Introduction: Navigating the Global Market for motorcycle seat cover fabric

In the competitive landscape of motorcycle seat cover fabric, international B2B buyers face a significant challenge: sourcing materials that not only meet quality standards but also align with diverse market needs across regions like Africa, South America, the Middle East, and Europe. The right fabric can enhance rider comfort, improve aesthetic appeal, and withstand the rigors of varied climates. This guide delves into the multifaceted world of motorcycle seat cover fabric, exploring various types, applications, and innovative materials tailored for different motorcycle models and riding conditions.

Throughout this comprehensive resource, buyers will gain insights into the latest trends in motorcycle upholstery, including durable vinyl options and custom design possibilities. We will also address critical factors such as supplier vetting processes, cost considerations, and logistics challenges unique to international markets. By equipping B2B buyers with actionable knowledge, this guide empowers them to make informed purchasing decisions that enhance their product offerings and meet customer demands effectively.

Understanding the nuances of motorcycle seat cover fabric sourcing is essential for businesses aiming to thrive in a global marketplace. Whether you are a manufacturer, retailer, or distributor, this guide serves as your roadmap to navigating the complexities of material selection, ensuring you can confidently cater to the diverse preferences of motorcycle enthusiasts worldwide.

Table Of Contents

- Top 6 Motorcycle Seat Cover Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for motorcycle seat cover fabric

- Understanding motorcycle seat cover fabric Types and Variations

- Key Industrial Applications of motorcycle seat cover fabric

- 3 Common User Pain Points for ‘motorcycle seat cover fabric’ & Their Solutions

- Strategic Material Selection Guide for motorcycle seat cover fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat cover fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat cover fabric’

- Comprehensive Cost and Pricing Analysis for motorcycle seat cover fabric Sourcing

- Alternatives Analysis: Comparing motorcycle seat cover fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for motorcycle seat cover fabric

- Navigating Market Dynamics and Sourcing Trends in the motorcycle seat cover fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat cover fabric

- Strategic Sourcing Conclusion and Outlook for motorcycle seat cover fabric

- Important Disclaimer & Terms of Use

Understanding motorcycle seat cover fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vinyl Upholstery | Water-resistant, abrasion-resistant, easy to clean | Custom motorcycle seat covers, DIY projects | Pros: Durable, stylish, low maintenance. Cons: Can be less breathable than other materials. |

| Neoprene | Flexible, shock-absorbing, resistant to UV rays | High-performance motorcycles, racing seats | Pros: Excellent comfort, good grip. Cons: Higher cost, may require more care. |

| Leather | Premium look, natural feel, durable | Luxury motorcycles, custom builds | Pros: Aesthetic appeal, long-lasting. Cons: Higher price, requires maintenance. |

| Fabric (Polyester) | Lightweight, breathable, varied designs | Casual motorcycles, budget-friendly options | Pros: Affordable, wide variety of patterns. Cons: Less durable compared to vinyl or leather. |

| Canvas | Heavy-duty, water-resistant, durable | Off-road motorcycles, utility applications | Pros: Very strong, resistant to wear. Cons: Can be heavier, limited color options. |

What Are the Characteristics of Vinyl Upholstery for Motorcycle Seats?

Vinyl upholstery is a popular choice for motorcycle seat covers due to its water resistance and durability. It is also easy to clean, making it ideal for various weather conditions. B2B buyers should consider the thickness and quality of the vinyl, as these factors can significantly affect the longevity and appearance of the seat cover. Vinyl is suitable for custom motorcycle seat covers and DIY projects, providing a balance between style and functionality.

How Does Neoprene Benefit Motorcycle Seat Comfort?

Neoprene is known for its flexibility and shock-absorbing properties, which enhance rider comfort. It is resistant to UV rays, making it suitable for high-performance motorcycles and racing applications. Buyers should evaluate the neoprene’s density and thickness, as these will influence the overall comfort and durability. While neoprene tends to be more expensive than vinyl, its superior comfort and grip can justify the investment for serious riders and manufacturers focusing on performance.

Illustrative image related to motorcycle seat cover fabric

Why Choose Leather for Luxury Motorcycle Seats?

Leather offers a premium look and natural feel that appeals to high-end motorcycle enthusiasts. It is durable and can withstand wear, making it a long-lasting option. However, buyers should consider the maintenance requirements, as leather needs regular conditioning to maintain its appearance. For B2B applications, leather is often selected for luxury motorcycles and custom builds, where aesthetics and quality are paramount.

What Are the Advantages of Using Polyester Fabric for Motorcycle Seats?

Polyester fabric is lightweight and breathable, making it a practical choice for casual motorcycles and budget-friendly options. It comes in a wide variety of designs and colors, allowing for customization. However, B2B buyers should be aware that while polyester is affordable, it may not be as durable as vinyl or leather. It is essential to assess the fabric’s weight and weave for better performance in different riding conditions.

When Should Canvas Be Considered for Motorcycle Seat Covers?

Canvas is a heavy-duty material known for its durability and water resistance, making it ideal for off-road motorcycles and utility applications. It can withstand harsh conditions and is resistant to wear and tear. However, canvas can be heavier than other options, and color choices may be limited. B2B buyers should evaluate the specific use cases for canvas, as it may be the best choice for rugged, outdoor environments where durability is critical.

Illustrative image related to motorcycle seat cover fabric

Key Industrial Applications of motorcycle seat cover fabric

| Industry/Sector | Specific Application of motorcycle seat cover fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom motorcycle seat covers | Enhanced brand differentiation and customer loyalty | Quality of materials, customization options, and durability |

| Motorcycle Retail | Aftermarket seat cover solutions | Increased sales from upgrades and repairs | Availability of diverse styles and materials, bulk pricing |

| Motorcycle Rental | Durable seat covers for rental fleets | Reduced maintenance costs and improved customer satisfaction | Resistance to wear and tear, ease of cleaning |

| Custom Upholstery | Tailored seat covers for bespoke motorcycles | Unique offerings that attract niche markets | Fabric quality, customization capabilities, and lead times |

| Marine Applications | Waterproof seat covers for marine motorcycles | Protection against harsh environments and longevity | UV resistance, waterproofing features, and color fastness |

How is Motorcycle Seat Cover Fabric Used in Automotive Manufacturing?

In the automotive manufacturing sector, motorcycle seat cover fabric is essential for creating custom seat covers that enhance the aesthetic appeal and comfort of motorcycles. Manufacturers can differentiate their products by offering unique designs and materials that cater to specific customer preferences. International buyers, particularly from Africa and South America, should prioritize sourcing high-quality, durable fabrics that withstand varying weather conditions while offering customization options to meet local market demands.

What Role Does Motorcycle Seat Cover Fabric Play in Motorcycle Retail?

Motorcycle retailers utilize aftermarket seat cover solutions to boost their sales by providing customers with options for upgrading or repairing their motorcycles. These covers not only enhance the look of the motorcycle but also improve comfort and functionality. For buyers in Europe and the Middle East, it’s crucial to consider the availability of diverse styles and materials, as well as attractive bulk pricing that can make these products more appealing to the end consumer.

How Are Durable Seat Covers Beneficial for Motorcycle Rental Services?

In the motorcycle rental industry, durable seat covers are vital to maintaining the fleet’s condition while ensuring customer satisfaction. These covers protect the seats from wear and tear, making them a cost-effective solution that reduces maintenance expenses. Buyers from regions with high tourist traffic, such as Brazil and Vietnam, should focus on sourcing seat covers that offer resistance to stains and easy cleaning, as this will significantly enhance the rental experience.

Illustrative image related to motorcycle seat cover fabric

Why Are Custom Upholstery Solutions Important for Tailored Motorcycles?

Custom upholstery businesses rely on motorcycle seat cover fabric to create bespoke seat covers tailored to individual customer needs. This sector thrives on offering unique products that cater to niche markets, allowing businesses to stand out in a competitive landscape. International buyers should seek suppliers that provide high-quality fabric options, robust customization capabilities, and reasonable lead times, ensuring that their offerings meet the specific demands of their clientele.

How Does Motorcycle Seat Cover Fabric Address Marine Applications?

In marine applications, motorcycle seat cover fabric is used to produce waterproof seat covers for marine motorcycles, protecting them from harsh environmental conditions. This application is particularly important for businesses operating in coastal regions where exposure to saltwater and UV rays is prevalent. Buyers should prioritize sourcing materials that offer UV resistance and waterproofing features, ensuring the longevity and performance of their products in challenging marine environments.

3 Common User Pain Points for ‘motorcycle seat cover fabric’ & Their Solutions

Scenario 1: Ensuring Durability in Varied Climates

The Problem: B2B buyers sourcing motorcycle seat cover fabric often face the challenge of finding materials that can withstand diverse climatic conditions. For example, a company operating in South America may need fabrics that resist high humidity and UV exposure, while a buyer in Europe might prioritize cold weather resistance. Choosing the wrong material can lead to premature wear and tear, resulting in customer dissatisfaction and increased returns.

The Solution: To address these durability concerns, buyers should prioritize sourcing high-quality fabrics specifically designed for varied environmental conditions. Look for upholstery vinyls with UV resistance and water-repellent properties, as well as those treated for abrasion resistance. Brands like Morbern™ and Naugahyde® offer specialized motorcycle vinyl that performs well under extreme weather. Additionally, conducting thorough market research to understand the specific climate conditions in your target regions will allow you to select the most suitable materials. Sample testing can also help ensure that the fabric meets durability standards before making larger orders.

Scenario 2: Balancing Comfort and Aesthetics

The Problem: Another common pain point for B2B buyers is finding a motorcycle seat cover fabric that offers both comfort and visual appeal. Customers increasingly demand stylish designs that do not compromise on comfort, especially for long rides. Buyers must navigate the fine line between selecting materials that enhance comfort (like gel inserts or padded fabrics) and those that provide an attractive finish.

Illustrative image related to motorcycle seat cover fabric

The Solution: To effectively balance comfort and aesthetics, consider fabrics that allow for customization. Many suppliers now offer options that can be combined with gel inserts or foam padding, enhancing comfort without sacrificing style. For instance, opting for a fabric that can be easily embroidered or printed with custom designs will cater to both aesthetic preferences and comfort needs. Additionally, providing your customers with a range of color and texture options can help them make informed decisions that align with their brand identity and consumer expectations. Engaging with suppliers who offer customization services can further enhance your product line.

Scenario 3: Managing Supply Chain Challenges

The Problem: Global supply chain disruptions can significantly impact the availability and delivery timelines of motorcycle seat cover fabrics. B2B buyers may find that they are unable to secure the necessary materials due to international shipping delays or production limitations, which can stall their production schedules and lead to lost revenue.

The Solution: To mitigate supply chain risks, B2B buyers should diversify their supplier base and consider sourcing materials from multiple regions. Establishing relationships with local manufacturers can reduce dependency on international shipping and improve lead times. Additionally, buyers should consider maintaining a buffer stock of essential materials to guard against future disruptions. Regularly communicating with suppliers about their inventory levels and production capabilities can also provide insights into potential delays, allowing buyers to adjust their procurement strategies proactively. Utilizing technology for real-time tracking of orders can further enhance visibility and help manage expectations with customers regarding delivery timelines.

Illustrative image related to motorcycle seat cover fabric

By addressing these common pain points with actionable strategies, B2B buyers can enhance their operations and provide better products to their customers, ultimately leading to improved satisfaction and loyalty.

Strategic Material Selection Guide for motorcycle seat cover fabric

When selecting materials for motorcycle seat cover fabric, several options stand out due to their unique properties, advantages, and limitations. Understanding these materials is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Vinyl for Motorcycle Seat Covers?

Vinyl is one of the most common materials used for motorcycle seat covers. It is known for its excellent water resistance, abrasion resistance, and UV stability, making it suitable for various climates. Vinyl’s temperature tolerance typically ranges from -60°F to 180°F, allowing it to perform well under extreme conditions.

Pros: Vinyl is durable, easy to clean, and available in a wide range of colors and textures. It is also cost-effective, making it a preferred choice for manufacturers.

Illustrative image related to motorcycle seat cover fabric

Cons: However, vinyl can be less breathable than other materials, which may lead to discomfort during long rides in hot weather. Additionally, its environmental impact is a concern, as it is not biodegradable.

How Does Leather Compare as a Motorcycle Seat Cover Material?

Leather is another popular choice for motorcycle seat covers, known for its aesthetic appeal and comfort. High-quality leather can withstand significant wear and tear, offering a luxurious feel that many riders prefer.

Pros: Leather is breathable, providing comfort in varying temperatures, and it can be treated for water resistance. Its natural look and feel can enhance the overall design of a motorcycle.

Illustrative image related to motorcycle seat cover fabric

Cons: The primary drawbacks of leather include its higher cost and maintenance requirements. It can be susceptible to damage from UV rays and moisture if not properly treated, which may affect its longevity.

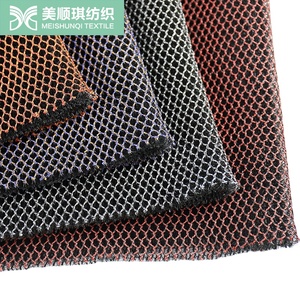

What Are the Benefits of Fabric-Based Materials for Motorcycle Seats?

Fabric-based materials, such as polyester blends, are increasingly being used for motorcycle seat covers. These materials are often treated to enhance their durability and resistance to wear.

Pros: Fabrics are generally lightweight, breathable, and available in various designs, making them a versatile option. They are often more affordable than leather and can be engineered for specific performance attributes, such as water resistance and UV protection.

Cons: On the downside, fabric materials may not offer the same level of abrasion resistance as vinyl or leather, which can lead to quicker wear in high-contact areas. Additionally, they may require more frequent cleaning to maintain appearance.

What Should B2B Buyers Consider When Choosing Motorcycle Seat Cover Materials?

International B2B buyers should consider compliance with local standards, such as ASTM, DIN, or JIS, which can vary by region. For instance, buyers in Europe may prioritize materials that meet stringent environmental regulations, while those in Africa and South America might focus on cost-effectiveness and availability. Understanding local preferences for aesthetics and performance can also guide material selection.

Illustrative image related to motorcycle seat cover fabric

Summary Table of Material Selection for Motorcycle Seat Covers

| Material | Typical Use Case for motorcycle seat cover fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | General-purpose motorcycle seats | Excellent water and abrasion resistance | Less breathable, environmental concerns | Low |

| Leather | Premium motorcycle seats | Luxurious feel, breathable | Higher cost, requires maintenance | High |

| Fabric (Polyester) | Sport and touring motorcycles | Lightweight, versatile designs | Less abrasion resistance, requires frequent cleaning | Medium |

By carefully evaluating these materials, B2B buyers can make informed decisions that align with their market demands and customer preferences, ensuring the production of high-quality motorcycle seat covers that meet diverse needs.

In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat cover fabric

What Are the Key Stages in the Manufacturing Process of Motorcycle Seat Cover Fabric?

The manufacturing of motorcycle seat cover fabric involves several critical stages that ensure the end product meets durability, comfort, and aesthetic standards. The primary phases are material preparation, forming, assembly, and finishing.

-

Material Preparation: This stage begins with the selection of appropriate fabrics, typically high-quality vinyl or synthetic materials that are resistant to water, UV rays, and abrasion. Suppliers often conduct rigorous assessments to ensure that the materials meet international standards, such as ISO 9001, which emphasizes quality management systems. Material samples are also tested for colorfastness and tensile strength before bulk production begins.

-

Forming: During this phase, the selected fabric is cut to specific patterns based on the design of the seat cover. Advanced cutting techniques, such as laser cutting or die-cutting, are often employed to ensure precision. This minimizes material waste and ensures that each piece fits perfectly during assembly. Manufacturers may also use CAD software to optimize cutting layouts, taking into account fabric grain and stretch characteristics.

-

Assembly: The assembly process involves sewing the cut fabric pieces together. Industrial sewing machines are utilized for this purpose, and skilled operators must be adept at handling various types of stitches, including straight, zigzag, and topstitching. Additional features, such as padding or gel inserts, may be integrated at this stage to enhance comfort. Quality checks are typically performed throughout this process to ensure that stitching is consistent and free of defects.

-

Finishing: The final stage includes the application of any additional treatments, such as water repellents or UV protectants. Each seat cover is inspected for quality, ensuring that there are no visible flaws and that all specifications are met. This may also involve pressing and packaging the products for distribution.

What Quality Assurance Measures Are Essential for Motorcycle Seat Cover Fabric?

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that the final product adheres to both international and industry-specific standards.

-

What Are the Relevant International Standards?: For B2B buyers, understanding the applicable international standards is vital. ISO 9001 is the primary standard for quality management systems, which helps organizations ensure they meet customer and regulatory requirements. Additionally, certifications such as CE mark for safety and API standards for performance may be relevant depending on the specific applications of the motorcycle seat covers.

-

What Are the Key Quality Control Checkpoints?: Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Materials must meet predefined specifications before they are approved for production.

– In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are performed to monitor the quality of workmanship and materials. This includes checking for proper stitching, alignment, and adherence to design specifications.

– Final Quality Control (FQC): This final checkpoint occurs after assembly and before packaging. The finished products are thoroughly inspected for defects, ensuring that they meet all quality standards before shipping. -

What Common Testing Methods Are Utilized?: Various testing methods are employed to assess the durability and performance of motorcycle seat cover fabrics. Common tests include:

– Abrasion Resistance Testing: Evaluates how well the fabric withstands wear and tear.

– Water Resistance Testing: Assesses the fabric’s ability to repel water, crucial for outdoor use.

– UV Resistance Testing: Measures the fabric’s ability to resist fading and degradation from sunlight exposure.

How Can B2B Buyers Verify Supplier Quality Control Processes?

When sourcing motorcycle seat cover fabric, B2B buyers must take proactive steps to ensure their suppliers adhere to robust quality control processes.

-

Conducting Supplier Audits: Regular audits allow buyers to assess the manufacturing processes and quality control measures firsthand. During these audits, it’s essential to evaluate the factory’s compliance with international standards and the effectiveness of their quality management system.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports that outline their testing methodologies, results, and any certifications obtained. This documentation serves as a valuable tool for buyers to verify that the products meet their quality requirements.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing process and the quality of the finished products. These inspectors can conduct pre-shipment inspections to ensure compliance with agreed specifications and standards.

What Nuances Should International Buyers Consider for Quality Control?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must navigate specific nuances related to quality control and supplier verification.

Illustrative image related to motorcycle seat cover fabric

-

Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality. Buyers should engage with suppliers to understand their quality management practices and ensure alignment with international standards.

-

Logistical Considerations: Shipping and logistics can impact the quality of the product during transit. Buyers should discuss packaging solutions with suppliers to minimize the risk of damage during transportation.

-

Regulatory Compliance: Understanding local regulations related to materials and product safety is essential. Buyers should ensure that their suppliers are compliant with both local and international regulations to avoid potential legal issues.

By comprehensively understanding the manufacturing processes and implementing effective quality assurance measures, B2B buyers can secure high-quality motorcycle seat cover fabrics that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat cover fabric’

The procurement of motorcycle seat cover fabric requires careful consideration and strategic planning to ensure the best outcomes for your business. This guide will provide a practical checklist to assist B2B buyers in sourcing high-quality materials that meet their specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in the sourcing process. Consider factors such as fabric type, thickness, water resistance, UV protection, and abrasion resistance. These specifications will guide your search for suitable suppliers and ensure the materials meet the performance needs of your motorcycle seat covers.

Step 2: Research Market Trends and Material Innovations

Stay informed about current trends in motorcycle seat cover fabrics. Innovations such as eco-friendly materials or enhanced durability features can give your products a competitive edge. Researching market trends helps you identify what consumers are looking for, allowing you to align your offerings with market demand.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is essential. Request comprehensive company profiles, production capabilities, and client references, especially from businesses in similar regions or industries. Assess their track record in delivering quality fabrics and their responsiveness to customer inquiries.

Illustrative image related to motorcycle seat cover fabric

- Look for Certifications: Ensure suppliers have relevant quality certifications, such as ISO or material safety standards, which reflect their commitment to quality and safety.

Step 4: Request Fabric Samples

Always request samples of the fabric you are considering. This allows you to evaluate the texture, color, and quality firsthand. Testing samples for durability, ease of cleaning, and overall appearance is crucial, as these factors significantly impact customer satisfaction.

Step 5: Assess Pricing and Payment Terms

Understanding the pricing structure is vital for budgeting and cost management. Request detailed quotes from potential suppliers, including any bulk purchase discounts or shipping costs. Additionally, clarify payment terms and conditions to avoid any misunderstandings later in the procurement process.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted suppliers, engage in negotiations to secure the best possible terms. Discuss lead times, minimum order quantities, and warranty options. A clear agreement will help mitigate risks and ensure both parties have aligned expectations.

Step 7: Establish Quality Control Processes

After selecting a supplier, set up quality control processes to monitor the consistency and quality of the fabric received. This may include regular inspections, testing for durability, and ensuring compliance with the initial specifications. Effective quality control ensures your final products maintain high standards and meet customer expectations.

Illustrative image related to motorcycle seat cover fabric

By following these steps, B2B buyers can streamline the sourcing process for motorcycle seat cover fabric, ensuring they secure high-quality materials that enhance their product offerings and satisfy their customers.

Comprehensive Cost and Pricing Analysis for motorcycle seat cover fabric Sourcing

What Are the Key Cost Components in Motorcycle Seat Cover Fabric Sourcing?

When sourcing motorcycle seat cover fabric, several cost components contribute to the overall pricing structure. Key elements include:

-

Materials: The choice of fabric significantly impacts costs. Vinyl upholstery, for instance, ranges from economical options to premium materials that offer enhanced durability and aesthetics. Specialty fabrics like marine-grade vinyl may also incur higher costs due to their specific properties.

-

Labor: Labor costs can vary based on the complexity of the seat cover design and the manufacturing location. Regions with lower labor costs may offer competitive pricing but can compromise on quality if not managed effectively.

-

Manufacturing Overhead: This encompasses costs related to equipment, facilities, and utilities. Efficient operations can minimize overhead, thus lowering the final price for buyers.

-

Tooling: Custom tooling for specialized designs or features, such as embroidery or unique stitching patterns, adds to upfront costs. However, these investments can result in higher-value products.

-

Quality Control (QC): Rigorous QC processes ensure that the final product meets the desired specifications. While this can increase costs, it minimizes returns and enhances customer satisfaction.

-

Logistics: Transporting materials and finished products can significantly affect pricing, especially for international buyers. Shipping costs can fluctuate based on distance, freight method, and current fuel prices.

-

Margin: Suppliers typically add a margin to cover their risks and ensure profitability. Understanding typical margins in the industry can aid in negotiation.

How Do Price Influencers Affect Motorcycle Seat Cover Fabric Costs?

Several factors influence the pricing of motorcycle seat cover fabrics:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders generally attract better pricing due to economies of scale. Suppliers are often willing to negotiate lower rates for larger commitments.

-

Specifications and Customization: Custom designs or specific fabric characteristics (e.g., UV resistance, waterproofing) can increase costs. Buyers should weigh the benefits of customization against potential budget constraints.

-

Material Quality and Certifications: Fabrics that meet specific quality standards or certifications may command higher prices. However, such investments often lead to better performance and customer satisfaction.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can also influence pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The agreed-upon shipping terms can significantly affect total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence the final price and who bears the shipping costs.

What Are the Best Buyer Tips for Sourcing Motorcycle Seat Cover Fabrics?

-

Negotiate Effectively: Always negotiate pricing, especially for larger orders. Suppliers may have flexibility in their margins, particularly when they seek to secure long-term relationships.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also logistics, maintenance, and durability. A slightly higher initial investment in quality materials can lead to lower long-term costs.

-

Understand Pricing Nuances: International buyers must be aware of currency fluctuations, tariffs, and local regulations that can impact pricing. For instance, importing materials into Africa or South America might involve additional costs that affect the final price.

-

Research Local Suppliers: For buyers in regions like Africa and South America, local suppliers may offer competitive pricing and reduced shipping costs. Engaging with regional manufacturers can provide better support and more responsive service.

-

Request Samples: Before committing to a large order, request samples to assess material quality and suitability. This step can prevent costly mistakes and ensure satisfaction with the final product.

By understanding these cost components, pricing influencers, and effective sourcing strategies, B2B buyers can make informed decisions when procuring motorcycle seat cover fabric. While indicative prices can vary widely based on the above factors, a thorough analysis will empower buyers to optimize their sourcing strategy.

Alternatives Analysis: Comparing motorcycle seat cover fabric With Other Solutions

Exploring Alternatives to Motorcycle Seat Cover Fabric

In the competitive landscape of motorcycle accessories, selecting the right seat cover solution is crucial for enhancing comfort, aesthetics, and durability. While motorcycle seat cover fabric remains a popular choice, several alternative solutions exist. This section examines these alternatives, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to motorcycle seat cover fabric

| Comparison Aspect | Motorcycle Seat Cover Fabric | Marine Grade Vinyl | Custom Upholstery Kits |

|---|---|---|---|

| Performance | Highly water-resistant, abrasion-resistant, stylish | Excellent durability, UV resistant, easy to clean | Customizable comfort and aesthetics, variable durability |

| Cost | Moderate ($20 – $250) | Moderate ($25 – $40 per yard) | High ($100 – $500+ depending on customization) |

| Ease of Implementation | Requires basic sewing skills | DIY-friendly with cutting and sewing | Requires professional skills or significant DIY experience |

| Maintenance | Low maintenance, easy to clean | Low maintenance, easy to clean | Varies based on materials used, potentially higher maintenance |

| Best Use Case | Standard motorcycle seats, custom designs | Marine applications, motorcycles exposed to elements | Custom projects requiring unique designs, high-end finishes |

What Are the Advantages and Disadvantages of Marine Grade Vinyl?

Marine grade vinyl is a robust alternative to motorcycle seat cover fabric, primarily designed for outdoor use. Its high UV resistance and waterproof properties make it an excellent choice for motorcycles frequently exposed to harsh weather. The cost is relatively moderate, making it accessible for both B2B buyers and end consumers. However, while it is easy to clean, it lacks the aesthetic versatility that some motorcycle seat cover fabrics offer, potentially limiting design options.

How Do Custom Upholstery Kits Compare to Standard Fabric Solutions?

Custom upholstery kits provide a tailored solution for motorcycle seats, allowing buyers to select specific materials, colors, and designs. This option is ideal for those seeking a unique finish or enhanced comfort features. However, the complexity of the installation process can be a drawback, often requiring professional skills or substantial DIY knowledge. The cost can also be significantly higher than standard fabric solutions, making it less accessible for budget-conscious buyers. Nonetheless, for high-end motorcycles or bespoke projects, the investment can yield impressive results.

Making the Right Choice for Your Motorcycle Seat Cover Needs

When selecting the most suitable seat cover solution, B2B buyers should consider their target market, budget constraints, and specific use cases. Motorcycle seat cover fabric offers a balance of performance and aesthetics, making it ideal for standard applications. In contrast, marine grade vinyl excels in durability and weather resistance, while custom upholstery kits provide unparalleled personalization at a higher cost and complexity. By evaluating these factors, businesses can make informed decisions that align with their strategic goals and customer preferences.

Essential Technical Properties and Trade Terminology for motorcycle seat cover fabric

What Are the Essential Technical Properties of Motorcycle Seat Cover Fabric?

When sourcing motorcycle seat cover fabric, understanding key technical properties is vital for ensuring product quality, durability, and customer satisfaction. Here are several critical specifications to consider:

-

Material Grade

The material grade refers to the quality and type of fabric used in seat covers. Common materials include vinyl, leather, and synthetic blends. High-grade materials offer enhanced durability, UV resistance, and water repellency, which are crucial for outdoor use. For B2B buyers, selecting the appropriate material grade can directly impact the longevity of the product and customer return rates. -

Abrasion Resistance

This property indicates how well the fabric can withstand wear and tear from friction. Fabrics are often tested against industry standards to measure their resistance to abrasion. For motorcycle seat covers, higher abrasion resistance ensures that the product maintains its appearance and functionality over time, which is particularly important for businesses aiming to minimize replacement costs and maintain customer loyalty. -

Water Resistance

Water resistance is critical for motorcycle seat covers, especially in regions with high humidity or frequent rain. Fabrics that are treated or inherently resistant to moisture can prevent water damage, mold growth, and deterioration. For B2B buyers, offering water-resistant products can enhance marketability and cater to customers in diverse climates. -

UV Stability

UV stability refers to a fabric’s ability to resist degradation from sunlight exposure. Motorcycle seats are often subjected to direct sunlight, which can fade colors and weaken materials. Fabrics with high UV stability ensure that the seat covers retain their color and structural integrity over time. For businesses, this feature can be a selling point, particularly in sunny regions. -

Flexibility and Stretchability

Flexibility indicates how well a fabric can bend and conform to the seat’s shape without compromising its integrity. Stretchability, often measured in terms of elasticity, allows the fabric to adjust to different seat designs while maintaining a snug fit. For B2B suppliers, offering flexible and stretchable fabrics can reduce installation issues and enhance the overall user experience. -

Flame Retardancy

Flame retardancy is an essential property for safety, particularly in environments where fire hazards are a concern. Fabrics that meet flame retardant standards can provide an additional layer of safety for motorcycle riders. For buyers, this property can be crucial for compliance with local regulations and for ensuring the safety of their products.

What Are Common Trade Terms Used in Motorcycle Seat Cover Fabric Procurement?

Familiarity with industry jargon can streamline communication and negotiation processes in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of motorcycle seat covers, OEMs often supply original seat cover materials for manufacturers. Understanding OEM relationships can help buyers identify reliable sources for high-quality materials. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For motorcycle seat cover fabrics, MOQs can vary widely depending on the supplier and material. Knowing the MOQ is essential for businesses to manage inventory effectively and avoid excess stock. -

RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers to request pricing and terms for specific products. In the motorcycle seat cover industry, sending an RFQ can help buyers compare offers from different suppliers and negotiate better terms. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in global transactions. Understanding these terms helps businesses navigate shipping, insurance, and risk transfer. For motorcycle seat cover fabric imports, clarity on Incoterms can prevent costly misunderstandings. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for planning production schedules and ensuring timely delivery to customers. -

Custom Fabrication

This term refers to the process of creating bespoke seat covers tailored to specific designs or requirements. Offering custom fabrication can set a business apart from competitors and cater to niche markets. For buyers, understanding customization options can enhance product appeal and meet diverse customer needs.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when sourcing motorcycle seat cover fabrics, ultimately leading to improved product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the motorcycle seat cover fabric Sector

What Are the Current Market Dynamics and Key Trends in the Motorcycle Seat Cover Fabric Sector?

The motorcycle seat cover fabric market is witnessing significant growth driven by the increasing popularity of motorcycles as a mode of transport, particularly in emerging markets across Africa, South America, and Asia. This trend is further supported by the rise in disposable income, leading to higher demand for premium motorcycle accessories, including seat covers. Additionally, the trend towards personalization is gaining traction, as consumers seek customized seat covers that reflect their style and enhance comfort.

Emerging B2B technologies, such as 3D printing and advanced textile manufacturing, are revolutionizing the sourcing landscape. These technologies enable companies to create bespoke seat covers with precision, reducing lead times and allowing for quicker responses to market demands. Digital platforms are also facilitating streamlined procurement processes, enabling international buyers to source materials more efficiently from global suppliers.

Illustrative image related to motorcycle seat cover fabric

Moreover, there is a growing emphasis on hybrid materials that combine durability with comfort, such as gel-infused fabrics and high-grade vinyl. These materials not only improve the riding experience but also cater to the increasing consumer preference for sustainable and eco-friendly products. As a result, B2B buyers should closely monitor these trends to align their sourcing strategies with evolving consumer preferences and technological advancements.

How Is Sustainability and Ethical Sourcing Impacting the Motorcycle Seat Cover Fabric Market?

Sustainability has become a critical focus in the motorcycle seat cover fabric sector, driven by increasing awareness of environmental issues and consumer demand for eco-friendly products. The environmental impact of traditional manufacturing processes, including the use of synthetic materials and chemical treatments, has prompted businesses to seek alternatives that minimize harm to the planet.

Ethical sourcing practices are gaining importance, as companies strive to ensure their supply chains are transparent and sustainable. This includes sourcing materials from suppliers who adhere to fair labor practices and environmentally responsible production methods. B2B buyers are encouraged to look for certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which signify compliance with stringent environmental and social criteria.

Furthermore, the integration of recycled materials into seat cover production is a growing trend. Manufacturers are now exploring options like recycled polyester and organic cotton, which not only reduce waste but also appeal to environmentally conscious consumers. By prioritizing sustainability and ethical sourcing, B2B buyers can differentiate themselves in a competitive market while contributing to a more sustainable future.

What Is the Historical Context of the Motorcycle Seat Cover Fabric Market?

The evolution of motorcycle seat cover fabrics reflects broader trends in the automotive and textile industries. Initially, motorcycle seats were covered with basic materials, primarily leather or simple vinyl, that prioritized function over form. As motorcycles gained popularity in the mid-20th century, manufacturers began to explore new materials that combined aesthetics with performance, leading to the introduction of synthetic fabrics.

By the late 20th century, advancements in textile technology allowed for the development of more durable, weather-resistant, and comfortable materials. The introduction of high-performance vinyl and gel-infused fabrics marked a significant turning point, enhancing rider comfort and safety. Today, the market is characterized by a diverse range of materials that cater to various consumer preferences, setting the stage for ongoing innovation and growth in the motorcycle seat cover fabric sector.

Illustrative image related to motorcycle seat cover fabric

This historical context is crucial for B2B buyers to understand the trajectory of the market and the factors influencing current trends, enabling them to make informed sourcing decisions that align with both consumer expectations and industry advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat cover fabric

-

How do I choose the right fabric for motorcycle seat covers?

Selecting the right fabric for motorcycle seat covers involves considering factors such as durability, weather resistance, and aesthetic appeal. Look for materials that are UV resistant and waterproof, as they will withstand harsh outdoor conditions. Vinyl and marine-grade fabrics are popular choices due to their longevity and ease of maintenance. Additionally, consider the thickness of the fabric, as it should be pliable yet strong enough to resist tearing and abrasion. -

What customization options are available for motorcycle seat cover fabric?

Most suppliers offer a range of customization options including color choices, patterns, and stitching styles. You can often choose to add personalized embroidery or unique panel configurations to create a distinct look. When sourcing, inquire about minimum order quantities (MOQs) for customized designs, as these can vary significantly between manufacturers. Collaborating with a supplier who provides design assistance can ensure your vision is accurately realized. -

What are the common payment terms in international B2B transactions?

Payment terms can vary by supplier and region, but common practices include 30% upfront payment with the balance due before shipment. Some suppliers may offer letters of credit or payment upon delivery. It’s crucial to clarify these terms during negotiation to avoid potential misunderstandings. Ensure that the payment methods are secure and accessible in your region, and consider utilizing escrow services for larger transactions to protect both parties. -

How can I vet suppliers of motorcycle seat cover fabric?

Vetting suppliers involves checking their reputation, production capabilities, and compliance with international quality standards. Request samples of their fabric to assess quality firsthand and ask for references from previous clients. Additionally, review their certifications, such as ISO or other relevant industry standards, to ensure they meet manufacturing excellence. Engaging in direct communication can also help gauge their responsiveness and reliability. -

What are the typical lead times for ordering motorcycle seat cover fabric?

Lead times can vary based on factors such as order size, customization, and the supplier’s location. Generally, standard orders may take 2-4 weeks, while customized products could take 4-8 weeks or longer. To ensure timely delivery, it’s advisable to discuss timelines upfront and confirm the supplier’s ability to meet your deadlines. Consider placing orders well in advance of peak seasons to accommodate any potential delays. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have a quality assurance process that includes material testing and inspection of finished products. Look for suppliers who can provide documentation of their quality control measures, such as testing for durability, UV resistance, and colorfastness. Inquire about their return policy and warranty options, as these can provide additional security and assurance regarding the quality of the fabric. -

How do logistics and shipping affect my order of motorcycle seat cover fabric?

Logistics and shipping play a critical role in the timely delivery of your motorcycle seat cover fabric. Factors to consider include shipping methods, freight costs, and customs regulations in your country. It’s essential to discuss delivery options with your supplier, including whether they offer door-to-door service. Be aware of potential delays due to customs processing and ensure all necessary documentation is in order to facilitate smooth transit. -

What are the benefits of sourcing motorcycle seat cover fabric from international suppliers?

Sourcing from international suppliers can offer a broader range of materials and designs, often at competitive prices. You may find unique fabrics and innovative technologies that aren’t available locally. Additionally, international suppliers can provide insights into global trends and customer preferences, enabling you to stay ahead in the market. However, it is crucial to weigh the benefits against potential challenges such as longer lead times and import regulations.

Top 6 Motorcycle Seat Cover Fabric Manufacturers & Suppliers List

1. Luimoto – Premium Motorcycle Seat Covers

Domain: luimoto.com

Registered: 2004 (21 years)

Introduction: Motorcycle Seat Covers, Tank Grips & More – Luimoto offers premium aftermarket Rider Seat Covers designed for comfort and style, made from marine-grade materials. Passenger Seat Covers enhance grip and styling for two-up seating. Custom Seat Covers allow for personalized designs with special stitching and embroidery, built on-site in Vancouver. Premium Gold Gel inserts reduce rider fatigue and abs…

2. Seattle Fabrics – 54 Moto-X Grabber Upholstery Vinyl

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “54” Moto-X Grabber Upholstery Vinyl”, “Price”: “$39.95/linear yard”, “Part Number”: “FUPHG”, “Width”: “54 inches”, “Material Type”: “NON-Slip Upholstery Vinyl”, “Features”: [“Mildew resistant”, “UV stabilized”], “Applications”: “Perfect for motorcycle seat applications”, “Availability”: “Sold by the yard in .25, .5, .75 yard increments, .5 yard minimum”, “Color”: “Black”, “Weight…

3. All Sport – Motorcycle Vinyl

Domain: diyupholsterysupply.com

Registered: 2004 (21 years)

Introduction: Motorcycle Vinyl by All Sport is a stretchable, pliable upholstery vinyl ideal for gaming rails, marine applications, ATVs, snow machines, and motorcycles. It features a -60°F cold crack resistance, 360° stretch, and is flame retardant. Available colors include Black, High-Tac Black, Chalk, Nu Bright Yellow, Bright Red, Silver Met, Royal Blue, Electric Blue, Marine Green, and Bright Violet, all pr…

4. Motorcycle Seat Recovery – Marine-Grade Vinyl & Polyester

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Marine-grade vinyl and polyester are recommended materials for re-covering motorcycle seats, particularly for ADV bikes. Marine-grade vinyl is noted for its durability and water resistance, while polyester is lightweight. Adding foam padding for extra comfort is also suggested.

5. Sailrite – Morbern™ Allsport 360º Stretch Vinyl Fabric

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Materials List: Morbern™ Allsport 360º Stretch Electric Blue 54″ Vinyl Fabric (#104175), Morbern™ Allsport 360º Stretch Black 54″ Vinyl Fabric (#104182), PremoBond® Tex 90 (V-92) White UV Bonded Polyester Thread 4 oz. (1,350 yds.) (#123337), Cushion Wrap Silk Film 54″ (#103933), 5-Ply Waxed Polyester Twine Bobbin (81 ft.) (#29206), 21 Gauge 3/8″ (10mm) Staples 10,000/Box (Stainless Steel) (#8010SS…

6. Motea – Fitted Seat Covers for Motorcycles

Domain: motea-shop.com

Registered: 2023 (2 years)

Introduction: Fitted Seat Covers for motorcycles, scooters, and quads. Made of imitation leather, durable, UV-resistant, and weatherproof. Various models compatible with specific motorcycle brands and models including BMW, Suzuki, Honda, KTM, and more. Prices range from $55.24 to $194.99 with discounts available using code TOP35. Products include mesh seat covers, waterproof options, and seat pads. Ratings avai…

Strategic Sourcing Conclusion and Outlook for motorcycle seat cover fabric

In the competitive landscape of motorcycle seat cover fabric, strategic sourcing emerges as a critical advantage for international B2B buyers. By prioritizing high-quality materials—such as UV-resistant vinyl and advanced foam technologies—companies can enhance product durability and aesthetic appeal, ultimately leading to increased customer satisfaction and loyalty. Additionally, leveraging customization options, as seen in successful brands, can set businesses apart in diverse markets across Africa, South America, the Middle East, and Europe.

Understanding the specific needs of each region is essential; for instance, sourcing materials that withstand harsh climates in the Middle East or vibrant colors that appeal to South American consumers can drive sales. Establishing strong relationships with reliable suppliers not only ensures consistent quality but also fosters innovation in product development.

Illustrative image related to motorcycle seat cover fabric

As you look to the future, consider integrating sustainable practices into your sourcing strategy to meet the growing demand for eco-friendly products. Embrace this opportunity to differentiate your offerings and expand your market reach. Start today by evaluating your supply chain and exploring new partnerships that align with these strategic goals. The right sourcing decisions now will pave the way for success in the evolving motorcycle seat cover fabric market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to motorcycle seat cover fabric