Introduction: Navigating the Global Market for microfiber by the yard

In today’s competitive landscape, sourcing high-quality microfiber by the yard presents a unique challenge for international B2B buyers. As businesses strive to enhance product offerings—from apparel to upholstery—finding reliable suppliers who can deliver durable and versatile microfiber fabrics becomes essential. This guide aims to equip you with the knowledge necessary to navigate the complexities of the microfiber market, addressing key factors such as fabric types, applications, supplier vetting, and pricing strategies.

Microfiber’s appeal lies in its exceptional absorbency, softness, and durability, making it suitable for a wide range of applications, including home décor, activewear, and automotive upholstery. However, with the global market’s diverse options, making informed purchasing decisions can be daunting. This comprehensive resource will provide insights into the various types of microfiber available, their specific uses, and the considerations necessary for selecting the right suppliers.

Targeting international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—this guide is designed to empower you with actionable insights. By understanding the nuances of sourcing microfiber by the yard, you can streamline your procurement process, enhance product quality, and ultimately drive your business’s success in a global marketplace.

Table Of Contents

- Top 7 Microfiber By The Yard Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for microfiber by the yard

- Understanding microfiber by the yard Types and Variations

- Key Industrial Applications of microfiber by the yard

- 3 Common User Pain Points for ‘microfiber by the yard’ & Their Solutions

- Strategic Material Selection Guide for microfiber by the yard

- In-depth Look: Manufacturing Processes and Quality Assurance for microfiber by the yard

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber by the yard’

- Comprehensive Cost and Pricing Analysis for microfiber by the yard Sourcing

- Alternatives Analysis: Comparing microfiber by the yard With Other Solutions

- Essential Technical Properties and Trade Terminology for microfiber by the yard

- Navigating Market Dynamics and Sourcing Trends in the microfiber by the yard Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of microfiber by the yard

- Strategic Sourcing Conclusion and Outlook for microfiber by the yard

- Important Disclaimer & Terms of Use

Understanding microfiber by the yard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| マイクロファイバー・スエード | Soft, luxurious feel; mimics real suede; durable | Upholstery, automotive interiors, fashion | Pros: Cost-effective, easy to clean; Cons: May not be as breathable as natural fabrics. |

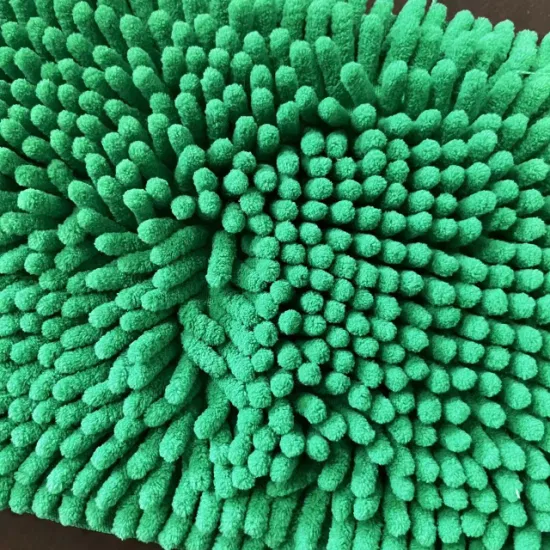

| Microfiber Chenille | Plush texture; highly absorbent; versatile | Home textiles, cushions, blankets | Pros: Softness, warmth; Cons: Requires careful washing to maintain appearance. |

| Microfiber Velvet | Rich, soft texture; available in various colors | Fashion apparel, drapery, upholstery | Pros: Luxurious look, good durability; Cons: Can show marks easily, may require special care. |

| Microfiber Fleece | Lightweight, soft, and warm; moisture-wicking | Activewear, blankets, outdoor gear | Pros: Excellent insulation, quick-drying; Cons: Can pill over time with wear. |

| Microfiber Nylon | Strong, durable; water-resistant properties | Industrial applications, outdoor gear | Pros: High durability, versatile; Cons: Less soft compared to other microfiber types. |

What are the Characteristics of Microfiber Suede and Its B2B Applications?

Microfiber suede is a synthetic fabric that emulates the softness and texture of natural suede while offering enhanced durability. This type of microfiber is often used in upholstery, particularly for automotive interiors and furniture, due to its luxurious feel and ease of maintenance. When purchasing, B2B buyers should consider factors such as color options, stain resistance, and the fabric’s ability to withstand heavy use, ensuring it meets the specific demands of their projects.

How Does Microfiber Chenille Stand Out in Home Textiles?

Microfiber chenille is characterized by its plush texture and exceptional absorbency, making it ideal for home textiles like cushions and blankets. Its soft feel provides comfort, while its versatility allows it to be used in various decorative applications. B2B buyers should focus on the fabric’s durability and ease of washing, as these factors significantly impact its long-term performance in consumer products.

Illustrative image related to microfiber by the yard

What Advantages Does Microfiber Velvet Offer for Fashion and Upholstery?

Microfiber velvet is known for its rich texture and variety of color options, making it a popular choice for fashion apparel and drapery. This type of microfiber combines aesthetic appeal with durability, making it suitable for high-traffic areas. Buyers should consider the fabric’s care requirements and its resistance to showing marks or wear, as these aspects can influence customer satisfaction and product longevity.

Why Choose Microfiber Fleece for Activewear and Outdoor Gear?

Microfiber fleece is lightweight yet provides excellent warmth and moisture-wicking properties, making it a favored choice for activewear and outdoor gear. Its ability to dry quickly adds to its appeal for B2B buyers targeting the sports and outdoor markets. When sourcing this material, buyers should evaluate its insulation properties and potential for pilling, ensuring the final product meets performance standards.

What Makes Microfiber Nylon Suitable for Industrial Applications?

Microfiber nylon is a strong and durable fabric with water-resistant qualities, making it particularly suitable for industrial applications and outdoor gear. Its versatility allows it to be used in various sectors, from automotive to outdoor equipment. B2B buyers should assess the fabric’s strength, water resistance, and overall performance to ensure it meets the rigorous demands of industrial use while providing value for their investment.

Key Industrial Applications of microfiber by the yard

| Industry/Sector | Specific Application of microfiber by the yard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel & Fashion | Production of activewear and loungewear | Lightweight, moisture-wicking properties enhance comfort and performance. | Look for durable, stretchable fabrics with vibrant colors and patterns suitable for fashion trends. |

| Automotive | Upholstery and interior components | High durability and stain resistance improve vehicle aesthetics and longevity. | Ensure compliance with automotive industry standards for fire resistance and colorfastness. |

| Home Textiles | Bedding, curtains, and upholstery | Soft, hypoallergenic material offers comfort and easy maintenance for consumers. | Source from suppliers with certifications for eco-friendliness and safety standards. |

| Hospitality | Linens and furnishings for hotels and restaurants | Enhances guest experience with luxurious feel while being cost-effective and easy to clean. | Consider bulk purchasing options and supplier reliability for consistent quality. |

| Sports & Recreation | Towels and gear for sports teams | Highly absorbent and quick-drying materials enhance performance and hygiene. | Look for moisture-wicking and antibacterial properties in sourcing decisions. |

How is Microfiber by the Yard Utilized in Apparel and Fashion?

In the apparel and fashion industry, microfiber by the yard is primarily used for producing activewear and loungewear. Its lightweight and moisture-wicking properties make it ideal for garments that require comfort and breathability during physical activities. B2B buyers in this sector must focus on sourcing durable fabrics that can withstand wear and tear while remaining stylish. They should also consider trending colors and patterns to appeal to their target demographic, particularly in regions where fashion is influenced by local styles, such as Africa and Europe.

What Role Does Microfiber Play in Automotive Applications?

Microfiber is essential in the automotive sector, particularly for upholstery and interior components. Its high durability and stain resistance significantly enhance the aesthetics and longevity of vehicle interiors. For international buyers, particularly in emerging markets, it is crucial to ensure that sourced microfiber meets automotive industry standards for fire resistance and colorfastness. This attention to quality can help manufacturers provide a competitive edge in a market that values both safety and style.

Illustrative image related to microfiber by the yard

Why is Microfiber Important in Home Textiles?

In the home textiles sector, microfiber by the yard is widely used for bedding, curtains, and upholstery. The soft, hypoallergenic nature of microfiber not only offers comfort but also appeals to consumers seeking easy maintenance solutions. B2B buyers should prioritize sourcing from suppliers who provide eco-friendly certifications and adhere to safety standards, especially in regions like South America and the Middle East, where sustainability is becoming increasingly important to consumers.

How Does Microfiber Enhance the Hospitality Industry?

The hospitality industry benefits significantly from microfiber by the yard for linens and furnishings. The luxurious feel of microfiber enhances guest experiences while being cost-effective and easy to clean. For B2B buyers in this sector, considering bulk purchasing options is essential, as is evaluating supplier reliability to ensure consistent quality and service. This focus on quality can lead to improved guest satisfaction and repeat business.

What Advantages Does Microfiber Offer in Sports and Recreation?

In the sports and recreation industry, microfiber is used for towels and gear, thanks to its highly absorbent and quick-drying properties. These features enhance performance and hygiene, making it a preferred choice for sports teams. B2B buyers should look for microfiber with moisture-wicking and antibacterial properties to meet the specific needs of athletes. Sourcing from reputable manufacturers ensures that the materials meet the rigorous demands of sports activities, particularly in competitive environments.

3 Common User Pain Points for ‘microfiber by the yard’ & Their Solutions

Scenario 1: Quality Assurance in Microfiber Fabric Procurement

The Problem: B2B buyers often face challenges ensuring the quality of microfiber fabric when sourcing it by the yard. Variability in production standards can lead to discrepancies in texture, durability, and overall performance. For businesses that depend on consistent quality—such as upholstery manufacturers or apparel companies—this can result in costly returns, dissatisfied customers, and damage to brand reputation.

Illustrative image related to microfiber by the yard

The Solution: To mitigate quality concerns, buyers should establish clear specifications and standards before placing orders. This includes requesting detailed product descriptions, samples, and certifications from suppliers. It’s advisable to conduct a thorough supplier audit, assessing their production processes and quality control measures. Additionally, implementing a quality assurance protocol upon receiving the fabric can help identify any issues before the material is put into production. Consider partnering with suppliers who offer transparent sourcing practices and are willing to provide test results for fabric durability and safety standards.

Scenario 2: Understanding Fabric Composition and Its Implications

The Problem: Many B2B buyers are unaware of the implications of different fiber compositions in microfiber fabrics, which can significantly affect their end-use applications. For instance, a higher polyester content may enhance durability but can compromise breathability, making it unsuitable for certain apparel applications. Without a clear understanding of how composition impacts performance, buyers may select the wrong fabric for their needs, leading to product failures and increased costs.

The Solution: Buyers should invest time in educating themselves about fiber compositions and their properties. This includes understanding the differences between polyester, nylon, and blends, as well as their respective strengths and weaknesses. Engaging with suppliers who provide comprehensive information about the fabric composition, including technical data sheets and usage guidelines, can empower buyers to make informed decisions. Additionally, conducting small-scale trials with different compositions in real-world applications can help determine the best fabric for specific needs, reducing the risk of costly errors in larger production runs.

Scenario 3: Managing Inventory and Waste in Fabric Usage

The Problem: Efficient inventory management can be a significant pain point for B2B buyers dealing with microfiber by the yard, particularly when the fabric is ordered in bulk. Overestimating needs can lead to excess inventory, while underestimating can result in production delays. Moreover, the synthetic nature of microfiber can create challenges in waste management, as leftover fabric often cannot be easily repurposed or recycled.

Illustrative image related to microfiber by the yard

The Solution: To optimize inventory management, buyers should adopt a just-in-time (JIT) procurement approach, aligning orders more closely with production schedules. Utilizing inventory management software can provide insights into usage patterns, helping to forecast needs more accurately. Implementing a fabric waste reduction strategy, such as partnering with manufacturers who can use offcuts for smaller products or donating excess fabric to local charities, can also minimize waste. Additionally, consider negotiating with suppliers for flexible order quantities that allow for adjustments based on real-time demand, which can help maintain a lean inventory while ensuring production efficiency.

Strategic Material Selection Guide for microfiber by the yard

What Are the Key Properties of Microfiber Materials for B2B Applications?

Microfiber fabrics are primarily composed of synthetic fibers such as polyester and nylon, which provide unique properties that enhance their performance in various applications. The following analysis covers three common types of microfiber materials used in B2B contexts, focusing on their properties, advantages, disadvantages, and implications for international buyers.

1. Polyester Microfiber

Key Properties: Polyester microfiber is known for its exceptional durability and resistance to shrinking and stretching. It typically withstands temperatures up to 150°C and exhibits good moisture-wicking capabilities, making it suitable for a variety of applications, including apparel and upholstery.

Pros & Cons: The primary advantage of polyester microfiber is its cost-effectiveness, as it is generally less expensive than other synthetic fibers. It is also easy to dye, allowing for a wide range of colors and patterns. However, it may not perform as well in high-temperature environments and can be less breathable compared to natural fibers.

Impact on Application: Polyester microfiber is often used in the production of clothing, home textiles, and cleaning products. Its moisture-wicking properties make it ideal for activewear, while its durability makes it suitable for upholstery.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local textile standards, which may include certifications for chemical safety and environmental sustainability.

2. Nylon Microfiber

Key Properties: Nylon microfiber is recognized for its strength and elasticity, with a temperature resistance of up to 200°C. It has excellent abrasion resistance, making it ideal for high-wear applications.

Pros & Cons: The key advantage of nylon microfiber is its superior durability and flexibility, which makes it suitable for items that require a high degree of wear resistance, such as outdoor gear and automotive interiors. However, it can be more expensive than polyester and may require more complex manufacturing processes.

Impact on Application: Nylon microfiber is commonly used in performance apparel, outdoor equipment, and upholstery. Its strength allows it to withstand rigorous use, making it a preferred choice for applications requiring longevity.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should be aware of stringent EU regulations regarding textile safety and environmental impact. Compliance with standards such as Oeko-Tex certification can enhance marketability.

Illustrative image related to microfiber by the yard

3. Acrylic Microfiber

Key Properties: Acrylic microfiber offers a soft texture and good thermal insulation properties, with a temperature resistance of approximately 180°C. It is lightweight and has a high moisture absorption capacity.

Pros & Cons: The primary advantage of acrylic microfiber is its softness and warmth, making it suitable for apparel and home textiles like blankets and throws. However, it can be less durable than polyester and nylon, leading to potential wear and tear over time.

Impact on Application: Acrylic microfiber is often used in fashion apparel, blankets, and plush toys. Its warmth and softness make it a popular choice for winter clothing and cozy home products.

Considerations for International Buyers: Buyers from the Middle East should consider the climate when selecting acrylic microfiber, as its moisture absorption properties may not be suitable for extremely humid environments. Additionally, understanding local market preferences can guide product design.

Illustrative image related to microfiber by the yard

Summary Table of Microfiber Materials

| 素材 | Typical Use Case for microfiber by the yard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester Microfiber | Apparel, upholstery, cleaning products | Cost-effective and durable | Less breathable in high heat | 低い |

| Nylon Microfiber | Performance apparel, outdoor gear | Superior strength and elasticity | Higher cost and manufacturing complexity | Medium |

| Acrylic Microfiber | Fashion apparel, blankets, plush toys | Soft texture and thermal insulation | Less durable than polyester/nylon | Medium |

This strategic material selection guide provides insights into the properties and applications of microfiber materials, enabling international B2B buyers to make informed purchasing decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for microfiber by the yard

What Are the Main Stages in the Manufacturing Process of Microfiber by the Yard?

The production of microfiber fabric involves several critical stages that ensure the final product meets the high standards expected by B2B buyers. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Chosen and Processed?

The manufacturing process begins with the selection of raw materials, primarily synthetic fibers such as polyester, nylon, or a blend of both. These fibers are chosen for their durability, absorbency, and softness. Once selected, the fibers undergo a series of treatments including carding, which separates and aligns the fibers, and drawing, which elongates and further aligns them. This preparation is crucial as it lays the groundwork for the quality and performance of the microfiber fabric.

Forming: What Techniques Are Used to Create the Fabric?

In the forming stage, the prepared fibers are spun into yarns using techniques such as ring spinning or open-end spinning. These yarns can be woven or knitted, depending on the desired fabric texture and application. Weaving techniques often include plain weave, twill, or satin weave, while knitting can involve warp or weft knitting. The choice of technique impacts the fabric’s characteristics, such as stretchability, breathability, and overall feel.

Assembly: How Are Microfiber Fabrics Constructed?

During the assembly phase, the formed fabric is treated to enhance its properties. This may involve dyeing, printing, or applying finishes such as moisture-wicking or anti-static treatments. The assembly phase is also when the fabric is cut to size, typically sold by the yard or in bulk rolls. Quality control checkpoints are implemented at this stage to ensure consistency in color, texture, and overall appearance.

Illustrative image related to microfiber by the yard

Finishing: What Final Touches Are Applied to Microfiber Fabrics?

The finishing stage is essential for achieving the desired aesthetic and functional qualities. Fabrics may undergo processes such as brushing, which raises the fibers to create a soft, plush surface, or calendaring, which smooths the fabric for a sleek finish. Additionally, treatments such as flame-retardancy or stain resistance can be applied, depending on the intended use of the microfiber fabric. Each of these finishing processes can significantly influence the final product’s appeal and utility.

What Quality Assurance Practices Are Essential in Microfiber Fabric Manufacturing?

Quality assurance is critical in ensuring that microfiber fabric meets international standards and customer expectations. The following practices are commonly employed in the industry.

What International Standards Should B2B Buyers Look For?

International standards, such as ISO 9001, provide a framework for quality management systems that ensure consistent product quality. For microfiber fabrics, compliance with additional standards such as Oeko-Tex Standard 100, which ensures the fabric is free from harmful substances, is also crucial. B2B buyers should verify that their suppliers adhere to these standards, as it reflects a commitment to quality and safety.

What Are the Key Quality Control Checkpoints in Microfiber Production?

Quality control in microfiber manufacturing typically includes several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps catch any deviations early.

- Final Quality Control (FQC): Before shipment, the finished products are thoroughly inspected for defects, ensuring they meet the required specifications.

These checkpoints are essential for maintaining high-quality standards throughout the manufacturing process.

What Common Testing Methods Are Used to Ensure Microfiber Quality?

Various testing methods are employed to assess the quality of microfiber fabrics. Common tests include:

Illustrative image related to microfiber by the yard

- Tensile Strength Testing: Measures the fabric’s strength and durability.

- Colorfastness Testing: Evaluates how well the fabric retains its color when exposed to washing, light, or rubbing.

- Water Absorbency Testing: Assesses the fabric’s absorbent properties, which is particularly important for applications such as cleaning cloths and apparel.

These tests provide valuable insights into the fabric’s performance, helping buyers make informed purchasing decisions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Ensuring that suppliers have robust quality control processes is crucial for B2B buyers. Here are some strategies to verify these practices:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality assurance documentation from suppliers, including audit reports and quality control certifications. Regular audits, conducted either internally or by third-party organizations, can provide insights into the supplier’s adherence to quality standards. This information helps buyers assess the reliability and competence of potential suppliers.

How Can Third-Party Inspections Enhance Confidence in Product Quality?

Engaging third-party inspection services can add an extra layer of assurance. These inspections typically occur at various stages of the manufacturing process, providing an unbiased evaluation of quality control measures. Buyers should consider incorporating third-party inspections as part of their procurement strategy, particularly for larger orders or when sourcing from new suppliers.

Illustrative image related to microfiber by the yard

What Are the Specific QC Considerations for International B2B Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances. Different markets may have varying standards and expectations regarding fabric quality and safety.

How Do Regional Standards Affect Microfiber Sourcing?

Understanding regional standards is vital. For instance, European buyers may prioritize compliance with REACH regulations, which govern chemical safety, while buyers in the Middle East might focus on durability and performance in high-temperature environments. Buyers should conduct thorough research to ensure that the products they source comply with local regulations and market expectations.

What Role Does Transparency Play in International Sourcing?

Transparency in the supply chain is increasingly important for international B2B buyers. Suppliers should be willing to share information about their sourcing practices, production processes, and quality control measures. This transparency fosters trust and enables buyers to make informed decisions that align with their quality standards and ethical sourcing commitments.

Illustrative image related to microfiber by the yard

Conclusion

Understanding the manufacturing processes and quality assurance practices for microfiber by the yard is essential for B2B buyers seeking reliable suppliers. By focusing on the key stages of production and implementing rigorous quality control measures, suppliers can ensure that their products meet the high standards demanded by international markets. Buyers should leverage this knowledge to make informed decisions, ensuring they partner with suppliers committed to quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber by the yard’

はじめに

This guide serves as a comprehensive checklist for B2B buyers looking to procure microfiber fabric by the yard. Microfiber is a versatile material widely used in various applications, from apparel to upholstery. Understanding the procurement process is crucial for ensuring quality, cost-effectiveness, and supplier reliability.

Step 1: Define Your Technical Specifications

Before starting your sourcing process, clearly outline the technical specifications for the microfiber fabric you require. This includes details such as fiber content (e.g., polyester, nylon), weight, texture, and intended applications. Defining these parameters helps streamline your search and ensures that potential suppliers can meet your specific needs.

- Considerations:

- What is the intended use (e.g., upholstery, clothing, accessories)?

- Are there specific performance characteristics required (e.g., moisture-wicking, durability)?

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in microfiber fabrics. Utilize online directories, trade shows, and industry contacts to compile a list of candidates. A diverse supplier base allows for competitive pricing and better negotiation options.

Illustrative image related to microfiber by the yard

- Tips:

- Look for suppliers with a strong online presence and positive customer reviews.

- Ensure they have experience in your specific market region, such as Africa or Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This due diligence ensures that you partner with reliable vendors who can deliver quality products consistently.

- What to assess:

- Supplier certifications (e.g., ISO, Oeko-Tex) that guarantee product quality and safety.

- Financial stability and business longevity to mitigate risks.

Step 4: Request Samples

Once you have narrowed down your list of potential suppliers, request samples of the microfiber fabric. This step allows you to evaluate the quality, texture, and performance of the fabric firsthand. Testing samples ensures that the product meets your specifications before placing a larger order.

- Key aspects to check:

- Colorfastness and durability during testing.

- Compliance with your desired technical specifications.

Step 5: Negotiate Pricing and Terms

After evaluating samples, initiate negotiations regarding pricing, payment terms, and delivery schedules. Transparent communication is vital to establish a mutually beneficial agreement. Be prepared to discuss bulk order discounts, shipping options, and potential long-term partnerships.

- Considerations:

- What are the minimum order quantities (MOQs)?

- Are there provisions for returns or exchanges in case of defects?

Step 6: Verify Shipping and Logistics

Ensure that the supplier can meet your logistical requirements, including shipping times and methods. Understanding the supplier’s capabilities in handling international shipping is crucial, especially when sourcing from different continents.

- Important points:

- Confirm lead times for production and delivery.

- Evaluate the supplier’s experience with customs and import regulations in your region.

Step 7: Establish Quality Control Procedures

Once you have finalized your supplier, set up quality control procedures to monitor the fabric’s quality throughout the production process. This step is vital to ensure that the final product adheres to your specifications and maintains consistent quality.

Illustrative image related to microfiber by the yard

- Actions to implement:

- Schedule periodic quality audits during production.

- Define clear criteria for acceptable quality standards to avoid discrepancies.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing microfiber fabric by the yard, ensuring they secure high-quality materials that meet their business needs.

Comprehensive Cost and Pricing Analysis for microfiber by the yard Sourcing

What Are the Key Cost Components in Sourcing Microfiber by the Yard?

Sourcing microfiber by the yard involves several cost components that significantly influence the final pricing. The primary costs include:

-

Materials: Microfiber is typically made from synthetic fibers such as polyester, nylon, or acrylic. The quality and sourcing of these materials can vary widely, impacting the cost. Higher-grade materials will naturally lead to increased prices.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process. Regions with lower labor costs can offer competitive pricing, but this may come at the expense of quality.

-

Manufacturing Overhead: This includes all indirect costs related to production, such as facility maintenance, utilities, and administrative expenses. Efficient operations can minimize overhead, translating to lower prices for buyers.

-

Tooling: The initial setup costs for machinery and tools used in production can be substantial. Customization of tooling for specific microfiber types can add to this cost.

-

Quality Control (QC): Ensuring that the microfiber meets specific standards requires investment in QC processes. Stringent QC measures may lead to higher prices but can enhance product reliability.

-

Logistics: Transportation costs from manufacturing facilities to buyers, including shipping and handling, are crucial. These costs can vary based on distance, mode of transportation, and regional tariffs.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure sustainability. This margin can vary depending on the supplier’s business model and market position.

How Do Price Influencers Impact Microfiber Pricing?

Several factors can influence the pricing of microfiber by the yard:

-

Volume/MOQ: Bulk purchasing often leads to discounts. Buyers should negotiate minimum order quantities (MOQ) that can lead to better pricing.

-

Specifications and Customization: Custom orders tailored to specific requirements (e.g., colors, patterns, certifications) may incur additional costs. Buyers should assess whether customization adds value to their offerings.

-

Materials: The choice of fiber quality, blend, and treatment (e.g., moisture-wicking or flame-retardant) directly affects pricing. Higher-quality materials justify a premium price.

-

Quality and Certifications: Products certified for safety, sustainability, or specific industry standards may command higher prices. Buyers should weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can influence costs. Established suppliers with a history of quality may charge more but provide peace of mind.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital as they define the responsibilities of buyers and sellers regarding shipping and logistics. Different terms can alter the total cost significantly.

What Are the Best Negotiation Tips for B2B Buyers Sourcing Microfiber?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips for effective negotiation:

Illustrative image related to microfiber by the yard

-

Understand Total Cost of Ownership (TCO): Beyond the initial price per yard, consider all associated costs, including shipping, import duties, and potential wastage. This comprehensive view will help in negotiating a more favorable deal.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and more favorable terms. Trust can often translate into discounts or improved service.

-

Compare Multiple Suppliers: Obtaining quotes from several suppliers can provide leverage during negotiations. It allows buyers to understand market pricing and select the best value.

-

Be Transparent About Needs: Clearly communicating volume, specifications, and delivery timelines can help suppliers offer tailored pricing that reflects the buyer’s actual needs.

-

Timing of Orders: Purchasing during off-peak seasons or when suppliers have excess inventory can lead to significant savings.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers should be mindful of several pricing nuances when sourcing microfiber:

-

Currency Fluctuations: Exchange rates can significantly impact final costs. Buyers should consider locking in prices or negotiating in a stable currency.

-

Tariffs and Duties: Import tariffs can add unexpected costs. Researching these beforehand can help in budgeting accurately.

-

Cultural Differences in Negotiation Styles: Understanding regional negotiation practices can facilitate smoother transactions and better relationships.

Disclaimer on Indicative Prices

Prices for microfiber by the yard can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough research and obtain detailed quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing microfiber by the yard With Other Solutions

Exploring Alternatives to Microfiber by the Yard

In the diverse world of fabric sourcing, B2B buyers often seek alternatives to standard options like microfiber by the yard. Understanding the comparative advantages and disadvantages of available solutions can help in making informed procurement decisions tailored to specific applications, whether for apparel, upholstery, or home decor.

| Comparison Aspect | Microfiber By The Yard | Alternative 1: Cotton Fabric | Alternative 2: Polyester Fabric |

|---|---|---|---|

| Performance | Highly absorbent, soft, and durable; excellent for apparel and upholstery. | Breathable and comfortable; good for casual wear but less durable than microfiber. | Strong and resilient; good moisture-wicking properties but can be less breathable than cotton. |

| Cost | Moderate; prices vary based on quality and sourcing. | Generally lower; cost-effective for bulk purchases. | Competitive; often cheaper than microfiber, especially in mass production. |

| Ease of Implementation | Easy to sew and work with; suitable for various applications. | Widely available and versatile; easy to source globally. | Similar ease of use; however, sourcing can be region-dependent. |

| Maintenance | Machine washable, quick-drying, and resistant to stains. | Requires regular washing; prone to wrinkling and shrinking. | Easy to care for, durable, and resistant to fading and shrinking. |

| Best Use Case | Ideal for high-end apparel, upholstery, and home goods requiring durability and comfort. | Best for everyday clothing, casual home textiles, and budget-conscious projects. | Suitable for activewear, promotional items, and cost-effective production needs. |

What are the Advantages and Disadvantages of Cotton Fabric as an Alternative?

Cotton fabric is a traditional alternative that offers a breathable and comfortable option for many applications. Its natural fibers provide softness, making it ideal for casual apparel and home textiles. However, cotton is generally less durable than microfiber, particularly in high-wear situations. It also requires more maintenance, as it can wrinkle and shrink after washing. Despite its lower cost, B2B buyers should consider the longevity and performance needs of their projects before opting for cotton.

Illustrative image related to microfiber by the yard

How Does Polyester Fabric Compare to Microfiber by the Yard?

Polyester fabric is another common alternative that offers excellent durability and resilience. It is particularly effective in moisture-wicking applications, making it a popular choice for activewear. Polyester is also typically more affordable than microfiber, especially when sourced in bulk. However, it may not provide the same level of breathability as cotton, which can be a consideration for apparel that requires comfort in warmer climates. Polyester’s ease of maintenance is an advantage; it resists fading and shrinking, making it a reliable choice for long-term use.

Making the Right Choice for Your B2B Fabric Needs

When selecting the appropriate fabric solution, B2B buyers should assess their specific requirements, such as performance, cost constraints, and intended applications. Microfiber by the yard excels in durability and comfort, making it suitable for high-end projects, while cotton and polyester offer viable alternatives that cater to different needs and budgets. By carefully evaluating these options, businesses can optimize their sourcing strategy to align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for microfiber by the yard

What Are the Key Technical Properties of Microfiber Fabric by the Yard?

Microfiber fabrics are increasingly favored in various industries due to their unique properties. Understanding these technical specifications is crucial for B2B buyers looking to make informed purchasing decisions.

1. Material Composition: What Types of Fibers Are Used?

Microfiber is primarily composed of synthetic fibers, most commonly polyester and nylon. The blend of these materials contributes to its softness, durability, and resistance to wear and tear. This is particularly important for applications in upholstery and apparel, where comfort and longevity are vital. Buyers should verify the fiber composition to ensure it meets the specific performance requirements for their intended use.

Illustrative image related to microfiber by the yard

2. Fabric Weight: Why Does It Matter?

Fabric weight, typically measured in grams per square meter (GSM), is a critical specification that affects the feel, drape, and durability of microfiber. A higher GSM indicates a thicker, more durable fabric, suitable for upholstery or heavy-duty applications, while a lower GSM may be appropriate for lightweight apparel. B2B buyers should consider the fabric weight based on the intended application to ensure it meets both aesthetic and functional needs.

3. Durability and Abrasion Resistance: How Is It Tested?

Durability is often assessed using the Martindale test, which measures how many rubs a fabric can withstand before showing signs of wear. Microfiber typically scores high on this test, making it ideal for high-traffic areas and products that undergo frequent use. For B2B buyers, understanding durability ratings helps in selecting materials that will maintain their appearance and functionality over time.

4. Moisture Wicking and Breathability: What Should Buyers Look For?

Microfiber fabrics are known for their moisture-wicking properties, allowing them to draw sweat away from the body. This feature is especially beneficial for activewear and home textiles like bedding. Buyers should inquire about the breathability of the microfiber fabric, as this affects comfort levels and suitability for specific uses.

5. Colorfastness: How Is It Ensured?

Colorfastness refers to a fabric’s ability to retain its color after exposure to washing, light, and other environmental factors. Microfiber can be treated for enhanced color retention, which is crucial for maintaining the visual appeal of products. For B2B buyers, understanding the colorfastness rating can help prevent issues related to fading, ensuring that products remain attractive over time.

What Are Common Trade Terms Associated with Microfiber Fabric?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions involving microfiber fabric.

1. MOQ (Minimum Order Quantity): What Does This Imply?

MOQ refers to the minimum quantity of fabric that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management. Buyers should consider their production needs to avoid overstocking or insufficient material supply.

2. OEM (Original Equipment Manufacturer): How Does It Impact Sourcing?

OEM refers to companies that produce goods for another company under that company’s brand. In the context of microfiber, OEM partnerships can offer customization options for specific markets. B2B buyers may benefit from exploring OEM relationships for tailored products that meet regional preferences.

3. RFQ (Request for Quotation): What Information Should It Include?

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of microfiber fabric. It should include details like material specifications, desired quantities, and delivery timelines. This helps streamline the procurement process and ensures accurate pricing.

4. Incoterms: Why Are They Important in International Trade?

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping arrangements. Understanding these terms is crucial for B2B transactions, as they dictate who bears the cost and risk at various stages of shipping. Buyers should familiarize themselves with relevant Incoterms to avoid unexpected costs.

5. Lead Time: What Should Buyers Expect?

Lead time refers to the time taken from placing an order to receiving the product. In the context of microfiber, lead times can vary based on factors such as production schedules and shipping methods. Buyers should account for lead times in their project timelines to ensure timely delivery of materials.

In conclusion, understanding the essential technical properties and industry terminology related to microfiber fabric by the yard is vital for international B2B buyers. This knowledge enables informed decision-making, ensuring that the chosen materials align with both performance requirements and market demands.

Navigating Market Dynamics and Sourcing Trends in the microfiber by the yard Sector

What Are the Key Market Dynamics and Trends Influencing Microfiber by the Yard?

The global microfiber by the yard market is experiencing significant growth driven by several factors. Increasing demand for durable, lightweight, and versatile fabrics across various industries—including fashion, automotive, and home decor—has positioned microfiber as a fabric of choice. Buyers from regions such as Africa, South America, the Middle East, and Europe are particularly interested in its multifunctional properties. Notably, the rise of e-commerce platforms has transformed sourcing dynamics, allowing international buyers to access a wider range of suppliers and products with ease.

Illustrative image related to microfiber by the yard

Emerging technologies, such as digital printing and automated cutting, are enhancing the efficiency of production processes. These innovations not only reduce lead times but also enable customization, catering to the growing demand for personalized products. Additionally, the trend towards sustainable materials is influencing sourcing decisions. Buyers are increasingly seeking suppliers who can provide microfiber fabrics made from recycled or eco-friendly materials, reflecting a broader shift toward sustainability in the textile industry.

How Is Sustainability and Ethical Sourcing Reshaping the Microfiber Fabric Market?

Sustainability is becoming a central tenet in the sourcing strategies of B2B buyers in the microfiber sector. Traditional microfiber production often involves synthetic fibers, which can have significant environmental impacts due to their non-biodegradable nature. Consequently, buyers are prioritizing suppliers that adhere to ethical and sustainable practices, such as using recycled polyester or nylon, which help mitigate environmental damage.

Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® Standard 100 are gaining traction among B2B buyers as they seek to validate the sustainability claims of suppliers. These certifications not only ensure the environmental integrity of the materials but also promote ethical labor practices throughout the supply chain. By choosing certified suppliers, businesses can enhance their brand reputation and appeal to increasingly eco-conscious consumers, thereby driving sales and fostering long-term relationships with clients.

What Is the Historical Context Behind the Microfiber Fabric Industry?

The microfiber fabric industry has its roots in the early 1970s when Japanese researchers developed ultra-fine synthetic fibers. Initially used for cleaning products due to their superior absorbency and durability, microfiber soon gained popularity in the fashion and upholstery sectors. Over the decades, advancements in manufacturing techniques have led to a diversification of microfiber applications, including apparel, automotive interiors, and home furnishings.

The evolution of consumer preferences towards lightweight, high-performance fabrics has further propelled the growth of microfiber. Today, it is widely regarded as a versatile solution that meets the demands of modern consumers while presenting significant opportunities for B2B buyers. As the market continues to evolve, understanding the historical context can provide valuable insights into current trends and future directions.

Frequently Asked Questions (FAQs) for B2B Buyers of microfiber by the yard

-

How do I choose the right microfiber fabric for my business needs?

Selecting the right microfiber fabric involves understanding your specific applications and customer demands. Consider factors such as fabric weight, texture, and durability. For apparel, opt for softer, more flexible options, while upholstery may require heavier, more robust materials. Request samples from suppliers to evaluate the fabric’s quality and performance before making bulk purchases, ensuring it meets your standards. -

What are the common applications of microfiber fabric in various industries?

Microfiber fabric is versatile and used across multiple sectors. In the apparel industry, it’s popular for making comfortable clothing like pajamas and activewear. In home textiles, it serves well for upholstery, curtains, and bedding. Additionally, industries such as automotive and healthcare utilize microfiber for its absorbency and durability, making it ideal for cleaning and protective gear. -

What minimum order quantities (MOQ) should I expect when sourcing microfiber by the yard?

MOQs for microfiber can vary significantly based on the supplier and fabric type. Typically, MOQs range from 10 to 100 yards for standard fabrics, while custom orders may require larger quantities. Always confirm with your supplier about their specific MOQ policies to ensure they align with your purchasing capabilities and project requirements. -

How can I ensure the quality of microfiber fabric when sourcing internationally?

To ensure quality, establish a robust vetting process for suppliers. Request certifications and quality assurance documents to verify compliance with international standards. Conduct factory audits if possible or rely on third-party inspection services. Additionally, ordering samples allows you to assess the fabric’s quality firsthand before committing to larger orders. -

What payment terms are typical for international purchases of microfiber fabric?

Payment terms can vary widely depending on the supplier and the buyer’s negotiation power. Common arrangements include a deposit upon order confirmation, with the balance due before shipment. Some suppliers might offer net payment terms (e.g., 30, 60, or 90 days) based on the buyer’s creditworthiness. Always clarify payment options and any potential fees associated with international transactions. -

What should I know about shipping logistics for microfiber fabric sourced internationally?

Shipping logistics are crucial for timely delivery. Consider factors such as shipping methods (air vs. sea), customs regulations, and potential delays. Work with suppliers experienced in international shipping to navigate logistics efficiently. Ensure you understand the incoterms (e.g., FOB, CIF) to clarify responsibilities for shipping costs, insurance, and customs clearance. -

Can I customize microfiber fabric, and what options are available?

Yes, many suppliers offer customization options for microfiber fabric, including color, pattern, and texture variations. You can also request specific treatments, such as moisture-wicking or flame-retardant finishes. Discuss your customization needs with suppliers early in the negotiation process to understand feasibility, costs, and lead times. -

What are the environmental considerations when sourcing microfiber fabric?

When sourcing microfiber, consider the environmental impact of production processes. Look for suppliers that use sustainable practices, such as recycled materials or eco-friendly dyes. Additionally, inquire about the fabric’s lifecycle and recyclability. Sustainable sourcing not only benefits the environment but can also enhance your brand’s image in an increasingly eco-conscious market.

Top 7 Microfiber By The Yard Manufacturers & Suppliers List

1. Fabric Wholesale Direct – Microfiber Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Microfiber Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Fabric Warehouse – Microfiber Faux Suede

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Microfiber Fabric By The Yard – Faux Suede for Upholstery. SHIPS FREE OVER $100. Available in various colors including Beige, Black, Blue, Bronze, Brown, Gold, Gray, Green, Ivory, Khaki, Orange, Pink, Purple, Red, Silver. Fabric weights include Extra Heavy Weight, Heavy Weight, Lightweight, Medium Weight. Available in Printed and Woven designs. Key products include: Calm in Ghost Velvet Upholstery…

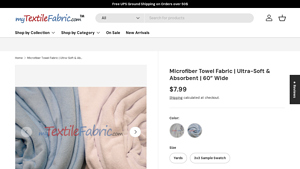

3. My Textile Fabric – Microfiber Towel Fabric

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Introduction: Microfiber Towel Fabric | Ultra-Soft & Absorbent | 60” Wide

– Price: $7.99 per yard, $1.99 for 3×3 sample swatch

– Colors Available: White, Baby Blue

– Material: 80% Polyester, 20% Polyamide

– Width: 60 inches

– Key Features: Ultra-soft, plush, absorbent, quick-drying, lint-free, durable

– Versatile Uses: Ideal for towels, bathrobes, spa wraps, pet towels, cleaning cloths

– Care Instructions: Mach…

4. Rockywoods – SunScreen50™ UPF50+ Fabric

Domain: rockywoods.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “SunScreen50™ UPF50+ Polyester Microfiber Fabric”, “sold_per”: “Yard”, “features”: [“UPF50+ protection”, “Polyester microfiber material”], “processing_time”: “Three Business Days”, “shipping_info”: “Next Day Air® & 2nd Day Air® shipments will be shipped same or next business day unless otherwise notified.”}

5. Microfiber Fabric – Bath Towels

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Microfiber fabric available by the yard, suitable for making bath towels. Variants include microfiber faux suede, minky (garment fabric), and micro-fleece/chamois/plush. Suggested sources for purchasing include Wazoodle for microfiber terry fabrics and various online fabric stores.

6. Wazoodle – Zorb® Microfiber Loop Terry

Domain: wazoodle.com

Registered: 2002 (23 years)

Introduction: Zorb® Microfiber Loop Terry is designed for rapid absorption. It is part of the Zorb fabric collection, known for its super absorbent properties. The fabric is suitable for various applications including activewear, medical gowns, nursing pads, and reusable bags. It features functions such as being absorbent, antimicrobial, food safe, waterproof, and hook-compatible. Zorb is available in multiple …

7. Etsy – Microfiber Fabric by the Yard

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Microfiber Fabric by the Yard, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for microfiber by the yard

As the demand for microfiber by the yard continues to rise, strategic sourcing becomes essential for B2B buyers looking to optimize their supply chains. This versatile fabric, renowned for its durability and absorbency, offers a multitude of applications across various sectors, from apparel to home décor. By establishing reliable partnerships with suppliers, businesses can ensure a steady flow of high-quality microfiber, catering to the diverse needs of their markets.

B2B buyers should prioritize sourcing from manufacturers that not only provide competitive pricing but also demonstrate a commitment to sustainability and innovation. This approach not only enhances product offerings but also aligns with global trends favoring eco-friendly materials.

Illustrative image related to microfiber by the yard

Looking ahead, the microfiber market is poised for growth, driven by evolving consumer preferences and technological advancements in fabric production. Now is the time for international buyers from Africa, South America, the Middle East, and Europe, including Germany and Vietnam, to seize opportunities in this expanding market. By leveraging strategic sourcing practices, businesses can position themselves to meet future demands and enhance their competitive edge. Explore your options today and unlock the potential of microfiber for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to microfiber by the yard