Introduction: Navigating the Global Market for stretch fake leather

In the competitive landscape of today’s global market, sourcing high-quality stretch fake leather presents unique challenges for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, including key players in Germany and Vietnam. As the demand for sustainable and ethically produced materials grows, understanding the nuances of stretch fake leather—often referred to as faux leather or pleather—becomes essential. This guide delves into the various types of stretch fake leather, their applications across multiple industries, and the critical factors to consider when vetting suppliers.

From fashion to upholstery, stretch fake leather offers a versatile and stylish alternative to traditional leather, appealing to eco-conscious consumers and businesses alike. Buyers will benefit from insights into material characteristics, pricing structures, and the latest market trends, enabling them to make informed purchasing decisions that align with their company’s values and operational needs.

This comprehensive resource aims to empower international B2B buyers by equipping them with the knowledge needed to navigate the complexities of sourcing stretch fake leather. By addressing the key considerations in supplier selection and cost analysis, this guide serves as a valuable tool for those looking to enhance their product offerings while remaining competitive in a rapidly evolving marketplace.

Table Of Contents

- Top 5 Stretch Fake Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for stretch fake leather

- Understanding stretch fake leather Types and Variations

- Key Industrial Applications of stretch fake leather

- 3 Common User Pain Points for ‘stretch fake leather’ & Their Solutions

- Strategic Material Selection Guide for stretch fake leather

- In-depth Look: Manufacturing Processes and Quality Assurance for stretch fake leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘stretch fake leather’

- Comprehensive Cost and Pricing Analysis for stretch fake leather Sourcing

- Alternatives Analysis: Comparing stretch fake leather With Other Solutions

- Essential Technical Properties and Trade Terminology for stretch fake leather

- Navigating Market Dynamics and Sourcing Trends in the stretch fake leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of stretch fake leather

- Strategic Sourcing Conclusion and Outlook for stretch fake leather

- Important Disclaimer & Terms of Use

Understanding stretch fake leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Two-Way Stretch Faux Leather | Stretchable in two directions; often smoother texture | Apparel (pants, tops), accessories | Pros: Versatile, easy to sew; Cons: Limited stretch compared to four-way options. |

| Four-Way Stretch Faux Leather | Stretchable in all four directions; more elastic and flexible | Fashion, upholstery, activewear | Pros: Excellent fit and comfort; Cons: Typically higher cost. |

| Textured Faux Leather | Features patterns or textures (e.g., crocodile, embossed) | Fashion, upholstery, high-end accessories | Pros: Unique aesthetic appeal; Cons: May require specialized sewing techniques. |

| Glossy Faux Leather | High-shine finish, often mimics patent leather | Fashion, costumes, statement pieces | Pros: Eye-catching; Cons: Can be prone to scuffing and scratches. |

| ヴィーガンレザー | Made from synthetic materials, often eco-friendly | Sustainable fashion lines, eco-conscious brands | Pros: Ethical alternative to leather; Cons: Quality can vary widely. |

What Are the Characteristics of Two-Way Stretch Faux Leather?

Two-way stretch faux leather is characterized by its ability to stretch in two directions, making it ideal for form-fitting apparel such as leggings and tops. Typically composed of a blend of polyester and spandex, this material is lightweight and easy to sew. B2B buyers should consider the fabric’s durability and maintenance requirements, as it is machine washable and resistant to tearing, making it suitable for high-usage items.

How Does Four-Way Stretch Faux Leather Differ from Other Types?

Four-way stretch faux leather offers superior elasticity, allowing for movement in all directions. This flexibility makes it a preferred choice for activewear and fashion applications where comfort and fit are essential. B2B buyers should evaluate the quality of the material, as higher-grade options provide better longevity and a more luxurious feel. While it may come at a higher price point, the long-term benefits often justify the investment.

What Makes Textured Faux Leather a Unique Option for B2B Buyers?

Textured faux leather incorporates various designs, such as embossed patterns or animal skins, adding a distinctive flair to products. This type is popular in high-end fashion and upholstery, where visual appeal is crucial. B2B buyers should be aware of the sewing and handling requirements, as textured materials may necessitate specialized techniques. The unique aesthetics can justify a premium price, appealing to brands targeting niche markets.

Why Choose Glossy Faux Leather for Fashion Applications?

Glossy faux leather is known for its shiny finish, often resembling patent leather. It is commonly used in fashion items and costumes, where a striking appearance is desired. However, B2B buyers should consider the potential for scratches and scuffs, which can detract from its visual appeal. While it offers a bold statement, understanding the care and maintenance needs is essential for ensuring product longevity.

How Does Vegan Leather Align with Sustainable Business Practices?

Vegan leather, made from synthetic materials, caters to the growing demand for ethical and sustainable products. It is increasingly used in eco-conscious brands looking to replace traditional leather. B2B buyers must assess the quality and sourcing of vegan leather, as the market is diverse and can vary significantly. Prioritizing high-quality options can enhance brand reputation while appealing to environmentally conscious consumers.

Key Industrial Applications of stretch fake leather

| Industry/Sector | Specific Application of Stretch Fake Leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Production of trendy clothing and accessories | Offers a stylish, animal-friendly alternative to genuine leather, appealing to eco-conscious consumers. | Ensure fabric meets international quality standards and is available in various colors and textures. |

| Upholstery | Furniture covering and automotive interiors | Enhances aesthetic appeal while providing durability and ease of maintenance. | Source materials that are resistant to wear and easy to clean; consider local climate effects on material performance. |

| Footwear | Design of shoes and boots | Combines flexibility and comfort with a high-end leather appearance, attracting diverse market segments. | Evaluate stretchability and durability, as well as compliance with safety and comfort standards. |

| Sports & Fitness | Activewear and performance apparel | Provides breathability and stretch, enhancing comfort during physical activities. | Ensure the fabric is lightweight, moisture-wicking, and retains shape after multiple washes. |

| Home Decor | Decorative items such as cushions and wall art | Adds a luxurious touch to interiors while being cost-effective and easy to maintain. | Assess fabric for color fastness and texture to ensure it complements existing decor themes. |

How is Stretch Fake Leather Transforming the Fashion & Apparel Industry?

In the fashion and apparel sector, stretch fake leather is widely used to create a range of trendy clothing and accessories, including jackets, leggings, and handbags. This material addresses the growing demand for sustainable and ethical fashion by providing a stylish alternative to genuine leather. For international B2B buyers, it’s crucial to source fabrics that comply with local regulations and meet the expectations of eco-conscious consumers, especially in markets like Europe and South America.

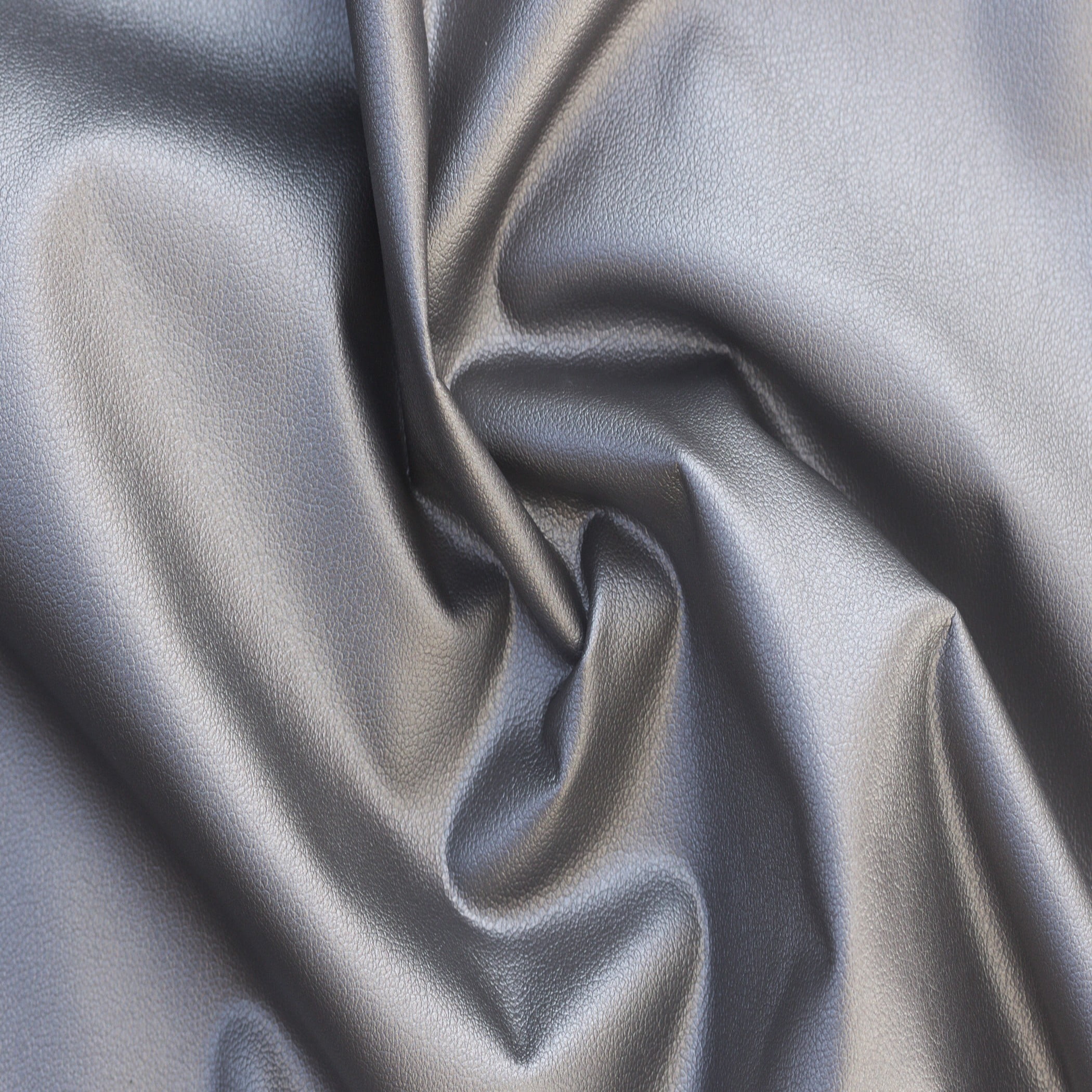

Illustrative image related to stretch fake leather

What Role Does Stretch Fake Leather Play in Upholstery?

In upholstery, stretch fake leather is utilized for covering furniture and automotive interiors, offering a sophisticated look without the associated ethical concerns of animal leather. This material is durable and easy to clean, which is particularly appealing for businesses in the hospitality and automotive industries. Buyers should focus on sourcing materials that are not only aesthetically pleasing but also resistant to wear and tear, especially in high-traffic environments prevalent in the Middle East and Africa.

How is Stretch Fake Leather Revolutionizing Footwear Design?

The footwear industry benefits significantly from stretch fake leather, which is used to design shoes and boots that combine flexibility and style. This material allows for the production of lightweight, comfortable footwear that can cater to various consumer preferences. International buyers must consider the stretchability and durability of the material, ensuring it meets safety and comfort standards, especially in competitive markets like Europe and Asia.

Why is Stretch Fake Leather Ideal for Sports & Fitness Apparel?

Stretch fake leather is increasingly popular in the sports and fitness sector, where it is used to produce activewear and performance apparel. This fabric offers breathability and elasticity, enhancing comfort during workouts. B2B buyers should prioritize lightweight and moisture-wicking properties, ensuring the material retains its shape after repeated use and washing, which is essential in markets with diverse climate conditions.

Illustrative image related to stretch fake leather

How Can Stretch Fake Leather Enhance Home Decor?

In the home decor sector, stretch fake leather is used for decorative items such as cushions, wall art, and upholstery. This versatile material adds a touch of luxury to interiors while remaining cost-effective and easy to maintain. Buyers should evaluate color fastness and texture to ensure compatibility with existing decor themes, particularly in markets across Europe and South America, where aesthetic preferences vary widely.

3 Common User Pain Points for ‘stretch fake leather’ & Their Solutions

Scenario 1: Sourcing Quality Stretch Fake Leather for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality stretch fake leather that meets their specific project requirements. This is particularly challenging when trying to source materials that vary in color, texture, and stretchability for different applications such as apparel, upholstery, and accessories. Poor sourcing can lead to inconsistent product quality, resulting in increased production costs, delayed timelines, and ultimately dissatisfied customers.

The Solution: To overcome these challenges, buyers should prioritize building relationships with reputable suppliers who specialize in stretch fake leather. Start by requesting samples of various materials to assess their quality firsthand. Look for suppliers who offer detailed specifications, including stretch ratios (2-way vs. 4-way), weight, and care instructions. Additionally, consider engaging in a collaborative design process with suppliers to customize colors or textures that align with your brand’s aesthetic. Establishing a reliable supply chain can significantly reduce the risk of quality issues and ensure that you receive the right material for your specific needs.

Scenario 2: Addressing Stretch and Durability Concerns in Production

The Problem: A common pain point for manufacturers using stretch fake leather is ensuring the material maintains its integrity and appearance over time, especially when subjected to frequent stretching or wear. For instance, items like leggings or fitted jackets require materials that not only stretch well but also recover without losing shape. Buyers may find that cheaper alternatives do not hold up under stress, leading to high return rates and customer dissatisfaction.

The Solution: To mitigate these durability concerns, buyers should invest in higher-quality stretch fake leather that features a blend of polyester and spandex or similar materials, which are known for their resilience. When placing orders, specify the weight and GSM (grams per square meter) to ensure that the fabric is suitable for the intended application. Furthermore, conducting pre-production tests can help identify potential issues before full-scale manufacturing begins. Collaborate with suppliers to understand the best practices for sewing and finishing to maintain the fabric’s elasticity and longevity.

Illustrative image related to stretch fake leather

Scenario 3: Navigating the Environmental Impact and Sustainability of Stretch Fake Leather

The Problem: As global consumers become increasingly conscious of sustainability, B2B buyers face pressure to choose materials that are not only stylish and functional but also environmentally friendly. Many stretch fake leather products are derived from synthetic materials that may not be biodegradable, leading to reputational risks for companies that fail to address these concerns.

The Solution: To align with sustainable practices, buyers should actively seek out suppliers who offer eco-friendly stretch fake leather options. This includes materials made from recycled plastics or bio-based substances that minimize environmental impact. Before sourcing, inquire about the manufacturing processes to ensure they comply with international sustainability standards. Additionally, consider engaging in transparency initiatives where your brand communicates its commitment to sustainability, thereby enhancing brand loyalty and attracting environmentally-conscious consumers. Implementing a lifecycle assessment of the materials can also help buyers make informed decisions that contribute to both product quality and environmental stewardship.

Strategic Material Selection Guide for stretch fake leather

What Are the Common Materials Used in Stretch Fake Leather?

In the realm of stretch fake leather, several materials stand out for their unique properties and applications. Understanding these materials can significantly influence purchasing decisions for international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

1. Polyester-Spandex Blend

Key Properties:

A common composition for stretch faux leather is a blend of 85% polyester and 15% spandex. This combination offers excellent elasticity and durability, making it suitable for various applications. It typically withstands temperatures ranging from -20°C to 60°C, ensuring versatility across climates.

Pros & Cons:

The polyester-spandex blend is known for its affordability and ease of manufacturing. It is lightweight, making it ideal for apparel such as leggings and tops. However, it may not be as resistant to wear and tear compared to other materials, which could limit its lifespan in high-traffic applications.

Impact on Application:

This material is particularly compatible with fashion items and light upholstery. Its flexibility allows for comfortable wear, making it a popular choice for activewear and casual clothing.

Considerations for International Buyers:

Buyers should ensure compliance with international textile standards, such as ASTM and DIN. The material’s affordability aligns with budget-conscious markets, but buyers in regions with high humidity may need to consider moisture management properties.

2. PVC (Polyvinyl Chloride)

Key Properties:

PVC faux leather is a synthetic material known for its durability and resistance to moisture and chemicals. It can withstand temperatures up to 70°C and is often used in environments where exposure to liquids is common.

Pros & Cons:

PVC is highly durable and easy to clean, making it suitable for upholstery and automotive applications. However, it can be less breathable than other materials, which may affect comfort in clothing applications. Additionally, the manufacturing process can be more complex due to the need for additives to enhance flexibility.

Impact on Application:

This material is ideal for high-wear applications like furniture and car interiors, where durability is paramount. Its water-resistant properties make it suitable for outdoor use as well.

Considerations for International Buyers:

Compliance with environmental regulations is crucial, especially in Europe, where PVC use is scrutinized. Buyers should also consider the potential for off-gassing, which may be a concern in enclosed spaces.

3. PU (Polyurethane)

Key Properties:

Polyurethane faux leather is celebrated for its high-quality finish and softness, closely mimicking genuine leather. It is resistant to abrasion and can tolerate temperatures between -10°C to 50°C.

Pros & Cons:

PU offers a luxurious feel and is more environmentally friendly than PVC, making it a preferred choice for high-end fashion items. However, it can be more expensive to produce, which may affect pricing in competitive markets.

Illustrative image related to stretch fake leather

Impact on Application:

This material is particularly suited for fashion apparel, accessories, and high-end upholstery. Its aesthetic appeal makes it a favorite among designers looking for sustainable yet stylish options.

Considerations for International Buyers:

Buyers in Europe and North America may prefer PU due to its eco-friendliness. Understanding local regulations regarding material sourcing and sustainability is essential for ensuring compliance and market acceptance.

4. Silicone-Based Materials

Key Properties:

Silicone faux leather is gaining popularity due to its flexibility and resistance to extreme temperatures, ranging from -40°C to 200°C. It is also hypoallergenic and non-toxic.

Illustrative image related to stretch fake leather

Pros & Cons:

The primary advantage of silicone is its durability and resistance to UV light, making it ideal for outdoor applications. However, it can be more expensive than traditional faux leather options, which may deter cost-sensitive buyers.

Impact on Application:

Silicone materials are excellent for outdoor furniture and automotive applications due to their weather resistance. Additionally, they are suitable for medical applications due to their hypoallergenic properties.

Considerations for International Buyers:

Buyers should be aware of the higher costs associated with silicone materials. However, the long-term durability and reduced maintenance needs can justify the investment, particularly in regions with harsh climates.

Summary Table of Stretch Fake Leather Materials

| 素材 | Typical Use Case for stretch fake leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester-Spandex Blend | Apparel, casual clothing | Affordable and flexible | Less durable for high-traffic use | 低い |

| PVC (Polyvinyl Chloride) | Upholstery, automotive interiors | Highly durable and water-resistant | Less breathable | Medium |

| PU (Polyurethane) | High-end fashion, accessories | Luxurious feel and eco-friendly | Higher production cost | 高い |

| Silicone-Based Materials | Outdoor furniture, medical applications | Extreme temperature resistance | Higher cost | 高い |

This guide provides a comprehensive overview of materials used in stretch fake leather, equipping B2B buyers with the insights needed to make informed purchasing decisions in their respective markets.

Illustrative image related to stretch fake leather

In-depth Look: Manufacturing Processes and Quality Assurance for stretch fake leather

What Are the Key Stages in the Manufacturing Process of Stretch Fake Leather?

The manufacturing process of stretch fake leather, also known as faux leather or synthetic leather, involves several critical stages, each contributing to the final product’s quality and functionality. Understanding these stages can help B2B buyers make informed decisions when sourcing materials.

Material Preparation: What Raw Materials Are Used?

The first stage of production begins with the selection and preparation of raw materials. The primary components typically include a base fabric, such as polyester or cotton, and a polymer coating, which provides the leather-like finish. Manufacturers often use polyurethane (PU) or polyvinyl chloride (PVC) as the primary synthetic materials due to their flexibility and durability.

During this stage, the base fabric is treated to enhance its properties, such as water resistance or UV stability. Proper preparation ensures that the material will hold the synthetic coating effectively, which is crucial for achieving the desired stretch characteristics.

How Is Stretch Fake Leather Formed?

The forming stage involves applying the polymer coating to the prepared fabric. This is achieved through various techniques, including:

-

Coating: The polymer is spread or sprayed onto the fabric, creating a thin layer that mimics the texture of real leather. This process can be done using a variety of methods, including knife-over-roll, gravure, or screen printing.

-

Lamination: In some cases, a laminated process is used, where two layers of materials are bonded together. This adds extra durability and a more realistic appearance.

-

Foaming: For stretch faux leather, a foaming process may be employed to create a softer, more pliable finish. This is particularly popular in applications requiring significant stretch, such as leggings or fitted garments.

What Steps Are Involved in Assembly and Finishing?

Once the faux leather has been formed, it undergoes assembly and finishing processes. Assembly often includes cutting the material into specific shapes or patterns for garment production, upholstery, or accessories. This stage may also involve stitching or bonding different pieces together.

Illustrative image related to stretch fake leather

Finishing is crucial for enhancing the material’s aesthetic and functional properties. Techniques such as embossing, polishing, and applying protective coatings can be employed to achieve the desired look and feel. For instance, a glossy finish may be applied to create a more luxurious appearance, while a matte finish may provide a more subdued look.

What Quality Assurance Practices Are Essential for Stretch Fake Leather?

Quality assurance (QA) is critical throughout the manufacturing process to ensure that the final product meets international standards and customer expectations. Here are some common practices and relevant standards.

Which International Standards Should B2B Buyers Consider?

International quality standards, such as ISO 9001, provide a framework for effective quality management systems. For manufacturers of stretch fake leather, adherence to these standards ensures consistent product quality and continuous improvement.

In addition to ISO standards, industry-specific certifications like CE marking (which indicates conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) standards for materials used in specific applications may also be relevant. These certifications can vary based on the target market and application of the faux leather.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to monitor quality and detect defects early. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified requirements. Material properties such as tensile strength, elasticity, and color consistency are often assessed.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections are conducted to monitor processes and prevent defects from progressing to the next stage. This includes checking the coating thickness and adhesion quality.

-

Final Quality Control (FQC): Once the product is completed, a thorough inspection is conducted to ensure it meets all specifications. This may involve physical tests, such as stretchability, durability, and colorfastness, as well as visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks. Here are several methods to achieve this:

Illustrative image related to stretch fake leather

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is a fundamental practice for verifying quality control. Audits can be performed by the buyer’s internal team or through third-party agencies. During an audit, buyers should assess the supplier’s quality management systems, production processes, and adherence to international standards.

How Can Buyers Request Quality Reports and Certifications?

B2B buyers should always request documentation, including quality reports and relevant certifications. This documentation should outline the supplier’s compliance with international standards, the results of quality inspections, and any testing conducted on the materials.

What Role Do Third-Party Inspections Play in Quality Assurance?

Third-party inspections can provide an unbiased assessment of a supplier’s quality control practices. Engaging independent inspectors to review production processes and final products can help ensure that the materials meet the specified standards and are free from defects.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International B2B buyers face specific challenges when sourcing stretch fake leather, particularly regarding quality control. Understanding these nuances can help mitigate risks:

-

Cultural Differences: Different regions may have varying approaches to quality assurance. Buyers should be aware of these differences and communicate their quality expectations clearly.

-

Regulatory Compliance: Depending on the destination market, products may need to meet specific regulations, such as REACH in Europe or specific import regulations in African and South American countries. Understanding these regulations is crucial for compliance.

-

Supply Chain Transparency: International buyers should seek suppliers that offer transparency in their supply chains. This includes understanding where raw materials are sourced and how they are processed to ensure ethical and sustainable practices.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing stretch fake leather, ensuring they receive high-quality products that meet their business needs.

Illustrative image related to stretch fake leather

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stretch fake leather’

To assist B2B buyers in successfully procuring stretch fake leather, this guide provides a structured checklist. Sourcing this material requires careful consideration of various factors, from technical specifications to supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring the material meets your project needs. Consider factors such as stretchability (2-way vs. 4-way), weight, and composition (e.g., polyester and spandex blends). This clarity will facilitate better communication with suppliers and help you avoid costly misalignments later on.

Step 2: Identify Your Target Market and Applications

Understanding your target market’s preferences and the intended applications of the stretch fake leather will guide your sourcing decisions. For instance, fashion applications may prioritize aesthetics, while upholstery might focus on durability. Tailor your sourcing strategy to align with regional trends and market demands in areas such as Africa, South America, the Middle East, and Europe.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in stretch fake leather. Utilize industry directories, trade shows, and online platforms to gather a list of reputable manufacturers. Shortlisting suppliers who have a proven track record in your target market can enhance your chances of finding high-quality materials.

Step 4: Evaluate Supplier Certifications and Compliance

Verification of supplier certifications is essential for ensuring the quality and safety of the materials. Look for compliance with international standards, such as ISO certifications and environmental sustainability credentials. This step not only mitigates risks but also enhances your brand reputation by aligning with ethical sourcing practices.

Step 5: Request Samples for Quality Assessment

Before making any bulk purchases, request samples from shortlisted suppliers. Assess the quality, texture, and stretch of the materials to ensure they meet your specifications. This hands-on evaluation can reveal inconsistencies and help you make informed decisions about which supplier to choose.

Step 6: Negotiate Pricing and Payment Terms

Engage in negotiations with suppliers to secure favorable pricing and payment terms. Consider factors such as minimum order quantities and shipping costs, which can significantly impact your overall budget. Establishing clear terms upfront can prevent misunderstandings and foster a more collaborative relationship.

Step 7: Finalize Logistics and Shipping Arrangements

After selecting a supplier, finalize logistics and shipping arrangements to ensure timely delivery of your materials. Discuss shipping methods, lead times, and potential customs regulations based on your location. Efficient logistics management is key to maintaining your production schedule and meeting market demands.

By following this checklist, B2B buyers can navigate the complexities of sourcing stretch fake leather effectively, ensuring they find materials that meet their needs while building strong supplier relationships.

Illustrative image related to stretch fake leather

Comprehensive Cost and Pricing Analysis for stretch fake leather Sourcing

What Are the Key Cost Components in Stretch Fake Leather Sourcing?

When sourcing stretch fake leather, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The base materials for stretch faux leather typically include a blend of polyester and spandex, which can vary in quality and price. Higher-quality materials may result in a higher initial cost but can lead to better durability and customer satisfaction in the long run.

-

Labor: Labor costs can significantly affect the final price. Regions with lower wage standards may offer more competitive pricing, but it’s essential to consider the skill level and expertise of the workforce, as these factors directly impact the quality of the finished product.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial setup costs for molds and cutting tools can be substantial, especially for custom designs. Buyers should factor in these costs, particularly if they require unique specifications.

-

Quality Control (QC): Ensuring that the final product meets quality standards incurs additional costs. Robust QC processes can prevent defects and returns, ultimately saving money.

-

Logistics: Transportation costs can vary based on distance, shipping methods, and trade regulations. International buyers need to be aware of these costs to avoid unexpected expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding the typical margins in the stretch fake leather market can help buyers negotiate better prices.

How Do Price Influencers Impact Stretch Fake Leather Sourcing?

Several factors influence the pricing of stretch fake leather, including:

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Understanding minimum order quantities (MOQs) can help buyers plan their purchases efficiently.

-

Specifications and Customization: Custom designs, colors, and finishes can increase costs. Buyers should balance their need for customization with budget constraints.

-

Material Quality and Certifications: Higher-quality materials or certifications (e.g., eco-friendly, hypoallergenic) can lead to higher prices but may justify the investment through enhanced product appeal and compliance with regulations.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may command higher prices but offer better service and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. These terms dictate who is responsible for shipping costs, insurance, and liabilities, impacting the overall cost.

What Tips Should Buyers Consider for Negotiating Stretch Fake Leather Prices?

To maximize cost-efficiency in sourcing stretch fake leather, consider the following strategies:

-

Negotiate Terms: Leverage relationships with suppliers to negotiate better pricing, especially for larger orders. Don’t hesitate to ask for discounts based on volume.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider the long-term costs associated with the material, including maintenance, durability, and potential returns due to quality issues.

-

Research Market Prices: Familiarize yourself with market rates by comparing different suppliers. Understanding the average pricing can empower you during negotiations.

-

Be Aware of Pricing Nuances for International Buyers: Currency fluctuations, import duties, and regional economic conditions can affect costs. Buyers from Africa, South America, the Middle East, and Europe should account for these factors in their budgeting.

-

Request Samples: Before placing a large order, request samples to assess quality and ensure it meets your specifications. This can save costs associated with returns and dissatisfaction.

Disclaimer on Indicative Prices

Prices for stretch fake leather can vary widely based on the factors discussed. The indicative prices observed in the market range from approximately $10 to $18 per yard, depending on quality, specifications, and supplier. Buyers should conduct thorough research and obtain quotes tailored to their specific needs.

Alternatives Analysis: Comparing stretch fake leather With Other Solutions

はじめに

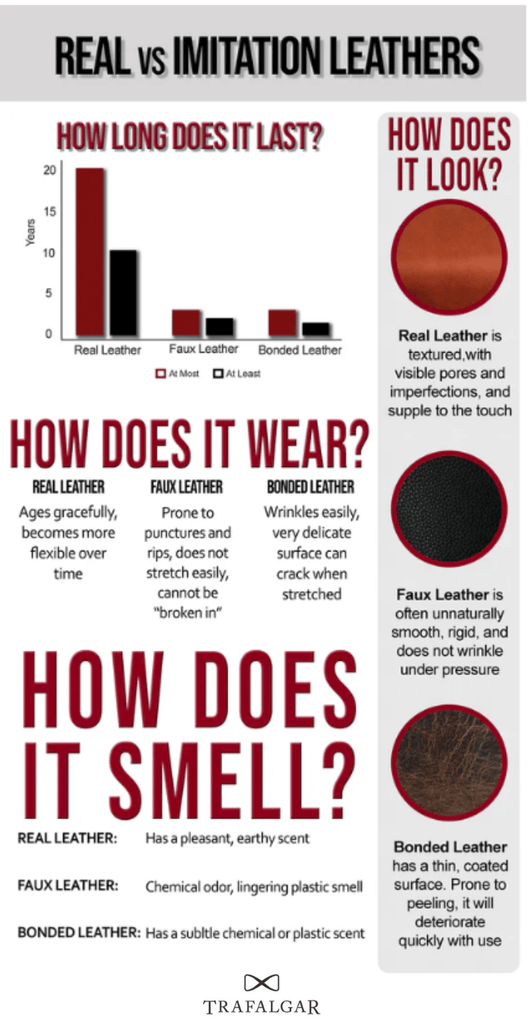

In the evolving textile industry, B2B buyers are constantly seeking alternatives to traditional materials, particularly in the realm of sustainable and ethical choices. Stretch fake leather, also known as faux leather or vegan leather, has gained popularity due to its appealing aesthetics and animal-friendly properties. However, buyers should consider other viable alternatives that may better suit their specific needs and applications. This analysis explores how stretch fake leather compares to two alternatives: natural leather and synthetic PVC leather.

Comparison Table

| Comparison Aspect | Stretch Fake Leather | Natural Leather | Synthetic PVC Leather |

|---|---|---|---|

| Performance | Good durability; flexible | Excellent durability; breathability | Moderate durability; water-resistant |

| Cost | Moderate ($10 – $16 per yard) | High (up to $100 per yard) | Low ($5 – $10 per yard) |

| Ease of Implementation | Easy to sew and maintain | Requires special tools for sewing | Easy to work with; no special tools needed |

| Maintenance | Machine washable | Requires conditioning | Easy to clean; resistant to stains |

| Best Use Case | Fashion, upholstery, accessories | High-end fashion, luxury goods | Budget-friendly apparel, home decor |

Detailed Breakdown

Natural Leather

Natural leather is renowned for its luxurious feel and long-lasting durability. It provides excellent breathability and develops a unique patina over time, enhancing its aesthetic appeal. However, the high cost and ethical concerns associated with animal sourcing may deter many buyers. Additionally, natural leather requires significant maintenance to preserve its quality, making it less suitable for fast-fashion applications.

Illustrative image related to stretch fake leather

Synthetic PVC Leather

Synthetic PVC leather offers a budget-friendly alternative with a similar appearance to genuine leather. It is lightweight and easy to clean, making it ideal for various applications, including budget apparel and home decor. However, PVC leather often lacks the durability and breathability of both stretch fake leather and natural leather. Its environmental impact is also a consideration, as PVC production can be harmful.

Conclusion

Choosing the right material ultimately depends on the specific requirements of a project. For businesses prioritizing sustainability and flexibility, stretch fake leather emerges as a strong contender due to its moderate cost, ease of use, and ethical attributes. Natural leather may be the go-to for high-end applications where durability and luxury are paramount, albeit at a higher price point. Conversely, synthetic PVC leather serves well for cost-sensitive projects where aesthetics matter, but buyers should weigh the long-term implications of using such materials. B2B buyers should evaluate their target market, budget, and ethical considerations to determine the best solution for their needs.

Essential Technical Properties and Trade Terminology for stretch fake leather

What Are the Key Technical Properties of Stretch Fake Leather?

When sourcing stretch fake leather, it is crucial for B2B buyers to understand the essential technical properties that define its quality and suitability for various applications. Here are some key specifications to consider:

Illustrative image related to stretch fake leather

-

Material Composition

Stretch fake leather is typically composed of synthetic materials, primarily polyester and spandex. The blend ratios can vary, with common compositions being 85% polyester and 15% spandex. This combination provides durability and flexibility, making it ideal for applications like fashion, upholstery, and accessories. Understanding the material composition helps buyers assess the fabric’s performance characteristics, such as breathability and stretchability. -

Stretch Type

Stretch fake leather is available in two-way and four-way stretch varieties. Two-way stretch allows for flexibility in one direction, while four-way stretch offers flexibility in both horizontal and vertical directions. This distinction is critical for buyers focused on specific applications, such as fitted clothing or upholstery, where enhanced elasticity is required for comfort and style. -

Weight (GSM)

The weight of the fabric, often measured in grams per square meter (GSM), significantly influences its application. A heavier GSM, such as 280 GSM, indicates a more robust fabric suitable for structured garments or upholstery, while a lighter GSM is preferable for more delicate applications like linings or fashion accessories. Buyers should consider weight in relation to their intended use to ensure optimal performance. -

Width

The width of stretch fake leather typically ranges around 58 inches. This specification is vital for manufacturers as it affects the yield of fabric per order and influences production costs. Understanding width helps buyers calculate material requirements for large projects and ensures compatibility with existing manufacturing processes. -

Durability and Care Instructions

Stretch fake leather is designed to withstand wear and tear, making it a practical choice for various applications. Care instructions, such as machine wash cold and air dry, ensure that the fabric maintains its quality over time. Buyers must prioritize durability and ease of maintenance, especially for products that will experience heavy use. -

Finish and Texture

The finish of stretch fake leather can vary from glossy to matte, and textures can range from smooth to embossed. This aspect plays a significant role in aesthetic appeal and application. Buyers should consider the desired look and feel for their products, as well as the market trends in their target regions.

What Are Common Trade Terms in the Stretch Fake Leather Industry?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms related to stretch fake leather:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of stretch fake leather, an OEM may produce the fabric that is then used in finished goods, such as clothing or upholstery. Knowing about OEM relationships can help buyers establish reliable supply chains. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. For stretch fake leather, MOQs can vary significantly based on the supplier and product type. Understanding MOQs is crucial for buyers to manage inventory levels and production costs effectively. -

RFQ (Request for Quotation)

An RFQ is a document that solicits quotes from suppliers for specific products or services. When sourcing stretch fake leather, submitting an RFQ can help buyers obtain competitive pricing and better understand supplier capabilities. This process is essential for informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade that define the responsibilities of buyers and sellers. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, which is particularly important when sourcing materials from international suppliers. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times for stretch fake leather is vital for inventory planning and project timelines, especially in fast-paced industries like fashion. -

Tensile Strength

This technical term refers to the maximum amount of tensile (stretching) stress that a material can withstand before failure. For stretch fake leather, high tensile strength indicates better durability and performance, making it a key consideration for B2B buyers focused on product longevity.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing stretch fake leather, ensuring quality and suitability for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the stretch fake leather Sector

What Are the Current Market Dynamics and Key Trends in the Stretch Fake Leather Sector?

The global stretch fake leather market is witnessing significant growth, driven by the rising demand for sustainable and cruelty-free materials in various industries, including fashion, automotive, and furniture. As consumers become more environmentally conscious, the shift towards synthetic alternatives that mimic the aesthetic and tactile qualities of genuine leather is gaining momentum. This trend is particularly pronounced in emerging markets across Africa, South America, and the Middle East, where local manufacturers are increasingly adopting stretch faux leather for its versatility and cost-effectiveness.

Technological advancements in textile manufacturing are also reshaping the landscape. Innovations such as digital printing and eco-friendly dyeing processes are making it easier for manufacturers to create customized patterns and textures that appeal to diverse consumer preferences. In Europe, particularly in Germany and other Western nations, there is a strong emphasis on high-quality, durable materials, which is influencing sourcing decisions. International B2B buyers are now more inclined to partner with suppliers who can provide detailed certifications of quality and sustainability.

Illustrative image related to stretch fake leather

Furthermore, the rise of e-commerce platforms is facilitating direct access to a broader range of suppliers. B2B buyers can now easily compare products, prices, and supplier ratings, enhancing their purchasing power. As the market evolves, understanding these dynamics is crucial for buyers looking to make informed sourcing decisions.

How Is Sustainability Shaping the Sourcing of Stretch Fake Leather?

Sustainability is at the forefront of sourcing decisions in the stretch fake leather sector. Traditional leather production is notorious for its environmental impact, from deforestation to toxic chemical use in tanning processes. In contrast, stretch fake leather offers a more sustainable alternative that significantly reduces environmental harm. Many manufacturers are now focusing on sourcing materials that incorporate recycled plastics and bio-based components, which not only minimize waste but also contribute to a circular economy.

The importance of ethical supply chains cannot be overstated. B2B buyers are increasingly seeking suppliers who adhere to ethical labor practices, ensuring fair wages and safe working conditions for workers involved in production. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® Standard 100 are becoming essential benchmarks for buyers looking to validate the sustainability claims of their suppliers. These certifications help ensure that the materials sourced are environmentally friendly and safe for consumers.

Incorporating green materials and ethical practices into supply chains not only enhances brand reputation but also aligns with growing consumer demand for responsible products. For international buyers, prioritizing sustainability in sourcing decisions can open doors to new markets and foster long-term relationships with eco-conscious consumers.

How Has the Stretch Fake Leather Sector Evolved Over Time?

The evolution of stretch fake leather can be traced back to the early 20th century when synthetic materials began to emerge as alternatives to traditional leather. Initially viewed as inferior, advancements in technology have dramatically improved the quality and appeal of faux leather, making it a viable option for a variety of applications.

Illustrative image related to stretch fake leather

By the 1980s and 1990s, with increasing awareness of animal rights and environmental issues, the demand for synthetic alternatives surged. Today, stretch fake leather is recognized not only for its aesthetic qualities but also for its adaptability in fashion and industrial applications. As the market continues to mature, buyers can expect ongoing innovations that enhance the functionality and sustainability of stretch fake leather, ensuring it remains a competitive choice in the global marketplace.

Understanding this historical context helps B2B buyers appreciate the trajectory of the industry and informs their sourcing strategies, enabling them to align with emerging trends while meeting consumer expectations for quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of stretch fake leather

-

How do I choose the right type of stretch fake leather for my project?

Selecting the appropriate type of stretch fake leather depends on your intended application. For fashion items like leggings or fitted garments, two-way stretch faux leather is ideal due to its flexibility. Conversely, four-way stretch options offer greater versatility for upholstery or more structured designs. Consider the fabric weight, texture, and finish that best align with your project needs. Always request samples to evaluate the fabric’s look and feel before making a bulk purchase. -

What are the minimum order quantities (MOQs) for stretch fake leather?

MOQs for stretch fake leather can vary significantly by supplier and region. Typically, suppliers might set MOQs ranging from 10 to 100 yards, depending on the fabric type and customization. It’s crucial to discuss your specific requirements with potential suppliers to negotiate terms that meet your production needs. Be mindful that lower MOQs may come at a higher cost per yard, while larger orders can lead to better pricing. -

What customization options are available for stretch fake leather?

Many manufacturers offer a range of customization options for stretch fake leather, including color selection, texture finishes, and even printed designs. You can often request specific widths or lengths to suit your production requirements. When considering customization, inquire about lead times, additional costs, and minimum order quantities. It’s advisable to obtain samples of custom designs to ensure they meet your quality expectations before placing a large order. -

How can I vet potential suppliers of stretch fake leather?

To effectively vet suppliers, begin by researching their reputation in the industry. Look for reviews, testimonials, and case studies from other B2B clients. Verify their certifications regarding quality and sustainability, as these can be critical factors in your decision. Additionally, request samples of their products and inquire about their production processes, lead times, and customer service policies to gauge their reliability and responsiveness. -

What payment terms are typically offered by suppliers of stretch fake leather?

Payment terms can vary widely depending on the supplier’s policies and your negotiation power. Common options include full payment upfront, a deposit with the balance due before shipment, or even net 30/60 terms for established relationships. Always clarify payment methods accepted, such as bank transfers, credit cards, or letters of credit. Ensure that the payment terms align with your cash flow needs and protect your interests in case of disputes. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have robust quality assurance protocols in place, including material inspections, testing for durability, and adherence to industry standards. Inquire about their quality control processes and whether they conduct third-party testing. Request documentation of quality certifications and any warranties offered on the fabric. Establishing clear expectations for quality at the outset can help mitigate issues during production. -

How does international shipping work for stretch fake leather?

International shipping for stretch fake leather typically involves freight forwarders, customs clearance, and potential import duties. Discuss shipping options with your supplier, including estimated costs and delivery times. Ensure that you understand the logistics involved, including who is responsible for shipping and insurance. Familiarize yourself with the import regulations in your country to avoid unexpected delays or costs. -

What are the common uses for stretch fake leather in various industries?

Stretch fake leather is widely used across several industries, including fashion, automotive, and furniture. In fashion, it’s popular for apparel, accessories, and footwear due to its flexibility and stylish appearance. The automotive sector utilizes it for seat covers and interior detailing, while the furniture industry employs it for upholstery on couches and chairs. Its versatility, ease of maintenance, and ethical appeal make it a preferred choice for many manufacturers.

Top 5 Stretch Fake Leather Manufacturers & Suppliers List

1. Kiki Textiles – Faux Leather Fabric

Domain: kikitextiles.com

Registered: 2021 (4 years)

Introduction: Faux leather (pleather) fabric by the yard, available in various colors and styles. Key features include:

– Ethical and animal-friendly alternative to genuine leather.

– Advanced technology for realistic texture, sheen, and durability.

– Suitable for fashion (jackets, handbags, clothing), upholstery (furniture), and accessories (wallets, belts, shoes).

– Easy to clean and resistant to wear and tea…

2. Reddit – Faux Leather D’Orsay Heels

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Faux leather shoes, specifically low d’orsay heels, intended for a presentation. Users are seeking methods to soften these shoes without causing foot pain.

3. Spandex World – Faux Leather Collection

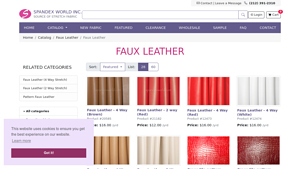

Domain: spandexworld.com

Registered: 2004 (21 years)

Introduction: Faux Leather Products:

1. Faux Leather – 4 Way (Brown)

– Product #20585

– Price: $16.00 /yrd

2. Faux Leather – 2 Way (Red)

– Product #21182

– Price: $12.00 /yrd

3. Faux Leather – 4 Way (Red)

– Product #12473

– Price: $16.00 /yrd

4. Faux Leather – 4 Way (White)

– Product #12474

– Price: $16.00 /yrd

5. Faux Leather – 4 Way (Nude)

– Product #12472

– Price: $16.00 /yr…

4. WikiHow – Stretching Faux Leather Shoes

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: Faux leather and synthetic shoes can stretch up to ½ a size bigger. To stretch faux leather, use a leather-stretching spray or a boot tree that is ½ size bigger. For nylon, vegan, and plastic materials, wear thick socks for 15-30 minutes to break them in. Plastic shoes can only stretch half a size and should not be overstretched to avoid tearing. Heating plastic shoes with a blow dryer can help sh…

5. Mood Fabrics – Faux Leather by the Yard

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: Faux Leather Fabric by the Yard | Ethical Alternative

Strategic Sourcing Conclusion and Outlook for stretch fake leather

As the demand for stretch fake leather continues to grow across diverse industries, strategic sourcing plays a pivotal role in ensuring that international B2B buyers secure high-quality materials at competitive prices. This innovative fabric not only offers a sustainable alternative to genuine leather but also provides versatility for applications in fashion, upholstery, and accessories. Key takeaways include the importance of partnering with reliable suppliers who offer a variety of colors and textures, as well as understanding the specific needs of your target market to effectively meet consumer preferences.

Illustrative image related to stretch fake leather

Moreover, the ongoing advancements in fabric technology are enhancing the realism and functionality of stretch fake leather, making it an increasingly attractive option. Buyers are encouraged to explore suppliers that prioritize ethical production practices, thereby aligning with the growing consumer demand for sustainable products.

Looking ahead, B2B buyers from Africa, South America, the Middle East, and Europe should actively seek partnerships that foster innovation and sustainability in their supply chains. By prioritizing strategic sourcing, businesses can not only enhance their product offerings but also position themselves as leaders in the competitive market of faux leather textiles. Embrace this opportunity to elevate your brand and meet the evolving needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.