Catalog

Material Insight: What Is Pu Learher

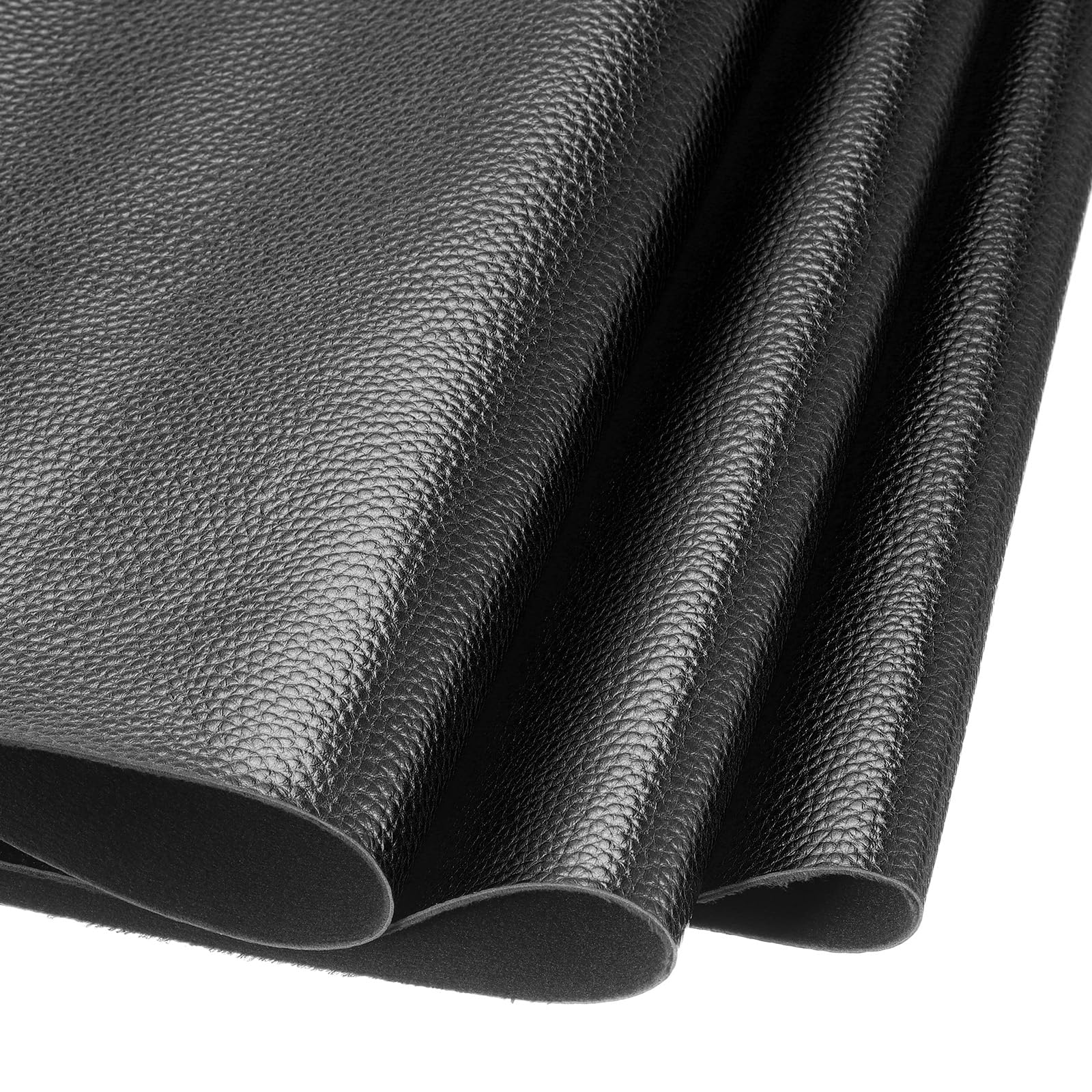

What Is PU Leather?

Polyurethane (PU) leather, also known as faux or synthetic leather, is a high-performance alternative to genuine leather that combines durability, flexibility, and aesthetic appeal without the environmental and ethical concerns associated with animal hide. Made by applying a polyurethane coating to a fabric backing—typically polyester or a blend—PU leather mimics the look and feel of real leather while offering enhanced consistency, easier maintenance, and greater design versatility. It is widely used across industries including furniture, automotive interiors, apparel, footwear, and accessories.

Why Is Faux Leather the Best Choice for This Application?

Faux leather, particularly high-grade PU leather, has become the preferred material in modern manufacturing due to its balanced performance and sustainability advantages. Unlike genuine leather, PU leather offers:

- Consistent texture and color across batches, ensuring quality control in large-scale production.

- Superior resistance to fading, cracking, and staining when properly formulated.

- Lower environmental impact—no animal byproducts, reduced water usage, and fewer toxic byproducts compared to traditional tanning.

- Cost-efficiency without sacrificing visual or tactile quality.

- Design flexibility, with options for custom textures, thicknesses, colors, and performance additives (e.g., UV resistance, anti-microbial properties).

For B2B clients focused on scalable, eco-conscious production, PU leather delivers a responsible yet premium solution tailored to evolving market demands.

WINIWについて

WINIW is a leading innovator in synthetic leather solutions with over 20 years of industry expertise. Specializing in high-performance PU leather for global B2B markets, WINIW combines advanced material science with sustainable manufacturing practices to deliver products that meet rigorous quality and environmental standards. Our R&D-driven approach enables customization for specific industrial applications, ensuring optimal durability, aesthetics, and compliance.

- ISO-certified production facilities with strict QC protocols.

- Eco-friendly formulations, including water-based PU and recycled substrates.

- Extensive product portfolio serving furniture, transportation, electronics, and lifestyle sectors.

- Dedicated technical support and rapid prototyping for OEM partners.

With a commitment to innovation and sustainability, WINIW empowers brands to create premium products responsibly—setting new benchmarks in synthetic leather performance.

Technical Performance & Standards

WINIW Premium PU Leather: Technical Product Guide for Industrial Applications

WINIW Premium PU Leather is a high-performance synthetic material engineered as a sustainable, cost-optimized alternative to genuine leather and conventional PVC leather. Formulated with advanced polyurethane resins and non-woven polyester backing, it delivers exceptional physical properties while adhering to stringent global environmental and quality standards. Ideal for automotive interiors, furniture upholstery, luggage, and technical textiles, WINIW PU Leather eliminates the inconsistencies and ecological burdens of animal leather without compromising on performance.

Core Technical Advantages for Industrial Buyers

- Cost-Effective Production Efficiency: Reduces total cost of ownership by 15-25% versus premium genuine leather through consistent roll yields (>98%), minimal cutting waste, and elimination of tanning/dyeing infrastructure. Compatible with standard cutting and sewing machinery, requiring no process retooling.

- Enhanced Durability Metrics: Engineered for 50,000+ double-rub Martindale abrasion resistance (ISO 12947) and 80 N peel strength (ASTM D3330), outperforming standard PVC leather by 40%. Resists cracking at -20°C and maintains integrity under continuous UV exposure (500+ hrs QUV testing).

- Precision Color Customization: Utilizes WINIW’s digital color matching system (ΔE < 0.5 tolerance) for 100% reproducibility across batches. Supports Pantone, RAL, and custom formulations with lightfastness rating 7-8 (ISO 105-B02), ensuring brand consistency for global supply chains.

- REACH SVHC Compliance: Fully documented absence of Substances of Very High Concern (SVHCs) per EU REACH Annex XIV. Independent lab certificates verify <10 ppm residual DMF and zero azo dyes, eliminating customs delays and market access risks.

- ISO 9001-Certified Quality Control: Integrated process control from resin synthesis to finishing ensures batch-to-batch uniformity. Includes real-time thickness monitoring (±0.05mm tolerance) and 100% visual inspection per ISO 2424 standards.

Technical Specifications Comparison

| Property | WINIW Premium PU Leather | Industry Standard PU Leather | Test Standard |

|---|---|---|---|

| Thickness Range | 0.6mm – 1.8mm | 0.8mm – 1.5mm | ISO 2424 |

| Weight (g/m²) | 350 – 750 | 400 – 650 | ISO 2286-2 |

| Tensile Strength (MD) | ≥ 45 N/mm² | ≥ 30 N/mm² | ISO 1765 |

| Elongation at Break | 250% – 350% | 180% – 250% | ISO 1765 |

| Color Fastness to Rubbing | Grade 4-5 (wet/dry) | Grade 3-4 | ISO 105-X12 |

| VOC Emissions | < 10 μg/g | 50 – 200 μg/g | ISO 12219-2 |

| Biodegradability (ADMP) | 35% in 180 days | < 5% | ISO 20200 |

WINIW PU Leather integrates circular economy principles through water-based coating technology (reducing VOC emissions by 90% vs. solvent systems) and recyclable backing substrates. Our ISO 14001-certified manufacturing ensures traceable raw materials and carbon-neutral production, providing B2B partners with verifiable sustainability metrics for ESG reporting. Request our full technical dossier and compliance certificates to validate performance for your specific application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: PU Leather vs. Real Leather

In the evolving landscape of sustainable and cost-effective materials, synthetic alternatives like PU leather have become increasingly popular across industries such as furniture, automotive, fashion, and accessories. Understanding the differences between PU leather and real leather is essential for businesses making informed sourcing decisions that align with performance, budget, and environmental goals.

What is PU Leather?

PU (polyurethane) leather is a synthetic material engineered to replicate the look and feel of genuine leather. It is created by applying a polyurethane coating to a fabric backing, typically made from polyester or cotton. Unlike real leather, it does not use animal hides, making it a cruelty-free and often more sustainable alternative. PU leather is known for its versatility, consistent texture, and ease of maintenance.

What is Real Leather?

Real leather is a natural product made from tanned animal hides, most commonly from cows. It is valued for its durability, breathability, and unique grain patterns that develop character over time. However, its production involves resource-intensive processes, including land use for livestock and chemical tanning, which raise environmental and ethical concerns.

Below is a comparative analysis of PU leather and real leather based on key business criteria:

| Criteria | PUレザー | Real Leather |

|---|---|---|

| Cost | Lower initial cost; cost-effective for high-volume production | Higher cost due to raw material scarcity and labor-intensive processing |

| 耐久性 | Moderate; resistant to fading and staining but may peel or crack over time (5–10 years typical lifespan) | High; develops patina and can last decades with proper care (15+ years) |

| Eco-Friendliness | Generally more eco-friendly; no animal sourcing, lower carbon footprint, and newer bio-based PU options available | Less eco-friendly; involves deforestation, methane emissions, and toxic tanning chemicals (e.g., chromium) |

Advantages of PU Leather for B2B Applications:

– Consistent appearance and texture across batches, ideal for mass production.

– Customizable in color, finish, and texture without the natural imperfections of animal hides.

– Easier to clean and maintain—resistant to moisture and stains.

– Aligns with vegan and cruelty-free product lines, appealing to eco-conscious markets.

– Reduced lead times due to stable supply chains and no dependency on livestock.

Considerations for Real Leather:

– Preferred in luxury markets for its premium feel and natural aging process.

– Offers superior breathability and comfort in high-use applications like seating and footwear.

– Higher perceived value in branding and customer experience.

– Requires responsible sourcing and certification (e.g., LWG-certified tanneries) to meet sustainability standards.

Conclusion

While real leather remains a symbol of luxury and longevity, PU leather presents a compelling alternative for businesses prioritizing sustainability, cost efficiency, and ethical production. Advances in synthetic technology have significantly narrowed the performance gap, making PU leather a viable, future-forward choice for a wide range of B2B applications.

WINIW Factory Capabilities

WINIW Synthetic Leather: Factory Capabilities & Global Assurance

WINIW operates a vertically integrated manufacturing ecosystem engineered for B2B excellence. Our 100,000 sqm facility in China represents one of Asia’s most advanced synthetic leather production hubs, combining scale with precision engineering to support global supply chain demands. This infrastructure enables consistent, high-volume output without compromising agility for custom formulations or rapid prototyping.

Core Manufacturing Advantages

- Integrated Scale: 100,000 sqm facility housing end-to-end production—from resin synthesis and base fabric preparation to finishing and quality validation—eliminating third-party dependencies.

- Dedicated R&D Team: 30+ material scientists and engineers focused on eco-innovation, including water-based PU development, recycled content integration (up to 40% PCR), and bio-based alternatives. 15+ patents filed in 2020–2023.

- Strict QC Protocol: Triple-stage quality control (raw material inspection, in-process monitoring, final product validation) with ISO 9001-certified processes. Batch traceability via blockchain ensures full transparency.

- Global Compliance Ready: All products pre-certified for EU REACH, US CPSIA, and CA Prop 65 standards. 98% of shipments clear customs on first submission.

Verified Global Export Performance

WINIW serves Tier-1 clients across 30+ countries, with 75% of annual output directed to environmentally regulated markets:

| Region | Key Compliance Met | Avg. On-Time Delivery | Sustainability Certification |

|---|---|---|---|

| Europe | REACH, OEKO-TEX® | 99.2% | GRS, ISO 14001 |

| North America | CPSIA, CA65 | 98.7% | SCS Recycled Content |

| APAC | GB/T 22892-2008 | 99.5% | Local eco-labels |

Our facility’s LEED-certified energy management system reduces carbon intensity by 22% versus industry averages, directly supporting client ESG goals. Partners gain not just a supplier, but a scalable manufacturing ally built for regulatory resilience and eco-conscious innovation.

WINIW: Engineered Responsibility. Global Results.

Contact Us for Samples

B2B Product Guide: Understanding PU Leather in Modern Manufacturing

Polyurethane (PU) leather is a high-performance synthetic material engineered to replicate the look, feel, and durability of genuine leather—without the environmental toll. As a leading innovator in sustainable materials, WINIW specializes in advanced microfiber PU leather solutions designed for industries ranging from automotive and furniture to fashion and electronics.

PU leather is created by applying a polyurethane coating onto a fabric backing, typically composed of polyester or microfiber. This process allows for precise control over texture, thickness, color, and performance properties, making it an ideal choice for brands seeking consistency, scalability, and eco-conscious alternatives to animal-derived leather.

Key Advantages of PU Leather:

– Environmentally responsible: Reduces reliance on animal agriculture and lowers carbon footprint

– Consistent quality: Uniform texture and thickness across large production runs

– Customizable: Available in a wide range of finishes, colors, and textures (suede, matte, glossy, embossed)

– Durable and easy to clean: Resistant to abrasion, UV light, and staining

– Cost-effective: Offers premium aesthetics at a fraction of the cost of genuine leather

WINIW’s PU leather exceeds industry standards with enhanced breathability, flexibility, and long-term performance. Our formulations are free from harmful solvents and heavy metals, aligning with global sustainability certifications and regulatory requirements.

| Feature | WINIW PU Leather |

|---|---|

| Base Material | Microfiber or knit fabric |

| Coating | High-grade polyurethane |

| Thickness Range | 0.6mm – 2.0mm |

| Width | Up to 150 cm |

| Weight | 200 – 500 g/m² |

| Certifications | REACH, RoHS, OEKO-TEX® |

| Eco-Friendly Options | Yes (water-based processes) |

Ideal for contract furniture, automotive interiors, luggage, footwear, and consumer electronics, WINIW’s PU leather delivers both aesthetic excellence and functional reliability.

For technical specifications, custom development, or material testing support, contact our materials team directly.

What is PU leather?

Discover how PU leather can transform your product line with sustainable performance and design flexibility.

Request a free sample today and experience the quality of WINIW microfiber PU leather firsthand.

Contact: MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.