Introduction: Navigating the Global Market for pu leather vs faux leather

Navigating the intricate landscape of PU leather versus faux leather presents a significant challenge for international B2B buyers, particularly those sourcing sustainable and cost-effective materials for their products. As the demand for eco-friendly alternatives continues to rise, understanding the nuances between these synthetic leather options is crucial. This guide delves into the various types of PU leather and faux leather, their manufacturing processes, applications across different industries, and essential supplier vetting criteria.

By providing a thorough analysis of cost considerations, durability, and environmental impact, this resource empowers decision-makers in Africa, South America, the Middle East, and Europe—such as Brazil and Germany—to make informed purchasing choices. Whether you’re a furniture manufacturer seeking stylish upholstery or a fashion retailer looking for trendy accessories, this guide will equip you with the insights needed to identify the best leather alternative for your specific needs. With a focus on practicality and sustainability, we aim to streamline your sourcing process and enhance your competitive edge in the global market.

Table Of Contents

- Top 6 Pu Leather Vs Faux Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pu leather vs faux leather

- Understanding pu leather vs faux leather Types and Variations

- Key Industrial Applications of pu leather vs faux leather

- 3 Common User Pain Points for ‘pu leather vs faux leather’ & Their Solutions

- Strategic Material Selection Guide for pu leather vs faux leather

- In-depth Look: Manufacturing Processes and Quality Assurance for pu leather vs faux leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu leather vs faux leather’

- Comprehensive Cost and Pricing Analysis for pu leather vs faux leather Sourcing

- Alternatives Analysis: Comparing pu leather vs faux leather With Other Solutions

- Essential Technical Properties and Trade Terminology for pu leather vs faux leather

- Navigating Market Dynamics and Sourcing Trends in the pu leather vs faux leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pu leather vs faux leather

- Strategic Sourcing Conclusion and Outlook for pu leather vs faux leather

- Important Disclaimer & Terms of Use

Understanding pu leather vs faux leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Leather | Made with a polyurethane layer; more realistic appearance | Fashion, upholstery, accessories | Pros: Durable, low maintenance; Cons: Limited breathability, higher cost than basic faux leather |

| PVC Faux Leather | Made from polyvinyl chloride; often more affordable | Budget-friendly fashion items | Pros: Cost-effective, versatile designs; Cons: Less durable, potential environmental concerns due to PVC |

| Microfiber Leather | Made from fine synthetic fibers; mimics the texture of genuine leather | Automotive interiors, furniture | Pros: High durability, good breathability; Cons: Can be pricier, requires specific care |

| Vegan Leather | Made from various plant-based materials; eco-friendly options | Eco-conscious fashion, furniture | Pros: Sustainable, animal-friendly; Cons: Varies in durability, may require careful maintenance |

| Bonded Leather | Made from leather scraps and fibers bonded together | Low-cost furniture, accessories | Pros: Affordable, can have a leather-like feel; Cons: Less durable, may not withstand heavy use |

What Are the Characteristics of PU Leather and Its Suitability for B2B Buyers?

PU leather is a synthetic material that features a polyurethane coating over a fabric base, offering a realistic look and feel similar to genuine leather. Its durability makes it suitable for various applications, particularly in fashion, upholstery, and accessories. Buyers should consider the balance between cost and quality, as PU leather is generally more expensive than basic faux leather but provides enhanced aesthetics and longevity. Its lower maintenance requirements can also be appealing for businesses looking to minimize upkeep costs.

How Does PVC Faux Leather Compare for Budget-Conscious Buyers?

PVC faux leather is produced using polyvinyl chloride, making it a more affordable alternative to PU leather. It is widely used in budget-friendly fashion items and accessories due to its versatility in design. However, while PVC is cost-effective, it may lack the durability of higher-quality materials and raise environmental concerns due to its production process. B2B buyers must weigh the initial savings against potential long-term performance issues, particularly in high-use environments.

What Are the Benefits of Microfiber Leather in Automotive and Furniture Applications?

Microfiber leather is crafted from finely woven synthetic fibers that replicate the texture of real leather. This material is particularly favored in automotive interiors and high-end furniture due to its durability and breathability. While it may come at a higher price point, its resistance to wear and tear and ease of maintenance can justify the investment for businesses focused on quality and longevity. Buyers should consider the specific care requirements to ensure the material retains its appearance over time.

Why Should B2B Buyers Consider Vegan Leather Options?

Vegan leather encompasses a variety of materials, including those made from plant-based sources, offering a sustainable and animal-friendly alternative. This type of leather is increasingly popular in eco-conscious fashion and furniture markets. While vegan leather can vary in durability and maintenance needs, its appeal lies in aligning with sustainability values. B2B buyers should assess the specific material composition and care instructions to ensure they meet their operational needs and brand ethos.

What Should Buyers Know About Bonded Leather for Cost-Effective Solutions?

Bonded leather is created by combining leather scraps and fibers, offering a lower-cost option for businesses. It is often used in affordable furniture and accessories, providing a leather-like appearance at a reduced price. However, bonded leather typically has lower durability and may not perform well under heavy use. Buyers should consider the intended application and lifecycle expectations when selecting bonded leather, as it may require more frequent replacement than higher-quality alternatives.

Key Industrial Applications of pu leather vs faux leather

| Industry/Sector | Specific Application of pu leather vs faux leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Enhanced durability and ease of maintenance for high-use environments | Consider long-term durability, stain resistance, and aesthetic appeal. |

| Automotive | Interior car upholstery and seating | Cost-effective, lightweight material with a premium look | Evaluate fire resistance standards and compatibility with automotive regulations. |

| Fashion and Apparel | Clothing, handbags, and accessories | Versatile design options and animal-friendly alternatives | Assess quality, texture variety, and consumer preferences in target markets. |

| Home Decor | Decorative items like cushions and wall panels | Eco-friendly options that appeal to sustainable living trends | Look for certifications regarding environmental impact and sourcing practices. |

| Sports Equipment | Gear such as bags, gloves, and protective padding | Lightweight and durable materials that enhance performance | Focus on performance specifications and compliance with industry standards. |

How is PU Leather Utilized in Furniture Manufacturing?

In the furniture manufacturing sector, PU leather is widely used for upholstery on sofas and chairs. Its durability and resistance to wear make it ideal for high-use environments, such as homes and commercial spaces. PU leather is also easy to clean, which is a significant advantage for businesses looking to maintain their products. International buyers should prioritize sourcing from manufacturers who can guarantee high-quality PU leather that meets regional standards for safety and sustainability.

What Role Does Faux Leather Play in Automotive Interiors?

Faux leather is increasingly popular in the automotive industry for interior car upholstery and seating. This material offers a cost-effective alternative to genuine leather while providing a premium look and feel. It is lightweight, which contributes to better fuel efficiency in vehicles. Buyers in this sector should consider the material’s compliance with fire safety regulations and its performance under varying climatic conditions, especially in regions like Africa and the Middle East.

Why is Faux Leather Important in Fashion and Apparel?

In the fashion and apparel industry, faux leather is favored for clothing, handbags, and accessories due to its versatile design options. This material allows brands to cater to an animal-friendly consumer base while still offering stylish products. International B2B buyers should assess the quality and variety of textures available, as well as the market demand for sustainable fashion. Sourcing from manufacturers committed to ethical practices can enhance brand reputation and consumer trust.

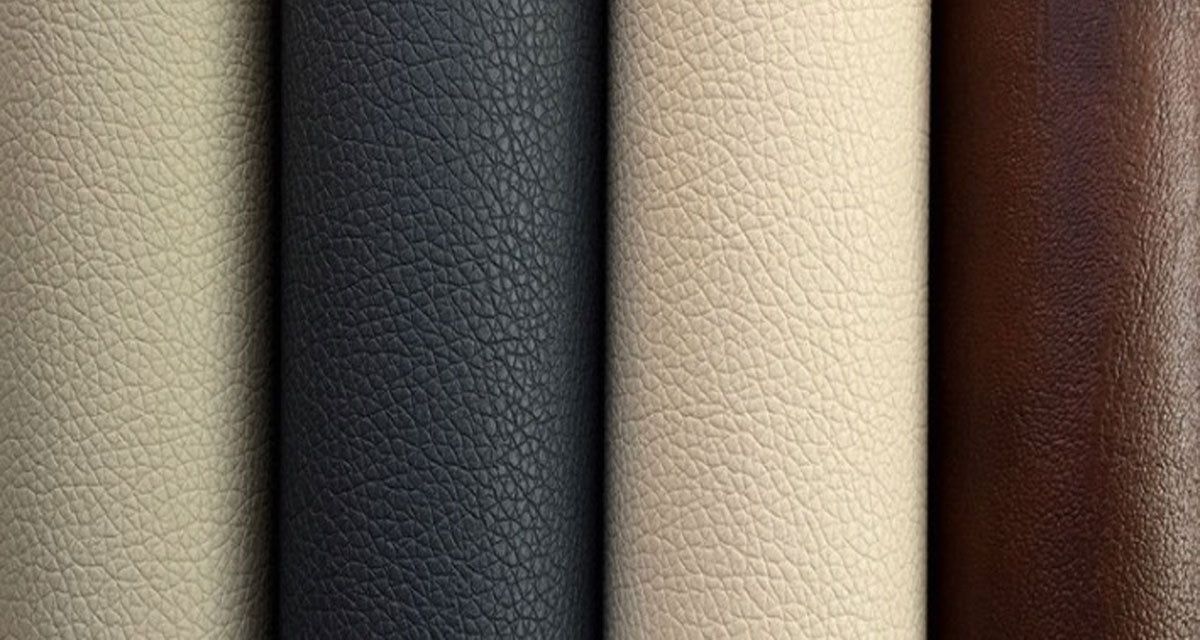

Illustrative image related to pu leather vs faux leather

How Does PU Leather Enhance Home Decor?

PU leather is also utilized in home decor, particularly for decorative items such as cushions and wall panels. Its aesthetic appeal and eco-friendly options attract consumers who are increasingly inclined towards sustainable living. For businesses, sourcing PU leather that meets environmental certifications can be a selling point. Buyers should consider the product’s lifecycle impact and the manufacturer’s commitment to sustainable practices when making procurement decisions.

What Advantages Does Faux Leather Offer in Sports Equipment?

In the sports equipment sector, faux leather is commonly used for gear such as bags, gloves, and protective padding. Its lightweight nature and durability enhance performance, making it a preferred choice for athletes and sports enthusiasts. Businesses should focus on sourcing materials that meet specific performance standards and regulations within the sports industry. Additionally, considering the environmental impact of sourcing practices can appeal to a growing segment of eco-conscious consumers.

3 Common User Pain Points for ‘pu leather vs faux leather’ & Their Solutions

Scenario 1: Confusion Over Material Quality Standards

The Problem: B2B buyers often grapple with discerning the quality of PU leather versus faux leather. The market is flooded with various grades and types, leading to confusion about which material aligns with their product requirements. For instance, a furniture manufacturer in Germany might face difficulties in sourcing PU leather that meets their high durability standards, while also ensuring it is environmentally sustainable. This uncertainty can lead to suboptimal purchasing decisions, impacting product quality and brand reputation.

The Solution: To overcome this challenge, buyers should establish a clear set of quality standards before initiating their procurement process. This includes defining the specific properties required for their application, such as durability, aesthetic appeal, and environmental impact. Collaborating with reputable suppliers who can provide certifications or samples of their materials can significantly aid in this process. Additionally, conducting comparative tests on different samples can provide firsthand insights into the performance of PU leather versus faux leather. Engaging in industry forums or networks can also provide valuable feedback from peers who have navigated similar challenges, enhancing the buyer’s decision-making process.

Scenario 2: Misalignment of Consumer Expectations

The Problem: Buyers often encounter a disconnect between the expectations of their end consumers and the characteristics of PU leather and faux leather. For instance, a fashion retailer in Brazil may promote a product as ‘leather-like’ but fails to deliver the durability and breathability that customers expect. This misalignment can lead to increased returns, negative customer feedback, and damage to brand loyalty.

The Solution: To effectively bridge this gap, B2B buyers should invest time in understanding their target audience’s preferences and expectations regarding leather alternatives. Conducting market research, such as surveys or focus groups, can provide insights into what consumers value most—be it aesthetics, longevity, or ethical sourcing. Based on this data, buyers can select materials that align with these preferences, ensuring they communicate the benefits and limitations of PU leather and faux leather accurately. Furthermore, providing transparent information about the sourcing and manufacturing processes can enhance consumer trust and satisfaction.

Illustrative image related to pu leather vs faux leather

Scenario 3: Environmental Concerns and Sustainability Challenges

The Problem: As sustainability becomes a focal point for businesses, B2B buyers face challenges in choosing between PU leather and faux leather from an environmental perspective. A manufacturer in the Middle East may want to pivot to more eco-friendly materials but finds conflicting information about the sustainability of each option. This can complicate their supply chain decisions and undermine their sustainability goals.

The Solution: Buyers should prioritize sourcing materials from manufacturers that adopt sustainable practices, such as using recycled or renewable resources. It is essential to request detailed information on the production processes of PU and faux leather from potential suppliers, including their carbon footprint and waste management strategies. Furthermore, establishing partnerships with organizations that specialize in sustainable materials can provide access to certifications and comprehensive reports on environmental impact. By aligning procurement strategies with sustainability goals, buyers can make informed decisions that resonate with their brand values and appeal to eco-conscious consumers.

Strategic Material Selection Guide for pu leather vs faux leather

What Are the Key Properties of PU Leather and Faux Leather?

When evaluating PU leather and faux leather, it is essential to understand the materials involved and their properties. PU leather, or polyurethane leather, is produced by applying a layer of polyurethane to a fabric backing, typically polyester or cotton. This method enhances durability and gives it a leather-like appearance. Conversely, faux leather encompasses a broader range of synthetic materials, often made from PVC or PU, bonded to a fabric base.

Both materials are generally less breathable than genuine leather, which can affect comfort, especially in warmer climates. PU leather tends to have a more realistic texture and appearance compared to other faux leathers, making it a preferred choice for high-end applications. In contrast, faux leather can vary significantly in quality and durability, depending on the manufacturing process.

What Are the Pros and Cons of PU Leather vs. Faux Leather?

PU Leather:

– Pros: PU leather offers superior durability, resistance to scratches, and a more authentic leather-like appearance. It is relatively easy to clean, requiring only a damp cloth, and is often available in a variety of colors and textures.

– Cons: The production of PU leather can be energy-intensive and relies on petroleum-based materials, raising sustainability concerns. It is also generally more expensive than other faux leathers.

Faux Leather:

– Pros: Faux leather is often more affordable and can be produced in a wide range of styles and finishes, appealing to fashion-forward consumers. Some manufacturers utilize recycled materials, making certain faux leathers more environmentally friendly.

– Cons: The durability of faux leather can be inconsistent, and it may require more careful maintenance. Additionally, some types of faux leather, particularly those made from PVC, can have negative environmental impacts.

How Do These Materials Impact Specific Applications?

For applications in upholstery, fashion, and automotive industries, the choice between PU leather and faux leather can significantly impact product performance. PU leather is often preferred for high-traffic areas due to its durability, while faux leather might be suitable for fashion items where aesthetics take precedence over longevity.

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider local climate conditions and consumer preferences when selecting materials. For instance, in hotter climates, breathability may be a critical factor, making certain faux leathers more appealing. Compliance with international standards such as ASTM, DIN, or JIS can also affect material selection, particularly in regulated industries.

Illustrative image related to pu leather vs faux leather

What Should International Buyers Consider?

International B2B buyers must account for various factors when selecting PU leather or faux leather. Compliance with local regulations regarding material safety and environmental impact is crucial. Additionally, understanding the supply chain and sourcing practices can ensure that the materials meet sustainability goals. Buyers should also be aware of the price fluctuations in the global market, which can affect the overall cost of materials.

Summary Table of PU Leather vs. Faux Leather

| Material | Typical Use Case for PU Leather vs Faux Leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PU Leather | High-end upholstery, fashion accessories | Superior durability and realistic look | Higher cost and energy-intensive production | High |

| Faux Leather | Fashion items, low-traffic upholstery | Cost-effective and versatile designs | Variable durability and maintenance needs | Medium |

| PVC Faux Leather | Budget upholstery, casual fashion | Affordable and widely available | Environmental concerns and durability issues | Low |

| Eco-Friendly Faux Leather | Sustainable fashion, eco-conscious products | Reduced environmental impact | Potentially higher cost and limited availability | Medium to High |

This structured approach provides B2B buyers with a clear understanding of the differences and considerations when selecting between PU leather and faux leather, enabling informed decisions that align with their business needs and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for pu leather vs faux leather

What Are the Main Stages in the Manufacturing Process of PU Leather and Faux Leather?

Understanding the manufacturing processes of PU leather and faux leather is crucial for B2B buyers who seek quality and reliability. Both materials undergo specific stages that affect their durability, aesthetics, and overall performance.

Material Preparation

The first stage involves sourcing the base materials. PU leather typically starts with a fabric backing made of polyester or cotton, which is then treated with a layer of polyurethane. Faux leather, on the other hand, can be made from various synthetic materials, including PVC or additional polyurethane layers. The quality of these base materials significantly influences the final product’s durability and appearance.

Forming

In this stage, the prepared fabric is coated with the synthetic layer. For PU leather, the polyurethane is applied through techniques such as spraying or rolling, ensuring a uniform thickness that mimics genuine leather. For faux leather, the coating process can be more intricate, often involving lamination or bonding techniques that secure the synthetic layer to the fabric backing. This step is critical as it defines the material’s texture and visual appeal.

Assembly

Once the base material is formed, it is cut and sewn into the desired product shape. This stage requires precision, as the quality of stitching and assembly directly impacts the durability and functionality of the final product. Manufacturers may use automated machines for efficiency, but skilled labor is also essential for ensuring high-quality finishes.

Finishing

The final stage includes additional treatments, such as applying protective coatings or finishes that enhance water resistance, UV protection, or stain resistance. This step is vital for both PU and faux leather, as it improves the longevity and usability of the products, especially in environments with high wear and tear.

How Is Quality Assurance Implemented in PU Leather and Faux Leather Production?

Quality assurance (QA) is a critical aspect of manufacturing PU and faux leather, ensuring that products meet international standards and client expectations.

International Standards to Consider

Many manufacturers adhere to ISO 9001, a global standard for quality management systems. This ensures that processes are consistently monitored and improved. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be applicable, particularly for products intended for specific markets.

Key Quality Control Checkpoints

Quality control is typically divided into three checkpoints:

-

Incoming Quality Control (IQC): This initial stage inspects raw materials for defects before they enter the production line. Buyers should inquire about the criteria used for material selection and any testing methods employed.

-

In-Process Quality Control (IPQC): This involves monitoring the production process to identify any deviations from quality standards. Regular inspections are conducted to ensure that the materials are applied correctly and that the manufacturing processes are followed.

-

Final Quality Control (FQC): After the product is assembled, FQC involves thorough inspections to ensure that the final product meets specified standards. This may include visual inspections, dimensional checks, and performance tests.

What Common Testing Methods Are Used to Ensure PU and Faux Leather Quality?

Various testing methods are employed to evaluate the performance and durability of PU and faux leather products. B2B buyers should be familiar with these to assess supplier capabilities.

Illustrative image related to pu leather vs faux leather

-

Physical Testing: This includes abrasion resistance, tensile strength, and tear resistance tests, which measure how well the material holds up under stress.

-

Chemical Testing: Evaluating the material’s resistance to chemicals, such as cleaning agents or oils, is crucial for determining its longevity and usability in different environments.

-

Environmental Testing: This assesses how the material reacts to different environmental conditions, such as UV exposure or moisture, which can significantly affect its performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure product reliability.

Supplier Audits

Conducting regular audits of potential suppliers is an effective way to assess their quality assurance processes. During these audits, buyers can review production methods, quality control checkpoints, and compliance with international standards.

Requesting Quality Reports

Suppliers should be able to provide detailed quality reports that outline the results of various testing methods, compliance with standards, and any corrective actions taken in response to quality issues. This documentation can provide buyers with confidence in the supplier’s commitment to quality.

Illustrative image related to pu leather vs faux leather

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These services can perform audits, testing, and evaluations, providing an additional layer of assurance for B2B buyers.

What Are the QC/Cert Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is vital for B2B buyers operating in different international markets.

-

Regional Standards: Each region may have specific quality standards and regulations that must be adhered to. Buyers should familiarize themselves with these standards, especially when dealing with suppliers from diverse geographical locations.

-

Sustainability Certifications: As sustainability becomes increasingly important, buyers may seek suppliers with certifications that demonstrate environmental responsibility. This could include certifications for the use of recycled materials or adherence to eco-friendly manufacturing processes.

-

Traceability: Ensuring traceability in the supply chain can help buyers verify the origins of materials used in production, particularly for environmentally conscious purchases. Asking suppliers about their sourcing practices can provide valuable insights into their commitment to quality and sustainability.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for PU leather and faux leather is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as implementing rigorous quality control standards, buyers can make informed decisions that align with their business needs and sustainability goals.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu leather vs faux leather’

Introduction

This practical sourcing guide provides B2B buyers with a comprehensive checklist for procuring PU leather and faux leather. As demand for sustainable and animal-friendly materials rises, understanding the nuances between these two synthetic options is crucial for making informed purchasing decisions. This guide will help you navigate the procurement process, ensuring you select the right material for your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clearly define your technical specifications. Consider the intended use of the leather, such as upholstery, fashion, or accessories, and the required durability, aesthetics, and texture. This step ensures that you communicate your needs effectively to suppliers and receive appropriate samples for evaluation.

Step 2: Research Material Characteristics

Understanding the differences between PU leather and faux leather is vital. PU leather typically offers a more realistic look and feel, while faux leather varies in quality and texture. Assess the specific characteristics of each material, including breathability, maintenance requirements, and environmental impact, to determine which option aligns best with your brand values and product expectations.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your standards. Request company profiles, product catalogs, and references from other buyers in your industry. Pay attention to their experience in sourcing PU leather and faux leather, as well as their ability to deliver consistent quality and compliance with international standards.

Step 4: Verify Certifications and Compliance

Check for certifications that indicate adherence to quality and sustainability standards. Look for certifications related to environmental impact, such as ISO 14001, and product safety, such as REACH compliance. Ensuring that your suppliers have the necessary certifications helps mitigate risks and enhances your brand’s reputation.

Illustrative image related to pu leather vs faux leather

Step 5: Request Material Samples

Always request samples of both PU leather and faux leather before making a bulk order. Evaluate the samples for texture, color accuracy, and overall quality. This hands-on assessment allows you to compare the materials side by side, ensuring that your final selection meets your aesthetic and functional requirements.

Step 6: Compare Pricing and Terms

Once you have identified potential suppliers, compare their pricing structures and terms of service. Consider not only the cost per unit but also minimum order quantities, shipping fees, and payment terms. A comprehensive understanding of the total cost of procurement will help you make more informed decisions and negotiate better terms.

Step 7: Assess Environmental Impact and Sustainability

Finally, evaluate the environmental impact of your chosen materials. Investigate the manufacturing processes and raw materials used by suppliers. Opt for options that prioritize sustainability, such as those made with recycled materials or eco-friendly production methods. This consideration will not only align with global sustainability trends but also resonate with environmentally conscious consumers.

By following these steps, B2B buyers can make informed decisions when sourcing PU leather and faux leather, ensuring they select the best materials for their business needs while contributing positively to sustainability efforts.

Illustrative image related to pu leather vs faux leather

Comprehensive Cost and Pricing Analysis for pu leather vs faux leather Sourcing

What Are the Key Cost Components in PU Leather and Faux Leather Sourcing?

When sourcing PU leather and faux leather, it’s crucial to understand the cost structure involved. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

-

Materials: PU leather typically incorporates a layer of polyurethane over a fabric backing, which can be more expensive than the PVC or other synthetic materials commonly used in faux leather. The choice of fabric backing, whether polyester or cotton, also influences costs. For both types, sourcing sustainable or recycled materials can further impact prices.

-

Labor: Labor costs can vary significantly by region. In countries with lower labor costs, such as those in parts of Africa and South America, the overall production costs may be reduced. However, labor quality and expertise in handling synthetic materials can affect the final product’s quality.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment. PU leather’s manufacturing process may be more energy-intensive, leading to higher overhead costs compared to some faux leather options.

-

Tooling: Custom tooling for specific designs or finishes can increase initial costs. For B2B buyers seeking unique products, investing in custom tooling may be necessary, but it’s important to assess whether the potential return justifies the expense.

-

Quality Control (QC): Implementing stringent QC measures can add to the overall costs but is essential for ensuring product consistency and durability. Buyers should consider the implications of QC processes on pricing and product reliability.

-

Logistics: Transportation costs can vary based on the origin of materials, shipping methods, and destination. Factors like Incoterms and tariffs also play a significant role in determining the final landed cost.

-

Margin: Supplier margins can differ widely based on market demand, competition, and the supplier’s reputation. Buyers should be aware that established suppliers may charge a premium for their reliability and quality assurance.

How Do Price Influencers Impact PU Leather vs. Faux Leather Sourcing?

Several key factors influence the pricing of PU leather and faux leather, including volume, specifications, material quality, and supplier factors.

-

Volume/MOQ: Bulk purchasing can lead to significant cost reductions. Suppliers often provide lower prices for larger orders, which can be beneficial for B2B buyers looking to scale their production.

-

Specifications and Customization: Custom designs or specific performance characteristics can increase costs. Clear communication of requirements can help mitigate unexpected price hikes.

-

Material Quality and Certifications: Higher-quality materials or those with environmental certifications often come at a premium. Buyers should evaluate whether the benefits justify the additional costs.

-

Supplier Factors: Building strong relationships with suppliers can lead to better pricing and terms. Negotiating based on long-term partnerships can yield favorable outcomes.

-

Incoterms: Understanding the implications of different Incoterms is crucial for managing logistics costs and responsibilities, affecting the overall pricing structure.

What Are the Best Buyer Tips for Cost-Efficiency in PU and Faux Leather Sourcing?

-

Negotiation: Engage in thorough negotiations with suppliers to secure the best possible prices. Highlighting your purchasing power, especially if you can commit to larger orders, can yield favorable terms.

-

Total Cost of Ownership (TCO): Consider the TCO when evaluating suppliers. This includes not just the purchase price but also factors like maintenance, durability, and potential waste costs over the product’s lifecycle.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, be aware of currency fluctuations and import duties that can affect overall costs. Local regulations can also influence pricing.

-

Research and Comparison: Conduct comprehensive market research to compare prices and product offerings from various suppliers. Utilize B2B platforms and industry contacts to identify competitive pricing.

-

Stay Informed on Trends: Keep abreast of trends in the synthetic leather market, including shifts towards sustainability and innovation, which may impact pricing and availability.

Disclaimer on Indicative Prices

Prices for PU leather and faux leather can fluctuate based on market conditions, material availability, and supplier pricing strategies. It is advisable for buyers to conduct due diligence and verify current pricing from multiple sources before making purchasing decisions.

Alternatives Analysis: Comparing pu leather vs faux leather With Other Solutions

Understanding Alternatives to PU Leather and Faux Leather

As businesses increasingly seek sustainable and ethical options in materials, PU leather and faux leather are often considered for their animal-friendly attributes and versatility. However, there are viable alternative solutions that can also fulfill similar needs. This section provides a comparative analysis of PU leather and faux leather against two other materials: natural leather and recycled materials. This will help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | PU Leather vs Faux Leather | Natural Leather | Recycled Materials |

|---|---|---|---|

| Performance | Durable, realistic look but less breathable | Highly durable, breathes well, develops character over time | Varies; typically good durability but dependent on the source |

| Cost | Moderate to high | High | Generally lower, depending on source and processing |

| Ease of Implementation | Easy to source and manufacture | Requires skilled labor for tanning and crafting | Can be readily sourced but may require additional processing |

| Maintenance | Low-maintenance, wipe clean | Requires regular conditioning to maintain quality | Maintenance varies; may require specialized care |

| Best Use Case | Fashion items, upholstery | High-end products, luxury goods | Eco-friendly products, casual wear |

In-Depth Analysis of Alternatives

Natural Leather

Natural leather is renowned for its durability and unique character that develops over time. It offers superior breathability, making it a preferred choice for high-end products such as luxury bags and automotive interiors. However, the sourcing and processing of natural leather can have significant environmental impacts, including water usage and chemical treatments. Additionally, its higher cost may be a barrier for budget-conscious businesses, making it less suitable for mass-market applications.

Recycled Materials

Recycled materials, including textiles and plastics, represent a growing trend in sustainable product development. They can provide an eco-friendly alternative to traditional materials, often at a lower cost. The performance of recycled materials can vary greatly depending on their source and processing methods. While they can be less durable than PU or natural leather, they appeal to environmentally conscious consumers. Businesses can leverage recycled materials for casual wear and innovative product lines, although careful consideration of durability and maintenance is necessary.

Conclusion: Choosing the Right Solution for Your Business Needs

In navigating the landscape of material choices, B2B buyers should consider their specific needs, including budget, environmental impact, and the intended use of the products. PU leather and faux leather offer a balance of affordability and aesthetic appeal, while natural leather provides unmatched quality but at a higher cost. Recycled materials present an opportunity for sustainable innovation, albeit with variability in performance. By assessing these factors, businesses can make strategic decisions that align with their operational goals and sustainability commitments, ultimately enhancing their product offerings in a competitive marketplace.

Essential Technical Properties and Trade Terminology for pu leather vs faux leather

What Are the Key Technical Properties of PU Leather and Faux Leather?

When considering PU leather and faux leather for business applications, understanding their technical properties is essential. Here are several critical specifications that buyers should be aware of:

Illustrative image related to pu leather vs faux leather

-

Material Grade

– Definition: Material grade refers to the quality classification of the synthetic leather. PU leather typically falls into higher grades compared to other faux leathers due to its manufacturing process and appearance.

– B2B Importance: Higher-grade materials often translate to better durability and aesthetics, making them suitable for high-end markets, thus impacting pricing strategies and customer satisfaction. -

Thickness

– Definition: Thickness is measured in millimeters and indicates the density of the material. PU leather usually ranges from 0.8 mm to 1.2 mm, while faux leather can vary significantly.

– B2B Importance: Thickness affects the material’s durability and suitability for various applications, such as upholstery or fashion items. Buyers must match thickness to the intended use to ensure longevity. -

Tensile Strength

– Definition: Tensile strength measures the resistance of a material to breaking under tension. It is crucial for assessing the durability of both PU and faux leather.

– B2B Importance: Understanding tensile strength helps businesses forecast the longevity and performance of products, which is vital when negotiating contracts and warranties. -

Water Resistance

– Definition: This property indicates how well the material can repel water. PU leather generally exhibits better water resistance than many faux leathers.

– B2B Importance: For applications like outdoor furniture or accessories, water resistance can significantly influence customer satisfaction and product performance, making it a key factor in supplier selection. -

Breathability

– Definition: Breathability refers to the ability of the material to allow air circulation, which affects comfort and moisture management.

– B2B Importance: Depending on the application—like clothing or upholstery—breathability can impact consumer comfort and product performance. Buyers should assess this feature based on the target market’s needs. -

Environmental Impact

– Definition: This term encompasses the ecological footprint of the materials, including production processes and disposal methods. PU leather tends to have a higher environmental cost due to its petroleum-based components.

– B2B Importance: As sustainability becomes a priority for consumers and businesses alike, understanding the environmental impact of materials can inform purchasing decisions and enhance brand reputation.

What Are Common Trade Terms in the PU Leather and Faux Leather Industry?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some essential trade terms relevant to PU leather and faux leather:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships helps businesses identify potential partners and navigate supply chains effectively. -

MOQ (Minimum Order Quantity)

– Definition: MOQ indicates the smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ is crucial for budgeting and inventory management, especially for businesses looking to minimize risk while entering new markets. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers to solicit price quotes for specified products or services.

– Significance: Utilizing RFQs enables buyers to compare offers systematically, ensuring they secure the best pricing and terms. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions.

– Significance: Understanding Incoterms helps businesses clarify shipping responsibilities and costs, minimizing disputes and ensuring smoother logistics. -

Lead Time

– Definition: Lead time refers to the amount of time it takes from placing an order to receiving the goods.

– Significance: Accurate lead time estimates are critical for inventory planning and customer satisfaction, influencing overall supply chain efficiency. -

Certification Standards

– Definition: These are industry-specific standards that materials must meet to ensure quality and safety, such as ISO or REACH compliance.

– Significance: Familiarity with certification standards helps businesses ensure that their products meet regulatory requirements and consumer expectations, which is vital for market access.

Understanding these technical properties and trade terms will empower B2B buyers in making informed decisions regarding PU leather and faux leather, ultimately enhancing their competitive edge in the marketplace.

Navigating Market Dynamics and Sourcing Trends in the pu leather vs faux leather Sector

What Are the Key Market Dynamics and Trends Influencing PU Leather and Faux Leather Sourcing?

The global market for PU leather and faux leather has been shaped by several key drivers, including the growing demand for sustainable and animal-friendly materials. As environmental awareness increases, businesses across Africa, South America, the Middle East, and Europe are increasingly seeking alternatives to genuine leather. The shift towards ethical consumerism is leading to a rise in demand for PU and faux leather, which offer a more sustainable option without compromising on aesthetics or functionality.

Emerging technologies in manufacturing are also playing a crucial role in the sourcing trends of these materials. Innovations in production processes, such as the use of recycled materials and advancements in synthetic alternatives, are enabling manufacturers to create high-quality products that meet consumer expectations. B2B buyers are advised to stay informed about these technological advancements, as they can significantly impact pricing, availability, and product quality.

Illustrative image related to pu leather vs faux leather

In regions like Brazil and Germany, the demand for customized solutions is increasing, prompting suppliers to offer a wider range of designs, textures, and colors. This trend is particularly relevant in industries such as fashion, automotive, and furniture, where the visual appeal of materials is paramount. As a result, international buyers should focus on partnerships with manufacturers that can provide innovative, tailored solutions that align with their market needs.

How Do Sustainability and Ethical Sourcing Impact B2B Decisions in the PU Leather and Faux Leather Market?

Sustainability is a critical consideration for B2B buyers navigating the PU leather and faux leather landscape. The environmental impact of these materials varies significantly, influenced by their production methods and raw materials used. PU leather, while generally more durable than faux leather, often relies on petroleum-based materials, raising concerns about its carbon footprint and non-biodegradability. Conversely, many faux leather options utilize recycled or renewable resources, presenting a more eco-friendly alternative.

Buyers are increasingly prioritizing ethical sourcing practices, necessitating a thorough understanding of the supply chain. This involves assessing the environmental certifications of suppliers and the sustainability of their manufacturing processes. Certifications such as OEKO-TEX and Global Recycled Standard (GRS) can serve as reliable indicators of a supplier’s commitment to sustainability. By aligning their sourcing strategies with these ethical standards, businesses can not only enhance their brand reputation but also meet the growing consumer demand for environmentally responsible products.

How Has the PU Leather and Faux Leather Market Evolved Over Time?

The evolution of PU leather and faux leather can be traced back to the mid-20th century when the demand for animal-friendly alternatives began to grow. Initially developed as a cost-effective substitute for genuine leather, these materials have undergone significant advancements in terms of quality and aesthetics. The introduction of polyurethane in the 1970s marked a turning point, enhancing the durability and appearance of PU leather compared to earlier synthetic options.

Today, the market continues to evolve with a focus on sustainability and innovation. The rise of eco-conscious consumers has led manufacturers to explore new technologies and materials that reduce environmental impact while maintaining the desirable qualities of leather. This ongoing evolution presents B2B buyers with a wealth of options, allowing them to select materials that align not only with their operational needs but also with their sustainability goals. Understanding this historical context is essential for making informed sourcing decisions in today’s dynamic market.

Illustrative image related to pu leather vs faux leather

Frequently Asked Questions (FAQs) for B2B Buyers of pu leather vs faux leather

-

How do I determine whether PU leather or faux leather is more suitable for my business needs?

To decide between PU leather and faux leather, consider factors like intended use, durability requirements, and aesthetic preferences. PU leather tends to offer better durability and a more realistic leather-like appearance, making it ideal for high-wear applications such as furniture and automotive upholstery. Conversely, if your focus is on fashion or less intensive use, faux leather might suffice. Assess your target market’s preferences and your budget to make an informed decision. -

What is the best application for PU leather versus faux leather?

PU leather is best suited for applications requiring durability and a premium look, such as high-end furniture, handbags, and footwear. Its resistance to wear and tear makes it favorable for items that see heavy use. Faux leather, on the other hand, is often used for fashion items, light upholstery, and accessories where cost-effectiveness and variety of textures are more critical. Evaluate your product line and customer expectations to choose the right material for each application. -

What are the minimum order quantities (MOQs) typically required for PU leather and faux leather?

MOQs can vary significantly between suppliers and regions. Generally, PU leather may have higher MOQs due to its manufacturing complexity and cost. Common MOQs range from 100 to 500 meters, depending on the supplier’s production capabilities. Faux leather often has lower MOQs, sometimes starting at 50 meters, making it more accessible for smaller businesses. Always confirm specific MOQs with your supplier to ensure they align with your production needs. -

How should I vet suppliers for PU leather and faux leather?

Vetting suppliers involves several steps: review their certifications for quality and sustainability, check for industry experience, and request samples to assess material quality firsthand. Additionally, inquire about their production methods and material sourcing to ensure compliance with environmental standards. It’s also beneficial to read customer testimonials and seek references to gauge reliability and service quality. Establishing a solid communication channel will facilitate smoother transactions. -

What payment terms are commonly offered when sourcing PU leather or faux leather internationally?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upfront with the remaining balance due before shipment. Some suppliers may offer net 30 or net 60 terms for established clients. It is essential to clarify payment methods accepted (e.g., wire transfer, PayPal) and any additional fees involved. Discussing terms upfront can help prevent misunderstandings and ensure a smoother transaction process. -

What quality assurance measures should I implement when sourcing PU leather or faux leather?

Implementing quality assurance involves setting clear specifications for material performance, appearance, and durability. Request samples for testing and establish criteria for evaluating the material against these standards. Regular audits of suppliers can help ensure compliance with your quality requirements. Additionally, consider engaging third-party quality control services, especially for large orders, to verify that the materials meet your expectations before shipment. -

How does international logistics affect the sourcing of PU leather and faux leather?

International logistics can significantly impact the cost and timing of your orders. Factors to consider include shipping methods (air vs. sea), customs regulations, and potential tariffs. Ensure that your supplier has experience in exporting to your target market and is familiar with the necessary documentation. Planning logistics early in the process can help mitigate delays and additional costs, ensuring a smoother supply chain operation. -

What are the environmental impacts of PU leather compared to faux leather?

Both PU leather and faux leather have lower environmental impacts than genuine leather; however, their production processes differ. PU leather often involves petroleum-based materials and can be energy-intensive, raising concerns about sustainability. Faux leather may offer more eco-friendly options, especially if made from recycled materials. When sourcing, assess suppliers’ sustainability practices and certifications to align with your company’s environmental values and goals.

Top 6 Pu Leather Vs Faux Leather Manufacturers & Suppliers List

1. Yorkshire Fabric Shop – PU Leather

Domain: yorkshirefabricshop.com

Registered: 2014 (11 years)

Introduction: PU leather is synthetic leather made from polyurethane, a plastic that mimics the feel and appearance of real leather without using animal products. It is known for its softness and durability. Faux leather, derived from upholstery fabric like polyester, offers a premium quality known as ultra-leather, which provides a luxurious look and feel similar to genuine leather. It can be water-resistant, …

2. Reddit – Faux Leather Overview

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Faux leather is often referred to as PU leather, which is a type of faux leather made from polyurethane. However, not all faux leather is PU; for example, PVC leather is another type. Faux leather is defined as any material that resembles leather but is not made from animal hides. The term ‘faux’ means ‘false’ or ‘fake’ in French. PU leather is the most popular form of modern artificial leather, b…

3. Manuel Dreesmann – Fiona Bag

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: What is PU leather – and why you should avoid! Skip to content Worldwide Free Shipping Over 100€ Manuel-dreesmann Open navigation menu New New Fiona bag Tote Bag With Zipper The Fiona Bag The perfect shoulder bag Tote bag with zipper Carry your belongings safely Bags Bags Tote Bags Shoulder Bags Crossbody Bags Handbags Clutches Pouches & Belt Bags Backpacks The Croissant Bag Discover our bestselle…

4. Picket & Rail – PU & PVC Leather Solutions

Domain: picketandrail.com

Registered: 2001 (24 years)

Introduction: PU (Polyurethane) Leather: Soft and flexible, breathable, durable, easy maintenance. PVC (Polyvinyl Chloride) Leather: Cost-effective, water and stain resistant, less breathable, susceptible to cracking. Faux Leather: Versatile, affordable, animal-friendly, durability varies.

5. Forbes & Lewis – Bonded Leather Solutions

Domain: forbesandlewis.com

Registered: 2012 (13 years)

Introduction: Bonded leather is made from leftover scraps of genuine leather (20-30%) bound with a polyurethane (PU) binder. It is cheaper, comes in multiple colors, and resembles genuine leather but is less durable and ages poorly. Faux leather, made from PU or PVC-Vinyl, is synthetic, water-resistant, and highly versatile, but not as durable as real leather. Leatherette is artificial leather that contains no …

6. Bostanten – PU Leather Bags

Domain: bostanten.com

Registered: 2010 (15 years)

Introduction: PU Leather: 1. Definition: Synthetic material designed to mimic genuine leather, made of a fabric base (polyester or cotton) coated with polyurethane. 2. Pros: Affordable, diverse options in colors and textures, cruelty-free, easy to maintain. 3. Popular in retail and production of bags. Faux Leather: 1. Definition: Sustainable and cruelty-free alternative to traditional leather, made from PU leat…

Strategic Sourcing Conclusion and Outlook for pu leather vs faux leather

In navigating the landscape of PU leather and faux leather, international B2B buyers must weigh critical factors such as durability, cost-effectiveness, and environmental impact. PU leather, while typically more expensive, offers superior durability and a more realistic aesthetic, making it an excellent choice for high-end applications. Conversely, faux leather provides a wider range of design options and potentially lower costs, catering well to fashion and decor markets where appearance is paramount.

Strategic sourcing of these materials requires a thorough understanding of their unique properties and the implications of their manufacturing processes. Buyers should assess their specific needs—whether for furniture, fashion, or automotive applications—while also considering sustainability goals. As consumer demand for eco-friendly products rises, sourcing from manufacturers who prioritize renewable resources in faux leather production may enhance brand reputation and market appeal.

Looking ahead, the choice between PU leather and faux leather will increasingly reflect broader trends in sustainability and ethical sourcing. By aligning procurement strategies with these evolving market dynamics, businesses can position themselves competitively in a global marketplace. Engage with suppliers who share your values and innovation goals to ensure your sourcing decisions lead to sustainable growth and success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to pu leather vs faux leather

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.