Introduction: Navigating the Global Market for make a leather knife sheath

In today’s competitive landscape, sourcing high-quality leather knife sheaths presents a unique challenge for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. As demand for durable and aesthetically pleasing knife sheaths rises, understanding the intricacies of the global market is essential for making informed purchasing decisions. This comprehensive guide delves into the diverse types of leather knife sheaths available, their various applications, and the critical factors to consider when vetting suppliers.

From traditional handcrafted options to modern manufacturing techniques, buyers will gain insights into the materials, craftsmanship, and design considerations that influence quality and pricing. Furthermore, this guide addresses key aspects such as supplier reliability, cost analysis, and regional variations in leather sourcing, ensuring that you can navigate the complexities of international procurement with confidence.

By empowering B2B buyers with actionable insights and expert knowledge, this guide not only facilitates informed decision-making but also enhances your ability to secure the best products for your business needs. Whether you are seeking to enhance your product offerings or establish new partnerships, understanding the global market for leather knife sheaths is the first step toward success.

Table Of Contents

- Top 1 Make A Leather Knife Sheath Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for make a leather knife sheath

- Understanding make a leather knife sheath Types and Variations

- Key Industrial Applications of make a leather knife sheath

- 3 Common User Pain Points for ‘make a leather knife sheath’ & Their Solutions

- Strategic Material Selection Guide for make a leather knife sheath

- In-depth Look: Manufacturing Processes and Quality Assurance for make a leather knife sheath

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘make a leather knife sheath’

- Comprehensive Cost and Pricing Analysis for make a leather knife sheath Sourcing

- Alternatives Analysis: Comparing make a leather knife sheath With Other Solutions

- Essential Technical Properties and Trade Terminology for make a leather knife sheath

- Navigating Market Dynamics and Sourcing Trends in the make a leather knife sheath Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of make a leather knife sheath

- Strategic Sourcing Conclusion and Outlook for make a leather knife sheath

- Important Disclaimer & Terms of Use

Understanding make a leather knife sheath Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Sheath | Simple design, often a single piece of leather, minimal embellishments | Craftsmanship, outdoor tools, hunting | Pros: Durable, classic look; Cons: Limited customization options. |

| Folded Sheath | Constructed from folded leather, often with a belt loop | Tactical gear, outdoor activities | Pros: Secure fit, easy to attach; Cons: Can be bulkier than other designs. |

| Pouch Sheath | Open-top design that allows for easy access to the knife | Culinary knives, everyday carry tools | Pros: Quick access, versatile; Cons: Less secure, knife may fall out. |

| Custom Embellished | Features decorative elements, stitching, or tooling | Luxury markets, gift items | Pros: Unique, personalized; Cons: Higher production costs. |

| Multi-Purpose Sheath | Designed to hold multiple knives or tools | Survival kits, camping gear | Pros: Versatile, space-efficient; Cons: May compromise individual knife fit. |

What are the Characteristics of Traditional Sheaths?

Traditional sheaths are often crafted from a single piece of leather, offering a minimalist design that emphasizes durability and functionality. They are particularly suited for artisans and craftsmen who appreciate classic aesthetics in their tools, making them ideal for B2B buyers in the craftsmanship and outdoor tools sectors. When purchasing traditional sheaths, consider the leather quality and thickness, as these factors influence durability and longevity in demanding environments.

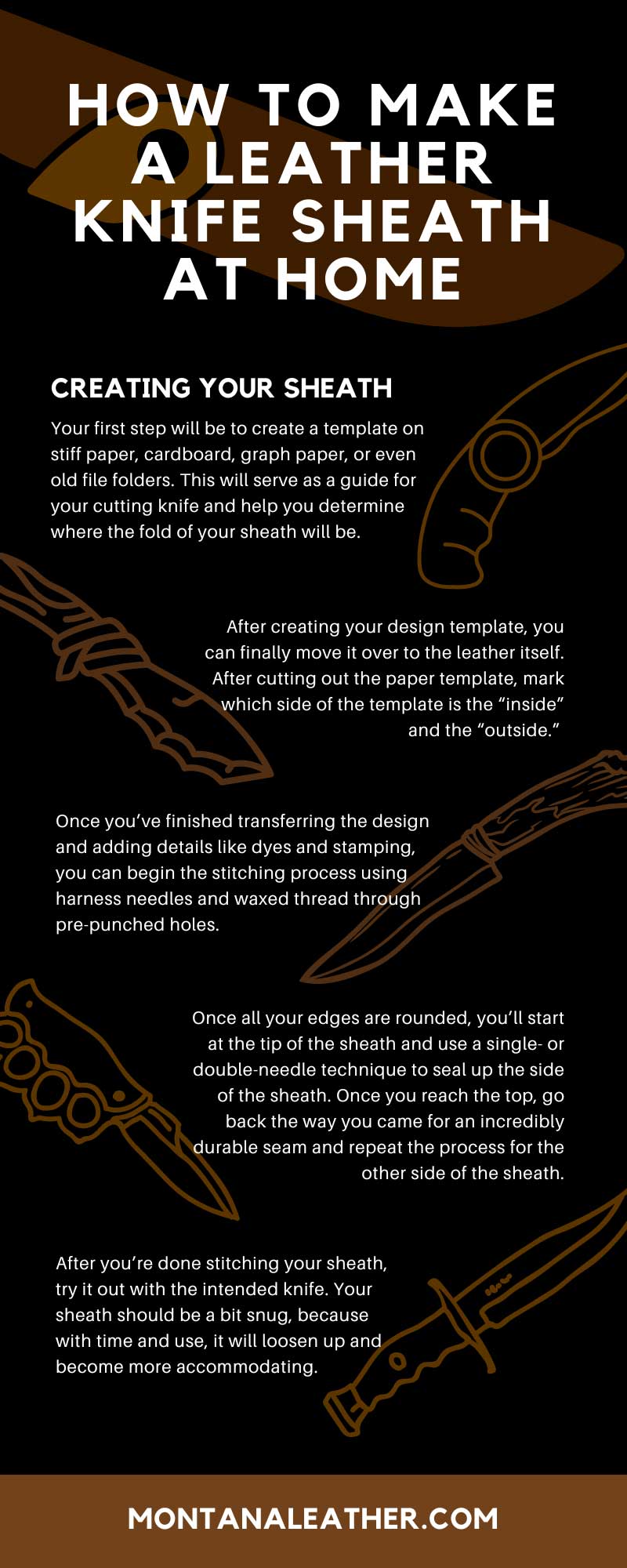

Illustrative image related to make a leather knife sheath

How Do Folded Sheaths Stand Out in the Market?

Folded sheaths are characterized by their unique design, which involves folding leather to create a secure compartment for the knife. This design often includes a belt loop for easy attachment. They are commonly used in tactical gear and outdoor activities, appealing to businesses that cater to adventure enthusiasts. Buyers should assess the sheath’s fit and ease of access to ensure it meets the functional needs of their customer base while also considering the leather’s resilience to wear and tear.

What Makes Pouch Sheaths a Practical Choice?

Pouch sheaths are designed with an open top, allowing for quick access to the knife. This design is particularly advantageous for culinary knives and everyday carry tools, making them popular among chefs and outdoor enthusiasts. B2B buyers should focus on the sheath’s material and construction quality, as these factors will directly affect the product’s usability and customer satisfaction. Additionally, consider the sheath’s weight and bulk, which can influence portability.

Why Invest in Custom Embellished Sheaths?

Custom embellished sheaths are distinguished by their decorative elements, such as intricate stitching or tooling, making them appealing for luxury markets and as gift items. Businesses that specialize in personalized products can leverage this type of sheath to attract customers looking for unique, high-quality items. When sourcing custom embellished sheaths, buyers should evaluate the craftsmanship and design options available, as these will impact the perceived value and marketability of the product.

What are the Advantages of Multi-Purpose Sheaths?

Multi-purpose sheaths are designed to accommodate several knives or tools, offering versatility for survival kits and camping gear. This design maximizes space efficiency, appealing to businesses focused on outdoor and survival markets. Buyers should consider the fit of individual knives within the sheath, as well as the overall durability of the construction. Assessing the ease of access and organization within the sheath will also be crucial for ensuring customer satisfaction.

Illustrative image related to make a leather knife sheath

Key Industrial Applications of make a leather knife sheath

| Industry/Sector | Specific Application of make a leather knife sheath | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Equipment | Custom sheaths for hunting and camping knives | Enhances product offerings and brand differentiation | Durable materials, weather resistance, customization options |

| Culinary Arts | Protective sheaths for chef knives | Increases safety and longevity of high-end knives | Quality leather, aesthetic appeal, functional design |

| Craftsmanship & Artisan | Handmade sheaths for bespoke knives | Supports artisan craftsmanship and unique sales | Sourcing local leather, skilled artisans, design flexibility |

| Military & Tactical | Sheaths for tactical knives | Provides reliable protection and accessibility | Military-grade materials, secure fasteners, ergonomic design |

| Retail & E-commerce | Retail display sheaths for knife sales | Enhances customer experience and product visibility | Attractive design, branding options, cost-effectiveness |

How is ‘make a leather knife sheath’ used in the outdoor equipment industry?

In the outdoor equipment sector, leather knife sheaths are essential for protecting hunting and camping knives during transport and storage. Custom sheaths can enhance the brand’s product offerings and provide a unique selling proposition. Buyers in this industry seek durable, weather-resistant materials that can withstand rugged outdoor conditions. Additionally, customization options are vital to meet specific customer needs and preferences, making sourcing local leather suppliers a strategic consideration.

What role does a leather knife sheath play in the culinary arts?

In culinary settings, protective sheaths for chef knives are crucial for maintaining safety and prolonging the life of high-quality knives. A well-crafted leather sheath not only protects the blade but also adds an aesthetic appeal that can attract customers. International buyers, particularly from regions with a strong culinary culture, require sheaths that are made from high-quality leather and designed for ease of use. Attention to detail in design is essential to ensure functionality and appeal in high-end culinary markets.

How does craftsmanship benefit from leather knife sheaths?

In the craftsmanship and artisan industry, handmade leather knife sheaths represent a blend of functionality and artistry. These sheaths support artisans by allowing them to showcase their craftsmanship while providing practical solutions for knife protection. Buyers in this sector often prioritize sourcing local leather to promote sustainability and support local economies. Flexibility in design is also crucial, enabling artisans to create unique, bespoke products that meet the diverse needs of their clientele.

Why are leather knife sheaths important in military and tactical applications?

In military and tactical environments, leather knife sheaths are vital for ensuring that tactical knives are securely stored and easily accessible. These sheaths need to provide reliable protection while also being designed for quick deployment. Buyers in this sector focus on military-grade materials that can withstand harsh conditions, along with secure fasteners and ergonomic designs for ease of use. The ability to source materials that meet stringent durability and safety standards is critical for international B2B buyers in this market.

How do retail and e-commerce benefit from leather knife sheaths?

In retail and e-commerce, leather knife sheaths serve as both protective and display solutions for knife sales. An attractive sheath can enhance the overall customer experience by improving product visibility and perceived value. Buyers in this sector look for designs that not only protect the knives but also align with branding strategies. Cost-effectiveness and aesthetic appeal are key considerations, making it essential to find suppliers that can deliver quality products at competitive prices.

3 Common User Pain Points for ‘make a leather knife sheath’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Leather for Knife Sheaths

The Problem: One of the primary challenges B2B buyers face when making leather knife sheaths is sourcing high-quality leather. In many regions, especially in developing countries, access to premium leather can be limited. Buyers may encounter inconsistent quality, leading to sheaths that do not meet their durability and aesthetic standards. This inconsistency can result in increased production costs, as subpar materials often lead to higher return rates and dissatisfied customers.

The Solution: To overcome this challenge, buyers should establish relationships with multiple leather suppliers. This approach allows for better negotiation on prices and ensures a consistent supply of quality leather. It’s also beneficial to seek out local tanneries that specialize in leather suitable for knife sheaths. By visiting suppliers and assessing the leather firsthand, buyers can evaluate its thickness, texture, and finish. Additionally, utilizing online platforms that connect buyers with global suppliers can help diversify sourcing options. Investing in a small batch of leather for testing before committing to larger orders can ensure the material meets quality standards and reduces the risk of costly mistakes.

Scenario 2: Inefficient Production Processes Leading to Waste

The Problem: B2B manufacturers often face inefficiencies in their production processes when crafting leather knife sheaths, which can lead to significant material waste. This issue is exacerbated by inadequate tools or techniques that result in uneven cuts, poorly stitched seams, or improperly finished edges. Not only does this waste raw materials, but it can also delay production timelines and impact overall profitability.

The Solution: To enhance efficiency, manufacturers should invest in proper tools, such as high-quality leather knives, punches, and burnishing tools. Implementing a standardized process for cutting and stitching can also minimize errors and waste. Training staff on best practices for leatherworking, such as the importance of using templates and maintaining sharp tools, can dramatically improve production quality. Additionally, adopting a lean manufacturing approach can help identify wasteful practices and streamline operations. Regularly reviewing and refining production techniques can ensure continuous improvement and optimal resource utilization.

Scenario 3: Meeting Diverse Customer Preferences

The Problem: Another significant pain point for B2B buyers is the challenge of meeting the diverse preferences of their customers when it comes to leather knife sheaths. Different markets may have varying demands for styles, colors, and functionalities, which can complicate production and inventory management. Buyers may struggle to balance custom orders with standard offerings, leading to potential stockouts or overproduction of less popular items.

The Solution: A proactive approach to understanding market trends and customer preferences is essential. Buyers should conduct market research to identify popular styles and materials in their target regions, such as Africa or South America, and tailor their offerings accordingly. Implementing a flexible manufacturing process that allows for customization can also cater to specific client needs without sacrificing efficiency. For example, incorporating modular designs that can be easily adjusted or personalized can reduce complexity in inventory management. Furthermore, establishing a feedback loop with customers can provide insights into evolving preferences, helping businesses stay ahead of market demands and ensure customer satisfaction.

Illustrative image related to make a leather knife sheath

Strategic Material Selection Guide for make a leather knife sheath

What Are the Key Materials for Making a Leather Knife Sheath?

When selecting materials for manufacturing leather knife sheaths, several options come into play, each with distinct properties, advantages, and drawbacks. Understanding these materials is crucial for international B2B buyers, especially those sourcing from regions like Africa, South America, the Middle East, and Europe.

How Does Vegetable-Tanned Leather Perform in Knife Sheath Applications?

Vegetable-tanned leather is a popular choice for knife sheaths due to its natural durability and aesthetic appeal. This type of leather is tanned using natural tannins found in plant matter, resulting in a material that is both strong and flexible. Key properties include a high resistance to wear and tear, making it suitable for everyday use. However, it can be sensitive to moisture, potentially leading to mold if not properly treated.

Pros: It offers excellent durability and a classic look that improves with age. Additionally, it is relatively easy to dye and finish, allowing for customization.

Cons: The cost can be higher than synthetic alternatives, and the tanning process can be time-consuming, impacting production timelines.

For buyers in regions like Brazil and Vietnam, understanding the local climate’s impact on moisture retention is essential. Compliance with environmental regulations regarding tanning processes may also be a consideration.

What Are the Benefits of Using Chrome-Tanned Leather?

Chrome-tanned leather is known for its flexibility and resistance to water, making it an ideal choice for knife sheaths that may encounter adverse weather conditions. This leather undergoes a faster tanning process, resulting in a softer and more pliable material. It is also less prone to mold and mildew, which is advantageous in humid environments.

Pros: The quick production cycle and lower cost make chrome-tanned leather an attractive option. Its water resistance enhances its suitability for various applications.

Illustrative image related to make a leather knife sheath

Cons: While durable, it may not have the same aesthetic appeal as vegetable-tanned leather. Additionally, chrome tanning processes can raise environmental concerns, which may affect compliance in certain markets.

For international buyers, understanding local regulations regarding chemical use in tanning processes is vital, especially in regions with strict environmental laws.

How Do Synthetic Leathers Compare for Knife Sheath Manufacturing?

Synthetic leathers, such as polyurethane (PU) or polyvinyl chloride (PVC), offer a cost-effective alternative to traditional leather. These materials are engineered to mimic the look and feel of leather while being more resistant to water and stains. They are lightweight and can be produced in a variety of colors and textures.

Illustrative image related to make a leather knife sheath

Pros: Synthetic leathers are generally more affordable and easier to clean. They also offer a consistent quality that can be advantageous in mass production.

Cons: They may lack the durability and breathability of natural leathers, leading to a shorter lifespan. Additionally, they can be less environmentally friendly, which may be a concern for eco-conscious buyers.

For B2B buyers in Europe and the Middle East, understanding the sustainability certifications of synthetic materials can influence purchasing decisions, especially among environmentally conscious consumers.

What Role Does Suede Play in Leather Knife Sheath Design?

Suede, a type of leather with a napped finish, is often used for lining or decorative elements in knife sheaths. It provides a soft touch and excellent grip, which can enhance user experience. Suede is generally lighter than full-grain leather and offers a unique aesthetic appeal.

Pros: Its softness and flexibility make it comfortable for handling. Suede can also be dyed easily, allowing for creative designs.

Cons: It is less durable than other leather types and can be more susceptible to stains and wear. Maintenance can be challenging, as suede requires special care to avoid damage.

Illustrative image related to make a leather knife sheath

International buyers should consider the application environment when choosing suede, as its performance may vary significantly in different climates.

Summary of Material Selection for Leather Knife Sheaths

| 素材 | Typical Use Case for make a leather knife sheath | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end, artisanal knife sheaths | Natural durability and aesthetic appeal | Sensitive to moisture, higher cost | Medium |

| Chrome-Tanned Leather | Everyday use knife sheaths | Water resistance and flexibility | Environmental concerns, less aesthetic | Medium |

| Synthetic Leather | Budget-friendly, mass-produced sheaths | Cost-effective and easy to clean | Shorter lifespan, less durability | 低い |

| スエード | Decorative or lining elements | Soft touch and grip | Less durable, maintenance intensive | Medium |

By carefully considering these materials, B2B buyers can make informed decisions that align with their product requirements and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for make a leather knife sheath

What Are the Main Stages of Manufacturing a Leather Knife Sheath?

Manufacturing a leather knife sheath involves several critical stages that ensure both functionality and aesthetic appeal. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

The choice of leather is paramount in sheath production. Typically, full-grain or top-grain leather is preferred for its durability and aesthetic qualities. The initial step involves sourcing high-quality leather, which may include upcycling scraps from other leather products, promoting sustainability.

Once the leather is procured, it undergoes treatment processes such as tanning, dyeing, and conditioning. Tanning preserves the leather, while dyeing adds color and enhances visual appeal. Conditioning ensures that the leather remains supple and resistant to environmental factors. Buyers should look for suppliers who adhere to environmentally friendly tanning processes to align with global sustainability trends.

How Is the Leather Formed Into a Sheath?

Forming the sheath involves cutting the leather into pre-defined shapes, often guided by templates. Precision cutting is crucial; tools such as rotary cutters or laser cutters can be employed to achieve clean edges. After cutting, the edges are burnished to prevent fraying and enhance appearance.

The next step is to create any necessary features, such as snap fasteners or belt loops. This typically involves additional cutting and stitching, where the leather is thinned out to ensure a flush finish. Techniques such as embossing or tooling can also be applied at this stage to add decorative elements, which can be a selling point for B2B buyers interested in customized products.

Illustrative image related to make a leather knife sheath

What Does the Assembly Process Involve?

How Are the Leather Pieces Assembled?

Assembly is a critical phase where individual leather pieces are glued and stitched together to form the sheath. Contact cement is commonly used for its strong bond, ensuring that the pieces stay together under stress. After applying the glue, the pieces are pressed together to create a lasting bond.

Sewing is another vital component of assembly. This can be done manually or with sewing machines designed for leather work. The use of double-needle stitching provides additional strength, ensuring that the sheath can withstand wear and tear. B2B buyers should inquire about the stitching techniques used, as this can significantly affect the product’s durability.

What Finishing Techniques Are Commonly Used?

How Is the Leather Finished for Aesthetic and Protective Qualities?

The finishing stage enhances the leather’s appearance and protects it from damage. This includes dyeing the edges, applying wax, and adding protective coatings. Burnishing is a common technique used to smooth and seal edges, giving them a polished look.

Additionally, some manufacturers may apply water-resistant treatments or protective finishes to prolong the sheath’s life, especially important for buyers in regions with humid climates. Quality finishing not only improves aesthetics but also extends the product’s lifespan, making it a crucial consideration for B2B buyers.

What Quality Assurance Measures Are Essential for Leather Knife Sheaths?

Quality assurance (QA) is paramount in the production of leather knife sheaths to ensure that the final product meets industry standards and customer expectations.

Illustrative image related to make a leather knife sheath

What International Standards Should Buyers Consider?

B2B buyers should be aware of relevant international standards such as ISO 9001, which outlines requirements for quality management systems. Compliance with ISO standards ensures that the manufacturing process is consistent and of high quality.

Additionally, specific industry certifications such as CE marking for products sold in Europe or API specifications for safety and performance may apply. These certifications signal to buyers that the products have undergone rigorous testing and comply with safety standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control should be integrated at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspect raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitor critical production stages, including cutting, stitching, and finishing, to catch defects early.

- Final Quality Control (FQC): Conduct a comprehensive inspection of the finished product to ensure it meets all design and functional requirements.

Common testing methods include visual inspections, tensile strength tests, and water resistance evaluations. These tests confirm that the sheath can withstand normal use and environmental factors.

Illustrative image related to make a leather knife sheath

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Should Buyers Take to Ensure Supplier QC Compliance?

B2B buyers must conduct due diligence when selecting suppliers. This includes requesting detailed quality assurance reports, third-party inspection results, and certifications to validate compliance with international standards.

Buyers should also consider conducting audits of potential suppliers. This not only assesses the supplier’s manufacturing capabilities but also provides insight into their quality management practices. Regular communication with suppliers about quality expectations and potential improvements can foster a collaborative relationship that prioritizes quality.

What Are the QC and Certification Nuances for International Buyers?

How Can Buyers Navigate Different Quality Standards Across Regions?

For international buyers, understanding the variances in quality standards across regions is critical. For instance, while ISO standards are globally recognized, certain markets may have additional local regulations or certifications that must be adhered to.

Buyers from regions such as Africa or South America may encounter different expectations regarding material quality, environmental impact, and labor practices. It is advisable to engage with local trade organizations or industry groups that can provide insights into regional compliance requirements.

Understanding these nuances ensures that buyers can confidently select suppliers who not only meet their quality standards but also align with their corporate social responsibility goals.

Illustrative image related to make a leather knife sheath

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions that enhance product offerings and ensure customer satisfaction in the competitive leather goods market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘make a leather knife sheath’

In the competitive landscape of B2B procurement, sourcing materials for making leather knife sheaths requires a strategic approach. This guide provides a practical checklist to help you navigate the sourcing process effectively, ensuring you acquire the right materials and establish reliable partnerships.

Step 1: Identify Your Material Requirements

Before initiating the sourcing process, clearly define the types of leather and other materials you will need. Consider the thickness, texture, and color of the leather, as well as any additional components like rivets, snaps, or glue. Knowing your specifications will streamline your search and help you communicate effectively with suppliers.

- Leather Types: Look for vegetable-tanned leather for durability and ease of dyeing.

- Additional Materials: Ensure you specify the types of fasteners and adhesives suitable for leatherwork.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in leather and related materials. Utilize online directories, trade shows, and industry forums to compile a list of potential vendors. A well-researched list will help you discover suppliers who align with your quality and ethical standards.

- Supplier Reputation: Check online reviews and testimonials to gauge supplier reliability.

- Location Considerations: Evaluate suppliers based on proximity to reduce shipping costs and lead times.

Step 3: Evaluate Supplier Capabilities

Once you have a list of potential suppliers, assess their production capabilities. Understanding their manufacturing processes, lead times, and minimum order quantities is crucial to ensure they can meet your demands.

Illustrative image related to make a leather knife sheath

- Production Flexibility: Confirm if they can accommodate custom orders or variations in material.

- Quality Assurance: Inquire about their quality control measures to ensure consistency in material quality.

Step 4: Request Samples

Before finalizing a supplier, request samples of the leather and other materials you intend to use. This step is essential to evaluate the material’s quality and suitability for your specific application.

- Sample Assessment: Inspect samples for texture, durability, and color accuracy.

- Cost Evaluation: Consider the cost of samples and any potential shipping fees when budgeting.

Step 5: Verify Certifications and Compliance

Ensure that your chosen suppliers comply with industry standards and environmental regulations. Certifications related to leather production, such as eco-friendly practices, can significantly impact your brand’s reputation.

- Certification Verification: Ask for documentation that confirms compliance with relevant standards.

- Sustainability Practices: Assess whether suppliers follow sustainable sourcing practices, which can enhance your brand image.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear agreements on these aspects can help prevent misunderstandings and ensure smooth transactions.

- Pricing Structures: Discuss bulk order discounts and payment options.

- Delivery Commitments: Set expectations for delivery timelines to avoid production delays.

Step 7: Establish a Long-Term Relationship

After successfully sourcing your materials, focus on building a long-term relationship with your supplier. Regular communication and feedback can lead to improved service and better pricing over time.

- Feedback Mechanism: Implement a system for providing feedback on material quality and service.

- Partnership Opportunities: Explore additional collaboration opportunities, such as co-developing new products or designs.

By following this checklist, B2B buyers can effectively source materials for leather knife sheaths, ensuring quality, reliability, and sustainability in their procurement processes.

Comprehensive Cost and Pricing Analysis for make a leather knife sheath Sourcing

What Are the Key Cost Components for Sourcing Leather Knife Sheaths?

When analyzing the cost structure for sourcing leather knife sheaths, it’s essential to break down the various components involved. The main cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Materials: The primary material is leather, which can vary significantly in price depending on quality and source. Other materials include thread, glue, and fasteners. Sourcing high-quality leather, especially if it’s sustainably produced or certified, can increase costs.

Illustrative image related to make a leather knife sheath

Labor: Labor costs encompass the wages paid to skilled artisans who craft the sheaths. The complexity of the design and the level of craftsmanship required will influence labor expenses. Regions with higher labor costs, such as parts of Europe, may see increased pricing compared to areas with lower labor costs, such as parts of South America or Asia.

Manufacturing Overhead: This includes expenses related to the production facility, utilities, and administrative costs. Depending on the production scale, overhead can be distributed across many units, reducing the per-unit cost.

Tooling: Initial costs for tooling can be significant, especially for custom designs. Tooling includes molds, dies, and other equipment necessary for the production process. Depending on the supplier, these costs may be amortized over a larger order volume.

Illustrative image related to make a leather knife sheath

Quality Control: Implementing rigorous QC processes ensures that the final products meet the required standards. This can add to the overall cost but is crucial for maintaining brand reputation and customer satisfaction.

Logistics: Shipping and handling costs must be factored into the total cost, particularly for international shipments. These costs can fluctuate based on shipping methods, distances, and trade regulations.

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary widely depending on the supplier’s business model, market position, and the competitive landscape.

How Do Pricing Influencers Affect Leather Knife Sheath Costs?

Several factors can influence the pricing of leather knife sheaths in the B2B marketplace:

Volume/MOQ: Suppliers often set minimum order quantities (MOQs), which can affect pricing. Larger orders usually result in lower per-unit costs due to economies of scale.

Illustrative image related to make a leather knife sheath

Specifications and Customization: Custom designs, special features, or unique specifications can increase costs. Buyers should be clear about their requirements to avoid unexpected expenses.

Material Quality and Certifications: Higher quality materials or those with certifications (e.g., eco-friendly, ethically sourced) can lead to increased prices. Buyers should assess the value of these certifications against their budget.

Supplier Factors: The supplier’s location, reputation, and production capabilities can significantly impact pricing. Established suppliers with a good track record may charge more for their reliability and quality assurance.

Illustrative image related to make a leather knife sheath

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can influence total costs.

What Buyer Tips Can Enhance Cost-Efficiency for Leather Knife Sheath Sourcing?

B2B buyers can leverage several strategies to improve cost-efficiency when sourcing leather knife sheaths:

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Building a good relationship can lead to better pricing and terms.

Assess Total Cost of Ownership: Beyond the initial purchase price, consider long-term costs such as maintenance, warranty services, and potential returns. A higher-quality product may have a higher upfront cost but could save money in the long run.

Illustrative image related to make a leather knife sheath

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import duties, and taxes that can affect overall costs. It’s advisable to seek suppliers who can provide all-inclusive pricing.

Research and Compare Suppliers: Conduct thorough market research to identify suppliers that offer the best balance of quality, price, and service. Comparing multiple quotes can provide leverage during negotiations.

Be Clear on Requirements: Clearly communicate your specifications and expectations upfront to avoid misunderstandings that could lead to additional costs.

Disclaimer

Prices and cost structures mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing make a leather knife sheath With Other Solutions

Understanding Alternatives to Making a Leather Knife Sheath

When considering the creation of a leather knife sheath, it is crucial to explore alternative methods and materials that can fulfill the same purpose. Each option has distinct advantages and drawbacks, making it essential for B2B buyers to evaluate which solution aligns best with their operational requirements, budget, and end-user expectations.

Illustrative image related to make a leather knife sheath

Comparison of Knife Sheath Solutions

| Comparison Aspect | Make A Leather Knife Sheath | Kydex Knife Sheath | Fabric Knife Sheath |

|---|---|---|---|

| Performance | Durable and aesthetically pleasing; offers a custom fit. | Highly durable; resistant to water and impact. | Lightweight but less durable; may wear out faster. |

| Cost | Moderate; costs vary based on leather quality and tools. | Generally low to moderate; cost-effective for mass production. | Low; inexpensive materials make it budget-friendly. |

| Ease of Implementation | Requires skills in leatherworking; time-consuming. | Easy to mold with heat; requires minimal tools. | Simple to create; suitable for rapid production. |

| Maintenance | Requires regular conditioning to prevent drying. | Low maintenance; easy to clean and maintain. | Moderate; may require washing or replacement. |

| Best Use Case | Ideal for custom, high-end knives; favored by artisans. | Best for tactical and outdoor knives; used in professional settings. | Suitable for lightweight, casual use; good for basic protection. |

Detailed Breakdown of Alternatives

Kydex Knife Sheath

Kydex is a thermoplastic material that has gained popularity among knife makers for its durability and ease of use. It can be heated and molded to fit the knife perfectly, providing a secure and protective sheath. The benefits of Kydex include its resistance to water, impact, and chemicals, making it an excellent choice for tactical and outdoor knives. However, Kydex may lack the aesthetic appeal of leather and can be less comfortable to carry, especially for extended periods.

Fabric Knife Sheath

Fabric sheaths are often made from nylon or other synthetic materials, offering a lightweight and cost-effective alternative to leather and Kydex. These sheaths are generally easier to produce, making them suitable for high-volume applications. While fabric sheaths provide basic protection, they are less durable and may wear out more quickly than leather or Kydex options. They are best suited for casual use and may not offer the same level of protection or style as leather.

Conclusion: How to Choose the Right Knife Sheath Solution

B2B buyers looking to select the appropriate knife sheath solution should consider factors such as performance requirements, cost constraints, and the intended use case of the knife. For high-end, custom applications, a leather sheath may be the best choice due to its durability and aesthetic qualities. Conversely, for tactical or outdoor knives, Kydex offers superior protection and ease of maintenance. Fabric sheaths can serve as a budget-friendly option for casual users but may not provide the same longevity. Ultimately, understanding the specific needs of the end-user and the operational context will guide the decision toward the most suitable sheath solution.

Essential Technical Properties and Trade Terminology for make a leather knife sheath

What Are the Key Technical Properties for Making a Leather Knife Sheath?

When creating a leather knife sheath, understanding the technical properties of the materials and processes involved is crucial for quality assurance and performance. Here are some essential specifications to consider:

1. Material Grade

The grade of leather used in the sheath is vital. Full-grain leather is the highest quality, retaining the natural grain and strength of the hide, making it durable and aesthetically pleasing. Top-grain leather is slightly lower in quality but still offers good durability. Buyers should prioritize full-grain for high-end products, as it affects both longevity and customer satisfaction.

2. Thickness

Leather thickness is measured in millimeters or ounces (1 ounce = 1/64 inch). Typical thickness for knife sheaths ranges from 4 to 8 ounces, depending on the intended use. Thicker leather provides better protection and durability but may be more challenging to work with. B2B buyers must consider the balance between strength and ease of crafting when selecting thickness.

3. Stitching Tension

The tension of stitching is crucial for the durability of the sheath. A tighter stitch will enhance the overall strength, preventing seams from coming apart under stress. B2B manufacturers should ensure that stitching is consistent and robust, particularly in high-use environments. The use of waxed thread can further enhance durability and resistance to wear.

4. Edge Finishing

The finishing of edges, such as burnishing, is essential for preventing fraying and improving aesthetics. Proper edge treatment protects the leather from moisture and wear, which is especially important in outdoor applications. B2B buyers should prioritize suppliers who employ effective edge-finishing techniques to enhance product longevity.

5. Adhesive Quality

The type of adhesive used can significantly impact the performance of the sheath. High-quality leather glue or contact cement ensures a strong bond that withstands stress and environmental conditions. Buyers should inquire about the adhesive properties to ensure they meet the expected performance standards for durability and flexibility.

6. Design Specifications

Custom design specifications such as size, shape, and features (like snap fasteners or belt loops) should be clearly defined in the order process. Providing detailed design requirements helps manufacturers produce consistent products that meet client expectations. B2B buyers should prepare precise technical drawings or templates to facilitate accurate production.

What Are Common Trade Terms Related to Leather Knife Sheath Manufacturing?

Navigating the B2B landscape requires familiarity with industry-specific terminology. Here are some common terms that are essential for buyers in the leather sheath market:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are marketed under another company’s brand. For leather sheaths, an OEM might create the sheath based on the specifications provided by a knife manufacturer. Understanding OEM relationships is crucial for ensuring quality control and brand integrity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important in B2B transactions as it impacts inventory management and cost. Buyers should negotiate MOQ terms that align with their sales forecasts to avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing for specific products or services. In the context of leather sheaths, an RFQ should detail material specifications, design requirements, and quantities. This process helps buyers compare offers and select the most cost-effective solution.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping. Understanding these terms is crucial for B2B transactions, particularly for international shipments of leather products. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight), which clarify who is responsible for costs and risks at various stages of transport.

5. Customization

Customization refers to the ability to modify a product to meet specific buyer requirements. In leather sheath manufacturing, this can include size, color, and additional features. Buyers should clearly communicate customization needs to ensure the final product aligns with their brand and market demands.

6. Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is essential for B2B buyers to manage inventory and meet customer demand. Buyers should ask suppliers for estimated lead times to plan their operations effectively.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing leather knife sheaths, ensuring quality, efficiency, and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the make a leather knife sheath Sector

What Are the Current Market Dynamics and Key Trends in the Leather Knife Sheath Sector?

The leather knife sheath market is experiencing significant growth driven by the rising demand for custom and handmade products. International buyers from Africa, South America, the Middle East, and Europe are increasingly seeking unique, high-quality leather goods that reflect craftsmanship and personalization. Key trends include the growing popularity of DIY leather crafting, fueled by online tutorials and workshops, which encourage businesses to offer starter kits and materials for novice artisans. Furthermore, advancements in technology, such as digital design tools and automated cutting machines, are enabling manufacturers to streamline production while maintaining quality.

Emerging sourcing trends also indicate a shift towards localized suppliers to reduce lead times and shipping costs. Businesses are now prioritizing suppliers that can provide flexibility and rapid response capabilities, particularly in regions like Brazil and Vietnam, where the leather industry is blossoming. Additionally, the integration of e-commerce platforms is transforming traditional supply chains, allowing small-scale producers to reach global markets effectively.

How Is Sustainability Influencing Sourcing Decisions in the Leather Knife Sheath Market?

Sustainability is becoming a cornerstone in the sourcing of materials for leather knife sheaths. The environmental impact of leather production, particularly concerning deforestation and water consumption, has led to a heightened awareness among international buyers. As a result, ethical sourcing practices are gaining traction, with businesses increasingly looking for suppliers that can demonstrate sustainable practices, such as using vegetable-tanned leather or sourcing from certified farms that adhere to humane treatment of animals.

Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for suppliers aiming to appeal to eco-conscious buyers. These certifications not only ensure that materials are sourced responsibly but also enhance the credibility of businesses in the eyes of consumers. By prioritizing sustainability, companies can differentiate themselves in a competitive market and attract a clientele that values ethical consumption.

What Is the Historical Context of Leather Knife Sheath Production?

The production of leather knife sheaths dates back centuries, originating from the need to protect blades and ensure safe transportation. Historically, artisans utilized local animal hides, crafting sheaths that reflected regional styles and techniques. As trade routes expanded, the exchange of materials and methods enriched the craftsmanship of leather goods across different cultures.

In recent decades, the rise of mass production led to a decline in artisanal methods, but a resurgence of interest in handmade products has revitalized the market. Today, businesses are leveraging this historical appreciation for craftsmanship to create modern designs while maintaining traditional techniques, appealing to a global audience that values both heritage and innovation. This evolution highlights the importance of understanding historical context in developing a compelling narrative for B2B marketing and sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of make a leather knife sheath

-

How do I ensure the quality of leather knife sheaths from suppliers?

To ensure quality, request samples from potential suppliers before placing bulk orders. Assess the leather’s thickness, texture, and overall craftsmanship. Look for consistent stitching and secure fasteners, as these elements indicate a higher standard of production. Additionally, consider conducting factory visits or audits to evaluate their manufacturing processes. Establishing a clear quality assurance protocol, including specific standards and testing methods, can also help maintain quality control throughout the production process. -

What is the best type of leather for knife sheaths?

The best types of leather for knife sheaths are vegetable-tanned and chrome-tanned leathers. Vegetable-tanned leather is durable, eco-friendly, and develops a beautiful patina over time, making it ideal for long-lasting products. Chrome-tanned leather, on the other hand, is more supple and water-resistant, which can be beneficial for certain applications. When sourcing, consider the end-use of the sheath to determine which leather type aligns best with your product requirements and customer preferences. -

What customization options should I consider when sourcing leather knife sheaths?

Customization options for leather knife sheaths can include size, shape, color, and additional features such as embossing or tooling. Consider offering personalized branding, such as logos or initials, to add value for your customers. You can also explore various fastener types and belt loop styles to cater to different user needs. Discuss these options with your supplier early in the process to ensure they can accommodate your specifications without compromising production timelines. -

What are the minimum order quantities (MOQs) for leather knife sheaths?

Minimum order quantities for leather knife sheaths can vary significantly among suppliers, often ranging from 50 to several hundred units. Factors influencing MOQs include the supplier’s production capacity, the complexity of the design, and material costs. It’s crucial to communicate your needs and negotiate MOQs that align with your business model. Some suppliers may offer lower MOQs for established relationships or longer-term contracts, so consider building a partnership for better terms. -

What payment terms are common in international B2B transactions for leather products?

Common payment terms in international B2B transactions typically include options such as advance payment, letters of credit, or 30-60 day payment terms after delivery. It’s advisable to negotiate terms that protect both parties, ensuring you have leverage if issues arise. Consider using escrow services for large transactions to mitigate risks. Always ensure that payment terms are clearly outlined in the contract to avoid misunderstandings and establish a smooth financial process. -

How can I vet suppliers for leather knife sheaths?

Vetting suppliers involves researching their reputation, production capabilities, and compliance with industry standards. Start by checking references and reading reviews from other B2B buyers. Request certifications, such as ISO or environmental compliance, to verify quality and sustainability practices. Additionally, assess their communication responsiveness and willingness to accommodate your needs. Conducting a small trial order can also provide insights into their reliability and product quality before committing to larger orders. -

What logistics considerations should I keep in mind when importing leather knife sheaths?

Logistics considerations for importing leather knife sheaths include understanding shipping costs, customs duties, and potential tariffs. It’s essential to work with a freight forwarder who can navigate international regulations and ensure compliance with import/export laws. Consider the lead time for production and shipping when planning your inventory. Additionally, be prepared for potential delays due to customs inspections, and ensure your supplier provides accurate documentation to facilitate smooth transit. -

What quality assurance measures should I implement for leather knife sheaths?

Implementing quality assurance measures involves establishing clear specifications and standards for the leather knife sheaths. Consider conducting pre-production inspections to ensure materials and workmanship meet your requirements. Regular in-process checks during production can help catch issues early. Post-production, request a final inspection before shipment, focusing on dimensions, finish, and functionality. Documenting these processes can create accountability and ensure consistent quality across all orders.

Top 1 Make A Leather Knife Sheath Manufacturers & Suppliers List

1. KnifeKits – Leather Sheath Making Supplies

Domain: knifekits.com

Registered: 2001 (24 years)

Introduction: Leather sheath making supplies, natural cow hide leather, tanned and ready for projects, available in different sizes and colors. Premium leather lace cord for lanyard design, compatible with upscale findings. Sheath making kits for custom leather knife sheaths, includes leather stamping tool kits with high-quality 3D stamping dies. Products include various leather knife sheath making kits (fits u…

Strategic Sourcing Conclusion and Outlook for make a leather knife sheath

How Can Strategic Sourcing Enhance Your Leather Knife Sheath Production?

In conclusion, the strategic sourcing of materials and components for crafting leather knife sheaths is paramount for businesses aiming to optimize quality and cost-efficiency. By leveraging local suppliers for leather scraps and utilizing tools that enhance productivity—such as specialized cutting and burnishing equipment—companies can significantly reduce production costs while maintaining high-quality standards.

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should focus on building strong relationships with suppliers who can provide not only materials but also expertise in leather craftsmanship. This collaboration can lead to innovative designs and enhancements in product offerings, catering to a diverse range of markets and consumer preferences.

Looking ahead, the demand for customized leather products, including knife sheaths, is likely to rise. Businesses that invest in sustainable sourcing practices and embrace upcycling will not only improve their brand image but also meet the growing consumer expectation for environmentally friendly products. Embrace this opportunity to refine your sourcing strategies and tap into new markets—your commitment to quality and sustainability can set you apart in the competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.