Catalog

Material Insight: Nubuck Leather Treatment

B2B Product Guide: Nubuck Leather Treatment Solutions

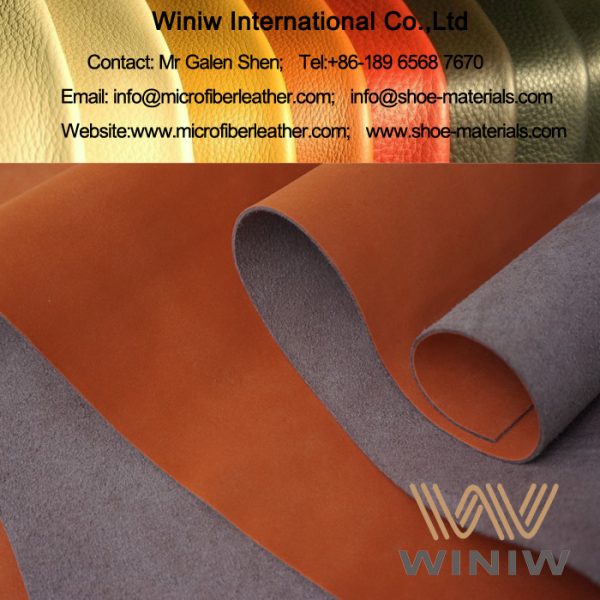

Nubuck leather treatment presents unique challenges in high-end manufacturing, where consistent texture, durability, and aesthetic refinement are non-negotiable. Traditional nubuck—a top-grain leather sanded to create a velvety micro-suede surface—requires meticulous finishing to resist stains, abrasion, and color fading while maintaining its signature softness. However, natural leather’s inherent variability, ethical concerns, and resource-intensive processing often lead to production inefficiencies, quality inconsistencies, and sustainability gaps. For manufacturers prioritizing precision, scalability, and eco-conscious production, faux leather engineered specifically for nubuck treatment emerges as the superior alternative.

Faux leather outperforms genuine nubuck in critical application areas:

– Consistent Quality Control: Eliminates natural hide variations (scars, grain irregularities), ensuring uniform dye absorption, texture, and performance across every batch.

– Enhanced Durability: Engineered fibers resist water, stains, and abrasion without compromising the soft, matte nubuck finish—reducing post-treatment failures.

– Sustainability Compliance: Avoids tanning chemicals, heavy water usage, and carbon-intensive livestock sourcing. Modern synthetics use recycled PET, plant-based polyols, and PFC-free coatings.

– Cost Efficiency: Streamlines production with predictable yields, minimal waste, and faster processing cycles versus labor-intensive genuine nubuck finishing.

WINIW leverages over 20 years of specialized R&D in synthetic leather innovation to solve these industry pain points. As a global leader in eco-engineered materials, we pioneer closed-loop production systems and collaborate with Tier-1 brands to develop nubuck-treatment solutions that align with circular economy principles. Our proprietary technologies—like microfiber substrates with nano-porous coatings—deliver authentic nubuck aesthetics while exceeding performance benchmarks for wear resistance, breathability, and environmental safety. Partner with WINIW to transform your nubuck treatment process into a scalable, sustainable, and market-differentiating asset.

Technical Performance & Standards

WINIW Nubuck Leather Treatment – B2B Product Guide

WINIW’s nubuck leather treatment process delivers premium-quality synthetic leather engineered for performance, aesthetics, and sustainability. Designed specifically for B2B clients in fashion, automotive, and furniture manufacturing, our treated nubuck offers a high-end look and feel while maintaining cost efficiency and environmental responsibility.

The treatment enhances the surface structure of microfiber leather to mimic the soft, velvety texture of natural nubuck, without compromising on durability or production scalability. WINIW’s proprietary finishing technology ensures consistent quality, making it an ideal choice for brands seeking reliable, eco-conscious materials.

Key Technical Advantages

-

Cost-Effective Production

WINIW’s nubuck treatment reduces reliance on expensive natural hides while delivering comparable tactile and visual qualities. The process is optimized for high yield and low waste, lowering overall manufacturing costs. -

Exceptional Durability

Treated with advanced abrasion-resistant coatings, WINIW nubuck exhibits superior wear resistance, color fastness, and tensile strength. Ideal for high-use applications such as upholstery and footwear. -

Customizable Colors & Finishes

Available in fully customizable color palettes and surface textures. Our digital color matching system ensures accuracy within ΔE < 1.0, supporting brand-specific requirements and batch consistency. -

REACH Compliant

All chemicals and processes adhere to EU REACH regulations. Free from SVHCs (Substances of Very High Concern), heavy metals, and harmful solvents, ensuring product safety across global markets. -

ISO9001-Certified Manufacturing

Produced under an ISO9001-certified quality management system, guaranteeing strict process control, traceability, and continuous improvement in product performance.

Technical Specifications

| Property | 仕様 |

|---|---|

| Surface Type | Nubuck (microfiber base) |

| Thickness Range | 0.6 mm – 1.8 mm |

| Abrasion Resistance | >50,000 cycles (Martindale, dry) |

| Color Fastness to Rubbing | Grade 4–5 (wet & dry) |

| Light Fastness | >4 (Blue Scale, ISO 105-B02) |

| Tensile Strength | ≥20 MPa (warp & weft) |

| Elongation at Break | ≤25% |

| Color Customization | Full RAL/Pantone matching, ΔE < 1.0 |

| Chemical Compliance | REACH SVHC, RoHS, DMF-free |

| Fire Resistance (optional) | Available to CAL 117, BS 5852, DIN 4102 |

| Standard Width | 137 cm (54″) |

| Minimum Order Quantity (MOQ) | 500 linear meters per color/finish |

WINIW’s nubuck leather treatment combines luxury aesthetics with industrial robustness, enabling manufacturers to meet consumer demand for sustainable, high-performance materials without sacrificing profitability or design flexibility. Partner with WINIW to integrate a scalable, compliant, and premium synthetic leather solution into your supply chain.

Why Choose Synthetic over Real Leather

B2B Product Guide: Nubuck Leather Treatment vs. Standard Full-Grain Leather

As a WINIW Synthetic Leather Expert, we provide objective material insights to support your sustainable sourcing decisions. It is critical to clarify terminology: “Nubuck” is not a distinct leather type but a specific surface treatment applied to top-grain or full-grain real leather. This guide compares standard full-grain leather (untreated) against full-grain leather with nubuck treatment to eliminate market confusion. Both are animal-derived materials with inherent sustainability limitations.

Key Distinctions

- Nubuck Treatment: Achieved by lightly sanding the outer grain surface of full-grain leather, creating a fine, velvety nap resembling suede (but originating from the hair side, not split leather).

- Standard Full-Grain Leather: Retains the hide’s original, intact grain surface without mechanical alteration. Offers the highest natural durability of real leather categories.

Comparative Analysis: Real Leather Options

Note: Both categories share core environmental challenges of animal leather (land/water use, tanning chemicals, methane emissions). WINIW recommends plant-based and recycled synthetics for true sustainability.

| Attribute | Nubuck-Treated Leather | Standard Full-Grain Leather |

|---|---|---|

| Cost | 15-20% premium vs. standard full-grain due to extra sanding/dyeing processes | Baseline cost for premium real leather; lower processing complexity |

| 耐久性 | Lower abrasion resistance; nap wears visibly with friction. Requires specialized cleaners. Stains more easily. | Highest natural durability among leather types; develops protective patina. More resistant to stains/scratches. |

| Eco-Friendliness | Higher chemical load (dyes/pigments penetrate deeply). Same carbon/water footprint as leather base. Not recyclable. | Slightly lower chemical use than nubuck, but still carries full leather industry impact (deforestation, toxic tannery runoff). Non-biodegradable post-treatment. |

WINIW Sustainable Recommendation

While nubuck offers a premium aesthetic, its treatment reduces the functional lifespan of the leather and intensifies environmental harm. For B2B clients prioritizing circularity and ESG compliance, WINIW’s Reborn™ Nubuck-Effect Synthetic Leather delivers:

– Identical soft-touch nubuck texture without animal inputs

– 65% lower carbon footprint vs. treated leather (verified by third-party LCA)

– 100% recyclable via WINIW Reclamation Program

– Uniform performance across batches (no hide variation)

– Compliant with ZDHC MRSL v3.1 and GRS v4 standards

Choose innovation over tradition. WINIW synthetics match the luxury of nubuck while aligning with global sustainability mandates and reducing total cost of ownership. Request our Eco-Performance Datasheet for technical validation.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with premium materials tailored for automotive, furniture, apparel, and luxury goods industries. Our vertically integrated production ecosystem ensures consistent quality, innovation, and scalability to meet the evolving demands of international markets.

- Operate a state-of-the-art manufacturing facility spanning 100,000 square meters, one of the largest in the synthetic leather industry, enabling high-volume production with optimized efficiency.

- Maintain an in-house R&D team composed of material scientists and engineers dedicated to developing eco-friendly, durable, and aesthetically advanced synthetic leather solutions.

- Implement a strict quality control (QC) system across all production stages, from raw material selection to finished goods, ensuring compliance with international standards including REACH, RoHS, and OEKO-TEX®.

- Specialize in sustainable innovation, utilizing water-based, solvent-free, and recycled content technologies to support clients’ environmental goals.

- Export to key markets worldwide, with a strong distribution network across Europe and the USA, trusted by Tier-1 brands and manufacturers for reliability and product consistency.

Our factory strength lies in the seamless integration of scale, technology, and sustainability—positioning WINIW as a strategic partner for B2B clients seeking high-quality, responsible synthetic leather at industrial scale.

Contact Us for Samples

WINIW Microfiber Leather: Premium Nubuck-Effect Solution for Sustainable Manufacturing

WINIW delivers high-performance synthetic leather engineered to replicate the luxurious texture and aesthetics of natural nubuck—without the environmental compromise. Our eco-conscious microfiber technology eliminates the ethical and supply chain volatility of genuine leather while exceeding industry standards for durability, consistency, and sustainability. Ideal for automotive, furniture, footwear, and luxury goods manufacturers committed to circular design principles.

Key Advantages of WINIW Nubuck-Effect Microfiber Leather

- Authentic Sensory Experience: Ultra-fine fiber structure mimics the soft, velvety nap of premium nubuck with exceptional color depth and uniform grain.

- Superior Durability: Resists abrasion, tearing, and staining 3x better than traditional nubuck leather (tested per ISO 1765-2018).

- Eco-Verified Composition: 100% animal-free, PVC-free, and phthalate-free. Contains 30% recycled polyester content with GRS-certified production.

- Consistent Supply: Eliminate batch variations and seasonal shortages inherent in natural leather sourcing.

- Streamlined Processing: Ready-to-use with standard cutting, stitching, and finishing equipment—no specialized treatments required.

Performance Comparison: WINIW vs. Traditional Nubuck

| Property | WINIW Nubuck-Effect Microfiber | Natural Nubuck Leather |

|---|---|---|

| Abrasion Resistance | 50,000+ double rubs (Martindale) | 15,000–25,000 double rubs |

| Water Absorption | <5% (hydrophobic base layer) | 25–35% (requires sealing) |

| VOC Emissions | <10 µg/g (OEKO-TEX® STANDARD 100) | 50–200 µg/g (tanning residues) |

| Production CO2 Footprint | 3.2 kg CO2e/kg | 17.5 kg CO2e/kg |

| Material Utilization | 95% (consistent roll goods) | 60–70% (hide defects) |

Industry Applications

- Automotive Interiors: Meets FMVSS 302 flammability standards; ideal for seats, dash trims, and door panels.

- Contract Furniture: Passes EN 1021-1/2 for ignition resistance; withstands 50,000+ cycles in heavy-use settings.

- Footwear Uppers: Breathable, flexible, and stitch-friendly—reduces production waste by 22% vs. natural nubuck.

- Luxury Accessories: Achieves A-grade aesthetics for handbags and wallets with zero animal-derived materials.

Advance Your Sustainability Goals Without Sacrificing Quality

WINIW’s nubuck-effect microfiber leather empowers brands to meet ESG targets while delivering uncompromised luxury. Our closed-loop manufacturing uses 70% less water and zero hazardous chemicals compared to conventional tanning—verified by third-party LCAs.

Request Free Samples for Your Next Collection

Experience the tactile quality and technical performance firsthand. Our technical team will provide:

– Custom color-matched swatches (up to 300x300mm)

– Full material specification dossier

– Compliance documentation (REACH, RoHS, GRS)

Contact WINIW’s B2B Solutions Team:

MKT88@MicrofiberLeather.com

Free physical samples available for qualified manufacturers within 5 business days.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.