Catalog

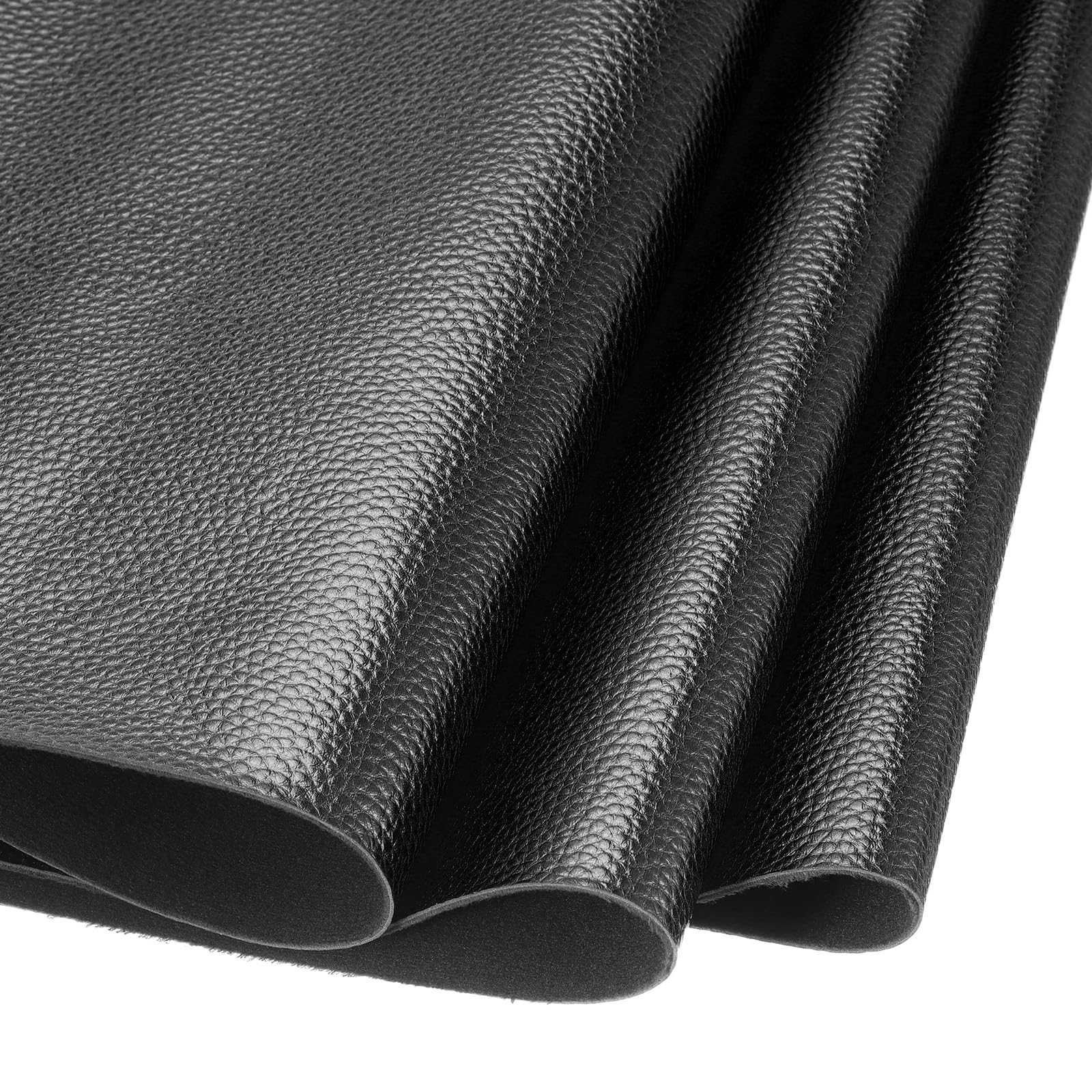

Material Insight: Leather Lining Material

B2B Product Guide: Leather Lining Material

Leather lining material plays a critical role in enhancing the comfort, durability, and aesthetic appeal of footwear, apparel, and accessories. As a functional interior layer, it must offer softness, breathability, and resistance to wear while supporting sustainable manufacturing practices. With increasing demand for high-performance, eco-conscious materials, manufacturers are shifting toward innovative alternatives that maintain luxury appeal without the environmental impact of traditional leather.

Faux leather has emerged as the best choice for lining applications due to its consistent quality, cost efficiency, and customizable properties. Unlike genuine leather, faux leather offers uniform texture and thickness, reducing waste during cutting and production. It is also highly engineered to deliver superior moisture management, abrasion resistance, and flexibility—key attributes for long-lasting comfort in high-friction areas. Modern faux leather linings are produced using eco-friendly processes, often incorporating recycled fibers and low-impact PU or water-based coatings, aligning with global sustainability standards.

WINIW is a trusted leader in synthetic leather innovation, with over 20 years of experience serving global B2B clients across footwear, fashion, and automotive industries. Specializing in high-performance microfiber and PU leather solutions, WINIW combines advanced material science with responsible manufacturing to deliver linings that meet rigorous technical and environmental standards. Our R&D-driven approach ensures that every product offers optimal softness, durability, and ecological integrity—making WINIW the preferred partner for brands seeking premium, sustainable lining materials.

Technical Performance & Standards

WINIW Premium Synthetic Leather Lining Material: Technical Product Guide

WINIW’s engineered synthetic leather lining material delivers uncompromising performance for high-volume B2B applications across automotive interiors, luxury packaging, furniture, and premium apparel. Designed for manufacturers prioritizing sustainability without sacrificing quality, our lining solution integrates advanced polymer science with rigorous quality control to exceed industry benchmarks. Below are the core technical advantages driving operational efficiency and market differentiation for our partners.

Key Technical Advantages

- Cost-Effective Performance: Achieve 30% lower total cost of ownership versus premium genuine leather linings through optimized material yield (95%+ utilization), reduced waste in cutting processes, and elimination of humidity-controlled storage requirements. Enhanced tear strength minimizes production line defects, lowering scrap rates by up to 18%.

- Engineered Durability: Withstands 50,000+ double-rub cycles (Martindale ASTM D4966) and maintains dimensional stability under 80°C/90% RH conditions for 72 hours. Resists plasticizer migration, hydrolysis, and UV degradation (ISO 105-B02), ensuring 5+ years of structural integrity in demanding environments.

- Precision Color Customization: Leverage our digital color matching system (ΔE < 0.5 tolerance) for Pantone® or custom color replication. Utilize eco-solvent printing for 100% color consistency across 50,000+ meter production runs, with no lot-to-lot variation. Options include matte, satin, or textured finishes.

- Full REACH Compliance: Contains zero SVHCs (Substances of Very High Concern) per ECHA regulations. Free from DMF, AZO dyes, phthalates (DEHP, BBP, DBP, DIBP), and heavy metals (Cd, Pb, Hg, Cr⁶⁺). Full material disclosure documentation (SVHC Declaration, SDS) provided with every shipment.

- ISO 9001-Certified Consistency: Manufactured in WINIW’s ISO 9001:2015 certified facilities with real-time inline spectrophotometer monitoring and automated thickness calibration. Batch traceability from raw material to finished roll ensures zero quality deviations.

Technical Specifications Overview

| パラメータ | 仕様 | Test Standard |

|---|---|---|

| Thickness | 0.6mm – 1.2mm (±0.05mm tolerance) | ISO 2421 |

| Weight | 280 – 420 g/m² | ISO 2286-2 |

| Tensile Strength | ≥ 25 N/mm² (warp), ≥ 22 N/mm² (weft) | ISO 1765 |

| Elongation at Break | ≤ 25% | ISO 1765 |

| Abrasion Resistance | ≥ 50,000 cycles (no wear-through) | ASTM D4966 (Martindale) |

| Colorfastness to Rubbing | Grade 4-5 (dry), Grade 4 (wet) | ISO 105-X12 |

| Lightfastness | ≥ Grade 6 (after 40 hrs) | ISO 105-B02 |

| Hydrolysis Resistance | Pass (50°C/70% RH, 168 hrs) | ISO 1419 (B method) |

| REACH SVHC Status | None detected (<0.1% by weight) | ECHA Guidance R.143 |

WINIW’s lining material eliminates the volatility of natural leather supply chains while meeting the highest environmental and performance demands of global brands. Our technical team collaborates with clients to optimize specifications for your production process—ensuring seamless integration, regulatory security, and measurable cost savings from prototype to mass production. Request a sample kit with full compliance documentation to validate performance against your requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Leather Lining Material vs. Real Leather

In the manufacturing of luxury goods, footwear, and accessories, the choice of lining material significantly impacts product performance, cost-efficiency, and environmental footprint. Two common options—leather lining material (typically synthetic or semi-synthetic) and real leather—offer distinct advantages and trade-offs. This guide provides a comparative analysis to support informed decision-making for B2B clients.

Leather Lining Material (Synthetic/PU-based)

Leather lining material refers to engineered alternatives designed to mimic the texture and function of real leather. Often made from polyurethane (PU) or microfiber substrates, these linings are tailored for consistency, cost control, and sustainability. WINIW’s advanced synthetic linings offer breathability, softness, and abrasion resistance, making them ideal for high-volume production without compromising quality.

- Consistent texture and thickness across batches

- Lower production cost and reduced waste

- Customizable color, finish, and performance properties (e.g., moisture-wicking)

- Suitable for vegan and eco-conscious product lines

- Reduced dependency on animal-derived inputs

Real Leather

Real leather, derived from animal hides (commonly bovine), has long been the traditional choice for premium linings. It offers natural breathability and a luxurious hand feel. However, its use presents challenges related to sustainability, ethical sourcing, and variability in quality.

- Natural material with excellent moisture absorption

- Unique grain patterns add perceived value

- Susceptible to inconsistencies in thickness and defects

- Higher environmental impact due to tanning processes

- Requires stringent sourcing compliance (e.g., LWG certification)

Comparative Overview

| Attribute | Leather Lining Material (PU/Microfiber) | Real Leather |

|---|---|---|

| Cost | Lower (30–50% reduction vs. real leather) | High (due to raw material and processing) |

| 耐久性 | High abrasion resistance; consistent performance | Variable; prone to cracking over time |

| Eco-friendliness | High (low water use, recyclable substrates, cruelty-free) | Moderate to Low (high water/chemical use, CO2 emissions) |

Conclusion

For B2B manufacturers seeking sustainable scalability without sacrificing performance, synthetic leather lining materials present a compelling alternative to real leather. WINIW’s eco-engineered linings deliver premium functionality while aligning with global ESG goals, making them a strategic choice for forward-thinking brands.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a cornerstone manufacturer of premium synthetic leather, engineered to meet the rigorous demands of international markets. Our vertically integrated production ecosystem ensures consistent quality, innovation, and sustainability—key priorities for discerning B2B partners across industries including automotive, furniture, fashion, and technical textiles.

Core Manufacturing Strengths

- Scale & Infrastructure: A state-of-the-art 100,000 sqm manufacturing facility in China, operating under ISO 9001 and ISO 14001 certifications. This scale enables agile production capacity while maintaining end-to-end process control.

- Dedicated R&D Leadership: A 120+ member technical team focused on material science innovation, developing eco-conscious solutions (e.g., water-based PU, recycled content, bio-based polymers) that align with EU/USA regulatory frameworks.

- Zero-Compromise Quality Assurance: Multi-stage QC protocols including AQL 1.0/2.5 inspections, in-house lab testing for colorfastness, abrasion resistance, and chemical compliance (REACH, CPSIA, OEKO-TEX®), and real-time production monitoring.

- Global Compliance Ready: All products undergo region-specific validation for European (EU Ecolabel, REACH SVHC) and North American (CPSC, Prop 65) markets, with full documentation traceability.

Proven Global Market Integration

WINIW exports to 50+ countries, with 65% of shipments serving Tier-1 suppliers in Europe and the USA. Our logistics network ensures seamless integration into complex international supply chains, supported by:

| Key Capability | Europe Focus | USA Focus |

|---|---|---|

| Regulatory Alignment | REACH, SCIP, EU Taxonomy compliant | CPSIA, TSCA, California Prop 65 |

| Sustainability | GRS-certified recycled options | USDA BioPreferred® compliant materials |

| Lead Time | 25-35 days (FOB Shanghai) | 22-30 days (FOB Shanghai) |

| Certifications | OEKO-TEX® STANDARD 100, ZDHC MRSL | SCS Recycled, LEED contribution data |

Our facility’s automation-driven processes reduce waste by 18% versus industry averages, while closed-loop water systems minimize environmental impact—proving that industrial scale and eco-accountability coexist. WINIW delivers not just materials, but certified, scalable solutions built for the world’s most demanding B2B applications. Partner with us to transform sustainability targets into tangible supply chain advantages.

Contact Us for Samples

B2B Product Guide: Premium Synthetic Leather Lining Materials by WINIW

WINIW is a trusted global manufacturer of high-performance synthetic leather, specializing in eco-friendly microfiber solutions for industries ranging from footwear and apparel to automotive and luxury goods. Our leather lining materials are engineered to deliver superior softness, durability, and breathability—perfect for brands seeking sustainable alternatives without compromising on quality.

Designed for B2B partners who value consistency, performance, and environmental responsibility, WINIW’s lining materials combine advanced production technology with rigorous quality control to meet international standards.

Key Features of WINIW Leather Lining Materials

- Ultra-soft hand feel with excellent drape and flexibility

- High breathability and moisture-wicking properties for enhanced comfort

- Superior abrasion resistance and dimensional stability

- Eco-conscious manufacturing: free from harmful solvents and phthalates

- Available in a wide range of colors, thicknesses, and finishes (suede, glossy, matte)

- Compliant with REACH, RoHS, and OEKO-TEX® standards

Applications

- Footwear: Ideal for shoe linings, tongue padding, and insole coverings

- Apparel: Used in jackets, gloves, and high-end garments requiring soft interior contact

- Accessories: Perfect for handbags, wallets, and watch straps

- Automotive: Interior trim and seat linings requiring consistent texture and durability

Product Specifications (Typical)

| Property | 仕様 |

|---|---|

| Base Material | Ultra-fine microfiber polyester & polyurethane |

| Thickness Range | 0.6 mm – 1.2 mm |

| Weight Range | 80 – 150 g/m² |

| Width | 137 cm (54”) or 150 cm (59”) |

| Roll Length | 30 m, 50 m (custom options available) |

| Color Fastness | ≥ Grade 4 (ISO 105-B02) |

| Martindale Abrasion | ≥ 20,000 cycles |

Why Choose WINIW?

- Decades of R&D in microfiber technology

- In-house dyeing and finishing for faster customization

- Scalable production for large-volume B2B orders

- Dedicated technical support for integration into your manufacturing process

- Commitment to sustainability: recyclable materials and low-impact production

Free samples are available for qualified business partners to evaluate performance and quality firsthand.

Request your free sample today and upgrade your lining material with WINIW.

For inquiries about leather lining material options, customization, or pricing, contact our marketing team:

MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.