Introduction: Navigating the Global Market for microfiber leather sofa

As the demand for stylish and functional furniture continues to grow, sourcing high-quality microfiber leather sofas has become a critical challenge for international B2B buyers. These versatile pieces not only enhance the aesthetic of various spaces but also offer durability and ease of maintenance, making them an attractive option for diverse markets, including Africa, South America, the Middle East, and Europe, particularly in regions like Saudi Arabia and Brazil. This guide aims to demystify the complexities of the global microfiber leather sofa market by providing comprehensive insights into types, applications, supplier vetting, and cost considerations.

Navigating this market requires a keen understanding of various factors that influence purchasing decisions. Buyers will find detailed information about different sofa styles, from rustic lodge designs to modern minimalist aesthetics, catering to a wide range of consumer preferences. Additionally, the guide emphasizes the importance of supplier reliability, offering strategies for vetting potential partners to ensure product quality and timely delivery.

By leveraging the insights presented in this guide, B2B buyers can make informed decisions that align with their business goals, ultimately enhancing customer satisfaction and driving sales. Whether you are looking to furnish commercial spaces or meet the growing demand for residential furniture, this guide equips you with the knowledge needed to confidently navigate the global market for microfiber leather sofas.

Table Of Contents

- Top 2 Microfiber Leather Sofa Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for microfiber leather sofa

- Understanding microfiber leather sofa Types and Variations

- Key Industrial Applications of microfiber leather sofa

- 3 Common User Pain Points for ‘microfiber leather sofa’ & Their Solutions

- Strategic Material Selection Guide for microfiber leather sofa

- In-depth Look: Manufacturing Processes and Quality Assurance for microfiber leather sofa

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber leather sofa’

- Comprehensive Cost and Pricing Analysis for microfiber leather sofa Sourcing

- Alternatives Analysis: Comparing microfiber leather sofa With Other Solutions

- Essential Technical Properties and Trade Terminology for microfiber leather sofa

- Navigating Market Dynamics and Sourcing Trends in the microfiber leather sofa Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of microfiber leather sofa

- Strategic Sourcing Conclusion and Outlook for microfiber leather sofa

- Important Disclaimer & Terms of Use

Understanding microfiber leather sofa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Microfiber Sofa | Soft, durable microfiber upholstery; variety of colors | Residential, Hospitality | Pros: Cost-effective, easy to clean. Cons: May not match luxury aesthetics. |

| Rustic Lodge Microfiber Sofa | Textured fabric resembling leather; rustic design elements | Cabins, Lodges, Country Homes | Pros: Unique aesthetic appeal, durable. Cons: Limited color options, heavier. |

| Reclining Microfiber Sofa | Integrated reclining mechanisms; adjustable seating options | Home Theaters, Lounges | Pros: Enhanced comfort, space-saving. Cons: More complex mechanisms may require maintenance. |

| Microfiber Sleeper Sofa | Convertible design; includes mattress for overnight guests | Apartments, Guest Rooms | Pros: Space-efficient, dual functionality. Cons: May compromise on seating comfort. |

| Contract Grade Microfiber Sofa | Meets commercial durability standards; designed for high use | Offices, Hotels, Restaurants | Pros: Long-lasting, withstands heavy use. Cons: Higher upfront cost, may require bulk purchasing. |

What Are the Key Characteristics of Standard Microfiber Sofas?

Standard microfiber sofas are characterized by their soft and plush upholstery, which is typically available in a wide range of colors. They are designed for both comfort and durability, making them suitable for residential and hospitality applications. When purchasing, B2B buyers should consider fabric cleaning options and warranty conditions, as these factors greatly impact the long-term usability and maintenance costs.

Why Choose Rustic Lodge Microfiber Sofas for Specific Settings?

Rustic lodge microfiber sofas feature a textured finish that mimics leather, often adorned with rustic design elements such as nailhead accents. These sofas are particularly suited for cabins, lodges, and country homes, where a warm, inviting atmosphere is desired. B2B buyers should evaluate their target market’s aesthetic preferences and the sofa’s weight, as heavier models may require special handling during delivery.

Illustrative image related to microfiber leather sofa

What Benefits Do Reclining Microfiber Sofas Offer?

Reclining microfiber sofas come equipped with mechanisms that allow for adjustable seating positions, enhancing comfort for users. They are ideal for home theaters and lounges where relaxation is a priority. Buyers should assess the ease of use of the reclining mechanisms and consider the potential need for repairs or replacements, as these features can add complexity to the product.

How Do Microfiber Sleeper Sofas Provide Versatility?

Microfiber sleeper sofas are designed to convert from a traditional sofa to a bed, making them a practical choice for apartments and guest rooms. Their dual functionality is particularly appealing to B2B buyers looking to maximize space in smaller living areas. However, it’s essential to consider the comfort level of the mattress and the ease of conversion, as these factors can affect customer satisfaction.

What Makes Contract Grade Microfiber Sofas Ideal for Commercial Use?

Contract grade microfiber sofas are built to meet rigorous commercial durability standards, making them suitable for high-traffic environments like offices, hotels, and restaurants. These sofas are designed to withstand heavy use while maintaining their aesthetic appeal. B2B buyers should factor in the initial investment cost and the long-term value, as these products often require bulk purchasing but provide significant durability benefits.

Key Industrial Applications of microfiber leather sofa

| Industry/Sector | Specific Application of microfiber leather sofa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel lobbies and guest rooms | Enhances guest experience with stylish, durable seating | Consider durability, stain resistance, and design aesthetics |

| Corporate Offices | Reception areas and lounge spaces | Provides a professional and inviting atmosphere | Look for customization options and ergonomic designs |

| Retail | Showrooms and customer waiting areas | Attracts customers and creates a comfortable shopping experience | Assess color and material variety to match branding |

| Healthcare | Patient waiting areas and staff lounges | Offers comfort and easy maintenance in high-traffic areas | Ensure compliance with hygiene standards and durability |

| Educational Institutions | Student lounges and common areas | Fosters a welcoming environment for students and visitors | Focus on affordability, durability, and ease of cleaning |

How is Microfiber Leather Sofa Utilized in the Hospitality Sector?

In the hospitality industry, microfiber leather sofas are commonly used in hotel lobbies, guest rooms, and lounges. Their stylish appearance and durability enhance the overall guest experience, making them a popular choice for upscale accommodations. International B2B buyers, especially from regions like the Middle East and Europe, should prioritize sourcing sofas that are stain-resistant and easy to maintain, as these features contribute to long-term cost savings and guest satisfaction.

What Role Does Microfiber Leather Sofa Play in Corporate Offices?

Corporate offices utilize microfiber leather sofas in reception areas and lounge spaces to create a professional and inviting atmosphere. These sofas provide a comfortable seating option for clients and employees alike, fostering a positive impression of the business. Buyers from South America and Africa should consider customization options that align with their corporate branding and ergonomic designs that support employee well-being.

Illustrative image related to microfiber leather sofa

How Do Retail Environments Benefit from Microfiber Leather Sofa?

In retail settings, microfiber leather sofas are strategically placed in showrooms and customer waiting areas to enhance the shopping experience. They attract customers with their modern aesthetic while providing a comfortable place to sit. B2B buyers should assess the color and material variety to ensure alignment with the store’s branding and ambiance, as well as durability to withstand high foot traffic.

Why is Microfiber Leather Sofa Important in Healthcare Facilities?

Healthcare facilities often incorporate microfiber leather sofas in patient waiting areas and staff lounges due to their comfort and ease of maintenance. These sofas can withstand the rigors of high-traffic environments while offering a welcoming atmosphere for patients and visitors. When sourcing for healthcare applications, buyers must ensure that the materials used comply with hygiene standards and are durable enough for frequent cleaning.

How is Microfiber Leather Sofa Used in Educational Institutions?

Educational institutions frequently utilize microfiber leather sofas in student lounges and common areas to create inviting environments for students and visitors. These sofas not only provide comfort but also contribute to the overall aesthetic of the campus. Buyers from educational sectors should focus on affordability, durability, and ease of cleaning, as these factors are crucial in high-use settings where maintenance is a priority.

3 Common User Pain Points for ‘microfiber leather sofa’ & Their Solutions

Scenario 1: Sourcing Quality Microfiber Leather Sofas for Diverse Markets

The Problem: B2B buyers often face the challenge of sourcing microfiber leather sofas that meet varying quality standards across international markets. For instance, buyers from regions like Africa or South America may encounter inconsistent quality, leading to dissatisfaction among end-users. Additionally, buyers must navigate diverse customer preferences, which can complicate the selection process and lead to costly returns or replacements if the products do not meet expectations.

The Solution: To ensure quality and consistency, B2B buyers should establish a rigorous vetting process for suppliers. This includes requesting samples of microfiber leather sofas and conducting quality assessments based on durability, texture, and stain resistance. Engaging with suppliers who offer detailed product specifications and certifications can also help in understanding the materials used. Furthermore, consider leveraging local partnerships in target markets to gain insights into regional preferences and compliance standards. This approach not only minimizes risk but also enhances customer satisfaction by aligning product offerings with local expectations.

Scenario 2: Addressing Maintenance and Durability Concerns

The Problem: One of the significant pain points for B2B buyers is the perceived fragility and maintenance requirements of microfiber leather sofas. Buyers worry that these sofas may not withstand heavy use, especially in commercial environments like hotels, offices, or event venues. Concerns about cleaning and maintaining the sofas can deter buyers from making a purchase, particularly if they fear high replacement costs or dissatisfied customers.

The Solution: Buyers can alleviate these concerns by seeking microfiber leather sofas specifically designed for high-traffic areas, which typically feature enhanced durability and stain resistance. Look for sofas with a high abrasion rating and warranties that cover commercial use. Additionally, provide end-users with comprehensive care guides that detail proper cleaning methods and recommended maintenance routines. Educating clients on the longevity and ease of care associated with high-quality microfiber leather can also help dispel myths about fragility, making the sofas a more attractive option for various settings.

Scenario 3: Customization to Fit Unique Space Requirements

The Problem: B2B buyers often need to fit microfiber leather sofas into unique or unconventional spaces, such as small office areas or large public lobbies. The challenge lies in finding sofas that not only meet aesthetic demands but also fit specific spatial constraints. This can lead to frustration and wasted resources if the wrong dimensions are selected, resulting in a poor fit or impractical seating arrangements.

The Solution: To address this issue, buyers should prioritize suppliers who offer customizable options for microfiber leather sofas. Customization can include variations in size, configuration (such as modular pieces), and color choices that align with the buyer’s brand identity. Utilizing design software or tools provided by suppliers can help visualize how different configurations will fit within a designated space. Additionally, consulting with an interior designer or a space planner during the selection process can further ensure that the chosen sofas meet both functional and aesthetic needs, ultimately resulting in a more successful purchase decision.

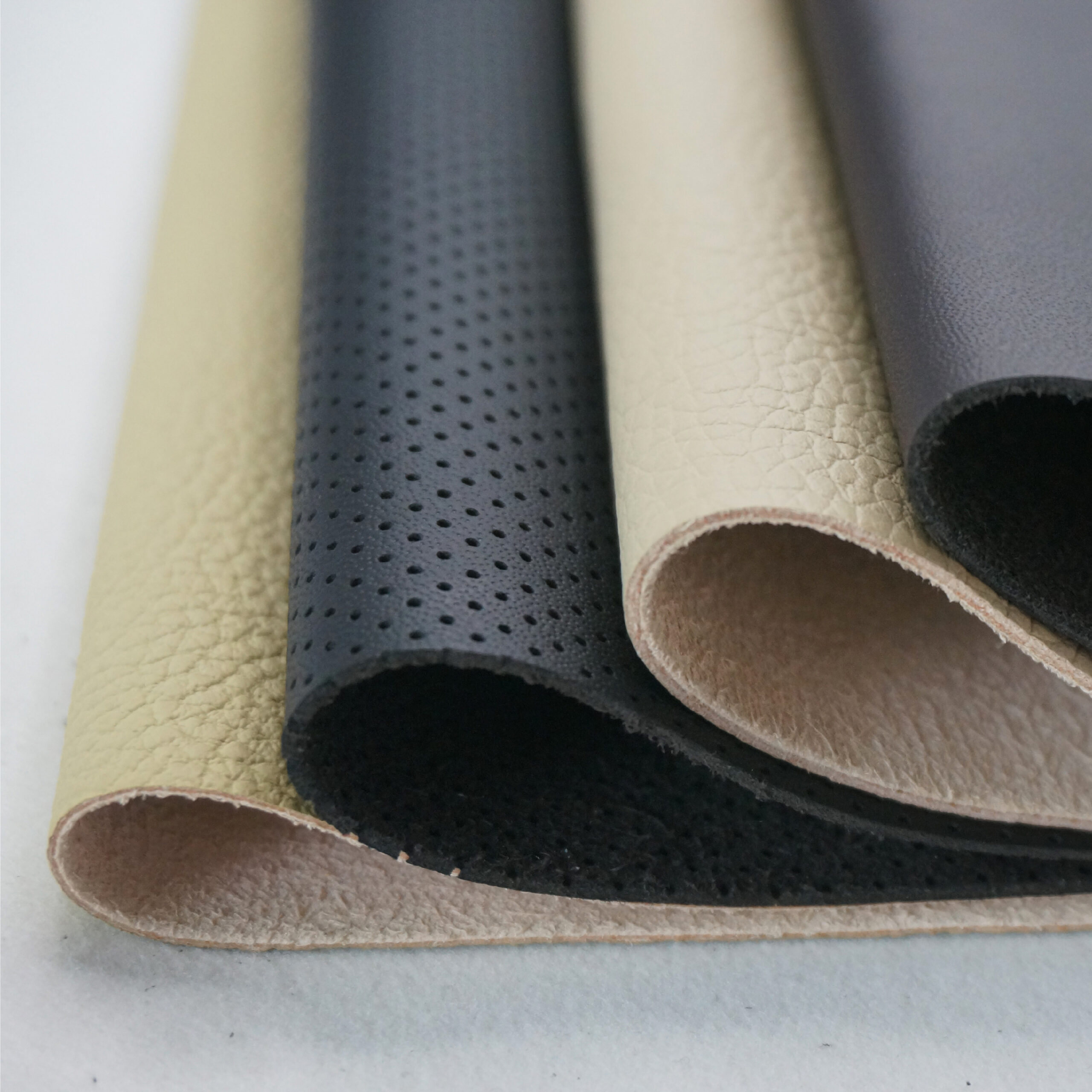

Strategic Material Selection Guide for microfiber leather sofa

What Are the Key Materials Used in Microfiber Leather Sofas?

When selecting materials for microfiber leather sofas, it’s crucial for B2B buyers to consider various factors that affect product performance, durability, and market preferences. Below are analyses of four common materials used in the construction of microfiber leather sofas.

1. Polyester Microfiber

Key Properties: Polyester microfiber is known for its soft texture and durability. It typically has a high abrasion resistance rating, often exceeding 30,000 double rubs, making it suitable for high-traffic areas. It also offers good resistance to stains and fading.

Pros & Cons: The primary advantage of polyester microfiber is its affordability and ease of maintenance. However, it can be less breathable compared to natural fibers, potentially leading to discomfort in hot climates. Additionally, while it is generally durable, it may not withstand extreme pressure as well as some other materials.

Impact on Application: Polyester microfiber is compatible with various cleaning agents, making it suitable for commercial applications where hygiene is a priority. However, buyers in regions with high humidity, such as parts of Africa and South America, should consider the breathability aspect.

Considerations for International Buyers: Compliance with international standards such as ASTM for flammability and durability is essential. Buyers should also be aware of regional preferences for color and texture, which may vary significantly.

2. Polyurethane (PU) Leather

Key Properties: PU leather is a synthetic material made from a polymer coating on a base fabric. It offers a temperature resistance of up to 80°C and is generally resistant to moisture and UV light.

Illustrative image related to microfiber leather sofa

Pros & Cons: PU leather is often praised for its aesthetic appeal, mimicking the look of genuine leather at a lower cost. However, it may not be as durable as other materials, with a lifespan that can be shorter in high-use environments. Additionally, it can be prone to cracking over time, especially in dry climates.

Impact on Application: PU leather is suitable for a variety of applications, including residential and commercial furniture. It is generally easy to clean but may require specific cleaning products to maintain its appearance.

Considerations for International Buyers: Buyers should ensure that PU leather meets local regulations regarding chemical emissions and environmental impact. In regions like Europe, compliance with REACH regulations is critical.

Illustrative image related to microfiber leather sofa

3. PVC (Polyvinyl Chloride) Leather

Key Properties: PVC leather is a synthetic material known for its high durability and resistance to water and stains. It typically has a high tensile strength and can withstand temperatures up to 70°C.

Pros & Cons: The main advantage of PVC leather is its cost-effectiveness and resistance to wear and tear. However, it can be less breathable than other materials, which may lead to discomfort in warmer climates. Additionally, the environmental impact of PVC production is a growing concern.

Impact on Application: PVC leather is often used in commercial settings due to its durability and ease of maintenance. However, it may not be suitable for high-end residential applications where aesthetics are a priority.

Considerations for International Buyers: Buyers should be aware of the environmental regulations surrounding PVC in their respective countries, particularly in Europe and North America, where there is a push for sustainable materials.

Illustrative image related to microfiber leather sofa

4. マイクロファイバー・スエード

Key Properties: Microfiber suede is a soft, plush material that offers excellent durability and a luxurious feel. It typically has a high abrasion resistance and is resistant to stains.

Pros & Cons: The key advantage of microfiber suede is its luxurious appearance and feel, making it appealing for high-end furniture. However, it can be more expensive than other synthetic options and may require special care to maintain its appearance.

Impact on Application: Microfiber suede is ideal for residential applications where aesthetics and comfort are priorities. However, it may not be the best choice for commercial settings with heavy use.

Considerations for International Buyers: Buyers should consider the specific cleaning and maintenance requirements for microfiber suede, as well as its compliance with international standards for upholstery materials.

Summary Table

| 素材 | Typical Use Case for microfiber leather sofa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester Microfiber | Residential & commercial upholstery | Affordable and easy to maintain | Less breathable, can wear over time | 低い |

| Polyurethane (PU) Leather | Residential & commercial upholstery | Aesthetic appeal, mimics genuine leather | Less durable, prone to cracking | Medium |

| PVC (Polyvinyl Chloride) Leather | Commercial upholstery | Cost-effective and durable | Less breathable, environmental concerns | 低い |

| マイクロファイバー・スエード | High-end residential furniture | Luxurious feel and appearance | Higher cost, requires special care | 高い |

This strategic material selection guide aims to equip B2B buyers with the necessary insights to make informed decisions when sourcing microfiber leather sofas, considering their unique market conditions and compliance requirements.

Illustrative image related to microfiber leather sofa

In-depth Look: Manufacturing Processes and Quality Assurance for microfiber leather sofa

What Are the Key Stages in the Manufacturing Process of Microfiber Leather Sofas?

The manufacturing of microfiber leather sofas involves several critical stages, each designed to ensure a high-quality end product. The process typically encompasses material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality microfiber and backing materials. Microfiber is a synthetic fabric made from polyester and polyamide fibers, known for its durability and softness. Suppliers often conduct tests to confirm the fabric’s resistance to wear and tear, which is essential for ensuring longevity in furniture use. The backing material, usually made from non-woven fabric, provides structural integrity to the sofa.

-

Forming: In this stage, the prepared materials are cut and shaped according to design specifications. Advanced cutting technologies, such as laser cutting, are often employed to ensure precision. This process also includes the crafting of frames, typically made from solid wood or metal, which forms the foundation of the sofa. The quality of the frame is crucial as it supports the entire structure, affecting both durability and comfort.

-

Assembly: The assembly phase involves stitching the microfiber cover to the frame, adding cushioning materials, and integrating any additional features such as recliners or storage compartments. Skilled labor is essential here, as precise stitching techniques and proper alignment of components are necessary to ensure aesthetic appeal and structural integrity. Quality control checks are often performed at this stage to ensure that the assembly meets the design specifications.

-

Finishing: The final stage includes the application of protective coatings, such as stain-resistant treatments, and quality checks to ensure that the sofa meets aesthetic and functional requirements. Finishing touches might also involve cleaning the sofa to remove any manufacturing residues and preparing it for packaging. This stage is critical as it impacts the product’s overall look and feel, which are significant factors for B2B buyers.

How Is Quality Assurance Implemented in Microfiber Leather Sofa Manufacturing?

Quality assurance (QA) is a pivotal aspect of the manufacturing process, ensuring that each microfiber leather sofa adheres to international and industry-specific standards. This process encompasses several checkpoints and testing methodologies.

-

What Are the Relevant International Standards for Quality Assurance?

International standards such as ISO 9001 play a vital role in establishing a framework for quality management systems. Compliance with ISO 9001 ensures that manufacturers have processes in place to consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications like CE marking and API standards may apply, particularly for furniture intended for specific markets. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints typically include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC). IQC involves inspecting raw materials upon arrival to ensure they meet specified standards. IPQC is conducted during the manufacturing process to monitor and control quality, while FQC verifies that the finished product meets all quality criteria before shipping. -

What Common Testing Methods Are Used?

Various testing methods are employed to assess the quality of microfiber leather sofas. These include abrasion resistance tests, colorfastness tests, and fire retardant tests. Additionally, tensile strength tests are conducted on the upholstery to ensure that it can withstand wear and tear. Manufacturers often document these tests, providing B2B buyers with essential data regarding product durability and safety.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers maintain rigorous quality control standards. There are several ways to verify these processes:

Illustrative image related to microfiber leather sofa

-

Supplier Audits: Conducting supplier audits is an effective way for buyers to assess the quality management systems in place. These audits can evaluate the supplier’s adherence to international standards and their internal QC processes.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC practices. These reports should include information on testing outcomes, compliance with standards, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections at various manufacturing stages, ensuring that the products meet specified quality standards before shipment.

What Are the Specific QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding QC and certification nuances is essential. Each region may have specific regulations regarding product safety and quality, impacting the buying decision.

-

Regional Compliance Standards: Buyers must be aware of regional compliance standards that may apply to microfiber leather sofas. For instance, certain countries may require specific fire safety standards or eco-friendly materials certifications. Familiarizing oneself with these regulations can prevent compliance issues and ensure market acceptance.

-

Cultural Preferences and Quality Expectations: Different regions may have unique aesthetic preferences and quality expectations. For example, buyers in Europe might prioritize sustainability and eco-friendly materials, while buyers in the Middle East may focus on luxury finishes and durability. Understanding these preferences can guide sourcing decisions and supplier negotiations.

-

Supply Chain Transparency: Transparency in the supply chain is increasingly important for international buyers. Understanding the source of materials and the manufacturing process can enhance trust and ensure compliance with ethical sourcing standards.

By thoroughly understanding the manufacturing processes, quality assurance protocols, and regional nuances, B2B buyers can make informed decisions when sourcing microfiber leather sofas, ultimately enhancing their competitive edge in the market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber leather sofa’

はじめに

This sourcing guide provides a structured approach for B2B buyers looking to procure microfiber leather sofas. With increasing demand across various markets, including Africa, South America, the Middle East, and Europe, understanding the essential steps in the sourcing process can ensure a successful purchase that meets both quality and business needs.

Illustrative image related to microfiber leather sofa

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications for the microfiber leather sofas you intend to procure. Consider factors such as size, style, color, and upholstery options. This step is crucial to ensure that the sofas will fit your target market’s preferences and your operational requirements.

- Key Specifications to Consider:

- Dimensions (length, width, height)

- Upholstery type (e.g., faux leather, microfiber blends)

- Design features (e.g., reclining options, modular setups)

Step 2: Identify Your Target Market

Understanding your target market is vital for making informed purchasing decisions. Research demographics, preferences, and purchasing behavior in your specific regions (e.g., Saudi Arabia, Brazil). Tailoring your selection based on this data can enhance your product’s appeal.

- Market Insights to Gather:

- Popular styles and colors

- Regional preferences for durability and comfort

- Price sensitivity and budget ranges

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation of their capabilities and reputation. Request company profiles, product samples, and references from previous clients, particularly those in similar industries or regions. A well-vetted supplier is crucial for ensuring product quality and reliability.

Illustrative image related to microfiber leather sofa

- Assessment Criteria:

- Years of experience in the industry

- Customer testimonials and case studies

- Certifications and compliance with international standards

Step 4: Request and Compare Quotations

Once you’ve shortlisted potential suppliers, request detailed quotations. Compare pricing, terms of delivery, and warranty options. This step helps you gauge the market rates and make cost-effective decisions without compromising on quality.

- Comparison Factors:

- Total cost (including shipping and taxes)

- Payment terms and conditions

- Return policies and warranty offerings

Step 5: Verify Quality Control Measures

Quality control is paramount when sourcing furniture. Inquire about the supplier’s quality assurance processes and how they handle defects or issues during production. Ensuring that the supplier adheres to strict quality standards minimizes the risk of receiving subpar products.

- Quality Assurance Questions to Ask:

- What testing processes are in place for materials and finished products?

- Can they provide documentation of quality certifications?

- How do they manage customer complaints and product returns?

Step 6: Establish Communication Protocols

Effective communication with your supplier can significantly enhance the procurement process. Establish clear communication channels and protocols for updates on order status, shipment tracking, and after-sales support. This ensures transparency and fosters a positive business relationship.

- Communication Practices to Implement:

- Regular updates via email or project management tools

- Designate a point of contact for seamless interactions

- Set expectations for response times and issue resolution

Step 7: Finalize the Purchase Agreement

Before completing the transaction, review and finalize the purchase agreement. Ensure all terms are clearly outlined, including product specifications, pricing, delivery timelines, and after-sales support. A well-defined agreement protects both parties and minimizes misunderstandings.

- Key Elements to Include:

- Detailed product descriptions and quantities

- Delivery schedules and penalties for delays

- Terms for warranty and maintenance services

By following these steps, B2B buyers can effectively navigate the sourcing process for microfiber leather sofas, ensuring they make informed decisions that align with their business objectives and market demands.

Comprehensive Cost and Pricing Analysis for microfiber leather sofa Sourcing

What Are the Key Cost Components in Microfiber Leather Sofa Production?

When sourcing microfiber leather sofas, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: Microfiber leather is often made from polyester or a blend of synthetic fibers, which can vary in quality and price. Higher-quality materials may offer better durability and aesthetics but come at a premium. Additionally, the cost of wood for frames and high-density foam for cushions significantly influences the overall price.

-

Labor: Labor costs can fluctuate based on the region and skill level of the workforce. Countries with lower wage standards may offer competitive pricing, but this could affect the craftsmanship and quality.

-

Manufacturing Overhead: This encompasses utilities, rent, and other operational costs associated with the production facility. Efficient manufacturing processes can help reduce these overheads, impacting the final pricing.

-

Tooling: Initial costs for molds and production equipment can be substantial, especially for custom designs. These costs are typically amortized over production runs, affecting the unit price.

-

Quality Control (QC): Robust QC processes ensure that the final product meets specified standards. However, implementing stringent QC measures can increase costs, which should be factored into pricing.

-

Logistics: Shipping and transportation costs play a crucial role, particularly for international buyers. Factors such as distance, mode of transport, and customs duties can significantly influence overall costs.

-

Margin: Suppliers will typically add a margin to cover their risks and profits. Understanding the expected margin can help buyers gauge fair pricing.

How Do Price Influencers Affect Microfiber Leather Sofa Sourcing?

Several factors can influence the pricing of microfiber leather sofas, especially for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to discounts. Negotiating for a lower MOQ can also yield better prices, but it may limit customization options.

-

Specifications and Customization: Custom designs or unique specifications can increase costs. Buyers should evaluate whether the added expense aligns with their market needs.

-

Material Quality and Certifications: Sofas made with eco-friendly or certified materials may come at a higher cost but can appeal to environmentally conscious consumers.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but offer better quality assurance and customer support.

-

Incoterms: Understanding shipping terms is crucial for cost analysis. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift financial responsibilities and impact overall costs.

What Are Some Effective Buyer Tips for Negotiating Microfiber Leather Sofa Prices?

Navigating the complexities of sourcing microfiber leather sofas requires strategic negotiation skills. Here are some actionable tips for B2B buyers:

-

Conduct Market Research: Understand the average market prices for different specifications. This knowledge will empower you during negotiations and help you recognize reasonable offers.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial costs, consider the TCO, including maintenance, durability, and any associated logistics costs. This broader perspective can inform your purchasing decisions.

-

Leverage Long-term Relationships: Building strong relationships with suppliers can lead to favorable terms, better pricing, and increased flexibility on future orders.

-

Consider Seasonal Trends: Timing your purchases around off-peak seasons can yield better prices as suppliers may be more willing to negotiate.

-

Be Clear About Your Needs: Articulate your requirements and expectations clearly to avoid misunderstandings that could lead to increased costs later on.

What Is the Disclaimer for Indicative Prices in Microfiber Leather Sofa Sourcing?

While indicative pricing can provide a general sense of costs, it is crucial to understand that actual prices may vary based on the aforementioned factors. Always request detailed quotes that reflect your specific needs and circumstances to ensure accurate budgeting and financial planning.

Illustrative image related to microfiber leather sofa

Alternatives Analysis: Comparing microfiber leather sofa With Other Solutions

Exploring Alternatives to Microfiber Leather Sofas for B2B Buyers

In the competitive landscape of furniture procurement, understanding the alternatives to microfiber leather sofas is crucial for B2B buyers. This analysis will provide insights into how microfiber leather compares to other popular upholstery options, enabling informed purchasing decisions tailored to specific business needs.

| Comparison Aspect | Microfiber Leather Sofa | Genuine Leather Sofa | Fabric Sofa |

|---|---|---|---|

| Performance | Durable, stain-resistant, and easy to clean | Highly durable, luxurious feel, but prone to scratches | Variety of styles, comfortable, but may wear out faster |

| Cost | Affordable, typically ranges from $500 to $1,500 | High-end, often ranges from $1,500 to $5,000+ | Budget-friendly, usually $300 to $1,200 |

| Ease of Implementation | Lightweight, easy to transport and set up | Requires careful handling, heavier | Lightweight, generally easy to transport |

| Maintenance | Simple, requires occasional vacuuming and spot cleaning | Requires regular conditioning to maintain quality | Varies by fabric type, may need frequent cleaning |

| Best Use Case | Ideal for high-traffic areas, family-friendly settings | Suitable for luxury settings, executive offices | Great for casual environments, less formal spaces |

What Are the Pros and Cons of Genuine Leather Sofas?

Genuine leather sofas are renowned for their durability and luxurious appearance, making them a status symbol in many business environments. They age well, developing a unique patina over time, which adds character. However, they come at a significantly higher price point and require regular maintenance to prevent drying and cracking. For B2B buyers in upscale markets, the investment may be justified, especially in environments where aesthetics are paramount.

How Do Fabric Sofas Compare to Microfiber Leather Sofas?

Fabric sofas offer a plethora of design options and materials, making them versatile for various settings. They are often more affordable than both microfiber and genuine leather options. However, their lifespan may be shorter due to wear and tear, especially in high-traffic areas. Maintenance can also be more demanding, as certain fabrics stain easily and may require professional cleaning. For businesses looking for a budget-friendly option that allows for frequent style changes, fabric sofas can be an excellent choice.

Conclusion: Choosing the Right Sofa for Your Business Needs

When selecting a sofa for a B2B context, the decision should align with the intended use, budget, and desired aesthetic. Microfiber leather sofas stand out for their durability and ease of maintenance, making them suitable for environments that experience heavy usage. Genuine leather offers a luxurious feel but requires a higher investment and ongoing upkeep. Conversely, fabric sofas provide flexibility and affordability but may not withstand the rigors of high-traffic areas. By carefully evaluating these alternatives, buyers can make strategic decisions that best serve their operational goals and enhance their business environment.

Essential Technical Properties and Trade Terminology for microfiber leather sofa

What Are the Essential Technical Properties of Microfiber Leather Sofas?

Microfiber leather sofas are gaining traction in the B2B market for their combination of aesthetic appeal and practical benefits. Understanding the key technical properties of these products is crucial for international buyers seeking quality and reliability.

1. Material Grade and Composition

Microfiber leather is typically made from synthetic fibers, primarily polyester or polyamide, which are tightly woven to create a soft and durable surface. The grade of microfiber can significantly affect the sofa’s durability, feel, and appearance. Higher-grade microfiber leathers are more resistant to wear and tear, making them suitable for high-traffic environments like hotels or offices. Buyers should prioritize sofas made from high-grade microfiber to ensure longevity and value for money.

2. Abrasion Resistance Rating

This property measures how well the fabric withstands friction and wear. It is quantified using the Martindale test, which evaluates the number of double rubs a material can endure before showing signs of wear. Sofas with an abrasion resistance rating of 30,000 rubs or more are considered heavy-duty, making them ideal for commercial settings. For B2B buyers, this rating is critical in assessing the longevity of the product in demanding environments.

3. Stain Resistance

Microfiber leather is often treated with stain-resistant coatings that repel liquids and dirt. This property is essential for maintaining the appearance and hygiene of the sofa, especially in commercial spaces where spills are more likely to occur. Buyers should inquire about the specific stain resistance treatments used and their effectiveness, as this can significantly reduce cleaning and maintenance costs.

4. Fire Retardancy Standards

In many regions, including Europe and North America, upholstery materials must meet specific fire safety regulations. Microfiber leather sofas may come with fire retardant treatments that comply with these standards. Buyers should verify the certifications of the sofas they are considering, as this will ensure compliance with local safety regulations and enhance the overall safety of the environment where the sofa will be used.

Illustrative image related to microfiber leather sofa

What Are Common Trade Terms Related to Microfiber Leather Sofas?

Understanding industry terminology is vital for B2B transactions, especially in the global market for microfiber leather sofas. Here are some key terms that buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products based on the specifications provided by another company. In the context of microfiber leather sofas, buyers often work with OEMs to produce custom designs that meet their specific needs. This relationship can lead to cost savings and tailored solutions.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a buyer must purchase from a supplier. This term is crucial for B2B transactions, as it helps buyers understand the scale of their orders. Suppliers may set higher MOQs for custom designs, which is essential for budgeting and inventory planning.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers invite suppliers to submit price quotes for specific products or services. For microfiber leather sofas, submitting an RFQ allows buyers to compare offers, negotiate terms, and ensure they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers, as they outline who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers mitigate risks and manage logistics more effectively.

Illustrative image related to microfiber leather sofa

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For microfiber leather sofas, this can vary based on factors such as customization and shipping. Understanding lead times is crucial for inventory management and meeting customer demands, especially in sectors where timely delivery is critical.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing microfiber leather sofas for their businesses, ensuring they select products that meet their quality standards and operational needs.

Navigating Market Dynamics and Sourcing Trends in the microfiber leather sofa Sector

What Are the Key Market Dynamics and Trends in the Microfiber Leather Sofa Sector?

The microfiber leather sofa market is experiencing robust growth driven by several global factors. Increasing urbanization, particularly in regions like Africa, South America, and the Middle East, is leading to a surge in demand for affordable, stylish, and durable furniture. The trend toward multifunctional living spaces, especially in urban environments, has made microfiber leather sofas appealing due to their compact designs and versatile applications. Additionally, the rise of e-commerce platforms is reshaping the sourcing landscape, enabling international B2B buyers to access a broader range of products and suppliers, often with competitive pricing.

Illustrative image related to microfiber leather sofa

Emerging technologies such as augmented reality (AR) and virtual reality (VR) are enhancing the purchasing experience, allowing buyers to visualize how microfiber leather sofas will fit into their spaces before making a commitment. Furthermore, advancements in manufacturing processes are leading to improved quality and sustainability in microfiber leather production, making these sofas more attractive to eco-conscious consumers. For international buyers, understanding local preferences and market nuances, such as color trends and design aesthetics, is crucial for successful sourcing.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions?

Sustainability has become a central concern in the microfiber leather sofa sector, impacting both product development and sourcing strategies. The environmental footprint of synthetic materials, including microfiber, has prompted manufacturers to explore eco-friendly alternatives and certifications. B2B buyers should prioritize suppliers who adhere to sustainable practices, such as using recycled materials or implementing waste-reduction strategies in their manufacturing processes. Certifications like GREENGUARD or OEKO-TEX can serve as indicators of a product’s safety and environmental impact, providing buyers with assurance regarding ethical sourcing.

Moreover, the importance of ethical supply chains cannot be overstated. Transparency in sourcing ensures that materials are procured responsibly, fostering trust between buyers and suppliers. This is particularly significant in markets such as Europe and the Middle East, where regulatory frameworks increasingly mandate sustainability disclosures. By aligning sourcing strategies with sustainability goals, B2B buyers can not only meet consumer expectations but also enhance their brand reputation in an increasingly eco-conscious marketplace.

Illustrative image related to microfiber leather sofa

How Has the Microfiber Leather Sofa Market Evolved Over Time?

The evolution of the microfiber leather sofa market has been marked by significant technological advancements and changing consumer preferences. Initially, microfiber was lauded for its durability and ease of maintenance, quickly becoming a popular alternative to traditional leather. As design trends evolved, manufacturers began to innovate, introducing a variety of textures and colors, which expanded the appeal of microfiber leather sofas across diverse demographics.

Over the years, the market has also adapted to the growing demand for sustainable and ethically sourced materials, leading to the development of eco-friendly microfiber alternatives. This shift reflects a broader trend in the furniture industry, where consumers are increasingly prioritizing sustainability alongside style and functionality. As a result, the microfiber leather sofa sector is poised for continued growth, fueled by a combination of innovative design, technological advancements, and a commitment to ethical sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of microfiber leather sofa

-

How do I choose the right microfiber leather sofa for my business needs?

Selecting the ideal microfiber leather sofa involves evaluating factors such as target market preferences, budget constraints, and intended use. Consider the style, color options, and seating capacity that align with your customers’ needs. Additionally, assess the durability and maintenance requirements of the material, as high-quality microfiber should resist stains and wear. Collaborating with manufacturers who offer customization options can further ensure the product meets specific market demands. -

What are the advantages of using microfiber leather in commercial settings?

Microfiber leather is a popular choice for commercial environments due to its durability, ease of cleaning, and aesthetic appeal. It is stain-resistant and can withstand heavy use, making it ideal for hotels, restaurants, and offices. Additionally, microfiber leather offers a sophisticated look similar to genuine leather at a lower cost, providing a budget-friendly option for businesses. Its hypoallergenic properties also make it suitable for environments where cleanliness is paramount. -

What should I consider when vetting suppliers for microfiber leather sofas?

When evaluating suppliers, prioritize their experience in manufacturing microfiber leather products and check their certifications for quality standards. Request samples to assess the material’s texture and durability. Additionally, investigate their production capacity and lead times to ensure they can meet your demand. Customer reviews and testimonials can provide insight into their reliability and service quality, while understanding their return policies is crucial for risk management. -

What is the typical minimum order quantity (MOQ) for microfiber leather sofas?

MOQs for microfiber leather sofas can vary significantly based on the supplier and the complexity of the design. Generally, you can expect MOQs to range from 50 to 200 units. It’s essential to discuss your specific needs with potential suppliers, as some may offer flexibility for smaller orders, especially for new business relationships. Understanding the MOQ helps in planning inventory and managing cash flow effectively. -

What payment terms are commonly accepted in international trade for sofa purchases?

Payment terms in international trade typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit (often 30%) before production, with the balance due before shipping. It’s advisable to negotiate terms that align with your cash flow capabilities and risk tolerance. Additionally, consider using secure payment methods to protect your investment and ensure a smooth transaction. -

How can I ensure quality assurance (QA) for my microfiber leather sofas?

Establishing a robust QA process is vital for maintaining product quality. Work with suppliers who provide detailed specifications and conduct regular inspections throughout the manufacturing process. Implementing a third-party inspection service can help verify that the products meet your quality standards before shipment. Additionally, consider setting up a returns policy for defective items to protect your business interests. -

What logistics considerations should I keep in mind when importing microfiber leather sofas?

Logistics for importing microfiber leather sofas involve understanding shipping options, customs regulations, and delivery timelines. Choose a reliable freight forwarder who can navigate the complexities of international shipping, including tariffs and duties. Ensure that the supplier provides appropriate packaging to prevent damage during transit. It’s also beneficial to plan for warehousing solutions upon arrival, especially if you have limited storage capacity. -

How can I customize microfiber leather sofas to meet my brand’s identity?

Customization options for microfiber leather sofas often include choices in fabric color, texture, and design elements such as stitching and cushion firmness. Collaborate with suppliers who have experience in bespoke furniture manufacturing, allowing you to create products that reflect your brand’s identity. Additionally, consider incorporating branding elements, such as logos or unique patterns, to differentiate your offerings in the market.

Top 2 Microfiber Leather Sofa Manufacturers & Suppliers List

1. Loft Home – Microfiber Leather Sofas

Domain: lofthome.com

Registered: 2020 (5 years)

Introduction: Microfiber Leather Sofas in SG | Stylish & Comfortable – Loft Home

30 Days No Reason Return & Refund

Spend Over $500, Free Delivery & Installation

5 Years Warranty

2. Suns Goods – Leather Couches

Domain: sunsgoods.com

Registered: 2017 (8 years)

Introduction: Leather couches are known for their durability, luxurious feel, and aesthetic appeal, available in genuine and faux leather. They last for decades with proper care, regulate temperature, and fit various decor styles, typically priced between $1,000 to $4,500. Microfiber couches are made from synthetic materials, offering affordability, a variety of colors and styles, and easy care, being resistant…

Strategic Sourcing Conclusion and Outlook for microfiber leather sofa

In conclusion, strategic sourcing of microfiber leather sofas presents a unique opportunity for international B2B buyers to capitalize on a growing market. The versatility, durability, and aesthetic appeal of microfiber leather make it an attractive choice for diverse consumer preferences across regions such as Africa, South America, the Middle East, and Europe. By leveraging strategic sourcing practices, businesses can secure competitive pricing, ensure quality control, and foster relationships with reliable suppliers.

Key takeaways include the importance of understanding local market demands and preferences, as well as the value of sourcing sustainably produced products to meet increasing consumer expectations. Engaging with manufacturers who offer customizable options can further enhance your product offerings, enabling you to cater to specific regional tastes and trends.

As you look toward the future, consider the expanding market for microfiber leather sofas and the potential for growth in your business. Establishing strong partnerships with suppliers and staying attuned to industry innovations will position you favorably in this competitive landscape. Embrace this opportunity to enhance your product portfolio and meet the evolving needs of your customers.

Illustrative image related to microfiber leather sofa

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.