Introduction: Navigating the Global Market for leather jacket custom embroidery

In the competitive landscape of the global market for leather jacket custom embroidery, B2B buyers face the challenge of sourcing quality products that meet diverse consumer demands while ensuring brand identity and uniqueness. The intricacies of custom embroidery not only enhance the aesthetic appeal of leather jackets but also provide opportunities for businesses to stand out in saturated markets, particularly in regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Nigeria.

This comprehensive guide delves into the multifaceted world of leather jacket custom embroidery, covering essential aspects such as types of embroidery techniques, applications across different industries, and strategies for effective supplier vetting. Additionally, it offers insights into cost considerations and quality assurance, enabling buyers to make informed decisions that align with their business goals.

By equipping international B2B buyers with actionable insights and practical knowledge, this guide empowers you to navigate the complexities of sourcing custom embroidered leather jackets. Whether you are a retailer seeking to expand your product line or a fashion brand aiming to create bespoke offerings, understanding the nuances of this market is crucial for achieving success and enhancing brand loyalty.

Table Of Contents

- Top 8 Leather Jacket Custom Embroidery Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather jacket custom embroidery

- Understanding leather jacket custom embroidery Types and Variations

- Key Industrial Applications of leather jacket custom embroidery

- 3 Common User Pain Points for ‘leather jacket custom embroidery’ & Their Solutions

- Strategic Material Selection Guide for leather jacket custom embroidery

- In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket custom embroidery

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket custom embroidery’

- Comprehensive Cost and Pricing Analysis for leather jacket custom embroidery Sourcing

- Alternatives Analysis: Comparing leather jacket custom embroidery With Other Solutions

- Essential Technical Properties and Trade Terminology for leather jacket custom embroidery

- Navigating Market Dynamics and Sourcing Trends in the leather jacket custom embroidery Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket custom embroidery

- Strategic Sourcing Conclusion and Outlook for leather jacket custom embroidery

- Important Disclaimer & Terms of Use

Understanding leather jacket custom embroidery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Logo Embroidery | Company logos or brand names prominently displayed | Corporate apparel, promotional items | Pros: Enhances brand visibility; Cons: Limited customization options. |

| Personalized Text Embroidery | Custom names, initials, or messages | Gifts, personal branding, team uniforms | Pros: Adds a personal touch; Cons: May require additional setup time. |

| Artistic Design Embroidery | Unique designs, patterns, or artwork | Fashion retailers, custom apparel lines | Pros: High visual appeal; Cons: More expensive due to complexity. |

| Military/Club Insignia | Specific symbols or patches representing affiliations | Military, motorcycle clubs, organizations | Pros: Fosters community identity; Cons: May have restrictions on designs. |

| Decorative Stitching | Intricate stitching patterns enhancing overall design | High-end fashion, bespoke leather goods | Pros: Elevates product aesthetics; Cons: Can increase production time. |

What Are the Key Features of Logo Embroidery for Leather Jackets?

Logo embroidery involves stitching company logos or brand names onto leather jackets. This type is especially popular among businesses looking to promote their brand through corporate apparel or promotional items. B2B buyers should consider the visibility and durability of the embroidery, as well as the potential for bulk orders, which can reduce costs. However, it may offer limited customization options compared to other types.

How Does Personalized Text Embroidery Enhance Leather Jackets?

Personalized text embroidery allows for the addition of names, initials, or custom messages, making it a great choice for gifts, team uniforms, or personal branding. This type of embroidery can enhance customer loyalty and brand recognition. B2B buyers should weigh the benefits of personalization against potential setup times and costs, especially if they require unique designs for multiple clients.

What Makes Artistic Design Embroidery Stand Out?

Artistic design embroidery features unique patterns, graphics, or artwork that can significantly elevate the visual appeal of leather jackets. This type is ideal for fashion retailers and custom apparel lines aiming to differentiate their products in a competitive market. B2B buyers should consider the complexity of designs, as intricate artwork can lead to higher production costs and longer lead times, but can also command a premium price point.

Why Choose Military/Club Insignia Embroidery?

Military or club insignia embroidery typically includes specific symbols or patches that represent affiliations, making it popular among military organizations and motorcycle clubs. This type fosters a sense of community and belonging among members. B2B buyers should be aware of any restrictions on designs and ensure they comply with regulations, as this can affect their purchasing decisions.

How Does Decorative Stitching Add Value to Leather Jackets?

Decorative stitching enhances the overall design of leather jackets through intricate patterns and styles. This type is often found in high-end fashion and bespoke leather goods, appealing to buyers looking for unique and luxurious products. However, B2B purchasers should consider the impact of decorative stitching on production time and costs, as it can complicate the manufacturing process and increase the final price.

Key Industrial Applications of leather jacket custom embroidery

| Industry/Sector | Specific Application of Leather Jacket Custom Embroidery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom branding for fashion lines | Enhances brand identity and customer loyalty | Quality materials, design flexibility, and turnaround time |

| Automotive | Embroidered jackets for automotive clubs and events | Builds community and brand recognition among enthusiasts | Compliance with safety standards and customization options |

| Hospitality | Staff uniforms with embroidered logos | Professional appearance and brand reinforcement | Durability, comfort, and easy maintenance |

| Sports and Recreation | Custom team jackets with logos and player names | Fosters team spirit and unity | Sizing options, fabric quality, and embroidery detail |

| Corporate Promotions | Promotional jackets for corporate gifts | Effective marketing tool and employee engagement | Customization capabilities and bulk order pricing |

How is Leather Jacket Custom Embroidery Used in the Fashion Retail Sector?

In the fashion retail industry, leather jacket custom embroidery serves as a powerful branding tool. Retailers can enhance their brand identity by adding logos or unique designs, making their products stand out in a competitive market. This application not only attracts customers but also fosters brand loyalty. For international B2B buyers, sourcing high-quality materials and ensuring design flexibility are critical, as they may be catering to diverse markets with varying tastes and preferences.

What Role Does Custom Embroidery Play in the Automotive Industry?

In the automotive sector, custom embroidered leather jackets are often produced for automotive clubs and events. These jackets can feature club logos, event names, or personalized designs, creating a sense of community among members. This application solves the problem of brand recognition and enhances the social aspect of automotive culture. Buyers in this sector need to ensure compliance with safety standards while also exploring various customization options to meet the specific demands of their clientele.

How Does Custom Embroidery Benefit the Hospitality Industry?

The hospitality industry utilizes leather jacket custom embroidery for staff uniforms, which can include embroidered logos or names. This application enhances the professional appearance of employees, thereby reinforcing the brand image of the establishment. For B2B buyers in this sector, sourcing durable and comfortable materials is essential, as uniforms must withstand frequent use while maintaining a polished look. Additionally, ease of maintenance is a key consideration, ensuring that jackets remain presentable over time.

In What Ways are Custom Embroidered Jackets Used in Sports and Recreation?

In sports and recreation, custom embroidered jackets are popular for teams, featuring logos and player names. This application fosters team spirit and unity, making members feel part of a cohesive unit. B2B buyers in this sector need to consider various sizing options and the quality of fabric to ensure a comfortable fit for all team members. Additionally, the level of detail in the embroidery is crucial, as it reflects the team’s branding and professionalism.

How Can Corporate Promotions Leverage Custom Embroidered Jackets?

Corporate promotions benefit significantly from leather jacket custom embroidery by using them as promotional gifts. These jackets can feature company logos and serve as effective marketing tools that enhance employee engagement and brand visibility. For B2B buyers, customization capabilities are essential, as they often need to fulfill bulk orders with specific designs. Additionally, competitive pricing is a key consideration, as companies aim to maximize their marketing budgets while delivering high-quality promotional items.

3 Common User Pain Points for ‘leather jacket custom embroidery’ & Their Solutions

Scenario 1: Navigating Quality Control in Custom Embroidery Orders

The Problem: One of the foremost challenges B2B buyers face when ordering custom embroidered leather jackets is maintaining consistent quality across large orders. Variations in stitching, color fidelity, and overall craftsmanship can lead to dissatisfaction and potential brand damage. This concern is particularly acute for buyers in regions with different manufacturing standards, such as Africa or South America, where local suppliers may not adhere to the same quality benchmarks as those in Europe or North America.

The Solution: To ensure quality control, buyers should establish clear quality standards and specifications prior to placing large orders. This includes detailed guidelines on thread types, color matching, and stitching techniques. It’s advisable to request samples before committing to bulk orders. Suppliers should be encouraged to produce a small batch of jackets based on your specifications, allowing you to evaluate the quality firsthand. Furthermore, implementing a third-party quality inspection service can provide an additional layer of assurance, ensuring that the finished products meet your defined criteria before they are shipped. By fostering a transparent relationship with suppliers and clearly communicating your expectations, you can significantly reduce the risk of quality discrepancies.

Scenario 2: Overcoming Cultural Sensitivity in Custom Designs

The Problem: For international B2B buyers, particularly those sourcing for diverse markets in the Middle East or Africa, cultural sensitivity in design elements is crucial. Embroidery designs that resonate in one culture might be viewed as inappropriate or offensive in another. This challenge is compounded when buyers are unfamiliar with local customs and trends, potentially leading to backlash from consumers.

The Solution: To navigate cultural sensitivities, it is essential to conduct thorough market research. Engage local experts or cultural consultants who can provide insights into design preferences and taboos. Additionally, consider using a collaborative design approach where you involve local stakeholders in the creation process. This not only enhances cultural relevance but also fosters goodwill and brand loyalty. Utilize tools like focus groups to test designs before finalizing them. Incorporating feedback from potential customers can help ensure that your embroidered designs resonate positively within the target market, thereby minimizing the risk of cultural missteps.

Illustrative image related to leather jacket custom embroidery

Scenario 3: Managing Lead Times and Delivery Challenges

The Problem: B2B buyers often face challenges related to lead times and delivery schedules when ordering custom embroidered leather jackets. Delays in production or shipping can disrupt sales timelines, especially if the jackets are intended for a specific event or season. This is particularly pressing for buyers in regions like Europe, where consumer expectations for timely delivery are high.

The Solution: To mitigate lead time issues, it is crucial to establish a robust project timeline with your suppliers. Start by discussing production timelines at the outset, ensuring that both parties agree on realistic deadlines. Incorporate buffer periods into your schedule to accommodate potential delays. Additionally, leverage local manufacturers when possible to shorten shipping times and reduce the risk of international shipping delays. For urgent needs, consider suppliers that offer expedited production services or flexible shipping options. Maintaining open communication with your suppliers throughout the process can help you stay informed about any potential delays, enabling you to manage expectations and make necessary adjustments in your distribution strategy.

Strategic Material Selection Guide for leather jacket custom embroidery

What Are the Key Properties of Common Materials Used in Leather Jacket Custom Embroidery?

When selecting materials for leather jacket custom embroidery, it is crucial to consider the properties of the leather itself, as well as the types of threads and embellishments used in the embroidery process. Here, we analyze four common materials: cowhide leather, lambskin leather, polyester thread, and nylon thread, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Cowhide Leather: A Durable Choice for Embroidery

Cowhide leather is one of the most commonly used materials for leather jackets. It is known for its durability and resistance to wear and tear. The key properties include a high tensile strength and excellent abrasion resistance, making it suitable for various climates, including the hot and humid conditions often found in regions like Nigeria and Saudi Arabia.

Illustrative image related to leather jacket custom embroidery

Pros: Cowhide is relatively affordable and widely available, making it a cost-effective option for bulk orders. Its durability ensures that embroidered designs remain intact over time.

Cons: The thickness of cowhide can make it challenging to work with for intricate embroidery designs. Additionally, it may require more complex manufacturing processes, which can increase lead times.

Impact on Application: Cowhide’s robust nature supports a wide range of embroidery techniques, but buyers should ensure that the chosen embroidery method is compatible with the leather’s thickness.

Illustrative image related to leather jacket custom embroidery

Lambskin Leather: A Luxurious Alternative

Lambskin leather is softer and more supple than cowhide, providing a luxurious feel. It has a lower temperature rating, making it less suitable for extreme conditions but ideal for fashionable jackets.

Pros: The softness of lambskin allows for intricate embroidery designs, enhancing the overall aesthetic appeal of the jacket. It is often preferred for high-end fashion markets.

Cons: Lambskin is more expensive than cowhide and less durable, making it susceptible to damage from environmental factors. This can be a concern for buyers in regions with harsher climates.

Impact on Application: While lambskin allows for detailed embroidery, buyers must consider its care requirements and potential for wear, especially in regions with high humidity or extreme temperatures.

Illustrative image related to leather jacket custom embroidery

Polyester Thread: Versatile and Cost-Effective

Polyester thread is commonly used in leather jacket embroidery due to its strength and resistance to fading. It can withstand high temperatures, making it suitable for various embroidery techniques.

Pros: Polyester is cost-effective and offers a wide range of colors, allowing for creative designs. Its durability ensures that embroidered elements maintain their vibrancy over time.

Cons: Polyester may not have the same luxurious feel as natural fibers, which could be a drawback for high-end products. Additionally, it may not be as environmentally friendly as other options.

Impact on Application: Polyester thread is compatible with most embroidery machines, making it a practical choice for international buyers looking to streamline production processes.

Illustrative image related to leather jacket custom embroidery

Nylon Thread: Strong and Resilient

Nylon thread is another popular choice for leather jacket embroidery due to its high strength and elasticity. It is particularly resistant to abrasion and UV light.

Pros: Nylon offers excellent durability and is less prone to fraying compared to other threads. It is ideal for jackets that will see heavy use, such as motorcycle or work jackets.

Cons: Nylon can be more expensive than polyester and may not be available in as wide a range of colors. Additionally, it can be sensitive to heat, which may affect the embroidery process.

Impact on Application: Buyers should consider the specific requirements of their embroidery designs when choosing nylon thread, particularly in terms of temperature and compatibility with various embroidery techniques.

Summary Table of Material Selection for Leather Jacket Custom Embroidery

| 素材 | Typical Use Case for leather jacket custom embroidery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Leather | Everyday leather jackets with durable embroidery | High durability and affordability | Thicker, challenging for intricate designs | Medium |

| Lambskin Leather | High-end fashion jackets with detailed designs | Soft, luxurious feel | Less durable, higher cost | 高い |

| Polyester Thread | General embroidery on various leather types | Cost-effective and color variety | Less luxurious feel | 低い |

| Nylon Thread | Heavy-use jackets requiring strong embroidery | Excellent durability | Higher cost, limited color range | Medium |

This strategic material selection guide provides essential insights for international B2B buyers looking to navigate the complexities of leather jacket custom embroidery. By understanding the properties and implications of each material, buyers can make informed decisions that align with their market needs and customer preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket custom embroidery

What Are the Key Manufacturing Processes for Custom Embroidered Leather Jackets?

The manufacturing of custom embroidered leather jackets involves several critical stages that ensure high-quality output and customer satisfaction. Each stage—from material preparation to finishing—plays a vital role in delivering a product that meets the expectations of B2B buyers.

How Is Material Prepared for Leather Jacket Production?

Material preparation is the foundational step in the manufacturing process. High-quality leather is sourced, often from reputable suppliers who adhere to sustainable practices. The leather is then carefully inspected for defects, color consistency, and thickness.

Illustrative image related to leather jacket custom embroidery

In addition to leather, other materials such as lining fabrics, zippers, and embroidery threads are selected based on durability and aesthetic appeal. Buyers should ensure that suppliers provide detailed material specifications and samples before production begins.

What Forming Techniques Are Used in Custom Leather Jacket Manufacturing?

Once materials are prepared, the forming stage begins. This involves cutting the leather into the required patterns and shapes based on the jacket design. Advanced cutting techniques, such as laser cutting, can be utilized for precision, especially in intricate designs that require embroidery.

This stage also includes the preparation of the embroidery area, where the design is digitized and transferred onto the leather. The use of computer-aided design (CAD) software allows for accurate placement of the embroidery, ensuring that logos and other designs are positioned correctly.

Illustrative image related to leather jacket custom embroidery

How Is Assembly Conducted for Leather Jackets with Custom Embroidery?

The assembly stage involves stitching the leather pieces together. Skilled artisans typically perform this task, as leather requires specialized handling to avoid damage. High-quality stitching techniques, such as double stitching, are used to enhance durability.

During this stage, the embroidery is integrated into the design. B2B buyers should inquire about the types of embroidery techniques employed, such as satin stitch or appliqué, as these can affect the overall look and longevity of the design.

What Finishing Processes Are Important for Custom Leather Jackets?

The finishing process involves several steps to enhance the jacket’s aesthetic and functional qualities. This includes cleaning, conditioning, and applying protective coatings to the leather. Additionally, any final adjustments are made, such as ensuring that the embroidery is secure and that the jacket fits the specified dimensions.

Illustrative image related to leather jacket custom embroidery

Quality control checks are conducted at this stage to ensure that the jacket meets the required standards before shipment. B2B buyers should ensure that suppliers have a clear finishing protocol to guarantee the quality of the final product.

What Quality Assurance Measures Are Essential in Leather Jacket Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process that ensures products meet international and industry-specific standards. Implementing a robust QA system not only protects the buyer but also enhances the reputation of the supplier.

Which International Standards Should B2B Buyers Look For?

For leather jacket manufacturers, compliance with international standards such as ISO 9001 is essential. This certification indicates that the supplier adheres to quality management principles, including strong customer focus, the involvement of top management, and a process-based approach.

Additionally, industry-specific certifications such as CE (Conformité Européenne) for safety and compliance in the European market, or API (American Petroleum Institute) for specialized materials, may also be relevant depending on the product’s intended use.

Illustrative image related to leather jacket custom embroidery

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control involves several checkpoints to ensure product integrity:

-

Incoming Quality Control (IQC): This stage assesses the quality of raw materials before production begins. It is crucial for ensuring that only high-quality leather and components are used.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, this step involves regular inspections to identify defects early, thereby reducing waste and rework.

-

Final Quality Control (FQC): Before shipping, the finished jackets undergo a comprehensive evaluation to check for adherence to design specifications, quality of stitching, and overall aesthetics.

B2B buyers should request detailed reports from suppliers on these checkpoints to ensure compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards, B2B buyers can implement several verification methods:

-

Supplier Audits: Conducting regular audits of the manufacturing facility can provide insights into the supplier’s quality control processes, working conditions, and adherence to standards.

-

Quality Control Reports: Requesting detailed reports on the quality control process, including testing results and compliance certifications, allows buyers to assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and product quality. This is particularly important for international buyers who may not be able to visit the supplier’s facility.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. For instance, regulatory requirements may differ significantly from one region to another, necessitating a thorough understanding of local standards.

Additionally, cultural differences in business practices may influence communication about quality expectations. Therefore, establishing clear lines of communication with suppliers and having comprehensive contracts that outline quality expectations is essential.

Illustrative image related to leather jacket custom embroidery

In summary, understanding the manufacturing processes and quality assurance measures for custom embroidered leather jackets is vital for B2B buyers. By focusing on these aspects, buyers can ensure they partner with suppliers who prioritize quality and sustainability, ultimately leading to successful business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket custom embroidery’

In today’s competitive market, sourcing leather jackets with custom embroidery can enhance brand identity and provide a unique offering. This guide serves as a practical checklist for B2B buyers looking to procure high-quality custom embroidered leather jackets. Follow these steps to ensure a successful sourcing experience.

Step 1: Define Your Design Requirements

Before engaging suppliers, outline your specific design needs, including logos, colors, and embroidery styles. This clarity will help communicate your vision effectively and ensure that suppliers can meet your expectations. Consider the target audience and market trends in regions like Africa, South America, and the Middle East to create designs that resonate.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers specializing in custom leather jacket embroidery. Utilize online platforms, industry directories, and trade shows to compile a list of potential vendors. Pay attention to their portfolio to assess their previous work and ensure they align with your design requirements.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each supplier by requesting samples of their embroidered jackets. Focus on the quality of embroidery, fabric selection, and overall craftsmanship. It’s essential to ensure that the supplier can handle your desired volume and maintains high standards for quality control.

- Quality Assurance: Inquire about their quality control processes to minimize defects and ensure consistency.

- 生産能力: Confirm that the supplier can meet your timelines without compromising quality.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers adhere to industry standards and regulations. Certifications such as ISO and compliance with labor laws are crucial for ethical sourcing. This step not only protects your brand’s reputation but also ensures that the products meet international quality standards.

Step 5: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotes that outline pricing, lead times, and payment terms. Be sure to clarify whether the pricing includes the cost of embroidery and any additional customization. Comparing quotes will help you make informed decisions and negotiate better terms.

Illustrative image related to leather jacket custom embroidery

- Transparency: Ensure that all costs are clearly defined to avoid hidden fees later on.

Step 6: Initiate a Trial Order

Before committing to a large order, consider placing a trial order to evaluate the supplier’s performance. This allows you to assess the quality of the final product, the accuracy of the embroidery, and the supplier’s ability to meet deadlines. Use this opportunity to provide feedback and make necessary adjustments.

Step 7: Establish a Clear Communication Plan

Effective communication is vital throughout the sourcing process. Set up regular check-ins and updates to address any issues promptly. Use collaborative tools and project management software to streamline communication and keep all stakeholders informed.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom embroidered leather jackets, ensuring that they find reliable suppliers who can deliver high-quality products tailored to their needs.

Comprehensive Cost and Pricing Analysis for leather jacket custom embroidery Sourcing

What Are the Key Cost Components in Leather Jacket Custom Embroidery?

When analyzing the costs associated with sourcing custom embroidered leather jackets, several critical components must be considered:

Illustrative image related to leather jacket custom embroidery

-

Materials: The primary cost driver in leather jacket production is the quality of leather used. Full-grain leather, for instance, is more expensive than corrected grain. Additionally, the cost of embroidery threads and backing materials can vary significantly depending on the quality and type selected.

-

Labor: Skilled labor is essential for both leather crafting and embroidery. Labor costs will vary based on the region, the complexity of the design, and the skill level required. For instance, intricate embroidery designs necessitate more time and expertise, thus increasing labor costs.

-

Manufacturing Overhead: This includes expenses related to the facility, utilities, and administrative costs that support the production process. Overhead can be a significant factor, especially for small-scale operations or bespoke manufacturers.

-

Tooling: Custom tooling may be required for specialized designs or embroidery patterns. The costs associated with creating and maintaining these tools should be factored into the overall pricing structure.

-

Quality Control (QC): Ensuring that each jacket meets quality standards incurs additional costs. Rigorous QC processes are essential to minimize defects and returns, which can be particularly impactful in international markets.

-

Logistics: Shipping costs, customs duties, and insurance are critical components of the logistics chain. These costs vary widely depending on the destination and the terms of shipment.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and to ensure business viability. Margins can vary based on the market position and competition.

How Do Price Influencers Affect Custom Embroidered Leather Jackets?

Several factors influence the pricing of custom embroidered leather jackets, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often result in lower per-unit costs. Suppliers may offer tiered pricing based on order volume, incentivizing larger purchases.

-

Specifications and Customization: The level of customization—such as unique designs, custom sizes, and special features—can significantly impact pricing. More complex designs typically require more time and resources.

-

Materials and Quality Certifications: Higher quality materials or certified sustainable leathers can increase costs. Buyers should be aware of the implications of material selection on both price and product durability.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established manufacturers with a proven track record may charge more due to their reliability and quality assurance.

-

Incoterms: Understanding the Incoterms used in the contract can affect the overall cost. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can determine who bears the shipping and insurance costs, impacting the total price.

What Tips Can Help Buyers Negotiate Better Prices for Leather Jacket Embroidery?

When sourcing custom embroidered leather jackets, international buyers should consider the following tips:

-

Negotiate Terms: Don’t hesitate to discuss pricing and terms with suppliers. Flexibility in payment terms or adjustments in order size can lead to better pricing.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, shipping, and potential return costs. A lower upfront cost may lead to higher long-term expenses.

-

Understand Pricing Nuances: Be mindful of regional pricing differences. For instance, suppliers in emerging markets may offer competitive rates, while suppliers in developed regions may provide higher quality but at a premium.

-

Leverage Volume: If you anticipate ongoing needs, negotiate pricing based on projected future orders. Establishing a long-term relationship can lead to better terms.

-

Research and Compare: Conduct thorough market research to understand the typical pricing structures and quality standards across different suppliers. This knowledge can enhance negotiation leverage.

Conclusion

Sourcing custom embroidered leather jackets involves a complex interplay of costs and pricing factors. By understanding these components and leveraging negotiation strategies, B2B buyers can make informed decisions that align with their business needs and budget constraints. Always keep in mind that indicative prices may fluctuate based on market conditions and supplier capabilities, so regular market assessments are recommended.

Alternatives Analysis: Comparing leather jacket custom embroidery With Other Solutions

Exploring Alternatives for Customizing Leather Jackets

In the world of personalized fashion, custom embroidery on leather jackets is a popular choice for businesses looking to enhance brand identity or offer unique products. However, other alternatives exist that can achieve similar goals, each with its own set of advantages and limitations. This analysis compares leather jacket custom embroidery with two viable alternatives: screen printing and heat transfer vinyl (HTV).

| Comparison Aspect | Leather Jacket Custom Embroidery | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|

| Performance | Durable and long-lasting; resistant to wear and tear | Good for bulk production; vibrant colors | High-quality finish; suitable for intricate designs |

| Cost | Higher initial investment; cost-effective for small batches | Lower cost per unit for large orders | Moderate cost; more expensive for small runs |

| Ease of Implementation | Requires skilled labor; longer lead times | Quick setup; easy for large volumes | Simple application; requires heat press |

| Maintenance | Easy to maintain; withstands washing | May fade over time; requires careful washing | Durable but can peel if not applied correctly |

| Best Use Case | High-end branding, unique designs | Large-scale promotional items, events | Custom designs for small businesses, fashion brands |

What Are the Pros and Cons of Screen Printing?

Screen printing is a widely used method for applying designs on various materials, including leather. One of its main advantages is cost-effectiveness for bulk orders; the more items printed, the lower the cost per unit. This method allows for vibrant colors and can cover large areas quickly, making it ideal for promotional events or corporate giveaways. However, screen printing may not be as durable as embroidery, and designs can fade over time, particularly if not cared for properly. Additionally, screen printing is less effective for intricate designs or logos that require fine detail.

How Does Heat Transfer Vinyl (HTV) Compare?

Heat transfer vinyl is another option for customizing leather jackets. It involves cutting designs from vinyl sheets and applying them to the fabric using heat. HTV offers a high-quality finish and is excellent for detailed designs, making it a popular choice among small businesses and fashion brands. The application process is relatively straightforward, requiring just a heat press and a cutting machine. However, HTV can be costlier for small runs compared to bulk screen printing. Additionally, if not applied correctly, the vinyl may peel over time, which could affect the jacket’s longevity.

Conclusion: Which Customization Method is Right for Your Business?

When choosing the right customization method for leather jackets, B2B buyers must consider factors such as budget, volume, and design complexity. Leather jacket custom embroidery is ideal for businesses seeking a durable, high-quality finish that enhances brand identity, particularly for high-end products. Screen printing is suitable for bulk orders where cost is a significant factor, while heat transfer vinyl provides flexibility for smaller runs with intricate designs. Ultimately, the best choice will depend on the specific needs and goals of the business, as well as the target market.

Essential Technical Properties and Trade Terminology for leather jacket custom embroidery

What Are the Key Technical Properties of Leather Jacket Custom Embroidery?

When engaging in leather jacket custom embroidery, understanding the technical properties involved is crucial for ensuring product quality and meeting client expectations. Here are some essential specifications:

-

Material Grade

The quality of the leather used in jackets can significantly affect the embroidery process. High-grade leather, such as full-grain or top-grain, is more durable and holds embroidery better than lower grades like corrected grain. For B2B buyers, selecting the right material grade ensures that the final product maintains its integrity, looks premium, and meets customer satisfaction. -

Embroidery Thread Count

This refers to the number of stitches per square inch in the embroidery design. A higher thread count typically results in a more detailed and visually appealing embroidery, enhancing the jacket’s aesthetic value. For businesses, understanding thread count is vital for pricing strategies and quality assurance, as it affects both the production cost and the perceived value of the jacket. -

Tolerance Levels

Tolerance indicates the acceptable range of variation in the embroidery placement and size. In leather jacket custom embroidery, maintaining tight tolerances is essential to ensure that designs are consistently aligned and proportionate across multiple units. This is particularly important for large orders where uniformity is expected, making it a key consideration for buyers looking for reliable suppliers. -

Backing Material

The backing used during embroidery can impact the final product’s durability and appearance. Common backings include tear-away, cut-away, and water-soluble types, each serving different purposes. Understanding these options allows businesses to choose the best backing for their specific designs, ensuring that the embroidery withstands wear and tear while maintaining its appearance. -

Color Fastness

This property measures how well the embroidered colors resist fading or running when exposed to various conditions, such as washing or sunlight. For B2B buyers, ensuring high color fastness is crucial for maintaining the jacket’s look over time, which can directly affect customer satisfaction and brand reputation. -

Puncture Resistance

This refers to the leather’s ability to withstand needle penetration during the embroidery process. High puncture resistance minimizes the risk of damage during production and ensures the longevity of the jacket. Buyers should consider this property when evaluating suppliers, as it impacts the overall quality and durability of the final product.

What Are the Common Trade Terms Used in Leather Jacket Custom Embroidery?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods that are then marketed by another firm under its brand. In the context of custom leather jackets, buyers may collaborate with OEMs to create unique embroidered designs while leveraging the OEM’s manufacturing expertise. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it affects inventory management and pricing. Suppliers often set MOQs to ensure that production costs are met, making it a critical factor in order planning. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes details about the desired products, such as material specifications, design requirements, and quantities. For buyers, issuing an RFQ is a vital step in comparing supplier offerings and negotiating favorable terms. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs and risks, ensuring smoother logistics. -

Lead Time

This term refers to the time taken from placing an order to delivery. In custom embroidery, lead time can vary based on order complexity and production capacity. Buyers must account for lead time when planning inventory and sales strategies, as it impacts customer satisfaction and business operations. -

Digitizing

Digitizing is the process of converting artwork into a format that embroidery machines can read. This step is crucial for achieving high-quality embroidery. B2B buyers should ensure their suppliers have skilled digitizers to accurately translate their designs into embroidered formats, affecting both the quality and efficiency of production.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions in the leather jacket custom embroidery market, ensuring that they meet their quality standards and customer expectations effectively.

Illustrative image related to leather jacket custom embroidery

Navigating Market Dynamics and Sourcing Trends in the leather jacket custom embroidery Sector

What Are the Current Market Dynamics and Key Trends in Leather Jacket Custom Embroidery?

The global leather jacket custom embroidery market is witnessing significant growth, driven by rising consumer demand for personalized and unique fashion items. Buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking products that reflect individual identity and cultural significance. The trend towards customization is supported by advancements in embroidery technology, allowing for more intricate designs and faster production times. Digital embroidery machines, for instance, enable businesses to offer high-quality, detailed embroidery at competitive prices, enhancing the appeal of custom leather jackets.

Additionally, the shift towards e-commerce has transformed how B2B buyers source products. Online platforms provide international buyers with access to a broader range of suppliers, facilitating easier price comparisons and product selections. The rise of social media also plays a pivotal role in shaping consumer preferences, with brands leveraging platforms like Instagram to showcase their unique offerings and engage with potential buyers. As markets evolve, partnerships with local artisans and designers are becoming increasingly popular, allowing businesses to tap into regional craftsmanship while enhancing their product portfolio.

How Does Sustainability and Ethical Sourcing Impact the Leather Jacket Custom Embroidery Market?

Sustainability and ethical sourcing are becoming non-negotiable aspects of the leather jacket custom embroidery sector. The environmental impact of leather production, including deforestation and chemical waste, has prompted a growing number of companies to adopt more sustainable practices. Buyers are now prioritizing suppliers that utilize eco-friendly materials, such as vegetable-tanned leather and recycled fabrics, alongside certifications like the Leather Working Group (LWG) that ensure responsible sourcing.

Moreover, ethical labor practices are gaining importance, with businesses increasingly expected to provide transparency in their supply chains. This trend is particularly relevant for international buyers from regions like Saudi Arabia and Nigeria, where consumers are becoming more socially conscious. Brands that invest in sustainable practices not only appeal to environmentally aware consumers but also enhance their market competitiveness. As a result, sourcing partners who can demonstrate a commitment to sustainability and ethical production processes will likely hold a significant advantage in this evolving market landscape.

Illustrative image related to leather jacket custom embroidery

What Is the Historical Context of Leather Jacket Custom Embroidery in B2B?

The tradition of leather craftsmanship dates back centuries, with leather jackets initially gaining popularity among aviators and military personnel. The incorporation of custom embroidery into leather apparel emerged as a means of personal expression, allowing individuals to showcase their identities through unique designs. Over the decades, the custom embroidery sector has evolved significantly, influenced by fashion trends, technological advancements, and changing consumer preferences.

In the modern B2B landscape, custom embroidery has become a vital tool for branding and marketing. Businesses now leverage this personalization to create distinctive products that resonate with their target audience, enhancing brand loyalty. As the demand for bespoke leather jackets continues to rise, the historical significance of this craft remains a key consideration for B2B buyers seeking to understand market dynamics and consumer behavior.

Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket custom embroidery

-

How do I ensure the quality of custom embroidered leather jackets?

To ensure the quality of custom embroidered leather jackets, start by vetting suppliers thoroughly. Look for manufacturers with positive reviews and a portfolio showcasing their work. Request samples to evaluate the stitching, fabric, and embroidery quality before placing a bulk order. Establish clear quality assurance (QA) processes, including inspection protocols at various production stages. It’s also advisable to communicate your quality expectations upfront and ask about their return or alteration policies in case the final product does not meet your standards. -

What customization options are available for leather jacket embroidery?

When customizing leather jackets, you can choose from various embroidery options, including logos, monograms, artwork, and text. Suppliers often allow you to upload your designs or collaborate with their design team. Additionally, consider the placement of the embroidery—whether on the back, sleeves, or front. Some manufacturers offer different thread colors and styles, which can enhance the uniqueness of your jacket. Always confirm the types of embroidery techniques they use, such as direct embroidery or patches, to ensure it aligns with your vision. -

What are the minimum order quantities (MOQs) for custom embroidered jackets?

Minimum order quantities (MOQs) for custom embroidered leather jackets can vary significantly between suppliers. Generally, MOQs can range from 10 to 100 units, depending on the complexity of the design and the manufacturer’s production capabilities. When sourcing, inquire about MOQs upfront to avoid surprises. If you are a smaller business, look for suppliers who are willing to accommodate lower MOQs, possibly at a higher per-unit cost. This flexibility can help you test the market before committing to larger orders. -

What payment terms should I expect when sourcing custom leather jackets?

Payment terms for custom leather jacket orders can differ widely based on the supplier and your negotiation. Common practices include a deposit of 30-50% upfront, with the remainder due upon completion or prior to shipping. It’s essential to clarify payment methods accepted, such as wire transfers, credit cards, or escrow services, to ensure secure transactions. For international orders, be aware of currency conversion fees and customs duties that may apply. Establishing clear payment terms in the contract can prevent misunderstandings later. -

How can I effectively communicate my design ideas to suppliers?

To effectively communicate your design ideas, prepare a detailed brief that includes images, sketches, and descriptions of what you envision. Use digital tools to create mock-ups or mood boards that visually represent your ideas. Additionally, consider discussing color palettes, fabric types, and embroidery techniques during initial consultations. Establishing a collaborative relationship with the supplier can facilitate better understanding and adjustments to your design. Regular updates and feedback throughout the production process will also help ensure the final product meets your expectations. -

What logistics considerations should I keep in mind for international shipping?

When planning international shipping for custom leather jackets, consider factors such as shipping costs, delivery timelines, and customs regulations in your destination country. Choose a reliable logistics partner with experience in handling apparel to ensure timely and safe delivery. Be aware of potential tariffs and taxes that may apply, which can affect your overall cost. It’s advisable to use expedited shipping options for urgent orders and to track shipments closely to manage any unforeseen delays effectively. -

What should I know about the return policy for custom embroidered jackets?

Understanding the return policy for custom embroidered jackets is crucial before finalizing your order. Many suppliers have strict return policies for custom items, often allowing returns only for defective or incorrectly made products. Clarify the conditions under which returns or exchanges are accepted, including timeframes and whether alterations are possible. Some suppliers may offer satisfaction guarantees, allowing for remakes or adjustments if the product does not meet your specifications. Always get the return policy in writing to protect your investment. -

How do I find reliable suppliers for custom leather jacket embroidery?

Finding reliable suppliers for custom leather jacket embroidery involves thorough research and due diligence. Utilize online B2B platforms and industry directories to identify potential manufacturers. Attend trade shows and exhibitions to meet suppliers in person and assess their capabilities. Request references from previous clients to gauge their reliability and service quality. Additionally, consider starting with small orders to evaluate the supplier’s performance before committing to larger contracts. Establishing a good relationship with your supplier can lead to better communication and quality assurance in future orders.

Top 8 Leather Jacket Custom Embroidery Manufacturers & Suppliers List

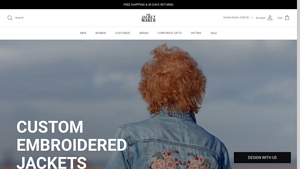

1. The Jacket Maker – Custom Embroidered Jackets

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom embroidered jackets available in various styles including denim jackets, leather jackets, bomber jackets, and coats. Options for customization include logos and artworks. Free shipping and 30 days returns are offered. Quantity discounts available for orders of 2-5, 6-20, 21-50, and 50+ jackets. Multiple countries supported for shipping.

2. Mahileather – Branded Leather Jacket

Domain: mahileather.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Branded Leather Jacket”, “price”: “$215.46”, “original_price”: “$239.40”, “discount”: “10% OFF”, “material”: “premium leather”, “shipping”: “Free Worldwide Shipping”, “warranty”: “1 Year Warranty”, “returns”: “30 day returns”, “sizes”: [“Small”, “Medium”, “Large”], “colors”: [“White”, “Grey”, “Black”, “Navy Suede”, “Grey Suede”], “branding_options”: [“remove MAHI branding”, “keep…

3. AllStar Logo – Custom Leather Jackets

Domain: allstarlogo.com

Registered: 2000 (25 years)

Introduction: Custom Leather Jackets available in various styles including:

– Women’s Lambskin Leather Jacket – $179.99

– Men’s Lamb Skin Leather Jacket – $179.99

– AllStar Logo Leather Jacket – $139.99

– Ladies Hornet Leather Jacket – $139.99

– Letterman Jacket (Leather and Wool) – $173.99

– Motorcycle Leather Jacket – $144.99

– Unisex Leather Vest – $53.99

– Ladies Custom Leather Jacket – $133.99

– Classic Bo…

4. The Cast – Custom Leather Jackets and Vests

Domain: thecast.com

Registered: 1999 (26 years)

Introduction: Custom Leather Jackets and Vests made in NYC by The Cast. Clients can choose from various styles including Bowery, Essex, Bronx, Rivington, Downtown, The ’68, or Johnnie. Options for customization include premium leather types (Cowhide, CalfSkin, Horsehide, Hair on Hide), linings (Solid Prints, Polka Dot, Animal Print), and hardware finishes (Nickel, Antique Nickel, Matte Black, Brass, Antique Bra…

5. Lusso Leather – Custom Leather Jacket

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: Product Name: Custom Leather Jacket

Regular Price: $502.00

Sale Price: $398.00

Shipping: Free shipping on all jackets

Return Policy: 30 days for returns/alterations

Sizes Available: XSmall, Small, Medium, Large, XLarge, XXL, Custom Size, Custom Plus Size

Custom Plus Size Price: $481.00

Customization Options: Select from a variety of fabrics and leathers, custom embroidery, sublimation printing, lo…

6. Jackets Kingdom – Custom Leather Jackets

Domain: jacketskingdom.com

Registered: 2023 (2 years)

Introduction: Custom-Made Leather Jackets – Design Your Own Leather Jacket. Free Worldwide Delivery on all orders. Options available for Men, Women, and Kids. Types of jackets include: Leather Jacket, Bomber Jacket, Biker Jacket, Cafe Racer Jacket, Trucker Jacket, Punk Jacket, Down Jacket, Suede Jacket, Hooded Jacket, Studded Jacket, Varsity Jacket, V-Bomber Jacket, Distressed Leather Jacket, Military Jacket, S…

7. Leather Skin Shop – Custom Leather Jackets

Domain: leatherskinshop.com

Registered: 2014 (11 years)

Introduction: Custom Leather Jackets available for men and women. Sizes range from XS to 4XL for men and XXS to 3XL for women. Measurements include chest, waist, and sleeves for accurate fitting. Customization options available for design, logos, and embroidery. Free shipping and premium leather used. Design consultation offered. The creation time for customized jackets varies.

8. Etsy – Custom Leather Jackets

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Custom Leather Jackets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather jacket custom embroidery

In conclusion, the landscape of leather jacket custom embroidery offers a wealth of opportunities for international B2B buyers. By embracing strategic sourcing, businesses can tap into a diverse range of suppliers that provide high-quality, personalized products tailored to their specific needs. The ability to customize leather jackets through embroidery not only enhances brand identity but also fosters customer loyalty by offering unique, one-of-a-kind pieces.

Illustrative image related to leather jacket custom embroidery

Key takeaways include the importance of selecting suppliers who prioritize craftsmanship and quality, as well as those who can accommodate varying design requests, from logos to intricate patterns. Moreover, establishing a collaborative relationship with manufacturers can streamline the production process, ensuring timely delivery and satisfaction.

Looking ahead, the demand for custom embroidered leather jackets is set to rise, driven by trends in personalization and fashion innovation. As buyers from Africa, South America, the Middle East, and Europe explore this vibrant market, now is the time to engage with reliable partners who can bring your vision to life. Leverage the potential of custom embroidery to differentiate your offerings and capture the attention of discerning consumers globally. Start your journey today by reaching out to potential suppliers and exploring the vast possibilities that await.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to leather jacket custom embroidery