Introduction: Navigating the Global Market for how to make leather wristbands

In today’s competitive landscape, international B2B buyers face the challenge of sourcing high-quality leather wristbands that meet diverse consumer demands. Whether you’re looking to provide stylish accessories for a fashion line or durable promotional items for corporate events, understanding how to make leather wristbands can significantly impact your purchasing decisions. This comprehensive guide delves into various types of leather wristbands, including decorative cuffs, personalized stamped options, and eco-friendly designs crafted from recycled materials.

Additionally, we will explore essential aspects such as supplier vetting processes, cost considerations, and market trends specific to regions including Africa, South America, the Middle East, and Europe. By equipping yourself with in-depth knowledge of the production techniques and materials involved, you can make informed choices that not only enhance your product offerings but also align with consumer preferences in your target markets.

This guide empowers B2B buyers by providing actionable insights and practical steps for sourcing and creating leather wristbands that resonate with their audience. As you navigate the global market, you will gain the tools necessary to foster successful partnerships with suppliers and elevate your brand’s presence in the ever-evolving leather accessory sector.

Table Of Contents

- Top 4 How To Make Leather Wristbands Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make leather wristbands

- Understanding how to make leather wristbands Types and Variations

- Key Industrial Applications of how to make leather wristbands

- 3 Common User Pain Points for ‘how to make leather wristbands’ & Their Solutions

- Strategic Material Selection Guide for how to make leather wristbands

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather wristbands

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather wristbands’

- Comprehensive Cost and Pricing Analysis for how to make leather wristbands Sourcing

- Alternatives Analysis: Comparing how to make leather wristbands With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make leather wristbands

- Navigating Market Dynamics and Sourcing Trends in the how to make leather wristbands Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather wristbands

- Strategic Sourcing Conclusion and Outlook for how to make leather wristbands

- Important Disclaimer & Terms of Use

Understanding how to make leather wristbands Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cuff Bracelet | Wide band, often featuring designs or embellishments | Fashion accessories, promotional items | Pros: High visibility, customizable. Cons: May require larger leather pieces. |

| Stamped Leather Bracelet | Personalized messages or designs stamped into the leather | Corporate gifts, branding merchandise | Pros: Unique, personal touch. Cons: Labor-intensive production. |

| Beaded Leather Bracelet | Combination of leather and beads for added texture and color | Fashion retail, artisan markets | Pros: Versatile design options. Cons: Bead sourcing can complicate inventory. |

| Recycled Leather Bracelet | Made from repurposed leather materials, eco-friendly approach | Sustainable fashion brands, artisan shops | Pros: Cost-effective, eco-conscious. Cons: Quality may vary with source material. |

| Double Wrap Bracelet | Longer leather strips that wrap around the wrist twice | Trendy fashion lines, casual wear | Pros: Stylish, allows for layering. Cons: Requires more material, may not fit all wrist sizes. |

What Are the Key Characteristics of Cuff Bracelets?

Cuff bracelets are characterized by their wide bands that can feature intricate designs or embellishments such as studs, embroidery, or patterns. They are often made from thicker leather, allowing for more robust customization and branding opportunities. B2B buyers in the fashion accessory space often seek cuff bracelets as promotional items or part of their retail offerings due to their high visibility and ability to showcase unique designs. However, the larger leather pieces required for production can increase costs.

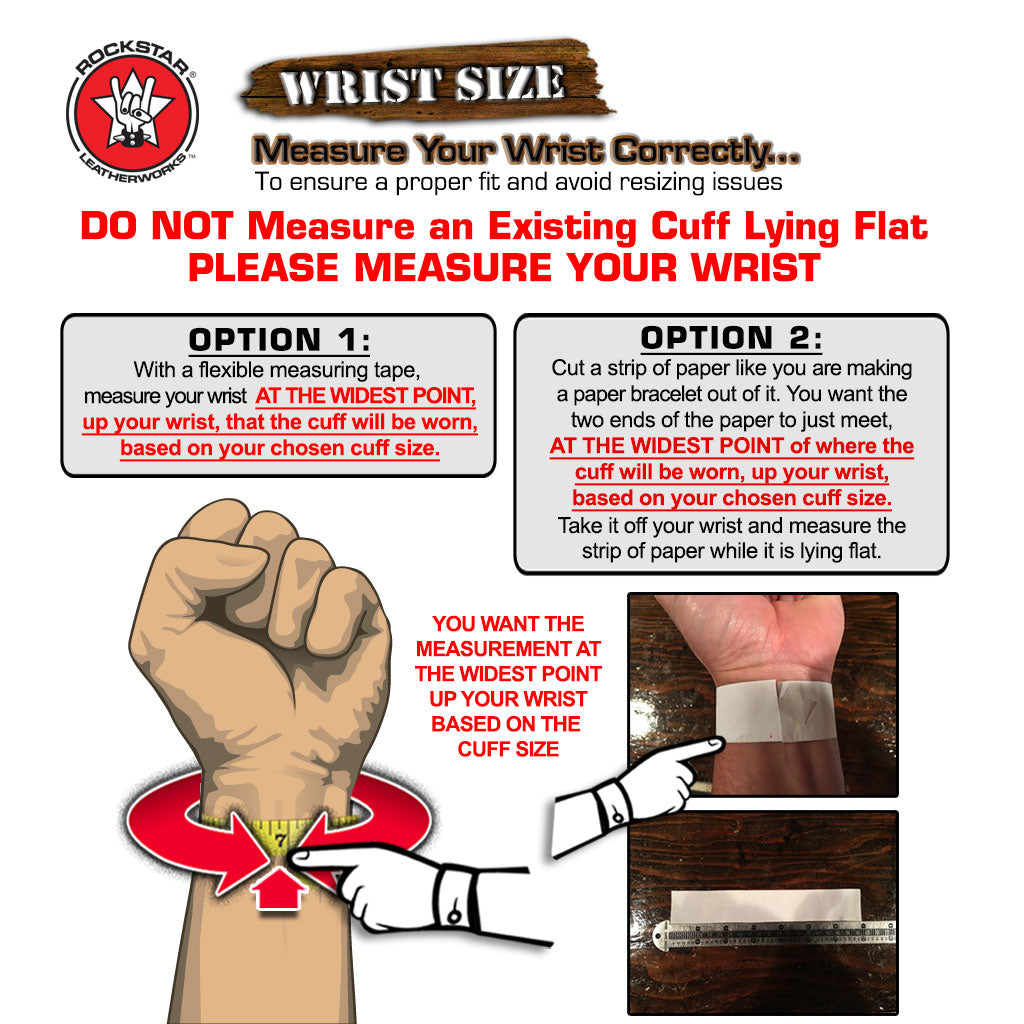

Illustrative image related to how to make leather wristbands

How Do Stamped Leather Bracelets Provide Unique Personalization?

Stamped leather bracelets are distinct due to the personalized messages or designs that are stamped into the leather surface. This makes them ideal for corporate gifts or branding merchandise, allowing companies to convey their values or messages directly to consumers. B2B buyers appreciate the unique touch that these bracelets offer, but the labor-intensive production process can lead to longer lead times and higher costs, which should be considered when planning inventory.

What Makes Beaded Leather Bracelets Versatile for Fashion Retail?

Beaded leather bracelets combine the durability of leather with the aesthetic appeal of beads, offering a textural and colorful accessory. This type of bracelet is particularly popular in fashion retail and artisan markets, where customization and personal expression are key. B2B buyers can benefit from the versatility in design, but they should also consider the complexities of sourcing beads and maintaining inventory, as this can complicate production schedules.

How Do Recycled Leather Bracelets Support Sustainable Practices?

Recycled leather bracelets are crafted from repurposed leather materials, aligning with eco-friendly fashion trends. This approach is increasingly appealing to sustainable fashion brands and artisan shops that prioritize environmental responsibility. While these bracelets can be cost-effective, B2B buyers must be cautious about the quality of the source materials, which can vary significantly and affect the final product.

Why Are Double Wrap Bracelets Popular in Trendy Fashion Lines?

Double wrap bracelets are designed to wrap around the wrist twice, creating a layered effect that is currently popular in fashion. They provide a stylish option that appeals to trend-conscious consumers and can easily be integrated into casual wear collections. However, B2B buyers should be aware that these bracelets require more leather material, which can influence production costs and pricing strategies. Additionally, ensuring a good fit for various wrist sizes can present challenges in production.

Key Industrial Applications of how to make leather wristbands

| Industry/Sector | Specific Application of how to make leather wristbands | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Accessories | Custom leather wristbands for fashion brands | Enhances brand identity and customer loyalty through unique designs | Quality of leather, customization options, and design capabilities |

| Promotional Products | Branded wristbands for events and promotions | Effective marketing tool that increases brand visibility | Cost-effectiveness, durability, and lead times for production |

| Retail and E-commerce | Personalized leather wristbands for online sales | Appeals to niche markets and increases customer engagement | Sourcing materials that allow for quick turnarounds and customization |

| Craft and DIY Industries | Kits for DIY leather wristband making | Promotes creativity and self-expression among consumers | Availability of quality tools and materials for DIY kits |

| Corporate Gifting | Leather wristbands as corporate gifts | Strengthens business relationships and enhances brand image | Customization options and bulk order pricing |

How Can the Fashion Industry Utilize Leather Wristbands for Brand Identity?

In the fashion and accessories sector, leather wristbands serve as a canvas for brands to express their identity. Custom designs can reflect the brand’s ethos, appealing to consumers seeking unique pieces. This not only enhances customer loyalty but also differentiates the brand in a competitive market. Buyers should prioritize high-quality leather and versatile design options to meet diverse customer preferences.

What Role Do Leather Wristbands Play in Promotional Products?

In the realm of promotional products, branded leather wristbands are an effective marketing tool. They can be distributed at events, enhancing brand visibility while offering a tangible takeaway for potential customers. The durability of leather ensures that these wristbands serve as long-lasting reminders of the brand. When sourcing, businesses must consider cost-effectiveness and the ability to produce in bulk without compromising quality.

How Can Retailers Benefit from Personalized Leather Wristbands?

For retail and e-commerce businesses, personalized leather wristbands present an opportunity to cater to niche markets. Offering customization options can significantly enhance customer engagement and satisfaction. Buyers in this sector need to focus on sourcing materials that allow for quick production times and adaptability to various design requests, ensuring they can meet consumer demands promptly.

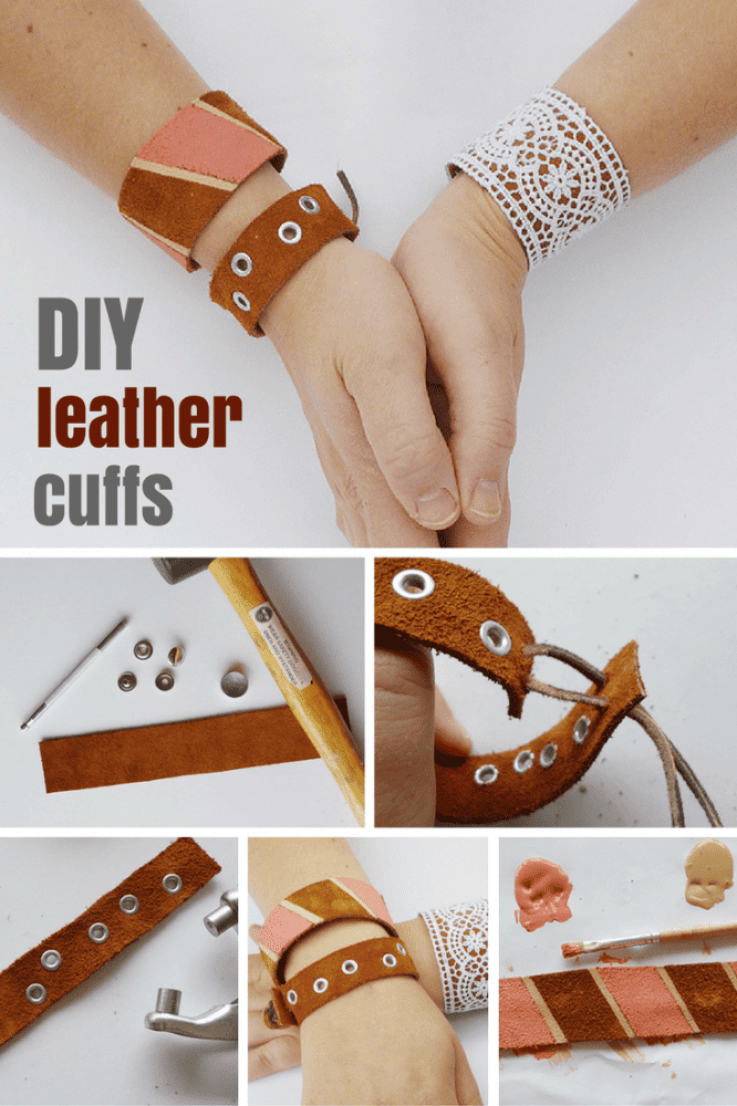

Illustrative image related to how to make leather wristbands

Why Are DIY Leather Wristband Kits Valuable in the Craft Industry?

The craft and DIY industries can leverage leather wristbands by offering kits that allow consumers to create their own pieces. This not only promotes creativity but also taps into the growing trend of personalized and handmade goods. Key sourcing considerations include the availability of quality tools and materials that facilitate a seamless DIY experience, ensuring that consumers have everything they need to succeed.

How Do Leather Wristbands Enhance Corporate Gifting Strategies?

In corporate gifting, leather wristbands can serve as thoughtful and stylish gifts that strengthen business relationships. Customizing these wristbands with company logos or messages enhances brand image and fosters goodwill among clients. For businesses, the focus should be on sourcing options that provide customization flexibility while ensuring bulk order pricing remains competitive.

3 Common User Pain Points for ‘how to make leather wristbands’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Wristbands

The Problem: Many B2B buyers face difficulties in sourcing high-quality leather that meets their design specifications and ethical standards. This challenge is particularly pronounced for companies looking to cater to international markets, where consumer preferences for sustainable and ethically sourced materials are increasingly important. Inadequate knowledge of local suppliers, varying quality standards, and the risk of counterfeit materials can lead to production delays and financial losses.

The Solution: To address these sourcing challenges, it’s essential to establish strong relationships with reputable leather suppliers. Begin by researching and vetting potential suppliers through trade shows, industry associations, or online platforms dedicated to B2B connections. Request samples to assess the quality and consistency of the leather before making bulk purchases. Additionally, consider suppliers who provide transparent information about their sourcing practices and sustainability efforts. This not only ensures you are receiving quality materials but also enhances your brand’s credibility in the eyes of environmentally conscious consumers.

Scenario 2: Mastering the Craft of Leather Working Techniques

The Problem: A common hurdle for businesses entering the leather wristband market is the lack of skilled artisans who can execute complex designs and techniques. Many companies may struggle to find employees proficient in leatherworking, leading to subpar products that fail to meet customer expectations. Moreover, insufficient training programs can hinder the development of in-house talent, resulting in a reliance on outsourced labor, which can be costly and inconsistent.

Illustrative image related to how to make leather wristbands

The Solution: Invest in comprehensive training programs for your staff to develop their leatherworking skills. Collaborate with experienced leather artisans to conduct workshops that cover essential techniques such as cutting, stamping, and finishing. Online courses and tutorials can also provide valuable resources for employees to learn at their own pace. By fostering a culture of craftsmanship within your organization, you not only enhance product quality but also empower your workforce, which can lead to greater employee satisfaction and retention.

Scenario 3: Navigating Regulatory Compliance in International Markets

The Problem: When producing leather wristbands for international markets, B2B buyers often encounter regulatory challenges related to material sourcing, environmental impact, and product safety. Different regions have varying regulations regarding the use of certain chemicals in leather treatment and the environmental practices of production facilities. Failure to comply with these regulations can result in fines, product recalls, or damage to brand reputation.

The Solution: To successfully navigate these regulatory landscapes, it is crucial to stay informed about the specific compliance requirements in each target market. Engage with legal consultants who specialize in international trade regulations to ensure your practices align with local laws. Regularly review and update your sourcing and production processes to incorporate sustainable practices that meet or exceed regulatory standards. Additionally, consider obtaining certifications such as ISO or Fair Trade, which can enhance your brand’s reputation and appeal to ethically minded consumers. By prioritizing compliance, you can mitigate risks and position your business for success in diverse markets.

Illustrative image related to how to make leather wristbands

Strategic Material Selection Guide for how to make leather wristbands

When selecting materials for crafting leather wristbands, it is essential to consider various factors that affect product performance, manufacturing complexity, and market compliance. The following analysis delves into four common materials used in leather wristband production, providing insights tailored for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Full-Grain Leather for Wristbands?

Full-grain leather is renowned for its durability and natural appearance. This material retains the original grain of the hide, making it highly breathable and resistant to wear and tear. Full-grain leather can withstand varying temperatures and pressures, making it suitable for outdoor use. Its natural oils provide some level of water resistance, although it is not entirely waterproof.

Pros: Full-grain leather is exceptionally durable and develops a unique patina over time, enhancing its aesthetic appeal. It is also easy to work with for various designs and can be dyed or stamped for customization.

Cons: The primary drawback is its cost, as full-grain leather is one of the more expensive options. Additionally, it requires more maintenance to keep it looking its best, as it can absorb moisture and dirt.

Impact on Application: Full-grain leather is ideal for high-end wristbands that target luxury markets. Its compatibility with various decorative techniques makes it suitable for personalized products.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding leather sourcing and treatment, particularly in regions with strict animal welfare laws. Standards such as ASTM D-2000 may apply.

How Does Top-Grain Leather Compare for Making Wristbands?

Top-grain leather is a slightly lower grade than full-grain leather, as it has been sanded and treated to remove imperfections. While it retains many of the desirable properties of full-grain leather, it is less durable and has a less pronounced natural grain.

Pros: Top-grain leather is more affordable than full-grain leather while still offering a good balance of durability and aesthetics. It is also easier to maintain, as it is less prone to staining.

Cons: The main limitation is its reduced lifespan compared to full-grain leather. It may not develop the same depth of character over time, making it less appealing for luxury products.

Impact on Application: This material is well-suited for mid-range wristbands that require a balance of quality and cost-effectiveness.

Considerations for International Buyers: Ensure that the leather meets local environmental regulations, particularly in Europe, where standards for chemical treatments are stringent.

What Are the Benefits of Using Recycled Leather for Wristbands?

Recycled leather, often derived from scraps or discarded leather products, offers an eco-friendly alternative for wristband production. This material can vary significantly in quality and appearance, depending on the source.

Pros: The primary advantage of recycled leather is its sustainability, appealing to environmentally conscious consumers. It is often more affordable than new leather and can be used creatively to produce unique designs.

Cons: The variability in quality can be a concern, as some recycled leather may not be as durable or aesthetically pleasing as new leather. Additionally, the sourcing process can be inconsistent.

Impact on Application: Recycled leather is ideal for brands targeting eco-friendly markets, allowing for innovative designs that tell a sustainability story.

Considerations for International Buyers: Buyers should verify the sourcing and treatment processes to ensure compliance with environmental regulations, especially in markets like the EU where sustainability is prioritized.

Why Consider Synthetic Leather for Wristbands?

Synthetic leather, or faux leather, is made from materials like polyurethane or PVC. It mimics the appearance of genuine leather while offering different performance characteristics.

Pros: Synthetic leather is typically more affordable and easier to clean than natural leather. It is also available in a wide range of colors and textures, allowing for extensive customization.

Cons: The main disadvantage is that synthetic leather may not be as durable as genuine leather and can degrade over time, particularly when exposed to heat or moisture.

Impact on Application: Synthetic leather is suitable for budget-conscious consumers and can be used for trendy, fashion-forward wristbands.

Considerations for International Buyers: Compliance with regulations regarding synthetic materials is crucial, particularly in regions that emphasize sustainability and environmental impact.

| 素材 | Typical Use Case for how to make leather wristbands | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end luxury wristbands | Exceptional durability and aesthetics | High cost and maintenance required | 高い |

| Top-Grain Leather | Mid-range wristbands | Good balance of quality and price | Less durable than full-grain leather | Medium |

| Recycled Leather | Eco-friendly wristbands | Sustainable and unique designs | Variable quality and sourcing issues | 低い |

| Synthetic Leather | Budget-friendly and trendy wristbands | Affordable and easy to clean | Less durable than genuine leather | 低い |

This strategic material selection guide equips B2B buyers with the necessary insights to make informed decisions regarding leather wristband production, considering both performance and market compliance.

Illustrative image related to how to make leather wristbands

In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather wristbands

What Are the Key Stages in the Manufacturing Process of Leather Wristbands?

The manufacturing process of leather wristbands involves several critical stages, each requiring specific techniques and materials to ensure high-quality outputs. These stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Leather Wristbands?

Material preparation begins with sourcing high-quality leather, which can vary in thickness and texture depending on the desired final product. Tanners often utilize a range of methods, including vegetable tanning or chrome tanning, to produce leather that meets the durability and aesthetic requirements of wristbands.

Once the leather is sourced, it undergoes cutting, where patterns for wristbands are marked and cut using tools such as rotary cutters or laser cutting machines. Precision in this stage is crucial, as it ensures consistency in size and shape across batches.

What Techniques Are Used in Forming Leather Wristbands?

The forming stage involves shaping the leather into the desired wristband structure. Techniques such as stamping, embossing, or laser engraving can be applied to add decorative elements or branding. This not only enhances the aesthetic appeal but also allows for personalization, which is a growing trend in the wristband market.

Additionally, techniques like dyeing and finishing can be applied at this stage to achieve specific colors or textures. B2B buyers should ensure that suppliers utilize eco-friendly dyes and processes, as sustainability is increasingly important to consumers.

How Are Leather Wristbands Assembled?

Assembly is where the individual components come together to form the final wristband product. This typically involves attaching closures, such as snaps or buckles, and adding decorative elements like beads or charms. Skilled artisans often perform this task to maintain a high level of craftsmanship, which is particularly valued in luxury markets.

In larger-scale manufacturing, automated assembly lines may be utilized, but quality should not be compromised. It’s essential for B2B buyers to inquire about the balance between automation and manual craftsmanship to ensure the product meets their quality expectations.

What Finishing Processes Are Essential for Leather Wristbands?

The finishing stage is critical for enhancing the durability and overall appearance of leather wristbands. This may involve applying protective coatings, polishing, or conditioning the leather to prevent cracking and ensure longevity. Quality control checks should be performed at this stage to catch any defects before the product is shipped.

Illustrative image related to how to make leather wristbands

Buyers should look for suppliers that implement finishing processes aligned with international standards, as this can significantly impact the product’s marketability.

What Quality Assurance Practices Should Be in Place for Leather Wristbands?

Quality assurance (QA) is an integral part of the manufacturing process for leather wristbands, ensuring that products meet industry standards and customer expectations. Effective QA practices should be established at multiple checkpoints throughout the production process.

Which International Standards Are Relevant for Leather Wristband Manufacturing?

International standards such as ISO 9001 provide a framework for quality management systems, which can help suppliers establish consistent quality across their production processes. Compliance with these standards indicates that a supplier has implemented systematic processes to manage quality effectively.

In addition, industry-specific certifications like CE marking (for products sold in the European Economic Area) or API standards (for certain specialized applications) may also be relevant depending on the target market.

What Are the Key Quality Control Checkpoints in Leather Wristband Manufacturing?

Quality control should be implemented at several critical points throughout the manufacturing process:

Illustrative image related to how to make leather wristbands

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet predefined specifications. For leather wristbands, checking for imperfections, thickness, and color consistency is crucial.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. Techniques such as visual inspections and measurements can help ensure that each stage adheres to quality standards.

-

Final Quality Control (FQC): Before shipping, final inspections should be conducted to assess the overall quality of the wristbands. This includes checking for assembly integrity, finish quality, and packaging standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. This can include:

-

Conducting Audits: Regular audits can provide insights into a supplier’s quality management systems and practices. Buyers may consider scheduling on-site visits to evaluate production facilities and processes.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation of their quality control processes, including inspection reports and certifications.

-

Engaging Third-Party Inspection Services: Independent third-party inspections can provide an unbiased assessment of product quality before shipment. This is especially important for international transactions, where buyers may not have direct access to the manufacturing facility.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of the nuances that can affect quality control in different regions. For instance, varying regulations, cultural practices, and material availability can impact the manufacturing process and quality standards.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following:

-

Local Regulations: Understanding local manufacturing regulations and standards can help ensure compliance and avoid potential legal issues.

-

Supply Chain Transparency: Establishing clear communication and transparency within the supply chain can help mitigate risks associated with quality inconsistencies.

-

Cultural Sensitivity: Being aware of cultural practices can enhance relationships with suppliers, which can lead to improved quality and collaboration.

In conclusion, the manufacturing processes and quality assurance practices for leather wristbands are multifaceted and require careful consideration. B2B buyers should prioritize working with suppliers who demonstrate a commitment to quality at every stage of production, ensuring that the final products meet both their standards and those of their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather wristbands’

To aid B2B buyers in procuring leather wristbands, this practical guide outlines essential steps for sourcing materials, suppliers, and production techniques. This checklist ensures a streamlined approach to acquiring high-quality leather wristbands, suitable for various markets.

Illustrative image related to how to make leather wristbands

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the leather wristbands meet your quality and design requirements. Consider factors such as leather type (e.g., full-grain, top-grain), thickness, color, and treatment. This clarity will help you communicate effectively with suppliers and avoid misunderstandings later in the sourcing process.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers specializing in leather products. Use industry directories, trade shows, and online platforms to find reputable manufacturers. Pay attention to their experience in producing wristbands and their capacity to fulfill your order volume.

Step 3: Evaluate Supplier Certifications and Compliance

Before entering into any agreements, it’s crucial to assess suppliers’ certifications and compliance with international quality standards. Look for certifications such as ISO 9001 for quality management and any relevant environmental certifications. This step ensures that the supplier adheres to ethical practices and provides high-quality materials.

Step 4: Request Samples for Quality Assurance

Always request samples of leather wristbands or materials before placing a bulk order. This allows you to evaluate the quality, craftsmanship, and durability of the products. Assess the samples for aspects like texture, color consistency, and stitching quality to ensure they align with your brand’s standards.

Step 5: Negotiate Pricing and Terms of Supply

Once you’ve identified a potential supplier and evaluated their products, negotiate pricing and terms. Discuss minimum order quantities, payment terms, lead times, and shipping options. Ensure that the pricing is competitive and reflects the quality of the materials, while also considering your target market’s price sensitivity.

Step 6: Establish Clear Communication Channels

Establishing effective communication channels with your supplier is essential for a successful partnership. Ensure that both parties agree on a point of contact for ongoing discussions and issue resolution. This clarity can prevent delays and misunderstandings during the production and delivery phases.

Step 7: Plan for Logistics and Distribution

Finally, develop a logistics plan for how the wristbands will be transported to your location or directly to customers. Consider factors such as shipping methods, import/export regulations, and storage needs. A well-thought-out logistics strategy can minimize delays and ensure timely delivery, enhancing customer satisfaction.

Illustrative image related to how to make leather wristbands

By following these steps, B2B buyers can effectively source high-quality leather wristbands that meet market demands and enhance their product offerings.

Comprehensive Cost and Pricing Analysis for how to make leather wristbands Sourcing

When sourcing leather wristbands, understanding the comprehensive cost structure is vital for B2B buyers. This section will break down the key components of costs involved, the influencers on pricing, and provide actionable tips for effective negotiation and purchasing strategies.

What Are the Key Cost Components in Leather Wristband Manufacturing?

-

Materials: The primary cost component includes the leather itself, which can vary significantly based on quality (genuine leather, synthetic alternatives, or recycled materials). Additional materials such as snaps, beads, or decorative elements will also contribute to the total material costs. For instance, eco-friendly or premium leather may increase costs by 20-30%.

-

Labor: Labor costs depend on the complexity of the wristband design. Simple designs may require less skilled labor, while intricate ones necessitate artisans with specialized skills. Labor costs can range from $1 to $5 per wristband depending on the region, with lower costs in countries like Vietnam or Brazil compared to European markets.

-

Manufacturing Overhead: This includes expenses such as utilities, rent, and administrative costs associated with the production facility. On average, manufacturing overhead can add 15-25% to the total production cost.

-

Tooling: Custom designs may require unique tooling or molds, which can be a significant upfront investment. Depending on the design complexity, tooling costs can range from a few hundred to several thousand dollars.

-

Quality Control (QC): Ensuring product quality is paramount, especially for international buyers. QC measures can add an additional 5-10% to the overall production cost but are essential for maintaining standards and avoiding costly returns.

-

Logistics: Shipping and handling costs must be factored in, especially for international shipments. These can fluctuate based on shipping methods, distance, and Incoterms (e.g., FOB, CIF). Logistics costs may add 10-20% to the overall cost depending on the chosen shipping route and method.

-

Margin: Suppliers typically mark up costs to ensure profitability. A standard margin in the leather goods industry is around 20-40%. Buyers should be aware of this when negotiating prices.

How Do Price Influencers Impact Leather Wristband Costs?

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounts. Buyers should negotiate MOQs that align with their sales forecasts to maximize cost-efficiency.

-

Specifications and Customization: Custom designs or specific quality certifications (e.g., eco-friendly or cruelty-free) can increase costs. Buyers should clarify these requirements early in negotiations to avoid unexpected expenses.

-

Material Choices: The choice between different types of leather (e.g., full-grain, top-grain) significantly affects pricing. Understanding the properties and market value of materials can guide better purchasing decisions.

-

Supplier Factors: Supplier reputation, location, and reliability can influence pricing. Established suppliers may charge more but offer better quality assurance and reliability.

-

Incoterms: Understanding shipping terms is crucial. For instance, choosing FOB (Free on Board) can shift more responsibility to the buyer, affecting overall costs.

What Are the Best Buyer Tips for Cost-Efficiency in Leather Wristband Sourcing?

-

Negotiation: Engage in open discussions about pricing and explore bulk purchase discounts. Establishing long-term relationships with suppliers can lead to better terms and prices.

-

Total Cost of Ownership (TCO): Consider all associated costs beyond just the purchase price. Factors like shipping, potential returns, and quality-related expenses should be evaluated to determine the true cost.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa or South America may face additional tariffs or trade regulations. It’s essential to research these aspects to avoid unexpected costs.

-

Market Research: Regularly analyze market trends and competitor pricing to stay informed. Understanding the market landscape can provide leverage during negotiations.

Disclaimer

Pricing information provided here is indicative and subject to change based on market fluctuations, supplier negotiations, and specific buyer requirements. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing how to make leather wristbands With Other Solutions

Exploring Alternatives for Creating Leather Wristbands

When considering how to make leather wristbands, it’s essential to evaluate alternative solutions that can achieve similar outcomes. This analysis will compare traditional leather wristband-making methods with two viable alternatives: using synthetic materials and utilizing 3D printing technology. Each method has its unique advantages and disadvantages that can impact B2B buyers’ decisions.

Comparison Table

| Comparison Aspect | How To Make Leather Wristbands | Synthetic Material Wristbands | 3D Printed Wristbands |

|---|---|---|---|

| Performance | High durability and aesthetic appeal | Moderate durability, can vary in quality | High precision, customizable designs |

| Cost | Moderate, depending on leather quality | Generally lower, but varies by type | Initial investment in printer, but low material costs |

| Ease of Implementation | Requires skilled craftsmanship | Easy to mass-produce, minimal skills required | Requires technical knowledge for design and printing |

| Maintenance | Requires occasional conditioning | Low maintenance, but may degrade over time | Minimal, durable unless damaged |

| Best Use Case | Custom, high-quality fashion items | Promotional items or bulk orders | Unique, intricate designs and prototypes |

Detailed Breakdown of Alternatives

Synthetic Material Wristbands

Using synthetic materials like polyurethane or vinyl provides a cost-effective alternative to leather. These materials can be produced quickly and in bulk, making them ideal for promotional items or mass-market wristbands. The primary advantage lies in their affordability and ease of production, which can appeal to businesses looking to minimize costs. However, synthetic wristbands may not offer the same level of durability or aesthetic appeal as genuine leather, potentially affecting brand perception for high-end products. Additionally, they might not provide the same comfort level as leather, especially for extended wear.

3D Printed Wristbands

3D printing technology represents a cutting-edge method for creating wristbands. This approach allows for high customization and intricate designs that can be tailored to specific branding needs. The precision of 3D printing enables businesses to create unique wristbands that stand out in the market. However, the initial investment in 3D printing equipment can be substantial, and the learning curve for designing and operating the printer can be steep. While the material costs are relatively low, the setup and maintenance of 3D printers require skilled personnel, which may not be feasible for all businesses.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, the choice between making leather wristbands and exploring alternatives depends on specific business objectives, budget constraints, and desired product quality. If you aim to create high-end, durable products that resonate with consumers, traditional leather wristbands may be the best option. Conversely, if cost-effectiveness and quick production are priorities, synthetic materials could be more suitable. Lastly, for businesses looking to innovate and offer unique designs, 3D printing could provide a competitive edge. By carefully evaluating these factors, buyers can select the method that aligns best with their strategic goals.

Essential Technical Properties and Trade Terminology for how to make leather wristbands

What Are the Key Technical Properties of Leather Wristbands?

When producing leather wristbands, understanding the technical properties of materials is essential for ensuring product quality and consistency. Here are some critical specifications that B2B buyers should consider:

-

Material Grade

Leather comes in various grades, such as full-grain, top-grain, and genuine leather. Full-grain leather is the highest quality, retaining the natural grain and durability, making it ideal for high-end wristbands. Understanding the material grade is crucial for targeting the right market segment and ensuring product longevity. -

Thickness

The thickness of the leather, typically measured in millimeters (mm), significantly impacts the wristband’s strength and flexibility. For example, a thickness of 1.5mm to 2.5mm is commonly used for standard wristbands, balancing durability and comfort. Selecting the appropriate thickness is vital for achieving the desired aesthetic and functional qualities. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions during production. Maintaining tight tolerances ensures that the wristbands fit consistently across different batches. For instance, a tolerance of ±0.5mm in width and length can prevent issues in production and enhance customer satisfaction, especially for custom orders. -

Finish Type

The finish of the leather can affect its appearance and usability. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather retains its natural look but is less resistant to stains, while pigmented leather offers durability and easier maintenance. Buyers should specify the finish type to match customer preferences and market demands. -

Color Fastness

This property measures the leather’s ability to retain color under various conditions, such as exposure to light, water, and friction. Color fastness is critical for ensuring that wristbands maintain their visual appeal over time. Conducting tests for color fastness can prevent returns and enhance brand reputation.

What Are Common Trade Terms in Leather Wristband Manufacturing?

Understanding industry jargon is vital for effective communication and negotiation in the leather wristband market. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather wristband industry, OEM services allow businesses to have their designs manufactured without investing in production facilities, facilitating quicker market entry. -

MOQ (Minimum Order Quantity)

MOQ is the smallest order quantity that a supplier is willing to process. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Understanding MOQs helps businesses plan their purchases to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. In the context of leather wristbands, an RFQ allows buyers to compare prices and terms from multiple suppliers, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Knowing the relevant Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for understanding shipping costs and liabilities. -

Lead Time

Lead time refers to the amount of time between placing an order and receiving the goods. In the leather wristband industry, lead time can vary based on production capacity and order complexity. Shorter lead times can provide competitive advantages, particularly in fast-paced markets. -

Customization

This term refers to the ability to tailor products to meet specific customer requirements, such as size, color, or design. Offering customization options in leather wristbands can increase market appeal and allow businesses to cater to niche markets.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring their leather wristbands meet market standards and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the how to make leather wristbands Sector

What are the Key Market Drivers and Trends for Leather Wristbands?

The leather wristband market is witnessing significant growth fueled by a combination of fashion trends, sustainability awareness, and technological advancements. Global demand for personalized and handcrafted products is on the rise, particularly among consumers looking for unique accessories. In regions like Africa and South America, local artisans are increasingly leveraging traditional techniques to create distinctive leather wristbands, catering to both local and international markets.

Emerging technologies such as laser cutting and 3D printing are transforming production methods, enabling manufacturers to create intricate designs with precision. Furthermore, the rise of e-commerce platforms allows B2B buyers to source leather wristbands from various suppliers worldwide, fostering competition and driving innovation. Notably, market dynamics are shifting toward customization and personalization, with buyers seeking options that reflect their brand identity or consumer preferences.

In Europe and the Middle East, the trend is leaning towards minimalist designs combined with high-quality materials, appealing to a demographic that values both style and durability. B2B buyers in these regions are also increasingly focused on suppliers that can provide detailed product specifications and ensure consistent quality, which is crucial for maintaining their brand reputation.

How is Sustainability and Ethical Sourcing Influencing the Leather Wristband Sector?

Sustainability has become a cornerstone of the leather wristband industry, reflecting a growing consumer demand for ethically sourced materials. B2B buyers are now prioritizing suppliers who can demonstrate sustainable practices, such as using vegetable-tanned leather or recycled materials. This shift is driven by an increasing awareness of the environmental impact of traditional leather production, which often involves harmful chemicals and unsustainable sourcing practices.

Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential for suppliers aiming to appeal to conscious buyers. These certifications not only assure buyers of the eco-friendliness of their products but also enhance brand credibility in the marketplace. Additionally, companies are exploring innovative materials such as mushroom leather and synthetic alternatives that reduce reliance on animal hides, further aligning with sustainable practices.

As B2B buyers seek to enhance their corporate social responsibility (CSR) profiles, the importance of transparency in the supply chain cannot be overstated. Buyers are increasingly demanding detailed information about sourcing practices, labor conditions, and environmental impacts, ensuring that their purchasing decisions align with their ethical standards.

How has the Leather Wristband Market Evolved Over Time?

Historically, leather wristbands have been utilized for practical purposes, such as securing items or as symbols of status. Over the years, they have evolved into fashion statements, reflecting personal style and cultural identity. In the late 20th century, the popularity of leather wristbands surged with the rise of punk and rock music cultures, embedding them in the fashion lexicon.

The 21st century has seen a significant transformation in the leather wristband market, as consumers began to favor artisanal craftsmanship and personalized designs. This evolution has been influenced by a growing appreciation for handmade products and the unique stories behind them. Today, the sector is marked by innovation, blending traditional techniques with modern aesthetics, which resonates well with the contemporary consumer’s desire for authenticity and individuality.

As the market continues to adapt to consumer preferences and global challenges, B2B buyers must stay informed about these dynamics to effectively navigate sourcing decisions in the leather wristband sector.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather wristbands

-

How do I solve quality issues when sourcing leather wristbands?

To address quality issues, it’s crucial to establish clear quality assurance (QA) protocols with your suppliers. Begin by requesting samples to evaluate the leather’s texture, durability, and finish. Utilize third-party inspection services to conduct quality checks before shipment, especially for bulk orders. Additionally, maintain open communication with suppliers to clarify specifications and expectations. Implementing a feedback loop can help resolve any discrepancies early, ensuring that the final products meet your quality standards. -

What is the best material for making leather wristbands?

The best materials for leather wristbands include full-grain and top-grain leather, as they offer durability, comfort, and a luxurious appearance. Full-grain leather, known for its natural imperfections, develops a unique patina over time, enhancing its aesthetic appeal. Top-grain leather, while slightly processed, is more affordable and still provides a high-quality finish. Consider the intended use of the wristbands—promotional items may require a more cost-effective option, whereas high-end fashion lines may benefit from premium materials. -

How can I customize leather wristbands for my brand?

Customization options for leather wristbands include embossing, stamping, or dyeing to incorporate your brand’s logo or specific designs. You can also choose from various leather colors, widths, and fastening mechanisms to create a unique product. Collaborate with your supplier to discuss available techniques and any minimum order quantities (MOQs) that may apply. Creating a prototype can help visualize the final product and make necessary adjustments before full-scale production. -

What are the typical minimum order quantities (MOQs) for leather wristbands?

MOQs for leather wristbands can vary significantly based on the supplier and the complexity of customization. Generally, you may encounter MOQs ranging from 100 to 500 units for standard designs, while highly customized products may require higher quantities. It’s advisable to communicate your needs early in the negotiation process to find a supplier willing to accommodate smaller orders or flexible arrangements, particularly if you’re testing a new market. -

What payment terms should I expect when sourcing leather wristbands?

Payment terms can vary by supplier and location, but common practices include a deposit (typically 30-50%) upfront with the balance due upon completion or before shipping. Some suppliers may offer net payment terms, allowing payment within a specified timeframe after delivery. Always clarify these terms in your contract to avoid misunderstandings. Additionally, consider using secure payment methods that provide buyer protection, especially for international transactions. -

How do I vet suppliers for leather wristbands effectively?

Vetting suppliers involves researching their reputation, production capabilities, and compliance with international standards. Look for reviews and testimonials from other B2B buyers, and consider visiting their facilities if possible. Request certifications, such as ISO or eco-friendly credentials, to ensure they adhere to quality and environmental standards. Building a relationship with potential suppliers can also provide insights into their reliability and business practices. -

What logistics considerations should I keep in mind when importing leather wristbands?

When importing leather wristbands, consider shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder experienced in handling leather goods to navigate the complexities of international shipping. Understand the import regulations in your country, as leather products may require specific documentation or compliance with regulations. Additionally, factor in lead times for production and shipping to manage customer expectations effectively. -

How can I ensure timely delivery of leather wristbands?

To ensure timely delivery, establish clear timelines with your supplier from the outset. Discuss production schedules and build in buffer time for unexpected delays. Regularly communicate with your supplier during the production phase to monitor progress. Utilizing tracking services during shipping can also help you stay informed about the delivery status. By proactively managing the logistics and maintaining open lines of communication, you can minimize delays and meet your market demands effectively.

Top 4 How To Make Leather Wristbands Manufacturers & Suppliers List

1. Weaver Leather Supply – Leather Bracelets

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Bracelets available include: Wristlet Keychain, Cuff Bracelet with Cross Hatch, Double Wrap Cuff Leather Bracelet, Leather Cuff Bracelet, Mystery Braid Cuff, Wrist Bands, Bund Style Watchband, Spanish Basket Weave Cuff.

2. Glowforge – Braided Leather Wristbands

Domain: community.glowforge.com

Registered: 2014 (11 years)

Introduction: Braided Leather Wristbands – Free Laser Designs

3. Pinterest – DIY Leather Bracelet Ideas

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: DIY leather bracelet ideas, 15 easy patterns, diverse designs including braided leather cords and gold-leaf accents, personal flair, wallet-friendly, eco-conscious choice.

4. Instructables – Recycled Leather Bracelets

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Leather bracelets made from recycled belts. Each belt can yield three bracelets. The process involves decorating the belt (using techniques like laser cutting or leather stamping), measuring and cutting the belt to fit, marking locations for holes, drilling or punching holes, and attaching heavy-duty snaps for closure. The final product can be worn or gifted.

Strategic Sourcing Conclusion and Outlook for how to make leather wristbands

In conclusion, the journey of creating leather wristbands offers substantial opportunities for B2B buyers across diverse markets. Key takeaways include the importance of sourcing high-quality leather, understanding the craftsmanship involved, and leveraging innovative techniques such as recycling materials for sustainability. By investing in strategic sourcing, businesses can enhance their product offerings, cater to the growing consumer demand for unique, eco-friendly accessories, and ultimately increase their market competitiveness.

As international buyers from regions like Africa, South America, the Middle East, and Europe explore these avenues, it is essential to embrace partnerships with reliable suppliers who prioritize quality and sustainability. This not only ensures a robust supply chain but also aligns with the evolving consumer preferences for ethically sourced products.

Looking ahead, the leather wristband market is poised for growth, driven by trends in personalization and eco-consciousness. Now is the opportune moment for B2B buyers to engage with manufacturers and artisans who can bring innovative designs to life. By taking action today, you can position your business at the forefront of this thriving industry, creating products that resonate with consumers and stand out in a competitive landscape.

Illustrative image related to how to make leather wristbands

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.