Introduction: Navigating the Global Market for leather sofa vs microfiber

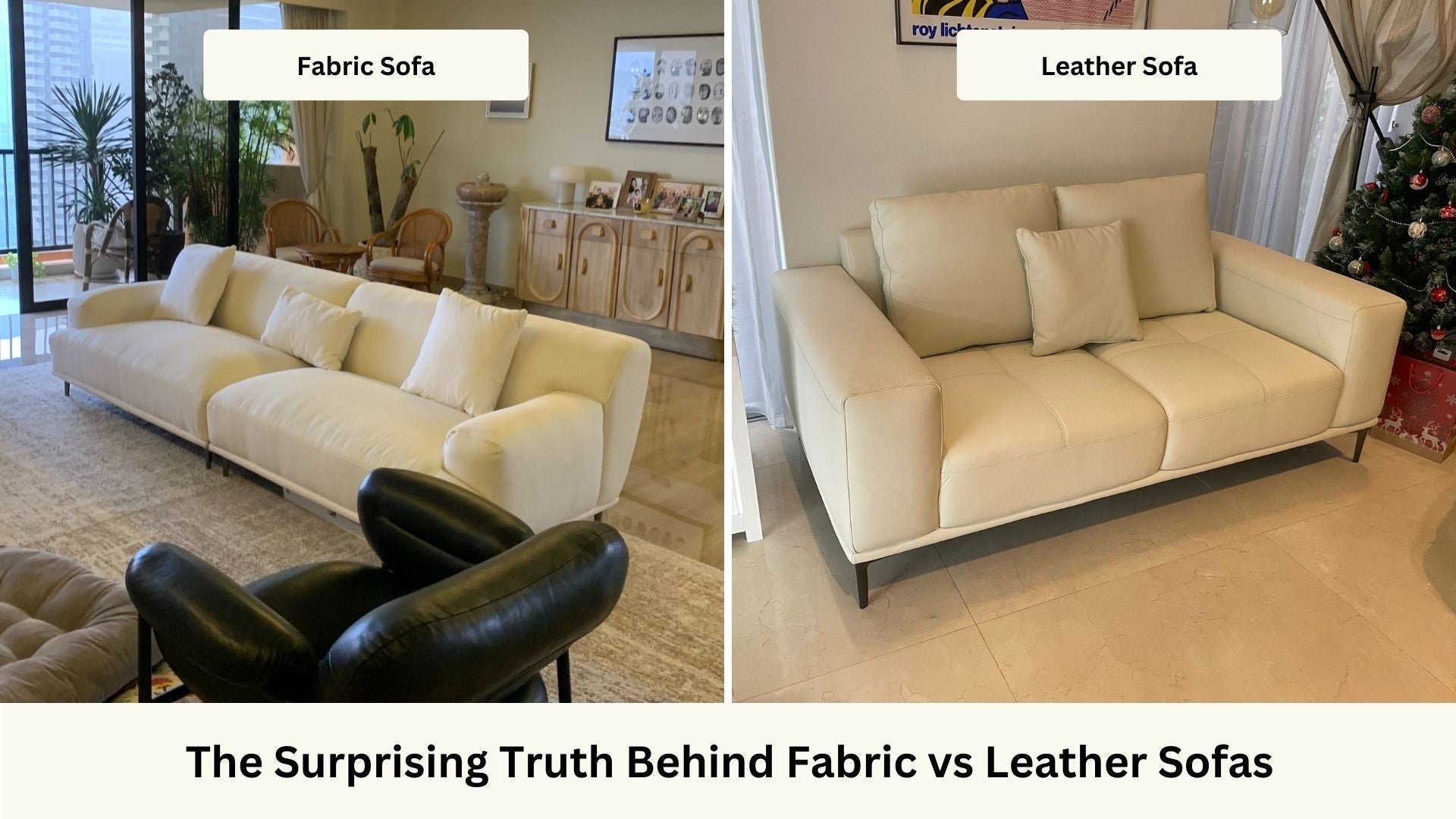

In the competitive landscape of global furniture sourcing, B2B buyers face the crucial decision of selecting the right upholstery material for their offerings, particularly when it comes to leather sofas versus microfiber options. The challenge lies in balancing aesthetics, durability, cost, and maintenance to meet diverse consumer preferences across regions, including Africa, South America, the Middle East, and Europe. This guide aims to provide a comprehensive analysis of these two popular materials, helping international buyers navigate their unique attributes, applications, and market trends.

Throughout this resource, we will delve into the various types of leather and microfiber, evaluate their suitability for different environments, and discuss key considerations for supplier vetting. Additionally, we will explore the cost implications of each material, ensuring that you have the insights needed to make informed purchasing decisions. By understanding the strengths and weaknesses of leather and microfiber, you can better cater to your target market’s needs while enhancing your product offerings.

Armed with this guide, B2B buyers will be empowered to make strategic choices that align with their business goals, ensuring they not only meet customer demands but also thrive in an increasingly competitive marketplace. Whether you are sourcing for retail, hospitality, or corporate environments, this guide will serve as your essential tool for navigating the complexities of leather and microfiber furniture procurement.

Table Of Contents

- Top 5 Leather Sofa Vs Microfiber Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather sofa vs microfiber

- Understanding leather sofa vs microfiber Types and Variations

- Key Industrial Applications of leather sofa vs microfiber

- 3 Common User Pain Points for ‘leather sofa vs microfiber’ & Their Solutions

- Strategic Material Selection Guide for leather sofa vs microfiber

- In-depth Look: Manufacturing Processes and Quality Assurance for leather sofa vs microfiber

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather sofa vs microfiber’

- Comprehensive Cost and Pricing Analysis for leather sofa vs microfiber Sourcing

- Alternatives Analysis: Comparing leather sofa vs microfiber With Other Solutions

- Essential Technical Properties and Trade Terminology for leather sofa vs microfiber

- Navigating Market Dynamics and Sourcing Trends in the leather sofa vs microfiber Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather sofa vs microfiber

- Strategic Sourcing Conclusion and Outlook for leather sofa vs microfiber

- Important Disclaimer & Terms of Use

Understanding leather sofa vs microfiber Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather | Highest quality, natural texture, develops a patina over time | Luxury furniture, high-end retail | Pros: Durable, luxurious; Cons: Higher cost, requires maintenance. |

| Top-Grain Leather | Sanded for a smoother finish, more affordable than full-grain | Office furniture, premium residential | Pros: Easier to clean, elegant; Cons: Less durable than full-grain. |

| Split-Grain Leather | Made from lower layers of hide, less durable, budget-friendly | Budget furniture, less-used items | Pros: Cost-effective; Cons: Not suitable for high-traffic areas. |

| Bonded Leather | Made from leather scraps bonded together, faux leather appearance | Affordable furniture, mass production | Pros: Low cost; Cons: Less durable, may peel over time. |

| マイクロファイバー | Synthetic, soft, and durable, available in various colors | Family furniture, commercial spaces | Pros: Easy to clean, affordable; Cons: Prone to staining and lint attraction. |

What Are the Key Characteristics of Full-Grain Leather?

Full-grain leather is the highest quality leather available, retaining the natural grain of the hide. It is known for its durability and ability to develop a unique patina over time, making it ideal for luxury furniture and high-end retail applications. B2B buyers should consider the long-term investment value, as full-grain leather can withstand significant wear and tear, making it suitable for high-traffic areas. However, the higher price point and the need for regular maintenance may be a consideration for budget-conscious businesses.

How Does Top-Grain Leather Compare to Other Types?

Top-grain leather is created from the top layer of the hide but is sanded to create a more refined finish. This makes it a popular choice for office furniture and premium residential applications. B2B buyers appreciate its balance of elegance and ease of maintenance, as it is less prone to staining than other leathers. However, it is important to note that while top-grain leather offers a pristine appearance, it may not be as durable as full-grain leather, making it less suitable for extremely high-traffic environments.

What Should Buyers Know About Split-Grain Leather?

Split-grain leather is derived from the lower layers of the hide, making it a more affordable option for businesses looking to furnish spaces without breaking the bank. It is commonly used in budget furniture and items that see less frequent use, like ottomans. While it provides a cost-effective solution, B2B buyers must be aware of its limited durability and suitability for high-traffic areas. This type of leather is not recommended for environments where longevity and high usage are expected.

Why Choose Bonded Leather for Budget-Friendly Solutions?

Bonded leather is made from leather scraps that are bonded together, offering a faux leather appearance at a lower cost. It is often used in mass-produced furniture, making it an attractive option for businesses needing to furnish spaces quickly and economically. However, buyers should consider the trade-off in durability; bonded leather may peel and wear out faster than genuine leather options. Thus, it is best suited for short-term applications or environments where furniture is not subjected to heavy use.

What Advantages Does Microfiber Offer for B2B Buyers?

Microfiber is a synthetic material known for its softness, durability, and ease of cleaning, making it a popular choice for family furniture and commercial spaces. B2B buyers appreciate its affordability and wide range of colors and styles, allowing for customization in various settings. However, microfiber does have its drawbacks, including a tendency to attract lint and pet hair, as well as susceptibility to staining. Businesses should weigh these factors, particularly in high-traffic areas or environments with pets, when considering microfiber upholstery.

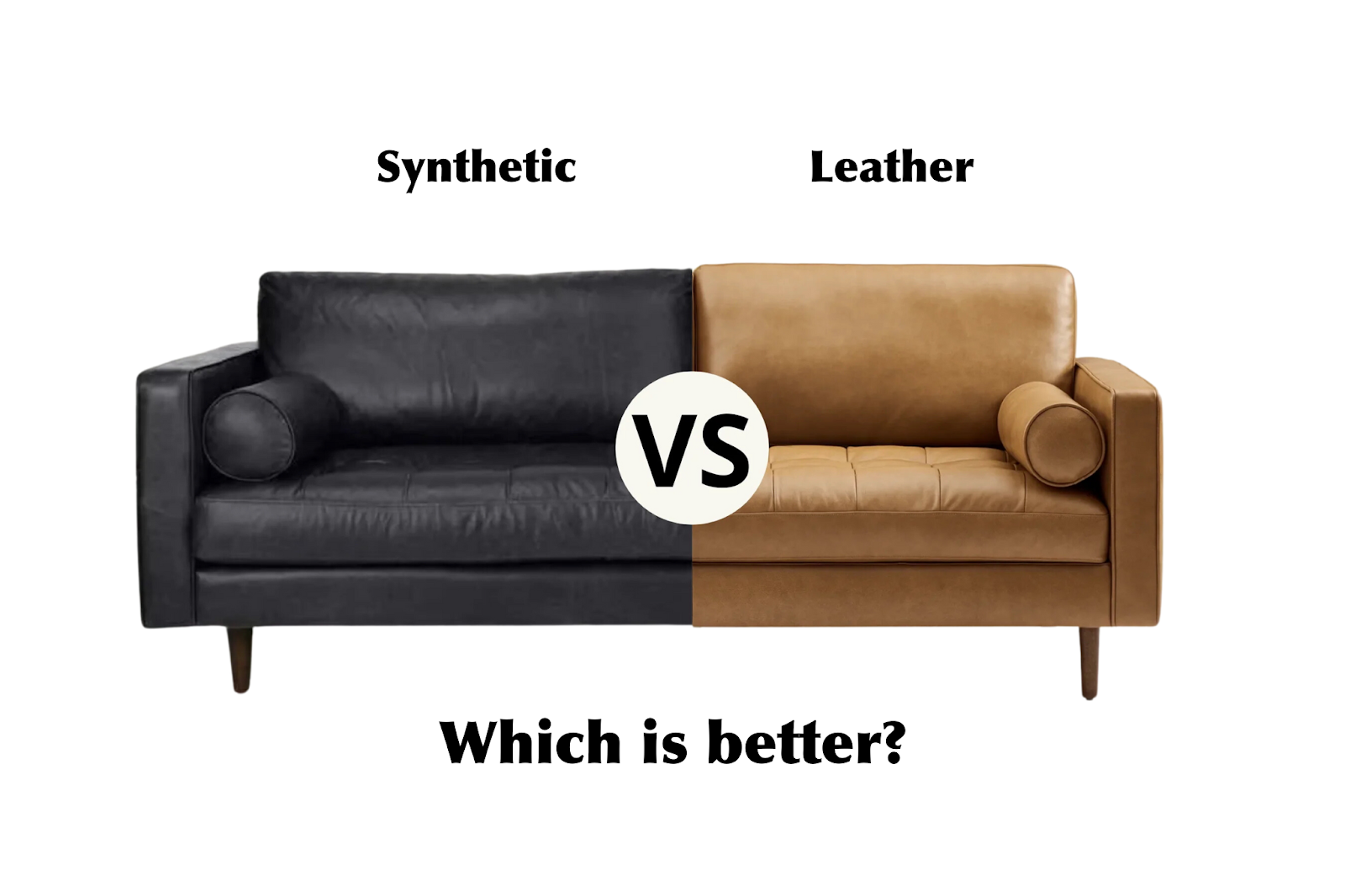

Illustrative image related to leather sofa vs microfiber

Key Industrial Applications of leather sofa vs microfiber

| Industry/Sector | Specific Application of leather sofa vs microfiber | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel lobbies and lounges | Enhances guest experience and reflects brand luxury | Durability, ease of maintenance, and aesthetic appeal |

| Corporate Offices | Executive suites and meeting rooms | Creates a professional environment and promotes comfort | Material longevity, style, and cost-effectiveness |

| Retail | Showrooms and waiting areas | Attracts customers and enhances brand image | Versatility in design, ease of cleaning, and durability |

| Healthcare | Patient waiting areas and staff lounges | Promotes comfort and hygiene in high-traffic areas | Stain resistance, ease of cleaning, and durability |

| Education | Student lounges and faculty offices | Supports a welcoming atmosphere conducive to collaboration | Affordability, comfort, and material resilience |

How is Leather Used in the Hospitality Industry?

In the hospitality sector, leather sofas are often utilized in hotel lobbies and lounges to create a luxurious ambiance that enhances the guest experience. The durability and stain resistance of leather make it ideal for high-traffic areas, as it can withstand wear and tear while maintaining its aesthetic appeal. For international buyers, particularly in regions like the Middle East and Europe, the choice of leather reflects a commitment to quality and a high-end brand image. Sourcing leather requires careful consideration of the type (full-grain or top-grain) to ensure longevity and ease of maintenance.

What are the Benefits of Microfiber in Corporate Offices?

In corporate offices, microfiber sofas are commonly found in executive suites and meeting rooms, providing a comfortable yet professional setting. The affordability and variety of styles available in microfiber allow businesses to furnish their spaces without breaking the budget. Additionally, the ease of cleaning is a significant advantage in maintaining a professional appearance. B2B buyers in Africa and South America should prioritize sourcing microfiber that is both durable and visually appealing to create an inviting atmosphere for clients and employees alike.

How Does Leather Enhance Retail Environments?

In retail spaces, leather sofas are strategically placed in showrooms and waiting areas to create a sophisticated and inviting environment that attracts customers. The luxurious feel of leather not only enhances the shopping experience but also elevates the brand image. For B2B buyers, it’s crucial to consider the sourcing of high-quality leather that aligns with the retail brand’s identity while ensuring durability in a bustling environment. This investment can lead to increased customer satisfaction and loyalty.

Why Choose Microfiber for Healthcare Facilities?

Microfiber sofas are particularly beneficial in healthcare settings, such as patient waiting areas and staff lounges, where hygiene and comfort are paramount. The stain resistance and ease of cleaning associated with microfiber make it a practical choice in these high-traffic areas. Buyers in the healthcare sector should focus on sourcing microfiber that meets strict hygiene standards while also providing comfort for patients and staff. This consideration can significantly improve the overall patient experience and staff satisfaction.

What Role Does Microfiber Play in Educational Institutions?

In educational institutions, microfiber sofas are ideal for student lounges and faculty offices, fostering a welcoming atmosphere conducive to collaboration and relaxation. The affordability of microfiber allows schools and universities to furnish these spaces effectively without compromising on comfort. For international B2B buyers, sourcing microfiber that is both durable and easy to clean is essential, especially in high-use areas where maintenance is a priority. This choice supports a positive educational environment that encourages interaction and engagement among students and faculty.

3 Common User Pain Points for ‘leather sofa vs microfiber’ & Their Solutions

Scenario 1: Balancing Cost and Quality in Upholstery Choices

The Problem: B2B buyers often face the challenge of selecting between leather and microfiber sofas while balancing budget constraints with quality expectations. In regions where cost-efficiency is paramount, like parts of Africa and South America, the allure of microfiber’s lower price can be tempting. However, the potential for quicker wear and the need for replacement can lead to higher long-term costs. Buyers are often unsure if they should invest in the higher upfront cost of leather for durability or settle for microfiber and risk frequent replacements.

The Solution: To navigate this dilemma, buyers should conduct a thorough cost-benefit analysis that considers both initial investment and long-term value. When sourcing furniture, it’s crucial to evaluate the specific context in which the sofas will be used. For commercial settings, such as hotels or lounges, opting for high-quality leather may be more cost-effective over time due to its durability and lower maintenance needs. Look for suppliers that offer warranties or guarantees on their leather products, ensuring protection against premature wear. Additionally, consider investing in maintenance training for staff to uphold the leather’s integrity. This proactive approach can significantly enhance the lifespan of the investment, making leather a more viable option despite its higher upfront cost.

Scenario 2: Addressing Maintenance and Cleaning Challenges

The Problem: Maintaining the appearance and hygiene of furniture can be a significant concern for businesses, especially in regions with high humidity or dust, like parts of the Middle East and South America. Microfiber sofas, while easier to clean than many fabrics, can still attract lint and pet hair, making them less desirable in environments where cleanliness is paramount. Conversely, leather requires specific cleaning products and techniques, leading to uncertainty about the best practices for upkeep.

The Solution: To effectively manage maintenance, B2B buyers should prioritize suppliers that provide comprehensive care instructions and recommend appropriate cleaning products tailored to each material. For microfiber, consider sourcing options treated with a stain-resistant finish, which can mitigate the challenges of lint and pet hair. Implementing a regular cleaning schedule, including vacuuming and spot cleaning, can also help maintain the sofa’s appearance. For leather, investing in quality leather conditioner and cleaner will ensure the material remains supple and resistant to damage. Training staff on proper cleaning techniques will also help in maintaining the aesthetic appeal of the furniture, regardless of the material chosen.

Scenario 3: Navigating Aesthetic Preferences Versus Practicality

The Problem: Aesthetic appeal is a major consideration for buyers looking to furnish spaces that attract clientele, such as cafes, hotels, and showrooms. Leather is often perceived as more luxurious and sophisticated, while microfiber is associated with a more casual look. Buyers may struggle to reconcile their desire for a stylish environment with practical concerns about durability and maintenance, leading to indecision.

The Solution: To strike a balance between aesthetics and practicality, B2B buyers should explore options that combine the best of both materials. For instance, consider sourcing high-quality leather in trendy colors or unique textures that elevate the design without compromising on luxury. Alternatively, some manufacturers offer microfiber that mimics the look of leather, providing a stylish yet practical solution. Establishing a relationship with a supplier who understands the nuances of design can help buyers select pieces that meet both aesthetic desires and functional needs. Additionally, engaging with interior designers familiar with both materials can provide valuable insights into creating cohesive, attractive spaces that appeal to the target market.

Illustrative image related to leather sofa vs microfiber

Strategic Material Selection Guide for leather sofa vs microfiber

What Are the Key Properties of Microfiber for Leather Sofas?

Microfiber is a synthetic material composed of tightly woven polyester fibers, known for its durability and ease of maintenance. It has a soft texture that mimics the feel of natural fabrics, making it a popular choice for upholstery. The material is resistant to wear and tear, with a pressure rating that allows it to withstand significant use without sagging or stretching. However, microfiber is less breathable than natural materials, which can lead to discomfort in warmer climates.

Pros & Cons of Microfiber in Upholstery

Microfiber’s affordability is a primary advantage, making it accessible for various market segments. Its variety of colors and styles allows for creative design applications. However, it can attract lint and pet hair due to its static charge, and it is prone to staining if spills are not addressed promptly. Additionally, while it offers a comfortable seating experience, it lacks the luxurious aesthetic that leather provides.

How Does Leather Compare as a Material for Sofas?

Leather, derived from animal hides, is renowned for its durability and luxurious appearance. It offers excellent resistance to stains and spills, making it a long-lasting choice for high-traffic areas. Leather’s temperature tolerance is superior, maintaining comfort in both hot and cold environments. The various types of leather, such as full-grain and top-grain, each have unique properties that affect their performance and maintenance requirements.

Pros & Cons of Leather in Upholstery

The primary advantage of leather is its premium feel and aesthetic, which can enhance the perceived value of furniture. It is relatively easy to clean and maintain, provided that proper care is taken. However, leather comes with a higher price tag, which can be a barrier for some buyers. Additionally, it requires regular maintenance to prevent cracking and fading, particularly in regions with high temperatures or direct sunlight.

What Are the Specific Considerations for International B2B Buyers?

When selecting between microfiber and leather, international B2B buyers must consider various factors, including compliance with local standards and preferences. For instance, in Europe, adherence to DIN standards for upholstery materials is crucial, while in the Middle East, buyers may prioritize materials that withstand high temperatures. In regions like Africa and South America, cost-effectiveness and durability are often significant considerations due to varying economic conditions. Understanding local market preferences can guide buyers in making informed decisions.

Summary Table of Material Selection for Leather Sofas vs. Microfiber

| 素材 | Typical Use Case for leather sofa vs microfiber | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| マイクロファイバー | Affordable furniture, family homes, high-traffic areas | Durable, easy to clean, versatile styles | Attracts lint/pet hair, prone to staining | 低い |

| Leather | Luxury furniture, high-end markets, long-lasting pieces | Luxurious feel, durable, stain-resistant | Higher cost, requires regular maintenance | 高い |

This analysis provides a clear comparison of microfiber and leather as materials for sofas, offering B2B buyers actionable insights into their properties, advantages, and limitations. Understanding these factors can aid in making informed purchasing decisions tailored to specific market needs and conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for leather sofa vs microfiber

What Are the Key Stages in the Manufacturing Process of Leather Sofas?

The manufacturing process for leather sofas involves several critical stages that ensure the final product meets quality standards and customer expectations. The main stages are material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality leather or microfiber. For leather, this includes sourcing animal hides from reputable tanneries. The hides undergo tanning, which preserves and enhances their durability. Microfiber, on the other hand, is synthesized from polyester or nylon, requiring careful formulation and blending of fibers to achieve desired properties.

-

Forming: In this stage, the prepared materials are cut into specific patterns that will be used for the sofa. For leather, this often involves using high-precision cutting tools to minimize waste and ensure the integrity of the material. Microfiber is typically cut using similar techniques but may also involve weaving processes to achieve various textures.

-

Assembly: Once the pieces are cut, they are sewn together. Leather requires special stitching techniques to accommodate its thickness and avoid damage. Microfiber can be stitched using standard methods but may also use advanced techniques to enhance durability and aesthetic appeal. This stage is crucial for ensuring the structural integrity of the sofa.

-

Finishing: The final stage involves applying protective coatings to both materials. Leather sofas may receive treatments to enhance their stain resistance and sheen, while microfiber can be treated to improve its durability and ease of cleaning. This stage also includes quality checks to ensure that the final product meets design specifications.

How Is Quality Assurance Implemented in Leather Sofa and Microfiber Manufacturing?

Quality assurance (QA) is integral to the manufacturing processes of leather sofas and microfiber furniture. Various international standards and industry-specific regulations guide these processes to ensure that products are safe, reliable, and of high quality.

-

International Standards: Compliance with ISO 9001, a widely recognized quality management system, ensures that manufacturers maintain consistent quality throughout the production process. This standard emphasizes continuous improvement and customer satisfaction, which are essential for B2B transactions.

-

Industry-Specific Certifications: Depending on the market, manufacturers may also seek certifications such as CE (Conformité Européenne) for products sold in Europe, ensuring they meet safety and environmental standards. In some cases, manufacturers in the Middle East and Africa may also adhere to local regulations that emphasize quality control.

-

Quality Control Checkpoints: The quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, random samples are taken to check for defects and ensure adherence to production standards.

– Final Quality Control (FQC): Before shipping, finished products undergo thorough inspections to confirm they meet quality and design specifications.

What Common Testing Methods Are Used for Quality Assurance in Furniture Manufacturing?

Manufacturers utilize various testing methods to ensure that leather sofas and microfiber furniture meet quality standards.

Illustrative image related to leather sofa vs microfiber

-

Durability Testing: Both materials undergo tests to assess their resistance to wear and tear, including abrasion tests, which simulate years of use. For leather, tests may also include checking for cracking and fading, while microfiber might be tested for pilling.

-

Stain Resistance Testing: This involves applying common household substances to the materials to evaluate how easily stains can be removed. Leather’s inherent properties often make it more resistant to stains compared to microfiber.

-

Fire Safety Testing: Given that furniture is often subjected to fire safety regulations, both materials may undergo fire resistance testing to ensure compliance with local and international safety standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is critical to ensure the reliability of products.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices. This includes reviewing their compliance with international standards and certifications.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that outline the results of their quality control processes, including IQC, IPQC, and FQC results. These documents can help buyers assess the reliability of the products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. This is particularly beneficial for buyers in regions with strict import regulations or quality standards.

What Are the Quality Control Nuances for B2B Buyers in Different Regions?

B2B buyers from different regions may face unique challenges regarding quality control in leather and microfiber furniture.

-

Cultural and Regulatory Differences: Buyers from Europe, particularly Germany, often emphasize stringent quality standards and sustainability practices. Understanding these regional nuances can help buyers choose suppliers that align with their expectations.

-

Logistical Considerations: In regions like Africa and South America, logistical challenges can impact the timely delivery of quality materials. Buyers should ensure that their suppliers have robust supply chain management practices in place.

-

Communication Barriers: Effective communication is crucial for quality assurance. Buyers should consider suppliers’ language capabilities and cultural understanding to ensure clear expectations regarding quality and standards.

By considering these factors, international B2B buyers can make informed decisions when selecting suppliers for leather sofas and microfiber furniture, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather sofa vs microfiber’

This guide serves as a comprehensive checklist for B2B buyers looking to procure sofas made of leather or microfiber. Understanding the nuances of these materials will help in making informed decisions that align with business needs, budget constraints, and customer preferences.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the sofas meet your requirements. Consider factors such as durability, aesthetics, and maintenance needs. For instance, if the furniture will be in high-traffic areas, prioritize durability and easy maintenance in your specifications.

Illustrative image related to leather sofa vs microfiber

Step 2: Conduct Market Research on Material Performance

Understanding the performance characteristics of leather and microfiber is essential. Research how these materials hold up under different conditions, including wear and tear, cleaning requirements, and potential longevity. Pay attention to customer reviews and case studies that highlight real-world applications and performance outcomes.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who specialize in either leather or microfiber, as their expertise will directly influence the quality of the products you receive.

Step 4: Assess Compliance with Quality Standards

Ensure that potential suppliers comply with international quality standards and certifications. This could include ISO certifications or adherence to environmental standards, particularly if your market is focused on sustainable practices. Verifying compliance not only ensures quality but also builds trust with your end customers.

Step 5: Review Pricing and Payment Terms

Understanding the pricing structure and payment terms is crucial for budget management. Compare prices for similar products across different suppliers, but also consider the total cost of ownership, including maintenance and potential replacement costs. Ensure that payment terms align with your cash flow requirements.

Step 6: Request Samples for Evaluation

Before finalizing your order, request samples from shortlisted suppliers. This allows you to assess the quality, feel, and overall aesthetic of the sofas. Pay attention to factors like stitching quality, color consistency, and texture, as these elements can significantly impact customer satisfaction.

Illustrative image related to leather sofa vs microfiber

Step 7: Plan for Logistics and Delivery

Consider the logistics involved in transporting the sofas from the supplier to your location. Discuss lead times, shipping methods, and delivery schedules with suppliers to ensure that they align with your project timelines. Proper logistics planning can prevent delays and additional costs.

By following this checklist, B2B buyers can navigate the complexities of sourcing leather and microfiber sofas effectively, leading to a purchase decision that meets both business objectives and customer expectations.

Comprehensive Cost and Pricing Analysis for leather sofa vs microfiber Sourcing

When considering the cost and pricing analysis for sourcing leather sofas versus microfiber options, it’s essential to break down the various cost components and factors influencing pricing. Understanding these elements can guide international B2B buyers in making informed purchasing decisions.

What Are the Key Cost Components in Leather and Microfiber Furniture Production?

Materials

The primary cost driver in furniture sourcing is the materials used. Leather, particularly high-quality varieties like full-grain and top-grain, tends to be significantly more expensive than microfiber. This is due to the sourcing of animal hides, which involve higher procurement and processing costs. Microfiber, being a synthetic material, generally has lower material costs, making it a more budget-friendly option.

Labor and Manufacturing Overhead

Labor costs can vary depending on the region of production. Countries in Europe may have higher labor rates compared to those in South America or Asia. Leather processing often requires skilled labor due to the complexity of handling and finishing, which can increase overall manufacturing overhead. In contrast, microfiber production is typically less labor-intensive, resulting in lower costs.

Illustrative image related to leather sofa vs microfiber

Tooling and Quality Control

Tooling costs for leather sofas can be higher due to the need for specialized equipment to handle the material. Quality control (QC) processes are also critical, especially for leather, where imperfections can lead to significant losses. Microfiber, being more uniform, may require less rigorous QC measures, thus lowering costs.

Logistics

Logistics costs will vary based on the geographical location of the supplier and the buyer. Import duties, shipping fees, and handling costs can add significantly to the total cost of ownership. Leather sofas, often heavier and bulkier, might incur higher shipping costs compared to microfiber options.

Margin

Manufacturers typically apply different margins based on the perceived value of the product. Leather sofas can command higher margins due to their luxury status, while microfiber products are positioned as cost-effective solutions, leading to different pricing strategies.

What Influences Pricing for Leather and Microfiber Furniture?

Volume and Minimum Order Quantity (MOQ)

Pricing can be significantly affected by the volume ordered. Higher quantities often lead to lower per-unit costs due to economies of scale. B2B buyers should negotiate MOQs that align with their demand forecasts to optimize pricing.

Customization and Specifications

Custom designs and specifications can lead to increased costs. Buyers looking for unique finishes or specific features in leather sofas may face premium pricing. In contrast, standard microfiber options tend to be more readily available and less costly.

Quality and Certifications

Quality certifications can impact pricing. For instance, leather that is certified for sustainability or sourced from ethical suppliers may come at a premium. Microfiber products without such certifications may offer lower prices but could compromise on quality.

Supplier Factors and Incoterms

The choice of supplier and the agreed-upon Incoterms can influence the final cost. Different suppliers may offer varying levels of service, quality, and pricing structures. Understanding Incoterms helps buyers navigate shipping responsibilities and costs effectively.

Illustrative image related to leather sofa vs microfiber

How Can International B2B Buyers Optimize Their Sourcing Costs?

Negotiation Strategies

Effective negotiation is crucial in securing the best pricing. Buyers should leverage market research to understand typical price ranges and be prepared to negotiate based on volume and long-term relationships.

Total Cost of Ownership (TCO)

Buyers should consider the total cost of ownership rather than just the initial purchase price. This includes maintenance, durability, and potential replacement costs. For instance, while leather sofas may have a higher upfront cost, their longevity could result in lower TCO compared to microfiber.

Pricing Nuances for Different Regions

Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing nuances, such as import tariffs and local market conditions. Understanding these factors can help in negotiating better deals and making strategic sourcing decisions.

Disclaimer

Prices for leather sofas and microfiber options can vary widely based on the aforementioned factors. The analysis provided is indicative and should be validated with suppliers for accurate and current pricing.

Alternatives Analysis: Comparing leather sofa vs microfiber With Other Solutions

Exploring Alternatives to Leather Sofa vs Microfiber: A Comprehensive Comparison

In today’s competitive market, B2B buyers must evaluate various upholstery options to meet diverse customer needs. While leather sofas and microfiber are popular choices, several alternative materials and methods may better serve specific applications. This analysis will compare leather and microfiber sofas against two viable alternatives: synthetic leather and natural fabrics, providing insights into their performance, cost, and maintenance.

| Comparison Aspect | Leather Sofa Vs Microfiber | Synthetic Leather | Natural Fabrics |

|---|---|---|---|

| Performance | Durable, luxurious feel, high maintenance | Durable, water-resistant, less luxurious | Comfortable, breathable, variable durability |

| Cost | High initial investment, long-term value | Moderate cost, budget-friendly | Variable, often cost-effective |

| Ease of Implementation | Requires skilled craftsmanship | Easier to produce, less skill required | Varies; some fabrics easy to work with, others complex |

| Maintenance | Regular upkeep needed, prone to scratches | Low maintenance, easy to clean | Varies; some fabrics require special care |

| Best Use Case | High-end residential and commercial spaces | Budget-conscious consumers, casual settings | Eco-friendly markets, casual environments |

What are the Pros and Cons of Synthetic Leather as an Alternative?

Synthetic leather, also known as faux leather, is made from various synthetic materials, primarily polyurethane (PU) or polyvinyl chloride (PVC). This material mimics the look and feel of genuine leather but often comes at a lower price point. The major advantage of synthetic leather is its water resistance and ease of cleaning, making it ideal for high-traffic areas or environments where spills are common, such as restaurants or family-oriented spaces. However, it may lack the authentic luxury appeal and durability of high-quality leather, leading to potential wear and tear over time.

How Do Natural Fabrics Compare to Leather and Microfiber?

Natural fabrics like cotton, linen, or wool offer a breathable and eco-friendly option for upholstery. These materials provide comfort and warmth, making them suitable for residential settings, especially in eco-conscious markets. Natural fabrics can be cost-effective, depending on the type and quality chosen. However, they often require more maintenance than synthetic options, as they can be prone to staining and may not hold up as well against heavy use. Additionally, the durability can vary widely, necessitating careful selection based on the intended use.

Conclusion: Which Upholstery Solution Should B2B Buyers Choose?

When selecting the right upholstery solution, B2B buyers must consider various factors such as target market, budget constraints, and maintenance requirements. Leather sofas offer a luxurious option for high-end markets but come with a higher price tag and maintenance demands. Microfiber provides a balance of affordability and durability, making it suitable for families and casual settings. Alternatives like synthetic leather and natural fabrics present unique advantages and drawbacks, appealing to different customer segments. Ultimately, the decision should align with the specific needs of the business and its clientele, ensuring the chosen upholstery meets both aesthetic and functional requirements.

Essential Technical Properties and Trade Terminology for leather sofa vs microfiber

What Are the Key Technical Properties of Leather Sofas and Microfiber?

When evaluating leather sofas and microfiber, several technical properties are crucial for B2B buyers to consider. Understanding these specifications can assist in making informed purchasing decisions that align with market demands and consumer expectations.

1. Material Grade

Definition: Material grade refers to the quality of the raw materials used in the production of furniture. For leather, grades include full-grain, top-grain, and split-grain. Microfiber grades can vary based on the type of synthetic fibers used, such as polyester or nylon.

Importance: Higher material grades often indicate better durability and aesthetic appeal, which can lead to higher customer satisfaction and lower return rates. B2B buyers should prioritize sourcing from suppliers who provide detailed information about material grades to ensure they are investing in quality products.

2. Durability Ratings

Definition: Durability ratings assess how well materials withstand wear and tear. For leather, this is often measured in terms of resistance to cracking and fading, while microfiber durability can be gauged by its abrasion resistance.

Importance: Products with higher durability ratings tend to have longer lifespans, reducing replacement costs. Buyers targeting markets with high traffic or demanding environments should focus on sourcing materials with superior durability ratings.

3. Maintenance Requirements

Definition: Maintenance requirements detail the care needed to keep the furniture in good condition. Leather often requires conditioning and specific cleaning agents, while microfiber may only need mild detergents for cleaning.

Importance: Understanding maintenance needs can help buyers communicate product care to end-users effectively, thus enhancing customer satisfaction and reducing the likelihood of damage due to improper care.

4. Breathability

Definition: Breathability refers to how well a material allows air and moisture to pass through. Leather typically offers better breathability compared to microfiber, which can trap heat and moisture.

Importance: Breathable materials contribute to comfort, especially in warmer climates. Buyers should consider breathability when targeting specific markets, as this can significantly impact consumer preferences.

5. Color Fastness

Definition: Color fastness measures how well a material retains its color when exposed to light, washing, or other conditions. This is particularly important for both leather and microfiber, as fading can impact aesthetics.

Importance: Products with high color fastness ratings are more appealing to consumers and can lead to higher sales. B2B buyers should inquire about color fastness testing results from suppliers to ensure product longevity in various environments.

What Are Common Trade Terms in the Leather and Microfiber Industry?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms relevant to leather sofas and microfiber.

1. OEM (Original Equipment Manufacturer)

Definition: An OEM produces parts or products that are used in another company’s end product. In the context of leather and microfiber furniture, an OEM may manufacture sofas for a brand that sells them under its name.

Importance: Knowing which suppliers are OEMs can help buyers identify reliable partners that adhere to quality standards and can meet specific design requirements.

2. MOQ (Minimum Order Quantity)

Definition: MOQ refers to the smallest amount of a product that a supplier is willing to sell. This can vary significantly between suppliers and product types.

Importance: Understanding MOQs is crucial for budgeting and inventory management. Buyers should negotiate MOQs to align with their sales forecasts and ensure they are not overcommitting financially.

3. RFQ (Request for Quotation)

Definition: An RFQ is a document that buyers send to suppliers to request pricing and terms for a specific quantity of products.

Importance: Issuing an RFQ allows buyers to compare offers from multiple suppliers, ensuring they secure competitive pricing and favorable terms. It’s a critical step in the procurement process.

4. Incoterms (International Commercial Terms)

Definition: Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs.

Importance: Familiarity with Incoterms helps buyers understand their obligations and risks in the shipping process. This knowledge is essential for ensuring smooth transactions and avoiding unexpected costs.

Illustrative image related to leather sofa vs microfiber

5. Lead Time

Definition: Lead time is the amount of time it takes from placing an order until the product is delivered. This includes production time and shipping duration.

Importance: Understanding lead times is vital for inventory planning and meeting customer demands. Buyers should consider lead times when negotiating with suppliers to ensure timely delivery.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their purchasing strategies and foster stronger supplier relationships, ultimately leading to better market performance.

Navigating Market Dynamics and Sourcing Trends in the leather sofa vs microfiber Sector

What Are the Current Market Dynamics Influencing Leather Sofa and Microfiber Sourcing?

The global furniture market is increasingly shaped by consumer preferences, technological advancements, and socio-economic factors. As B2B buyers from regions like Africa, South America, the Middle East, and Europe (including Germany and Vietnam) navigate the complexities of sourcing furniture materials, several key trends emerge.

One significant driver is the rising demand for affordable yet durable furniture, which positions microfiber as an attractive option. Its ease of maintenance and affordability appeal to budget-conscious consumers, particularly in emerging markets. Conversely, the luxury segment continues to thrive, with leather sofas representing a status symbol and a long-term investment for consumers willing to pay a premium.

Additionally, technology plays a crucial role in sourcing trends. Digital platforms facilitate direct connections between manufacturers and buyers, streamlining the procurement process. Innovations such as 3D printing and virtual reality are increasingly being integrated into design and production, allowing for customization that meets local market demands. Furthermore, the impact of global supply chain disruptions, particularly post-pandemic, has prompted buyers to reconsider their sourcing strategies, focusing on local suppliers to mitigate risks associated with international logistics.

How Are Sustainability and Ethical Sourcing Shaping the Leather Sofa and Microfiber Market?

Sustainability is becoming a pivotal concern for B2B buyers in the furniture industry, influencing sourcing decisions significantly. Both leather and microfiber materials present unique environmental challenges and opportunities. The leather industry faces scrutiny over animal welfare and deforestation linked to cattle farming. As a result, ethically sourced leather, often certified by reputable organizations, is gaining traction. Certifications like the Leather Working Group (LWG) provide assurance regarding responsible sourcing practices, making them attractive to environmentally conscious buyers.

Illustrative image related to leather sofa vs microfiber

On the other hand, microfiber, primarily derived from petroleum-based materials, raises concerns regarding its environmental footprint. However, advancements in recycling technologies and the emergence of biodegradable options are paving the way for more sustainable microfiber alternatives. Buyers are increasingly seeking suppliers who can demonstrate a commitment to sustainable practices, such as using recycled materials or implementing eco-friendly manufacturing processes.

Incorporating ‘green’ certifications and prioritizing ethical supply chains not only meets consumer demand but also enhances brand reputation. As such, B2B buyers must navigate these sustainability trends to align their sourcing strategies with market expectations.

What Is the Evolution of Leather and Microfiber in the Furniture Market?

The evolution of leather and microfiber in the furniture sector reflects broader socio-economic changes and consumer preferences. Leather has long been synonymous with luxury and durability, with historical roots dating back centuries. Its status has remained relatively unchanged, although the introduction of alternative materials like microfiber in the late 20th century provided a competitive edge.

Microfiber emerged as a practical solution for budget-conscious consumers seeking durability without sacrificing style. Its rapid adoption in various markets can be attributed to its versatility and ease of maintenance. Today, both materials coexist in the marketplace, catering to diverse consumer needs and preferences. As the industry continues to evolve, it will be essential for B2B buyers to stay informed on market trends and consumer preferences to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of leather sofa vs microfiber

-

How do I choose between leather and microfiber for my furniture sourcing needs?

When deciding between leather and microfiber, consider factors such as durability, maintenance, cost, and aesthetic appeal. Leather offers a luxurious look and is more durable but requires regular maintenance and is typically more expensive. Microfiber is budget-friendly, easy to clean, and versatile in style, but it may attract lint and pet hair. Evaluate your target market preferences, the intended use of the furniture, and the overall design theme to make an informed decision. -

What are the advantages of sourcing leather sofas compared to microfiber?

Leather sofas provide a high-end appeal, durability, and resistance to stains and spills, making them suitable for high-traffic areas. They age well, developing a unique patina over time. In contrast, microfiber is more affordable and easier to maintain, making it a practical choice for families or commercial settings. Ultimately, the best option will depend on your customer base’s preferences and the desired price point. -

What are the minimum order quantities (MOQs) for leather and microfiber sofas?

MOQs can vary significantly between suppliers and regions. Typically, leather sofas may have higher MOQs due to the cost of materials and manufacturing processes. Microfiber sofas often have lower MOQs, making them more accessible for smaller businesses or startups. Always clarify MOQs with potential suppliers and consider your inventory needs and cash flow when making a decision. -

What payment terms should I expect when sourcing leather or microfiber sofas internationally?

Payment terms can vary by supplier and region, but common options include upfront payment, a deposit followed by the balance on delivery, or net terms (e.g., net 30 or net 60). It’s crucial to negotiate terms that align with your cash flow and risk management strategies. Additionally, consider using secure payment methods, such as letters of credit, to protect your investment in international transactions. -

How can I ensure quality assurance (QA) when sourcing sofas from international suppliers?

Implement a rigorous quality assurance process by requiring suppliers to adhere to specific standards and certifications. Conduct pre-shipment inspections and, if possible, visit manufacturing facilities to assess production practices. Establish clear communication regarding quality expectations and consider third-party inspection services to mitigate risks associated with international sourcing. -

What customization options should I discuss with suppliers for leather and microfiber sofas?

Customization can range from selecting materials and colors to specific design elements such as cushion firmness and sofa dimensions. Discuss your customers’ preferences to tailor the product to market demands. Additionally, inquire about the supplier’s capabilities for custom branding or features, which can enhance the appeal of your offerings in competitive markets. -

What logistics considerations should I keep in mind when importing sofas?

Logistics is critical in ensuring timely delivery and minimizing costs. Assess shipping methods, transit times, and potential tariffs or customs duties associated with importing leather and microfiber sofas. Partner with reliable freight forwarders and customs brokers to navigate the complexities of international trade and ensure compliance with local regulations. -

How do I vet suppliers for leather and microfiber sofas effectively?

To vet suppliers, research their reputation through industry reviews and references. Evaluate their production capabilities, adherence to quality standards, and experience in the furniture industry. Request samples to assess material quality and craftsmanship before placing large orders. Establish clear communication channels to gauge their responsiveness and willingness to collaborate on your specific needs.

Top 5 Leather Sofa Vs Microfiber Manufacturers & Suppliers List

1. Homestratosphere – Faux Leather

Domain: homestratosphere.com

Registered: 2014 (11 years)

Introduction: Faux Leather: Made from PVC and polyurethane, animal-friendly, affordable alternative to genuine leather. Maintenance is simple, can be cleaned with faux leather cleaner and microfiber cloth. Not prone to cracking, UV resistant, but not very durable (3-5 years longevity). Price range: ±$250-$1400. Microfiber: Lightweight synthetic material, imitates suede, made from natural and synthetic fibers. W…

2. Stay Home Body – Leather vs Fabric Sofas Guide

Domain: stayhomebody.com

Registered: 2022 (3 years)

Introduction: Leather vs Fabric Sofas Comparison Guide:

**Quick Comparison Sheet**

– **Comfort**:

– Fabric Sofas: Immediately soft and warm.

– Leather Sofas: Starts firm, softens over time.

– **Durability**:

– Fabric Sofas: Durable with high-quality material; stain-resistant options available.

– Leather Sofas: Very durable, lasts longer with care.

– **Maintenance**:

– Fabric Sofas:…

3. Houzz – Microfiber and Leather Furniture

Domain: houzz.com

Registered: 2006 (19 years)

Introduction: Microfiber and leather are two popular materials for furniture, particularly for pet owners. Microfiber is often praised for its affordability and ease of cleaning pet hair, as it does not have loops that trap fur, making it easier to remove with a lint roller or vacuum. However, it may still collect pet hair and requires regular maintenance. Leather, on the other hand, is easier to clean pet hair…

4. Clover Furniture – Best Durable Office Sofa Materials

Domain: cloverfurniture.com

Registered: 2013 (12 years)

Introduction: Best Durable Office Sofa Materials: Leather vs. Fabric vs. Microfiber. 1. Leather: Timeless Elegance and Durability. Key Benefits: Durability – High-quality leather is incredibly durable, resistant to stains, spills, and minor scratches. Easy Maintenance – Regular wiping and conditioning keep it looking new. Aesthetic Appeal – Adds class and professionalism. Considerations: Cost – More expensive u…

5. Microfiber – Stylish Alternative to Leather

Domain: forums.welltrainedmind.com

Registered: 1999 (26 years)

Introduction: This company, Microfiber – Stylish Alternative to Leather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather sofa vs microfiber

The choice between leather and microfiber sofas ultimately hinges on strategic sourcing decisions that align with business objectives and market demands. Leather offers unparalleled luxury and durability, appealing to high-end markets seeking premium products. Its long-term value makes it an attractive investment, especially for businesses targeting affluent consumers in Europe and the Middle East. On the other hand, microfiber presents an economical alternative, providing durability and ease of maintenance that suits budget-conscious buyers in regions like Africa and South America.

For B2B buyers, the key takeaway is to thoroughly evaluate the target market’s preferences and price sensitivity. Understanding local trends and consumer behavior can inform sourcing strategies, ensuring that businesses select materials that resonate with their clientele.

As you look ahead, consider how evolving consumer preferences may impact your sourcing decisions. Engaging with suppliers who can provide both leather and microfiber options will enhance your product offerings and adaptability in a competitive landscape. Embrace the opportunity to innovate and diversify your inventory, positioning your business for success in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.