Introduction: Navigating the Global Market for polyurethane bags

In today’s fast-paced global market, sourcing high-quality polyurethane bags presents a unique challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. With the rising demand for durable, cost-effective, and versatile packaging solutions, understanding the nuances of polyurethane bags becomes essential for making informed purchasing decisions. This comprehensive guide aims to equip international buyers with the insights needed to navigate the complexities of sourcing these innovative products.

Throughout this guide, we will explore various types of polyurethane bags, including their applications across diverse industries, from retail to logistics. Additionally, we will delve into critical factors for supplier vetting, ensuring that you partner with reputable manufacturers committed to quality and sustainability. Understanding the cost implications and market trends associated with polyurethane bags will also be covered, enabling you to identify competitive pricing strategies that align with your budgetary constraints.

By providing actionable insights and practical recommendations, this guide empowers B2B buyers to make confident decisions that not only meet their immediate needs but also align with long-term business goals. As you navigate the global marketplace, let this resource serve as your trusted companion, helping you secure the best polyurethane bags for your business needs while fostering sustainable and profitable partnerships.

Table Of Contents

- Top 2 Polyurethane Bags Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for polyurethane bags

- Understanding polyurethane bags Types and Variations

- Key Industrial Applications of polyurethane bags

- 3 Common User Pain Points for ‘polyurethane bags’ & Their Solutions

- Strategic Material Selection Guide for polyurethane bags

- In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane bags

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane bags’

- Comprehensive Cost and Pricing Analysis for polyurethane bags Sourcing

- Alternatives Analysis: Comparing polyurethane bags With Other Solutions

- Essential Technical Properties and Trade Terminology for polyurethane bags

- Navigating Market Dynamics and Sourcing Trends in the polyurethane bags Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane bags

- Strategic Sourcing Conclusion and Outlook for polyurethane bags

- Important Disclaimer & Terms of Use

Understanding polyurethane bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Coated Bags | Lightweight, water-resistant, varying thickness | Retail packaging, promotional items | Pros: Cost-effective, customizable; Cons: Limited durability compared to other types. |

| PU Leather Bags | Synthetic leather look, easy to maintain | Fashion accessories, corporate gifts | Pros: Stylish, affordable; Cons: May crack over time, less breathable. |

| Heavy-Duty PU Bags | Reinforced seams, high tensile strength | Industrial packaging, shipping | Pros: Durable, suitable for heavy loads; Cons: Heavier, potentially higher cost. |

| Biodegradable PU Bags | Eco-friendly alternatives, made with sustainable materials | Eco-conscious brands, retail | Pros: Environmentally friendly, compostable; Cons: Higher manufacturing costs, limited availability. |

| Transparent PU Bags | Clear visibility, often used for display | Retail displays, storage solutions | Pros: Enhances product visibility; Cons: Less secure than opaque options. |

What Are PU Coated Bags and Their B2B Applications?

PU coated bags are characterized by their lightweight nature and water-resistant properties, making them ideal for various retail applications, including packaging and promotional items. These bags are often produced in various thicknesses to cater to different needs. Buyers should consider the cost-effectiveness and customization options available, though they may sacrifice some durability compared to heavier materials.

Illustrative image related to polyurethane bags

How Do PU Leather Bags Serve the B2B Market?

PU leather bags offer a synthetic alternative to traditional leather, providing a stylish appearance at a lower cost. They are widely used in the fashion industry for accessories and corporate gifts. While they are easy to maintain and appealing, B2B buyers should be aware of potential longevity issues, such as cracking over time, especially in high-use scenarios.

What Makes Heavy-Duty PU Bags Ideal for Industrial Use?

Heavy-duty PU bags are designed with reinforced seams and high tensile strength, making them suitable for industrial applications like packaging and shipping. These bags can handle heavy loads, providing a reliable solution for businesses that require durability. However, their weight and potentially higher costs may be a consideration for budget-conscious buyers.

Why Choose Biodegradable PU Bags for Eco-Conscious Brands?

Biodegradable PU bags are crafted from sustainable materials, appealing to brands that prioritize environmental responsibility. These bags are suitable for retail businesses looking to enhance their eco-friendly image. Although they may come with higher manufacturing costs and limited availability, the long-term benefits of promoting sustainability can outweigh these challenges for many B2B buyers.

Illustrative image related to polyurethane bags

What Are the Benefits of Using Transparent PU Bags?

Transparent PU bags provide clear visibility of their contents, making them an excellent choice for retail displays and storage solutions. They enhance product visibility, attracting customer attention. However, buyers should note that while they are visually appealing, transparent bags may offer less security than opaque options, which could be a concern in certain applications.

Key Industrial Applications of polyurethane bags

| Industry/Sector | Specific Application of Polyurethane Bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Packaging for perishable goods | Enhanced shelf life and protection against contamination | Ensure compliance with food safety regulations and certifications. |

| Pharmaceutical | Storage and transport of medical supplies | Protection from moisture and contamination | Look for bags with specific barrier properties and certifications for medical use. |

| Construction & Industrial | Containment for hazardous materials | Improved safety and compliance with regulations | Select durable, puncture-resistant materials suitable for harsh environments. |

| Retail & Fashion | Carrying bags for retail products | Cost-effective, lightweight, and customizable | Consider branding options and the environmental impact of materials used. |

| Agriculture | Seed and fertilizer storage | Protection from moisture and pests | Source bags that are UV resistant and suitable for long-term storage. |

How Are Polyurethane Bags Used in the Food & Beverage Industry?

In the food and beverage sector, polyurethane bags are commonly used for packaging perishable goods, including fruits, vegetables, and meats. These bags provide an excellent barrier against moisture and air, extending shelf life and ensuring product freshness. For international buyers, particularly from regions like Africa and South America, sourcing bags that comply with local food safety regulations is critical. Additionally, it’s essential to consider the sustainability of the materials used, as consumers increasingly favor eco-friendly packaging.

What Role Do Polyurethane Bags Play in the Pharmaceutical Sector?

Polyurethane bags are vital in the pharmaceutical industry for the safe storage and transportation of medications and medical supplies. They offer moisture-resistant properties, protecting sensitive products from contamination. For B2B buyers in the Middle East and Europe, it is crucial to source bags that meet stringent regulatory requirements and certifications, ensuring safety and efficacy. Companies should also prioritize suppliers who can provide bags with specific barrier properties tailored to the unique needs of pharmaceutical products.

How Are Polyurethane Bags Beneficial in Construction and Industrial Applications?

In construction and industrial settings, polyurethane bags are utilized for containing hazardous materials and waste. Their durability and puncture resistance make them ideal for safely transporting and storing chemicals, ensuring compliance with safety regulations. Buyers in Europe and the Middle East must focus on sourcing bags that meet specific industry standards and regulations, as well as those that can withstand harsh environmental conditions. Proper selection can significantly enhance workplace safety and operational efficiency.

Why Are Polyurethane Bags Popular in Retail and Fashion?

Polyurethane bags serve as an attractive and cost-effective solution for retail packaging. They are lightweight, customizable, and can be designed to enhance brand visibility. For B2B buyers in South America and Africa, it’s essential to consider the environmental impact of the materials used, as well as the potential for branding opportunities. Suppliers should provide options for sustainable materials to align with consumer preferences for eco-friendly products.

How Do Polyurethane Bags Support Agricultural Needs?

In agriculture, polyurethane bags are used for storing seeds and fertilizers, providing protection against moisture and pests. Their UV resistance is crucial for long-term outdoor storage, ensuring that agricultural inputs remain viable. International buyers, particularly in regions with diverse climates, should seek suppliers that offer bags tailored to specific agricultural needs, including those that can withstand local environmental conditions. Sourcing high-quality bags can lead to improved crop yields and better resource management.

3 Common User Pain Points for ‘polyurethane bags’ & Their Solutions

Scenario 1: Quality Concerns with Polyurethane Bags

The Problem: Many B2B buyers face challenges related to the quality and durability of polyurethane bags. Low-quality bags can lead to frequent replacements, affecting the company’s bottom line and customer satisfaction. For instance, a distributor in Saudi Arabia might source bags that quickly degrade under high temperatures or during heavy usage, leading to complaints and loss of business. Buyers need to be cautious about the materials used and the manufacturing processes employed by suppliers to avoid these pitfalls.

The Solution: To mitigate quality issues, B2B buyers should prioritize sourcing from reputable manufacturers known for their rigorous quality control standards. Conducting thorough research and requesting samples is essential. Buyers can ask for certifications that verify the materials’ quality and durability, such as ISO certifications. Additionally, establishing clear specifications regarding weight, thickness, and resistance to environmental factors can help ensure that the bags meet their intended use. Building a relationship with suppliers who provide transparent information about their production processes and sourcing practices will also lead to better long-term partnerships.

Illustrative image related to polyurethane bags

Scenario 2: Environmental Impact of Polyurethane Bags

The Problem: As global awareness of environmental sustainability increases, many B2B buyers are concerned about the ecological impact of polyurethane bags. Companies in Europe and South America, for example, are facing pressure from consumers and regulatory bodies to adopt more sustainable practices. The use of polyurethane, which can be less eco-friendly compared to natural alternatives, creates a dilemma for businesses trying to balance performance with environmental responsibility.

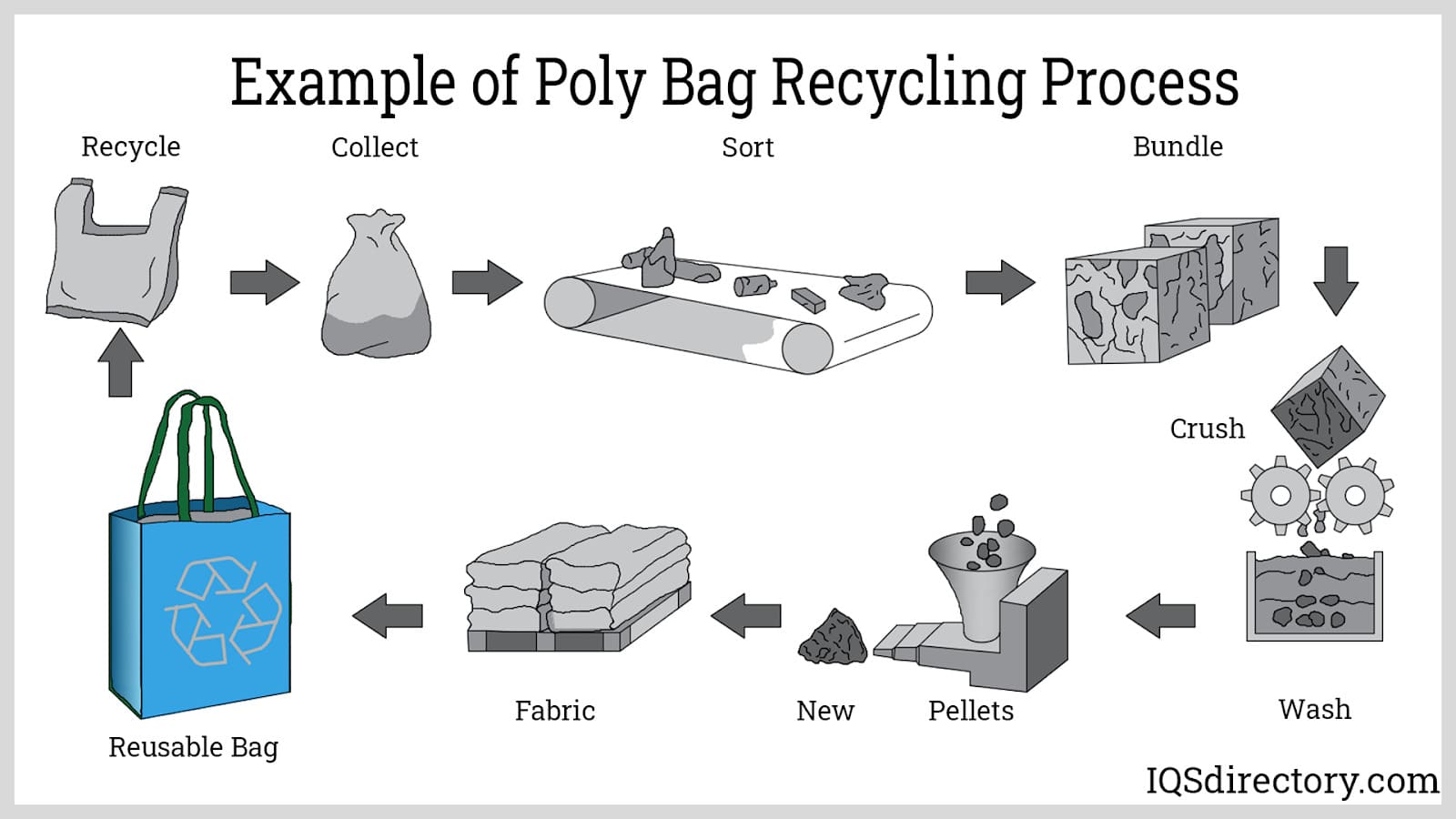

The Solution: To address these concerns, buyers should seek out manufacturers that offer eco-friendly polyurethane options or alternatives that minimize environmental impact. This includes sourcing bags made from recycled materials or those that adhere to environmentally friendly production methods. Engaging with suppliers who can provide detailed information about their sustainability practices can help businesses make informed decisions. Additionally, implementing a recycling program for used bags can further enhance a company’s commitment to sustainability and attract environmentally-conscious customers.

Scenario 3: Inconsistent Sizing and Customization Challenges

The Problem: Another common pain point for B2B buyers is the inconsistency in sizing and customization options for polyurethane bags. For businesses in sectors like retail or logistics, having bags that do not meet specific dimensions or branding requirements can lead to operational inefficiencies and a negative brand image. For instance, a company in Brazil might order bags for specific products only to find that the sizes vary, leading to wasted resources and frustrated employees.

The Solution: To overcome sizing and customization challenges, buyers should communicate their precise specifications clearly before placing orders. Providing detailed drawings or dimensions can help ensure that the supplier understands the requirements. It’s advisable to work with manufacturers who offer flexible customization options and can accommodate specific requests, such as printing logos or adjusting sizes. Establishing a strong communication channel with suppliers will facilitate better collaboration and reduce the risk of errors in orders. Regular audits of sample products before full-scale production can also help catch inconsistencies early in the process.

Strategic Material Selection Guide for polyurethane bags

When selecting materials for polyurethane bags, it is crucial for international B2B buyers to consider various factors that influence product performance, cost, and suitability for specific applications. Below, we analyze several common materials used in the production of polyurethane bags, focusing on their properties, advantages, disadvantages, and implications for buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Polyurethane Materials?

1. Polyurethane Foam

Polyurethane foam is a versatile material known for its lightweight and cushioning properties. It has a temperature rating ranging from -30°C to 90°C, making it suitable for various climates. Its excellent shock absorption capabilities make it ideal for protective bags.

Pros & Cons:

– Advantages: Highly durable, lightweight, and cost-effective. It provides excellent insulation and cushioning.

– Disadvantages: It can degrade under UV exposure and may not be as resistant to chemicals as other materials.

Impact on Application: This material is particularly well-suited for bags that require protection for sensitive items, such as electronics or fragile goods.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM D3574 for foam testing, especially in regions with strict product safety regulations.

Illustrative image related to polyurethane bags

2. Polyester Coated Polyurethane

Polyester-coated polyurethane combines the durability of polyester with the flexibility of polyurethane. It typically offers a pressure rating of up to 2,000 psi and is resistant to abrasion and tearing.

Pros & Cons:

– Advantages: High durability and resistance to wear, making it suitable for heavy-duty applications.

– Disadvantages: While more durable, it can be more expensive and may require specialized manufacturing processes.

Impact on Application: This material is ideal for bags used in industrial settings, where exposure to rough handling and various chemicals is common.

Considerations for International Buyers: Buyers should be aware of local regulations regarding chemical resistance and durability standards, such as DIN EN 14470-1 in Europe.

3. TPU (Thermoplastic Polyurethane)

Thermoplastic polyurethane is a popular choice for its elasticity and resistance to oil and grease. It can withstand temperatures from -40°C to 80°C and is known for its high tensile strength.

Pros & Cons:

– Advantages: Excellent flexibility, chemical resistance, and abrasion resistance. It is also recyclable, which appeals to environmentally conscious buyers.

– Disadvantages: Higher manufacturing costs and potential challenges in achieving desired thickness and finish.

Impact on Application: TPU is suitable for bags that require flexibility and durability, such as outdoor gear and sports bags.

Considerations for International Buyers: Compliance with environmental standards is critical, particularly in regions like Europe, where sustainability is a key purchasing factor.

4. PVC (Polyvinyl Chloride) Blended with Polyurethane

While not a pure polyurethane material, PVC blends are often used to enhance the properties of polyurethane bags. They offer good chemical resistance and can be produced at lower costs.

Illustrative image related to polyurethane bags

Pros & Cons:

– Advantages: Cost-effective and provides good resistance to water and chemicals.

– Disadvantages: Less durable than pure polyurethane options and may have environmental concerns due to the production process.

Impact on Application: This material is often used for promotional bags or lower-cost products where durability is less critical.

Considerations for International Buyers: Buyers should consider the environmental impact and regulatory compliance related to PVC, particularly in regions with stringent environmental laws.

Summary Table of Material Selection for Polyurethane Bags

| Material | Typical Use Case for Polyurethane Bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Foam | Protective bags for electronics | Lightweight and cushioning | Degrades under UV exposure | Low |

| Polyester Coated Polyurethane | Heavy-duty industrial bags | High durability and wear resistance | Higher cost and complex manufacturing | Medium |

| TPU (Thermoplastic Polyurethane) | Outdoor gear and sports bags | Excellent flexibility and chemical resistance | Higher manufacturing costs | High |

| PVC Blended with Polyurethane | Promotional bags | Cost-effective and water-resistant | Less durable and environmental concerns | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various materials used in polyurethane bags. Understanding these factors will enable informed purchasing decisions that align with specific market needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane bags

What Are the Key Stages in the Manufacturing Process of Polyurethane Bags?

The manufacturing process of polyurethane (PU) bags encompasses several critical stages that ensure the final product meets quality, durability, and aesthetic standards. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to polyurethane bags

-

Material Preparation: The process begins with sourcing high-quality polyurethane materials. Manufacturers often use different grades of PU to achieve desired characteristics such as flexibility, durability, and resistance to wear. During this stage, the raw materials are tested for quality, ensuring they meet specific performance criteria.

-

Forming: This stage involves shaping the prepared materials into the desired bag design. Techniques such as die-cutting, heat sealing, and ultrasonic welding are commonly employed. Die-cutting allows for precise shapes and sizes, while heat sealing ensures that seams are airtight and watertight. Ultrasonic welding is increasingly popular for its ability to bond materials without the need for additional adhesives, thus enhancing the bag’s strength and integrity.

-

Assembly: Once the individual components are formed, they are assembled into the final product. This stage includes attaching straps, zippers, and other functional elements. Skilled labor is essential here, as precise assembly affects the bag’s overall durability and usability. Quality checks at this stage often involve visual inspections to catch any defects early.

-

Finishing: The final stage involves adding any aesthetic touches, such as logos, labels, or decorative elements. This is also when the bags undergo additional treatments, such as waterproofing or UV resistance applications, depending on the intended use. The finishing touches not only enhance appearance but also add functionality and longevity to the bags.

How Is Quality Assurance Implemented in Polyurethane Bag Manufacturing?

Quality assurance (QA) is a vital aspect of PU bag manufacturing, ensuring that products meet both international and industry-specific standards. A robust QA process helps manufacturers minimize defects and maintain high customer satisfaction levels.

-

International Standards: Compliance with international quality standards, such as ISO 9001, is crucial for manufacturers targeting B2B markets globally. ISO 9001 outlines criteria for a quality management system (QMS) that can enhance operational efficiency and product quality. Additionally, certifications such as CE mark or API (American Petroleum Institute) standards may be relevant for specific applications, particularly in regions with stringent regulatory environments.

-

Quality Control Checkpoints: Effective QA practices incorporate several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Materials that fail to meet these standards are rejected.

– In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process. This may include checking the integrity of seams during the forming stage or verifying the accuracy of assembly.

– Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive final inspection is conducted. This includes functional testing, visual inspections, and measurements to confirm that the bags meet the required specifications. -

Common Testing Methods: Various testing methods are utilized to assess the durability and performance of PU bags. These may include:

– Tensile strength testing to measure the material’s ability to withstand pulling forces.

– Waterproof testing to ensure the bags can resist water penetration.

– Abrasion testing to evaluate how well the bags can withstand wear and tear over time.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are several strategies:

-

Conducting Supplier Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s adherence to quality standards. Audits can be conducted by the buyer’s quality assurance team or through third-party inspection agencies. These audits assess the entire manufacturing process, from raw material sourcing to final product inspection.

-

Reviewing Quality Reports: Requesting documentation of quality control processes, including IQC, IPQC, and FQC reports, can help buyers understand how the supplier manages quality. These reports should detail any defects found, corrective actions taken, and overall production metrics.

-

Utilizing Third-Party Inspection Services: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality assurance practices. These services often include pre-shipment inspections, where inspectors verify that the products meet the agreed-upon specifications before they are shipped.

-

Understanding QC Nuances for International Markets: Buyers should be aware of the specific quality requirements and standards applicable in their regions. For instance, certain markets may have unique regulations regarding the materials used in PU bags. Understanding these nuances can help buyers make informed decisions and ensure compliance with local laws.

What Should B2B Buyers Consider When Sourcing Polyurethane Bags?

When sourcing polyurethane bags, B2B buyers should consider several key factors to ensure they partner with the right manufacturers:

-

Supplier Reputation: Researching the supplier’s reputation in the industry can provide insights into their reliability and quality. Look for reviews, testimonials, and case studies from other businesses that have worked with the supplier.

-

Customization Capabilities: Depending on the target market, buyers may require specific designs or features. Ensure that the manufacturer has the capability to customize products according to your specifications.

-

Sustainability Practices: As environmental concerns grow, many buyers prefer suppliers who implement sustainable practices in their manufacturing processes. Inquire about the materials used and whether the manufacturer has any eco-certifications.

-

Lead Times and Flexibility: Understanding the supplier’s lead times is crucial for inventory management. Additionally, assess their flexibility in adjusting production schedules to meet changing demands.

-

Cost vs. Quality: While cost is a significant factor, prioritizing quality over price can lead to better long-term value. Low-cost suppliers may compromise on material quality or QC processes, resulting in increased returns and customer dissatisfaction.

By thoroughly understanding the manufacturing processes and quality assurance practices for polyurethane bags, B2B buyers can make informed decisions that align with their business needs and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane bags’

To assist B2B buyers in navigating the complexities of procuring polyurethane bags, this guide provides a structured checklist to ensure a successful sourcing process. By following these steps, buyers can make informed decisions, mitigate risks, and establish fruitful partnerships with suppliers.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for polyurethane bags. This includes dimensions, design features, weight capacity, and intended use cases. Understanding these specifications will help you communicate your needs effectively, ensuring that suppliers can provide appropriate options that meet your expectations.

Step 2: Research the Market Landscape

Conduct thorough market research to identify potential suppliers. Look for manufacturers with a solid reputation in producing polyurethane bags. Utilize platforms like trade directories and industry-specific websites to gather a list of candidates, and pay attention to customer reviews and ratings to gauge their reliability.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it is crucial to vet them thoroughly. Request company profiles, certifications, and references from previous clients in similar industries or regions. Verify their production capabilities and experience in producing polyurethane bags to ensure they align with your quality and quantity requirements.

- Tip: Ask for samples to assess the quality and durability of their products before making a bulk order.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers comply with relevant industry standards and regulations. Look for certifications such as ISO 9001 for quality management and any environmental certifications that may be applicable. This step is essential to ensure that the materials used in the production of polyurethane bags are safe and sustainable.

Step 5: Assess Pricing and Payment Terms

Request detailed quotations from shortlisted suppliers, including pricing, payment terms, and any additional costs (e.g., shipping, taxes). Compare these quotes to ensure you are getting a competitive price while considering the quality of the bags. Negotiate payment terms that align with your cash flow needs, such as upfront payments or payment upon delivery.

Step 6: Understand Lead Times and Delivery Schedules

Discuss lead times with your suppliers to understand how long it will take to fulfill your order. Reliable suppliers should provide clear timelines for production and delivery. Ensure that these timelines fit within your operational needs, allowing for any potential delays that may arise.

Illustrative image related to polyurethane bags

Step 7: Establish a Communication Plan

Once you have selected a supplier, set up a clear communication plan to facilitate ongoing dialogue. Regular updates regarding production status, shipping, and any potential issues are crucial for maintaining a strong supplier relationship. This proactive approach will help mitigate risks and ensure that you receive your orders on time and in the expected condition.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for polyurethane bags, ensuring quality and reliability while building strong partnerships with suppliers.

Comprehensive Cost and Pricing Analysis for polyurethane bags Sourcing

What Are the Key Cost Components for Sourcing Polyurethane Bags?

When sourcing polyurethane bags, understanding the cost structure is crucial for international B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The primary material, polyurethane, varies in quality and price. Higher-grade PU often offers better durability and aesthetics but comes at a premium. Buyers should assess the material specifications based on their end-use requirements.

-

Labor: Labor costs differ significantly by region. For instance, labor may be more affordable in South America compared to Europe. Understanding local labor rates can help buyers evaluate total production costs.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and facility management. A manufacturer with advanced machinery may have higher overhead but offer better quality and efficiency.

-

Tooling: Initial tooling costs for custom designs can be substantial. Buyers seeking unique specifications must factor in these costs when negotiating contracts.

-

Quality Control (QC): Ensuring the final product meets quality standards can incur additional costs. Investing in rigorous QC processes is essential to minimize returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely based on distance, mode of transportation, and volume. Buyers must consider the logistics costs associated with international shipping, including tariffs and duties.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Affect the Cost of Polyurethane Bags?

Several factors influence pricing in the polyurethane bags market, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract lower per-unit prices due to economies of scale. Buyers should evaluate their inventory needs against MOQ requirements to optimize costs.

-

Specifications and Customization: Custom designs or specifications can increase production costs. Buyers should balance their desire for unique features with budget constraints.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as ISO) can affect pricing. Higher-quality materials typically result in longer-lasting products, potentially offering better value over time.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can impact pricing. Building relationships with reputable suppliers can lead to better pricing negotiations and quality assurance.

-

Incoterms: Understanding Incoterms is vital in international trade. They define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can affect the overall cost.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing?

International B2B buyers should employ strategic approaches to maximize cost-efficiency when sourcing polyurethane bags:

-

Negotiate Wisely: Engage suppliers in discussions about pricing, especially regarding bulk orders or long-term contracts. Leverage competitive quotes from multiple suppliers to strengthen your negotiating position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the potential costs related to durability, maintenance, and logistics over the product’s lifecycle. A lower-cost bag may end up being more expensive if it requires frequent replacement.

-

Understand Pricing Nuances for Different Regions: Be aware of economic conditions, currency fluctuations, and local market trends in the regions you are sourcing from. For instance, fluctuations in the currency exchange rate can significantly impact costs when dealing with suppliers in Europe or the Middle East.

-

Research and Verify Supplier Credentials: Conduct due diligence on potential suppliers to ensure they meet quality standards and have a track record of reliability. This can prevent costly issues down the line.

Disclaimer for Indicative Prices

Pricing for polyurethane bags can vary widely based on the factors outlined above. It is advisable for buyers to obtain detailed quotes from multiple suppliers and consider all cost components before making procurement decisions.

Alternatives Analysis: Comparing polyurethane bags With Other Solutions

Understanding Alternatives to Polyurethane Bags in the B2B Market

As international B2B buyers seek effective packaging solutions, understanding the alternatives to polyurethane (PU) bags becomes crucial. Polyurethane bags are popular for their durability and cost-effectiveness; however, other materials and technologies may offer distinct advantages depending on specific business needs. This analysis compares polyurethane bags with two viable alternatives: biodegradable bags and woven polypropylene bags.

Illustrative image related to polyurethane bags

| Comparison Aspect | Polyurethane Bags | Biodegradable Bags | Woven Polypropylene Bags |

|---|---|---|---|

| Performance | High durability, water-resistant | Varies; generally lower durability | Strong, tear-resistant |

| Cost | Moderate cost, affordable | Typically higher cost | Generally low cost |

| Ease of Implementation | Straightforward; widely available | May require supplier education | Easy to implement; widely available |

| Maintenance | Low maintenance, easy to clean | Limited lifespan; may degrade | Low maintenance, durable |

| Best Use Case | Everyday use, retail packaging | Environmentally conscious brands | Bulk packaging, construction materials |

What Are the Pros and Cons of Biodegradable Bags Compared to Polyurethane Bags?

Biodegradable bags are designed to break down naturally over time, making them an attractive option for companies focused on sustainability. The primary advantage is their reduced environmental impact, aligning with the increasing consumer preference for eco-friendly products. However, they often come at a higher cost and may not offer the same durability or water resistance as polyurethane bags. They are best suited for businesses that prioritize environmental responsibility and are willing to invest more upfront for long-term sustainability.

How Do Woven Polypropylene Bags Stack Up Against Polyurethane Bags?

Woven polypropylene bags are another alternative, known for their strength and resistance to tearing. These bags are typically more affordable than PU bags and offer excellent performance for bulk packaging applications. They are widely used in industries such as agriculture and construction. However, woven polypropylene bags lack the aesthetic appeal and water resistance of polyurethane bags, which may be a consideration for retail applications. They are ideal for companies that require robust packaging at a lower cost and are less concerned with appearance.

Making the Right Choice: Which Packaging Solution is Best for Your Business?

When evaluating packaging solutions, B2B buyers should consider several factors, including performance requirements, cost constraints, and environmental impact. Polyurethane bags provide a balance of durability and affordability, making them suitable for everyday use across various industries. In contrast, biodegradable bags appeal to companies prioritizing sustainability, while woven polypropylene bags serve well in bulk applications. Ultimately, the right choice will depend on your specific business needs, target market, and commitment to environmental responsibility. By carefully weighing these options, you can select the most effective packaging solution that aligns with your operational goals and brand values.

Essential Technical Properties and Trade Terminology for polyurethane bags

What Are the Key Technical Properties of Polyurethane Bags?

When considering polyurethane (PU) bags for B2B procurement, understanding the essential technical properties can significantly impact product selection and overall satisfaction. Here are some critical specifications to keep in mind:

Illustrative image related to polyurethane bags

1. Material Grade

Material grade refers to the specific type of polyurethane used in manufacturing the bags. Higher-grade PU materials typically provide better durability, flexibility, and resistance to wear and tear. For B2B buyers, selecting the right material grade is crucial as it directly affects product longevity and performance in various applications, from retail to industrial use.

2. Thickness

Thickness is a key parameter that determines the strength and durability of PU bags. Measured in millimeters, thicker bags offer enhanced protection against punctures and tearing. For businesses, investing in the appropriate thickness can ensure that the bags maintain their structural integrity during shipping and handling, reducing the risk of product loss or damage.

3. Tensile Strength

Tensile strength indicates the maximum stress that a material can withstand while being stretched or pulled before breaking. For PU bags, a higher tensile strength means increased durability and reliability, which is essential for carrying heavy loads. B2B buyers should consider tensile strength to ensure that the bags can meet their operational demands without compromising on safety.

4. Water Resistance

Water resistance is a significant property for polyurethane bags, especially in regions prone to rain or humidity. This feature is critical for protecting the contents of the bags from moisture damage. B2B buyers in industries such as logistics and retail must prioritize water-resistant bags to maintain product integrity and customer satisfaction.

5. Colorfastness

Colorfastness refers to the ability of the PU material to retain its color when exposed to light, washing, or abrasion. High colorfastness is particularly important for brands that want to maintain a consistent aesthetic in their products. For B2B buyers, selecting bags with excellent colorfastness ensures that their brand image remains intact throughout the product lifecycle.

Illustrative image related to polyurethane bags

What Are Common Trade Terms in the Polyurethane Bag Industry?

Understanding industry-specific jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms that buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are marketed under another company’s brand. In the context of polyurethane bags, many businesses collaborate with OEMs to produce customized bags that meet specific design and functionality requirements. This term is vital for buyers looking to create unique products without investing in manufacturing infrastructure.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it impacts inventory management and cash flow. Suppliers often set MOQs to ensure profitability, so it’s essential for buyers to negotiate terms that align with their purchasing needs.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent by a buyer to potential suppliers requesting a detailed quote for specific products or services. In the polyurethane bag industry, an RFQ can help buyers compare pricing, specifications, and delivery options from multiple suppliers, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaging in international trade, as they clarify the terms of delivery and potential liabilities during transport.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead time is critical for inventory planning and meeting customer demands. Longer lead times can affect supply chain efficiency, making it essential to negotiate favorable terms with suppliers.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when sourcing polyurethane bags, ensuring that they meet their operational requirements while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the polyurethane bags Sector

What Are the Current Market Dynamics and Key Trends in the Polyurethane Bags Sector?

The global polyurethane (PU) bags market is experiencing significant growth driven by several factors. One of the primary drivers is the increasing demand for lightweight, durable, and versatile bags across various industries, including fashion, travel, and consumer goods. In regions like Africa and South America, rising disposable incomes are leading to an uptick in consumer spending on quality products, thereby expanding the market for PU bags. In the Middle East, the luxury retail segment is leveraging PU’s affordability and aesthetic appeal, catering to a growing consumer base that values both style and functionality.

Emerging B2B technology trends, such as the integration of e-commerce platforms and digital supply chain management tools, are reshaping the sourcing landscape for PU bags. International buyers are increasingly utilizing data analytics to make informed purchasing decisions, ensuring they are aligned with market demands and consumer preferences. Additionally, automation in manufacturing is improving production efficiency, allowing suppliers to respond quickly to changing trends, such as the growing preference for customizable products. This responsiveness is particularly vital for buyers in regions like Europe, where rapid shifts in fashion trends can dictate inventory turnover rates.

How Is Sustainability and Ethical Sourcing Influencing the Polyurethane Bags Market?

Sustainability has become a pivotal concern for international B2B buyers, particularly in the context of polyurethane bags. The environmental impact of PU production, primarily due to the use of chemicals and synthetic materials, has led to increased scrutiny from consumers and businesses alike. Ethical sourcing practices are now essential for companies looking to maintain their brand reputation and customer loyalty. Many buyers are prioritizing suppliers who adhere to sustainable manufacturing processes and demonstrate a commitment to reducing their carbon footprint.

Illustrative image related to polyurethane bags

Green certifications, such as OEKO-TEX and Global Recycle Standard (GRS), are becoming increasingly important in the sourcing of PU bags. These certifications assure buyers that the materials used meet specific environmental and safety standards, thereby enhancing the appeal of products in eco-conscious markets. As consumers become more aware of the environmental implications of their purchases, B2B buyers must ensure their supply chains reflect these values, opting for suppliers who utilize recycled materials or environmentally friendly production methods. This shift not only meets consumer demand but can also lead to long-term cost savings through increased operational efficiency.

What Is the Brief Evolution and History of Polyurethane Bags in the B2B Context?

The evolution of polyurethane bags can be traced back to the development of polyurethane itself in the mid-20th century. Initially utilized for its durability and versatility in various applications, PU quickly gained traction in the fashion and accessories sectors due to its affordability compared to genuine leather. Over the decades, advancements in manufacturing techniques have significantly improved the quality and aesthetics of PU bags, making them a desirable alternative for both consumers and businesses.

In the B2B context, polyurethane bags have transitioned from being seen as a low-cost substitute to a viable option that offers both style and functionality. This shift has been particularly evident in emerging markets, where the demand for quality yet affordable products is high. Today, PU bags are synonymous with modernity and practicality, catering to a diverse range of sectors, from retail to corporate gifting. As the market continues to evolve, international buyers are increasingly recognizing the potential of PU bags as a sustainable and ethical choice, aligning with broader trends toward responsible consumption and production.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane bags

-

How do I ensure the quality of polyurethane bags before purchasing?

To ensure the quality of polyurethane bags, it’s essential to vet potential suppliers thoroughly. Request samples to evaluate the material, stitching, and overall construction. Look for suppliers who comply with international quality standards and certifications. Additionally, consider conducting factory audits if feasible, or using third-party inspection services to assess production practices and material quality. This proactive approach can help mitigate risks and ensure you receive durable and high-quality products. -

What customization options are available for polyurethane bags?

Customization options for polyurethane bags can vary widely among manufacturers. Common options include size, color, branding (such as logos), and design modifications. Discuss your specific needs with potential suppliers to understand their capabilities. Ensure they can accommodate your requirements, especially if you have unique designs or branding guidelines. Additionally, inquire about the minimum order quantities (MOQs) for customized products, as these can differ based on the complexity of the customization. -

What is the typical minimum order quantity (MOQ) for polyurethane bags in B2B transactions?

Minimum order quantities (MOQs) for polyurethane bags typically range from 100 to 1,000 units, depending on the manufacturer and the complexity of the order. Some suppliers may offer lower MOQs for standard designs, while custom orders might require higher MOQs. When negotiating with suppliers, consider your budget and storage capabilities, and always confirm the MOQ before placing an order to avoid unexpected costs. -

What payment terms should I expect when ordering polyurethane bags internationally?

Payment terms for international orders of polyurethane bags can vary by supplier and region. Common practices include a deposit of 30-50% upfront, with the balance due before shipping or upon receipt of goods. Some suppliers may offer more flexible terms, such as letters of credit or payment upon delivery. It’s crucial to clarify payment terms and conditions in your contract to avoid misunderstandings and ensure a smooth transaction. -

How do I choose a reliable supplier for polyurethane bags?

Choosing a reliable supplier involves researching their reputation, experience, and production capabilities. Look for suppliers with positive reviews and testimonials from previous clients. Verify their compliance with international quality standards and certifications. Engaging in direct communication can help gauge their responsiveness and professionalism. If possible, request references or case studies from similar projects to assess their reliability and track record. -

What are the shipping options for polyurethane bags, and how do they affect costs?

Shipping options for polyurethane bags typically include air freight, sea freight, and courier services. Air freight is faster but generally more expensive, making it suitable for urgent orders. Sea freight is more cost-effective for larger shipments but takes longer. Discuss shipping options with your supplier to understand costs and delivery timelines. Consider the total landed cost, including shipping, customs duties, and taxes, to make informed budgeting decisions. -

Are there specific regulations or standards for importing polyurethane bags into my country?

Import regulations for polyurethane bags can vary significantly by country. It’s essential to familiarize yourself with local customs regulations, import duties, and any specific standards related to material safety and environmental impact. Some regions may have restrictions on certain chemicals used in synthetic materials. Consulting with a local customs broker or trade expert can help you navigate these regulations and ensure compliance to avoid delays or penalties. -

What are the common uses for polyurethane bags in various industries?

Polyurethane bags are versatile and commonly used across various industries, including fashion, retail, food packaging, and electronics. In fashion, they serve as stylish and durable handbags or accessories. In retail, they are used for packaging and carrying products. The food industry benefits from their moisture resistance, while electronics companies use them for protective storage. Understanding the specific applications can help you tailor your product offerings to meet market demands effectively.

Top 2 Polyurethane Bags Manufacturers & Suppliers List

1. Reddit – PU Bags vs. Leather

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: PU bags are made from polyurethane (PU) material, which tends to peel and crumble over time, especially if not used frequently. The author experienced significant deterioration in their collection of PU bags, leading to a preference for leather products in the future. The discussion also touches on the environmental impact of PU and vegan leather, with some users expressing skepticism about the ma…

2. The Store Bags – PU Tote Bag

Domain: thestorebags.com

Registered: 2019 (6 years)

Introduction: Best Women’s PU Leather Bags | The Store Bags

– Collection: PU Bags

– Customer Rating: 4.2/5 based on 1338 reviews

1. PU Tote Bag

– Regular Price: $51.00 USD

– Sale Price: $51.00 USD

2. PU Leather Tote

– Regular Price: $57.00 USD

– Sale Price: $57.00 USD

3. Beaded Leather Crossbody Bag

– Regular Price: $53.00 USD

– Sale Price: $53.00 USD

4. Leather Flap Over Shoulder Bag

…

Strategic Sourcing Conclusion and Outlook for polyurethane bags

In conclusion, the strategic sourcing of polyurethane bags presents a compelling opportunity for international B2B buyers across diverse markets, particularly in Africa, South America, the Middle East, and Europe. The advantages of polyurethane bags, including their affordability, durability, and ease of maintenance, make them an attractive alternative to traditional materials. As businesses increasingly prioritize sustainability, sourcing high-quality PU bags from reputable manufacturers can align with environmental considerations while meeting consumer demand.

For B2B buyers, understanding the nuances of PU materials and their manufacturing processes is essential for making informed purchasing decisions. Engaging with suppliers who prioritize quality and environmental responsibility can enhance brand reputation and customer satisfaction.

Illustrative image related to polyurethane bags

Looking ahead, the market for polyurethane bags is poised for growth, driven by evolving consumer preferences and increased demand for versatile, stylish, and cost-effective solutions. Now is the time to explore strategic partnerships with manufacturers who can provide innovative products that meet your business needs. Take the initiative to strengthen your supply chain and capitalize on the benefits of polyurethane bags—your customers will appreciate the quality and value you deliver.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to polyurethane bags