Introduction: Navigating the Global Market for custom leather straps

Navigating the global market for custom leather straps presents unique challenges for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. Sourcing high-quality, bespoke leather straps that meet specific design and durability requirements can be daunting. This guide serves as an essential resource for international buyers, offering a comprehensive overview of the various types of custom leather straps available, their applications across different industries, and crucial insights into supplier vetting processes.

From understanding the nuances of materials such as Horween Shell Cordovan and full-grain vegetable-tanned leather to evaluating pricing strategies and lead times, this guide empowers decision-makers to make informed purchasing choices. We will delve into the intricacies of custom strap manufacturing, exploring the craftsmanship behind each product and the importance of selecting reputable suppliers who can deliver quality and consistency.

By addressing key considerations such as compliance with regional standards, shipping logistics, and customization options, this guide is tailored to equip B2B buyers with the knowledge necessary to successfully navigate the complexities of the custom leather strap market. Whether you are a retailer looking to enhance your product offering or an industrial buyer seeking durable solutions, this resource will help you streamline your sourcing strategy and build fruitful partnerships in the global leather industry.

Table Of Contents

- Top 5 Custom Leather Straps Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather straps

- Understanding custom leather straps Types and Variations

- Key Industrial Applications of custom leather straps

- 3 Common User Pain Points for ‘custom leather straps’ & Their Solutions

- Strategic Material Selection Guide for custom leather straps

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather straps

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather straps’

- Comprehensive Cost and Pricing Analysis for custom leather straps Sourcing

- Alternatives Analysis: Comparing custom leather straps With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather straps

- Navigating Market Dynamics and Sourcing Trends in the custom leather straps Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather straps

- Strategic Sourcing Conclusion and Outlook for custom leather straps

- Important Disclaimer & Terms of Use

Understanding custom leather straps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Durable, retains natural texture, develops a rich patina | Luxury watch brands, high-end accessories | Pros: Exceptional longevity, aesthetic appeal. Cons: Higher cost, requires maintenance. |

| Exotic Leather | Unique textures (e.g., alligator, ostrich), limited availability | Niche markets, luxury goods | Pros: Exclusive, high perceived value. Cons: Pricey, ethical sourcing concerns. |

| Vegetable Tanned Leather | Eco-friendly, develops character with age, robust | Sustainable brands, artisanal products | Pros: Environmentally friendly, durable. Cons: Longer tanning process, may be less uniform. |

| Rubberized Leather | Water-resistant, flexible, ideal for active use | Sports watches, outdoor gear | Pros: Functional, easy to clean. Cons: Less luxurious feel, limited aesthetic options. |

| Suede Leather | Soft texture, available in various colors, lightweight | Fashion accessories, casual wear | Pros: Comfortable, stylish. Cons: Less durable, stains easily. |

What are the Characteristics of Full Grain Leather Straps?

Full grain leather is renowned for its durability and natural texture. It retains the hide’s original imperfections, which adds character and uniqueness to each strap. This type of leather develops a rich patina over time, enhancing its visual appeal and making it particularly desirable for luxury watch brands and high-end accessories. Buyers should consider the initial investment, as full grain leather typically comes at a premium, but its longevity and aesthetic benefits can justify the cost.

Why Choose Exotic Leather Straps for Niche Markets?

Exotic leather straps, such as those made from alligator or ostrich, offer unique textures and patterns that set them apart. Their limited availability makes them highly sought after in niche markets, especially for luxury goods. While they command a higher price point due to their exclusivity, buyers must also consider ethical sourcing practices and sustainability when purchasing these materials to maintain brand integrity.

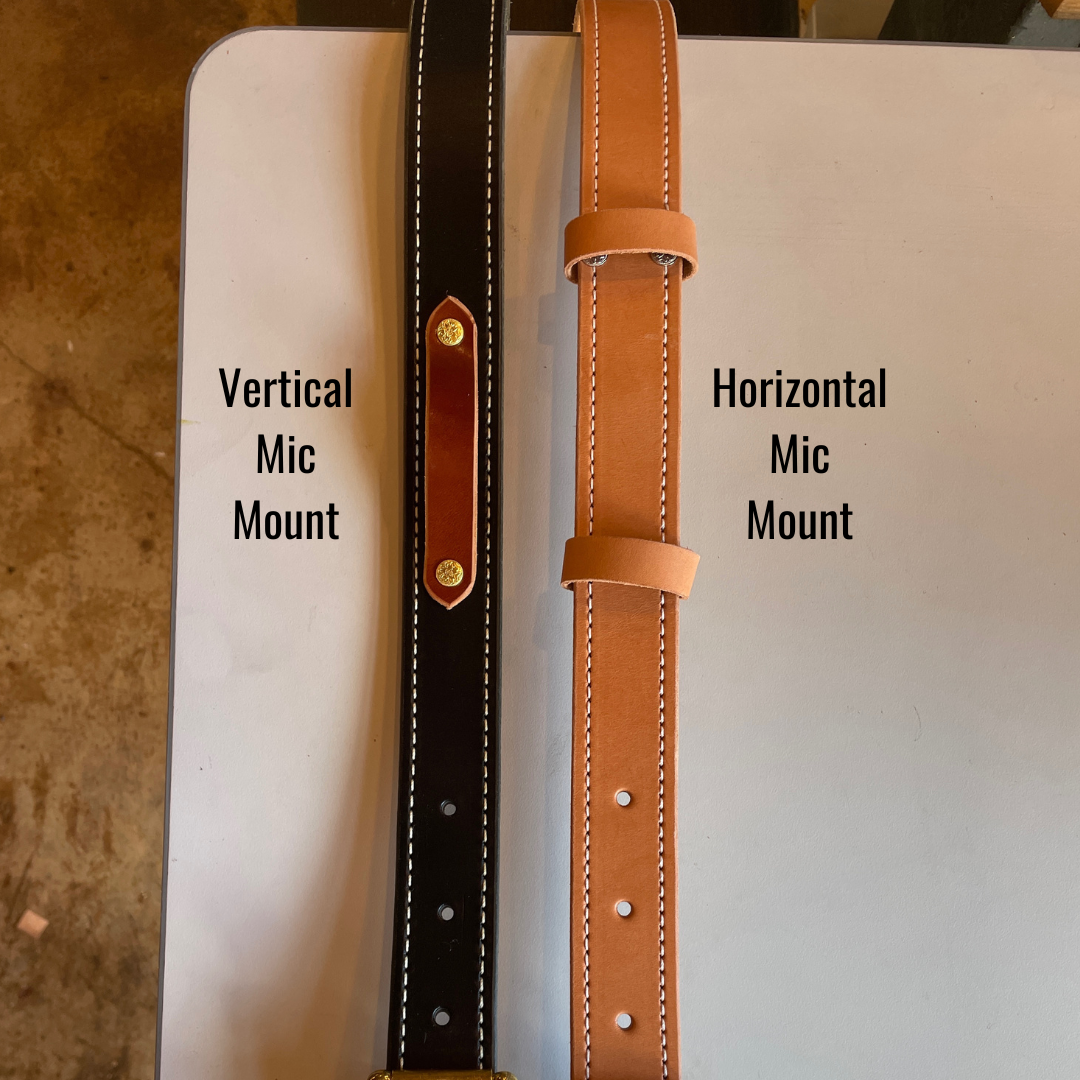

Illustrative image related to custom leather straps

How Does Vegetable Tanned Leather Stand Out in Sustainability?

Vegetable tanned leather is processed using natural tannins from plant sources, making it an eco-friendly choice for businesses focused on sustainability. This type of leather develops character over time, showcasing a unique look that appeals to environmentally conscious consumers. While it may require a longer tanning process and can be less uniform in appearance, the durability and natural aging process make it a solid investment for brands prioritizing sustainability.

What are the Advantages of Rubberized Leather Straps?

Rubberized leather offers practicality and flexibility, making it ideal for sports watches and outdoor gear. Its water-resistant properties and ease of cleaning are significant advantages for active users. However, while it provides a functional alternative, it may lack the luxurious feel associated with traditional leather, which is a consideration for brands aiming for a high-end market.

What Makes Suede Leather Straps Popular in Fashion?

Suede leather is known for its soft texture and lightweight feel, making it a popular choice for fashion accessories and casual wear. Available in a variety of colors, suede can enhance the visual appeal of any product. However, buyers should be aware that suede is less durable than other types of leather and can be prone to staining, which may impact long-term usability.

Illustrative image related to custom leather straps

Key Industrial Applications of custom leather straps

| Industry/Sector | Specific Application of Custom Leather Straps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Watch Manufacturing | Custom watch straps tailored for luxury timepieces | Enhances brand image through personalization and quality | Quality of leather, craftsmanship, and design options |

| Fashion & Accessories | Unique leather straps for handbags and belts | Differentiates products in a competitive market | Material sourcing, durability, and aesthetic appeal |

| Automotive | Custom leather straps for car interiors | Improves luxury appeal and customer satisfaction | Compatibility with vehicle models and leather quality |

| Sports & Outdoor Equipment | Straps for sports watches and gear | Provides functionality and style for active consumers | Weather resistance and custom sizing options |

| Medical Devices | Straps for wearable health monitoring devices | Enhances comfort and usability for patients | Biocompatibility and durability of materials |

How Are Custom Leather Straps Utilized in Watch Manufacturing?

In the watch manufacturing industry, custom leather straps are essential for luxury timepieces. They are tailored to fit specific models and can be personalized with unique colors, textures, and stitching patterns. This customization not only enhances the aesthetic appeal of the watches but also strengthens brand loyalty among consumers who seek exclusivity. For international buyers, it’s vital to consider the quality of leather used, as well as the craftsmanship involved in the production process, to ensure that the final product meets high standards.

What Role Do Custom Leather Straps Play in Fashion & Accessories?

In the fashion and accessories sector, custom leather straps serve as a key differentiator for handbags, belts, and other items. By offering unique designs and materials, brands can attract discerning customers looking for exclusive products. The ability to customize these straps allows businesses to cater to local tastes and preferences, particularly in diverse markets like Africa and South America. Buyers should focus on sourcing materials that are both durable and aesthetically appealing, ensuring that the final product resonates with their target audience.

How Are Custom Leather Straps Enhancing Automotive Interiors?

Custom leather straps are increasingly being used in automotive interiors to enhance the luxury appeal of vehicles. They can be integrated into seat designs, steering wheels, and other interior elements, providing a sophisticated touch that appeals to high-end consumers. For businesses in the automotive sector, sourcing straps that are compatible with specific vehicle models and ensuring the quality of leather is crucial. This attention to detail not only improves customer satisfaction but also elevates the overall brand image.

In What Ways Are Custom Leather Straps Beneficial for Sports & Outdoor Equipment?

In the sports and outdoor equipment industry, custom leather straps are employed for watches and gear that require both functionality and style. These straps can be designed to withstand harsh conditions while providing comfort during physical activities. For international buyers, it’s essential to consider the weather resistance and custom sizing options available, ensuring that the straps meet the specific needs of active consumers. This focus on durability and performance can significantly enhance product appeal in competitive markets.

Illustrative image related to custom leather straps

How Are Custom Leather Straps Used in Medical Devices?

Custom leather straps are also utilized in medical devices, particularly for wearable health monitoring technologies. These straps can be designed for comfort and usability, ensuring that patients can wear their devices for extended periods without discomfort. For businesses in the medical field, sourcing straps that are biocompatible and durable is crucial to meet regulatory standards and patient needs. By prioritizing quality and comfort, companies can enhance the user experience and promote better health outcomes.

3 Common User Pain Points for ‘custom leather straps’ & Their Solutions

Scenario 1: Sizing Confusion for Custom Leather Straps

The Problem: One of the most frequent challenges B2B buyers face when ordering custom leather straps is ensuring they have the correct sizing. Inaccurate measurements can lead to straps that do not fit properly, resulting in dissatisfaction and potential returns. This issue is particularly pressing for businesses that cater to a wide range of watch brands and models, each with unique lug widths and strap lengths. Furthermore, the inability to visualize how the strap will look on a specific watch can exacerbate the issue, leading to further complications down the line.

The Solution: To overcome sizing challenges, B2B buyers should implement a systematic approach to measurement. First, always refer to the manufacturer’s specifications for each watch model to determine the correct lug width. Utilizing a strap finder tool, if available, can streamline this process. Additionally, providing customers with a sizing guide that includes visual aids can help them understand how to measure their watches accurately. Establishing a clear communication channel for customers to ask questions about sizing before placing their orders can also significantly reduce errors. Lastly, consider offering a sample strap service, allowing buyers to test fit before committing to larger orders.

Illustrative image related to custom leather straps

Scenario 2: Quality Assurance in Custom Leather Straps

The Problem: Quality inconsistency is another prevalent pain point for B2B buyers in the custom leather strap market. Many suppliers may promise high-quality materials and craftsmanship, but the reality can fall short, resulting in products that do not meet expectations. This inconsistency can lead to customer complaints, damage to a company’s reputation, and financial losses due to returns or replacements.

The Solution: To ensure the highest quality of custom leather straps, B2B buyers should prioritize working with reputable suppliers known for their craftsmanship and material sourcing. Conducting thorough research, including reading reviews and seeking testimonials from other businesses, can provide insights into a supplier’s reliability. Establishing a quality assurance process is essential; this can include requesting samples before placing bulk orders, conducting inspections upon arrival, and using clear quality benchmarks for the materials used (such as leather grades). Additionally, implementing a feedback loop with customers can help identify quality issues early, allowing for prompt resolution and maintaining a high standard of product delivery.

Scenario 3: Long Lead Times and Delivery Issues

The Problem: Another significant concern for B2B buyers is the long lead times associated with custom leather strap orders. Delays can occur due to various factors such as production backlogs, shipping issues, or unexpected demand fluctuations. For businesses relying on timely deliveries to meet customer expectations, these delays can lead to lost sales and strained relationships with clients.

The Solution: To mitigate lead time issues, B2B buyers should establish clear timelines and communicate them upfront with suppliers. When placing an order, request a detailed timeline that outlines each phase of production and shipping. It can also be beneficial to diversify your supplier base; having multiple suppliers can reduce dependency on a single source and help maintain steady supply. Additionally, consider placing orders well in advance of peak seasons or anticipated demand spikes, allowing for extra time to accommodate any unforeseen delays. Establishing a proactive relationship with suppliers, including regular check-ins on order status, can also help address any potential issues before they become significant problems.

Strategic Material Selection Guide for custom leather straps

What Are the Key Properties of Common Materials Used for Custom Leather Straps?

When selecting materials for custom leather straps, understanding the properties, advantages, and limitations of each option is essential for B2B buyers. Here we analyze four common materials: Horween Shell Cordovan, Chromexcel Leather, Bridle Leather, and Full Grain Vegetable Tanned Leather. Each material has unique characteristics that influence their suitability for various applications.

Illustrative image related to custom leather straps

How Does Horween Shell Cordovan Perform in Custom Leather Straps?

Horween Shell Cordovan is a premium leather sourced from the hindquarters of a horse. It undergoes a meticulous tanning process that can take up to six months, resulting in a highly durable and resilient material. Its key properties include exceptional resistance to creasing and a rich color that develops a beautiful patina over time.

Pros: The durability and luxurious appearance make it ideal for high-end watch straps. Its non-creasing ability ensures that it maintains its aesthetic appeal even with frequent use.

Cons: The manufacturing complexity and longer production time can lead to higher costs. Additionally, its limited availability can affect supply chains, particularly for international buyers.

Impact on Application: Horween Shell Cordovan is particularly suitable for luxury watches, where aesthetics and durability are paramount. However, buyers should consider compliance with international standards, such as ASTM for leather quality.

Illustrative image related to custom leather straps

What Makes Chromexcel Leather a Popular Choice for Custom Straps?

Chromexcel Leather is characterized by its rich pull-up effect, which enhances its visual appeal. This leather is known for its softness and comfort, making it ideal for straps that require a snug fit against the wrist.

Pros: Its ability to develop a unique patina over time adds to its appeal. Chromexcel is also relatively affordable compared to other high-end leathers.

Cons: While it is durable, it may not withstand extreme conditions as well as some other leathers. Additionally, it can be susceptible to water damage if not properly treated.

Impact on Application: Chromexcel Leather is versatile and can be used for both casual and formal watch straps. Buyers from regions with varying climates should ensure proper treatment for moisture resistance.

Illustrative image related to custom leather straps

Why Choose Bridle Leather for Custom Leather Straps?

Bridle Leather is a full-grain vegetable-tanned leather that is both tough and hardwearing. It is hot stuffed with oils and waxes, resulting in a smooth, waxy texture that is resistant to wear.

Pros: Its durability makes it suitable for everyday use, and it can withstand significant wear and tear. The waxy finish also provides some water resistance.

Cons: The initial stiffness may require a break-in period, which could affect comfort initially. It may also be more expensive than other leather options.

Impact on Application: Bridle Leather is ideal for rugged or outdoor watch straps. B2B buyers should consider local preferences for leather types and ensure compliance with relevant standards.

Illustrative image related to custom leather straps

What Are the Benefits of Full Grain Vegetable Tanned Leather?

Full Grain Vegetable Tanned Leather is known for its robustness and natural appearance. This leather undergoes a labor-intensive tanning process that preserves its natural imperfections, resulting in a unique look.

Pros: Its durability and ability to age beautifully over time make it a popular choice. It is also biodegradable, appealing to environmentally conscious buyers.

Cons: The lack of synthetic coatings means it can be more susceptible to stains and water damage. Additionally, it may require more maintenance than other leathers.

Illustrative image related to custom leather straps

Impact on Application: Full Grain Vegetable Tanned Leather is suitable for custom straps that prioritize aesthetics and sustainability. Buyers should be aware of regional preferences and standards regarding leather sourcing and treatment.

Summary Table of Material Properties

| 素材 | Typical Use Case for custom leather straps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Horween Shell Cordovan | Luxury watch straps | Exceptional durability and aesthetic appeal | High cost and limited availability | 高い |

| Chromexcel Leather | Casual to formal watch straps | Softness and comfort with unique patina | Susceptible to water damage | Medium |

| Bridle Leather | Everyday rugged watch straps | Tough and hardwearing | Initial stiffness and potentially higher cost | Medium |

| Full Grain Vegetable Tanned Leather | Aesthetic and eco-friendly watch straps | Unique aging and natural appearance | Susceptible to stains and requires maintenance | Medium |

This guide should assist international B2B buyers in making informed decisions regarding material selection for custom leather straps, ensuring that they align with both performance requirements and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather straps

What Are the Key Stages in the Manufacturing Process of Custom Leather Straps?

The manufacturing of custom leather straps involves several meticulous stages that ensure both functionality and aesthetic appeal. Understanding these stages can help B2B buyers assess the quality and craftsmanship of the straps they intend to purchase.

Material Preparation: How Is Leather Selected and Processed?

The first step in producing high-quality leather straps is selecting the right type of leather. This can include full-grain leather, vegetable-tanned leather, and exotic leathers like crocodile or python. Each type offers unique characteristics such as durability, softness, and patina development.

Once the leather is selected, it undergoes a tanning process that can take weeks or even months. This process preserves the leather and enhances its color and texture. Techniques like hot stuffing with oils and waxes can be used to ensure the leather remains supple and resistant to wear. For instance, Horween’s Chromexcel leather is known for its rich pull-up effect and durability, making it a preferred choice for watch straps.

Forming: What Techniques Are Used to Shape Leather Straps?

After the leather is prepared, the next step is forming it into the desired shape. This involves cutting the leather into specific dimensions based on the strap design and the watch it is intended for. Precision is critical here, as even minor discrepancies can affect the fit and aesthetic of the strap.

Cutting can be done manually or with automated machines, depending on the scale of production. Techniques like edge burnishing and hole punching are employed to refine the edges and ensure that the strap has a polished look. Additionally, custom embossing or stitching can be added at this stage to enhance the strap’s uniqueness.

Assembly: How Are Leather Straps Constructed?

The assembly of leather straps is where craftsmanship truly shines. Skilled artisans carefully sew the pieces together, often using high-quality threads that match the leather. Various stitching techniques, such as saddle stitching, are utilized for their durability and visual appeal.

Once assembled, additional components like buckles or clasps are attached. The choice of hardware can significantly impact both the functionality and style of the strap. High-quality materials like stainless steel or brass are often used for buckles to ensure longevity.

Illustrative image related to custom leather straps

Finishing: What Steps Are Taken to Ensure Quality and Aesthetics?

The finishing stage is crucial for enhancing the visual appeal and durability of the leather strap. This can include processes like dyeing, polishing, and applying protective coatings. The finishing touches not only improve the strap’s appearance but also its resistance to environmental factors such as moisture and UV light.

Quality control checks are often conducted at this stage to ensure that the finished product meets specific standards before it is packaged and shipped.

How Is Quality Assurance Implemented in Custom Leather Strap Manufacturing?

Quality assurance is a vital aspect of the manufacturing process, especially in international B2B transactions. Buyers must ensure that their suppliers adhere to recognized quality standards to minimize risks associated with defective products.

What International Standards Should B2B Buyers Be Aware Of?

One of the most recognized international quality standards is ISO 9001, which focuses on ensuring consistent quality in products and services. Manufacturers of custom leather straps should ideally be ISO 9001 certified, indicating that they have established a quality management system.

In addition to ISO standards, industry-specific certifications such as CE marking (for safety compliance in Europe) and API specifications (for specific industrial applications) can also be relevant. These certifications assure buyers that the products have been tested and meet specific safety and quality criteria.

What Are the Key Quality Control Checkpoints in Leather Strap Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that defects are identified and rectified promptly.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Buyers should verify that the leather meets specified quality criteria.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing checks are performed to monitor the quality of the work being done. This includes assessing stitching consistency and ensuring that measurements are accurate.

-

Final Quality Control (FQC): Once the straps are completed, a final inspection is conducted to check for defects, ensure that the straps meet design specifications, and verify that all finishing processes have been applied correctly.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, verifying a supplier’s quality assurance processes is essential to ensure they receive high-quality products. Here are some actionable steps:

-

Request Certification Documentation: Ask suppliers for copies of their quality management certifications, such as ISO 9001. This documentation can provide insights into their commitment to quality.

-

Conduct Audits: Periodic audits of the supplier’s manufacturing facility can help assess compliance with quality standards. Buyers may choose to conduct these audits themselves or hire third-party inspection agencies.

-

Review Quality Reports: Suppliers should provide quality reports detailing the results of their QC checks. These reports can highlight any issues found during production and how they were resolved.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality processes and the products being manufactured.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality assurance. For instance, import regulations and standards can vary significantly between countries, affecting the acceptance of products.

Illustrative image related to custom leather straps

-

Understanding Local Regulations: Buyers should familiarize themselves with the local regulations in their target markets. For example, certain materials may be restricted or require specific certifications.

-

Cultural Considerations: Different regions may have varying expectations regarding product quality and craftsmanship. Engaging with local experts can help buyers navigate these nuances effectively.

-

Communication Channels: Establishing clear communication channels with suppliers can help address any quality concerns promptly. Regular updates on production progress and quality checks can foster transparency and trust.

By understanding the manufacturing processes and quality assurance measures involved in custom leather strap production, B2B buyers can make informed purchasing decisions that align with their business needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather straps’

This guide provides a structured approach for B2B buyers looking to procure custom leather straps, ensuring that every aspect of the sourcing process is covered. From defining specifications to evaluating suppliers, following these steps will help streamline your procurement efforts and enhance the quality of your final product.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the custom leather straps meet your specific needs. This includes determining the type of leather, dimensions, color, and design features. A well-defined specification helps avoid misunderstandings later and ensures that suppliers can deliver exactly what you require.

- Leather Type: Decide between options like full-grain, suede, or exotic leathers based on durability and aesthetics.

- Dimensions: Specify precise measurements, including strap width and length.

Step 2: Identify Your Target Market Needs

Understanding the preferences and requirements of your target market is essential. Different regions may have varying tastes in leather quality, color, and style.

- Market Research: Conduct research to identify popular trends in your target regions, such as Africa or Europe.

- Customization Options: Determine if customers prefer personalized features like embossing or color variations.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. This includes reviewing their company profiles, production capabilities, and previous work.

- Request Samples: Ask for samples of their leather straps to assess quality and craftsmanship.

- Supplier Reputation: Look for testimonials or case studies from other businesses in your industry to gauge reliability.

Step 4: Verify Compliance and Certifications

Ensure that your suppliers meet industry standards and have the necessary certifications. This step is particularly important for international transactions, as compliance can vary by region.

- Quality Certifications: Check for certifications like ISO or specific leather quality standards.

- Sustainability Practices: Inquire about their sourcing and tanning processes to ensure ethical production.

Step 5: Discuss Pricing and Payment Terms

Pricing transparency is key in B2B transactions. Engage in discussions about pricing, payment terms, and any potential bulk discounts.

- Negotiation: Be prepared to negotiate prices while ensuring that quality is not compromised.

- Payment Flexibility: Discuss options like upfront payments, net terms, or escrow services for larger orders.

Step 6: Establish a Clear Communication Channel

Effective communication can prevent misunderstandings and ensure that your specifications are met. Establish a dedicated point of contact for your orders.

- Regular Updates: Set expectations for regular updates on the production status and delivery timelines.

- Language Considerations: Ensure that communication is clear, especially if dealing with suppliers in different countries.

Step 7: Plan for Quality Control and Returns

Implementing a quality control process before accepting delivery is vital. Establish clear return policies in case the straps do not meet your expectations.

Illustrative image related to custom leather straps

- Inspection Criteria: Define what quality checks will be performed upon receipt of the products.

- Return Policy: Ensure the supplier has a fair return policy in case of defects or discrepancies.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing custom leather straps, ensuring high-quality products that meet market demands.

Comprehensive Cost and Pricing Analysis for custom leather straps Sourcing

What Are the Key Cost Components in Custom Leather Straps Sourcing?

When sourcing custom leather straps, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of leather significantly impacts cost. High-quality leathers such as Horween Shell Cordovan or full-grain vegetable-tanned leather are more expensive due to their durability and aesthetic appeal. Additionally, exotic leathers may command even higher prices due to their rarity and processing requirements.

-

Labor: Skilled craftsmanship is essential in producing custom leather straps. Labor costs can vary depending on the region and the expertise of the artisans. Countries with a rich tradition in leather crafting, such as Italy, may have higher labor costs but often deliver superior quality.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, rent, and administrative expenses. These costs are often reflected in the final pricing, making it crucial to assess the supplier’s operational efficiency.

-

Tooling: Customization often requires specialized tools and dies, which adds to the initial investment. Tooling costs are typically amortized over the production run, so larger orders can help reduce the per-unit expense.

-

Quality Control (QC): Ensuring that each strap meets quality standards incurs additional costs. Effective QC processes might involve inspections at various stages of production, which can influence the overall pricing structure.

-

Logistics: Shipping costs can vary widely based on the destination and shipping method. International shipments may involve additional tariffs or customs duties, which can significantly affect the total cost.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure sustainability. Understanding industry standards for margins can help buyers gauge whether a price is reasonable.

How Do Price Influencers Affect Custom Leather Strap Costs?

Several factors can influence pricing beyond the basic cost structure:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capabilities while securing favorable terms.

-

Specifications and Customization: Unique design requirements or specific dimensions can drive up costs. Providing clear specifications can minimize miscommunication and unexpected costs.

-

Material Quality and Certifications: Higher-quality materials, or those with specific certifications (e.g., eco-friendly tanning processes), can elevate pricing. Buyers should consider the long-term value of investing in quality materials.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is essential for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift cost responsibilities between buyer and seller.

What Buyer Tips Can Help Negotiate Better Prices for Custom Leather Straps?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can enhance cost-efficiency:

Illustrative image related to custom leather straps

-

Negotiate Terms: Leverage your purchasing power by negotiating payment terms, shipping costs, and bulk discounts. Highlighting potential long-term partnerships can also incentivize suppliers to offer better rates.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront costs but also the long-term implications of your purchase. Higher-quality straps might have a higher initial cost but could save money over time through durability and reduced replacement needs.

-

Understand Pricing Nuances: Pricing can vary significantly across different regions and suppliers. Research market rates and establish a baseline for what constitutes a fair price for the quality you seek.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and service. Regular communication and trust can facilitate smoother negotiations and collaboration.

Disclaimer for Indicative Prices

Prices for custom leather straps can vary widely based on the aforementioned factors. It is essential for buyers to conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing that aligns with their specific needs.

Alternatives Analysis: Comparing custom leather straps With Other Solutions

Understanding Alternatives to Custom Leather Straps

In the world of watch accessories and fashion, custom leather straps are often celebrated for their craftsmanship, aesthetic appeal, and ability to personalize timepieces. However, several alternative solutions exist that can achieve similar goals, providing buyers with options that may better suit their needs or budgets. This analysis compares custom leather straps with two viable alternatives: synthetic straps and metal bracelets, helping B2B buyers make informed decisions.

| Comparison Aspect | Custom Leather Straps | Synthetic Straps | Metal Bracelets |

|---|---|---|---|

| Performance | High durability, excellent comfort, develops patina over time | Good durability, less comfort, can retain moisture | Extremely durable, good comfort, heavy |

| Cost | Typically higher ($100+) | Generally lower ($20-$60) | Moderate to high ($50-$300) |

| Ease of Implementation | Requires precise fitting, customization process | Easy to fit and change, often universal | Requires specific sizing, can be complex to adjust |

| Maintenance | Requires regular conditioning, cleaning | Low maintenance, easy to clean | Low maintenance, requires occasional polishing |

| Best Use Case | Luxury watches, formal occasions | Casual wear, sports activities | Versatile, formal and casual settings |

What Are the Advantages and Disadvantages of Synthetic Straps?

Synthetic straps, often made from materials like silicone or nylon, present a cost-effective alternative to custom leather straps. They are lightweight, water-resistant, and easy to clean, making them ideal for outdoor or sports activities. However, synthetic straps may lack the luxury feel and aesthetic appeal of leather, potentially detracting from the overall elegance of high-end watches. Additionally, their lifespan can be shorter due to wear and tear from environmental exposure.

Illustrative image related to custom leather straps

How Do Metal Bracelets Compare to Custom Leather Straps?

Metal bracelets, crafted from materials like stainless steel or titanium, offer exceptional durability and a modern aesthetic. They are highly resistant to wear and can withstand various environments, making them suitable for both casual and formal settings. However, they can be heavier than leather or synthetic alternatives and may require professional adjustments to fit properly. While metal bracelets add a robust look to timepieces, they may not provide the same level of comfort as custom leather straps, particularly during extended wear.

How Can B2B Buyers Choose the Right Solution?

Selecting the right strap or bracelet for a watch involves considering several factors, including the target audience, intended use, and budget. For luxury brands or high-end watches, custom leather straps may enhance the product’s perceived value and offer a unique selling proposition. In contrast, for brands targeting active consumers or those seeking affordability, synthetic straps could be a more appropriate choice. Metal bracelets strike a balance, appealing to a wide range of customers with their versatility and durability. Ultimately, understanding the specific needs of your market will guide you toward the most suitable solution.

Essential Technical Properties and Trade Terminology for custom leather straps

What Are the Key Technical Properties of Custom Leather Straps?

Understanding the technical specifications of custom leather straps is essential for B2B buyers to make informed purchasing decisions. Here are critical properties to consider:

-

Material Grade

– Definition: This refers to the quality and type of leather used in strap production, such as full-grain, top-grain, or genuine leather.

– Importance: Higher-grade materials typically offer better durability, comfort, and aesthetic appeal. For businesses, investing in high-quality leather can enhance brand reputation and customer satisfaction. -

Thickness

– Definition: The measurement of the leather’s thickness, usually specified in millimeters (mm).

– Importance: Thickness impacts the strap’s durability and comfort. Thicker straps may be more robust and suitable for heavier watches, while thinner options might cater to a more refined look. Buyers should match thickness to the intended use and customer preferences. -

Tensile Strength

– Definition: This measures the leather’s ability to withstand tension before breaking.

– Importance: High tensile strength indicates that a strap can endure stress and wear over time, making it essential for B2B buyers who want long-lasting products. A robust strap minimizes returns and increases customer satisfaction. -

Water Resistance

– Definition: The ability of the leather to resist water penetration.

– Importance: Depending on the end-use, water resistance can be a crucial factor. Buyers targeting outdoor or active lifestyle markets may prioritize water-resistant straps to meet consumer needs and expectations. -

Finish Type

– Definition: This refers to the surface treatment applied to the leather, such as matte, glossy, or distressed finishes.

– Importance: The finish affects the strap’s aesthetic appeal and tactile feel. Understanding different finishes helps buyers select products that align with market trends and consumer preferences. -

Color Fastness

– Definition: The ability of the leather to maintain its color when exposed to light, water, and friction.

– Importance: Color fastness is vital for ensuring that straps retain their appearance over time. B2B buyers should prioritize suppliers that provide materials with high color fastness to ensure product longevity and customer satisfaction.

What Are Common Trade Terms in the Custom Leather Strap Industry?

Familiarity with industry jargon can facilitate smoother transactions and communications. Here are essential terms for B2B buyers:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Context: In the custom leather strap industry, OEM relationships can provide businesses with tailored products that meet specific branding or design needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest order size that a supplier is willing to accept.

– Context: Understanding MOQ helps businesses plan their inventory and budget. Suppliers with lower MOQs can be beneficial for smaller enterprises or those testing new products. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to request pricing and other information from suppliers.

– Context: An RFQ is essential for obtaining competitive pricing and evaluating multiple suppliers. It streamlines the procurement process for custom leather straps. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) related to international shipping and freight.

– Context: Familiarity with Incoterms is crucial for understanding shipping responsibilities, costs, and risks. This knowledge helps buyers avoid potential disputes and ensures smooth logistics. -

Lead Time

– Definition: The time taken from placing an order to delivery.

– Context: Understanding lead time is critical for supply chain planning. Buyers should communicate their timeline needs to suppliers to align production schedules effectively. -

Customization Options

– Definition: Various possibilities for tailoring a product to meet specific customer requirements, such as size, color, or hardware.

– Context: Knowing the available customization options allows businesses to offer unique products that cater to diverse customer preferences, enhancing market competitiveness.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing custom leather straps, ultimately leading to better customer satisfaction and business success.

Navigating Market Dynamics and Sourcing Trends in the custom leather straps Sector

What Are the Key Market Trends in the Custom Leather Straps Sector?

The custom leather straps market is experiencing notable growth driven by several global factors. Increasing demand for personalized accessories and the rise of luxury watch brands are key drivers. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking unique, high-quality leather products that reflect individual style and craftsmanship. The proliferation of e-commerce platforms has made it easier for buyers to connect with suppliers worldwide, thereby enhancing market accessibility.

Emerging technologies, such as digital customization tools, are reshaping sourcing practices. Companies are investing in advanced manufacturing techniques, including 3D printing and laser engraving, to create bespoke leather straps that cater to specific customer preferences. This trend is particularly appealing to younger consumers who prioritize individuality and quality. Additionally, the integration of supply chain management software is enabling buyers to track orders and manage inventories more efficiently, reducing lead times and improving overall service levels.

How Important Is Sustainability and Ethical Sourcing in the Custom Leather Straps Market?

Sustainability is becoming a cornerstone of the custom leather straps sector, driven by increasing consumer awareness and regulatory pressures. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to ethical sourcing and environmental responsibility. The leather industry has historically faced scrutiny regarding its environmental impact, particularly concerning deforestation and chemical pollution. As a result, suppliers are adopting greener practices, such as using vegetable-tanned leather and sourcing from certified sustainable farms.

Illustrative image related to custom leather straps

Certification programs, like the Leather Working Group (LWG) and Forest Stewardship Council (FSC), are gaining traction among B2B buyers as they signify compliance with environmental standards. Moreover, the use of alternative materials, such as recycled leather and plant-based leathers, is becoming increasingly popular. This shift not only addresses environmental concerns but also meets the growing demand for sustainable products in the luxury market. By prioritizing ethical sourcing, buyers can enhance their brand reputation and appeal to environmentally conscious consumers.

How Has the Custom Leather Straps Market Evolved Over Time?

The evolution of the custom leather straps market reflects broader trends in consumer preferences and technological advancements. Historically, leather straps were primarily utilitarian, serving as simple accessories for watches and other items. However, with the rise of luxury brands and the shift towards personalization, these straps have transformed into fashion statements that convey individuality and style.

In recent years, the market has seen a surge in artisanal craftsmanship, with skilled leatherworkers employing traditional techniques to create bespoke products. This artisanal approach has gained popularity among consumers seeking quality and authenticity in their purchases. As global trade continues to expand, international B2B buyers now have access to a diverse range of materials and styles, enabling them to curate unique offerings that resonate with their target markets. This evolution highlights the importance of adaptability and innovation in the custom leather straps sector, making it crucial for businesses to stay informed about emerging trends and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather straps

-

1. How do I choose the right supplier for custom leather straps?

Choosing the right supplier involves several key steps. First, assess the supplier’s reputation by checking reviews and testimonials from previous clients. Look for experience in producing custom leather straps and their ability to meet international quality standards. Additionally, request samples to evaluate the leather quality and craftsmanship. It’s essential to communicate your specific needs and ensure the supplier can accommodate customization requests. Finally, verify their logistics capabilities and shipping options to ensure timely delivery to your location. -

2. What are the minimum order quantities (MOQ) for custom leather straps?

Minimum order quantities for custom leather straps can vary significantly between suppliers. Generally, MOQs can range from 50 to 500 pieces, depending on the complexity of the design and the materials used. When sourcing, inquire about flexible options, especially if you’re starting small or testing the market. Some suppliers may offer lower MOQs for first-time buyers or specific product lines. Always confirm the MOQ in writing to avoid any misunderstandings during the order process. -

3. What customization options are available for leather straps?

Customization options for leather straps are extensive. Buyers can select from various materials, including full-grain, suede, or exotic leathers. Additionally, options include choosing colors, textures, widths, and buckle types. Some suppliers also offer personalization features such as embossing or stitching patterns. When discussing customization, provide detailed specifications and examples to ensure the final product aligns with your brand identity and customer expectations. -

4. How can I ensure the quality of custom leather straps?

To ensure the quality of custom leather straps, start by requesting samples from potential suppliers. Examine the craftsmanship, material durability, and overall finish. Ask about the production process, including the tanning and dyeing methods used, as these greatly affect quality. Implement a quality assurance (QA) process by establishing clear specifications and conducting inspections during production. Additionally, consider suppliers who offer warranties or guarantees on their products, demonstrating confidence in their craftsmanship. -

5. What payment terms should I expect when ordering custom leather straps?

Payment terms for custom leather strap orders typically vary by supplier. Common arrangements include upfront deposits (ranging from 30% to 50%) before production, with the balance due upon completion or before shipping. Some suppliers may offer net payment terms, allowing payment within a specified period after delivery. Discuss and negotiate these terms upfront to ensure clarity and avoid potential cash flow issues. Always secure payment terms in writing to protect both parties. -

6. How do international shipping and logistics work for custom leather straps?

International shipping for custom leather straps involves several considerations, including customs regulations and shipping costs. Most suppliers will provide shipping options, including express or standard delivery. Ensure you understand the estimated delivery times and any additional charges that may apply, such as duties or taxes upon arrival. It’s advisable to work with suppliers who have experience in international shipping to navigate these complexities smoothly. Keep communication open to track your shipment effectively. -

7. What are common challenges when sourcing custom leather straps internationally?

Common challenges in sourcing custom leather straps internationally include communication barriers, quality control issues, and logistics complications. Time zone differences can hinder timely responses, so establish clear communication channels. Quality control can be difficult when dealing with overseas suppliers, making it crucial to request samples and establish QA protocols. Additionally, be prepared for potential delays due to customs clearance or shipping disruptions. Building a strong relationship with your supplier can help mitigate these challenges. -

8. How do I handle disputes with my supplier over custom leather strap orders?

Handling disputes with suppliers requires a systematic approach. Start by clearly communicating your concerns and providing evidence, such as photos or documentation. Most suppliers will have a dispute resolution policy; familiarize yourself with it before escalation. If the issue remains unresolved, consider mediation or arbitration as a next step. Maintain professionalism throughout the process, as a good relationship with your supplier is valuable for future orders. Always document communications and agreements to protect your interests.

Top 5 Custom Leather Straps Manufacturers & Suppliers List

1. Delugs – Custom Handcrafted Watch Straps

Domain: delugs.com

Registered: 2018 (7 years)

Introduction: Custom Watch Strap – Delugs

– Price: USD 150.00

– Free Shipping for First Order (minimum spend of US$100, use code FREE-FIRST-SHIPPING)

– Custom handcrafted leather watch straps

– 100% handmade to fit your timepiece

– Material Options: Alcantara, Alligator/Crocodile, Babele, Baranil, Buttero, Chevre, Crazy Horse, Epsom, Lizard, Nubuck, Ostrich (Body and Leg), Pueblo, Rubberised Leather (Smooth and…

2. Vintager Straps – Custom Leather Watch Straps

Domain: vintagerstraps.com

Registered: 2006 (19 years)

Introduction: Vintager Straps offers custom leather watch straps for all brands, handcrafted in the Napa Valley, USA. The turnaround time for orders is 3 to 4 weeks, and they provide free worldwide shipping. The product categories include Fine Leather (64 products), Gator (8 products), Horween Straps (15 products), Rolled Canvas (7 products), Leather Backed Canvas (4 products), and Shark (8 products). Each stra…

3. Roarcraft – Handmade Leather Watch Straps

Domain: roarcraft.com

Registered: 2016 (9 years)

Introduction: Handmade Leather Watch Straps – Custom Made Apple Watch Band. Price Range: $89.00 – $119.00 USD. Available Colors: Black, Brown, Burgundy, Cognac, Gray, Green, Antique Brown, Indigo Blue, Forest Green, Antique Gray, Dark Beige, Lemon Saffiano, Lime Saffiano, Chocolate Saffiano. Customizable for various watch brands including Apple Watch, Panerai, Tudor, Rolex, Omega. Features minimalist, useful, a…

4. Monstraps – Custom Leather Straps

Domain: monstraps.com

Registered: 2020 (5 years)

Introduction: Customise Leather Straps – Monstraps

**New Collection**: Sailcloth Straps Collection (August 2025)

**Material Types**:

– Handcrafted Leather

– Alligator Leather

– Lizard Leather

– Ostrich Leather

– Shell Cordovan

– Epsom

– Saffiano

– Swift Leather

– Rally Style

– Vintage Distressed

– Vintage Waxed

– Fabric Leather

– Nubuck & Suede

– Rubber

– Sailcloth / Canvas

– Adjustable Nylon …

5. Velle Alexander – Bespoke Leather Watch Straps

Domain: vellealexander.com

Registered: 2019 (6 years)

Introduction: Velle Alexander offers bespoke leather watch straps handcrafted in the USA. Each strap is made from a curated selection of premium materials including American alligator, Italian calf, French goatskin, Horween shell cordovan, and more. The straps are tailored to individual watch models and are crafted by Alex Gravelle, a sole artisan and FHH-certified Watch Advisor, in his Minneapolis atelier. The…

Strategic Sourcing Conclusion and Outlook for custom leather straps

As the demand for custom leather straps continues to rise globally, strategic sourcing remains a pivotal factor for B2B buyers looking to capitalize on this trend. By forging partnerships with reputable suppliers, businesses can ensure access to high-quality materials, such as Horween Chromexcel and full-grain vegetable-tanned leather, which enhance product offerings. Additionally, prioritizing suppliers that offer customization options can provide significant competitive advantages, allowing businesses to cater to diverse consumer preferences across regions.

Investing in strategic sourcing not only mitigates risks associated with supply chain disruptions but also promotes sustainability and ethical sourcing practices. This is particularly relevant for buyers in Africa, South America, the Middle East, and Europe, where consumer awareness around quality and ethical production is growing.

Illustrative image related to custom leather straps

Looking ahead, it is essential for B2B buyers to leverage market insights and emerging trends to stay ahead of the curve. Engaging with innovative suppliers, exploring new materials, and embracing customization will be key to capturing market share in the evolving landscape of custom leather straps. Take the initiative today—evaluate your sourcing strategies and position your business for success in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.