Introduction: Navigating the Global Market for how to make a leather bag

Navigating the intricate landscape of leather bag production presents a unique challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. As businesses seek to make informed purchasing decisions, understanding how to make a leather bag becomes essential. This guide not only explores the various types of leather bags available in the market—ranging from totes and crossbody bags to bespoke designs—but also delves into the applications of these products across different sectors.

Key considerations such as supplier vetting, material sourcing, design trends, and cost implications are meticulously addressed, providing a comprehensive framework for buyers. Whether you are looking to source high-quality leather for fashion accessories or durable bags for utility purposes, our guide equips you with the necessary insights to navigate supplier relationships and market dynamics effectively.

By empowering you with actionable knowledge, this resource aims to enhance your decision-making process, ensuring you can select the right products that align with your brand’s vision and customer expectations. With the global leather market continuously evolving, staying informed is crucial for maintaining a competitive edge in the industry.

Table Of Contents

- Top 3 How To Make A Leather Bag Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather bag

- Understanding how to make a leather bag Types and Variations

- Key Industrial Applications of how to make a leather bag

- 3 Common User Pain Points for ‘how to make a leather bag’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather bag

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather bag

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather bag’

- Comprehensive Cost and Pricing Analysis for how to make a leather bag Sourcing

- Alternatives Analysis: Comparing how to make a leather bag With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather bag

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather bag Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather bag

- Strategic Sourcing Conclusion and Outlook for how to make a leather bag

- Important Disclaimer & Terms of Use

Understanding how to make a leather bag Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tote Bags | Open top design, large capacity, often with handles | Retail, promotional giveaways | Pros: Versatile, easy to produce; Cons: Less secure, may lack structure. |

| Crossbody Bags | Adjustable straps, worn across the body, compact design | Fashion retail, travel accessories | Pros: Convenient for consumers; Cons: May limit storage capacity. |

| Backpacks | Dual shoulder straps, larger compartments, ergonomic design | Education, corporate use | Pros: High demand, practical for daily use; Cons: Requires more materials. |

| Clutch Bags | Small, handheld design, often used for formal occasions | Evening wear, luxury retail | Pros: High margin potential; Cons: Limited functionality and space. |

| Briefcases | Structured, professional appearance, often with compartments | Corporate sector, business professionals | Pros: Appeals to professionals; Cons: Higher production cost. |

What are the Characteristics and Suitability of Tote Bags in B2B Markets?

Tote bags are characterized by their open top design and spacious interiors, making them ideal for carrying a variety of items. Their simplicity and ease of customization make them popular in retail and promotional sectors, particularly for businesses looking to enhance brand visibility. B2B buyers should consider the material quality and durability, as these factors directly influence the perceived value of the product to end consumers.

How Do Crossbody Bags Serve B2B Buyers?

Crossbody bags feature adjustable straps and a compact design that appeals to a wide range of consumers, especially in the travel and fashion sectors. Their ergonomic design promotes comfort, making them suitable for everyday use. When purchasing, B2B buyers should focus on the bag’s material and stitching quality, as these elements can significantly impact the bag’s longevity and customer satisfaction.

Why are Backpacks Important for Corporate and Educational Applications?

Backpacks are designed with dual shoulder straps and multiple compartments, catering to the needs of students and professionals alike. Their ergonomic design promotes ease of transport, making them a staple in educational and corporate environments. B2B buyers should evaluate the backpack’s capacity and organizational features, as these attributes can enhance user experience and drive sales.

What Makes Clutch Bags a Unique Offering in the Luxury Market?

Clutch bags are small, handheld accessories often designed for formal occasions, making them a staple in luxury retail. Their sleek design allows for high-margin sales, particularly during seasonal events. B2B buyers must consider the aesthetics and material quality, as these factors are crucial for attracting discerning customers looking for elegance and sophistication.

How Do Briefcases Cater to Business Professionals?

Briefcases are structured bags that convey professionalism, often featuring multiple compartments for organization. They are essential for corporate buyers looking to provide employees with functional yet stylish options. When sourcing briefcases, B2B buyers should assess the quality of craftsmanship and materials, as these elements significantly affect the product’s marketability and durability.

Key Industrial Applications of how to make a leather bag

| Industry/Sector | Specific Application of how to make a leather bag | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Custom Leather Handbags | Enhances brand identity and customer loyalty with unique designs | Quality of leather, craftsmanship, and design adaptability |

| Travel & Tourism | Durable Travel Bags | Provides reliable and stylish options for travelers, enhancing customer experience | Weight, durability, and weather resistance of materials |

| Corporate & Business | Professional Briefcases | Projects a professional image while offering functional storage | Material quality, design aesthetics, and brand customization |

| Artisanal & Craft Goods | Handmade Leather Goods | Supports local artisans and promotes sustainable practices | Sourcing local materials, craftsmanship skills, and design uniqueness |

| E-commerce & Retail | DIY Leather Bag Kits | Engages customers by allowing personalization, boosting sales | Quality of kit components, ease of assembly, and market trends |

How is ‘how to make a leather bag’ utilized in the Fashion & Accessories sector?

In the fashion industry, custom leather handbags are a significant application of leather crafting. Brands leverage unique designs to differentiate themselves in a saturated market. This approach not only enhances brand identity but also fosters customer loyalty by offering personalized products. For international B2B buyers, sourcing high-quality leather and skilled artisans is crucial, as the craftsmanship directly affects the final product’s marketability.

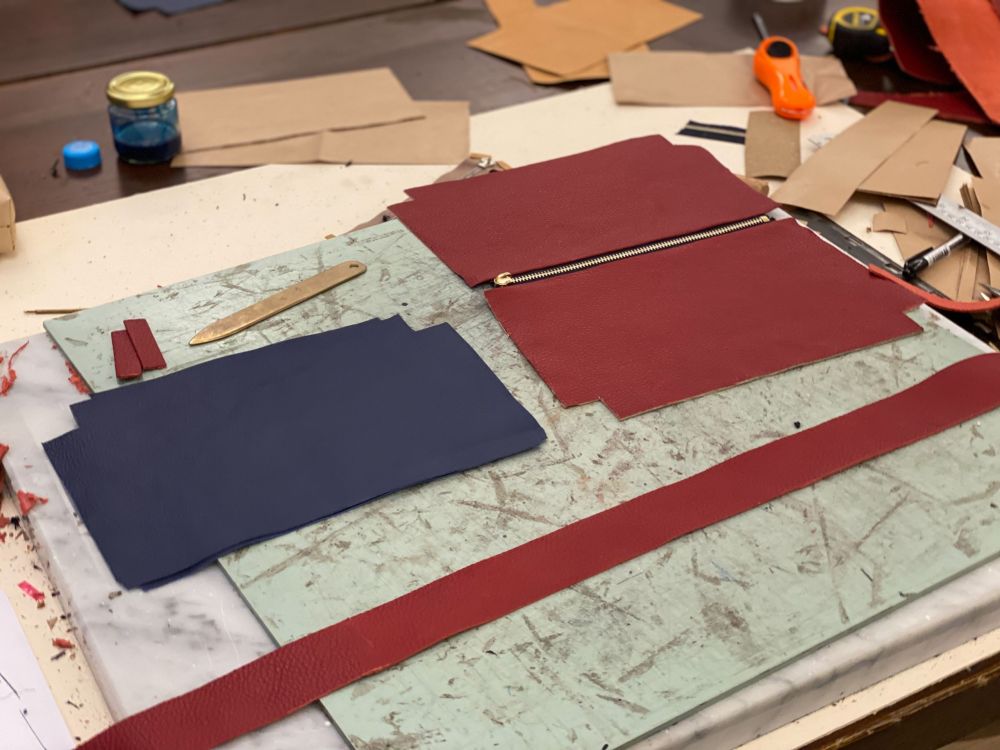

Illustrative image related to how to make a leather bag

What role does leather bag making play in the Travel & Tourism industry?

The travel industry benefits from durable leather bags designed for travelers. These bags combine style and functionality, providing reliable options that enhance the travel experience. International buyers, particularly from regions with diverse climates, need to consider the weight and weather resistance of materials when sourcing. Ensuring that the bags can withstand various conditions while maintaining aesthetic appeal is essential for meeting customer expectations.

How does leather bag making contribute to Corporate & Business needs?

In the corporate sector, professional briefcases made from leather serve as a vital application. They not only project a professional image but also offer functional storage for documents and devices. B2B buyers must prioritize material quality and design aesthetics to align with corporate branding strategies. Customization options can further enhance appeal, allowing businesses to create a cohesive brand presence.

Why is artisanal leather bag making important for Craft Goods?

Artisanal leather goods are increasingly popular, reflecting a growing consumer interest in handmade products. This application supports local artisans and promotes sustainable practices, appealing to eco-conscious buyers. For international B2B buyers, sourcing local materials and ensuring craftsmanship quality are critical. Unique designs and storytelling around the products can significantly enhance marketability and consumer connection.

How do DIY leather bag kits impact the E-commerce & Retail sector?

DIY leather bag kits represent a unique application in e-commerce, allowing customers to engage in the creation process. This personalization boosts sales by tapping into consumer desires for unique, hands-on experiences. Buyers in this sector should focus on the quality of kit components and ease of assembly, as these factors will influence customer satisfaction and repeat purchases. Understanding current market trends can also help in designing appealing kits that resonate with targeted demographics.

3 Common User Pain Points for ‘how to make a leather bag’ & Their Solutions

Scenario 1: Sourcing Quality Leather Materials for Bag Production

The Problem: B2B buyers often struggle with sourcing high-quality leather materials that meet their specific needs. The market is flooded with options, but not all suppliers provide leather that aligns with desired durability, aesthetics, and ethical standards. Buyers may face issues with inconsistent quality, limited availability, or high costs, leading to production delays and increased overhead.

The Solution: To effectively source quality leather, buyers should establish relationships with reputable suppliers known for their craftsmanship and ethical practices. Start by researching suppliers that specialize in the type of leather needed—be it full-grain, top-grain, or vegan alternatives. Request samples to evaluate the quality firsthand and conduct thorough due diligence, including checking for certifications related to sustainability and fair trade. Additionally, consider forming partnerships with local artisans or cooperatives in regions known for leather production, such as Italy or Brazil, to ensure not only quality but also a reliable supply chain that can adapt to changing market demands. By strategically sourcing materials, buyers can improve product quality and reduce the risk of supply chain disruptions.

Scenario 2: Mastering the Design Process for Leather Bags

The Problem: Many B2B buyers encounter difficulties in the design phase of leather bag production. They may lack the necessary design expertise or struggle to translate their ideas into a viable product, which can lead to misaligned expectations and wasted resources. The design process can be overwhelming, especially when considering trends, functionality, and target audience preferences.

The Solution: To streamline the design process, buyers should invest in design tools and software tailored for leather goods. Programs like Adobe Illustrator or CAD software can aid in creating precise patterns and prototypes. Additionally, collaborating with experienced leather designers or consultants can provide valuable insights and mentorship throughout the design phase. Conduct market research to understand current trends and customer preferences, and use this data to inform your designs. By creating mood boards and sketches, buyers can better visualize their concepts before moving to production. Regular feedback loops during the design process can also ensure that the final product aligns with market expectations, thereby reducing the risk of costly redesigns.

Scenario 3: Ensuring Efficient Production and Quality Control

The Problem: B2B buyers often face challenges in maintaining consistent production quality and efficiency when making leather bags. Discrepancies in craftsmanship, variations in leather texture, and differences in stitching can lead to subpar products that fail to meet customer expectations. This inconsistency can damage brand reputation and lead to increased returns or complaints.

The Solution: Implementing a robust quality control system is essential for ensuring production consistency. Buyers should establish clear quality benchmarks and communicate these standards to all production teams, whether in-house or outsourced. Regular training sessions for artisans on proper techniques, as well as periodic inspections throughout the production process, can help maintain high standards. Additionally, utilizing a standardized checklist during production can catch potential defects early. Leveraging technology, such as RFID tracking or production management software, can streamline operations and provide real-time insights into the manufacturing process. By prioritizing quality control and efficient production practices, buyers can enhance product reliability and ultimately increase customer satisfaction.

Illustrative image related to how to make a leather bag

Strategic Material Selection Guide for how to make a leather bag

What Are the Key Properties of Common Leather Materials for Bag Making?

When selecting materials for leather bags, it is crucial to consider various types of leather and their specific properties. The most commonly used materials include full-grain leather, top-grain leather, genuine leather, and synthetic leather. Each of these materials offers unique characteristics that can significantly influence the performance and appeal of the final product.

What Are the Key Properties of Full-Grain Leather?

Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain and imperfections, which adds to its aesthetic appeal. Full-grain leather is known for its exceptional durability, breathability, and resistance to wear and tear. It can withstand high temperatures and pressure, making it suitable for various environments.

Pros: Full-grain leather is highly durable, ages beautifully, and develops a unique patina over time. It is also resistant to moisture and can be treated for additional water resistance.

Cons: The cost of full-grain leather is typically high due to its quality and the complex manufacturing process. It may also require special care to maintain its appearance.

Impact on Application: Full-grain leather is ideal for high-end bags that require longevity and a premium look. However, it may not be suitable for budget-conscious consumers.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding leather sourcing and animal welfare. Certifications like ISO 14001 for environmental management may also be relevant.

How Does Top-Grain Leather Compare to Other Options?

Top-grain leather is the second-highest quality leather, made by sanding down the top layer of the hide to remove imperfections. This process makes it more uniform in appearance than full-grain leather, but it sacrifices some durability.

Pros: Top-grain leather is more affordable than full-grain leather and easier to work with, making it a popular choice for manufacturers. It also offers a good balance of durability and aesthetics.

Cons: While it is durable, top-grain leather is less resistant to scratches and wear compared to full-grain leather. It may also require regular conditioning to prevent drying.

Illustrative image related to how to make a leather bag

Impact on Application: This type of leather is suitable for mid-range bags where a balance of cost and quality is desired. It is often used in fashion bags and accessories.

Considerations for International Buyers: Ensure that top-grain leather meets local standards for chemical treatments, especially in regions with strict environmental regulations.

What Are the Advantages of Using Genuine Leather?

Genuine leather is made from the lower layers of the hide and is often treated with dyes and finishes. While it is not as durable as full-grain or top-grain leather, it is widely available and cost-effective.

Pros: Genuine leather is affordable and can be produced in various colors and finishes, making it versatile for different styles.

Illustrative image related to how to make a leather bag

Cons: It is less durable and can wear out more quickly than higher-quality leathers. It may also lack the natural aesthetics that full-grain leather offers.

Impact on Application: Genuine leather is often used for budget-friendly bags and accessories, appealing to consumers looking for style without the high price tag.

Considerations for International Buyers: Buyers should verify the quality and authenticity of genuine leather, as the term can be misleading. Compliance with local labeling standards is essential.

Illustrative image related to how to make a leather bag

What Role Does Synthetic Leather Play in Bag Manufacturing?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), provides an alternative to animal leather. It is designed to mimic the look and feel of leather while being more affordable.

Pros: Synthetic leather is often more resistant to stains and moisture, making it easier to clean. It is also available in a wide range of colors and textures.

Cons: While it is cost-effective, synthetic leather may not offer the same durability or breathability as natural leathers. It can also be less environmentally friendly, depending on the manufacturing process.

Impact on Application: Synthetic leather is ideal for fashion-forward bags that prioritize style and affordability. It is popular among younger consumers and those looking for vegan options.

Illustrative image related to how to make a leather bag

Considerations for International Buyers: Ensure that synthetic leather complies with local regulations regarding chemical content and environmental impact, especially in Europe where standards can be stringent.

Summary Table of Material Selection for Leather Bags

| 素材 | Typical Use Case for how to make a leather bag | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end luxury bags | Exceptional durability and aesthetics | High cost and complex manufacturing process | 高い |

| Top-Grain Leather | Mid-range fashion bags | Good balance of quality and cost | Less durable than full-grain | Medium |

| Genuine Leather | Budget-friendly bags | Affordable and versatile | Less durable and may lack natural aesthetics | 低い |

| Synthetic Leather | Fashion-forward and vegan bags | Easy to clean and wide color range | Less durable and potentially less eco-friendly | 低い |

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather bag

What Are the Main Stages of the Leather Bag Manufacturing Process?

The manufacturing process for leather bags is intricate and requires a blend of craftsmanship and modern techniques. Understanding the main stages can help B2B buyers appreciate the complexity involved and make informed purchasing decisions.

Material Preparation: How Is Leather Processed for Bag Making?

The first step in manufacturing leather bags involves sourcing high-quality leather. The type of leather—be it full-grain, top-grain, or synthetic—will significantly influence the bag’s durability and aesthetic appeal.

Illustrative image related to how to make a leather bag

Once sourced, the leather undergoes a tanning process to enhance its longevity and flexibility. This can be done through vegetable tanning or chrome tanning, each offering distinct qualities. After tanning, the leather is conditioned and dyed to achieve the desired color and texture. Buyers should inquire about the sourcing practices and tanning methods used by suppliers to ensure ethical and sustainable practices.

Forming: What Techniques Are Used to Shape Leather?

After preparation, the next stage is forming the leather into the desired shape. This typically involves cutting the leather into specific patterns that correspond to the bag’s design. Precision cutting tools, such as die-cutting machines or laser cutters, are often employed to ensure uniformity and minimize waste.

Some manufacturers may also use molding techniques to create unique shapes or styles, particularly for structured bags. The choice of forming techniques can affect both the cost and the final appearance of the bag, making it crucial for buyers to understand these methods when selecting suppliers.

Assembly: How Are Leather Bags Constructed?

The assembly phase is where the individual components come together. This includes stitching, attaching hardware like zippers and clasps, and adding linings. Hand-stitching remains popular for high-end bags, as it provides durability and a luxurious finish. However, many manufacturers also use industrial sewing machines for efficiency.

Quality control during assembly is vital. For instance, checking stitch density and alignment ensures that the bag will withstand wear and tear. B2B buyers should consider suppliers that prioritize skilled craftsmanship and adhere to high assembly standards.

Finishing: What Are the Final Touches Applied to Leather Bags?

The finishing stage involves polishing and conditioning the leather to enhance its appearance. This may include applying waxes, oils, or protective coatings to improve water resistance and shine. Additionally, final inspections are conducted to check for any defects or inconsistencies.

Buyers should request details about the finishing processes and any specific treatments that may be used, as these can significantly affect the bag’s durability and aesthetic appeal.

How Is Quality Assurance Implemented in Leather Bag Production?

Quality assurance (QA) is a critical aspect of leather bag manufacturing, ensuring that products meet both international and industry-specific standards. Understanding these QA measures can help B2B buyers verify the reliability of their suppliers.

Illustrative image related to how to make a leather bag

What Are the Relevant International Standards for Leather Bags?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with this standard indicates that the manufacturer has a robust quality management process in place.

In addition, industry-specific certifications like CE marking (for products sold in Europe) and API standards (for oil and gas industry-related products) may also apply. Buyers should confirm whether their suppliers comply with these standards, as this can affect marketability in different regions.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control in leather bag manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Buyers should ensure their suppliers perform thorough inspections at this stage.

-

In-Process Quality Control (IPQC): During the manufacturing process, random checks should be conducted to identify any defects early. This may include checking stitching accuracy, leather quality, and hardware attachment.

-

Final Quality Control (FQC): Before shipment, a final inspection is performed to ensure the finished product meets all quality standards. This includes checking for defects in appearance, functionality, and durability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain rigorous quality control processes, B2B buyers should consider the following approaches:

-

Audits: Conducting regular audits of suppliers can provide insights into their manufacturing practices and quality control measures. Buyers may also request third-party audit reports for transparency.

-

Quality Control Reports: Suppliers should provide documentation detailing their quality control procedures, including results from IQC, IPQC, and FQC stages. This transparency can help buyers make informed decisions.

-

Third-Party Inspections: Engaging independent inspectors to assess the manufacturing process and finished products can further verify compliance with quality standards. This is particularly important for international transactions where standards may vary.

What Are the Nuances of Quality Control for International B2B Buyers?

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Different regions may have varying expectations regarding product quality, certifications, and manufacturing standards.

Illustrative image related to how to make a leather bag

Buyers should familiarize themselves with local regulations and standards in their target markets. For instance, Europe has stringent regulations regarding materials used in consumer goods, including leather. Ensuring that suppliers comply with these regulations can prevent costly recalls and enhance brand reputation.

Additionally, cultural differences may influence the perception of quality and craftsmanship. Buyers should engage in open communication with suppliers to align expectations and ensure that the final products meet their specific requirements.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures is vital for B2B buyers in the leather bag industry. By focusing on these areas, buyers can ensure they partner with reliable suppliers that meet their quality standards and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather bag’

To assist international B2B buyers in successfully procuring the necessary components and resources for making leather bags, this guide outlines critical steps to follow. Each step ensures that buyers are well-informed and prepared to navigate the leather bag production process effectively.

Illustrative image related to how to make a leather bag

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the final product meets quality and functionality standards. Consider aspects such as size, style, materials, and any special features like pockets or closures. A well-defined specification helps suppliers understand your needs, reducing the chances of miscommunication.

- Material Quality: Specify the type of leather (e.g., full grain, top grain, or vegan options) based on your target market.

- Design Features: Outline specific design elements, such as stitching patterns or hardware requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in leather products. Use online directories, trade shows, and industry networks to compile a list of candidates. This step is vital as the right supplier can significantly impact the quality and cost-effectiveness of your products.

- Supplier Background: Look for suppliers with a proven track record in leather craftsmanship.

- Product Range: Ensure they offer a variety of materials and styles that align with your specifications.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your potential suppliers hold the necessary certifications. This can include quality management systems (ISO), sustainability certifications, and compliance with international labor standards. Valid certifications provide assurance that the supplier meets industry standards.

- Quality Assurance: Check if they have quality control processes in place.

- Sustainability Practices: Consider suppliers who prioritize environmentally-friendly practices.

Step 4: Request Samples and Prototypes

Requesting samples or prototypes allows you to assess the quality of materials and craftsmanship firsthand. This step is essential for evaluating whether the supplier can meet your design specifications and quality standards before placing a larger order.

- Sample Evaluation: Analyze the leather’s texture, durability, and overall finish.

- Prototype Testing: If possible, test the prototype for functionality and user experience.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish terms and conditions that are beneficial for both parties. This includes pricing, payment terms, delivery timelines, and return policies. Clear agreements help prevent misunderstandings and ensure a smooth transaction.

- Pricing Structure: Discuss bulk order discounts and payment options.

- Lead Times: Agree on realistic timelines for production and delivery.

Step 6: Establish a Communication Plan

Effective communication is key to a successful partnership. Establish a clear communication plan that outlines how and when you will communicate with your supplier. This ensures that both parties are aligned throughout the production process.

- Regular Updates: Set up scheduled check-ins to discuss progress and address any issues.

- Feedback Mechanism: Create a process for providing feedback on samples and production.

Step 7: Plan for Logistics and Distribution

Consider the logistics of transporting your finished leather bags from the supplier to your market. This includes shipping methods, customs regulations, and warehousing options. A well-thought-out logistics plan ensures timely delivery to your customers.

- Shipping Options: Explore different shipping methods based on cost and delivery speed.

- Customs Requirements: Familiarize yourself with import regulations in your target markets.

By following this checklist, B2B buyers can navigate the complexities of sourcing materials and production for leather bags, ensuring a successful and efficient process from start to finish.

Comprehensive Cost and Pricing Analysis for how to make a leather bag Sourcing

What Are the Key Cost Components in Leather Bag Production?

When sourcing leather bags, understanding the cost structure is crucial for effective budgeting and pricing strategies. The primary cost components include:

-

Materials: Leather quality significantly impacts cost. Full-grain leather is typically more expensive than top-grain or bonded leather due to its durability and aesthetic appeal. Additionally, hardware (zippers, clasps) and linings (cotton, synthetic) contribute to the overall material costs.

-

Labor: Labor costs vary based on the region and the complexity of the bag design. Skilled artisans in regions with high living costs, such as Europe, may demand higher wages compared to those in emerging markets like Nigeria or Brazil.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with the production facility. Overhead costs can fluctuate based on the production scale and location.

-

Tooling: Initial costs for tools and machinery can be substantial, especially for custom designs. However, these costs can be amortized over time with increased production volumes.

-

Quality Control (QC): Implementing QC processes ensures product consistency and meets international standards. This might involve additional costs related to inspections and testing, particularly for markets with stringent regulations.

-

Logistics: Shipping and handling costs are influenced by the distance to the buyer, shipping methods, and the volume of the order. International shipping can incur additional fees such as customs duties and taxes.

-

Margin: Finally, suppliers will incorporate their profit margin, which typically ranges between 15% to 30% of the total cost, depending on market conditions and competition.

How Do Price Influencers Impact Leather Bag Sourcing?

Several factors can influence the pricing of leather bags, particularly for international buyers:

-

Volume/MOQ: Larger orders often lead to reduced per-unit costs. Minimum order quantities (MOQ) can vary significantly between suppliers, affecting overall pricing.

-

Specifications and Customization: Custom designs or unique specifications can increase production costs. Buyers seeking tailored products should expect higher prices due to additional labor and material requirements.

-

Material Quality and Certifications: Higher-quality materials and certified sustainable practices can elevate costs. Buyers should assess whether the investment aligns with their target market’s expectations.

-

Supplier Factors: The reputation and reliability of the supplier play a critical role in pricing. Established suppliers may charge more but can offer better quality assurance and delivery times.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is essential for calculating total costs, including freight and insurance. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect pricing strategies.

What Buyer Tips Can Enhance Cost Efficiency in Leather Bag Sourcing?

To optimize sourcing costs, B2B buyers should consider the following strategies:

-

Negotiate Effectively: Leverage relationships and volume commitments to negotiate better pricing and terms. Suppliers may be open to discounts or favorable payment terms for bulk orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price, but also shipping, potential returns, and durability of the leather bags. A lower upfront cost might lead to higher long-term costs due to quality issues.

-

Understand Pricing Nuances for International Markets: Each region has unique market dynamics. For instance, buyers in Africa may have different price sensitivities than those in Europe. Tailoring approaches based on local expectations and economic conditions can yield better results.

-

Stay Informed About Market Trends: Being aware of fluctuations in leather prices and global economic conditions can help buyers time their purchases better and negotiate effectively.

Disclaimer on Indicative Prices

Prices for leather bags can vary widely based on the factors outlined above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are getting competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing how to make a leather bag With Other Solutions

Exploring Alternatives for Leather Bag Creation

In the realm of leather goods manufacturing, the method of crafting leather bags can be complemented or substituted by various alternative solutions. Understanding these alternatives allows businesses to optimize their production processes, reduce costs, and enhance product offerings. Below, we compare the traditional method of making leather bags against two viable alternatives: utilizing pre-made leather bag kits and opting for synthetic leather production.

| Comparison Aspect | How To Make A Leather Bag | Pre-Made Leather Bag Kits | Synthetic Leather Production |

|---|---|---|---|

| Performance | High-quality, customizable bags | Quality varies; limited customization | Consistent quality; eco-friendly options |

| Cost | Higher initial costs for materials | Moderate cost; includes materials/tools | Generally lower material costs |

| Ease of Implementation | Requires skill and tools | User-friendly; minimal skills needed | Requires industrial machinery |

| Maintenance | Can last a lifetime with care | Variable lifespan; depends on quality | Durable, but can degrade over time |

| Best Use Case | Custom, high-end products | Hobbyists, beginners, or small businesses | Mass production, budget-friendly items |

What Are the Pros and Cons of Pre-Made Leather Bag Kits?

Pre-made leather bag kits are designed for individuals or small businesses looking to create leather bags with minimal prior experience. These kits usually include pre-cut leather pieces, hardware, and instructions, making them user-friendly. The primary advantage of these kits is their affordability and ease of use, allowing even beginners to produce quality bags. However, the quality of the final product can vary significantly based on the kit’s components, and customization options are limited. This approach is best suited for hobbyists or small businesses seeking to enter the leather goods market without extensive investment in materials or tools.

How Does Synthetic Leather Production Compare?

Synthetic leather production, commonly known as “vegan leather,” offers an alternative to traditional leather crafting. This method utilizes materials like polyurethane or PVC to create leather-like textures. One of the significant advantages of synthetic leather is its lower cost, which can be beneficial for businesses aiming for mass production. Additionally, synthetic leather is often marketed as a more environmentally friendly option. However, while the consistency in quality is a strong point, synthetic materials may lack the durability and aesthetic appeal of genuine leather. This method is ideal for businesses focusing on budget-friendly products or targeting eco-conscious consumers.

How Can B2B Buyers Choose the Right Leather Bag Production Method?

When selecting the appropriate method for leather bag production, B2B buyers should consider their target market, budget constraints, and product positioning. For businesses aiming to provide high-end, customizable leather goods, traditional bag-making methods may be the best choice despite the higher costs and skill requirements. Conversely, those looking to enter the market with lower investment and production scalability might find pre-made kits or synthetic leather production more suitable. Understanding the strengths and weaknesses of each option will empower buyers to make informed decisions that align with their business objectives and customer needs.

Illustrative image related to how to make a leather bag

Essential Technical Properties and Trade Terminology for how to make a leather bag

What Are the Key Technical Properties to Consider When Making a Leather Bag?

When venturing into the leather bag manufacturing process, understanding the critical technical properties is essential. Here are the key specifications that B2B buyers should prioritize:

-

Material Grade

Leather quality can vary significantly, and the grade is a primary determinant of durability and appearance. Common grades include full-grain, top-grain, and corrected grain leather. Full-grain leather, for instance, retains the natural grain and is the most durable, making it ideal for high-end products. In contrast, corrected grain leather undergoes more processing and may not offer the same longevity. Choosing the right grade is crucial for meeting customer expectations and ensuring product longevity. -

Thickness (Gauge)

The thickness of the leather, often measured in ounces (1 oz = 1/64 inch), affects the bag’s sturdiness and overall feel. Thicker leather is generally more durable but can be less flexible, which may impact the bag’s design. For instance, a travel bag may benefit from thicker leather for added strength, while a fashion handbag may require thinner leather for a more refined look. Understanding the appropriate thickness for the intended use helps manufacturers strike a balance between durability and aesthetics. -

Finish Type

The finish applied to leather can influence its look and feel, as well as its resistance to moisture and wear. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather is dyed with soluble dyes, maintaining a natural appearance but may be more susceptible to stains. Pigmented leather, on the other hand, features a protective coating, making it more resilient. Selecting the right finish is vital for aligning with market demands and enhancing the product’s appeal. -

Tolerance Levels

Tolerance refers to the acceptable variation in dimensions during the manufacturing process. This is crucial in ensuring that parts fit together correctly and that the final product meets design specifications. For example, a tolerance of ±1 mm may be acceptable for stitching, but tighter tolerances may be needed for hardware fittings. Establishing clear tolerance levels helps maintain quality control and minimizes returns due to production errors. -

Weight Capacity

Understanding the weight capacity of a leather bag is important, especially for utility or travel bags. This property dictates how much load the bag can safely carry without compromising its structure. Manufacturers must consider the material, stitching, and overall design to ensure that the bag can withstand its intended use, which is vital for customer satisfaction and brand reputation.

What Common Trade Terms Should B2B Buyers Know in Leather Bag Manufacturing?

Familiarity with industry jargon can streamline communication and negotiation in the leather bag market. Here are essential terms for B2B buyers:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or products that are marketed by another company. In the leather bag industry, an OEM might create bags that feature a buyer’s branding. Understanding OEM relationships can help buyers find reliable manufacturers that meet their design and quality specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It’s a crucial factor for B2B buyers as it affects the initial investment and inventory management. Knowing the MOQ helps buyers plan their purchases and manage cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for a specific quantity of goods. In leather bag manufacturing, an RFQ allows buyers to compare prices, terms, and conditions from various suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. For instance, FOB (Free On Board) indicates that the seller covers costs until the goods are loaded on the transport vessel. Understanding these terms is essential for managing shipping logistics and cost expectations. -

Lead Time

This term refers to the time it takes from placing an order to receiving the finished product. In leather bag manufacturing, lead times can vary based on material availability and production schedules. Knowing the lead time is critical for inventory planning and meeting market demands. -

Sustainability Standards

With increasing consumer awareness of environmental issues, sustainability standards refer to the practices and materials used in manufacturing that minimize environmental impact. Buyers should be aware of certifications such as the Global Organic Textile Standard (GOTS) or Leather Working Group (LWG) ratings, which can enhance brand reputation and appeal to eco-conscious consumers.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed decisions in the leather bag manufacturing process. This insight not only aids in selecting the right products but also fosters better relationships with suppliers and manufacturers.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather bag Sector

What Are the Key Market Drivers and Trends in the Leather Bag Sector?

The leather bag sector is experiencing a dynamic shift driven by several global trends. Increasing demand for bespoke and artisanal products is reshaping the landscape, particularly among consumers in Africa, South America, the Middle East, and Europe. As buyers become more discerning, they are seeking unique designs that reflect personal style, leading to a surge in DIY kits and customizable options. This shift is complemented by advancements in B2B technology, such as digital platforms that facilitate direct trade between manufacturers and buyers, enhancing supply chain efficiency and reducing costs.

Illustrative image related to how to make a leather bag

Moreover, there is a notable rise in the use of e-commerce platforms, allowing businesses to tap into international markets with relative ease. The COVID-19 pandemic accelerated this trend, prompting many manufacturers to establish an online presence to reach a broader audience. In addition, the integration of augmented reality (AR) in the shopping experience allows buyers to visualize products before purchase, further enhancing customer engagement. These trends are critical for international B2B buyers looking to stay competitive and meet evolving consumer preferences.

How Is Sustainability Shaping Sourcing Practices in Leather Bag Production?

Sustainability is increasingly becoming a cornerstone of sourcing strategies in the leather bag sector. The environmental impact of leather production, particularly concerning water usage and chemical runoff, has prompted a significant shift towards ethical sourcing. B2B buyers are now prioritizing suppliers who adhere to sustainable practices, such as using vegetable-tanned leather or sourcing from certified farms that practice responsible animal husbandry.

Moreover, certifications like the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining traction among buyers seeking to ensure their supply chains are environmentally friendly. Incorporating recycled materials and exploring alternative leather sources, such as vegan leather, are becoming common practices. These sustainable initiatives not only meet regulatory requirements but also resonate with an increasingly eco-conscious consumer base, providing a competitive edge in the market.

What Is the Historical Context of Leather Bag Production?

The art of leather bag making has evolved significantly over the centuries. Initially, leather bags were crafted for utility, serving as essential items for transporting goods. The craftsmanship was primarily passed down through generations, with techniques rooted in traditional practices. As industrialization took hold in the 19th century, mass production began to dominate, making leather bags more accessible to the general public.

In recent decades, however, there has been a resurgence of interest in artisanal techniques and handmade products, spurred by a growing appreciation for craftsmanship and individual expression. This evolution has led to a rich diversity in styles and materials, enabling B2B buyers to cater to a broad range of consumer preferences while maintaining a focus on quality and sustainability. Understanding this historical context is crucial for buyers aiming to source leather bags that not only meet current market demands but also resonate with the heritage of leather craftsmanship.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather bag

1. How do I select the right leather supplier for my bag production?

Choosing the right leather supplier involves several steps. First, assess their reputation by checking reviews, testimonials, and their history in the leather industry. Ensure they provide high-quality materials that meet your specifications, including types of leather and tanning processes. Request samples to evaluate the texture, durability, and finish. Additionally, verify their capacity to handle your order volume, lead times, and compliance with international quality standards. Finally, consider their communication responsiveness and willingness to accommodate customization requests, as these factors significantly influence your production experience.

2. What are the key factors to consider when customizing leather bags?

When customizing leather bags, focus on design specifications, material choices, and manufacturing techniques. Begin by defining your target audience and their preferences, which will guide your design decisions. Choose high-quality leather types that align with your brand’s identity, such as full-grain or top-grain leather. Ensure you consider hardware, stitching patterns, and additional features like pockets or closures that enhance functionality. Collaborate closely with your supplier to create prototypes, allowing for adjustments based on feedback before final production.

3. What is the typical minimum order quantity (MOQ) for leather bags?

The minimum order quantity (MOQ) for leather bags varies significantly based on the supplier and the complexity of the design. Generally, MOQs can range from 50 to 500 units per style. Smaller manufacturers may offer lower MOQs, which can be beneficial for startups or smaller businesses. However, keep in mind that higher MOQs often result in better pricing per unit. Always discuss your specific needs with potential suppliers to negotiate an MOQ that aligns with your budget and business goals.

4. How can I ensure quality assurance (QA) in leather bag production?

To ensure quality assurance in leather bag production, establish clear quality standards and guidelines before commencing manufacturing. Conduct regular inspections during the production process, focusing on stitching quality, material defects, and overall craftsmanship. Partner with suppliers who have robust QA protocols in place and consider third-party inspections for large orders. Implement a final inspection before shipment to catch any discrepancies. Document all QA processes and feedback to continuously improve production quality over time.

5. What payment terms should I expect when sourcing leather bags internationally?

Payment terms for international sourcing can vary widely among suppliers. Common practices include upfront deposits (typically 30-50%) followed by the balance upon completion or before shipment. Some suppliers may offer flexible terms based on your relationship and order volume. It’s crucial to clarify payment methods accepted (e.g., wire transfer, credit card, or escrow services) and ensure they align with your financial processes. Always review contracts carefully to avoid misunderstandings and establish a clear timeline for payments.

6. How do I handle logistics and shipping for my leather bag orders?

Managing logistics for leather bag orders involves coordinating with your supplier for timely production and shipment. Determine the most cost-effective shipping methods based on your delivery timeline and destination. Consider factors such as customs clearance, duties, and taxes when calculating total costs. Work with reliable freight forwarders experienced in handling leather goods to ensure proper handling and documentation. Establish a communication plan with your supplier to track shipment status and resolve any issues promptly.

7. What certifications should I look for in a leather supplier?

When vetting leather suppliers, look for certifications that indicate compliance with industry standards and ethical practices. Key certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and the Leather Working Group (LWG) certification for sustainable leather production. Additionally, inquire about any certifications related to labor practices and animal welfare, which can enhance your brand’s reputation and appeal to ethically conscious consumers.

8. How can I find inspiration for designing unique leather bags?

Finding inspiration for unique leather bag designs can be achieved through various channels. Explore fashion trends through magazines, online platforms, and social media to identify emerging styles. Attend trade shows and exhibitions to see new materials and designs firsthand. Analyze competitors and their offerings to find gaps in the market. Additionally, consider cultural influences from your target regions, as these can provide distinctive elements that resonate with your audience and set your products apart.

Top 3 How To Make A Leather Bag Manufacturers & Suppliers List

1. POPSEWING® – DIY Leather Handbag Kits

Domain: popsewing.com

Registered: 2021 (4 years)

Introduction: DIY Leather Handbag Making Kit – Make Your Own Handbag

– POPSEWING®

– Availability: In stock (47), Out of stock (11)

– Price Range: $43.99 – $279.99

– Featured Products:

– POPSEWING® Leather Patterns Bucket Bag DIY Kit – $80.99

– POPSEWING® Top Grain Leather New Platinum Bag DIY Kit – from $159.99

– POPSEWING® Full Grain Leather Inspired Loop Handbag – Advanced DIY Kit – $199.99

– POPSEWIN…

2. Reddit – User Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – User Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Sailrite – DIY Leather Tote Bag

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Easy DIY Leather Tote Bag

– Project Type: DIY Leather Tote Bag

– Skill Level: Beginner

– Estimated Time: A few hours

Materials List:

1. Natural Vegetable Tanned Leather Side 4 to 5 oz. (#123698)

2. Otter Wax Saddle Soap Leather Cleaner 2 oz. (#123759)

3. Double-Cap Rivets Antique Brass (24 pack) 6mm Post Length x 8mm Cap (#122576)

4. Tex 90 UV Bonded Polyester Thread (#123337)

Tools List:

1. Sai…

Strategic Sourcing Conclusion and Outlook for how to make a leather bag

In the realm of leather bag production, strategic sourcing plays a pivotal role in ensuring quality, cost-effectiveness, and sustainability. By carefully selecting suppliers who prioritize ethical practices and high-quality materials, businesses can enhance their brand reputation and meet the growing consumer demand for responsible fashion. Collaborating with manufacturers across regions such as Africa, South America, the Middle East, and Europe can also diversify product offerings and tap into unique local craftsmanship.

Investing in advanced DIY kits and training resources can empower artisans and manufacturers alike, fostering innovation in design and production techniques. This approach not only nurtures local talent but also creates a competitive edge in the global market. As international buyers, it is essential to stay attuned to emerging trends and consumer preferences, which are increasingly leaning towards bespoke and sustainable products.

Illustrative image related to how to make a leather bag

Looking ahead, the leather goods market presents vast opportunities for growth. By leveraging strategic partnerships and embracing new technologies, businesses can adapt to market shifts and fulfill the evolving needs of consumers. We encourage B2B buyers to explore these opportunities and invest in their sourcing strategies today, ensuring a prosperous future in the leather bag industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how to make a leather bag

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.