Introduction: Navigating the Global Market for pu coated

In the competitive landscape of international procurement, sourcing high-quality PU coated materials presents a unique set of challenges for B2B buyers. Whether you are seeking durable outdoor gear, protective clothing, or robust industrial applications, understanding the nuances of polyurethane (PU) coatings is crucial. This guide serves as a comprehensive resource, delving into the various types of PU coatings, their applications across diverse industries, and the critical factors to consider when vetting suppliers.

As buyers from regions like Africa, South America, the Middle East, and Europe navigate this complex market, they face the dual challenge of ensuring product quality while managing costs. This guide empowers you to make informed purchasing decisions by providing insights into the latest innovations in PU coating technology, environmental considerations, and best practices for supplier evaluation. With actionable strategies and expert advice, we aim to streamline your sourcing process, enabling you to identify reliable suppliers who meet your specific needs and budget constraints.

By the end of this guide, you will be equipped with the knowledge to confidently engage with suppliers, negotiate favorable terms, and ultimately enhance your product offerings with superior PU coated materials.

Table Of Contents

- Top 2 Pu Coated Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pu coated

- Understanding pu coated Types and Variations

- Key Industrial Applications of pu coated

- 3 Common User Pain Points for ‘pu coated’ & Their Solutions

- Strategic Material Selection Guide for pu coated

- In-depth Look: Manufacturing Processes and Quality Assurance for pu coated

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu coated’

- Comprehensive Cost and Pricing Analysis for pu coated Sourcing

- Alternatives Analysis: Comparing pu coated With Other Solutions

- Essential Technical Properties and Trade Terminology for pu coated

- Navigating Market Dynamics and Sourcing Trends in the pu coated Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pu coated

- Strategic Sourcing Conclusion and Outlook for pu coated

- Important Disclaimer & Terms of Use

Understanding pu coated Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Coated PU | One layer of PU, lighter weight | Outdoor apparel, tents | Pros: Lightweight, cost-effective. Cons: Less durable than multi-coated options. |

| Multi-Coated PU | Multiple layers of PU for enhanced protection | High-performance outdoor gear | Pros: Superior waterproofing, durability. Cons: Heavier and bulkier. |

| Microporous PU | Contains tiny holes for breathability | Athletic wear, breathable jackets | Pros: Breathable, maintains waterproofing. Cons: May be pricier, less insulating. |

| PU Coated Cordura | Reinforced with Cordura fabric for strength | Workwear, tactical gear | Pros: Exceptional abrasion resistance. Cons: Heavier than standard fabrics. |

| PU Coated Nylon | Lightweight nylon with PU coating | Backpacks, outdoor gear | Pros: Lightweight, flexible. Cons: Less durable than other PU blends. |

What Are the Key Characteristics of Single-Coated PU?

Single-coated PU fabrics are characterized by a single layer of polyurethane applied to the textile. This coating provides a basic level of water resistance and is often utilized in outdoor apparel and tents. Buyers should consider that while single-coated fabrics are lighter and more cost-effective, they may not withstand extreme conditions as well as multi-coated options. This makes them suitable for less demanding environments or casual use.

How Does Multi-Coated PU Enhance Performance?

Multi-coated PU fabrics feature multiple layers of polyurethane, significantly improving their waterproofing and durability. These fabrics are commonly used in high-performance outdoor gear, such as jackets and pants designed for extreme weather conditions. B2B buyers should note that while these fabrics offer superior protection, they also come with increased weight and bulk. Therefore, they are best suited for applications where durability and weather resistance are paramount.

Why Choose Microporous PU for Breathability?

Microporous PU technology introduces tiny pores into the polyurethane coating, allowing moisture vapor to escape while keeping water droplets out. This innovation makes microporous PU ideal for athletic wear and breathable jackets, where both waterproofing and breathability are essential. B2B buyers should weigh the benefits of this technology against its potential higher cost and ensure it aligns with their product specifications and target markets.

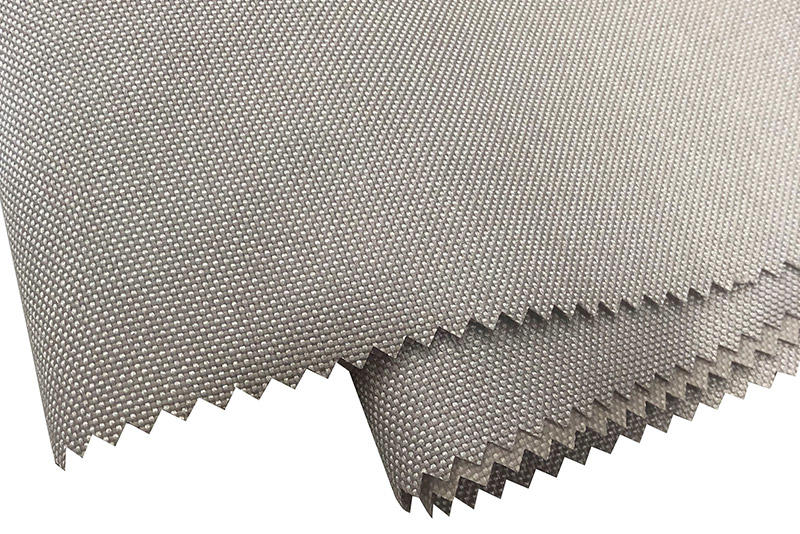

Illustrative image related to pu coated

What Advantages Does PU Coated Cordura Offer?

PU coated Cordura combines the strength of Cordura fabric with the protective qualities of polyurethane. This variation is especially suited for workwear and tactical gear, where durability against abrasion and punctures is critical. B2B buyers should consider the balance between weight and strength, as while these fabrics are heavier, their long-lasting nature can justify the investment in demanding applications.

When Is PU Coated Nylon the Right Choice?

PU coated nylon is a lightweight option that offers flexibility and moderate water resistance. It is commonly used in backpacks and outdoor gear, appealing to buyers seeking a balance between weight and performance. However, it is less durable than other PU blends, making it more suitable for casual or less rugged applications. B2B buyers should assess the intended use and environment to determine if this option meets their needs.

Key Industrial Applications of pu coated

| Industry/Sector | Specific Application of pu coated | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Apparel | Waterproof jackets and gear | Enhanced durability and protection against elements | Ensure compliance with local regulations and sustainability standards; evaluate breathability and weight for comfort. |

| Construction | Protective coatings for building materials | Increased resistance to weathering and abrasion | Assess compatibility with existing materials; consider environmental impact of coatings. |

| Automotive | PU coatings for interior and exterior parts | Improved wear resistance and aesthetic appeal | Look for customization options to meet specific design needs; durability under varying climate conditions. |

| Sports Equipment | Coatings for tents and outdoor gear | Enhanced performance in adverse weather conditions | Prioritize lightweight options for ease of transport; check for UV resistance and longevity. |

| Industrial Fabrics | Coatings for protective workwear | Increased safety through waterproofing and durability | Ensure compliance with safety standards; evaluate breathability for comfort during extended wear. |

How is PU Coated Used in Outdoor Apparel and What Problems Does It Solve?

In the outdoor apparel sector, PU coatings are commonly applied to jackets and gear to create a waterproof barrier. This application is crucial for outdoor enthusiasts who face unpredictable weather conditions. The PU coating not only provides long-lasting waterproofing but also enhances the durability of fabrics against tears and abrasions. For international buyers, particularly from regions with varying climates like Africa and Europe, sourcing PU-coated materials involves ensuring compliance with local regulations and evaluating the breathability and weight of the fabric to ensure comfort during use.

What are the Benefits of PU Coatings in Construction?

In the construction industry, PU coatings are utilized to protect building materials, such as concrete and wood, from weathering and abrasion. This application significantly extends the lifespan of structures, making it a cost-effective solution for contractors. For businesses in emerging markets like South America and the Middle East, sourcing PU-coated materials requires an assessment of compatibility with existing building systems and consideration of the environmental impact of the coatings. Buyers should also prioritize suppliers who can provide certifications for durability and sustainability.

How Do PU Coatings Enhance Automotive Applications?

In the automotive sector, PU coatings are used for both interior and exterior components, providing improved wear resistance and enhancing the aesthetic appeal of vehicles. This application is vital for manufacturers looking to increase the longevity and marketability of their products. International buyers, especially from regions with harsh climates, should consider customization options that meet specific design requirements and durability standards. Ensuring that the coatings can withstand varying temperature and humidity levels is also crucial for performance.

What Role Do PU Coatings Play in Sports Equipment?

For sports equipment, PU coatings are applied to tents and outdoor gear to enhance performance in adverse weather conditions. This application is essential for manufacturers aiming to provide reliable products for outdoor activities. Buyers, particularly from regions with diverse outdoor sports markets like Africa and Vietnam, should prioritize lightweight options for ease of transport and check for UV resistance to ensure longevity. Sourcing PU-coated materials involves evaluating the balance between weight and durability to meet the demands of active users.

Why are PU Coatings Important for Industrial Fabrics?

In the realm of industrial fabrics, PU coatings are critical for protective workwear, offering waterproofing and increased durability. This application enhances safety for workers in various industries, including construction and manufacturing. For businesses, especially in developing regions, sourcing PU-coated workwear requires ensuring compliance with safety standards and evaluating the breathability of the fabrics for comfort during prolonged use. Buyers should also seek suppliers who can provide detailed information on the environmental impact of their coatings.

3 Common User Pain Points for ‘pu coated’ & Their Solutions

Scenario 1: Weight Concerns in PU Coated Fabrics for Outdoor Gear

The Problem: B2B buyers in the outdoor apparel industry often face challenges with the weight of PU coated fabrics. While these materials provide essential waterproofing and durability, they can also add significant bulk to garments, making them less appealing for customers seeking lightweight options. This issue is particularly relevant in regions where outdoor activities demand agility and speed, such as hiking or cycling. Buyers must balance the need for protection against the potential downsides of heavier fabrics, which could deter end-users.

The Solution: To address weight concerns, buyers should focus on sourcing advanced PU coated materials designed for lightweight applications. Manufacturers are increasingly offering options that use micro-coating techniques or lighter polyurethane formulations that maintain waterproof capabilities without excessive bulk. When specifying PU coated fabrics, it is critical to inquire about the weight per square meter and consider the intended use of the garment. Engaging with suppliers who specialize in innovative textile technologies can lead to finding lighter alternatives that do not compromise on performance. Additionally, educating customers on the benefits of modern PU coatings can help them understand the value of durability and waterproofing, even if the fabric is slightly heavier.

Scenario 2: Breathability Issues in High-Intensity Activities

The Problem: Buyers of PU coated garments often encounter the challenge of breathability, especially in high-intensity outdoor activities. Traditional PU coatings have been criticized for trapping moisture, leading to discomfort for users engaged in activities such as trail running or mountain biking. This lack of breathability can result in overheating, sweat accumulation, and ultimately dissatisfaction with the product, which can harm a brand’s reputation.

The Solution: To overcome breathability issues, B2B buyers should seek out suppliers that offer PU coatings with microporous technology. These coatings contain tiny holes that allow moisture vapor to escape while preventing water from penetrating. When sourcing materials, buyers should prioritize certifications that demonstrate breathability performance, such as RET (Resistance to Evaporative Heat Transfer) ratings. Collaborating with manufacturers who specialize in high-performance textiles can also yield customized solutions tailored to specific activity levels. Providing education to end-users about the benefits of these advanced materials can enhance their experience and satisfaction with the product.

Scenario 3: Environmental Concerns with PU Coatings

The Problem: With increasing awareness of environmental sustainability, B2B buyers face pressure to select PU coated materials that minimize ecological impact. Traditional PU coatings can raise concerns due to their production and disposal processes, especially in regions like Europe where regulatory scrutiny is high. Buyers must navigate the balance between performance and sustainability to meet market demands and consumer expectations.

The Solution: To address environmental concerns, buyers should prioritize sourcing PU coated fabrics that are produced using eco-friendly practices. Look for suppliers that utilize water-based PU coatings or those that adhere to strict environmental standards, such as Oeko-Tex certification. Engaging with manufacturers who are transparent about their sustainability initiatives can also provide insights into their production processes and the lifecycle of their products. Additionally, consider advocating for recycling programs or biodegradable alternatives to PU coatings, which can further enhance a brand’s commitment to sustainability. By positioning products as environmentally friendly, buyers can attract a more conscientious customer base and differentiate themselves in the market.

Strategic Material Selection Guide for pu coated

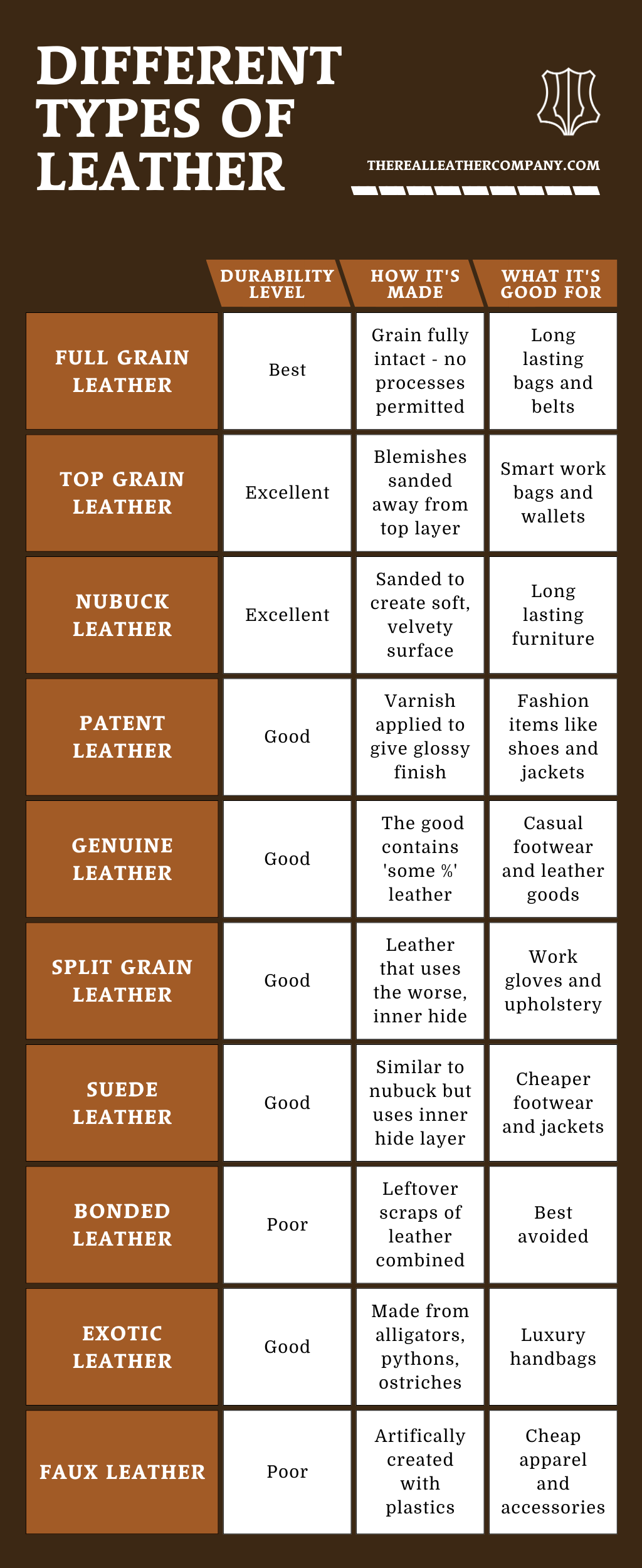

What Are the Key Materials Commonly Used for PU Coatings?

Polyurethane (PU) coatings are widely utilized across various industries due to their versatility and protective properties. Understanding the materials commonly used for PU coatings is essential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in PU coatings, highlighting their properties, advantages, disadvantages, and specific considerations for buyers.

1. Polyester Fabric

Key Properties:

Polyester fabrics are known for their strength, durability, and resistance to shrinking and stretching. They can withstand temperatures up to 150°C and have good resistance to UV light and mildew.

Pros & Cons:

Polyester is relatively low-cost and lightweight, making it suitable for various applications, including outdoor clothing and gear. However, it can be less breathable compared to natural fibers, which may limit its use in high-performance outdoor gear.

Illustrative image related to pu coated

Impact on Application:

Polyester-coated products are compatible with a range of media, including water and mild chemicals, but may not perform well against harsh solvents.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN, especially regarding environmental regulations. Polyester is widely accepted in many markets, including Nigeria and Vietnam, where durability is a key concern.

2. Nylon Fabric

Key Properties:

Nylon is recognized for its exceptional tensile strength and elasticity, withstanding temperatures up to 120°C. It also offers good abrasion resistance and is less prone to tearing.

Pros & Cons:

While nylon is lightweight and durable, it can be more expensive than polyester. Its hydrophilic nature means it absorbs moisture, which can be a disadvantage in humid climates.

Impact on Application:

Nylon is highly suitable for high-performance applications, such as outdoor gear and industrial textiles, where strength and flexibility are critical. However, it may not be the best choice for applications requiring chemical resistance.

Considerations for International Buyers:

Nylon’s global acceptance is high, but buyers should be mindful of local preferences for synthetic materials, particularly in regions like South America, where durability is paramount.

3. Cordura Fabric

Key Properties:

Cordura is a brand of fabric known for its durability and resistance to abrasions, tears, and scuffs. It can withstand high temperatures and is often treated to be water-resistant.

Pros & Cons:

The primary advantage of Cordura is its strength, making it ideal for heavy-duty applications such as military gear, luggage, and workwear. However, it tends to be heavier and more expensive than other fabrics, which may limit its use in lightweight applications.

Illustrative image related to pu coated

Impact on Application:

Cordura is highly suitable for applications requiring extreme durability and resistance to wear, making it ideal for outdoor and industrial environments. Its compatibility with PU coatings enhances its protective properties.

Considerations for International Buyers:

Buyers should consider local regulations regarding the use of synthetic materials. In Europe, for instance, there is a strong emphasis on sustainable sourcing, which may influence purchasing decisions.

4. Cotton Fabric

Key Properties:

Cotton is a natural fiber known for its breathability and comfort. When coated with PU, it can achieve water resistance while maintaining a soft feel.

Illustrative image related to pu coated

Pros & Cons:

Cotton is generally more affordable and environmentally friendly compared to synthetic options. However, it is less durable and can degrade more quickly under harsh conditions.

Impact on Application:

Cotton-coated products are suitable for applications where comfort and breathability are prioritized, such as casual wear. However, they may not be ideal for high-performance outdoor gear.

Considerations for International Buyers:

Cotton’s appeal in markets like Africa and the Middle East is strong due to its natural properties. Compliance with organic standards may also be a consideration for buyers focused on sustainability.

Summary Table

| Material | Typical Use Case for pu coated | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor clothing, gear | Low-cost, durable | Less breathable | Low |

| Nylon | High-performance outdoor gear | Exceptional strength and elasticity | More expensive, moisture-absorbing | Medium |

| Cordura | Military gear, heavy-duty workwear | High durability and abrasion resistance | Heavier, more costly | High |

| Cotton | Casual wear, comfort-focused apparel | Breathable, environmentally friendly | Less durable | Low |

This guide provides a comprehensive overview of the materials used for PU coatings, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pu coated

What Are the Key Stages in the Manufacturing Process of PU Coated Fabrics?

The production of PU coated fabrics involves several meticulous stages, each designed to ensure the final product meets both performance and quality expectations. Understanding these stages is crucial for B2B buyers looking to procure high-quality PU coated materials.

Illustrative image related to pu coated

Material Preparation: How Are Raw Materials Sourced and Processed?

The manufacturing process begins with the selection of high-quality base fabrics, typically polyester or nylon, which are chosen for their durability and performance characteristics. These fabrics are pre-treated to enhance their bonding capabilities with the PU coating. The preparation involves cleaning, drying, and sometimes applying a primer to ensure optimal adhesion of the polyurethane layer.

Forming: What Techniques Are Used to Apply the PU Coating?

Once the base fabric is ready, the next step is the application of the PU coating. This can be accomplished through various techniques:

-

Coating Methods: The most common methods include:

– Knife Over Roll: This technique involves spreading a liquid PU solution over the fabric using a blade, ensuring even coverage.

– Laminate Coating: This involves adhering a separate PU film to the fabric, providing a robust waterproof layer.

– Spray Coating: This method allows for precise application but may not be as uniform as the knife method. -

Curing Process: After application, the coated fabric is subjected to a curing process, often involving heat, to solidify the PU layer. This step is critical as it affects the durability and performance of the coating.

Assembly: How Are PU Coated Fabrics Constructed into Final Products?

Following the curing process, the PU coated fabrics are cut and sewn into finished products, such as outdoor clothing, tents, or gear. During assembly, manufacturers must ensure that seams are properly sealed to maintain the waterproof characteristics of the fabric. Techniques such as seam taping or heat sealing are commonly employed to enhance the integrity of the seams.

What Quality Assurance Measures Are Critical in PU Coating Production?

Quality assurance is paramount in the manufacturing of PU coated fabrics, as it directly impacts the performance, durability, and safety of the final products. B2B buyers must be familiar with the standards and practices that ensure high-quality outcomes.

What International Standards Should Buyers Look For?

Manufacturers of PU coated fabrics should adhere to recognized international standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific standards may apply, including:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Relevant for PU coatings used in industrial applications, particularly in oil and gas.

These certifications provide assurance that the products have undergone rigorous testing and meet the necessary quality benchmarks.

What Are the Key Quality Control Checkpoints?

Quality control (QC) should be integrated into various stages of the manufacturing process, including:

Illustrative image related to pu coated

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, continuous monitoring ensures that processes are maintained within control limits, reducing defects.

- Final Quality Control (FQC): The final products are subjected to comprehensive testing to verify their performance against defined criteria, including waterproofing, breathability, and durability.

What Testing Methods Are Commonly Used for PU Coated Fabrics?

To ensure that the PU coatings perform as expected, several testing methods are employed:

- Water Resistance Testing: Methods such as the hydrostatic head test measure the fabric’s ability to withstand water pressure without leaking.

- Abrasion Resistance Testing: This assesses the durability of the coating against wear and tear, crucial for outdoor applications.

- Breathability Testing: Evaluates how well moisture vapor can escape from the fabric, an essential feature for comfort in various climates.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure that their suppliers adhere to stringent quality control practices. Here are actionable strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and adherence to international standards firsthand.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that outline testing results, compliance with standards, and any certifications held by the manufacturer.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing processes and product quality, ensuring that the buyer’s standards are met.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions may have unique regulatory requirements. Understanding these can prevent compliance issues and delays in product acceptance.

-

Cultural Sensitivity in Quality Expectations: Quality perceptions can vary across cultures. Clear communication about quality standards and expectations is essential to align both parties.

-

Logistical Challenges: Consider the impact of shipping and transportation on product quality. Ensure that the supplier employs appropriate packaging and handling to preserve product integrity during transit.

Conclusion: Ensuring Quality in PU Coated Fabric Procurement

For B2B buyers, understanding the manufacturing processes and quality assurance measures for PU coated fabrics is essential to making informed procurement decisions. By focusing on recognized standards, rigorous quality control checkpoints, and effective verification strategies, buyers can secure high-quality materials that meet their needs and expectations. This proactive approach not only ensures product performance but also fosters strong supplier relationships, ultimately driving business success in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu coated’

To assist B2B buyers in procuring PU-coated materials effectively, this guide outlines essential steps to ensure a successful sourcing process. The focus is on identifying the right suppliers and ensuring that the products meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s crucial to clearly define what you need in terms of PU coatings. Consider the intended application, required durability, waterproofing levels, and any specific environmental standards you may need to meet. This clarity will help you communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in PU-coated materials. Look for companies with a proven track record in your industry and region. Utilize online platforms, industry trade shows, and professional networks to gather information about potential partners.

- Focus on Reviews and Testimonials: Seek feedback from previous clients to gauge supplier reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO standards or environmental compliance certifications. These credentials demonstrate a commitment to quality and sustainability, which are increasingly important in the global market.

Illustrative image related to pu coated

- Ask for Documentation: Request copies of certifications to ensure they are current and relevant to your needs.

Step 4: Request Samples

Once you have narrowed down your options, request samples of the PU-coated materials. This will allow you to assess the quality, feel, and performance of the products firsthand. Pay attention to the coating’s weight, breathability, and water resistance.

- Conduct Testing: If possible, perform tests under conditions that mimic your actual use cases to evaluate performance.

Step 5: Inquire About Production Capabilities

Understanding the production capabilities of your suppliers is vital. Ask about their manufacturing processes, lead times, and capacity to handle large orders. This information will help you gauge whether they can meet your demand consistently.

- Discuss Customization Options: If you require specific modifications or custom formulations, ensure the supplier can accommodate these requests.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate the terms of your agreement. Discuss pricing, payment terms, delivery schedules, and return policies. Clear agreements will help prevent misunderstandings and ensure a smooth transaction.

- Consider Long-term Partnerships: If the supplier meets your expectations, explore options for long-term contracts to secure favorable terms and stability.

Step 7: Monitor Quality Control

After placing your order, establish a process for monitoring the quality of the PU-coated materials upon delivery. Implement a system for inspecting products against your specifications to ensure they meet your standards.

- Plan for Regular Reviews: Schedule periodic evaluations of supplier performance to maintain quality and address any issues promptly.

By following these steps, B2B buyers can effectively navigate the sourcing process for PU-coated materials, ensuring they select the right suppliers and products for their specific needs.

Comprehensive Cost and Pricing Analysis for pu coated Sourcing

What Are the Key Cost Components in PU Coated Sourcing?

When sourcing PU coated materials, understanding the cost structure is vital for effective budgeting and negotiation. The main cost components include:

-

Materials: The primary expense is the polyurethane itself, which can vary significantly based on quality and sourcing location. Prices for raw materials fluctuate due to market demand, availability, and geopolitical factors, impacting overall costs.

-

Labor: Labor costs encompass the workforce involved in the application of PU coatings, manufacturing, and quality control. Regions with lower labor costs can offer competitive pricing, but it’s essential to balance this with quality and expertise.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can lower overhead, which is crucial for keeping prices competitive.

-

Tooling: Initial costs for specialized equipment and molds can be significant, especially for custom orders. These costs are often amortized over larger production runs, making economies of scale a vital consideration.

-

Quality Control (QC): Ensuring the durability and performance of PU coatings requires rigorous QC processes. While this adds to costs, it is a necessary investment to avoid future liabilities and maintain customer satisfaction.

-

Logistics: Transportation, warehousing, and handling costs must be accounted for, especially for international shipments. Incoterms will influence these expenses, dictating who is responsible for shipping and handling at various stages.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely based on market competition and perceived value of the product.

How Do Price Influencers Affect PU Coated Material Costs?

Several factors can influence the pricing of PU coated materials:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders often result in lower per-unit costs due to economies of scale, but smaller orders may incur higher rates.

-

Specifications and Customization: Custom specifications, such as specific performance characteristics or unique finishes, can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., environmental certifications) typically come at a premium. Buyers should evaluate the necessity of these factors based on their end-use applications.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to capture market share.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can influence total costs. Buyers should understand the implications of these terms on shipping costs and responsibilities.

What Tips Can Help Buyers Negotiate Better Prices for PU Coated Materials?

To maximize value when sourcing PU coated materials, consider these strategies:

-

Negotiate Volume Discounts: If your business anticipates ongoing needs, negotiate for bulk purchasing agreements. Suppliers are often willing to offer discounts for larger commitments.

-

Evaluate Total Cost of Ownership: Consider not just the purchase price but also the long-term costs associated with durability, maintenance, and potential replacements. A higher-quality PU coating may offer better value over time.

-

Research Pricing Nuances: Understand market conditions, including trends in material costs and regional pricing differences. This knowledge can empower you in negotiations and help you identify the best supplier options.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, priority service, and access to exclusive offers or product lines.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, exploring local suppliers can reduce logistics costs and lead times, enhancing overall supply chain efficiency.

Disclaimer

Prices for PU coated materials can vary widely based on numerous factors, including market conditions and supplier specifics. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing and value.

Illustrative image related to pu coated

Alternatives Analysis: Comparing pu coated With Other Solutions

Exploring Alternatives to PU Coated Solutions

When evaluating protective coatings for textiles and outdoor gear, it’s essential to consider various alternatives that offer similar benefits to PU coatings. Each option has its unique attributes, catering to different needs, performance requirements, and budget constraints. In this analysis, we will compare PU coatings with two viable alternatives: Durable Water Repellent (DWR) treatments and PVC coatings.

Comparison Table

| Comparison Aspect | Pu Coated | Durable Water Repellent (DWR) | PVC Coatings |

|---|---|---|---|

| Performance | Highly waterproof, durable | Water-resistant, less durable | Excellent waterproofing, heavy |

| Cost | Moderate to high | Low to moderate | Moderate to high |

| Ease of Implementation | Requires specialized application | Easy, can be done at home | Industrial application needed |

| Maintenance | Requires periodic reproofing | Needs frequent reapplication | Low maintenance, long-lasting |

| Best Use Case | Extreme weather conditions | Light rain, everyday use | Heavy-duty applications |

Understanding Durable Water Repellent (DWR) Treatments

DWR treatments are widely used in the textile industry for their ease of application and cost-effectiveness. They provide a water-resistant finish that repels water but does not create a fully waterproof barrier. The main advantage of DWR is its lightweight nature, making it suitable for garments intended for high-intensity activities. However, DWR treatments require frequent reapplication, especially after washing, to maintain their effectiveness. While they are less durable than PU coatings, they are ideal for everyday use in light rain or misty conditions.

Evaluating PVC Coatings

PVC (polyvinyl chloride) coatings are another alternative, primarily known for their excellent waterproofing capabilities. These coatings are often used in heavy-duty applications, such as industrial tarps and waterproof clothing. One of the significant advantages of PVC is its durability and low maintenance requirements, as it can withstand harsh environmental conditions without degrading. However, PVC is heavier than PU coatings and may not be suitable for applications requiring lightweight fabrics. Additionally, the environmental impact of PVC production and disposal is a concern, making it a less sustainable choice compared to PU coatings.

Conclusion: How to Choose the Right Solution for Your Needs

Choosing the right coating solution depends largely on the specific requirements of your application. For extreme weather protection and durability, PU coatings are an excellent choice, albeit with a higher weight and cost. If your needs lean towards lightweight and breathable options for everyday use, DWR treatments may be more appropriate. On the other hand, if you require heavy-duty waterproofing with minimal maintenance, PVC coatings could be the way to go. By carefully considering the performance, cost, ease of implementation, and maintenance of each option, B2B buyers can make informed decisions that best fit their operational needs and sustainability goals.

Illustrative image related to pu coated

Essential Technical Properties and Trade Terminology for pu coated

Understanding the essential technical properties and trade terminology of PU coatings is crucial for B2B buyers, particularly when sourcing materials for various applications across sectors like outdoor apparel, industrial fabrics, and more. Below, we outline the key specifications and jargon that decision-makers need to know to make informed purchasing choices.

What Are the Key Technical Properties of PU Coatings?

1. Waterproof Rating (mm H2O)

The waterproof rating measures how much water pressure a fabric can withstand before it begins to leak. This rating is expressed in millimeters of water column (mm H2O). A higher rating indicates better waterproofing capabilities, which is vital for outdoor gear that needs to perform in wet conditions. For B2B buyers, understanding the waterproof rating helps in selecting the right materials for specific environmental challenges.

2. Breathability (g/m²/24h)

Breathability refers to the amount of moisture vapor that can escape from the fabric over a 24-hour period, measured in grams per square meter (g/m²). This property is essential for ensuring comfort, especially in active wear. High breathability ratings allow moisture from sweat to escape, reducing the risk of overheating during physical activities. B2B buyers should prioritize this specification when sourcing fabrics for applications requiring comfort in dynamic environments.

3. Durability and Abrasion Resistance (Martindale Test)

Durability is often assessed through the Martindale test, which measures a fabric’s resistance to wear through abrasion. Fabrics that pass this test are deemed suitable for high-use environments, such as outdoor and industrial applications. For buyers, knowing the abrasion resistance can inform choices that balance longevity with performance, particularly in challenging settings.

4. Weight (g/m²)

The weight of PU-coated fabrics is a critical factor for both performance and transportability. Heavier fabrics tend to offer more durability but may be less suitable for lightweight applications, such as running gear. Buyers need to consider the weight specifications to align the fabric choice with the intended use, ensuring that products meet performance expectations without unnecessary bulk.

Illustrative image related to pu coated

5. Tensile Strength (N)

Tensile strength measures how much force a fabric can withstand when being pulled before breaking, expressed in newtons (N). This property is crucial for applications requiring robust and durable materials that can endure stress and strain. Understanding tensile strength allows B2B buyers to select materials that will maintain integrity in demanding conditions.

What Are Common Trade Terms Related to PU Coatings?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of PU coatings, understanding OEM relationships can help buyers establish partnerships that ensure quality and consistency in the materials they source.

2. MOQ (Minimum Order Quantity)

MOQ signifies the minimum number of units a supplier is willing to sell in a single order. This term is essential for B2B buyers to know as it impacts inventory management and overall procurement costs. Buyers should clarify MOQ requirements to avoid over-committing resources.

3. RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to solicit price proposals from suppliers. This process is crucial for obtaining competitive pricing and understanding the cost implications of various options. For effective procurement, buyers should ensure their RFQs are detailed and clear.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery obligations, which are vital for managing supply chain logistics effectively.

Illustrative image related to pu coated

5. DWR (Durable Water Repellent)

DWR is a chemical finish applied to fabrics to enhance water resistance. While not as robust as PU coatings, understanding DWR can help buyers make comparisons between different fabric treatments and their respective performance in waterproofing.

By grasping these essential technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that their selections align with both performance needs and business objectives.

Navigating Market Dynamics and Sourcing Trends in the pu coated Sector

What Are the Current Market Dynamics and Key Trends in the PU Coated Sector?

The global market for polyurethane (PU) coatings is experiencing significant growth, driven by increasing demand in various industries, including textiles, automotive, and construction. Key trends indicate a rising preference for PU coatings due to their durability, waterproofing capabilities, and flexibility. Notably, in regions like Africa, South America, the Middle East, and Europe, the demand for high-performance outdoor gear is on the rise. This is particularly relevant for international B2B buyers sourcing materials for outdoor apparel, where PU coatings provide essential protection against harsh weather conditions.

Emerging technologies such as microporous coatings are enhancing the breathability of PU fabrics, making them more suitable for high-intensity activities while retaining waterproof characteristics. Buyers should be aware of the importance of sourcing materials that incorporate these advanced technologies, as they can significantly enhance product performance and consumer satisfaction. Furthermore, with the shift towards online sourcing platforms, B2B buyers are increasingly leveraging digital tools to assess supplier capabilities, compare pricing, and evaluate product specifications more efficiently.

Additionally, market dynamics are influenced by fluctuating raw material costs and supply chain challenges. Buyers in regions such as Nigeria and Vietnam should remain agile, considering local suppliers that can offer competitive pricing and shorter lead times, thus mitigating the impact of global supply chain disruptions.

How Does Sustainability and Ethical Sourcing Impact the PU Coated Sector?

Sustainability is becoming a cornerstone of procurement strategies in the PU coated sector. As environmental concerns rise, B2B buyers are increasingly prioritizing suppliers that adopt sustainable practices. The environmental impact of PU production, while less harmful than alternatives like fluorocarbon DWR treatments, still poses challenges. This necessitates a focus on suppliers who employ eco-friendly manufacturing processes and offer products with reduced environmental footprints.

Ethical sourcing is equally critical. Buyers should seek suppliers who are transparent about their supply chains and adhere to fair labor practices. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX can serve as benchmarks for assessing the environmental and social governance of suppliers. Opting for PU coatings that use recycled materials or are part of a circular economy can further enhance a company’s sustainability profile.

Additionally, as consumer preferences shift towards environmentally responsible products, B2B buyers can capitalize on this trend by sourcing PU coatings that align with green certifications. This not only meets regulatory compliance but also positions companies favorably in the market, appealing to environmentally conscious consumers.

What Is the Historical Context Behind PU Coatings in B2B Applications?

The evolution of polyurethane coatings began in the early 20th century, with significant advancements in the 1930s when Otto Bayer synthesized the material. Initially utilized for rigid foam insulation, PU quickly found applications in various industries due to its versatility and durability. By the 1940s, PU coatings began to be integrated into textiles, particularly for outdoor apparel, where their waterproofing properties were invaluable.

Over the decades, technological advancements have led to the development of more sophisticated PU coatings, including breathable options that cater to the outdoor market’s evolving demands. This historical context is crucial for B2B buyers, as it highlights the continuous innovation in PU technology and underscores the importance of sourcing from manufacturers who are at the forefront of these developments. Understanding the historical trajectory also helps buyers appreciate the long-term value and reliability of PU-coated products in various applications, from outdoor gear to industrial uses.

Frequently Asked Questions (FAQs) for B2B Buyers of pu coated

-

How do I determine the quality of PU-coated materials from suppliers?

To assess the quality of PU-coated materials, request samples from potential suppliers and conduct tests for waterproofing, durability, and breathability. Look for certifications or standards compliance, such as ISO or ASTM ratings, which indicate reliable quality. Additionally, inquire about the manufacturing processes and materials used, as these can significantly impact performance. Engaging in discussions about their quality control measures will provide insights into their commitment to producing high-quality products. -

What is the best application for PU-coated fabrics?

PU-coated fabrics are ideal for applications requiring waterproof and durable materials, such as outdoor clothing, tents, and protective gear. Their robust nature makes them suitable for harsh environments, while modern microporous technology allows for breathability, enhancing comfort. However, they may not be optimal for high-intensity activities due to weight considerations. Assess your specific needs and environmental conditions to determine if PU coatings align with your product requirements. -

What customization options are available for PU-coated products?

Many suppliers offer customization options for PU-coated products, including different colors, thicknesses, and coatings tailored to specific applications. Discuss your requirements with potential manufacturers to explore available choices. Additionally, inquire about minimum order quantities (MOQs) for customized products, as these can vary significantly between suppliers. Providing detailed specifications will help suppliers understand your needs and deliver appropriate solutions. -

What are the typical payment terms when sourcing PU-coated materials internationally?

Payment terms for international sourcing of PU-coated materials can vary widely depending on the supplier and your relationship with them. Common options include letters of credit, advance payments, or payment upon delivery. It’s crucial to negotiate terms that balance risk and cash flow considerations. Always ensure that payment methods are secure and that you have clear agreements in place to avoid disputes. -

How can I verify the reputation of a PU-coated materials supplier?

To verify a supplier’s reputation, conduct thorough research by checking online reviews, testimonials, and case studies. Request references from previous clients to gauge their satisfaction with the supplier’s products and services. Additionally, consider visiting the supplier’s facilities if feasible, or participating in trade shows where you can engage with them directly. A reputable supplier will be transparent about their processes and eager to provide information. -

What logistics considerations should I keep in mind when importing PU-coated products?

When importing PU-coated products, consider factors such as shipping methods, customs regulations, and potential tariffs. Work with a reliable logistics provider familiar with international trade to navigate these complexities efficiently. Ensure that your supplier provides accurate documentation to facilitate customs clearance. Additionally, plan for lead times, as production and shipping can affect your delivery schedules. -

What quality assurance measures should I expect from PU-coated suppliers?

Reputable PU-coated suppliers should have established quality assurance measures, including regular inspections, testing protocols, and adherence to international standards. Inquire about their quality control processes, such as pre-production samples and final product inspections. A commitment to continuous improvement and customer satisfaction should be evident in their practices. Ensure that they can provide documentation of compliance with relevant quality standards. -

Are there environmental considerations I should be aware of when sourcing PU-coated materials?

When sourcing PU-coated materials, consider the environmental impact of the production processes and the materials used. Inquire about the supplier’s sustainability practices, including waste management and the use of eco-friendly chemicals. Polyurethane coatings are generally more environmentally friendly than traditional DWR treatments, but it’s essential to assess each supplier’s commitment to sustainability. Certifications such as OEKO-TEX can also indicate a more environmentally responsible product.

Top 2 Pu Coated Manufacturers & Suppliers List

1. Ripstop by the Roll – PU Coating

Domain: ripstopbytheroll.com

Registered: 2013 (12 years)

Introduction: PU Coating (Polyurethane Coating) is a widely used coating in outdoor textiles due to its cost-effectiveness, ease of sealing with seam tapes, and durability. It is typically applied to the back of fabrics to make them waterproof and protect the coating. Pros include simple seam taping, low cost, high waterproof capability, and compatibility with fire retardant chemicals, making it suitable for ba…

2. Columbia – PU Coated Shells

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: PU Coated: Low breathability, superior waterproofing, silicon coated material, usually nylon backer, requires frequent venting in cold environments, no maintenance needed. Example: Columbia shells.

Goretex (EPTFE): Very waterproof and breathable up to a point, lets vapor through if outside gradient is lower, can trap moisture in warm, rainy conditions, medium maintenance due to DWR reapplication…

Strategic Sourcing Conclusion and Outlook for pu coated

In the evolving landscape of B2B sourcing, understanding the nuances of PU coatings is essential for international buyers, especially in regions like Africa, South America, the Middle East, and Europe. PU coatings offer significant advantages, including durability, waterproofing, and flexibility, making them ideal for various applications—from outdoor clothing to industrial textiles. The ability to source high-quality PU-coated materials can directly impact product performance and customer satisfaction.

Strategic sourcing of PU-coated products not only enhances product offerings but also ensures compliance with environmental standards, as PU coatings present a more sustainable alternative to traditional DWR treatments. As global markets increasingly prioritize sustainability, aligning sourcing strategies with these trends will be crucial for maintaining competitive advantage.

Looking ahead, international buyers should focus on building partnerships with reliable suppliers who can provide innovative and environmentally friendly PU-coated solutions. Engaging with manufacturers that prioritize quality and sustainability will not only meet current market demands but also prepare businesses for future challenges. Now is the time to leverage the benefits of PU coatings in your sourcing strategy to ensure resilience and success in an ever-changing marketplace.

Illustrative image related to pu coated

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.