opportunities.

Illustrative image related to embossed leather fabric

The Solution: To navigate pricing and order minimums effectively, buyers should conduct thorough market research to understand typical pricing trends for embossed leather in their region. It’s advisable to request detailed quotes from multiple suppliers, ensuring that these quotes include all potential costs, such as shipping and handling. This comparison not only aids in identifying competitive pricing but also helps buyers negotiate better terms. Additionally, some suppliers may be willing to accommodate lower minimum order quantities, especially for first-time buyers or repeat customers. Establishing a clear communication channel with suppliers about budget constraints can foster flexibility in order sizes, allowing smaller manufacturers to participate in the embossed leather market without being financially overburdened.

Strategic Material Selection Guide for embossed leather fabric

What Are the Key Properties of Common Materials Used in Embossed Leather Fabric?

Embossed leather fabric can be made from various materials, each offering unique properties that cater to different applications. The most common materials include genuine leather, synthetic leather (PU and PVC), and embossed fabric. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers looking to make informed purchasing decisions.

How Does Genuine Leather Perform in Embossed Applications?

Genuine leather is a traditional choice for embossed leather fabric, known for its durability and aesthetic appeal. It typically boasts excellent temperature resistance, withstanding a range of conditions without significant degradation. The natural fibers provide good breathability, making it suitable for upholstery in various climates.

Pros: Genuine leather is highly durable, offering a luxurious feel and appearance. It can be embossed with intricate designs, enhancing its visual appeal. However, the cost is generally higher than synthetic alternatives, and it requires regular maintenance to preserve its quality.

Cons: The primary limitation of genuine leather is its susceptibility to water damage and stains. Additionally, sourcing high-quality leather can be challenging, especially for international buyers who must consider compliance with animal welfare regulations and sourcing standards.

Illustrative image related to embossed leather fabric

What Advantages Do Synthetic Leathers Offer for Embossed Fabrics?

Synthetic leathers, such as polyurethane (PU) and polyvinyl chloride (PVC), are increasingly popular for embossed applications. These materials are engineered to mimic the look and feel of genuine leather while offering enhanced resistance to moisture and stains.

Pros: Synthetic leathers are generally more affordable and easier to maintain than genuine leather. They are available in a wide range of colors and finishes, making them versatile for various applications. Additionally, they can be produced in large quantities, which is beneficial for bulk orders.

Cons: The main drawback is that synthetic leathers may not offer the same level of durability or breathability as genuine leather. They can also be less environmentally friendly, depending on the manufacturing process and materials used.

How Do Embossed Fabrics Compare in Performance and Application?

Embossed fabrics, often made from textiles like cotton or polyester, can also be treated to achieve a leather-like appearance. These materials are lightweight and can be produced in various patterns, making them suitable for fashion and decorative applications.

Illustrative image related to embossed leather fabric

Pros: Embossed fabrics are typically less expensive and can be produced in various designs, appealing to a broader market. They are also easier to clean and maintain, making them ideal for high-traffic areas.

Cons: However, they lack the durability and luxury feel of genuine leather. Their performance under heavy use may be limited, and they may not withstand environmental stressors as effectively as leather.

What Should International Buyers Consider When Selecting Embossed Leather Materials?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several factors when selecting embossed leather materials. Compliance with international standards such as ASTM, DIN, and JIS is crucial to ensure product quality and safety. Additionally, understanding local preferences and market trends can help in making more targeted purchasing decisions. For instance, buyers in Brazil may prefer vibrant colors and patterns, while those in Nigeria might prioritize durability and weather resistance.

Illustrative image related to embossed leather fabric

Summary Table of Material Selection for Embossed Leather Fabric

| Material | Typical Use Case for embossed leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end upholstery, luxury goods | Exceptional durability and aesthetic appeal | Higher cost and maintenance requirements | High |

| Synthetic Leather | Affordable upholstery, fashion accessories | Cost-effective and moisture-resistant | Less durable and potentially less eco-friendly | Medium |

| Embossed Fabrics | Fashion items, decorative applications | Lightweight and versatile in design | Limited durability compared to leather | Low |

This guide provides a comprehensive overview of the strategic material selection for embossed leather fabric, enabling B2B buyers to make informed decisions based on their specific needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for embossed leather fabric

What Are the Main Stages in the Manufacturing Process of Embossed Leather Fabric?

The manufacturing process of embossed leather fabric involves several critical stages, each contributing to the final product’s quality and appeal. Understanding these stages is crucial for B2B buyers looking to source high-quality embossed leather.

Material Preparation: How Is Leather Selected and Processed?

The first step in manufacturing embossed leather is the selection of raw leather hides, which can be sourced from various animal skins, such as cow, goat, or exotic leathers. Buyers should look for suppliers who utilize sustainable and ethically sourced hides. Once selected, the hides undergo a tanning process, which preserves the leather and enhances its durability. This stage may involve vegetable tanning or chrome tanning, with each method affecting the leather’s texture and environmental footprint.

Post-tanning, the hides are conditioned to achieve the desired suppleness. This includes moisture balancing and applying oils or waxes, which prepare the leather for embossing.

Illustrative image related to embossed leather fabric

What Techniques Are Used in Forming Embossed Leather?

After material preparation, the next stage is forming, where the actual embossing occurs. This is achieved through the use of engraved steel plates that press specific patterns onto the leather. The plates can vary in size, with typical dimensions ranging from 26″ to 29″ in height and 48″ to 54″ in width.

The embossing process can be either heat-based or pressure-based, and each method creates distinct patterns and textures. For instance, heat embossing uses heated plates to create a deeper impression, while pressure embossing offers a more subtle texture. Buyers should inquire about the specific techniques used by their suppliers, as these can significantly influence the final appearance and tactile quality of the leather.

How Is the Assembly of Embossed Leather Fabric Managed?

Once the leather is embossed, it moves to the assembly stage, where it is cut into specified sizes and shapes for various applications, such as upholstery or fashion items. This stage requires precision to minimize waste and ensure that patterns align correctly on the finished products.

Quality control during assembly is vital. For instance, B2B buyers should seek suppliers who employ skilled artisans to oversee the cutting and stitching processes, ensuring that the final products meet high standards of craftsmanship.

What Finishing Techniques Enhance the Quality of Embossed Leather?

The finishing stage involves applying protective coatings, dyes, or additional textures to the embossed leather. This not only enhances the visual appeal but also improves the leather’s resistance to wear and environmental factors. Common finishing techniques include polishing, lacquering, and applying water-repellent treatments.

Buyers should ask about the finishing processes used, as different treatments can affect the leather’s longevity and suitability for specific applications. For instance, some finishes may be more appropriate for high-traffic upholstery, while others may be tailored for luxury goods.

What Quality Assurance Practices Should B2B Buyers Look For?

Quality assurance is paramount in the embossed leather manufacturing process. Buyers should ensure that their suppliers adhere to recognized international standards, such as ISO 9001, which focuses on quality management systems. Compliance with these standards helps guarantee that suppliers maintain consistent quality in their products.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) should occur at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival at the facility. Suppliers should check for defects, dimensions, and compliance with specifications before production begins.

-

In-Process Quality Control (IPQC): During the embossing and assembly processes, ongoing inspections should be conducted to ensure that all manufacturing steps adhere to established quality standards. This includes monitoring the embossing depth, alignment of patterns, and stitching quality.

-

Final Quality Control (FQC): Once the leather products are completed, a final inspection should be performed to assess overall quality, aesthetics, and functionality. This is crucial for ensuring that the products meet the expectations of B2B buyers.

How Can B2B Buyers Verify Supplier Quality Assurance?

To ensure that suppliers maintain high-quality standards, B2B buyers can implement several verification methods:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing processes, quality control measures, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports can help buyers understand how often defects occur, what corrective actions are taken, and overall production performance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices. These inspections can focus on various aspects, including raw material quality, production processes, and final product assessments.

What Are the Unique QC Considerations for International Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, additional QC considerations may come into play. Import regulations can vary significantly by country, affecting how embossed leather products are certified for sale.

Buyers should familiarize themselves with local regulations regarding leather imports, which may include specific certifications or compliance with environmental standards. Additionally, understanding cultural preferences and market demands can help buyers communicate effectively with suppliers to ensure that the products meet regional expectations.

Conclusion: Why Is Quality Assurance Essential in Sourcing Embossed Leather Fabric?

In summary, the manufacturing and quality assurance processes for embossed leather fabric are intricate and critical to ensuring high-quality products. B2B buyers must engage with suppliers who prioritize quality at every stage, from material preparation through to finishing. By understanding these processes and implementing effective verification methods, buyers can secure reliable partnerships that meet their business needs and uphold their brand’s reputation.

Practical Sourcing Guide: A Step-by-Step Checklist for ’embossed leather fabric’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure embossed leather fabric. Understanding the nuances of sourcing this specialized material is crucial for ensuring quality, consistency, and suitability for your specific applications. Whether you are in the furniture, automotive, or fashion industries, following these steps will help you make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements for embossed leather fabric. Consider factors such as thickness, finish, and embossing patterns that align with your project’s needs.

– Key Details: Specify whether you need full hides or half hides, as this will impact the quantity and cost.

Illustrative image related to embossed leather fabric

Step 2: Research Reliable Suppliers

Invest time in researching potential suppliers who specialize in embossed leather. Look for companies with a solid reputation and experience in producing high-quality materials.

– Key Details: Utilize online marketplaces, trade shows, and industry forums to gather information. Check supplier reviews and ratings to gauge their reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions to understand their capabilities.

– Key Details: Inquire about their production capacity, lead times, and whether they can accommodate custom embossing patterns.

Step 4: Verify Material Certifications

Ensure that the leather meets international quality standards and certifications. This is particularly important for buyers in regulated markets.

– Key Details: Ask for certifications such as ISO 9001 or environmental compliance certificates to verify the supplier’s commitment to quality and sustainability.

Step 5: Request Samples for Testing

Always request samples before finalizing your order. This allows you to assess the texture, durability, and overall quality of the embossed leather fabric.

– Key Details: Examine the sample for joint marks and directional patterns that may affect your project’s aesthetic. Conduct tests to ensure it meets your performance requirements.

Illustrative image related to embossed leather fabric

Step 6: Understand Pricing Structures

Discuss pricing openly with potential suppliers to understand their pricing models. Be aware of factors that can influence costs, such as custom embossing, order volume, and shipping expenses.

– Key Details: Ask for a detailed quotation that breaks down costs, ensuring there are no hidden fees.

Step 7: Establish Clear Terms and Conditions

Before placing an order, ensure that you have clear terms and conditions regarding payment, delivery, and returns. This will protect your interests in case of any discrepancies.

– Key Details: Pay attention to the warranty policies and after-sales support offered by the supplier, as these can be critical for long-term satisfaction.

By following this checklist, B2B buyers can navigate the complexities of sourcing embossed leather fabric effectively, ensuring they secure the best materials for their needs.

Comprehensive Cost and Pricing Analysis for embossed leather fabric Sourcing

What Are the Key Cost Components of Sourcing Embossed Leather Fabric?

When sourcing embossed leather fabric, understanding the cost structure is essential for effective budgeting and pricing negotiation. The main cost components include:

-

Materials: The quality of the leather significantly impacts costs. Premium materials such as full-grain leather will command higher prices than lower grades. Additionally, the complexity of the embossing design can lead to variations in material costs.

-

Labor: Skilled craftsmanship is necessary for embossing leather. Labor costs can vary based on geographic location, with higher wages in developed regions compared to emerging markets.

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, and administrative expenses. A supplier’s operational efficiency can influence the overall pricing.

-

Tooling: Custom embossing plates are a significant upfront investment. The design and manufacture of these plates can add to the initial costs, especially for unique or intricate patterns.

-

Quality Control (QC): Ensuring that the embossed leather meets specific quality standards is vital. QC processes may involve testing for durability, color consistency, and adherence to specifications, all of which incur additional costs.

-

Logistics: Transportation costs can be substantial, particularly for international shipments. Factors such as distance, shipping method, and customs duties must be accounted for in the total cost.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure business sustainability. This margin can vary significantly based on market demand and competition.

How Do Volume and Customization Influence Embossed Leather Prices?

Several factors can significantly influence the pricing of embossed leather fabric:

-

Volume/MOQ: Larger orders typically benefit from economies of scale, leading to lower per-unit costs. Minimum order quantities (MOQs) may also dictate pricing structures, with suppliers often offering better rates for bulk purchases.

-

Specifications and Customization: Custom designs and specific leather grades can increase costs. Buyers should be clear about their specifications upfront to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality leather or those with specific certifications (e.g., eco-friendly, cruelty-free) may attract premium pricing. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can impact pricing. Established suppliers may charge more due to their track record, but they often provide better quality assurance.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) used in the transaction is crucial. They dictate who is responsible for shipping costs, insurance, and tariffs, directly affecting the total cost.

What Tips Can Help Buyers Negotiate Better Prices for Embossed Leather?

When negotiating prices for embossed leather fabric, buyers can employ several strategies to achieve cost-efficiency:

Illustrative image related to embossed leather fabric

-

Understand Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term factors such as durability, maintenance costs, and potential waste, which can affect overall expenses.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can establish trust and lead to favorable negotiations.

-

Research Market Trends: Being informed about current market trends and pricing can strengthen your negotiation position. Buyers should be aware of price fluctuations based on demand and availability.

-

Be Flexible with Specifications: If possible, consider alternative materials or designs that may offer cost savings without significantly compromising quality.

-

Explore Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can reduce logistics costs and lead times, ultimately resulting in better pricing.

Conclusion: What Should Buyers Keep in Mind About Pricing Nuances?

B2B buyers in Africa, South America, the Middle East, and Europe should be aware of regional pricing nuances. Factors such as currency fluctuations, import tariffs, and local market demand can influence prices. Always request detailed quotes that break down all components to ensure clarity in pricing and avoid unexpected costs.

As pricing can vary widely based on these factors, it’s essential to approach each sourcing opportunity with a comprehensive understanding of the costs involved and a strategic negotiation plan.

Alternatives Analysis: Comparing embossed leather fabric With Other Solutions

Exploring Alternatives to Embossed Leather Fabric for B2B Buyers

In the competitive landscape of upholstery and decorative materials, embossed leather fabric stands out for its unique aesthetics and durability. However, buyers should consider various alternatives that may offer distinct advantages depending on their specific needs and applications. This section will compare embossed leather fabric with two viable alternatives: synthetic leather and fabric with embossed leather looks.

| Comparison Aspect | Embossed Leather Fabric | Synthetic Leather | Fabric with Embossed Leather Look |

|---|---|---|---|

| Performance | High durability; natural feel; breathability | Good durability; water-resistant; less breathable | Varies; not as durable; may lack breathability |

| Cost | Higher initial investment; long-term value | Generally lower cost; variable quality | Lower cost; budget-friendly option |

| Ease of Implementation | Requires skilled labor for cutting and sewing | Easy to work with; often lighter | Simple to implement; versatile design options |

| Maintenance | Requires specific cleaning; can be conditioned | Easy to clean; resistant to stains | Machine washable; easy upkeep |

| Best Use Case | High-end upholstery; luxury applications | Everyday use; automotive; commercial furniture | Cost-effective solutions; fashion applications |

Pros and Cons of Synthetic Leather

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), serves as a popular alternative to embossed leather fabric. One of its primary advantages is cost-effectiveness, making it accessible for budget-conscious projects. Additionally, synthetic leather is generally easier to clean and maintain, which is particularly beneficial for high-traffic environments. However, it often lacks the natural feel and breathability of genuine leather, which can affect user comfort and overall aesthetic appeal. Moreover, synthetic options may not provide the same level of durability, especially in high-end applications.

Illustrative image related to embossed leather fabric

Pros and Cons of Fabric with Embossed Leather Look

Fabric with an embossed leather look offers a versatile and budget-friendly alternative, making it suitable for a variety of applications, from fashion to home décor. This option can emulate the aesthetic appeal of embossed leather while being significantly lighter and often machine washable, thus simplifying maintenance. However, it typically does not match the durability or tactile experience of genuine embossed leather, which can limit its effectiveness in long-term upholstery projects. Additionally, the performance can vary widely depending on the quality of the fabric used, so buyers must be diligent in their selection.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right material for your projects, consider the specific requirements of your application. Embossed leather fabric is ideal for high-end, luxurious applications where durability and aesthetics are paramount. In contrast, synthetic leather may be the best choice for cost-sensitive projects that still require a degree of sophistication and ease of maintenance. Finally, fabric with an embossed leather look is suitable for those seeking budget-friendly options without sacrificing style. By evaluating performance, cost, ease of implementation, and maintenance needs, B2B buyers can make informed decisions that align with their project goals and customer expectations.

Essential Technical Properties and Trade Terminology for embossed leather fabric

What Are the Key Technical Properties of Embossed Leather Fabric?

When sourcing embossed leather fabric, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

1. Material Grade

Material grade refers to the quality of leather used in the embossed fabric. Higher grades, such as full-grain leather, retain the natural texture and durability of the hide, while lower grades may be corrected or synthetic. Selecting the appropriate material grade is vital for ensuring the longevity and aesthetic appeal of the finished product, especially in applications like upholstery or high-end fashion.

2. Tolerance

Tolerance in leather refers to the allowable variation in thickness and texture across different sections of the hide. This specification is crucial for manufacturers who require consistency in their products. For instance, a tolerance of ±0.5 mm ensures that the embossed leather maintains uniformity, which is essential for achieving a professional finish in upholstery and accessories.

3. Embossing Pattern Dimensions

Embossing patterns are created using plates that vary in size, typically ranging from 26″ to 29″ in height and 48″ to 54″ in width. Understanding the dimensions of these plates is important for buyers to determine how many hides will be required for large projects. Additionally, it helps in anticipating joint marks, which can impact the visual appeal of the final product.

4. Hide Size

Embossed leather is generally sold in half hides (approximately 20-23 square feet) or full hides (approximately 40-50 square feet). Knowing the size of the hides is essential for buyers to calculate material needs accurately. This information directly affects inventory management and cost calculations, particularly for large-scale production.

5. Finish Type

The finish type refers to the surface treatment applied to the embossed leather, influencing its appearance and durability. Common finishes include matte, glossy, and metallic. Buyers should select a finish that aligns with their product requirements, as it affects not only aesthetics but also the leather’s resistance to wear, staining, and moisture.

What Are Common Trade Terms Used in the Embossed Leather Industry?

Familiarity with industry jargon can enhance communication and streamline transactions in the embossed leather market. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces goods for another company to sell under its brand name. In the embossed leather sector, understanding OEM partnerships can help buyers identify reliable suppliers who can meet specific design and quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for embossed leather can assist buyers in planning their purchases and inventory levels effectively, especially when dealing with custom designs or large projects.

Illustrative image related to embossed leather fabric

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain price quotes for specific products. When dealing with embossed leather, submitting an RFQ can help buyers compare costs, terms, and lead times from different vendors, facilitating informed purchasing decisions.

4. Incoterms

Incoterms are a set of international commercial terms that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms relevant to embossed leather transactions can help buyers negotiate better terms, manage shipping risks, and clarify obligations regarding freight costs and delivery points.

5. Custom Embossing

Custom embossing refers to the process of creating unique patterns or logos on leather using specialized plates. This term is particularly important for B2B buyers looking to differentiate their products in competitive markets, as custom designs can enhance brand identity and product exclusivity.

Illustrative image related to embossed leather fabric

By grasping these technical properties and trade terms, B2B buyers can better navigate the embossed leather fabric market, ensuring they make informed decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the embossed leather fabric Sector

What Are the Key Market Trends Influencing the Embossed Leather Fabric Sector?

The embossed leather fabric sector is experiencing robust growth driven by several global factors. A primary driver is the rising demand for premium materials in various industries, including automotive, fashion, and furniture, particularly in emerging markets across Africa, South America, and the Middle East. As economies in countries like Brazil and Nigeria expand, so does the appetite for high-quality, aesthetically appealing products, pushing B2B buyers to seek out unique embossed leather options that stand out in the market.

Technological advancements are also reshaping the sourcing landscape. The introduction of digital printing and advanced embossing techniques allows manufacturers to create intricate designs quickly and efficiently. This capability supports customization, enabling buyers to order small quantities of bespoke designs tailored to their specific needs, rather than relying solely on mass-produced options. Moreover, platforms that facilitate direct sourcing from manufacturers are gaining traction, reducing the reliance on intermediaries and enhancing transparency in the supply chain.

Market dynamics are further influenced by shifting consumer preferences toward sustainable and ethically produced materials. Buyers are increasingly prioritizing suppliers who can demonstrate responsible sourcing practices and environmental stewardship. This trend is not only shaping purchasing decisions but is also leading to innovations in embossed leather production, such as the use of vegetable-tanned leathers and water-based adhesives.

How Can Sustainability and Ethical Sourcing Shape B2B Purchasing Decisions in Embossed Leather Fabric?

Sustainability is becoming a critical consideration for B2B buyers in the embossed leather fabric sector. The environmental impact of leather production, including water usage, chemical processing, and waste generation, has led to growing scrutiny from consumers and businesses alike. As a result, suppliers are under increasing pressure to adopt more sustainable practices, making it essential for buyers to evaluate their supply chains carefully.

Ethical sourcing practices are now a key differentiator in the market. Buyers should seek out suppliers who can provide clear documentation on their sourcing processes, including animal welfare standards and the environmental impact of their operations. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) can offer reassurance that the materials sourced are both environmentally friendly and ethically produced.

Additionally, innovations in materials are paving the way for more sustainable alternatives. Biodegradable embossed leather options and synthetic leathers made from recycled materials are gaining popularity, allowing buyers to meet their sustainability goals without compromising on quality or aesthetics. By prioritizing suppliers that embrace sustainable practices, B2B buyers can enhance their brand image while contributing to a more responsible industry.

What Is the Historical Evolution of Embossed Leather Fabric and Its Relevance Today?

The history of embossed leather dates back centuries, with artisans using various techniques to create distinctive patterns and textures for both functional and decorative purposes. Traditionally, embossed leather was used in high-end fashion and luxury goods, symbolizing status and craftsmanship. As industrialization took hold, the production of embossed leather became more mechanized, allowing for mass production and wider availability.

In today’s context, this historical craftsmanship is experiencing a renaissance, particularly as consumers seek authenticity and uniqueness in their purchases. B2B buyers are increasingly drawn to embossed leather for its rich heritage and the artisanal appeal it brings to modern products. This evolution reflects a broader trend where heritage and innovation intersect, offering opportunities for businesses to connect with customers who value both tradition and contemporary design.

By understanding these market dynamics, sustainability considerations, and the historical context, B2B buyers can make informed decisions that align with their business objectives and the evolving preferences of their clientele.

Frequently Asked Questions (FAQs) for B2B Buyers of embossed leather fabric

-

How do I choose the right embossed leather fabric for my project?

Choosing the right embossed leather fabric involves considering several factors such as the intended use, pattern, color, and texture. For upholstery, opt for durable options like full hides, which provide larger coverage. Consider the design that aligns with your brand aesthetics—rustic, modern, or themed. Additionally, assess the leather’s thickness and finish, as these can affect both appearance and functionality. Don’t hesitate to request samples to evaluate the quality and suitability for your specific application. -

What are the typical minimum order quantities (MOQs) for embossed leather fabric?

Minimum order quantities for embossed leather can vary significantly by supplier. Generally, you may find MOQs ranging from one half-hide to several full hides, depending on the supplier’s production capacity and the specific embossing patterns. It’s essential to discuss your needs with potential suppliers to understand their policies. If you’re looking for custom embossing, be prepared for higher MOQs, as custom runs typically require more substantial production volumes. -

How can I ensure the quality of embossed leather before making a purchase?

To ensure the quality of embossed leather, start by vetting suppliers through reviews and testimonials from previous clients. Request samples to examine the leather’s texture, durability, and embossing clarity. Additionally, inquire about their quality assurance processes and certifications. A reliable supplier should provide detailed information about the leather’s origin, tanning process, and any warranties. Establishing a solid communication channel can also help clarify any concerns regarding quality. -

What customization options are available for embossed leather?

Customization options for embossed leather are extensive. Many suppliers offer the ability to create unique patterns or incorporate logos into the embossing. You can also choose from a variety of finishes, such as matte, gloss, or metallic. Discuss your specific requirements with the supplier, including dimensions and color preferences. Be aware that custom designs may involve higher costs and longer lead times, so plan accordingly. -

What payment terms should I expect when sourcing embossed leather internationally?

Payment terms when sourcing embossed leather can vary widely among suppliers. Common terms include upfront payments, letters of credit, or payment upon delivery. It’s crucial to clarify payment expectations before finalizing any agreements. Consider negotiating terms that provide security for both parties, such as a deposit followed by the balance upon successful delivery. Additionally, be aware of any currency fluctuations or international transaction fees that may impact your overall costs. -

How long does it typically take to receive an order of embossed leather?

The delivery time for embossed leather orders can depend on several factors, including the supplier’s location, the complexity of the order, and the availability of the chosen materials. Standard orders usually ship within 2-3 business days, while custom orders may take several weeks. When placing an order, ask the supplier for a detailed timeline, including production and shipping times, to plan your project schedule effectively. -

What are the best practices for shipping embossed leather internationally?

When shipping embossed leather internationally, consider working with a logistics provider experienced in handling delicate materials. Ensure that the leather is properly packaged to prevent damage during transit. Confirm the shipping method, whether air or sea freight, and understand the associated costs and timelines. Additionally, familiarize yourself with import regulations in your country to avoid unexpected tariffs or delays. -

How can I verify the ethical sourcing of embossed leather?

To verify the ethical sourcing of embossed leather, inquire about the supplier’s practices regarding animal welfare, environmental sustainability, and labor conditions. Look for certifications such as the Leather Working Group (LWG) certification, which indicates adherence to responsible sourcing standards. Request documentation that outlines the supply chain, including the origin of the hides. Engaging suppliers who are transparent about their sourcing practices will ensure you align with your corporate social responsibility goals.

Top 4 Embossed Leather Fabric Manufacturers & Suppliers List

1. Barbarossa Leather – Western Embossed Designs

Domain: barbarossaleather.com

Registered: 2005 (20 years)

Introduction: Western Embossed Leather features designs inspired by the American West, including Big Sky, Southwest, and Texas styles. The patterns include cattle skulls, intricate paisley motifs, and iconic tribal designs. Notable patterns include Aztec, Birchbark, Bits, Brandito, Brands, Cheyenne, Corona, Derby, Driftwood, Indiano, Loredo, Navajo, Odyssey, Paisley, Plumas, Roses, Secoya, Skulls, Sugar Skulls,…

2. A Leather Store – Embossed Leather Collection

Domain: aleatherstore.com

Registered: 2021 (4 years)

Introduction: Embossed Leather collection includes various types of embossed leather products such as:

1. CASHMERE – embossed vegetable tanned natural Double Shoulder from $18.70

2. AMBER – embossed glossy double shoulders, hand dyed and embossed from $18.70

3. LACE – embossed vegetable tanned natural Double Shoulder from $16.26

4. FONTANELLAS & MARTÍ BULL SIDES – TORRO – 2.0/2.2mm from $16.09 (Sold Out)

5. MAL…

3. Spoonflower – Embossed Leather Look Fabrics & Home Decor

Domain: spoonflower.com

Registered: 2005 (20 years)

Introduction: Embossed-leather-look designs available in fabric by the yard, fabric by the meter, wallpaper, and home decor items such as curtains, bedding, pillows, and dining products. Supports Spoonflower’s community of artists. Custom design upload option available.

4. Leather Hide Store – Premium Embossed Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Premium Embossed Leather, 100% full grain cowhide, ideal for upholstery, custom auto, and general leathercraft use. Popular prints include croc and gator, with additional options like florals, lizard, and stingray. Hand finished by leather artisans. Closeouts available at discounted prices.

Strategic Sourcing Conclusion and Outlook for embossed leather fabric

In the evolving landscape of embossed leather fabric, strategic sourcing remains paramount for B2B buyers aiming to enhance their product offerings. Understanding the diverse range of embossed leather options—from traditional patterns to modern designs—allows businesses to cater to varied market demands. Sourcing from reputable suppliers ensures not only the quality of materials but also compliance with sustainability practices that are increasingly important to consumers worldwide.

As international buyers, particularly those from Africa, South America, the Middle East, and Europe, it is essential to establish strong relationships with manufacturers who can provide customization options and timely delivery. The ability to procure half hides or full hides based on specific project needs adds flexibility to inventory management, enabling companies to optimize costs while meeting customer expectations.

Illustrative image related to embossed leather fabric

Looking ahead, embracing the latest trends in embossed leather, including custom designs and eco-friendly materials, will be crucial in staying competitive. Engage with suppliers who can support your vision and innovation in product design. By prioritizing strategic sourcing today, you position your business for sustained growth and success in the dynamic global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to embossed leather fabric