Introduction: Navigating the Global Market for leather belt thickness

In the intricate world of leather goods, understanding leather belt thickness is crucial for B2B buyers looking to make informed sourcing decisions. The challenge often lies in identifying the right thickness that balances durability, style, and functionality. This comprehensive guide delves into the nuances of leather belt thickness, covering essential aspects such as types of leather, their applications in various markets, supplier vetting processes, and cost implications.

By equipping international buyers from Africa, South America, the Middle East, and Europe—particularly regions like Vietnam and Brazil—with the knowledge to navigate this complex landscape, this guide empowers them to select high-quality leather products that meet their specific needs. The content provides actionable insights into how different thicknesses can impact the performance and longevity of leather belts, enabling businesses to enhance their product offerings and customer satisfaction.

As you explore the guide, you will gain a deeper understanding of how to assess leather quality, evaluate supplier reliability, and ultimately optimize your purchasing strategy. With a focus on informed decision-making, this resource is designed to facilitate successful procurement in the global leather market.

Table Of Contents

- Top 6 Leather Belt Thickness Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather belt thickness

- Understanding leather belt thickness Types and Variations

- Key Industrial Applications of leather belt thickness

- 3 Common User Pain Points for ‘leather belt thickness’ & Their Solutions

- Strategic Material Selection Guide for leather belt thickness

- In-depth Look: Manufacturing Processes and Quality Assurance for leather belt thickness

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather belt thickness’

- Comprehensive Cost and Pricing Analysis for leather belt thickness Sourcing

- Alternatives Analysis: Comparing leather belt thickness With Other Solutions

- Essential Technical Properties and Trade Terminology for leather belt thickness

- Navigating Market Dynamics and Sourcing Trends in the leather belt thickness Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather belt thickness

- Strategic Sourcing Conclusion and Outlook for leather belt thickness

- Important Disclaimer & Terms of Use

Understanding leather belt thickness Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 8.5 – 9.5 Ounce | Thick, durable, typically full-grain leather | High-end belts, luxury goods | Pros: Exceptional durability, develops patina; Cons: Higher cost, may require more care. |

| 6 – 7 Ounce | Moderate thickness, versatile applications | Casual belts, fashion accessories | Pros: Good balance of durability and flexibility; Cons: Less robust than heavier options. |

| 4 – 5 Ounce | Thinner, softer leather, often corrected grain | Fashion belts, women’s accessories | Pros: Lightweight, more affordable; Cons: Less durable, may not withstand heavy use. |

| 2 – 3 Ounce | Very thin, often bonded or genuine leather | Low-cost, promotional items | Pros: Extremely affordable; Cons: Poor durability, limited lifespan. |

| Custom Thickness | Tailored to specific requirements | Specialty belts, bespoke products | Pros: Meets unique needs, can enhance branding; Cons: Longer lead times, potentially higher costs. |

What Are the Characteristics of 8.5 – 9.5 Ounce Leather Belts?

Belts made from 8.5 to 9.5-ounce leather are typically crafted from full-grain hides. This thickness is ideal for high-end products, providing exceptional strength and durability. The leather’s ability to develop a rich patina over time enhances its aesthetic appeal. B2B buyers should consider the investment required for these premium belts, as they cater to a market seeking quality and longevity in their products.

How Does 6 – 7 Ounce Leather Compare for Versatile Applications?

Leather belts in the 6 to 7-ounce range strike a balance between durability and flexibility. This moderate thickness is suitable for casual and fashion accessories, appealing to a broader consumer base. While these belts are more affordable than their heavier counterparts, they still maintain a respectable level of strength. B2B buyers should evaluate the target market’s preferences for style versus durability when choosing this thickness.

Why Choose 4 – 5 Ounce Leather for Fashion Belts?

Belts made from 4 to 5-ounce leather are lighter and often use corrected grain, making them suitable for fashion-focused products. They provide a softer feel and greater comfort, appealing to consumers seeking trendy designs. However, their thinner nature may compromise durability, making them less ideal for heavy use. Buyers should weigh the importance of style against longevity when considering this thickness for their product lines.

What Are the Implications of Using 2 – 3 Ounce Leather?

Leather in the 2 to 3-ounce range is typically bonded or made from lower-quality materials, making it suitable for low-cost promotional items. While the affordability of these belts can attract budget-conscious consumers, their durability is significantly compromised. B2B buyers should be cautious, as these products may not meet the expectations of customers seeking quality, potentially harming brand reputation.

How Can Custom Thickness Leather Belts Benefit My Business?

Custom thickness leather belts offer the advantage of tailored solutions for specific market needs. These bespoke products can enhance brand identity and cater to niche markets, such as specialty belts for unique applications. However, longer lead times and potential cost increases are important considerations for buyers. Understanding the target audience’s expectations can help businesses effectively leverage custom leather thickness for competitive advantage.

Key Industrial Applications of leather belt thickness

| Industry/Sector | Specific Application of leather belt thickness | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-quality leather belts | Enhances brand reputation and customer satisfaction | Focus on full-grain or top-grain leather for durability |

| Automotive | Leather seat belts and interior trim | Provides safety, comfort, and aesthetic appeal | Ensure compliance with safety standards and durability |

| Manufacturing | Conveyor belts for heavy machinery | Increases efficiency and reduces downtime | Prioritize thickness for load-bearing capacity |

| Agriculture | Leather harnesses for livestock | Improves animal handling and reduces wear and tear | Select thicker leather for durability and comfort |

| Furniture | Leather belts for upholstery | Enhances product longevity and aesthetic value | Consider leather quality and thickness for durability |

How is leather belt thickness utilized in the fashion and apparel industry?

In the fashion and apparel sector, leather belt thickness plays a pivotal role in product quality and brand positioning. High-quality belts made from full-grain or top-grain leather not only offer durability but also enhance the overall aesthetic appeal of fashion items. This is particularly crucial for brands targeting discerning consumers in markets across Africa, South America, and Europe, where craftsmanship and material quality are highly valued. Buyers should prioritize sourcing from reputable tanneries to ensure the leather meets industry standards for thickness and durability.

What are the applications of leather belt thickness in the automotive sector?

In the automotive industry, leather belt thickness is essential for creating reliable seat belts and interior trims. The thickness must meet stringent safety standards while providing comfort and a premium feel. International buyers, especially from regions with varying climate conditions, should consider the leather’s ability to withstand wear and environmental stressors. Sourcing from suppliers who offer treated leather can ensure longevity and maintain the aesthetic appeal of automotive interiors.

Illustrative image related to leather belt thickness

How does leather belt thickness contribute to manufacturing efficiency?

For manufacturers, particularly in sectors utilizing heavy machinery, leather belt thickness is critical in the design of conveyor belts. Thicker leather belts can bear heavier loads, increasing operational efficiency and minimizing downtime due to wear. Sourcing considerations should include the specific thickness required for load-bearing applications and the leather’s resistance to abrasion and tearing. This is especially important for international buyers looking to optimize supply chains and production processes.

What is the significance of leather belt thickness in agriculture?

In agriculture, leather belt thickness is vital for harnesses used in livestock management. Thicker leather provides enhanced durability and comfort, reducing wear on both the equipment and the animals. Buyers in this sector should focus on sourcing leather that can withstand the rigors of outdoor use and varying weather conditions. Ensuring that the leather is both thick and flexible can help improve animal handling and overall operational efficiency.

Why is leather belt thickness important in the furniture industry?

In the furniture industry, leather belt thickness impacts the longevity and aesthetic quality of upholstered items. Thicker leather not only enhances durability but also contributes to the overall look and feel of the furniture, appealing to high-end markets. Buyers should prioritize sourcing high-quality leather that meets specific thickness requirements to ensure that the final products maintain their integrity and aesthetic appeal over time. This is particularly relevant for international buyers looking to meet diverse consumer preferences across different regions.

3 Common User Pain Points for ‘leather belt thickness’ & Their Solutions

Scenario 1: Balancing Durability and Flexibility in Leather Belts

The Problem: B2B buyers often struggle to find leather belts that strike the right balance between durability and flexibility. For instance, a manufacturer may require belts that can withstand heavy use in industrial settings while still being comfortable for workers who wear them for long hours. Choosing leather that is either too thick can lead to stiffness and discomfort, while leather that is too thin may not endure the rigors of daily use.

Illustrative image related to leather belt thickness

The Solution: To overcome this challenge, buyers should focus on sourcing leather within the optimal thickness range of 8.5 to 9.5 ounces, specifically using full-grain leather from double butt cuts. This thickness offers a robust yet flexible option suitable for work environments. When placing orders, it is essential to communicate the intended use clearly and request samples to assess comfort and durability. Building a relationship with suppliers who can provide detailed information about leather properties and variations in thickness will ensure better alignment with performance needs.

Scenario 2: Misalignment Between Product Specifications and Customer Expectations

The Problem: A common issue faced by B2B buyers is the misalignment between the specifications provided by manufacturers and the expectations of end-users. For example, a retailer may order leather belts claiming a certain thickness, but upon delivery, they find that the products vary significantly in weight and feel. This discrepancy can lead to customer dissatisfaction and returns, impacting the retailer’s reputation.

The Solution: To mitigate this issue, buyers should establish clear specifications and quality control measures before placing bulk orders. Requesting a comprehensive leather thickness chart from suppliers will allow buyers to understand the potential variations and choose the right products that meet customer expectations. Additionally, implementing a testing phase where a small batch of belts is produced and evaluated based on real-world usage can help identify any discrepancies early. Regular communication with manufacturers about quality assurance practices will also contribute to more consistent product delivery.

Illustrative image related to leather belt thickness

Scenario 3: Uncertainty About Leather Grades and Their Impact on Thickness

The Problem: B2B buyers may encounter uncertainty regarding the impact of leather grades on the overall thickness and performance of leather belts. For example, a buyer may choose a lower-grade leather believing it to be a cost-effective solution, only to find that the belt fails to hold up over time, resulting in increased replacement costs and dissatisfied customers.

The Solution: To address this issue, buyers should prioritize sourcing high-quality leather, specifically full-grain or top-grain options, which are known for their durability and aesthetic appeal. Understanding the differences between leather grades is crucial; therefore, buyers should educate themselves on the characteristics of each grade and their suitability for specific applications. Collaborating closely with experienced suppliers who can provide insights into the longevity and performance of different leather grades will ensure that buyers make informed decisions. Moreover, considering leather thickness in relation to the intended use—such as opting for thicker leather for heavy-duty applications—will enhance overall product satisfaction and reduce long-term costs.

Strategic Material Selection Guide for leather belt thickness

What Are the Key Properties of Different Leather Types for Belt Thickness?

When selecting leather for belts, thickness is a critical factor that influences durability, comfort, and overall performance. Below, we analyze four common leather types that are frequently used in belt manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to leather belt thickness

Full-Grain Leather: The Premium Choice

Key Properties: Full-grain leather is derived from the top layer of the hide, retaining its natural texture and grain. It is highly breathable, resistant to wear, and develops a unique patina over time.

Pros & Cons: The primary advantage of full-grain leather is its exceptional durability and aesthetic appeal, making it suitable for high-end belts. However, it comes at a higher cost and may require more careful maintenance to preserve its appearance.

Impact on Application: Full-grain leather is ideal for belts that will experience regular wear and tear, as it can withstand significant stress without compromising integrity.

Considerations for International Buyers: Buyers from regions like Africa and South America may seek full-grain leather for its quality, but they should consider local climate conditions that could affect leather longevity. Compliance with international quality standards such as ASTM or DIN is also essential.

Top-Grain Leather: A Balanced Option

Key Properties: Top-grain leather is slightly less durable than full-grain but still offers a high level of quality. It has a smoother finish due to the removal of the outer layer, making it easier to maintain.

Illustrative image related to leather belt thickness

Pros & Cons: This type of leather provides a good balance between quality and cost, making it suitable for mid-range belts. However, it may not develop as rich a patina as full-grain leather, which some consumers may find less appealing.

Impact on Application: Top-grain leather is suitable for belts that require a polished look while still being durable enough for everyday use.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer top-grain leather for its aesthetic qualities. Understanding local preferences and compliance with leather sourcing regulations is crucial.

Corrected Grain Leather: An Economical Alternative

Key Properties: Corrected grain leather is made from top-grain leather that has been sanded and embossed to create a uniform appearance. It is less expensive than full-grain and top-grain options.

Pros & Cons: The main advantage of corrected grain leather is its affordability, making it accessible for budget-conscious buyers. However, it may not be as durable as higher-grade leathers, and the artificial grain can detract from its natural beauty.

Illustrative image related to leather belt thickness

Impact on Application: This leather is suitable for belts intended for casual use or for consumers who prioritize cost over longevity.

Considerations for International Buyers: Buyers from regions with lower purchasing power, such as parts of South America, may find corrected grain leather appealing. However, awareness of quality standards is essential to avoid subpar products.

Bonded Leather: The Budget Option

Key Properties: Bonded leather is made from leather scraps that are glued together, often resulting in a product that is less durable and of lower quality.

Pros & Cons: The primary advantage is its low cost, making it an attractive option for mass-produced items. However, bonded leather is prone to cracking and wear, making it unsuitable for high-quality belts.

Illustrative image related to leather belt thickness

Impact on Application: This material is best used for promotional items or low-cost fashion accessories rather than durable belts.

Considerations for International Buyers: Buyers should be cautious when purchasing bonded leather, particularly in markets like Europe, where quality standards are stringent. Understanding the long-term value of investments in leather products is crucial.

Summary Table of Leather Types for Belt Thickness

| 素材 | Typical Use Case for leather belt thickness | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end belts for daily wear | Exceptional durability and unique patina | Higher cost and requires maintenance | 高い |

| Top-Grain Leather | Mid-range belts for everyday use | Good balance of quality and cost | Less durable than full-grain | Medium |

| Corrected Grain Leather | Casual belts for budget-conscious buyers | Affordable and uniform appearance | Less durable and may lack natural beauty | 低い |

| Bonded Leather | Promotional items or low-cost accessories | Very low cost | Prone to cracking and wear | 低い |

In-depth Look: Manufacturing Processes and Quality Assurance for leather belt thickness

What Are the Main Stages of Leather Belt Manufacturing?

The manufacturing of leather belts involves several crucial stages, each requiring precision and expertise to ensure the final product meets the desired quality and specifications. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Leather Selected and Processed?

The first step in manufacturing leather belts is the selection of high-quality leather, typically full-grain or top-grain leather, which provides durability and aesthetic appeal. Leather thickness is measured in ounces, with optimal thickness for belts generally ranging from 8.5 to 9.5 ounces. This thickness ensures the belt can withstand daily wear while retaining flexibility.

Illustrative image related to leather belt thickness

Once the leather is selected, it undergoes a preparation process that may include tanning (vegetable or chrome), conditioning, and cutting. The leather is often split into consistent thicknesses using a splitting machine, which helps reduce variations. Quality assurance starts here, as any flaws or inconsistencies in the leather can impact the final product.

How Are Leather Belts Formed and Assembled?

In the forming stage, the prepared leather is cut into specific shapes and sizes suitable for belt production. Manufacturers typically use dies for precision cutting, ensuring uniformity across batches. The double butt cut is preferred for its consistency and strength, providing a reliable material for belt crafting.

The assembly process involves stitching, riveting, or bonding the cut pieces together. Techniques such as edge finishing and burnishing are applied to enhance durability and aesthetics. High-quality belts often feature reinforced stitching, which adds to their strength and longevity. Quality control measures during this stage include checking stitch density and alignment, ensuring that the assembly meets the required standards.

Illustrative image related to leather belt thickness

What Are the Key Finishing Techniques for Leather Belts?

Finishing is the final stage in the manufacturing process, where belts undergo treatments to enhance their appearance and protect against wear. This may involve dyeing, polishing, and applying protective coatings to the leather surface. Finishing techniques can significantly affect the belt’s color, texture, and resistance to environmental factors.

For B2B buyers, understanding the finishing processes can help in selecting products that align with market demands. For instance, belts designed for outdoor use may require additional water-resistant treatments, whereas those aimed at fashion markets might prioritize aesthetic finishes.

What Are the International Quality Standards for Leather Belts?

Quality assurance in leather belt manufacturing is governed by several international standards, such as ISO 9001, which emphasizes effective quality management systems. Compliance with these standards ensures that products meet customer and regulatory requirements consistently.

Additionally, industry-specific certifications like CE marking and API standards may apply, depending on the target market and application of the leather products. For B2B buyers, verifying adherence to these standards can be crucial in ensuring product reliability and market acceptance.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) in leather belt manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): Before production begins, incoming leather hides are inspected for defects, consistency in thickness, and overall quality. This step is vital to ensure that only high-quality materials are used.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted at various stages, including cutting, assembly, and finishing. This ensures that any issues can be identified and rectified promptly, preventing defects from progressing to the final product.

-

Final Quality Control (FQC): Once the belts are completed, a thorough inspection is conducted to check for overall quality, including stitching integrity, color consistency, and finishing quality. This step is crucial for ensuring that the final products meet the specified standards.

What Common Testing Methods Are Used in Leather Belt Quality Assurance?

Several testing methods can be employed to assess the quality and durability of leather belts. Common tests include:

-

Thickness Measurement: Using calipers or micrometers to verify that the leather thickness aligns with specifications.

-

Tensile Strength Testing: Assessing the strength of the leather by measuring how much weight it can bear before breaking.

-

Flexural Testing: Evaluating the leather’s ability to withstand bending without cracking, which is essential for belts that experience frequent movement.

-

Colorfastness Testing: Ensuring that dyes used in the leather do not fade or bleed when exposed to water or other environmental factors.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is critical to ensuring product reliability. Buyers can take several steps:

-

Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality assurance protocols. This allows buyers to assess compliance with international standards and identify any potential issues.

-

Quality Reports: Requesting detailed quality assurance reports can help buyers understand the methodologies and results of testing conducted on the leather belts.

-

Third-Party Inspections: Engaging third-party inspection services can provide unbiased assessments of the supplier’s quality control measures. These services can evaluate compliance with international standards and ensure that the products meet the required specifications.

What Are the Quality Control Nuances for Different Regions?

When sourcing leather belts from various regions, B2B buyers should be aware of the specific quality control nuances that may exist. For example, suppliers in Africa may have different regulatory requirements compared to those in Europe or South America. Buyers should familiarize themselves with local standards, certifications, and market expectations.

Illustrative image related to leather belt thickness

Additionally, cultural differences in craftsmanship and production methods can affect the quality of leather goods. Engaging with suppliers who have a solid understanding of international quality standards and practices can help mitigate risks and ensure that the products align with global market demands.

Conclusion: Ensuring Quality in Leather Belt Manufacturing

The manufacturing processes and quality assurance protocols for leather belts are integral to producing high-quality products that meet international standards. By understanding the stages of production, quality control checkpoints, and testing methods, B2B buyers can make informed decisions when sourcing leather belts. Careful selection of suppliers who adhere to stringent quality practices will ultimately lead to successful partnerships and satisfied customers in diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather belt thickness’

To assist B2B buyers in navigating the complexities of sourcing leather belt thickness, this guide provides a structured checklist to ensure that all aspects of procurement are addressed effectively. The right thickness of leather is critical for durability, appearance, and overall product quality, making informed decisions essential.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for leather belt thickness is the first step in the sourcing process. Determine the required thickness in ounces, typically ranging from 8.5 to 9.5 ounces for high-quality belts. This specification will guide your supplier discussions and ensure you receive materials that meet your product standards.

Illustrative image related to leather belt thickness

Step 2: Research Leather Grades and Cuts

Understanding the different grades of leather and their cuts is vital for selecting the right material. Focus on full-grain and top-grain leathers, as they provide the best durability and aesthetic qualities. Avoid lower-quality options like split grain and bonded leather, which can compromise the integrity of the final product.

- Full-Grain Leather: Offers natural beauty and strength, ideal for premium belts.

- Top-Grain Leather: Slightly more processed but still high quality, suitable for a variety of belt designs.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that potential suppliers have the necessary certifications. Look for compliance with industry standards such as ISO certifications and environmental regulations. This ensures that the leather is sourced ethically and processed responsibly, which is increasingly important in global trade.

Step 4: Request Sample Thickness Specifications

Always request samples of the leather along with detailed thickness specifications. This allows you to physically assess the leather’s quality and gauge its suitability for your intended use. Pay attention to the consistency of thickness, as variations can affect the final product’s durability and performance.

Step 5: Analyze Production Capabilities

Inquire about the supplier’s production capabilities to ensure they can meet your order volumes and timelines. Discuss their ability to handle custom thickness requests or adjustments based on your needs. A reliable supplier should be flexible and responsive to your specific requirements.

Step 6: Negotiate Terms and Conditions

Once you’ve narrowed down your options, negotiate terms that include price, delivery timelines, and payment conditions. Ensure that the agreement covers quality assurance measures, including thickness consistency checks and return policies for non-compliant products. This protects your investment and helps maintain product quality.

Step 7: Conduct a Final Quality Check

Before placing a bulk order, arrange for a final quality check of the leather samples. This step is crucial to confirm that the thickness, cut, and overall quality meet your specifications. A thorough inspection can prevent costly mistakes and ensure that the leather belts produced will meet market expectations.

By following these steps, B2B buyers can effectively source leather belt thickness that aligns with their quality standards and market demands, paving the way for successful product offerings.

Comprehensive Cost and Pricing Analysis for leather belt thickness Sourcing

In the leather belt industry, the thickness of the leather used is a significant factor influencing both costs and pricing. Understanding the various components that contribute to the overall cost structure is vital for B2B buyers looking to make informed purchasing decisions.

What Are the Key Cost Components in Leather Belt Thickness Sourcing?

-

Materials: The primary cost driver is the leather itself, which varies significantly in quality and thickness. High-quality full-grain leather, typically used for premium belts, ranges from 8.5 to 9.5 ounces in thickness. The price per square foot can vary based on the grade of leather, with full-grain being the most expensive. Additionally, other materials, such as buckles and linings, contribute to the overall material costs.

-

Labor: Skilled labor is required for crafting leather belts, especially when intricate designs or customizations are involved. Labor costs can vary by region, with countries in Europe generally having higher wage standards compared to those in South America or Africa.

-

Manufacturing Overhead: This includes the costs associated with running a production facility, such as utilities, equipment maintenance, and indirect labor. Efficient production processes can help reduce overhead costs, making it crucial for buyers to evaluate supplier capabilities.

-

Tooling: Initial setup costs for tooling can be significant, particularly for custom designs. Buyers should consider whether the supplier charges tooling fees and how these might affect pricing.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the belts meet specified standards. While this adds to costs, it is essential for maintaining quality, especially for international buyers who may have specific certification requirements.

-

Logistics: Shipping costs are influenced by distance, weight, and the chosen Incoterms. Import duties and tariffs can also significantly affect the total cost, particularly for buyers from regions with varying trade agreements.

-

Margin: Suppliers will typically mark up prices to ensure profitability. Understanding the typical margins in the leather goods industry can help buyers negotiate better deals.

What Factors Influence Pricing in Leather Belt Thickness Sourcing?

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Larger orders usually qualify for volume discounts, which can be beneficial for businesses looking to reduce unit costs.

-

Specifications and Customization: Custom designs or specific thickness requirements can lead to higher costs. Buyers should be prepared to discuss their specifications in detail to ensure accurate quotes.

-

Material Quality and Certifications: The presence of certifications (e.g., eco-friendly tanning processes) can impact pricing. Buyers should inquire about the quality and certification of the leather to ensure it aligns with their brand values.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with a track record of quality may charge a premium, but this often translates to better overall value.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is crucial for determining who bears the shipping costs and responsibilities. This can impact the overall price and should be clearly negotiated before finalizing contracts.

What Tips Should Buyers Consider for Cost-Efficiency in Leather Belt Sourcing?

-

Negotiation: Engage in discussions about pricing and terms. Suppliers may be willing to offer better rates for long-term contracts or bulk orders.

-

Total Cost of Ownership: Consider not just the purchase price but also the longevity and durability of the belts. Investing in higher-quality leather may result in lower replacement costs over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, regional tariffs, and import duties when sourcing from different countries. This knowledge can help mitigate unexpected costs.

In conclusion, understanding the multifaceted costs and pricing dynamics of leather belt thickness sourcing is essential for B2B buyers. By considering these factors, businesses can make strategic purchasing decisions that align with their operational goals and budget constraints. Keep in mind that indicative prices can fluctuate based on market conditions, so it’s prudent to regularly review supplier pricing and market trends.

Alternatives Analysis: Comparing leather belt thickness With Other Solutions

Exploring Alternatives to Leather Belt Thickness

In the quest for durable and effective fastening solutions, leather belts have long been a staple in various industries. However, as manufacturers and buyers seek alternatives that meet specific needs, understanding how leather belt thickness compares to other solutions is essential. This section evaluates leather belt thickness against synthetic materials and webbing belts, providing insights that can guide B2B buyers in their decision-making process.

| Comparison Aspect | Leather Belt Thickness | Synthetic Belts | Webbing Belts |

|---|---|---|---|

| Performance | High durability; develops a unique patina; excellent for heavy use. | Good resistance to wear and tear; less breathable. | Very strong; excellent tensile strength; lightweight. |

| Cost | Moderate to high; depends on leather quality and thickness. | Generally lower; varies based on material quality. | Low to moderate; cost-effective for bulk purchases. |

| Ease of Implementation | Requires skilled craftsmanship; longer production time. | Easy to manufacture; can be produced in large quantities quickly. | Simple to produce; often available off-the-shelf. |

| Maintenance | Requires regular conditioning; can last many years with care. | Minimal maintenance; often resistant to stains. | Easy to clean; quick-drying, but may fray over time. |

| Best Use Case | Ideal for fashion and heavy-duty applications requiring durability. | Suitable for industrial settings and casual wear. | Best for outdoor activities and tactical uses. |

Detailed Breakdown of Alternatives

Synthetic Belts

Synthetic belts, often made from materials like nylon or polyester, present a viable alternative to leather belts. They offer good resistance to wear and tear, making them suitable for various applications. However, while they are generally more affordable than leather options, synthetic belts may lack breathability and comfort, especially in hot climates. Additionally, they do not develop the same aesthetic appeal over time, as leather does.

Webbing Belts

Webbing belts are crafted from woven fabric materials, providing significant tensile strength and lightweight properties. They are often used in outdoor and tactical environments due to their durability and ease of use. Webbing belts can be produced quickly and are available in various colors and patterns, making them a versatile choice. However, they may not offer the same level of refinement as leather belts, and their lifespan can be affected by fraying or wear over time.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a belt solution, B2B buyers should consider the specific requirements of their industry and end-use applications. Leather belt thickness offers unparalleled durability and a classic aesthetic, making it ideal for premium products. Conversely, synthetic and webbing belts provide cost-effective and functional alternatives suitable for various applications. By weighing the performance, cost, and maintenance of each option, buyers can make informed decisions that align with their operational needs and customer expectations.

Essential Technical Properties and Trade Terminology for leather belt thickness

What Are the Key Technical Properties of Leather Belt Thickness?

Understanding the technical properties of leather belt thickness is crucial for B2B buyers to ensure the quality, durability, and suitability of their products. Here are the essential specifications to consider:

Illustrative image related to leather belt thickness

1. Material Grade

Material grade refers to the quality classification of leather, which can significantly impact the performance and longevity of the belt. High-quality grades such as full-grain and top-grain leather are preferred for belts due to their durability and natural aesthetics. In contrast, lower grades like bonded or genuine leather are often unsuitable for high-wear applications. Buyers should prioritize sourcing from suppliers that offer premium materials to enhance product reputation and customer satisfaction.

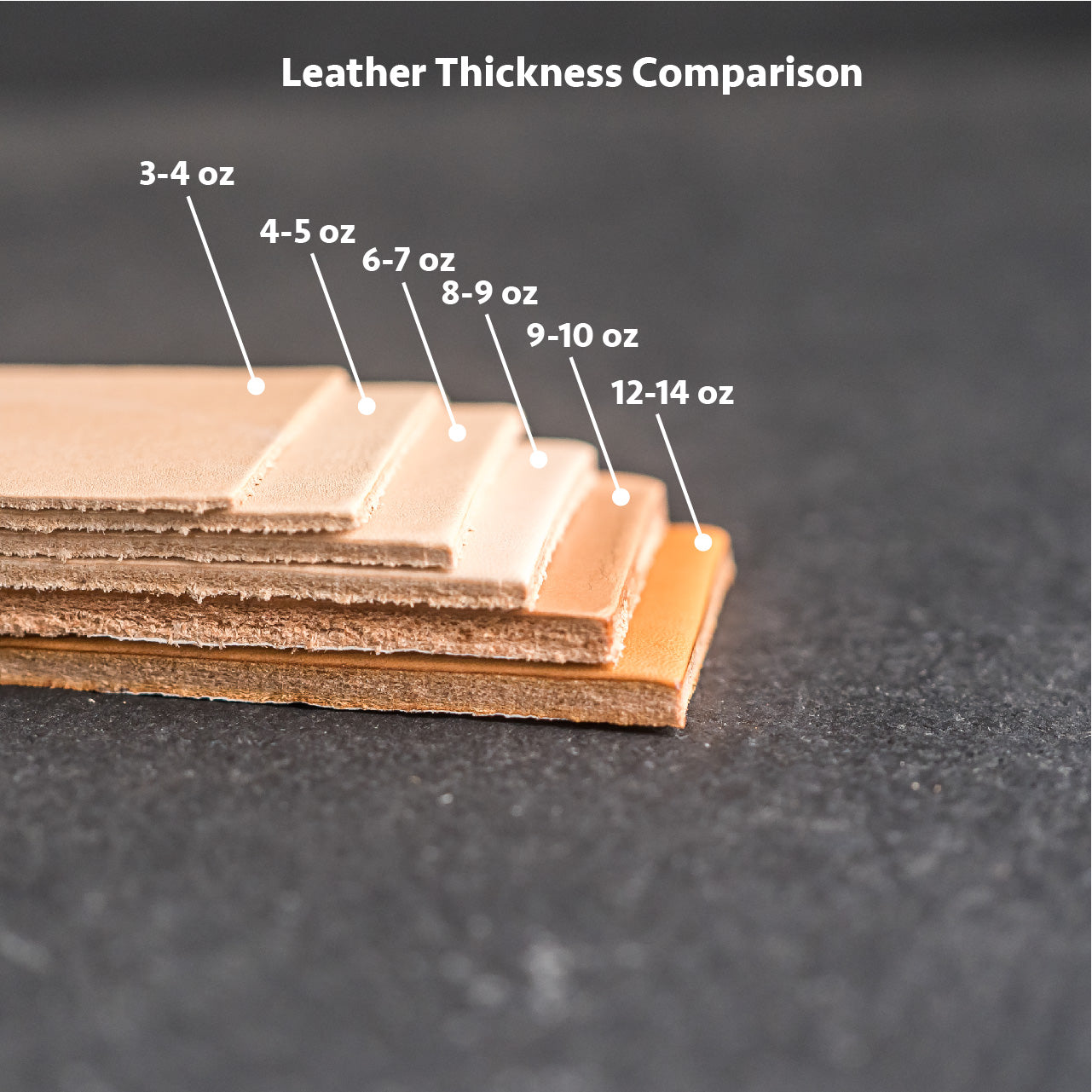

2. Thickness Measurement

Leather thickness is often measured in ounces, where one ounce equals 1/64 of an inch. For example, a belt made from 8-9 ounce leather will typically be between 1/8″ and 1/9″ thick. The thickness affects both the weight and durability of the belt. Thicker leather is generally more robust and suitable for heavy-duty use, while thinner leather may be more flexible but less durable. Buyers should align the thickness of the leather with the intended use of the belt to optimize performance.

3. Tolerance Levels

Tolerance levels refer to the acceptable range of variation in leather thickness. Given the natural variability in hides, understanding these tolerances is critical for manufacturers to ensure consistency in production. A tight tolerance may be necessary for high-end products, while a looser tolerance might be acceptable for lower-quality items. Buyers should communicate their tolerance requirements clearly to suppliers to avoid issues in production.

4. Cut Type

The cut of the leather, such as double butt, side, or belly cuts, influences not only the thickness but also the overall quality and usability of the leather. Double butt cuts are preferred for belts due to their thickness and consistency, while belly cuts may introduce irregularities that compromise durability. Buyers should inquire about the cut type when sourcing leather to ensure they are getting the best material for their products.

5. Finish and Treatment

The finish applied to leather can affect both its appearance and performance. Vegetable tanning, for example, enhances the leather’s natural characteristics and makes it more environmentally friendly. Different treatments can also increase resistance to wear and moisture. Buyers should consider the type of finish and treatment when evaluating leather options, as this can impact both the quality and marketability of the final product.

Illustrative image related to leather belt thickness

What Are Common Trade Terms Related to Leather Belt Thickness?

Familiarity with industry terminology is essential for effective communication and negotiation in the leather goods market. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, an OEM may supply pre-manufactured leather belts that can be customized with specific branding or design elements for B2B clients. Understanding OEM relationships can help buyers streamline their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to consider when sourcing leather belts, as it can affect inventory management and production costs. Knowing the MOQ helps buyers plan their orders effectively and negotiate better terms with suppliers.

Illustrative image related to leather belt thickness

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other information for specific products. B2B buyers should prepare a detailed RFQ when seeking leather belts to ensure they receive accurate quotes that reflect their specific requirements, including leather thickness, grade, and treatment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B transactions, as it clarifies who is responsible for costs and risks at different stages of the shipping process.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the leather goods industry, lead times can vary based on factors such as material availability and production capacity. Buyers should account for lead times in their supply chain planning to avoid stock shortages.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions, ensuring they select high-quality leather belts that meet their market needs.

Navigating Market Dynamics and Sourcing Trends in the leather belt thickness Sector

What Are the Current Market Dynamics in the Leather Belt Thickness Sector?

The leather belt thickness market is witnessing significant transformations driven by global consumer preferences and technological advancements. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek premium leather products, the demand for high-quality leather belts—particularly those made from full-grain and top-grain leathers—has surged. Current trends show a preference for belts that range between 8.5 to 9.5 ounces in thickness, which are recognized for their durability and aesthetic appeal. Buyers are increasingly leveraging digital platforms for sourcing, utilizing data analytics to assess market trends and supplier reliability.

Illustrative image related to leather belt thickness

Emerging technologies such as AI and machine learning are shaping sourcing strategies, allowing buyers to forecast demand more accurately and optimize inventory management. Additionally, the integration of blockchain technology in supply chains enhances transparency, which is increasingly becoming a purchasing criterion for buyers concerned about authenticity and ethical sourcing. As manufacturers adapt to these technologies, they are also innovating in design, leading to a growing interest in customizable leather belts, thus catering to diverse market needs.

How Is Sustainability Influencing Sourcing Trends in Leather Belt Thickness?

Sustainability has become a cornerstone of sourcing practices in the leather industry, particularly for B2B buyers who prioritize environmental responsibility. The tanning process traditionally poses environmental challenges, but there is a significant shift towards more sustainable practices. Buyers are increasingly seeking suppliers that utilize vegetable tanning methods, which reduce chemical waste and promote eco-friendly production. Certifications like the Leather Working Group (LWG) and the Global Organic Textile Standard (GOTS) are essential for buyers looking to ensure that their leather products are sourced ethically.

Moreover, the emphasis on circular economy principles is encouraging manufacturers to explore ways to recycle leather scraps and reduce waste. Sustainable sourcing not only aligns with ethical consumerism but also enhances brand reputation in competitive markets. As a result, businesses that prioritize these factors can differentiate themselves and attract environmentally-conscious customers, thereby fostering long-term loyalty and sustainability in their supply chains.

What Is the Historical Context of Leather Belt Thickness in B2B Markets?

Historically, leather has been a valuable material in various industries, with belt-making being one of its most enduring applications. The evolution of leather thickness standards can be traced back to the artisanal practices of leatherworkers who recognized the importance of thickness for both functionality and aesthetics. Initially, leather belts were crafted from a variety of hides without standardized measurements, leading to inconsistencies in quality.

Illustrative image related to leather belt thickness

As demand grew, particularly in the fashion and accessories sectors, the industry began to formalize leather thickness classifications, paving the way for the current metrics used today. This evolution has been marked by a shift from low-quality, mass-produced belts to a focus on premium materials, such as full-grain leather from double butt cuts, which offer enhanced durability and style. Understanding this historical context provides B2B buyers with insights into the material’s evolution and the importance of sourcing high-quality leather to meet modern consumer expectations.

Conclusion

Navigating the leather belt thickness sector requires an awareness of market dynamics, sustainability trends, and historical context. For B2B buyers, particularly those in emerging markets, aligning sourcing strategies with these insights can lead to more informed purchasing decisions, ultimately enhancing product quality and brand reputation. As the landscape continues to evolve, staying abreast of these trends will be crucial for maintaining competitiveness and meeting customer demands effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of leather belt thickness

-

How do I determine the appropriate leather belt thickness for my needs?

To determine the appropriate leather belt thickness, consider the intended use and target market. For high-quality belts aimed at premium consumers, opt for leather between 8.5 to 9.5 ounces, which provides durability and a luxurious feel. Additionally, assess your customer base’s preferences regarding style and functionality. If your market demands more casual belts, a slightly thinner leather (around 6-8 ounces) may suffice, but ensure it still meets quality standards to maintain brand reputation. -

What is the best leather thickness for crafting durable belts?

The ideal leather thickness for crafting durable belts typically ranges from 8 to 10 ounces. This thickness offers a balance between sturdiness and flexibility, ensuring that the belt can withstand regular wear while maintaining its shape. Full-grain leather in this thickness range is recommended, as it is the most durable and develops a unique patina over time, enhancing its aesthetic appeal. Always verify with suppliers about their specific thickness measurements, as they can vary slightly. -

How does leather thickness impact the quality of the final product?

Leather thickness directly impacts the durability, flexibility, and overall quality of the final product. Thicker leather tends to be more robust and can better resist wear and tear, making it ideal for items like belts that endure daily use. Conversely, thinner leather may be more comfortable but can lead to quicker degradation. It’s essential to strike the right balance based on your product positioning and customer expectations to ensure satisfaction. -

What should I consider when sourcing leather thickness from international suppliers?

When sourcing leather thickness from international suppliers, consider factors such as compliance with local quality standards, shipping times, and potential tariffs. Verify the supplier’s reputation by checking references and their track record in delivering consistent quality. Additionally, be aware of the variations in leather thickness measurement systems used globally; ensure you specify your requirements clearly to avoid misunderstandings regarding the product delivered. -

What are the minimum order quantities (MOQs) for leather belts, and how can I negotiate them?

Minimum order quantities (MOQs) for leather belts vary by supplier and can depend on the type of leather and customization options. Typically, MOQs range from 100 to 500 units. To negotiate MOQs, demonstrate your long-term purchasing potential, discuss flexible payment terms, or consider bundling orders with other products to meet the supplier’s requirements. Building a good relationship with your supplier can also lead to more favorable terms. -

What payment terms are common in international leather trade?

Common payment terms in international leather trade include advance payments, letters of credit, and payment upon delivery. The choice often depends on the supplier’s policies, your business relationship, and the order’s size. Consider negotiating partial payments upfront, with the balance due upon shipment. Ensure that payment methods are secure and provide adequate protection against fraud or non-delivery, especially in cross-border transactions. -

How can I ensure quality assurance (QA) for leather thickness?

To ensure quality assurance for leather thickness, establish clear specifications and standards before placing orders. Request samples to evaluate thickness, texture, and durability. Consider implementing third-party quality inspections during production to verify compliance with your standards. Additionally, maintaining open communication with your supplier throughout the process can help address any potential issues early on. -

What logistics considerations should I be aware of when importing leather belts?

When importing leather belts, consider logistics factors such as shipping methods, customs regulations, and lead times. Opt for reliable freight forwarders familiar with the leather industry to streamline the import process. Be aware of any import duties or tariffs that may apply, and ensure all necessary documentation is prepared to avoid delays. It’s also beneficial to plan for potential fluctuations in shipping costs and timelines due to geopolitical factors or global supply chain disruptions.

Top 6 Leather Belt Thickness Manufacturers & Suppliers List

1. Reddit – Leather Belt Strips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1) 3.2~3.5 mm strip of leather (0.126 ~0.137 inch) 2) Two strips of 2mm each, glued and stitched together to achieve a belt 4mm thick (0.078 inches each).

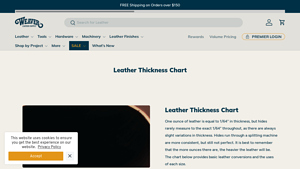

2. Weaver Leather Supply – Leather Thicknesses & Ounces Chart

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Leather Thicknesses & Ounces Chart – One ounce of leather is equal to 1/64″ in thickness. Hides may vary slightly in thickness. Hides processed through a splitting machine are more consistent. The chart provides basic leather conversions and uses for each size. More ounces indicate heavier leather.

3. Obscure Belts – Stone Fractal 2.0 Buckle on Leather Belt

Domain: obscurebelts.com

Registered: 2005 (20 years)

Introduction: High quality leather belts are made using full grain leather from a double butt cut hide in 8.5 – 9.5 ounce thickness. The key products mentioned include: 1. Stone Fractal 2.0 Buckle on Leather Belt – Regular price $105.00 2. Black Ops Fractal 2.0 Buckle on Leather Belt – Regular price $105.00 3. Outlaw Gun Buckle on Western Leather Belt – Regular price $125.00 4. Series 7 Space Dial on Leather Be…

4. Facebook – High Quality Leather Belts

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Leather thickness for a high quality belt

5. H.N. Williams – Amish Extra Thick Leather Belt

Domain: hnwilliams.com

Registered: 2003 (22 years)

Introduction: USA Made Thick Leather Belt – Amish Extra Thick Leather Belt, Dark Brown. Rated 4.73 out of 5 based on 22 customer ratings. Price: $59.00. Handmade in the USA. Thickness: 14-16oz leather. Width: 1.5 inches. Features: heavy-duty roller buckle, 8 holes for custom fit, can replace buckle with your own. Recommended sizing: Order 2-4 inches up from your pant waist size for everyday fit, or 4-6 inches u…

6. Montana Leather – Thickness Chart

Domain: montanaleather.com

Registered: 2000 (25 years)

Introduction: Leather Thickness & Ounces Chart – Montana Leather Company. Leather thickness is measured in ounces, with 1 ounce equivalent to 1/64 of an inch. The chart provides thickness ranges from 2 to 11 oz, with corresponding inch and millimeter measurements, and common project applications. For example, 2 to 3 oz (1/32 to 3/64 in, 0.8 to 1.2 mm) is suitable for lining and embossing, while 10 to 11 oz (5/3…

Strategic Sourcing Conclusion and Outlook for leather belt thickness

In the competitive landscape of leather goods, understanding the nuances of leather belt thickness is paramount for international B2B buyers. The ideal thickness for high-quality leather belts typically falls within the 8.5 to 9.5-ounce range, particularly for full-grain leather sourced from double butt cuts. This ensures durability and longevity, characteristics that are highly sought after in markets across Africa, South America, the Middle East, and Europe.

Illustrative image related to leather belt thickness

Strategic sourcing plays a crucial role in securing the right materials. By establishing relationships with reputable suppliers who prioritize quality and consistency, businesses can enhance their product offerings while minimizing waste. Additionally, understanding the various grades and cuts of leather allows buyers to make informed decisions that align with their brand’s values and customer expectations.

Looking ahead, as the demand for sustainable and ethically sourced materials grows, B2B buyers should prioritize partnerships that emphasize quality craftsmanship and environmental responsibility. Investing in high-quality leather not only elevates the brand but also fosters customer loyalty. Engage with suppliers today to explore the best sourcing strategies that will position your business for success in the evolving leather market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to leather belt thickness