Introduction: Navigating the Global Market for how to make a leather gun holster

In the intricate world of leather craftsmanship, understanding how to make a leather gun holster presents a unique challenge for international B2B buyers. This guide serves as an essential resource for sourcing high-quality materials, mastering various construction techniques, and navigating the complexities of supplier vetting. From selecting the right type of leather—such as durable vegetable-tanned options—to understanding the nuances of design for different firearm models, this comprehensive guide empowers businesses across Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany.

As the demand for customized leather holsters grows, it is crucial for B2B buyers to be informed about the latest trends, applications, and pricing strategies. This guide will delve into the various types of holsters available, their specific applications, and the costs associated with high-quality production. By equipping buyers with actionable insights and expert recommendations, we aim to facilitate informed purchasing decisions that align with their business needs.

Whether you are a wholesaler seeking reliable suppliers or a manufacturer looking to enhance your product offerings, this guide will help you navigate the global market with confidence, ensuring that your investments in leather gun holsters yield substantial returns.

Table Of Contents

- Top 5 How To Make A Leather Gun Holster Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather gun holster

- Understanding how to make a leather gun holster Types and Variations

- Key Industrial Applications of how to make a leather gun holster

- 3 Common User Pain Points for ‘how to make a leather gun holster’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather gun holster

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather gun holster

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather gun holster’

- Comprehensive Cost and Pricing Analysis for how to make a leather gun holster Sourcing

- Alternatives Analysis: Comparing how to make a leather gun holster With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather gun holster

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather gun holster Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather gun holster

- Strategic Sourcing Conclusion and Outlook for how to make a leather gun holster

- Important Disclaimer & Terms of Use

Understanding how to make a leather gun holster Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fitted Leather Holster | Custom-molded to fit specific firearm models, often vacuum-formed | Law enforcement, military, custom shops | Pros: Excellent fit, enhanced retention. Cons: Time-consuming to produce. |

| OWB (Outside Waistband) Holster | Designed for outside the waistband carry, often has adjustable cant | Retail, personal defense, outdoor activities | Pros: Easy access, versatile. Cons: Can be bulkier than IWB options. |

| IWB (Inside Waistband) Holster | Concealed carry option that sits inside the waistband | Concealed carry markets, self-defense | Pros: Discreet, comfortable for prolonged wear. Cons: Limited accessibility. |

| Shoulder Holster | Suspended from the shoulders, distributing weight evenly | Law enforcement, private security | Pros: Comfortable for extended wear, good for larger firearms. Cons: Slower draw time. |

| Cross-Draw Holster | Designed for drawing across the body, positioned on the opposite hip | Tactical operations, hunting | Pros: Quick access while seated. Cons: May be less secure during movement. |

What are the Characteristics of Fitted Leather Holsters?

Fitted leather holsters are tailored to the unique dimensions of specific firearms, often utilizing techniques such as vacuum forming for a precise fit. This type of holster is ideal for B2B buyers in law enforcement and military sectors, where firearm retention and accessibility are paramount. When purchasing, consider the leather quality and the potential for customization, as these factors can significantly impact durability and user satisfaction.

Illustrative image related to how to make a leather gun holster

How Do OWB Holsters Serve Different Markets?

OWB holsters are designed for outside the waistband carry, providing easy access and quick draw capabilities. They are popular in retail environments and for personal defense applications. Buyers should evaluate the adjustability of the cant and the belt attachment options, as these features can enhance comfort and usability during various activities, such as outdoor excursions or tactical training.

What Makes IWB Holsters Ideal for Concealed Carry?

IWB holsters are designed to fit inside the waistband, making them a popular choice for concealed carry enthusiasts. Their discreet nature allows for comfortable all-day wear while maintaining a low profile. B2B buyers should consider the material’s breathability and flexibility to ensure comfort, as well as the holster’s ability to securely hold the firearm in place during movement.

Why Choose Shoulder Holsters for Comfort and Weight Distribution?

Shoulder holsters are designed to suspend the firearm from the shoulders, distributing its weight evenly across the body. This design is particularly appealing to law enforcement and private security professionals who may need to carry larger firearms for extended periods. Buyers should look for adjustable straps and padding to enhance comfort, as well as materials that can withstand rigorous use.

What are the Benefits of Cross-Draw Holsters in Tactical Settings?

Cross-draw holsters are positioned on the opposite hip, allowing for a quick draw across the body. This design is particularly beneficial for tactical operations and hunting scenarios where quick access is necessary, especially when seated. B2B buyers should assess the security features, such as retention straps, to ensure the firearm remains secure during movement, while also considering the holster’s compatibility with various firearm types.

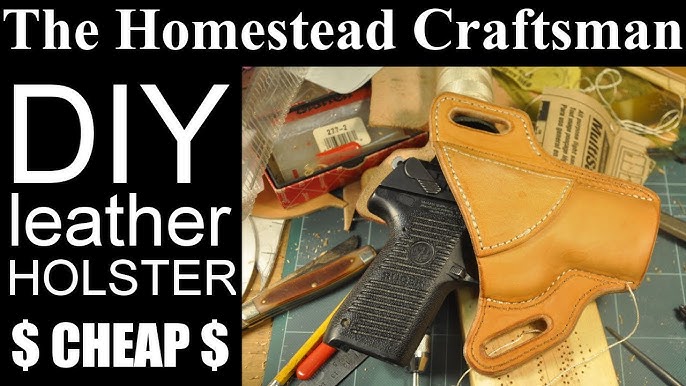

Illustrative image related to how to make a leather gun holster

Key Industrial Applications of how to make a leather gun holster

| Industry/Sector | Specific Application of how to make a leather gun holster | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Custom holsters for firearms used by police and security personnel | Enhanced safety and accessibility for officers in the field | Sourcing durable, high-quality leather that meets safety standards |

| Military | Tactical holsters for soldiers’ sidearms | Improved functionality and readiness during operations | Requirements for military-grade materials and compliance with regulations |

| Sporting Goods Retailers | Retailing custom leather holsters for firearm enthusiasts | Ability to offer personalized, high-quality products to customers | Ensuring availability of various leather types and custom design options |

| Film and Theater Production | Props for actors that require realistic gun holsters | Authenticity in production design enhances viewer experience | Collaboration with skilled artisans for bespoke holster designs |

| Outdoor and Adventure Gear | Holsters for hunting and outdoor activities | Providing practical solutions for carrying firearms safely | Consideration of environmental factors and durability of materials |

How Is ‘How to Make a Leather Gun Holster’ Utilized in Law Enforcement?

In the law enforcement sector, the process of making leather gun holsters is critical for crafting custom-fit solutions that enhance officers’ safety and accessibility. A well-fitted holster ensures that firearms are securely held while allowing quick access when needed. Buyers in this sector must prioritize sourcing durable leather that meets stringent safety standards and can withstand the rigors of daily use in various environments.

What Are the Military Applications of Leather Gun Holsters?

Military applications for leather gun holsters focus on tactical gear designed for soldiers. These holsters must provide quick access to sidearms while being robust enough to endure harsh conditions. Businesses in this field should seek military-grade materials that comply with regulations, ensuring that the holsters are not only functional but also capable of meeting the demands of combat scenarios.

How Do Sporting Goods Retailers Benefit from Custom Leather Holsters?

Sporting goods retailers can leverage the production of custom leather holsters to cater to firearm enthusiasts. Offering personalized products enhances customer satisfaction and loyalty, as buyers appreciate high-quality craftsmanship tailored to their specific firearms. Retailers should focus on sourcing a variety of leather types and design options to meet diverse consumer needs, ensuring they remain competitive in the market.

What Role Do Leather Gun Holsters Play in Film and Theater Productions?

In film and theater, leather gun holsters are essential for creating authentic props that enhance the storytelling experience. The demand for realistic designs means that production companies often collaborate with skilled artisans to create bespoke holsters that fit specific actors and scenes. Key considerations for businesses include the aesthetic quality of the leather and the ability to produce items quickly to meet tight production schedules.

How Are Leather Holsters Used in Outdoor and Adventure Gear?

In the outdoor and adventure gear sector, leather gun holsters serve practical purposes for hunters and outdoor enthusiasts. These holsters must be designed to provide safe and convenient firearm storage during activities like hunting or hiking. Businesses should consider environmental factors, such as water resistance and durability, when sourcing materials to ensure that the holsters can withstand various outdoor conditions while maintaining functionality.

Illustrative image related to how to make a leather gun holster

3 Common User Pain Points for ‘how to make a leather gun holster’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Leather for Holsters

The Problem: B2B buyers often face challenges when sourcing high-quality leather suitable for gun holsters. Many leather options available in the market may not be durable enough or could potentially harm the firearm due to chemical treatments. This issue is particularly acute for businesses in regions with limited access to specialized leather suppliers, leading to product inconsistencies and potential customer dissatisfaction.

The Solution: To overcome this challenge, it is crucial for buyers to establish relationships with reputable suppliers known for their high-quality leather, specifically vegetable-tanned full-grain leather. This type of leather is not only durable but also less likely to cause rust or damage to firearms. B2B buyers should consider leveraging online platforms or industry trade shows to connect with trusted manufacturers. Additionally, conducting sample testing before placing bulk orders can ensure the leather meets specific requirements. When sourcing leather, buyers should inquire about the origin, tanning process, and thickness (ideally between 7-8 oz) to guarantee its suitability for holster-making.

Scenario 2: Challenges in Achieving Proper Fit and Design

The Problem: Many B2B buyers struggle with creating holsters that fit specific firearm models accurately. The lack of precise templates or design guidelines can result in holsters that are either too loose or too tight, affecting usability and safety. This is particularly problematic for businesses that cater to a diverse range of firearms, leading to wasted materials and increased production costs.

The Solution: To tackle design issues, buyers should invest in custom templates tailored to the specific models they intend to produce. Utilizing CAD (Computer-Aided Design) software can help in creating accurate patterns that can be adjusted based on the firearm dimensions. Additionally, attending workshops or training sessions on holster design can provide valuable insights into proper fitting techniques. Collaborating with experienced leather artisans or consultants can also streamline the design process, ensuring that the holsters not only fit well but also incorporate ergonomic features that enhance user experience.

Illustrative image related to how to make a leather gun holster

Scenario 3: Inefficient Assembly and Finishing Processes

The Problem: Many businesses encounter inefficiencies in the assembly and finishing stages of holster production. These inefficiencies can stem from inadequate tools, improper techniques, or a lack of skilled labor, leading to inconsistencies in product quality and longer production times. This not only affects profitability but can also tarnish the brand’s reputation if customers receive subpar products.

The Solution: To improve assembly and finishing processes, buyers should invest in high-quality tools and equipment that streamline production. For example, using professional-grade stitching machines can enhance sewing precision and speed. Additionally, creating a standardized operating procedure (SOP) for each step of the holster-making process can help maintain consistency. Providing training for workers on proper assembly techniques and finishing methods is equally important, as this can significantly reduce errors and improve overall quality. Lastly, implementing quality control checkpoints throughout the production process can help catch issues early, reducing waste and ensuring that only the best products reach the market.

Strategic Material Selection Guide for how to make a leather gun holster

What Are the Key Materials for Making a Leather Gun Holster?

When creating leather gun holsters, the selection of materials is crucial to ensure durability, comfort, and functionality. Below, we analyze several common materials used in the manufacturing of leather gun holsters, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to how to make a leather gun holster

Which Types of Leather Are Most Suitable for Gun Holsters?

Vegetable-Tanned Leather

Key Properties: Vegetable-tanned leather is known for its rigidity and strength. It offers excellent moisture resistance and is less prone to corrosion, making it suitable for gun holsters that may encounter various environmental conditions.

Pros & Cons: This type of leather is highly durable and ages well, developing a unique patina over time. However, it can be more expensive than other types of leather and requires more complex manufacturing processes, such as precise cutting and shaping to achieve the desired fit.

Impact on Application: Its rigidity allows for a secure fit around the firearm, which is essential for safety and accessibility. However, its stiffness may require a break-in period for user comfort.

International Considerations: Buyers in regions such as Europe may prefer vegetable-tanned leather due to its eco-friendly production methods. Compliance with EU regulations on chemical usage in leather production can also influence purchasing decisions.

Chrome-Tanned Leather

Key Properties: Chrome-tanned leather is softer and more pliable than vegetable-tanned leather, providing a comfortable fit right out of the box. It is resistant to water and stains, making it easier to maintain.

Pros & Cons: While chrome-tanned leather is less expensive and quicker to produce, it is not as durable as vegetable-tanned leather and can lead to rusting of firearms due to chemical leaching. This can be a significant drawback for holster applications.

Impact on Application: Its flexibility may enhance user comfort, but the potential for corrosion makes it less suitable for long-term use with firearms.

International Considerations: Buyers from South America and Africa might find chrome-tanned leather appealing due to its lower cost, but they must be aware of the potential long-term implications for firearm maintenance.

Illustrative image related to how to make a leather gun holster

Full-Grain Leather

Key Properties: Full-grain leather retains the entire grain layer, making it the most durable and breathable option available. It offers excellent resistance to wear and tear, as well as moisture.

Pros & Cons: The primary advantage of full-grain leather is its longevity and the ability to develop a rich character over time. However, it is often the most expensive option and requires skilled craftsmanship to work with effectively.

Impact on Application: Its durability makes it ideal for holsters that will see heavy use. The breathability also contributes to comfort during extended wear.

International Considerations: In regions like Germany, where craftsmanship is highly valued, full-grain leather is often preferred despite its higher cost. Compliance with strict environmental standards in Europe may also affect sourcing decisions.

Suede Leather

Key Properties: Suede leather, made from the underside of the hide, is soft and flexible. It provides a unique aesthetic and can be treated for additional durability.

Pros & Cons: The softness of suede makes it comfortable to wear, but it is less durable than other leather types and can be more susceptible to stains and damage from moisture.

Impact on Application: Suede can be used for holsters that prioritize comfort over ruggedness, but its lower durability may limit its suitability for daily carry applications.

International Considerations: Buyers in the Middle East may appreciate the aesthetic appeal of suede but should be cautious about its maintenance requirements, particularly in hot and humid climates.

Illustrative image related to how to make a leather gun holster

Summary Table of Material Selection for Leather Gun Holsters

| 素材 | Typical Use Case for how to make a leather gun holster | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Custom holsters for firearms requiring durability | Excellent durability and moisture resistance | Higher cost and complex manufacturing | 高い |

| Chrome-Tanned Leather | Budget-friendly holsters for casual use | Soft and comfortable | Potential for rusting firearms | Medium |

| Full-Grain Leather | Premium holsters for heavy-duty use | Long-lasting and breathable | Most expensive and requires skill | 高い |

| Suede Leather | Comfortable holsters for occasional use | Soft and flexible | Less durable and stain-prone | Medium |

This analysis provides a comprehensive overview of the key materials used in leather gun holster production, equipping B2B buyers with the insights necessary to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather gun holster

What Are the Main Stages in the Manufacturing Process of Leather Gun Holsters?

The manufacturing of leather gun holsters involves several critical stages that ensure both functionality and quality. The typical process can be broken down into four main phases: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Leather Gun Holsters?

The choice of leather is paramount in the manufacturing process. High-quality holsters typically utilize vegetable-tanned, full-grain leather, ranging from 7 to 8 ounces in thickness. This leather offers durability and resistance to wear while minimizing the risk of rusting the firearm.

Illustrative image related to how to make a leather gun holster

During the material preparation phase, leather is sourced from reputable suppliers, ensuring it meets industry standards. It is essential to avoid chrome-tanned leathers, which can negatively affect the firearm. The leather is then cut into appropriate shapes based on specific gun models, ensuring that the patterns are aligned with the leather’s grain for optimal strength.

What Techniques Are Used in the Forming Process?

The forming process is where the leather is shaped to fit the specific firearm. This typically involves soaking the leather to make it pliable, a crucial step that allows for a precise fit. Some manufacturers prefer using water instead of alcohol for soaking, as alcohol can lead to drying and cracking.

Once soaked, the leather is often vacuum-formed around the firearm using a mold. This technique creates a snug fit, which is critical for the holster’s functionality. After forming, the leather is allowed to dry in position, ensuring it retains the desired shape.

How Is the Assembly of Leather Gun Holsters Executed?

After the leather has dried and set, assembly begins. The two halves of the holster are glued together using strong adhesives like Barge Cement or E6000, ensuring that they align perfectly. Clamping or vacuum-bagging during this stage helps maintain the alignment while the adhesive cures.

The next step involves outlining the final shape of the holster, including belt loops and stitching holes. Precision is vital; using tools such as leather stitching groovers and overstitching tools ensures accurate placements. Cutting is done with sharp instruments to avoid fraying and ensure clean edges.

What Finishing Techniques Enhance the Quality of Leather Holsters?

Finishing is the final stage and is crucial for both aesthetics and durability. This phase often includes sanding edges for a smooth finish and applying protective oils, such as Neatsfoot oil, to condition the leather and enhance its appearance. Additional treatments may include dyeing or sealing to protect against moisture and wear.

Quality finishing not only impacts the look of the holster but also its longevity and usability. Manufacturers often employ techniques to ensure that the finishing process does not compromise the structural integrity of the leather.

What Are the Key Quality Assurance Practices in Leather Holster Manufacturing?

Quality assurance (QA) is vital in the leather gun holster manufacturing process to ensure that products meet both safety and performance standards. This section outlines the relevant international standards, QC checkpoints, and common testing methods.

Illustrative image related to how to make a leather gun holster

Which International Standards Should B2B Buyers Be Aware Of?

For leather gun holster manufacturers, adhering to international standards such as ISO 9001 is crucial. This standard focuses on quality management systems and ensures that manufacturing processes meet customer and regulatory requirements.

Additional certifications that may be relevant include CE marking for products sold in Europe and API specifications for manufacturers supplying to the oil and gas industry. Understanding these standards is essential for B2B buyers looking for reliable suppliers.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control involves several checkpoints throughout the manufacturing process, typically categorized into:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival. Leather must be checked for defects, consistency in thickness, and overall quality.

-

In-Process Quality Control (IPQC): During the manufacturing phases, regular inspections ensure that processes such as cutting, forming, and assembling meet established quality benchmarks.

-

Final Quality Control (FQC): The finished product undergoes a comprehensive review, assessing fit, finish, and functional performance. This stage is critical to ensure that the holster meets all specifications before shipment.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify a supplier’s quality control processes. Regular audits, which can be conducted by the buyer or an independent third party, help assess compliance with quality standards. These audits should focus on the entire manufacturing process, from material sourcing to final product inspection.

Additionally, requesting detailed QC reports and certifications can provide insight into a supplier’s commitment to quality. Buyers should also inquire about any testing methods used, such as stress tests or fit tests, to ensure that the holsters meet performance criteria.

What Are the Common Testing Methods Used in Quality Assurance?

Testing methods for leather gun holsters can vary based on the intended use and market regulations. Common methods include:

-

Durability Testing: Assessing the wear and tear of the holster through repeated use.

-

Moisture Resistance Testing: Evaluating how well the leather withstands exposure to moisture, which is critical for outdoor applications.

-

Fit Testing: Ensuring that the holster securely fits the designated firearm, preventing movement or accidental discharge.

How Do Regional Differences Impact Quality Control Nuances for International B2B Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and market expectations is essential. Different regions may have specific requirements regarding materials used, product safety, and environmental considerations.

Illustrative image related to how to make a leather gun holster

Buyers should be aware that certifications accepted in one region may not hold the same weight in another. As such, it is advisable to engage with suppliers who are knowledgeable about regional compliance and can provide the necessary documentation.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can better navigate the leather gun holster market, ensuring they select reliable suppliers that meet their operational needs and compliance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather gun holster’

はじめに

This guide serves as a comprehensive checklist for B2B buyers interested in sourcing materials and processes for creating leather gun holsters. By following these steps, you can ensure that you procure high-quality materials, partner with reliable suppliers, and ultimately produce holsters that meet the demands of your target market.

Step 1: Identify Your Leather Specifications

Before beginning the sourcing process, clearly define the type of leather you need. Seek high-quality vegetable-tanned leather, ideally between 7-8 oz in thickness, as it provides durability and prevents rusting of firearms. Understanding the specific requirements for leather quality will help you avoid inferior products that could compromise the integrity of your holsters.

Illustrative image related to how to make a leather gun holster

Step 2: Source Reliable Leather Suppliers

Once you have your specifications, research potential leather suppliers. Look for suppliers with a proven track record in the leather industry, particularly those who specialize in gun holster materials. Ensure they can provide certificates of authenticity and quality assurance.

- Check for Reviews: Look for testimonials from other B2B buyers who have purchased from these suppliers.

- Request Samples: Before making a bulk order, obtain samples to assess the quality and suitability of the leather.

Step 3: Evaluate Hardware and Accessory Suppliers

In addition to leather, quality hardware (like rivets, screws, and buckles) is essential for durable holsters. Identify suppliers who offer high-quality, rust-resistant metal components.

- Compatibility Check: Ensure that the hardware you select is compatible with your leather specifications and design.

- Durability Testing: Inquire about the testing processes for their hardware to confirm that they can withstand wear and tear.

Step 4: Verify Manufacturing Capabilities

Assess the manufacturing capabilities of your potential partners. Understanding their production processes will help ensure they can meet your volume requirements and quality standards.

- 生産能力: Ask about their capacity to handle large orders, especially if you plan to scale your operations.

- Lead Times: Inquire about their typical lead times for production and delivery to avoid delays in your supply chain.

Step 5: Understand Local Regulations and Compliance

Before finalizing any orders, familiarize yourself with the legal regulations surrounding the production and sale of leather gun holsters in your target markets. Compliance with local laws is crucial to avoid legal issues that could affect your business.

- Import Regulations: Research any import restrictions or tariffs that may apply to leather goods in your region.

- Safety Standards: Ensure that the materials and products meet the safety standards required in your target countries.

Step 6: Establish Quality Control Measures

Implement quality control measures to ensure that the materials and finished holsters meet your standards. This can include regular inspections and testing of materials and finished products.

Illustrative image related to how to make a leather gun holster

- Inspection Protocols: Develop a protocol for inspecting incoming materials and outgoing products to ensure consistency.

- Feedback Loop: Create a system for collecting feedback from customers to continually improve quality and address any issues promptly.

Step 7: Build Strong Supplier Relationships

Finally, foster strong relationships with your suppliers. Open communication will facilitate better collaboration and can lead to favorable terms and conditions in the long run.

- Regular Check-Ins: Schedule regular meetings or calls to discuss performance and address any concerns.

- Negotiation on Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and pricing to better align with your business needs.

By following these steps, B2B buyers can effectively source the necessary materials and expertise required to create high-quality leather gun holsters, ensuring a successful venture in the competitive leather goods market.

Comprehensive Cost and Pricing Analysis for how to make a leather gun holster Sourcing

What Are the Key Cost Components in Making Leather Gun Holsters?

When considering the manufacturing of leather gun holsters, a B2B buyer must understand the essential cost components involved in the process. These typically include:

-

Materials: The primary cost driver is the leather itself. High-quality vegetable-tanned full-grain leather (7-8 oz) is preferred for its durability and aesthetic appeal. Prices can vary significantly based on the hide’s origin and tanning process, ranging from $5 to $15 per square foot. Additional materials such as threads, adhesives (like Barge Cement), and finishing products (e.g., Neatsfoot oil) also contribute to the overall material cost.

-

Labor: Labor costs encompass the time required for skilled artisans to cut, assemble, stitch, and finish the holsters. Depending on the complexity of the design and the skill level of the labor force, this can range from $20 to $50 per hour. Customization and intricate designs may require more time and expertise, further increasing labor costs.

-

Manufacturing Overhead: This includes indirect costs related to production facilities, utilities, equipment maintenance, and administrative expenses. Overhead can typically add an additional 15-30% on top of direct labor and material costs.

-

Tooling: Initial tooling costs for custom molds or cutting dies can be significant, especially for specialized designs. These costs can range from $500 to $2,000 depending on the complexity and the number of variations.

-

Quality Control (QC): Ensuring that each holster meets quality standards may involve additional labor and processes, adding another 5-10% to the overall cost.

-

Logistics: Shipping and handling fees can vary widely depending on the destination and shipping method. International buyers should consider customs duties and taxes that can further impact the total cost.

-

Margin: Manufacturers typically apply a profit margin of 20-50% based on the product’s perceived value and market demand.

How Do Price Influencers Affect Leather Gun Holster Costs?

Several factors can influence the pricing of leather gun holsters, particularly in international B2B transactions:

-

Volume/MOQ: Larger orders generally lead to lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can help negotiate better pricing.

-

Specifications and Customization: Custom designs or specific requirements (such as special finishes or fittings) can increase costs. Buyers should be clear about their specifications to avoid unexpected charges.

-

Material Quality and Certifications: The choice of leather and its certifications (such as environmental compliance) can impact pricing. High-quality, certified materials often command a premium.

-

Supplier Factors: The supplier’s reputation, location, and production capacity can influence pricing. Established suppliers with a track record of quality may charge more but provide better reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers as they define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs.

What Buyer Tips Can Enhance Cost-Efficiency in Leather Holster Sourcing?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, payment terms, and bulk discounts. Establishing a long-term relationship can lead to better deals over time.

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, quality, and potential replacements. A more expensive holster may be a better investment if it lasts longer.

-

Pricing Nuances for International Transactions: Be aware of currency fluctuations, international shipping costs, and customs duties. Utilizing a local supplier may mitigate some of these costs.

-

Research and Comparison: Compare multiple suppliers and gather quotes to ensure competitive pricing. Look for reviews or case studies that validate the supplier’s quality and service.

Disclaimer on Indicative Prices

Prices mentioned throughout this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct thorough research and obtain detailed quotes tailored to their specific needs.

Alternatives Analysis: Comparing how to make a leather gun holster With Other Solutions

When considering the production of gun holsters, businesses must evaluate various methods and materials to determine the most suitable approach. While crafting a leather gun holster is a time-honored method, there are alternative solutions that may offer different advantages. This analysis compares the traditional leather crafting method with two viable alternatives: synthetic material holsters and molded kydex holsters.

Illustrative image related to how to make a leather gun holster

| Comparison Aspect | How To Make A Leather Gun Holster | Synthetic Material Holsters | Molded Kydex Holsters |

|---|---|---|---|

| Performance | High durability and aesthetic appeal | Moderate durability; varies by material | High durability; excellent retention |

| Cost | Higher initial investment in leather and tools | Generally lower; depends on material quality | Moderate cost; often affordable |

| Ease of Implementation | Requires skill and experience; time-consuming | Easy to assemble; minimal skills needed | Requires some skill; quick to produce |

| Maintenance | Needs regular conditioning and care | Low maintenance; easy to clean | Low maintenance; resistant to moisture |

| Best Use Case | Ideal for custom, aesthetic, and traditional applications | Suitable for budget-conscious users and mass production | Excellent for tactical and law enforcement applications |

How Does Synthetic Material Compare to Leather Holsters?

Synthetic material holsters, often made from nylon or other plastics, present a practical alternative to leather. They are typically lighter and may be less expensive to produce, making them attractive for mass production. However, they may lack the aesthetic appeal and durability of leather. While synthetic holsters can be sufficient for casual use, they may not provide the same level of comfort or longevity as leather options. Businesses targeting budget-conscious consumers or those needing quick, lightweight solutions may find synthetic materials advantageous.

What Are the Benefits of Molded Kydex Holsters Over Leather?

Molded kydex holsters are gaining popularity due to their robust performance and ease of use. They are custom-molded to fit specific firearms, ensuring excellent retention and security. Kydex is waterproof and resistant to various environmental conditions, making it ideal for tactical applications and law enforcement. However, while kydex holsters are highly functional, they may lack the classic aesthetic appeal of leather. For businesses focused on tactical markets or requiring quick production, kydex may be the preferred choice.

How Can B2B Buyers Make the Right Choice for Their Needs?

Choosing the right holster solution depends on several factors, including the target market, intended use, and budget constraints. Companies focused on high-end custom products may lean towards leather for its durability and aesthetic value. In contrast, businesses looking to serve tactical clients or budget-conscious consumers may find kydex or synthetic materials more aligned with their operational goals. By carefully evaluating the performance, cost, ease of implementation, and maintenance requirements of each option, B2B buyers can make informed decisions that align with their strategic objectives.

Illustrative image related to how to make a leather gun holster

Essential Technical Properties and Trade Terminology for how to make a leather gun holster

What Are the Key Technical Properties Required for Making a Leather Gun Holster?

When creating a leather gun holster, several critical technical properties must be considered to ensure quality and functionality. Here are some essential specifications:

-

Material Grade

The primary material for a durable holster is typically 7-8 oz vegetable-tanned leather. This weight provides the necessary thickness and sturdiness to protect the firearm while maintaining comfort for the user. Vegetable-tanned leather is preferred over chrome-tanned leather due to its durability and non-reactive nature, which prevents rust on firearms. For B2B buyers, understanding material grades ensures that they source leather that meets the specific needs of their product line. -

Tolerances

Precision in cutting and stitching is crucial. Tolerances refer to the allowable deviations in measurements during the manufacturing process. For instance, a tolerance of ±1 mm in dimensions ensures that the holster fits the firearm snugly without being overly tight or loose. This specification is essential for maintaining product consistency, which is vital for customer satisfaction and brand reputation. -

Stitching Strength

The stitching used in a holster must withstand significant stress. A common practice is to use a nylon or polyester thread, which offers superior tensile strength compared to cotton. Stitching should be at least 1.5 mm in width and spaced evenly to provide both durability and an aesthetically pleasing finish. This property is particularly important for B2B buyers who are looking to deliver high-quality, long-lasting products. -

Finish Quality

The finishing process, which includes edge treatment and application of leather conditioners, affects both the aesthetics and longevity of the holster. A well-finished edge prevents fraying and enhances the overall look of the product. B2B buyers should prioritize manufacturers who employ rigorous finishing standards to ensure that the final product meets market expectations. -

Water Resistance

While leather naturally offers some water resistance, additional treatments can enhance this property. A water-resistant holster is crucial for users in various climates, particularly in regions prone to rain or humidity. Understanding the water resistance levels can help B2B buyers select products that cater to specific environmental needs.

What Are Common Trade Terms Used in Leather Gun Holster Manufacturing?

Familiarizing yourself with industry jargon is crucial for effective communication and negotiation in the leather goods market. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of leather holsters, an OEM might design and produce holsters based on specifications provided by a firearm manufacturer. This term is essential for B2B buyers seeking custom solutions. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for B2B buyers as it affects inventory costs and the ability to test new products in the market without significant upfront investment. -

RFQ (Request for Quotation)

An RFQ is a document that an organization sends to suppliers to request pricing and terms for specific products or services. For buyers in the leather holster industry, issuing an RFQ helps in comparing prices and negotiating better deals. -

Incoterms (International Commercial Terms)

These are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers, particularly those importing leather goods, as it clarifies shipping responsibilities, costs, and risk management. -

Lead Time

Lead time is the period between the initiation of an order and the delivery of the product. In the leather holster manufacturing process, lead times can vary based on the complexity of the design and production capacity. B2B buyers must manage lead times effectively to align with customer expectations and market demands.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure high-quality leather gun holsters that meet their operational and customer needs.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather gun holster Sector

What Are the Current Market Dynamics and Key Trends in the Leather Gun Holster Sector?

The leather gun holster market is witnessing a surge in demand driven by several global factors. Increased firearm ownership across various regions, particularly in Africa and South America, is contributing to the rising need for reliable and durable holsters. Additionally, the Middle East and Europe are seeing a heightened focus on custom-made solutions, aligning with the growing trend towards personalization in consumer products. This shift is largely fueled by advancements in technology, enabling manufacturers to utilize sophisticated design software and production methods that enhance the quality and precision of leather goods.

Moreover, the emergence of e-commerce platforms is transforming how B2B buyers engage with suppliers. International buyers can now source materials and finished products directly from manufacturers worldwide, streamlining the procurement process. The integration of AI and data analytics is also becoming prevalent, allowing businesses to analyze market trends and consumer preferences more effectively, thereby optimizing inventory management and production schedules.

Illustrative image related to how to make a leather gun holster

How Is Sustainability and Ethical Sourcing Impacting the Leather Gun Holster Sector?

Sustainability is increasingly becoming a pivotal concern for businesses in the leather gun holster market. The environmental impact of leather production, including deforestation and chemical pollution, is prompting buyers to seek ethically sourced materials. This shift is leading to a growing demand for vegetable-tanned leather, which is not only biodegradable but also less harmful to the environment compared to chrome-tanned alternatives.

Ethical supply chains are gaining traction, with buyers prioritizing suppliers who adhere to responsible sourcing practices. Certifications such as the Leather Working Group (LWG) and ISO 14001 are becoming essential for manufacturers aiming to demonstrate their commitment to sustainability. By investing in ‘green’ materials and processes, businesses can enhance their brand reputation and meet the increasing expectations of environmentally conscious consumers.

What Is the Historical Context of the Leather Gun Holster Market?

The leather gun holster has a rich history that dates back to the early days of firearms. Originally crafted for military use, holsters evolved in design and function as firearms became more prevalent in civilian life. The early 20th century saw the rise of custom leatherwork, with artisans creating holsters tailored to specific gun models and user preferences. This trend continues today, with a focus on craftsmanship, durability, and style.

Over the years, technological advancements have revolutionized the production of leather holsters, allowing for enhanced precision in fit and comfort. The modern consumer’s desire for personalization has further propelled the market, leading to a diverse range of options available for international buyers. As the industry continues to evolve, the emphasis on quality and sustainability will likely shape its future trajectory.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather gun holster

-

How do I choose the right leather for making a gun holster?

Selecting the appropriate leather is crucial for durability and functionality. For gun holsters, vegetable-tanned leather in the 7-8 oz range is recommended due to its sturdiness and resistance to wear. Avoid chrome-tanned leather as it can corrode firearms. Additionally, when sourcing leather, prioritize full-grain options and ensure that the pieces are cut from the back of the hide for optimal strength. Always verify the quality of the leather through samples before making bulk purchases. -

What are the essential tools needed to make a leather gun holster?

To create a leather gun holster, you’ll need several key tools: a sharp utility knife for cutting, a leather stitching groover for creating stitch channels, a hole punch for stitching holes, and clamps or a vacuum bag for forming the leather. Additionally, having edge tools for finishing and a sewing machine or hand stitching supplies is crucial. Investing in high-quality tools will ensure a professional finish and enhance the overall quality of the holster. -

What is the typical lead time for custom leather gun holster orders?

Lead times for custom leather gun holsters can vary widely based on complexity, order volume, and supplier capabilities. Generally, expect around 4 to 8 weeks for production once the design is finalized and materials are sourced. If you are ordering from international suppliers, factor in additional time for shipping and customs clearance. It’s advisable to communicate timelines upfront and consider establishing a buffer period for larger orders. -

How can I ensure the quality of the leather gun holsters I purchase?

To ensure quality, conduct thorough supplier vetting, including checking references, certifications, and reviews. Request samples before committing to larger orders, and consider visiting manufacturing facilities if possible. Implementing quality assurance protocols—such as inspections during production and before shipment—can help maintain standards. Establish clear specifications regarding leather type, stitching quality, and finish to avoid discrepancies. -

What are the minimum order quantities (MOQ) for leather gun holsters?

MOQs for leather gun holsters can vary significantly depending on the manufacturer. Some suppliers may accept small orders of 50-100 units, while others may require larger commitments of 500 units or more. When sourcing, inquire about MOQs and negotiate terms that align with your business needs. Consider discussing flexibility in MOQs for custom designs, as this can facilitate smaller batches for specific markets. -

What customization options are available for leather gun holsters?

Customization options for leather gun holsters can include design alterations, color choices, and added features like retention straps or personalized engravings. Discuss your specific requirements with suppliers to explore available options. Some manufacturers may offer pre-made templates for popular firearm models, while others may work with you to create entirely unique designs. Ensure that any customization aligns with your target market’s preferences and regulations. -

What payment terms should I expect when sourcing leather gun holsters?

Payment terms can vary by supplier and are often negotiable. Common arrangements include deposits of 30-50% upfront with the balance due upon completion or delivery. Some suppliers may offer net 30 or net 60 terms for established buyers. Always clarify payment methods accepted (e.g., wire transfer, credit card) and any additional fees related to international transactions. Document all agreements to avoid misunderstandings. -

How can I manage logistics and shipping for international orders of leather gun holsters?

Managing logistics for international orders involves selecting reliable shipping partners and understanding customs regulations for each target market. Work with freight forwarders experienced in handling leather products to ensure compliance with import/export laws. It’s also crucial to factor in shipping costs and potential delays caused by customs inspections. Keep communication open with suppliers regarding shipping schedules, and consider using incoterms to clarify responsibilities for shipping and insurance.

Top 5 How To Make A Leather Gun Holster Manufacturers & Suppliers List

1. Instructables – Fitted Leather Holster for Colt 1911

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Fitted Leather Holster for Colt Model 1911 .45 Caliber pistol; made from heavy weight leather (approximately 8 oz); formed using isopropyl alcohol (recommended to use water instead); assembly involves Barge Cement or E6000; features belt loops for proper angle; stitched with a technique involving two passes over each set of holes; finished with Neatsfoot oil to darken leather; includes Chicago scr…

2. Reddit – Holster Making Techniques

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Holster making techniques for fitting leather to a gun’s silhouette, specifically for a 1911. Suggestions include tracing the gun on paper, leaving extra room for fit, ensuring the trigger is covered, and using a thick folder for accurate measurements. Techniques mentioned include wet molding leather and marking stitch lines.

3. Tandy Leather – Holster Design Tutorial

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Holster Design Tutorial, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. MR Lentz – Leather Holster Tutorial

Domain: mrlentz.com

Registered: 2009 (16 years)

Introduction: How to Make a Leather Holster tutorial includes the following key product details: 1. Leather Type: 7-8 oz vegetable tanned full grain leather recommended. 2. Leather Size: Approximately 2 square feet needed. 3. Tools Required: Mallet, 5/16 hole punch, PVA leather glue, silicon tipped glue spreader, 6 stitch per inch marking wheel, beveler for tight curves, beveler size #2, stitch line marking too…

5. Leatherworker – Cowboy Holster Tutorial

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Cowboy Holster Tutorial by Jim, September 29, 2009. The tutorial provides step-by-step instructions for making a template for any size or model Six Shooter, leading to a finished holster. It includes methods for creating lined and un-lined holsters without wet molding, ensuring a proper fit. The tutorial is accessible for beginners, featuring text and photographs for clarity. A downloadable PDF is…

Strategic Sourcing Conclusion and Outlook for how to make a leather gun holster

In conclusion, the process of making a leather gun holster requires careful consideration of materials and techniques to ensure both functionality and durability. Key takeaways for B2B buyers include the importance of sourcing high-quality, vegetable-tanned leather, which significantly enhances the longevity and appearance of the final product. Additionally, adopting precise assembly methods, such as vacuum forming and appropriate stitching techniques, can elevate the craftsmanship of holsters, appealing to discerning customers in various markets.

Strategic sourcing not only mitigates risks associated with inferior materials but also fosters relationships with reliable suppliers who understand the nuances of leather quality and craftsmanship. For international buyers from Africa, South America, the Middle East, and Europe, this is a pivotal moment to invest in premium leather goods.

By prioritizing quality and innovation in your sourcing strategy, you position your business to meet the growing demand for customized leather products. Embrace this opportunity to collaborate with skilled artisans and suppliers to expand your offerings and enhance your market presence. The future of leather gun holsters is bright—let’s shape it together.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to how to make a leather gun holster

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.