Introduction: Navigating the Global Market for diamond stitch leather fabric roll

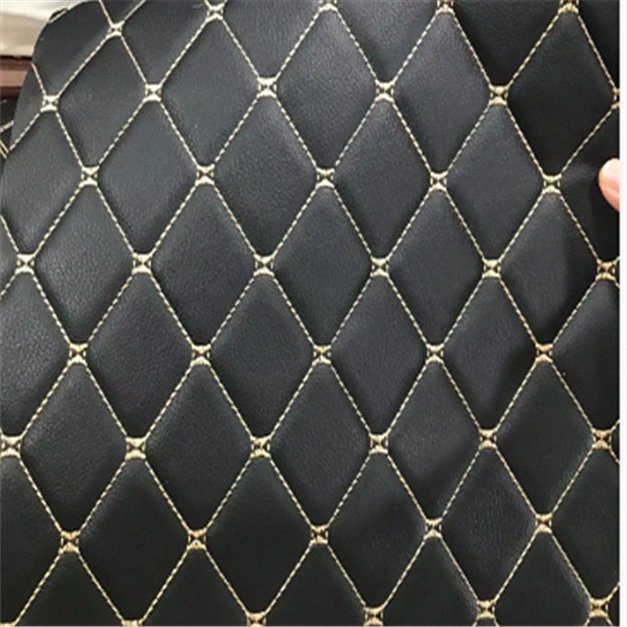

In an increasingly competitive global market, sourcing high-quality diamond stitch leather fabric rolls can be a daunting task for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. This guide addresses the critical challenge of identifying reliable suppliers and understanding the nuances of this luxurious material. Whether you’re looking to enhance automotive interiors, upholstery, or decorative applications, the diamond stitch leather fabric roll offers a blend of aesthetic appeal and durability that meets various industry needs.

This comprehensive guide delves into the different types of diamond stitch leather fabrics available, their diverse applications, and key considerations for supplier vetting. It also provides insights into pricing structures and cost-effective purchasing strategies tailored to specific regional markets. By equipping buyers with in-depth knowledge about material specifications, fire safety standards, and maintenance requirements, this resource empowers businesses to make informed decisions that align with their operational goals.

From discerning the quality of genuine versus faux leather to understanding the implications of various backing materials, this guide is designed to enhance your sourcing strategy and ensure that your procurement processes yield the best possible outcomes. As you navigate the global landscape of diamond stitch leather fabric rolls, let this guide be your trusted companion in making choices that elevate your product offerings and drive business success.

Table Of Contents

- Top 4 Diamond Stitch Leather Fabric Roll Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for diamond stitch leather fabric roll

- Understanding diamond stitch leather fabric roll Types and Variations

- Key Industrial Applications of diamond stitch leather fabric roll

- 3 Common User Pain Points for ‘diamond stitch leather fabric roll’ & Their Solutions

- Strategic Material Selection Guide for diamond stitch leather fabric roll

- In-depth Look: Manufacturing Processes and Quality Assurance for diamond stitch leather fabric roll

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘diamond stitch leather fabric roll’

- Comprehensive Cost and Pricing Analysis for diamond stitch leather fabric roll Sourcing

- Alternatives Analysis: Comparing diamond stitch leather fabric roll With Other Solutions

- Essential Technical Properties and Trade Terminology for diamond stitch leather fabric roll

- Navigating Market Dynamics and Sourcing Trends in the diamond stitch leather fabric roll Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of diamond stitch leather fabric roll

- Strategic Sourcing Conclusion and Outlook for diamond stitch leather fabric roll

- Important Disclaimer & Terms of Use

Understanding diamond stitch leather fabric roll Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Leather Diamond Stitch | Made from real animal hides, offering superior durability and luxury feel. | High-end automotive interiors, luxury furniture | Pros: Premium quality, long-lasting, natural look. Cons: Higher cost, requires more care. |

| Faux Leather Diamond Stitch | Crafted from synthetic materials, available in various colors and finishes. | Budget-friendly automotive interiors, consumer goods | Pros: Cost-effective, easy to clean, versatile. Cons: Less durable than genuine leather, may not have the same luxury appeal. |

| Foam Backed Diamond Stitch | Features a foam backing for added comfort and support, ideal for seating. | Automotive seats, home upholstery | Pros: Enhanced comfort, sound insulation. Cons: Heavier, may not be suitable for all design aesthetics. |

| Embossed Diamond Stitch | Textured surface adds depth and visual interest, often fire-retardant. | Commercial upholstery, wall coverings | Pros: Attractive design, safe for various applications. Cons: May be more expensive due to embossing process. |

| Quilted Vinyl Diamond Stitch | Made from vinyl with a quilted pattern, typically lightweight and water-resistant. | Marine applications, outdoor furniture | Pros: Water-resistant, lightweight, easy to maintain. Cons: Can be less breathable, may wear faster than other materials. |

What are the Characteristics of Genuine Leather Diamond Stitch?

Genuine leather diamond stitch fabric rolls are crafted from high-quality animal hides, providing a luxurious touch and exceptional durability. This type is often used in high-end automotive interiors and premium furniture, where aesthetics and longevity are paramount. Buyers should consider the maintenance requirements and higher price point, as genuine leather can be more costly upfront but offers a long-term investment through durability and timeless appeal.

How Does Faux Leather Diamond Stitch Compare?

Faux leather diamond stitch fabric is made from synthetic materials, making it a more affordable alternative to genuine leather. It is available in a wide array of colors and finishes, allowing for flexibility in design. This type is commonly utilized in budget-friendly automotive interiors and consumer goods. While it is easier to clean and maintain, buyers should weigh its lower durability against the cost savings, especially in high-traffic applications.

Why Choose Foam Backed Diamond Stitch Fabric?

Foam backed diamond stitch fabric rolls incorporate a layer of foam, enhancing comfort and support, making them ideal for automotive seats and home upholstery. This added cushioning also provides sound insulation, which is beneficial in automotive applications. Buyers should consider the weight and potential design limitations, as the foam backing can make it bulkier compared to other options.

What Makes Embossed Diamond Stitch Unique?

Embossed diamond stitch fabric features a textured surface that adds depth and visual interest to any application. This type is often treated to be fire-retardant, making it suitable for commercial upholstery and wall coverings in public spaces. While the embossed design enhances aesthetic appeal, buyers should be prepared for a potentially higher cost due to the embossing process, which can also affect the fabric’s overall durability.

How Does Quilted Vinyl Diamond Stitch Perform in Different Environments?

Quilted vinyl diamond stitch fabric is lightweight and water-resistant, making it particularly well-suited for marine applications and outdoor furniture. Its easy maintenance and vibrant color options make it a popular choice for various settings. However, buyers should note that while it is practical and affordable, it may not offer the same breathability and longevity as natural leather options, potentially leading to quicker wear in demanding environments.

Key Industrial Applications of diamond stitch leather fabric roll

| Industry/Sector | Specific Application of diamond stitch leather fabric roll | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for car seats and interiors | Enhances aesthetic appeal and comfort, attracting premium customers | Ensure compliance with fire safety standards and durability requirements |

| Furniture Manufacturing | Upholstery for sofas and chairs | Provides a luxurious look while ensuring durability and ease of maintenance | Source materials that meet specific color and texture preferences |

| Marine Industry | Interior coverings for boats | Offers water resistance and style, improving customer satisfaction | Consider marine-grade treatments for added durability against moisture |

| Fashion and Accessories | Handbags and fashion items | Adds a high-end finish to products, appealing to luxury markets | Verify material authenticity and eco-friendliness for sustainable branding |

| Interior Design | Wall coverings and decorative accents | Creates a sophisticated ambiance in residential and commercial spaces | Look for customizable options to match specific design themes |

How is diamond stitch leather fabric roll used in the automotive industry?

In the automotive sector, diamond stitch leather fabric roll is predominantly used for upholstery in car seats, door panels, and dashboards. The quilted design not only enhances the visual appeal of the vehicle interior but also adds a layer of comfort due to the foam backing. For international buyers, particularly in regions like Africa and the Middle East, it is crucial to ensure the fabric meets fire safety regulations and withstands varying climate conditions. Additionally, sourcing from reliable suppliers who can provide consistent quality and color matching is essential for maintaining brand integrity.

What role does diamond stitch leather fabric play in furniture manufacturing?

In furniture manufacturing, diamond stitch leather fabric is favored for upholstering sofas, chairs, and other seating options. The fabric’s durability and luxurious appearance make it an attractive choice for high-end furniture lines. Buyers from Europe and South America should focus on suppliers that can provide custom colors and textures to align with current design trends. Moreover, understanding the maintenance requirements of the fabric, such as cleaning and care instructions, is vital for ensuring longevity and customer satisfaction.

Why is diamond stitch leather fabric important for the marine industry?

The marine industry utilizes diamond stitch leather fabric rolls for interior coverings in boats, enhancing both style and functionality. This fabric is often treated to resist water and UV damage, making it ideal for marine environments. Buyers should prioritize sourcing materials that are specifically designed for marine use to ensure durability and safety. Additionally, understanding the specific aesthetic preferences for different types of vessels can help in selecting the right fabric options that appeal to boat owners.

Illustrative image related to diamond stitch leather fabric roll

How can the fashion industry benefit from diamond stitch leather fabric?

In the fashion and accessories sector, diamond stitch leather fabric is used for creating high-end handbags, wallets, and other luxury items. Its elegant appearance and tactile quality can significantly enhance the perceived value of products. For B2B buyers, particularly in markets like Africa and Europe, sourcing sustainable and ethically produced materials can be a strong selling point. Additionally, verifying the authenticity of the leather, whether genuine or faux, is crucial to align with brand values and consumer expectations.

What advantages does diamond stitch leather fabric offer in interior design?

Diamond stitch leather fabric is increasingly popular in interior design for wall coverings and decorative accents. Its ability to create a sophisticated ambiance makes it suitable for both residential and commercial spaces. Buyers should consider sourcing customizable options to fit specific design themes, ensuring that the fabric complements existing decor. Furthermore, understanding the durability and maintenance requirements of the fabric is essential for long-term use in high-traffic areas.

3 Common User Pain Points for ‘diamond stitch leather fabric roll’ & Their Solutions

Scenario 1: Sourcing Quality Diamond Stitch Leather Fabric Rolls

The Problem: Many B2B buyers often struggle with sourcing high-quality diamond stitch leather fabric rolls that meet their specific requirements. This challenge is particularly acute for businesses operating in regions like Africa and South America, where access to reliable suppliers may be limited. Buyers may find themselves navigating a market filled with subpar products that lack durability, aesthetic appeal, or compliance with local regulations. Additionally, the lack of clear product specifications can lead to confusion, resulting in costly mistakes when the materials arrive.

Illustrative image related to diamond stitch leather fabric roll

The Solution: To effectively source diamond stitch leather fabric rolls, buyers should first develop a comprehensive understanding of their specific needs, including the intended application—be it automotive upholstery or furniture design. Engaging with suppliers who offer samples is crucial; this allows buyers to assess texture, color, and quality before committing to a bulk order. Additionally, buyers should prioritize suppliers with a track record of positive customer reviews and industry certifications. Using platforms like Alibaba or industry-specific trade shows can facilitate connections with verified suppliers, ensuring the materials meet both quality and compliance standards.

Scenario 2: Ensuring Compliance with Fire Safety Standards

The Problem: Fire safety regulations can be a significant concern for businesses utilizing diamond stitch leather fabric in their products. Buyers may encounter challenges ensuring that the materials they purchase comply with local fire safety standards, particularly in sectors like automotive and commercial furnishings. Non-compliance not only poses safety risks but can also lead to legal repercussions and financial losses if products are recalled or rejected.

The Solution: Buyers should proactively seek out diamond stitch leather fabric rolls that are explicitly labeled as fire retardant. It is essential to request certification documents from suppliers that detail compliance with local and international fire safety standards. Furthermore, businesses should establish a clear communication channel with suppliers to discuss any specific regulatory requirements pertinent to their industry or region. Conducting a small-scale trial of the fabric in a controlled environment can also help verify its performance against fire safety standards before full-scale implementation.

Scenario 3: Managing Inventory and Cost Efficiency

The Problem: Effective inventory management can be a daunting task for B2B buyers, especially when dealing with diamond stitch leather fabric rolls that can vary significantly in price and quality. Fluctuating market prices, combined with the need to maintain adequate stock levels for production, can lead to either excess inventory or shortages. This imbalance not only affects cash flow but also hampers operational efficiency, potentially causing delays in fulfilling customer orders.

Illustrative image related to diamond stitch leather fabric roll

The Solution: To optimize inventory management, buyers should implement a just-in-time (JIT) inventory system that aligns closely with production schedules and customer demand. This strategy minimizes excess stock and reduces storage costs. Collaborating with suppliers who offer flexible order quantities and quick turnaround times can also alleviate pressure. Establishing strong relationships with multiple suppliers allows buyers to negotiate better pricing and terms, ensuring that they can respond swiftly to market fluctuations. Additionally, using inventory management software can provide real-time insights, helping buyers make informed decisions about when to reorder and how much to stock, ultimately leading to cost savings and improved operational efficiency.

Strategic Material Selection Guide for diamond stitch leather fabric roll

What Are the Common Materials Used for Diamond Stitch Leather Fabric Rolls?

When selecting diamond stitch leather fabric rolls for various applications, understanding the material options is crucial for B2B buyers. The primary materials used in these fabric rolls include genuine leather, faux leather (PVC), vinyl, and embossed leather. Each material has distinct properties, advantages, and limitations that can significantly impact the end product’s performance and suitability.

How Does Genuine Leather Compare in Performance?

Genuine leather is renowned for its durability and luxurious feel. Its natural fibers provide excellent tensile strength, making it resistant to wear and tear. Additionally, genuine leather has a high-temperature tolerance, which makes it suitable for automotive interiors exposed to varying climates. However, it can be more expensive than synthetic alternatives and may require special care to maintain its appearance. For international buyers, genuine leather must comply with various regulations, such as REACH in Europe, which governs chemical safety.

What Advantages Does Faux Leather (PVC) Offer?

Faux leather, particularly PVC, is a popular choice due to its cost-effectiveness and ease of maintenance. It is water-resistant and can be produced in a variety of colors and textures, allowing for customization in design. However, PVC may not offer the same level of breathability as genuine leather, which can affect comfort in applications like automotive seating. For B2B buyers, it’s essential to ensure that the faux leather meets local fire safety standards, especially in regions like the Middle East where such regulations are stringent.

Why Choose Vinyl for Diamond Stitch Leather Fabric Rolls?

Vinyl is another widely used material for diamond stitch leather fabric rolls. It is highly resistant to moisture and stains, making it suitable for a range of applications, from automotive interiors to home furnishings. Vinyl can also be treated to be fire retardant, enhancing its safety profile. However, its environmental impact is a concern, as vinyl production can involve harmful chemicals. International buyers should look for suppliers who adhere to sustainability practices and certifications, as this is increasingly becoming a purchasing criterion.

What Is the Role of Embossed Leather in This Market?

Embossed leather combines the aesthetic appeal of genuine leather with the affordability of synthetic materials. This material is often treated to enhance its durability and can mimic the look of high-end leather without the associated costs. While embossed leather can be a good option for decorative applications, it may not hold up as well in high-wear scenarios compared to genuine leather. Buyers should consider the intended use and durability requirements when selecting embossed leather, ensuring compliance with relevant industry standards.

Summary Table of Material Options for Diamond Stitch Leather Fabric Rolls

| Material | Typical Use Case for diamond stitch leather fabric roll | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end automotive interiors, luxury furniture | Exceptional durability and luxury feel | Higher cost and maintenance requirements | High |

| Faux Leather (PVC) | Budget-friendly automotive interiors, upholstery | Cost-effective and easy to maintain | Less breathable and may not age as well | Low |

| Vinyl | Automotive interiors, home furnishings | Moisture and stain resistant | Environmental concerns and potential toxicity | Medium |

| Embossed Leather | Decorative applications, furniture accents | Aesthetic appeal at a lower cost | May not withstand high wear as well as genuine leather | Medium |

By understanding these material options, B2B buyers can make informed decisions that align with their specific needs, budget constraints, and compliance requirements, ensuring successful procurement and application of diamond stitch leather fabric rolls.

In-depth Look: Manufacturing Processes and Quality Assurance for diamond stitch leather fabric roll

What Are the Main Stages in the Manufacturing Process of Diamond Stitch Leather Fabric Rolls?

The manufacturing of diamond stitch leather fabric rolls is a multi-stage process that integrates advanced textile technology with traditional craftsmanship. Each stage is crucial to ensuring the final product meets the high standards expected by B2B buyers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing involves the careful selection and preparation of raw materials. Depending on the product specifications, manufacturers may choose genuine leather, faux leather, or a combination of both. Each material is sourced based on quality parameters, including texture, durability, and aesthetic appeal.

Once selected, the raw materials undergo a conditioning process where they are cleaned, treated, and sometimes dyed. This stage may also involve the application of fire retardants and other protective coatings, especially for automotive applications where safety is paramount. The goal is to ensure the materials are ready for further processing and can withstand the stresses of everyday use.

Forming: What Techniques Are Used to Create the Diamond Stitch Pattern?

The formation of the diamond stitch pattern is achieved through specialized quilting techniques. Manufacturers utilize advanced machinery that stitches the fabric in a diamond pattern, typically using high-strength threads that enhance both durability and visual appeal.

This process often involves the use of foam backing, which adds comfort and structure to the final product. The thickness and density of the foam can be adjusted based on the intended application, such as upholstery or automotive interiors. The precision in this stage is vital, as any inconsistencies can affect the overall quality of the fabric roll.

Assembly: How Is the Fabric Roll Prepared for Distribution?

After forming, the fabric rolls are cut to specified lengths and widths based on customer orders. This customization allows B2B buyers to obtain the exact amount of material needed for their projects. The fabric is then carefully packaged to prevent damage during transit.

During this assembly phase, any additional components, such as color-matching threads or binding tapes, may be included to facilitate the final application. Attention to detail is critical here, as improper handling can lead to defects that compromise the product’s integrity.

Illustrative image related to diamond stitch leather fabric roll

Finishing: What Final Touches Are Applied to Ensure Quality?

The finishing stage includes several processes designed to enhance the fabric’s appearance and functionality. This may involve additional treatments such as waterproofing, UV resistance, or enhanced colorfastness, particularly for fabrics intended for outdoor use or high-traffic areas.

Quality checks are also implemented during this phase, ensuring that all products meet the established standards before being shipped. This attention to detail ensures that B2B buyers receive a product that not only looks good but also performs well in its intended application.

What Quality Assurance Measures Are Implemented in the Production of Diamond Stitch Leather Fabric Rolls?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets both international standards and customer expectations. Here’s a closer look at the QA measures typically implemented.

Which International Standards Are Relevant to Quality Assurance?

Manufacturers often adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems. This certification ensures that the company has established processes for continuous improvement and customer satisfaction.

Additionally, industry-specific standards, such as CE marking for safety compliance in Europe and API specifications for automotive products, may also be relevant. These certifications signal to B2B buyers that the products have undergone rigorous testing and comply with essential safety and quality benchmarks.

Illustrative image related to diamond stitch leather fabric roll

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is generally divided into several key checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the specified criteria. Any substandard materials are rejected at this stage.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are conducted to monitor production quality. This includes verifying stitching accuracy and foam density during the forming stage.

-

Final Quality Control (FQC): Before packaging, a comprehensive inspection is performed. This includes checking for defects, measuring dimensions, and ensuring that all treatments have been correctly applied.

These checkpoints are critical in maintaining the integrity of the manufacturing process and ensuring that only high-quality products are delivered to buyers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify a supplier’s quality control practices:

-

Request Certification Documentation: Ask for copies of relevant certifications, such as ISO 9001 or CE markings, to verify compliance with industry standards.

-

Conduct Supplier Audits: Consider performing on-site audits to assess the manufacturing processes and quality control measures firsthand. This can provide insights into the supplier’s commitment to quality.

-

Review Quality Reports: Request access to quality control reports and testing results. This documentation can provide transparency regarding the quality of the materials and processes used.

-

Third-Party Inspections: Engage third-party inspection services to conduct independent evaluations of the manufacturing facility. This can help ensure that the supplier adheres to the promised quality standards.

What Are the Unique Quality Control Challenges for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control:

-

Cultural Differences: Variations in quality expectations across different regions can lead to misunderstandings. Clear communication regarding quality standards is essential.

-

Logistics and Supply Chain Issues: Delays in shipping or customs clearance can affect the timely delivery of high-quality products. Establishing strong logistics partnerships can mitigate these risks.

-

Regulatory Compliance: Different regions have distinct regulations regarding materials and safety standards. Buyers must ensure that their suppliers comply with both local and international regulations to avoid legal issues.

By understanding these challenges and implementing robust verification processes, B2B buyers can better navigate the complexities of sourcing diamond stitch leather fabric rolls in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diamond stitch leather fabric roll’

This guide provides a practical checklist for B2B buyers looking to procure diamond stitch leather fabric rolls. This material is sought after for its aesthetic appeal and durability, particularly in industries like automotive upholstery and interior design. By following these steps, buyers can ensure they make informed decisions and secure high-quality products.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to outline the specific requirements for the diamond stitch leather fabric roll. Consider factors such as material type (genuine vs. faux leather), thickness, and backing options. This clarity will guide your sourcing efforts and help you communicate effectively with potential suppliers.

- Material Type: Decide if you need genuine leather for premium applications or faux leather for cost-effective solutions.

- Thickness and Backing: Determine the necessary thickness and whether a foam backing is needed for comfort and durability.

Step 2: Research and Identify Reliable Suppliers

Finding the right suppliers is crucial for ensuring quality and reliability. Start by researching suppliers that specialize in diamond stitch leather fabric rolls and have a proven track record in your target market.

- Industry Reputation: Look for suppliers with positive reviews and testimonials from other B2B clients.

- Product Range: Evaluate the variety of options they offer, including colors, patterns, and customization capabilities.

Step 3: Request Samples for Evaluation

Once you have identified potential suppliers, request samples of their diamond stitch leather fabric rolls. This step is vital to assess the quality, texture, and color fidelity of the materials before placing a larger order.

- Quality Check: Examine the samples for stitching consistency, material durability, and overall finish.

- Fit for Purpose: Ensure the samples align with your intended applications, whether for automotive or upholstery projects.

Step 4: Verify Supplier Certifications and Compliance

It’s important to confirm that your chosen suppliers adhere to industry standards and regulations. Verify any relevant certifications, such as fire retardancy, which is crucial for materials used in automotive interiors.

Illustrative image related to diamond stitch leather fabric roll

- Quality Certifications: Look for ISO certifications or other quality assurance measures.

- Material Safety: Ensure that the materials comply with local regulations regarding safety and environmental impact.

Step 5: Negotiate Terms and Pricing

Once you have selected a supplier, enter negotiations regarding pricing, minimum order quantities (MOQs), and payment terms. Clear and fair negotiations can lead to better pricing and favorable terms for future orders.

- Pricing Transparency: Request a detailed breakdown of costs to understand the price structure.

- Payment Flexibility: Discuss payment options that suit both parties, including potential discounts for bulk purchases.

Step 6: Establish Clear Communication Channels

Effective communication is key to a successful sourcing process. Set up clear lines of communication with your supplier to ensure smooth operations from order placement to delivery.

- Point of Contact: Designate a primary contact person on both sides to streamline communication.

- Regular Updates: Agree on regular check-ins to monitor order progress and address any issues promptly.

Step 7: Plan for Logistics and Delivery

Finally, consider logistics and delivery timelines when placing your order. Coordinate with your supplier to ensure timely shipping, especially if you have tight project deadlines.

- Shipping Options: Discuss available shipping methods and associated costs.

- Lead Times: Confirm lead times for production and delivery to manage your project timelines effectively.

By following this checklist, B2B buyers can navigate the procurement process for diamond stitch leather fabric rolls with confidence, ensuring they secure quality materials that meet their specific needs.

Illustrative image related to diamond stitch leather fabric roll

Comprehensive Cost and Pricing Analysis for diamond stitch leather fabric roll Sourcing

What are the Key Cost Components for Sourcing Diamond Stitch Leather Fabric Rolls?

When evaluating the cost structure for diamond stitch leather fabric rolls, several components must be considered. The primary factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of materials varies significantly based on whether you are sourcing genuine leather or high-quality faux leather. Genuine leather tends to be more expensive due to its durability and premium appeal, while faux leather offers a cost-effective alternative. Additionally, the choice of foam backing (e.g., 6mm vs. 8mm) can influence costs.

-

Labor: Labor costs can fluctuate depending on the region of production. Countries with lower wage standards may offer more competitive labor costs, but this must be balanced against the quality of craftsmanship. Skilled labor is essential for maintaining the aesthetic integrity of the diamond stitching.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. Manufacturers with advanced technology may have higher initial costs but can achieve better efficiency and consistency in production.

-

Tooling: Initial tooling costs for creating molds and patterns can be significant. These costs are typically amortized over larger production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Implementing rigorous QC processes is vital to ensure the fabric meets international standards, particularly for fire retardancy and durability. These processes incur additional costs but are necessary for maintaining product integrity.

-

Logistics: Shipping costs depend on the origin of the material, destination, and chosen Incoterms (International Commercial Terms). For international buyers, understanding the logistics involved, including customs duties and tariffs, is critical for accurate cost estimation.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and the supplier’s positioning within the market.

How Do Price Influencers Impact the Cost of Diamond Stitch Leather Fabric Rolls?

Several factors can influence pricing in the B2B market for diamond stitch leather fabric rolls:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Larger orders often qualify for bulk discounts, which can lead to substantial savings for buyers.

-

Specifications and Customization: Custom specifications, such as unique colors, textures, or patterns, can lead to increased costs. Buyers should consider whether customization is necessary for their project or if standard options will suffice.

-

Material Quality and Certifications: Fabrics that meet specific industry certifications (e.g., fire retardant) may command higher prices. Buyers should assess whether these certifications are essential for their intended applications.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms can affect overall pricing. Terms that place more responsibility on the buyer, such as DAP (Delivered at Place), may lead to additional costs in shipping and customs clearance.

What Tips Should Buyers Consider for Cost-Efficient Sourcing?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies for cost-efficient sourcing of diamond stitch leather fabric rolls:

-

Negotiation: Always engage in negotiations with suppliers. Understanding the cost components can empower buyers to negotiate better terms, especially regarding pricing and payment conditions.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. This includes logistics, potential wastage, and any necessary post-purchase adjustments. A lower initial price may lead to higher overall costs if quality issues arise.

-

Market Research: Conduct thorough market research to understand prevailing prices and quality standards. This knowledge will help in making informed decisions and identifying trustworthy suppliers.

-

Long-term Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Frequent purchases may allow for negotiated discounts or priority service.

-

Understand Pricing Nuances: Be aware of regional pricing differences and the impact of currency fluctuations on international orders. This knowledge can help in budgeting and forecasting expenses more accurately.

Disclaimer for Indicative Prices

Prices for diamond stitch leather fabric rolls can vary widely based on the aforementioned factors. Buyers should seek quotes from multiple suppliers to obtain a comprehensive understanding of the market and ensure they are making a cost-effective purchasing decision.

Illustrative image related to diamond stitch leather fabric roll

Alternatives Analysis: Comparing diamond stitch leather fabric roll With Other Solutions

Exploring Alternatives to Diamond Stitch Leather Fabric Roll

In the competitive landscape of upholstery materials, diamond stitch leather fabric rolls are highly valued for their aesthetic appeal and durability. However, understanding alternative solutions can provide B2B buyers with a broader perspective on options that may suit their specific needs better. This section compares diamond stitch leather fabric rolls against other viable alternatives, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Diamond Stitch Leather Fabric Roll | Faux Leather Vinyl Fabric | Bentley Stitch Diamond Embossed Faux Leather |

|---|---|---|---|

| Performance | High durability; fire retardant | Moderate durability; less breathable | Good durability; fire retardant |

| Cost | Medium to high | Low to medium | Medium |

| Ease of Implementation | Moderate; requires specialized tools | Easy; can be cut with standard tools | Moderate; requires care to maintain aesthetic |

| Maintenance | Requires regular cleaning | Easy to clean; wipeable | Easy to clean; wipeable |

| Best Use Case | Automotive interiors, furniture | General upholstery, crafts | Furniture, automotive, decorative applications |

What Are the Pros and Cons of Faux Leather Vinyl Fabric?

Faux leather vinyl fabric presents a cost-effective alternative to diamond stitch leather fabric rolls. It is relatively inexpensive and widely available, making it an attractive option for budget-conscious projects. Its ease of implementation means that it can be cut and sewn with standard tools, appealing to businesses seeking efficiency. However, the durability is moderate compared to genuine leather, and it may not offer the same luxurious feel or breathability, making it less ideal for high-end applications.

How Does Bentley Stitch Diamond Embossed Faux Leather Compare?

Bentley stitch diamond embossed faux leather offers a unique aesthetic with its embossed pattern, providing a sophisticated appearance similar to diamond stitch leather. This fabric is also fire retardant, ensuring safety in commercial applications. While it boasts good durability, it may require more careful handling to maintain its appearance over time. The cost is moderate, making it a feasible option for businesses looking to balance quality and budget. Its versatility allows for use in both automotive and decorative applications, although it may not provide the same level of support and comfort as padded diamond stitch options.

Conclusion: How Should B2B Buyers Choose the Right Upholstery Solution?

Selecting the appropriate upholstery material hinges on understanding the specific needs of your project. For high-end automotive interiors or luxurious furniture, diamond stitch leather fabric rolls are often the best choice due to their combination of durability and aesthetic appeal. In contrast, faux leather vinyl fabric is ideal for budget-sensitive projects where cost and ease of use are paramount. Meanwhile, Bentley stitch diamond embossed faux leather can serve as a middle ground, offering a premium look at a reasonable price. B2B buyers should carefully assess their priorities—whether they are focused on aesthetics, budget constraints, or the specific application—to make an informed decision that aligns with their business goals.

Illustrative image related to diamond stitch leather fabric roll

Essential Technical Properties and Trade Terminology for diamond stitch leather fabric roll

What are the Essential Technical Properties of Diamond Stitch Leather Fabric Roll?

When sourcing diamond stitch leather fabric rolls, understanding key technical specifications is vital for making informed purchasing decisions. Here are some of the critical properties that B2B buyers should consider:

1. Material Composition

Diamond stitch leather fabric can be made from genuine leather, faux leather, or a combination of both. Genuine leather typically offers superior durability and an upscale appearance, while faux leather provides a cost-effective alternative that is often lighter and easier to clean. Buyers should evaluate their specific application needs to determine the appropriate material composition for their projects.

2. Foam Backing Thickness

The thickness of the foam backing can significantly impact comfort and durability. Common thicknesses include 6mm to 8mm, which provide a plush feel and added support. A thicker backing is particularly advantageous for applications like automotive interiors, where added cushioning can enhance user comfort. Understanding the foam thickness helps buyers select the right fabric for their intended use.

3. Fire Retardant Treatment

Many diamond stitch leather options come with fire retardant treatments, which are essential for compliance with safety regulations, especially in commercial and automotive applications. This treatment reduces flammability and helps prevent the spread of fire, making it a critical consideration for B2B buyers concerned about safety standards in their respective industries.

4. Weight per Yard

The weight of the fabric, typically measured in pounds per yard, is another crucial factor. A heavier fabric often indicates a higher quality and durability, which can be essential for high-traffic areas or heavy-use applications. Buyers should assess the weight of the fabric to ensure it meets their performance requirements.

5. Width and Length Specifications

Diamond stitch leather fabric is generally sold by the meter or yard, with standard widths ranging from 54 inches to 137 centimeters. Understanding the dimensions is vital for ensuring that the material will fit the intended application without excessive waste. Buyers should clarify their requirements regarding width and length to optimize their purchasing efficiency.

Illustrative image related to diamond stitch leather fabric roll

What are Common Trade Terms Used in the Diamond Stitch Leather Fabric Industry?

Familiarity with industry jargon can streamline communication and transactions. Here are several essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that may be marketed by another manufacturer. In the context of diamond stitch leather fabric, an OEM might provide customized solutions for automotive or furniture manufacturers, allowing them to brand the product as their own.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it can affect purchasing decisions, especially when balancing budget constraints with inventory needs. Knowing the MOQ helps buyers negotiate better terms and manage their stock effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and availability information from suppliers. This term is especially relevant in B2B transactions, as it allows businesses to compare offers and make informed purchasing decisions based on detailed quotations.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including the delivery of goods and the transfer of risk. Familiarity with these terms can help buyers understand shipping costs, insurance, and liability, ultimately aiding in smoother cross-border transactions.

Illustrative image related to diamond stitch leather fabric roll

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. In the diamond stitch leather fabric sector, knowing the lead time is essential for planning production schedules and managing customer expectations. Buyers should inquire about lead times to ensure timely delivery of materials.

By grasping these technical properties and trade terms, B2B buyers can navigate the market for diamond stitch leather fabric rolls more effectively, ensuring they make choices that align with their operational and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the diamond stitch leather fabric roll Sector

What Are the Current Market Dynamics and Key Trends Affecting the Diamond Stitch Leather Fabric Roll Sector?

The diamond stitch leather fabric roll market is experiencing robust growth, driven by several global factors. The increasing demand for premium automotive interiors, particularly in regions like Africa and South America, is a significant driver. As consumers increasingly prioritize aesthetics and durability in vehicle upholstery, manufacturers are responding with high-quality diamond stitch leather options. Moreover, the rise of custom automotive interiors and restorations is fueling the need for diverse color palettes and textures, making the sourcing of unique diamond stitch patterns more relevant.

Technological advancements in textile manufacturing are also reshaping this sector. Innovations such as automated quilting techniques and improved foam backing options enhance the durability and comfort of diamond stitch leather products. B2B buyers are increasingly leveraging online platforms for sourcing, allowing them to compare prices and specifications efficiently. E-commerce is particularly prominent in Europe and the Middle East, where buyers expect rapid delivery and customizable options.

Additionally, sustainability is becoming a crucial factor in purchasing decisions. Buyers are now more inclined to seek out suppliers who prioritize eco-friendly practices and materials. This shift is evident in the growing preference for faux leather alternatives that replicate the luxurious appearance of genuine leather while reducing environmental impact.

How Are Sustainability and Ethical Sourcing Impacting the Diamond Stitch Leather Fabric Roll Market?

Sustainability and ethical sourcing are increasingly vital in the diamond stitch leather fabric roll market. The environmental impact of leather production, including resource-intensive practices and greenhouse gas emissions, has prompted a shift towards more sustainable alternatives. B2B buyers are now prioritizing suppliers who offer products certified for sustainability, such as those made from recycled materials or produced in environmentally friendly processes.

The availability of ‘green’ certifications, such as Global Organic Textile Standard (GOTS) and OEKO-TEX, is becoming a significant consideration for international buyers. These certifications assure buyers that the materials are sourced responsibly and produced without harmful chemicals. Additionally, many manufacturers are adopting practices such as waste reduction and energy-efficient production methods, which not only appeal to eco-conscious consumers but also enhance brand reputation.

Illustrative image related to diamond stitch leather fabric roll

In regions like Africa and South America, where ethical sourcing can significantly impact local communities, buyers are encouraged to establish transparent supply chains. This practice not only ensures compliance with international standards but also fosters goodwill and strengthens relationships with local suppliers.

What Has Been the Evolution of the Diamond Stitch Leather Fabric Roll Industry?

The diamond stitch leather fabric roll has evolved significantly over the past few decades. Initially popularized in high-end automotive upholstery, the diamond stitch pattern emerged as a symbol of luxury and craftsmanship. The design’s structural integrity and aesthetic appeal made it a favored choice among luxury car manufacturers.

As consumer preferences shifted towards customization and personalization, manufacturers began to explore a wider range of colors, textures, and materials, including both genuine and faux leather. The advent of modern manufacturing techniques allowed for more intricate designs and improved durability, expanding the applications of diamond stitch leather beyond automotive use to furniture, home décor, and fashion accessories.

Today, the diamond stitch leather fabric roll is not only a staple in the automotive industry but also a versatile material used in various sectors, reflecting changing consumer demands for both style and sustainability. As the industry continues to adapt, it remains crucial for B2B buyers to stay informed about market trends and sourcing practices that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of diamond stitch leather fabric roll

-

How do I ensure the quality of diamond stitch leather fabric rolls before purchasing?

To verify the quality of diamond stitch leather fabric rolls, request samples from potential suppliers. Evaluate the texture, color consistency, and stitching quality. Look for certifications such as ISO or fire retardant standards, especially for automotive applications. Additionally, inquire about the manufacturing processes and material sourcing to ensure compliance with international quality standards. Establishing a relationship with reliable suppliers and conducting periodic quality audits can also help maintain consistent standards. -

What is the best way to determine the right supplier for diamond stitch leather fabric?

When selecting a supplier for diamond stitch leather fabric, consider their reputation, experience, and customer reviews. Look for suppliers with a strong track record in the industry, particularly in your target market regions like Africa, South America, the Middle East, and Europe. Request references and evaluate their responsiveness and willingness to accommodate custom orders. Visiting their facilities, if feasible, can provide further insights into their operations and quality control measures. -

What customization options are available for diamond stitch leather fabric rolls?

Most suppliers offer various customization options for diamond stitch leather fabric rolls, including color selection, material type (genuine or faux leather), and size specifications. You can also request specific stitch patterns or additional treatments such as waterproofing or UV resistance. Discuss your requirements with the supplier to explore these options and any potential additional costs associated with customization. -

What are the typical minimum order quantities (MOQs) for diamond stitch leather fabric rolls?

Minimum order quantities for diamond stitch leather fabric rolls can vary significantly between suppliers. Typically, MOQs may range from 50 to 500 meters, depending on the supplier’s production capabilities and your customization requirements. Be sure to clarify the MOQ upfront to avoid surprises later in the procurement process. Some suppliers may offer flexibility for smaller orders, especially for first-time clients or samples. -

What payment terms should I expect when sourcing diamond stitch leather fabric rolls?

Payment terms for diamond stitch leather fabric rolls can vary by supplier and may include options such as upfront deposits, net 30/60/90 days, or letter of credit arrangements. It’s important to negotiate terms that align with your cash flow and risk management strategy. Always confirm accepted payment methods and ensure that the payment process is secure to protect against fraud. -

How can I handle logistics when importing diamond stitch leather fabric rolls?

To manage logistics effectively when importing diamond stitch leather fabric rolls, partner with a reliable freight forwarder who understands international shipping regulations. Consider factors such as shipping costs, customs duties, and lead times. Ensure that the supplier provides all necessary documentation, including certificates of origin and quality. Planning for potential delays in customs clearance is also crucial to maintaining your supply chain. -

What are the fire safety standards for diamond stitch leather fabric in commercial applications?

When sourcing diamond stitch leather fabric for commercial applications, particularly in automotive or public spaces, ensure that the material complies with relevant fire safety standards. Check for certifications like NFPA, EN 1021, or other local regulations that specify flammability requirements. Request documentation from suppliers proving compliance to ensure the safety and legality of your products in the target market. -

What are the common applications for diamond stitch leather fabric rolls?

Diamond stitch leather fabric rolls are versatile and commonly used in automotive interiors, including seat covers, door panels, and dashboards. They are also suitable for furniture upholstery, wall coverings, and decorative accents due to their aesthetic appeal and durability. The padded texture adds comfort, making it an ideal choice for both functional and decorative purposes in various industries.

Top 4 Diamond Stitch Leather Fabric Roll Manufacturers & Suppliers List

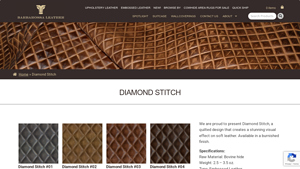

1. Barbarossa Leather – Diamond Stitch Embossed Leather

Domain: barbarossaleather.com

Registered: 2005 (20 years)

Introduction: {“design_name”: “Diamond Stitch”, “description”: “A quilted design that creates a stunning visual effect on soft leather.”, “finish”: “Available in a burnished finish.”, “specifications”: {“raw_material”: “Bovine hide”, “weight”: “2.5 – 3.5 oz.”, “type”: “Embossed Leather”, “hide_size”: “Full 40-50 sqft.”, “thickness”: “1.0 – 1.4mm”, “flammability”: “Meets CA 117E”}, “color_options”: [“Bolero Ceme…

2. eBay – Diamond Stitch Leather Fabric

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Diamond Stitch Leather Fabric available in various colors including Beige, Black, Blue, Brown, Gray, Multicolor, Pink, Purple, Red, and White. Suitable for upholstery, car upholstery, motorcycle upholstery, bedding, quilting, crafts, and accessories like bags and purses. Patterns include Argyle, Diamond, Solid/Plain, Textured, and Embossed. Features include being embroidered, waterproof, quilted, …

3. Fashion Fabric LA – Diamond Quilted Foam Backed Faux Leather

Domain: fashionfabricla.com

Registered: 2014 (11 years)

Introduction: Diamond Quilted Foam Backed Faux Leather Automotive Upholstery Fabric – By The Yard

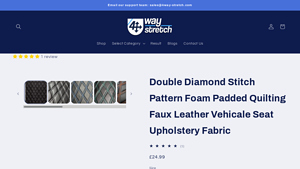

4. 4Way Stretch – Double Diamond Stitch Faux Leather Upholstery Fabric

Domain: 4way-stretch.com

Registered: 2024 (1 years)

Introduction: {“name”: “Double Diamond Stitch Pattern Foam Padded Quilting Faux Leather Vehicle Seat Upholstery Fabric”, “price”: “£24.99”, “unit”: “per meter”, “colors_available”: [“Black”, “Silver”, “White”, “Red”, “Blue”, “Green”, “Orange”, “Pink”, “Purple”], “width”: “1.5M”, “thickness”: “5mm”, “features”: [“Durable faux leather material”, “Soft and supple texture”, “Diamond quilted pattern”, “Comfortable p…

Strategic Sourcing Conclusion and Outlook for diamond stitch leather fabric roll

As the demand for diamond stitch leather fabric rolls continues to rise across various sectors, it is crucial for international B2B buyers to leverage strategic sourcing to enhance their competitive edge. This fabric, characterized by its luxurious appearance and durability, serves a multitude of applications, from automotive interiors to bespoke furniture. By carefully selecting suppliers who offer high-quality materials, buyers can ensure they meet industry standards while also catering to the aesthetic preferences of their target markets.

A key takeaway for buyers is the importance of understanding the diverse options available, including genuine and faux leather, as well as various color and texture choices. This versatility not only allows for customization but also opens doors to new market opportunities. Additionally, sourcing from manufacturers who prioritize fire retardant treatments can significantly enhance product safety, a vital consideration in many regions.

Looking ahead, the potential for growth in markets across Africa, South America, the Middle East, and Europe remains robust. By forging strategic partnerships and staying informed about market trends, B2B buyers can position themselves advantageously. Engage with reliable suppliers today to explore the rich possibilities that diamond stitch leather fabric rolls offer for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.