Introduction: Navigating the Global Market for leather backing

In an increasingly interconnected world, sourcing high-quality leather backing can present significant challenges for international B2B buyers. With a diverse array of products available, including various weights, finishes, and treatments, selecting the right leather backing for your specific application—whether for upholstery, fashion, or industrial uses—can be daunting. This guide serves as a comprehensive resource, outlining the different types of leather backing, their applications across various industries, and essential considerations for supplier vetting, pricing strategies, and logistics.

Understanding the nuances of leather backing is crucial for companies looking to ensure durability, aesthetic appeal, and cost-effectiveness in their products. As B2B buyers from Africa, South America, the Middle East, and Europe (including key markets like Germany and Vietnam) navigate their sourcing options, this guide empowers them to make informed purchasing decisions. It offers actionable insights into identifying reliable suppliers, comparing product specifications, and leveraging market trends to optimize procurement strategies. By addressing the complexities of the leather backing market, this resource equips you with the knowledge needed to enhance your product offerings and stay competitive in a global landscape.

Table Of Contents

- Top 7 Leather Backing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather backing

- Understanding leather backing Types and Variations

- Key Industrial Applications of leather backing

- 3 Common User Pain Points for ‘leather backing’ & Their Solutions

- Strategic Material Selection Guide for leather backing

- In-depth Look: Manufacturing Processes and Quality Assurance for leather backing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather backing’

- Comprehensive Cost and Pricing Analysis for leather backing Sourcing

- Alternatives Analysis: Comparing leather backing With Other Solutions

- Essential Technical Properties and Trade Terminology for leather backing

- Navigating Market Dynamics and Sourcing Trends in the leather backing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather backing

- Strategic Sourcing Conclusion and Outlook for leather backing

- Important Disclaimer & Terms of Use

Understanding leather backing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather Backing | Made from the top layer of the hide, retains natural texture and grain. | High-end leather goods, luxury upholstery | Pros: Durable, high-quality appearance. Cons: Higher cost, may require more care. |

| Split Leather Backing | Derived from the lower layers of the hide, often more affordable. | Budget-friendly leather products, footwear | Pros: Cost-effective, decent durability. Cons: Less aesthetic appeal, may wear faster. |

| Thin Backing Leather | Lightweight and flexible, used for repairs and sub-patching. | Leather repairs, upholstery restoration | Pros: Easy to work with, ideal for repairs. Cons: Limited applications, may not be as durable. |

| Puncture Resistant Backing | Composite material designed to withstand heavy use and punctures. | Commercial upholstery, high-traffic areas | Pros: Long-lasting, reduces replacement costs. Cons: Heavier, potentially higher initial investment. |

| Backing Fabric | Versatile fabric with heat-activated adhesive for leather repairs. | General leather repairs, crafting | Pros: Easy application, adaptable to various needs. Cons: May not provide the same durability as leather. |

What are the Characteristics of Full Grain Leather Backing?

Full grain leather backing is prized for its durability and natural beauty, as it is made from the top layer of the hide. This type retains the hide’s original grain and texture, making it ideal for luxury leather goods and high-end upholstery. Buyers should consider the higher cost associated with full grain leather, as well as the need for regular maintenance to preserve its aesthetic appeal. Its resilience makes it suitable for products that require longevity and a premium finish.

How Does Split Leather Backing Compare to Other Types?

Split leather backing is derived from the lower layers of the hide, making it a more budget-friendly option compared to full grain leather. It is commonly used in the production of affordable leather goods and footwear. While it offers decent durability, buyers should be aware that it may not have the same visual appeal or longevity as higher-grade leather. This type is suitable for businesses looking to balance cost and quality in their product offerings.

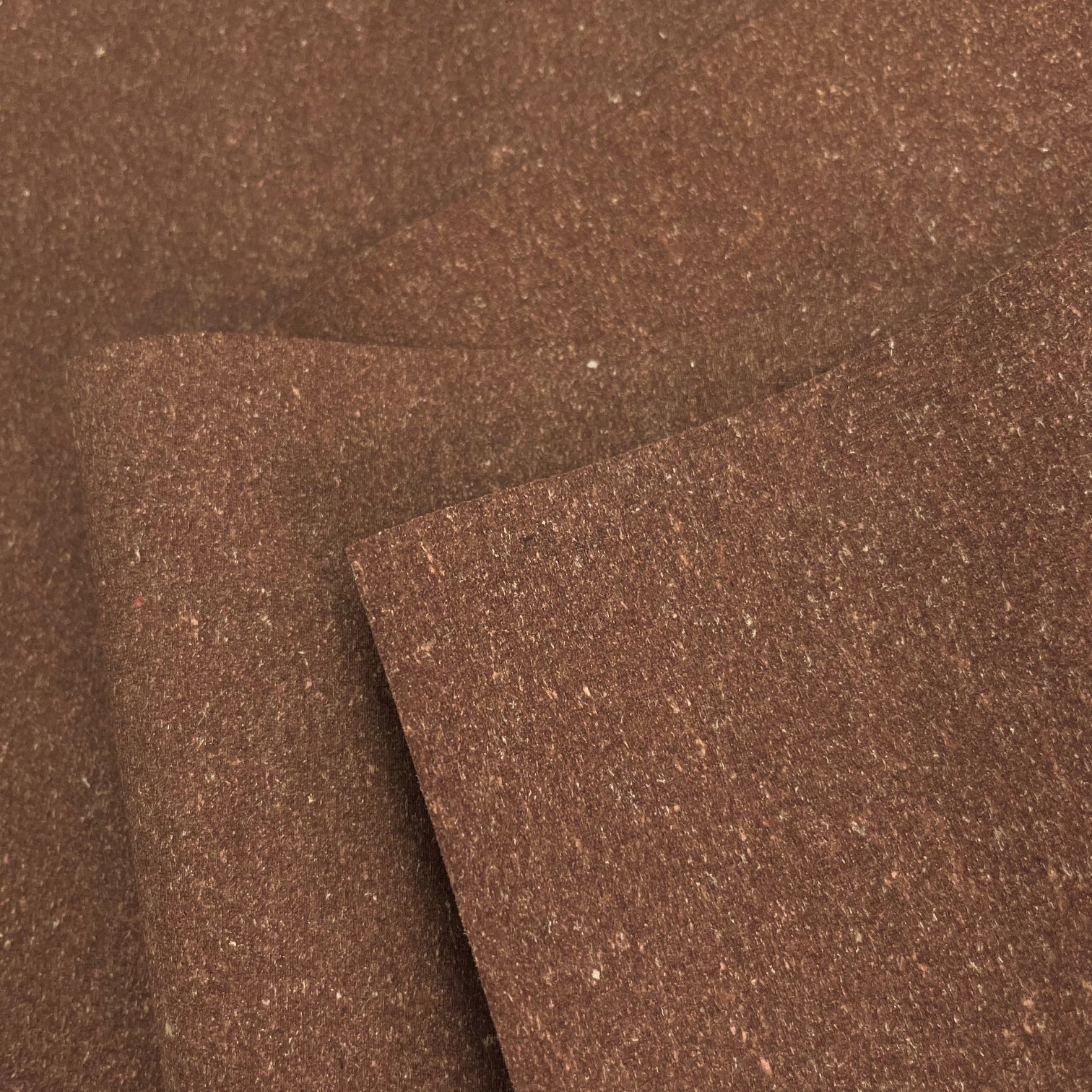

Why Choose Thin Backing Leather for Repairs?

Thin backing leather is lightweight and flexible, making it an excellent choice for leather repairs and sub-patching. Typically used in upholstery restoration, this type allows for easy handling and application. However, its limited thickness may restrict its use in more demanding applications. Buyers should consider this option for projects requiring minimal bulk and ease of use, especially in repair scenarios.

What are the Advantages of Puncture Resistant Backing?

Puncture resistant backing is designed for high-traffic areas, providing added durability to leather and fabric. This composite material is ideal for commercial upholstery in restaurants, hotels, and other venues where wear and tear is common. While it offers significant long-term cost savings by reducing replacement frequency, buyers should note that it may come at a higher initial investment and added weight.

How Can Backing Fabric Enhance Leather Repair Projects?

Backing fabric is a versatile option that features a heat-activated adhesive, making it suitable for a range of leather repair applications. It can be used in crafting and general repairs, offering ease of application. However, while it is adaptable, it may not provide the same level of durability as leather options. Businesses should evaluate their specific repair needs to determine if this fabric aligns with their project requirements.

Key Industrial Applications of leather backing

| Industry/Sector | Specific Application of Leather Backing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for seats and interiors | Enhances durability and aesthetic appeal of vehicle interiors | Sourcing high-quality, flexible leather that meets safety standards. |

| Furniture Manufacturing | Upholstered furniture and seating solutions | Provides a premium look while ensuring longevity | Consider thickness, texture, and color matching with existing designs. |

| Leather Goods Production | Bags, wallets, and accessories | Adds structural integrity and a luxurious feel | Ensure compatibility with various leather types and processing methods. |

| Footwear | Shoe linings and insoles | Improves comfort and durability in footwear production | Focus on sourcing lightweight, breathable leather that complies with international regulations. |

| Hospitality and Commercial Spaces | Booths and seating in restaurants and hotels | Increases lifespan of furniture, reducing replacement costs | Look for puncture-resistant and easy-to-clean leather backing options. |

How is Leather Backing Used in the Automotive Industry?

In the automotive sector, leather backing is primarily utilized for upholstery in seats and interior panels. This application enhances both durability and aesthetic appeal, making vehicles more attractive to consumers. International buyers should consider sourcing leather that meets safety standards and can withstand varying climates, particularly in regions like Africa and the Middle East where temperatures can be extreme.

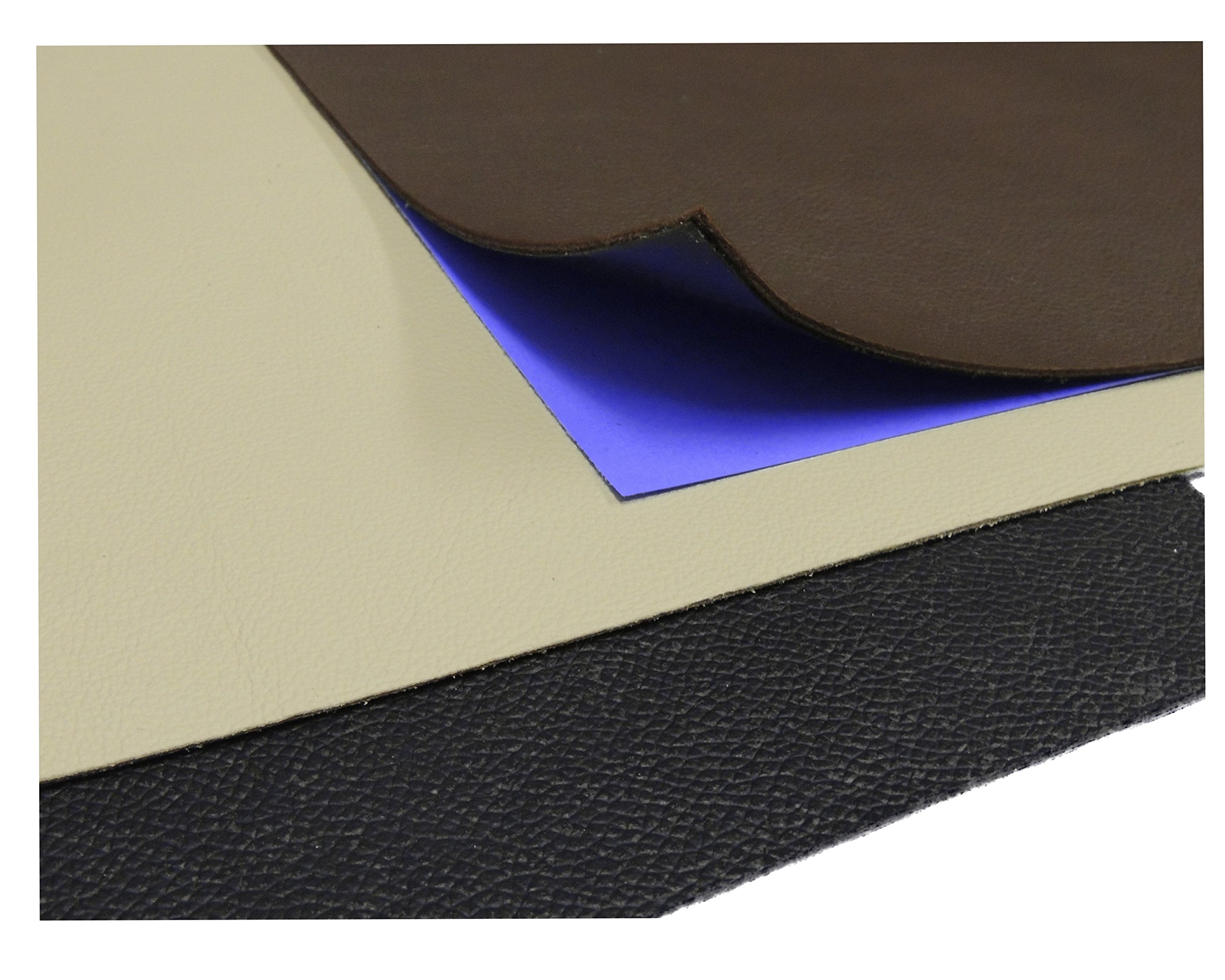

Illustrative image related to leather backing

What Role Does Leather Backing Play in Furniture Manufacturing?

Furniture manufacturers often employ leather backing for upholstered items such as sofas and chairs. This backing not only adds a premium look but also significantly enhances the longevity of the furniture. Buyers should focus on sourcing leather that matches their design requirements in terms of thickness and texture while ensuring that it can endure wear and tear, especially in high-traffic commercial environments in Europe and South America.

In What Ways is Leather Backing Important for Leather Goods Production?

In the production of leather goods such as bags, wallets, and accessories, leather backing serves to provide structural integrity and a luxurious feel. It is essential for manufacturers to ensure that the backing material is compatible with various leather types and processing methods. International buyers should be aware of the quality standards and regulations in their respective markets, particularly in Europe, to ensure product compliance.

How is Leather Backing Used in Footwear Production?

Leather backing finds significant application in footwear, particularly for linings and insoles. This use enhances comfort and durability, which are critical factors for consumer satisfaction in the competitive footwear market. Buyers should prioritize sourcing lightweight and breathable leather that adheres to international regulations, particularly in regions like Germany and Vietnam, where quality standards are stringent.

Illustrative image related to leather backing

What Benefits Does Leather Backing Provide in Hospitality and Commercial Spaces?

In hospitality settings, leather backing is used for booths and seating in restaurants and hotels. This application not only increases the lifespan of the furniture but also reduces replacement costs, making it a cost-effective solution for business owners. When sourcing leather backing for these applications, buyers should look for options that are puncture-resistant and easy to clean, as these features are essential for maintaining hygiene and appearance in high-traffic areas.

3 Common User Pain Points for ‘leather backing’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather Backing for Durable Applications

The Problem: B2B buyers often struggle to find leather backing that meets the durability and quality requirements for their specific applications. Whether it’s for upholstery in high-traffic areas like restaurants or for luxury goods, the risk of sourcing inferior quality materials can lead to premature wear and increased costs. Buyers may face issues such as inconsistent thickness, poor adhesion, or the leather failing to withstand environmental factors like moisture or UV exposure.

The Solution: To ensure the procurement of high-quality leather backing, buyers should establish clear specifications that include thickness, weight, and treatment methods. Partnering with reputable suppliers known for their stringent quality control processes can significantly mitigate risks. It’s advisable to request samples before placing bulk orders, as this allows buyers to assess the leather’s performance in real-world conditions. Additionally, considering products with added features like puncture resistance or moisture-proofing can enhance durability, particularly in commercial environments. Regular communication with suppliers about specific needs and industry trends can foster better relationships and ensure that the materials sourced align with the latest standards and innovations.

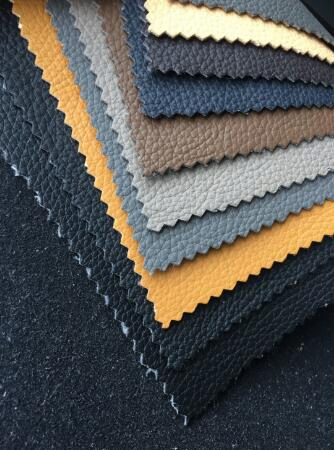

Scenario 2: Managing Variability in Leather Color and Texture

The Problem: Variability in color and texture can pose a significant challenge for B2B buyers, especially when consistency is critical for branding and customer satisfaction. Leather backing can exhibit natural variations that lead to discrepancies between batches, making it difficult for manufacturers to maintain uniformity in their products. This inconsistency can result in costly returns, delays in production, and reputational damage.

The Solution: To address this issue, buyers should prioritize working with suppliers that provide detailed product descriptions and color matching services. Implementing a standardized color reference system can help in achieving consistency across different batches. Buyers should also consider investing in color-matching tools or software that allows them to compare new shipments against existing stock. Establishing a close relationship with suppliers can facilitate better communication regarding color expectations and allow for adjustments in future orders. Additionally, utilizing leather finishing techniques that enhance uniformity without compromising the material’s natural appeal can be beneficial.

Illustrative image related to leather backing

Scenario 3: Ensuring Proper Adhesion and Application Techniques for Leather Backing

The Problem: A common pain point for buyers is the challenge of achieving effective adhesion between leather backing and other materials, which is crucial for the longevity and performance of finished products. Incorrect application techniques or unsuitable adhesives can lead to peeling or bubbling, undermining the integrity of the final product. This issue is particularly prevalent in industries like upholstery and fashion, where aesthetics and functionality must align.

The Solution: To ensure proper adhesion, buyers should invest in training for their application teams, focusing on the best practices for bonding leather backing to various substrates. It’s essential to choose the right type of adhesive based on the specific materials being bonded, considering factors such as moisture resistance and flexibility. Conducting preliminary tests with different adhesives and application methods can help identify the most effective solutions. Additionally, suppliers often provide technical support and product recommendations that can guide buyers in selecting the appropriate products for their needs. Regular maintenance and inspection of bonded areas can help catch any issues early, ensuring the longevity of the final product.

Strategic Material Selection Guide for leather backing

What Are the Key Properties of Common Leather Backing Materials?

When selecting leather backing materials, it is essential to consider their properties, performance characteristics, and suitability for specific applications. Here, we analyze four common materials used for leather backing: genuine leather, synthetic leather, fabric backing, and puncture-resistant backing.

How Does Genuine Leather Perform as a Backing Material?

Genuine leather is a traditional and widely used backing material known for its durability and aesthetic appeal. It typically boasts a temperature tolerance of up to 150°F (65°C) and can withstand moderate pressure, making it suitable for various applications, including upholstery and fashion accessories.

Pros: The primary advantage of genuine leather is its longevity and ability to age beautifully, which can enhance the product’s value. It is also breathable and provides a luxurious feel.

Cons: However, genuine leather can be expensive, and its manufacturing process is complex, requiring significant resources and time. Additionally, it may not be suitable for environments with high humidity, as it can absorb moisture and become damaged.

Considerations for International Buyers: B2B buyers from regions like Africa and the Middle East should be aware of local regulations regarding animal products. Compliance with standards such as ASTM for leather quality can also impact purchasing decisions.

What Advantages Does Synthetic Leather Offer?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is increasingly popular due to its versatility and lower cost. It can withstand temperatures of up to 120°F (49°C) and offers good resistance to wear and tear.

Pros: The key advantage of synthetic leather is its affordability and ease of maintenance. It is also available in various colors and textures, allowing for greater design flexibility.

Cons: On the downside, synthetic leather may not offer the same level of breathability as genuine leather, which can lead to discomfort in certain applications. Additionally, it may not have the same aesthetic appeal, which can be a drawback for high-end products.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should consider compliance with environmental regulations regarding synthetic materials. Certifications such as OEKO-TEX can enhance marketability.

Illustrative image related to leather backing

How Does Fabric Backing Enhance Leather Applications?

Fabric backing, often made from polyester or cotton, serves as a supportive layer for leather products. It can improve the overall strength and flexibility of leather applications, withstanding temperatures of up to 140°F (60°C).

Pros: Fabric backing is lightweight and can be cost-effective, making it suitable for a variety of applications, including automotive upholstery and fashion items.

Cons: However, fabric backing may not provide the same level of durability as leather, particularly in high-stress applications. It can also absorb moisture, which may lead to mold or mildew if not properly treated.

Considerations for International Buyers: Buyers should ensure that fabric backings meet local flammability and safety standards, especially in regions with stringent regulations.

What Is the Role of Puncture-Resistant Backing in Leather Products?

Puncture-resistant backing is designed to enhance the durability of leather products, particularly in high-traffic environments. This backing typically consists of a composite material that can withstand punctures and tears, making it ideal for commercial upholstery.

Pros: The primary advantage is its ability to significantly extend the lifespan of leather products, reducing replacement costs over time. This is particularly beneficial in industries such as hospitality and automotive.

Cons: The complexity of manufacturing puncture-resistant backing can lead to higher costs. Additionally, it may require specific adhesives or bonding processes, which can complicate production.

Considerations for International Buyers: Buyers should verify that puncture-resistant materials comply with local safety and performance standards, such as those set by ASTM or ISO, to ensure product reliability.

Summary Table of Leather Backing Materials

| Material | Typical Use Case for leather backing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Upholstery, fashion accessories | Longevity and luxurious feel | High cost and complex manufacturing | High |

| Synthetic Leather | Fashion items, upholstery | Affordability and design flexibility | Less breathable and aesthetic appeal | Medium |

| Fabric Backing | Automotive upholstery, fashion items | Lightweight and cost-effective | Lower durability and moisture absorption | Low |

| Puncture-Resistant Backing | Commercial upholstery, flooring | Extends product lifespan, cost-saving | Higher production costs and complexity | Medium |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding leather backing materials. Understanding the properties, advantages, and limitations of each option can lead to better product performance and customer satisfaction.

Illustrative image related to leather backing

In-depth Look: Manufacturing Processes and Quality Assurance for leather backing

What Are the Main Stages of Manufacturing Leather Backing?

The manufacturing process for leather backing involves several critical stages that ensure the final product meets industry standards and customer expectations. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection and preparation of raw materials. Leather hides are sourced from reputable suppliers, ensuring they meet quality standards. The hides are then treated to remove impurities, with careful attention paid to their thickness, grain quality, and color consistency. This stage often involves soaking the hides in a solution to soften them, making them easier to work with. Additionally, various treatments may be applied to enhance durability and resistance to wear and tear.

Forming the Leather Backing

Once the materials are prepared, the next step is forming. This involves cutting the leather into specific shapes and sizes based on customer specifications. Advanced cutting techniques, such as die-cutting or laser cutting, are employed to ensure precision and reduce waste. This stage may also involve layering thinner pieces of leather or other materials to create a composite backing that offers enhanced strength and flexibility.

Assembly of Components

After forming, the assembly stage comes into play. For leather backing products designed for specific applications, such as upholstery or automotive interiors, additional components like adhesives or reinforcement fabrics may be integrated. This assembly process requires skilled labor to ensure that all components are securely bonded and aligned correctly. Quality checks are performed at this stage to verify that the assembly meets design specifications.

Finishing Touches

The final stage is finishing, which involves adding any surface treatments or coatings that enhance the leather’s appearance and functionality. This may include dyeing, polishing, or applying protective finishes to improve resistance to stains and moisture. Each product undergoes a thorough inspection during this stage to ensure it meets quality standards before packaging and shipping.

How is Quality Assurance Implemented in Leather Backing Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for leather backing, ensuring that the final products are durable, reliable, and meet international standards. Various quality control (QC) checkpoints and testing methods are employed throughout the production process.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers must familiarize themselves with relevant international standards that govern the leather industry. ISO 9001 is a widely recognized standard that outlines criteria for a quality management system. Compliance with this standard ensures that manufacturers maintain consistent quality in their products and processes. Other industry-specific certifications may include CE marking for products sold in Europe, which indicates compliance with health and safety standards, and API standards for specific applications in the oil and gas industry.

What Are the Key Quality Control Checkpoints?

Quality control in leather backing manufacturing typically involves several key checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival. Suppliers must provide documentation that verifies the quality and specifications of the leather hides. Any discrepancies are addressed before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor adherence to specifications. This includes checking the accuracy of cuts, the strength of adhesive bonds, and the overall assembly quality. Any defects identified at this stage are rectified immediately to avoid further issues down the production line.

-

Final Quality Control (FQC): Before products are packaged for shipment, a final inspection is performed. This includes checking for defects in appearance, verifying dimensions, and ensuring that all specifications have been met. Products that do not pass this inspection are either reworked or discarded.

Which Testing Methods Are Commonly Used for Leather Backing?

To ensure the quality and durability of leather backing, manufacturers employ various testing methods, including:

-

Tensile Strength Testing: This test measures the leather’s resistance to being pulled apart, ensuring it can withstand the stresses it will encounter in use.

-

Tear Resistance Testing: This assesses how well the leather can endure tearing forces, which is crucial for applications where the material may be subjected to sharp objects.

-

Flexibility Testing: This examines the leather’s ability to bend without cracking, an essential quality for applications requiring mobility and flexibility.

-

Water Resistance Testing: This evaluates how well the leather backing can repel water, which is particularly important for products used in environments exposed to moisture.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers. Here are some actionable strategies:

-

Conduct Audits: Regular audits of manufacturing facilities can provide insight into the processes and quality assurance practices in place. Buyers should request to see documentation related to ISO certifications and quality management processes.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC practices, testing methods, and results. This transparency can help buyers assess the reliability of the products they are considering.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance processes. This is especially important for international transactions, where distance may complicate direct oversight.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Differences in regulations, standards, and testing methods can impact the purchasing decision.

Buyers should be aware of:

-

Regional Standards: Different regions may have specific standards for leather products. For example, European buyers may prioritize CE marking, while buyers in other regions may look for different certifications.

-

Communication Barriers: Language and cultural differences can impact the understanding of quality requirements. Buyers should ensure clear communication with suppliers regarding expectations and specifications.

-

Logistical Considerations: Shipping and logistics can affect the quality of leather backing products. Buyers should consider how products are packaged and transported to mitigate risks of damage during transit.

By understanding these elements of manufacturing processes and quality assurance, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality and performance requirements for leather backing products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather backing’

Introduction

Sourcing leather backing requires careful consideration of various factors to ensure quality, durability, and suitability for your specific applications. This guide provides a practical checklist to aid B2B buyers in navigating the complexities of procuring leather backing, emphasizing critical steps to enhance decision-making and supplier selection.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the leather backing meets your product requirements. Consider factors such as thickness, weight, and size, as these attributes will influence the performance and application of the backing material. For instance, a heavier backing may offer increased durability for high-traffic uses, while a lighter option might be preferable for more delicate applications.

Step 2: Identify Your Application Needs

Understanding the specific applications for the leather backing will guide your sourcing decisions. Different uses, such as upholstery, automotive interiors, or fashion accessories, may demand varying properties, like moisture resistance or flexibility. Clarify whether you need backing for heavy-duty commercial use or lighter consumer products, as this will affect the type of leather and its treatment options.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Request detailed company profiles, product samples, and case studies that showcase their experience in your industry. Pay attention to customer reviews and testimonials to gauge the reliability and quality of the supplier’s offerings. Additionally, consider suppliers who provide transparent information about sourcing and manufacturing processes.

Step 4: Verify Quality Standards and Certifications

Ensure that the leather backing complies with relevant industry standards and certifications. This might include environmental regulations, such as those set by REACH in Europe, or quality assurance standards like ISO 9001. Verified certifications can not only safeguard your business against compliance issues but also assure customers of product quality and ethical sourcing.

Step 5: Request Samples for Testing

Before finalizing your purchase, it’s advisable to request samples from shortlisted suppliers. Testing samples allows you to evaluate the physical properties of the leather backing, such as texture, durability, and flexibility. This step is particularly important if you are working on a project that requires specific performance characteristics, ensuring that the chosen material aligns with your expectations.

Step 6: Understand Pricing and Payment Terms

Discuss pricing structures and payment terms thoroughly with potential suppliers. Understanding the cost per unit, bulk discounts, and shipping fees will help you budget effectively. Additionally, clarify payment terms to avoid any surprises, such as upfront deposits or net payment schedules, ensuring that they align with your cash flow management.

Step 7: Establish a Clear Communication Plan

Effective communication is vital throughout the sourcing process. Establish a clear line of communication with your chosen supplier to facilitate updates on order status, delivery timelines, and any potential issues. Regular communication can help build a strong supplier relationship, leading to better service and responsiveness in future transactions.

Illustrative image related to leather backing

By following this checklist, B2B buyers can enhance their sourcing strategy for leather backing, ensuring that they select the right materials and suppliers to meet their business needs effectively.

Comprehensive Cost and Pricing Analysis for leather backing Sourcing

What Are the Key Cost Components in Leather Backing Sourcing?

When evaluating the cost structure for leather backing, several components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of leather used significantly influences the cost. For instance, full-grain leather typically commands a higher price compared to split or synthetic leather. Prices can range from $5 to $90 per hide, depending on quality and specifications.

-

Labor: Skilled labor is essential for processing leather backing, impacting overall costs. Labor rates vary by region, with higher costs in developed markets compared to emerging economies.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can reduce these overheads, thereby lowering the final product price.

-

Tooling: Custom tooling for specific designs or features can incur additional costs. Buyers should consider whether the tooling cost is justified by the anticipated volume of orders.

-

Quality Control (QC): Ensuring the leather backing meets industry standards requires investment in quality assurance processes. This can add approximately 5-10% to the total cost.

-

Logistics: Transportation costs vary based on distance, shipping methods, and Incoterms. Buyers should evaluate the total logistics costs, especially when sourcing from international suppliers.

-

Margin: Supplier profit margins typically range from 10% to 30%, depending on market conditions and competition.

How Do Price Influencers Affect Leather Backing Costs?

Several factors can influence the pricing of leather backing, making it crucial for buyers to understand these nuances.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts due to economies of scale. Buyers should negotiate MOQs that align with their business needs to optimize costs.

-

Specifications and Customization: Customized products usually come at a premium. Buyers should clearly define their requirements to avoid unexpected costs later in the sourcing process.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., environmentally friendly or cruelty-free) can increase costs. Buyers need to balance quality with budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge higher prices but offer better quality assurance and service.

-

Incoterms: The choice of Incoterms impacts the total cost of ownership. Terms like CIF (Cost, Insurance, and Freight) can lead to higher upfront costs, while FOB (Free on Board) may result in lower initial expenses but higher logistics responsibility for the buyer.

What Are the Best Negotiation Tips for B2B Buyers in Leather Backing Sourcing?

Effective negotiation is vital to achieving cost efficiency in leather backing sourcing. Here are some actionable tips for international buyers:

Illustrative image related to leather backing

-

Understand Total Cost of Ownership (TCO): Evaluate all costs associated with the product, including shipping, customs duties, and potential returns. This holistic view will help in negotiations.

-

Research Market Rates: Being informed about current market prices for leather backing can empower buyers during negotiations. Utilize industry reports and trade publications for insights.

-

Leverage Long-term Relationships: Building rapport with suppliers can lead to better pricing and terms. Suppliers may offer discounts or improved terms to loyal customers.

-

Be Flexible: If a supplier cannot meet the desired price, consider negotiating other terms, such as payment schedules or delivery timelines, to create a win-win situation.

-

Explore Alternative Suppliers: Diversifying suppliers can create competitive pressure, allowing buyers to negotiate better terms.

Conclusion: How to Approach Leather Backing Sourcing for Cost Efficiency?

International buyers from regions such as Africa, South America, the Middle East, and Europe need to approach leather backing sourcing strategically. Understanding the cost components, price influencers, and negotiation tactics will enable them to make informed decisions and optimize their sourcing processes. While indicative prices can serve as a guideline, the actual costs may vary based on specific requirements and supplier capabilities. Engaging in thorough research and maintaining open communication with suppliers will be essential for achieving favorable outcomes.

Alternatives Analysis: Comparing leather backing With Other Solutions

When considering leather backing, it’s essential to evaluate alternative solutions that can serve similar purposes in various applications. Understanding the strengths and weaknesses of these alternatives can help B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Leather Backing | Puncture and Tear Resistant Backing | Backing Fabric (Vinyl Pro) |

|---|---|---|---|

| Performance | Durable, flexible, and aesthetically pleasing. Ideal for high-end applications. | Extremely durable, designed for high-traffic areas, puncture-resistant. | Good for repairs, offers adhesion with heat activation. |

| Cost | Higher cost, typically ranges from $90 for half hides. | Mid-range pricing, cost-effective for commercial use. | Lower cost, approximately $5.95 for small sizes. |

| Ease of Implementation | Requires skilled handling for cutting and application. | Easy to apply, designed for straightforward use in upholstery. | Simple to use, generally requires minimal skills. |

| Maintenance | Requires regular care to maintain appearance and longevity. | Low maintenance, resistant to wear and tear. | Easy to maintain, usually washable and reusable. |

| Best Use Case | Premium upholstery, luxury goods, and artisanal products. | Commercial upholstery and flooring in high-traffic environments. | Quick fixes for leather and vinyl repairs. |

What Are the Advantages and Disadvantages of Puncture and Tear Resistant Backing?

Puncture and tear-resistant backing is specifically engineered for demanding environments, such as restaurants and clubs. Its primary advantage is durability; it withstands heavy use and resists damage from sharp objects, making it ideal for commercial applications. However, while it excels in performance, it may lack the aesthetic appeal and premium feel that leather backing offers, which can be a consideration for brands focused on luxury and design.

How Does Backing Fabric (Vinyl Pro) Compare to Leather Backing?

Backing fabric, such as that offered by Vinyl Pro, provides a practical alternative for repairs, particularly for minor damage on leather or vinyl surfaces. It is cost-effective and easy to implement, requiring minimal skill to apply. However, its performance may not match the durability and flexibility of leather backing, especially in high-stress applications. While it is useful for quick fixes, it may not provide the same long-term solution or aesthetic quality as leather backing.

Illustrative image related to leather backing

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right backing solution hinges on several factors, including the intended use, budget constraints, and required performance characteristics. For high-end applications where aesthetics matter, leather backing remains a superior choice. Conversely, for environments that experience heavy wear and tear, puncture and tear-resistant backing could be more suitable. If quick repairs are needed at a lower cost, backing fabrics might serve the purpose effectively. Ultimately, B2B buyers should assess their unique requirements and weigh the pros and cons of each option to find the best fit for their specific applications.

Essential Technical Properties and Trade Terminology for leather backing

When sourcing leather backing for various applications, understanding its technical properties and the associated trade terminology is crucial for effective procurement and product development. Here’s a breakdown of essential specifications and terms that international B2B buyers should be familiar with.

What Are the Key Technical Properties of Leather Backing?

1. Material Grade

Material grade refers to the quality and type of leather used in the backing. Common grades include full-grain, top-grain, and split leather. Full-grain leather, being the highest quality, maintains the original grain and is more durable, making it ideal for high-end applications. Understanding the grade helps buyers select the right product for their specific needs, ensuring longevity and performance.

2. Weight (Oz)

The weight of leather backing, typically measured in ounces (oz), indicates its thickness and sturdiness. For instance, leather backing can range from 2.5 to 3 oz. A heavier weight often correlates with increased durability and resistance to wear, which is particularly important in high-traffic environments. Buyers should consider the weight in relation to the intended use to ensure optimal performance.

Illustrative image related to leather backing

3. Size and Dimensions

Leather backing is often sold in specific sizes, such as half hides or smaller patches. Typical dimensions can range from 18 to 20 square feet for larger pieces, while smaller patches may be as little as 5” x 6”. Knowing the size options available helps buyers gauge how much material they need for their projects and can affect cost and waste management.

4. Puncture and Tear Resistance

This property indicates the material’s ability to withstand physical stress without compromising its integrity. Leather backing with puncture and tear-resistant features is essential for applications like commercial upholstery, where it faces daily wear from high heels or other sharp objects. Understanding these resistance metrics can lead to better product choices, reducing replacement costs in the long run.

5. Adhesion Properties

Some leather backings come with special coatings or treatments that enhance their adhesion capabilities. This is particularly relevant for applications where the leather is bonded to other materials, such as vinyl or fabric. Buyers should assess these properties to ensure compatibility with their intended manufacturing processes.

What Are Common Trade Terms Related to Leather Backing?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. In the leather industry, buyers may work with OEMs to obtain custom leather backing that meets specific design and functional requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For leather backing, MOQs can vary significantly based on the supplier and the material grade. Understanding the MOQ helps buyers plan their inventory and budget effectively.

Illustrative image related to leather backing

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. In the context of leather backing, an RFQ can help buyers compare different suppliers and make informed purchasing decisions based on price, quality, and delivery options.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Familiarity with Incoterms is vital for buyers engaged in global sourcing, as it clarifies shipping costs and risk management.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the product. For leather backing, lead times can vary based on the supplier’s location, production capacity, and the complexity of the order. Understanding lead times is essential for effective project planning and inventory management.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right leather backing for their specific applications while optimizing procurement processes.

Navigating Market Dynamics and Sourcing Trends in the leather backing Sector

The leather backing sector is experiencing a significant transformation, driven by various global market dynamics and sourcing trends. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are navigating a landscape marked by increased demand for high-quality materials, technological advancements, and evolving consumer preferences. Key drivers include a growing emphasis on durability and performance in applications ranging from upholstery to fashion. Buyers are increasingly seeking leather backing solutions that not only meet aesthetic standards but also offer enhanced strength and resistance to wear, which are crucial for high-traffic environments.

Emerging technologies are also reshaping the sourcing landscape. The rise of digital platforms facilitates direct connections between manufacturers and buyers, streamlining procurement processes. Advanced analytics and machine learning are being utilized to predict trends and optimize inventory management, allowing suppliers to respond swiftly to changing market demands. Furthermore, the integration of automation in production processes is enhancing efficiency and reducing lead times. As sustainability becomes a priority, many manufacturers are investing in eco-friendly practices, offering products that align with the ethical considerations of modern consumers.

How Is Sustainability Influencing B2B Sourcing in the Leather Backing Sector?

Sustainability is increasingly at the forefront of purchasing decisions in the leather backing market. The environmental impact of leather production, particularly in relation to water usage, chemical treatments, and waste, is prompting buyers to prioritize ethical sourcing. B2B buyers are now more informed and concerned about the origins of their materials, pushing for transparency in supply chains. This shift is prompting suppliers to adopt sustainable practices, such as utilizing vegetable-tanned leather, which reduces the reliance on harmful chemicals, and sourcing hides from certified farms that prioritize animal welfare.

Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming vital for suppliers aiming to attract environmentally conscious buyers. These certifications not only validate the sustainable practices of manufacturers but also provide buyers with assurance about the ethical integrity of their sourcing decisions. As a result, the demand for leather backing products that are certified organic or eco-friendly is on the rise, influencing sourcing strategies across the globe.

Illustrative image related to leather backing

What Is the Historical Context of Leather Backing in B2B Markets?

The evolution of leather backing can be traced back to its origins as a byproduct of the meat industry, where hides were used primarily for functional applications. Over time, as fashion and upholstery markets expanded, the demand for high-quality leather backing grew, leading to innovations in tanning and finishing processes. The introduction of synthetic alternatives in the late 20th century provided competition, but genuine leather has maintained its status due to its unique qualities.

In the last decade, the leather backing sector has witnessed a resurgence as consumers increasingly value craftsmanship and authenticity. This trend is further fueled by a growing appreciation for sustainable and ethically sourced materials, reflecting broader shifts in consumer behavior. As a result, the leather backing market is not only adapting to current trends but also redefining its identity in the context of modern B2B sourcing, making it a dynamic area for international buyers to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of leather backing

-

How do I choose the right leather backing for my products?

When selecting leather backing, consider the intended application and required durability. For upholstery, opt for thicker leather (2.5-3 oz) to provide strength and resilience. If you need a flexible backing for repairs, thinner options (around 1.6 oz) may be suitable. Additionally, evaluate the hide’s characteristics, such as color and texture, to ensure compatibility with your final product. It’s also advisable to request samples from suppliers to assess quality before making bulk purchases. -

What are the key factors in evaluating leather backing suppliers?

Key factors include the supplier’s reputation, product quality, and ability to meet your specific requirements. Check for certifications that demonstrate adherence to industry standards. Assess their production capacity to ensure they can handle your order volume and timelines. Customer reviews and case studies can provide insights into their reliability. Additionally, clear communication and responsiveness during your inquiry process are critical indicators of a good partnership. -

What is the minimum order quantity (MOQ) for leather backing?

MOQs for leather backing can vary widely based on the supplier and the type of leather. Typically, you may encounter MOQs ranging from 50 to 500 square feet. However, some suppliers may offer lower MOQs for custom orders or sample runs. Always confirm the MOQ with potential suppliers early in negotiations to ensure it aligns with your business needs and budget. -

How can I ensure the quality of leather backing before purchasing?

To ensure quality, request samples of the leather backing you intend to purchase. Inspect the samples for thickness, texture, and color consistency. Additionally, inquire about the supplier’s quality assurance processes, including any testing or certifications they conduct. Establishing clear specifications and expectations in your purchase agreement can also help mitigate risks associated with quality discrepancies. -

What payment terms should I expect when sourcing leather backing internationally?

Payment terms vary by supplier and region but typically include options like upfront payment, deposits, or net terms (e.g., net 30, net 60). It’s common for suppliers to require a deposit before processing an order, especially for larger quantities. Discuss and negotiate terms that are favorable for your cash flow while ensuring security for both parties. Using secure payment methods, such as letters of credit or escrow services, can provide additional protection. -

What are the logistics considerations when importing leather backing?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Determine whether air or sea freight best suits your delivery speed and budget. Ensure that your supplier provides necessary documentation for customs, such as invoices and certificates of origin. Additionally, familiarize yourself with import regulations in your country to avoid delays and unexpected tariffs. Working with a reliable freight forwarder can streamline the process. -

How can I customize leather backing to suit my specific needs?

Customization options may include variations in thickness, color, texture, and size. Discuss your requirements with potential suppliers, as many are willing to accommodate custom orders. Some suppliers may also offer printing or branding on the leather backing. Be prepared to provide detailed specifications and, if necessary, work on prototypes to ensure the final product meets your expectations. -

What should I know about leather backing certifications and compliance?

Certifications related to leather backing can vary based on regional standards and industry requirements. Look for certifications such as ISO, REACH, or other environmental and quality standards that demonstrate responsible sourcing and manufacturing practices. Compliance with these standards can enhance your product’s marketability and meet consumer demands for sustainable and ethically sourced materials. Always verify the certifications with the supplier to ensure authenticity.

Top 7 Leather Backing Manufacturers & Suppliers List

1. District Leathers – Thin Recycled Leather Bonded Backing

Domain: districtleathers.com

Registered: 2016 (9 years)

Introduction: {‘name’: ‘Thin Recycled Leather Bonded Backing’, ‘price’: ‘$24.99’, ‘width’: ’55 inches’, ‘thickness’: ‘0.3 mm / 0.75 oz’, ‘description’: “Our recycled leather backing is the perfect material to use for making bags, small leather goods, wallets, and other leather crafts that would require a touch of stiffness. Both sides of the interfacing are not backed and can be glued to either leather or suede…

2. Amblard Leather Atelier – Durable Leather Backing

Domain: amblardleatheratelier.com

Registered: 2011 (14 years)

Introduction: Leather backing for various applications, available in multiple colors and textures, designed for durability and versatility in crafting.

3. Refinish Coatings – Thin Backing Leather

Domain: refinishcoatings.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Thin Backing Leather”, “price”: “$7.00”, “description”: “Very thin but strong piece of leather used for sub-patching material.”, “size”: “5\” x 6\””, “weight”: “1.6 oz”, “dimensions”: “5 × 6 × 0.25 in”, “intended_use”: “professional use only”}

4. Vinyl Pro – Backing Fabric

Domain: vinylpro.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Backing Fabric”, “brand”: “Vinyl Pro”, “regular_price”: “$5.95”, “sizes”: [{“size”: “Small (12″ x 3″)”, “price”: “$5.95”}, {“size”: “Medium (12″ x 10″)”, “price”: “$11.95”}, {“size”: “Large (12″ x 24″)”, “price”: “$14.95”}], “description”: “A supportive piece of fabric for vinyl and leather repairs (holes, slices). One side is heat activated for adhesion to repair area.”, “substr…

5. FabTuff® – Puncture and Tear Resistant Backing

Domain: fabricback.com

Registered: 2009 (16 years)

Introduction: Puncture and Tear Resistant Backing for Fabric and Leather, branded as FabTuff®. Provides added durability to fabrics and flooring, specifically designed for commercial upholstery and flooring applications. Typical uses include restaurant booths, chairs, nightclub dance floors, and other high traffic areas. FabTuff® is available in two types: FabTuff® 1, which is a puncture and tear resistant back…

6. Leather Touch – 9 x 10 Leather Repair Cloth

Domain: leathertouchupdye.com

Registered: 2012 (13 years)

Introduction: {“name”: “9 x 10″ Leather Repair Cloth”, “price”: “USD $3.95”, “sku”: “LTUD-LRC”, “dimensions”: “9 x 10 inches”, “description”: “An excellent backing for all your leather repairs will bend and flex at the same rate as the leather. The leather filler bonds into the fibers of the cloth making an excellent quality backing for all thickness of leather. Does not produce backing indentations.”, “weight”…

7. WLHTex – Polyester Leather Backing Fabric

Domain: wlhtex.com

Registered: 2019 (6 years)

Introduction: 100% polyester leather backing fabric, thickness: 0.6-0.65, poly wet process PU leather backer, 0.73 brushing dull velvet PU base, 0.70 super high tear strength, 250GMS polyester material, 0.45 thickness cheap B imitation cotton polyvinyl backing, wet process PU faux suede backer, recycled PET knitted tricot, PVC backed polyester fabric, electronic packing leather back fabric, imitation suede, tec…

Strategic Sourcing Conclusion and Outlook for leather backing

What Are the Key Takeaways for B2B Buyers in Leather Backing Sourcing?

In today’s competitive landscape, strategic sourcing of leather backing materials offers significant advantages for B2B buyers across various industries. Understanding the diverse options available—from thin backing leather for sub-patching to puncture-resistant composites for high-traffic applications—enables buyers to make informed decisions that enhance product durability and customer satisfaction. Prioritizing quality and compatibility with existing materials is crucial to achieving optimal results in leather repair and upholstery projects.

How Can Strategic Sourcing Enhance Your Supply Chain?

Implementing a strategic sourcing approach not only reduces costs but also fosters stronger relationships with suppliers, ensuring timely access to innovative products and materials. This is particularly important for buyers from Africa, South America, the Middle East, and Europe, where the demand for high-quality leather backing is on the rise. By engaging with reputable suppliers and leveraging their expertise, businesses can gain a competitive edge in their respective markets.

Illustrative image related to leather backing

What’s Next for International Buyers in Leather Backing?

Looking ahead, the demand for sustainable and high-performance leather backing solutions will continue to grow. B2B buyers are encouraged to stay informed about emerging trends and technologies in leather backing materials. By doing so, they can anticipate market shifts and better align their sourcing strategies with future demands. Take the next step in your sourcing journey by exploring partnerships with reliable suppliers who can provide the innovative solutions you need to thrive in an evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.