Introduction: Navigating the Global Market for custom printed leather

In today’s competitive landscape, sourcing high-quality custom printed leather can be a daunting challenge for international B2B buyers. With diverse applications ranging from fashion to furniture, the demand for bespoke leather solutions is surging, particularly in emerging markets such as Nigeria and Vietnam. This guide addresses the complexities of navigating the global market for custom printed leather, offering insights into various types of leather, innovative printing techniques, and potential applications.

Buyers will discover the significance of supplier vetting processes to ensure quality and reliability, as well as cost considerations that can impact profitability. Additionally, this comprehensive resource delves into the latest trends and technologies in leather printing, empowering businesses to make informed purchasing decisions. By understanding the nuances of the custom printed leather market, B2B buyers can leverage their investments, enhance product offerings, and ultimately meet the growing consumer demand for personalized and sustainable leather goods.

Whether you are a manufacturer, retailer, or designer, this guide serves as a valuable tool to navigate the complexities of sourcing custom printed leather, enabling you to seize opportunities in a dynamic and evolving marketplace. With actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe, you can confidently approach your next procurement project with a strategic advantage.

Table Of Contents

- Top 7 Custom Printed Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom printed leather

- Understanding custom printed leather Types and Variations

- Key Industrial Applications of custom printed leather

- 3 Common User Pain Points for ‘custom printed leather’ & Their Solutions

- Strategic Material Selection Guide for custom printed leather

- In-depth Look: Manufacturing Processes and Quality Assurance for custom printed leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom printed leather’

- Comprehensive Cost and Pricing Analysis for custom printed leather Sourcing

- Alternatives Analysis: Comparing custom printed leather With Other Solutions

- Essential Technical Properties and Trade Terminology for custom printed leather

- Navigating Market Dynamics and Sourcing Trends in the custom printed leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom printed leather

- Strategic Sourcing Conclusion and Outlook for custom printed leather

- Important Disclaimer & Terms of Use

Understanding custom printed leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Smooth Nappa Leather | Soft, supple texture; high-quality finish | Fashion apparel, luxury accessories | Pros: Premium feel, excellent print quality. Cons: Higher cost compared to other types. |

| Textured Nappa Leather | Unique surface texture; enhanced grip | Bags, shoes, upholstery | Pros: Distinctive appearance, durable. Cons: May require more care in cleaning. |

| Vegan Leather | Eco-friendly alternative; made from synthetic materials | Fashion, home decor, promotional items | Pros: Sustainable, animal-friendly. Cons: Perceived lower quality by some buyers. |

| Suede Leather | Soft, velvety finish; absorbs dye well | High-end fashion, accessories | Pros: Luxurious look, excellent color depth. Cons: Less durable; prone to staining. |

| Bubble Nappa Leather | Unique bubble-like texture; lightweight | Fashion items, novelty products | Pros: Eye-catching design, lightweight. Cons: Limited applications due to texture. |

What Are the Characteristics of Smooth Nappa Leather and Its Suitability for B2B Buyers?

Smooth Nappa leather is renowned for its soft, supple texture and luxurious appearance, making it a favored choice for high-end fashion apparel and accessories. Its ability to hold vibrant colors during the printing process results in striking designs. B2B buyers looking for premium materials for upscale products will find that the investment in Smooth Nappa leather pays off in terms of customer satisfaction and brand reputation. It’s important to consider the higher cost associated with this type, which may affect pricing strategies.

How Does Textured Nappa Leather Differ from Other Types for Business Applications?

Textured Nappa leather features a unique surface pattern that not only enhances grip but also adds a distinctive aesthetic to products. This type is particularly suitable for bags, shoes, and upholstery, where durability and style are crucial. B2B buyers should weigh the advantages of its durability and unique appearance against the potential need for careful maintenance, as the texture can be more challenging to clean than smoother alternatives.

Why Choose Vegan Leather for Sustainable Business Practices?

Vegan leather is an eco-friendly alternative made from synthetic materials, appealing to businesses focused on sustainability. Its use spans various applications, including fashion, home decor, and promotional items. B2B buyers may find that promoting products made from vegan leather can enhance their brand image among environmentally conscious consumers. However, some may perceive vegan leather as lower quality compared to genuine leather, so it’s essential to communicate its benefits effectively to target markets.

What Are the Unique Qualities of Suede Leather for Fashion and Accessories?

Suede leather is characterized by its soft, velvety finish, which absorbs dye exceptionally well, allowing for rich color saturation. This makes it an excellent choice for high-end fashion items and accessories. B2B buyers must consider the luxurious appeal of suede against its susceptibility to staining and less overall durability compared to other leather types. Proper care and maintenance strategies should be discussed with clients to ensure longevity and satisfaction.

Illustrative image related to custom printed leather

In What Situations is Bubble Nappa Leather Most Effective for B2B Products?

Bubble Nappa leather features a distinctive bubble-like texture that is lightweight and visually striking, making it ideal for fashion items and novelty products. Its unique design can attract attention and differentiate products in a crowded marketplace. B2B buyers should evaluate its limited applications due to its specific texture, ensuring that it aligns with their product offerings and target audience preferences.

Key Industrial Applications of custom printed leather

| Industry/Sector | Specific Application of custom printed leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom jackets, handbags, and accessories | Unique branding opportunities and differentiation | Quality of leather, printing technology, and durability |

| Automotive | Interior upholstery and trim | Enhanced aesthetic appeal and brand customization | Color matching, durability, and fire-retardant options |

| Furniture | Upholstery for chairs and sofas | Customization for unique designs and market appeal | Material compatibility, stain resistance, and longevity |

| Promotional Products | Customized leather goods for giveaways | Increased brand visibility and customer engagement | Cost-effectiveness, design complexity, and lead times |

| Footwear | Personalized shoe designs | Competitive edge through unique offerings | Sourcing sustainable materials and ensuring comfort |

How Is Custom Printed Leather Used in Fashion and Apparel?

In the fashion industry, custom printed leather is utilized for creating bespoke items such as jackets, handbags, and accessories. This application allows brands to showcase their unique designs and branding, setting themselves apart in a competitive market. International buyers, particularly from Africa and South America, should prioritize the quality of the leather and the printing technology used, as well as the durability of the final product to ensure longevity and customer satisfaction.

What Role Does Custom Printed Leather Play in Automotive Interiors?

In the automotive sector, custom printed leather is often used for upholstery and trim, enhancing the vehicle’s aesthetic appeal. This application allows manufacturers to offer personalized options that cater to consumer preferences, thereby increasing brand loyalty. Buyers in the Middle East and Europe should focus on color matching and the durability of the leather, along with fire-retardant properties, to meet safety and design standards.

How Is Custom Printed Leather Transforming Furniture Design?

Furniture manufacturers leverage custom printed leather for upholstery on chairs and sofas, enabling them to create unique, marketable designs that appeal to consumers looking for something distinctive. This approach not only enhances the visual appeal of furniture but also allows for greater customization based on client needs. Buyers should consider material compatibility and stain resistance when sourcing, as these factors significantly impact product longevity and maintenance.

Illustrative image related to custom printed leather

In What Ways Can Custom Printed Leather Benefit Promotional Products?

Custom printed leather is a popular choice for promotional products, such as personalized leather goods and giveaways. This application provides businesses with a unique way to increase brand visibility and engage customers. When sourcing these products, companies must evaluate cost-effectiveness, design complexity, and lead times to ensure they meet marketing timelines and budget constraints.

How Is Custom Printed Leather Used in Footwear Design?

In the footwear industry, custom printed leather allows manufacturers to create personalized shoe designs that cater to consumer preferences. This application provides a competitive edge, as unique offerings can attract a wider customer base. Buyers should prioritize sourcing sustainable materials and ensuring comfort, as these factors are crucial for customer satisfaction and brand reputation.

3 Common User Pain Points for ‘custom printed leather’ & Their Solutions

Scenario 1: Quality Consistency in Custom Printed Leather Products

The Problem: One of the most significant challenges B2B buyers face when sourcing custom printed leather is ensuring quality consistency across different batches. Variations in texture, color fidelity, and durability can occur, especially when dealing with multiple suppliers or different manufacturing runs. For businesses relying on custom leather for products like handbags, apparel, or upholstery, inconsistent quality can result in customer dissatisfaction, increased returns, and potential damage to brand reputation.

The Solution: To mitigate these issues, it is crucial to establish a strong relationship with a reputable supplier who specializes in custom printed leather. Request comprehensive samples before placing a bulk order to assess the texture and print quality. It is also advisable to create a detailed specification sheet outlining the desired qualities, including color accuracy, grain texture, and thickness. Regular communication with your supplier regarding quality standards and expectations can help ensure that each batch meets your specifications. Additionally, consider implementing a quality control process that includes random checks on samples from each batch before they are used in production.

Scenario 2: Understanding the Environmental Impact of Leather Choices

The Problem: With growing awareness of environmental issues, many B2B buyers are concerned about the sustainability of the materials they use, including custom printed leather. Traditional leather production can have a significant environmental footprint, from resource-intensive cattle farming to chemical tanning processes that may harm ecosystems. Buyers from regions with strict environmental regulations may find themselves facing scrutiny over their sourcing decisions.

The Solution: To address these concerns, buyers should explore options for sustainable and eco-friendly printed leather. Engaging with suppliers who offer vegan leather alternatives, made from materials like pineapple fibers or recycled plastics, can reduce the environmental impact while still providing the aesthetic and functional qualities of traditional leather. Additionally, inquire about the supplier’s tanning processes and certifications related to sustainability. Request documentation that outlines their commitment to environmentally friendly practices, such as using low-impact dyes and reducing water waste. By choosing sustainable options, businesses can align their product offerings with consumer preferences for environmentally responsible materials.

Scenario 3: Navigating Complex Customs and Import Regulations

The Problem: For international B2B buyers, importing custom printed leather can be fraught with complications related to customs regulations and tariffs. Different countries have varying import requirements, and failure to comply can lead to delays, unexpected costs, or even seizure of goods at the border. This complexity can be particularly challenging for buyers in regions like Africa or South America, where local regulations may be less familiar to foreign suppliers.

The Solution: To effectively navigate these challenges, buyers should conduct thorough research on the import regulations specific to their country. Collaborating with a logistics provider experienced in handling leather products can streamline the import process. They can assist with documentation, tariffs, and compliance checks to ensure a smooth transaction. Additionally, consider working with suppliers who have a solid understanding of international shipping and can provide guidance on necessary paperwork and customs requirements. Establishing clear communication with your supplier regarding shipping methods, expected delivery times, and any potential customs issues can help anticipate and mitigate delays, ensuring that your products reach you on time and without additional complications.

Strategic Material Selection Guide for custom printed leather

When selecting materials for custom printed leather, B2B buyers must consider various factors that influence product performance, cost, and suitability for specific applications. Below, we analyze four common materials used in custom printed leather, focusing on their properties, advantages, disadvantages, and considerations for international markets.

What Are the Key Properties of Smooth Nappa Leather for Custom Printing?

Smooth Nappa leather is a premium choice for custom printed leather due to its soft texture and flexibility. It typically offers good temperature resistance, maintaining its integrity under varying conditions. This material is also known for its excellent color retention, making it suitable for vibrant designs.

Illustrative image related to custom printed leather

Pros: The softness and durability of Smooth Nappa make it ideal for high-end products such as jackets, handbags, and upholstery. Its ability to withstand wear and tear ensures longevity.

Cons: However, it can be more expensive compared to other leather types, and its manufacturing process may require specialized techniques to achieve the desired print quality.

Impact on Application: Smooth Nappa leather is compatible with a wide range of printing techniques, including digital and screen printing, making it versatile for various design applications.

Illustrative image related to custom printed leather

How Does Textured Nappa Leather Compare in Terms of Performance and Suitability?

Textured Nappa leather offers a unique aesthetic with its embossed surface, providing additional grip and a distinct look. This material generally has a good pressure rating, making it suitable for items that experience frequent handling.

Pros: Its textured surface enhances the tactile experience, making it popular for accessories like wallets and belts. The durability of Textured Nappa ensures it withstands everyday use without significant wear.

Cons: The textured surface may complicate the printing process, requiring careful consideration of ink adhesion and color fidelity. Additionally, it may be slightly more expensive than smooth variants.

Impact on Application: Textured Nappa leather is particularly effective for products where tactile feedback is essential, such as fashion accessories and furniture.

What Are the Advantages of Vegan Leather in Custom Printed Applications?

Vegan leather, made from synthetic materials, is increasingly popular among environmentally conscious consumers. It is often more affordable than traditional leather and can be produced in a variety of textures and colors.

Pros: Vegan leather is lightweight and easy to clean, making it suitable for a wide range of applications, including fashion and home decor. It is also free from animal products, appealing to a growing market segment.

Cons: However, vegan leather may not offer the same level of durability or breathability as genuine leather. It can also be less resistant to heat and pressure, affecting its longevity in high-use environments.

Impact on Application: Vegan leather is compatible with various printing methods and is an excellent choice for fashion items aimed at younger, eco-conscious consumers.

Illustrative image related to custom printed leather

What Should Buyers Consider When Choosing Suede for Custom Printing?

Suede, with its soft and luxurious feel, is often used for high-end products. It has a unique texture that can enhance the overall aesthetic of custom printed items. However, it has a lower temperature and pressure rating compared to other leather types.

Pros: Suede offers a distinct look and feel, making it ideal for premium products such as shoes and bags. Its softness adds a tactile quality that enhances the user experience.

Cons: The porous nature of suede can make it more susceptible to stains and damage from moisture. Additionally, the printing process can be challenging, requiring specialized inks and techniques to achieve satisfactory results.

Impact on Application: Suede is best suited for luxury items where aesthetic appeal is prioritized over practicality, making it a popular choice in high-fashion markets.

Illustrative image related to custom printed leather

Summary Table of Material Options for Custom Printed Leather

| Material | Typical Use Case for custom printed leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Smooth Nappa | High-end jackets, handbags, upholstery | Excellent color retention and softness | Higher cost and complex manufacturing | High |

| Textured Nappa | Wallets, belts, fashion accessories | Unique aesthetic and durability | Complicated printing process | Med |

| Vegan Leather | Fashion items, home decor | Eco-friendly and affordable | Lower durability and heat resistance | Low |

| Suede | Luxury shoes, bags | Luxurious feel and distinct texture | Susceptible to stains and challenging print | Med |

This guide provides a comprehensive overview of the materials available for custom printed leather, aiding B2B buyers in making informed decisions that align with their specific product needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for custom printed leather

What Are the Key Manufacturing Stages for Custom Printed Leather?

The manufacturing process for custom printed leather involves several key stages that ensure the final product meets the required specifications and quality standards. Understanding these stages is crucial for B2B buyers seeking reliable suppliers.

1. Material Preparation: How is Leather Selected and Processed?

The first stage in the manufacturing of custom printed leather is material preparation. High-quality leather is sourced from reputable tanneries, ensuring it is tanned and treated before printing. Various types of leather, including smooth Nappa, textured Nappa, and vegan alternatives, are available for selection. The leather undergoes rigorous testing to assess its durability, texture, and suitability for printing.

Before printing, the leather is prepared by ensuring it is free from blemishes and imperfections. This may involve sorting and grading the hides, as well as applying a base treatment to enhance print adhesion. Buyers should inquire about the origin of the leather and the specific treatments it has undergone to ensure compliance with ethical sourcing and sustainability practices.

Illustrative image related to custom printed leather

2. Forming: What Techniques Are Used for Customization?

Once the leather is prepared, the next stage is forming. This involves the digital printing process, where custom designs are applied to the leather surface. Advanced printing technologies, such as UV printing or dye-sublimation, are employed to ensure vibrant colors and intricate details are achieved.

Digital printing penetrates the leather fibers, resulting in a durable finish that maintains the leather’s original texture. Buyers should look for suppliers that utilize high-resolution printing equipment and quality inks that are resistant to fading and wear. The ability to print on various leather types allows for a wide range of applications, from fashion items to upholstery.

3. Assembly: How Are Custom Printed Leather Products Constructed?

After the leather has been printed, the assembly process begins. This stage involves cutting the printed leather into the desired shapes and sizes, followed by stitching or bonding to create the final product. Skilled artisans or automated machinery may be used, depending on the complexity of the design and the scale of production.

Illustrative image related to custom printed leather

Quality control during assembly is crucial. Each piece must be inspected for alignment, stitching quality, and finish. B2B buyers should ensure that suppliers follow standardized assembly protocols to maintain product consistency and quality.

4. Finishing: What Final Touches Enhance the Product Quality?

The finishing stage is where custom printed leather products receive their final touches. This may include applying protective coatings, embossing, or adding hardware such as zippers and buckles. Finishing techniques can significantly affect the overall aesthetic and durability of the product.

Buyers should inquire about the specific finishing processes used by suppliers, as these can impact the product’s lifespan and usability. Additionally, it is essential to confirm that the finishing materials comply with international safety standards, especially for products intended for markets with stringent regulations.

What Quality Assurance Measures Are Essential for Custom Printed Leather?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final products meet both industry standards and customer expectations. Understanding these measures can help B2B buyers make informed decisions when selecting suppliers.

Illustrative image related to custom printed leather

International Standards: Which Certifications Should Buyers Look For?

International quality standards, such as ISO 9001, provide a framework for quality management systems that suppliers should adhere to. This certification indicates that the supplier has established processes to ensure consistent quality in their products and services.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for specific applications can further assure buyers of the product’s safety and compliance. Buyers should request documentation of these certifications during the supplier selection process.

Quality Control Checkpoints: What Are the Key Inspection Stages?

Quality control (QC) checkpoints are essential to maintaining product quality throughout the manufacturing process. The primary QC stages include:

Illustrative image related to custom printed leather

- Incoming Quality Control (IQC): This is the initial inspection stage where raw materials, including leather, are evaluated for quality before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, samples are taken at various points to ensure that production adheres to established quality standards. This can include checking print quality, stitching integrity, and overall aesthetics.

- Final Quality Control (FQC): After assembly and finishing, the final products undergo a comprehensive inspection to ensure they meet the required specifications and standards.

Implementing these checkpoints helps identify defects early, reducing the risk of delivering subpar products to customers.

Common Testing Methods: How Are Products Evaluated for Quality?

Testing methods for custom printed leather can include:

- Rub Testing: To assess the durability of the print and leather against wear and tear.

- Colorfastness Testing: To ensure colors do not fade or bleed when exposed to various conditions, such as light or moisture.

- Flexibility and Stiffness Testing: To evaluate the leather’s ability to maintain its properties over time.

B2B buyers should request information about the testing methods used by suppliers and the results of any relevant tests to ensure product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for establishing trust and ensuring product quality.

Supplier Audits: What Should Buyers Look For?

Conducting supplier audits can provide insights into a supplier’s quality management practices. During an audit, buyers can assess the supplier’s manufacturing processes, quality control measures, and adherence to international standards.

Buyers should look for suppliers willing to share audit results and be open to third-party inspections. This transparency can foster a more reliable partnership.

Illustrative image related to custom printed leather

Quality Reports and Documentation: How Can Buyers Ensure Compliance?

Requesting quality reports and documentation from suppliers is another effective way to verify quality control. These reports should detail the results of quality inspections, testing methods, and compliance with international standards.

Additionally, buyers should ask for samples of previous work to assess the quality firsthand. This can provide a clearer understanding of what to expect from the supplier.

Conclusion: Why Quality Assurance Is Key for Custom Printed Leather

Understanding the manufacturing processes and quality assurance measures for custom printed leather is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as implementing robust quality control measures, buyers can ensure they partner with suppliers who deliver high-quality, durable products. This attention to detail not only enhances the buyer’s reputation but also contributes to customer satisfaction and brand loyalty in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom printed leather’

To assist B2B buyers in sourcing custom printed leather, this practical checklist outlines essential steps to ensure quality, compliance, and satisfaction with your procurement process. Custom printed leather can elevate your products, but selecting the right materials and suppliers is crucial.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications of the custom printed leather you need. Consider factors such as the type of leather (e.g., Nappa, suede, vegan), weight, texture, and intended use. Defining these parameters helps streamline your sourcing process and ensures that suppliers understand your requirements.

Illustrative image related to custom printed leather

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in custom printed leather. Look for manufacturers with a proven track record in your target market regions, such as Africa, South America, the Middle East, and Europe. Use online directories, industry associations, and trade shows to compile a list of potential candidates.

Step 3: Evaluate Supplier Capabilities

Assess each supplier’s capabilities to ensure they can meet your specific requirements. Inquire about their printing technology, the range of materials they offer, and their production capacity. A reliable supplier should be able to provide samples of their work and demonstrate their ability to produce high-quality prints consistently.

- Check for Certifications: Ensure that suppliers adhere to relevant industry standards and certifications, which can indicate their commitment to quality and sustainability.

Step 4: Request Samples

Before finalizing your order, request samples of the custom printed leather. This step is vital for evaluating the quality of the material, the accuracy of the printing, and how well it meets your specifications. Assess the durability, texture, and color fidelity of the samples to determine if they align with your expectations.

Step 5: Verify Production and Delivery Timelines

Discuss and confirm the production and delivery timelines with your chosen supplier. Understanding their lead times is essential for aligning your project schedules and ensuring timely delivery of your custom printed leather. Be cautious of suppliers who offer unrealistic timelines, as this can indicate potential issues down the line.

Illustrative image related to custom printed leather

Step 6: Understand Pricing and Payment Terms

Clarify the pricing structure and payment terms before committing to a supplier. Compare quotes from multiple suppliers to ensure you receive competitive pricing without compromising quality. Additionally, inquire about payment methods, discounts for bulk orders, and any potential hidden fees.

Step 7: Establish Communication Channels

Effective communication is key to a successful procurement process. Establish clear channels for ongoing communication with your supplier to address any questions or concerns that may arise during production. Regular updates can help ensure that your project stays on track and that any issues are promptly resolved.

By following these steps, B2B buyers can confidently navigate the sourcing process for custom printed leather, ensuring they select high-quality materials that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for custom printed leather Sourcing

What Are the Key Cost Components in Custom Printed Leather Sourcing?

When sourcing custom printed leather, several cost components must be considered to ensure a comprehensive understanding of the total investment. The main cost components include:

-

Materials: The choice of leather type significantly impacts the cost. High-quality leathers such as Nappa or exotic leathers command premium prices compared to synthetic or lower-grade options. Vegan leathers, while often cheaper, may require additional processing for printing.

-

Labor: Skilled labor is essential for both the printing and crafting of leather products. Labor costs can vary based on geographical location and the complexity of the design. In regions with a lower cost of living, labor costs may be more favorable.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, making it essential to assess suppliers based on their operational efficiency.

-

Tooling: Custom tooling for unique designs can add to initial costs. However, investing in high-quality tools can lead to better production quality and longevity, ultimately saving costs in the long run.

-

Quality Control (QC): Ensuring that the final product meets quality standards is crucial. QC processes can incur additional costs but are necessary to avoid costly reworks and maintain customer satisfaction.

-

Logistics: Transportation and shipping costs can vary widely based on distance and the mode of transport. International shipping may require customs fees and tariffs, which can add significantly to the total cost.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding the average markup within the industry can help buyers gauge whether they are receiving a fair price.

What Influences the Pricing of Custom Printed Leather?

Several factors can influence the pricing of custom printed leather:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer tiered pricing based on order volumes. Larger orders typically benefit from lower per-unit costs, making it more economical for buyers to consolidate their purchases.

-

Specifications and Customization: The more intricate the design or specific the requirements (e.g., embossing, special dyes), the higher the cost. Customization often necessitates additional setup and production time, impacting pricing.

-

Materials Quality and Certifications: Leather sourced from reputable suppliers with certifications (such as environmental or ethical standards) can be more expensive. Buyers should consider the importance of these certifications in their purchasing decisions.

-

Supplier Factors: The reliability, reputation, and location of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers may offer competitive rates to build their clientele.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers in shipping and logistics, directly affecting overall costs.

What Are the Best Practices for Negotiating and Achieving Cost Efficiency?

-

Negotiation: Leverage volume purchases to negotiate better pricing. Establish long-term relationships with suppliers, which can lead to more favorable terms and discounts over time.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, handling, and potential returns or reworks. A lower initial price may not always translate to cost savings.

-

Pricing Nuances for International Buyers: Understand currency fluctuations and their impact on pricing. Buyers from Africa, South America, the Middle East, and Europe should also consider import duties and taxes when calculating total costs.

-

Indication of Prices: Be aware that prices can fluctuate based on market demand, raw material costs, and economic conditions. Always request updated quotes and consider potential price changes in your budgeting.

By understanding these cost components and pricing influencers, B2B buyers can make informed decisions that align with their budgetary constraints while ensuring high-quality outcomes in their custom printed leather sourcing endeavors.

Alternatives Analysis: Comparing custom printed leather With Other Solutions

Exploring Alternatives to Custom Printed Leather: What Are Your Options?

In the realm of bespoke materials for fashion, upholstery, and accessories, custom printed leather stands out due to its durability and aesthetic appeal. However, businesses often seek alternatives that can meet specific needs, whether related to cost, sustainability, or ease of use. Below, we compare custom printed leather with other viable solutions to help B2B buyers make informed decisions.

| Comparison Aspect | Custom Printed Leather | Alternative 1: Digital Fabric Printing | Alternative 2: Synthetic Leather |

|---|---|---|---|

| Performance | High durability, retains texture and color | Varies based on fabric; can be less durable | Good initial appearance, but may wear out quickly |

| Cost | Moderate to high, depending on leather type | Generally lower cost, varies by fabric | Usually the most affordable option |

| Ease of Implementation | Requires design upload and printing setup | Simple design process, quick turnaround | Readily available, minimal setup required |

| Maintenance | Requires care to maintain appearance | Varies; generally lower care needs | Easy to clean, but may degrade over time |

| Best Use Case | High-end fashion, bespoke accessories | Casual wear, home decor, promotional items | Budget-conscious products, mass production |

What Are the Benefits and Drawbacks of Digital Fabric Printing?

Digital fabric printing is a compelling alternative for businesses looking to produce custom designs on various textiles. It allows for vibrant prints and complex patterns, making it ideal for casual apparel and home décor. The advantages include a lower cost and quicker turnaround times compared to custom printed leather. However, the durability can vary significantly based on the fabric used, and it may not hold up as well under wear and tear, especially in high-use applications.

How Does Synthetic Leather Compare to Custom Printed Leather?

Synthetic leather, often made from polyvinyl chloride (PVC) or polyurethane (PU), provides a budget-friendly alternative to custom printed leather. It offers an appealing appearance and is easy to clean, making it suitable for a wide range of products, including furniture and fashion items. However, while synthetic leather can mimic the look of real leather, it often lacks the durability and luxurious feel of custom printed leather. Additionally, synthetic options may not offer the same level of customization in terms of prints and textures.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right material depends on various factors such as budget, intended use, and desired aesthetic. For businesses targeting high-end markets or requiring long-lasting products, custom printed leather remains an excellent choice due to its durability and customization options. On the other hand, companies focused on affordability and quick production might lean towards digital fabric printing or synthetic leather, especially for promotional items or casual wear. Understanding the specific needs of your business and your target market will guide you in making the best choice.

Essential Technical Properties and Trade Terminology for custom printed leather

What Are the Key Technical Properties of Custom Printed Leather?

Understanding the technical properties of custom printed leather is crucial for B2B buyers to make informed purchasing decisions. Here are several critical specifications that define the quality and usability of printed leather.

1. Material Grade

Material grade refers to the quality and classification of the leather used for printing. Common grades include full-grain, top-grain, and corrected-grain leather. Full-grain leather, known for its durability and natural look, is often preferred for high-end products. Understanding material grade helps buyers assess the longevity and aesthetic value of the leather, influencing their cost and end-use applications.

2. Thickness

Thickness is a vital property that affects the leather’s flexibility, durability, and application suitability. Typically measured in millimeters, leather thickness can range from 0.5 mm for lightweight applications to over 2 mm for heavier goods. Buyers should consider thickness based on their product requirements, as it impacts not only the feel and drape but also the printing capabilities and overall design execution.

Illustrative image related to custom printed leather

3. Surface Texture

Surface texture can vary significantly, from smooth finishes to embossed or textured surfaces. This property affects both the visual appeal and the tactile experience of the final product. A smoother surface allows for more detailed prints, while textured surfaces can add depth and character to designs. Buyers need to select the right texture based on their product line to achieve the desired look and feel.

4. Color Fastness

Color fastness refers to the resistance of the printed colors to fading or running when exposed to various environmental factors, such as light, water, and abrasion. High color fastness ratings are crucial for products intended for outdoor use or frequent handling. Buyers should inquire about the specific color fastness tests conducted on the printed leather to ensure that their products maintain vibrant colors over time.

5. Durability and Rub Resistance

Durability is a measure of how well the leather withstands wear and tear over time, while rub resistance indicates its ability to resist abrasion. These properties are particularly important for items like bags, shoes, and upholstery. Buyers should look for leather that has undergone rigorous testing for durability and rub resistance to ensure that their products will last and maintain quality through regular use.

Illustrative image related to custom printed leather

What Common Trade Terms Should B2B Buyers Know in the Custom Printed Leather Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some common trade terms related to custom printed leather.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of custom printed leather, an OEM might create leather goods for brands that sell them under their own label. Understanding OEM relationships can help buyers identify potential manufacturing partners and assess the capabilities of suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of a product that a supplier is willing to sell. This term is critical for buyers as it affects inventory management and cost efficiency. Knowing the MOQ helps businesses plan their purchases and negotiate better terms, especially when considering bulk orders of custom printed leather.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the custom printed leather market, sending an RFQ allows buyers to compare offers from multiple suppliers, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. These terms clarify aspects such as shipping costs, insurance, and liability. Understanding Incoterms is essential for B2B buyers to manage logistics effectively and minimize risks in cross-border transactions.

Illustrative image related to custom printed leather

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the finished product. In the custom printed leather industry, lead time can vary based on factors such as production schedules and shipping methods. Buyers should account for lead time in their planning to ensure timely delivery of their products to market.

By grasping these essential technical properties and trade terminologies, B2B buyers can enhance their purchasing strategies and foster stronger relationships with suppliers in the custom printed leather industry.

Navigating Market Dynamics and Sourcing Trends in the custom printed leather Sector

What Are the Current Market Dynamics and Key Trends in Custom Printed Leather?

The custom printed leather market is experiencing significant growth driven by several global factors. Firstly, the demand for personalized and unique products is on the rise, especially among consumers in Africa, South America, the Middle East, and Europe. This shift is particularly evident in sectors like fashion, automotive, and home décor, where custom designs can differentiate offerings and enhance brand loyalty. Additionally, advancements in digital printing technology have made it more feasible for manufacturers to produce high-quality prints quickly and cost-effectively, allowing for shorter lead times and increased customization options.

Emerging technologies such as 3D printing and AI-driven design software are also influencing sourcing trends. B2B buyers are increasingly leveraging these tools to create intricate designs and streamline the production process. Moreover, the rise of e-commerce platforms facilitates easier access to global suppliers, enabling buyers to source custom printed leather from diverse regions without geographical constraints. This interconnectedness allows for competitive pricing and a broader selection of materials, such as vegan leather alternatives that cater to environmentally conscious consumers.

How Are Sustainability and Ethical Sourcing Influencing the Custom Printed Leather Market?

Sustainability has become a cornerstone of the custom printed leather sector. The environmental impact of traditional leather production has prompted both consumers and businesses to seek more sustainable practices. Ethical sourcing is increasingly critical, with buyers prioritizing suppliers who demonstrate a commitment to environmentally friendly production methods. This includes using natural dyes, minimizing waste, and ensuring humane treatment of animals in the leather supply chain.

Illustrative image related to custom printed leather

B2B buyers should also look for suppliers that hold certifications like the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification. These certifications indicate adherence to strict environmental and social criteria, providing assurance of responsible sourcing. Additionally, the availability of innovative materials, such as pineapple leather and other plant-based alternatives, is expanding the landscape of sustainable options for custom printed leather. By prioritizing these factors, businesses not only contribute to environmental preservation but also enhance their brand reputation and appeal to a growing base of eco-conscious consumers.

What Is the Brief Evolution and History of Custom Printed Leather?

The history of leather dates back thousands of years, with its use evolving significantly over time. Initially, leather was primarily utilized for practical purposes such as clothing and shelter. However, as techniques for tanning and processing advanced, leather became a symbol of luxury and craftsmanship. The introduction of printing technologies in the 20th century marked a significant turning point, allowing for the application of patterns and colors that transformed leather into a canvas for artistic expression.

In recent years, the advent of digital printing has revolutionized the custom printed leather market, enabling brands to offer personalized products on a large scale. This technological evolution has not only enhanced the aesthetic appeal of leather goods but has also made it possible for businesses to cater to niche markets and individual consumer preferences. As the industry continues to innovate, the potential for custom printed leather is bound to expand, offering new opportunities for B2B buyers looking to differentiate their offerings in a competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of custom printed leather

1. How can I ensure the quality of custom printed leather before placing a large order?

To ensure the quality of custom printed leather, request sample swatches from potential suppliers. This allows you to evaluate the texture, print quality, and color accuracy of the leather. Additionally, inquire about the printing process and the types of inks used, as these can affect durability. Look for suppliers who offer quality assurance certifications and have positive reviews from previous clients. Establishing a strong communication channel with your supplier can also help address any concerns before finalizing your order.

2. What types of leather are available for custom printing?

Custom printed leather is available in various types, including smooth Nappa, textured Nappa, and vegan leather options. Each type has its unique properties, such as thickness, flexibility, and finish. Depending on your project requirements, you can choose full-grain or corrected-grain leather. Additionally, some suppliers may offer specialty leathers, such as suede or eco-friendly alternatives like pineapple leather. Understanding the characteristics of each type will help you select the best material for your specific application, whether it be fashion accessories or upholstery.

Illustrative image related to custom printed leather

3. What is the minimum order quantity (MOQ) for custom printed leather?

Minimum order quantities (MOQ) for custom printed leather vary by supplier and can range from as low as 5 meters to several hundred meters. It’s essential to discuss MOQs during the initial conversation with potential suppliers, as this can impact your budget and production timelines. Some suppliers may offer lower MOQs for first-time buyers or specific product lines. If your order is below the MOQ, consider pooling orders with other businesses or discussing the possibility of a custom arrangement with the supplier.

4. What customization options are available for printed leather products?

Customization options for printed leather products typically include size, color, and design. Buyers can upload their artwork or select from existing designs. Some suppliers also offer debossing or embossing, allowing for tactile elements on the leather surface. Consider discussing your specific needs with the supplier to explore all available options. Additionally, inquire about the possibility of creating prototypes or small batch runs to test your designs before committing to a larger order.

5. How do I vet suppliers for custom printed leather?

Vetting suppliers for custom printed leather involves checking their industry experience, client references, and production capabilities. Look for suppliers with a strong portfolio and positive feedback from previous clients. Request information about their quality control processes and certifications, such as ISO standards. Attend trade shows or industry events to meet suppliers in person, or consider third-party verification services for added assurance. Establishing a good rapport and clear communication can also indicate a supplier’s reliability.

Illustrative image related to custom printed leather

6. What are the typical payment terms for international orders of custom printed leather?

Payment terms for international orders of custom printed leather can vary, but common practices include a deposit upfront (often 30-50%) with the balance due upon completion or delivery. Some suppliers may offer flexible payment options, such as letters of credit or escrow services for larger orders. It’s crucial to clarify payment terms before finalizing your order to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees when dealing with international suppliers.

7. What logistics considerations should I keep in mind when importing custom printed leather?

When importing custom printed leather, consider shipping methods, customs duties, and lead times. Choose a reliable freight forwarder familiar with handling leather products and customs regulations in your country. Understand the import duties and taxes applicable to your shipment, as these can significantly affect your overall costs. Ensure that your supplier can provide necessary documentation, such as certificates of origin and compliance with international standards, to facilitate smooth customs clearance.

8. How do I handle quality assurance and returns for custom printed leather?

Establish a clear quality assurance process with your supplier, including agreed-upon standards for print quality, material integrity, and overall finish. Document these standards in your contract. Discuss the return policy upfront, including conditions for returns or exchanges in case of defects or discrepancies. Conduct thorough inspections upon receipt of goods to catch any issues early. Good communication with your supplier will help resolve any quality concerns promptly and maintain a positive business relationship.

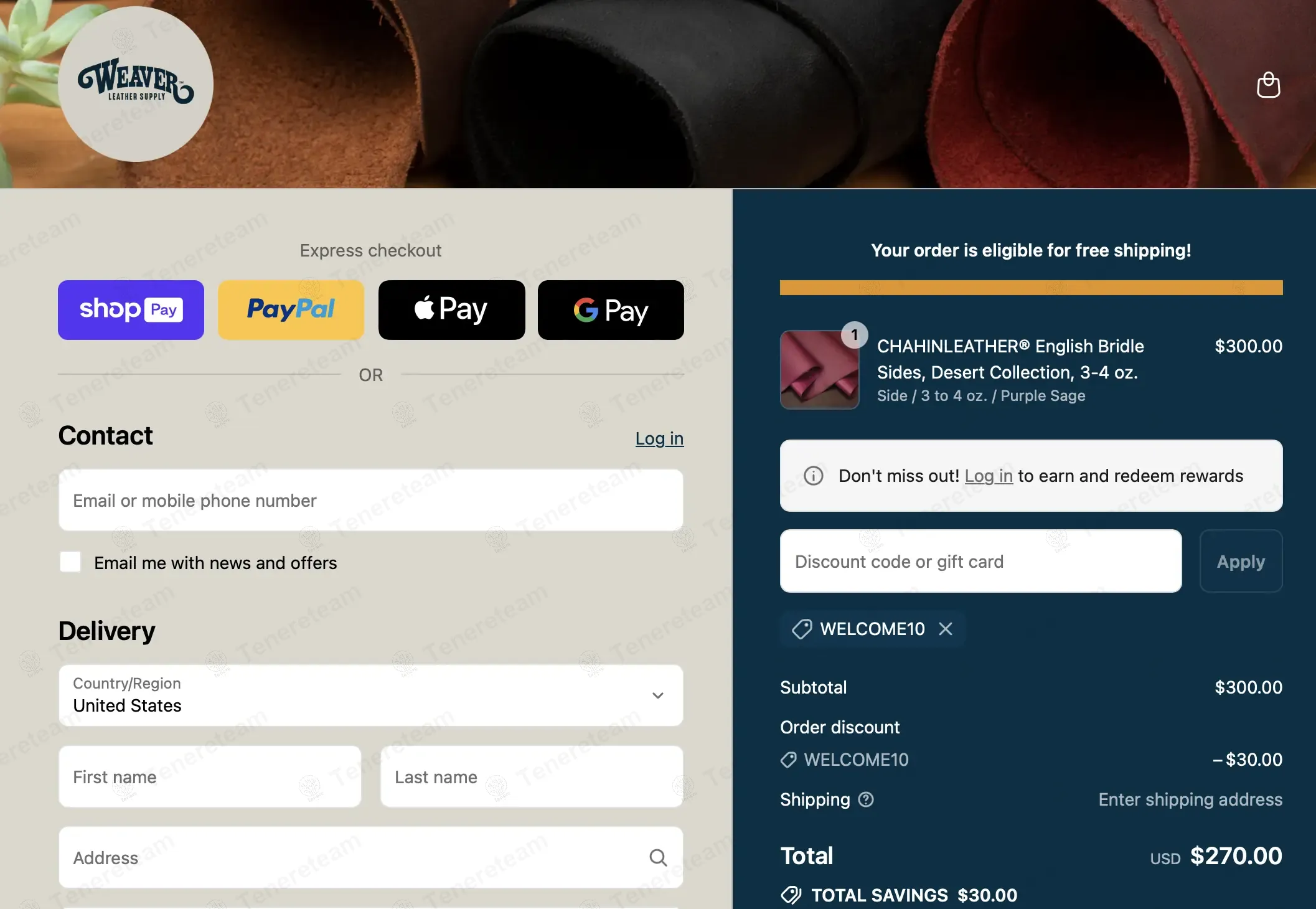

Top 7 Custom Printed Leather Manufacturers & Suppliers List

1. Contrado – Custom Leather Prints

Domain: contrado.com

Registered: 2004 (21 years)

Introduction: Printed Leather allows you to create custom leather prints using your artwork or designs. Available options include Smooth Nappa Leather, Textured Nappa Leather, Bubble Nappa Leather, Vegan Leather, Furnishing Leatherette, and Suede. The printing method uses specific dyes that penetrate deep into the fibers of the leather, ensuring strong and rich colors with exceptional accuracy. Products include…

2. Bags of Love – Custom Printed Leather Products

Domain: bagsoflove.com

Registered: 2003 (22 years)

Introduction: Printed Leather allows you to use your photos and designs to create personalized leather products. It is suitable for items like leather jackets and handbags, as well as reupholstering furniture. The range includes 100% real leather, custom printed faux leather (vegan alternative), fire-rated suede (vegan alternative), and leather swing tags. Key products include: 1. Real Leather Printing – $26.25…

3. Leathergenix – Custom Leather Printing Services

Domain: leathergenix.com

Registered: 2009 (16 years)

Introduction: Leathergenix is a custom leather printing specialist offering high-end luxury leather printing services. They print any image on leather for various products including jackets, handbags, shoes, and aviation seat interiors. Their services extend to interior design with custom printed leather for hospitality environments, furniture, and automotive interiors. They also provide lifestyle accessories s…

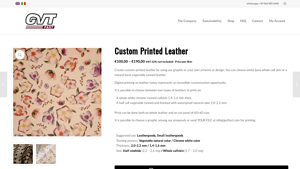

4. GVT Fast – Custom Printed Leather

Domain: gvtfast.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Custom Printed Leather”, “price_range”: “€100,00 – €190,00”, “VAT”: “22% not included”, “base_materials”: [“white chrome-tanned calfskin (1.4-1.6 mm thick)”, “vegetable tanned leather (2.0-2.2 mm thick)”], “print_options”: [“whole leather”, “cut panel (60×60 cm)”, “custom artwork or graphic”], “suggested_use”: [“Leathergoods”, “Small leathergoods”], “tanning_process”: [“Vegetable…

5. Rainbow Leather – Custom Foiling & Printing Solutions

Domain: rainbowleather.com

Registered: 1999 (26 years)

Introduction: Foiling: Special effect for standout appearance. Digital Printing: Customizable colors and effects. Embossing: Custom plates or extensive library available. Cutting: Custom plates or extensive library available. Perforation: Custom plates or extensive library available. Monogramming: Custom gold, silver, and blind embossed options. Cork Catalog: Customizable natural cork sheets. Cow Suede Catalog:…

6. Duke and Dexter – Custom Leather Printing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Duke and Dexter prints on leather using UV printing. It is recommended to treat the leather before printing to prevent ink absorption. A specific ink mentioned is lus-120, used with Mimaki UV machines. There are custom finished leather products available with print made on demand, and the leather is of premium quality (Italian).

7. Beautiful Displays – Custom Patent Leather Printing Services

Domain: beautifuldisplays.com

Registered: 2002 (23 years)

Introduction: Patent Leather Printing Services | Custom Printed Leather

1. **Ordering Process**:

– **Step 1**: Find & Purchase – Browse and purchase online or call 800.697.4670 for assistance.

– **Step 2**: Art & Approval – Upload print-ready files or collaborate with the design team. Electronic proof sent within one business day.

– **Step 3**: Relax! – After proof approval, production begins. Tracki…

Strategic Sourcing Conclusion and Outlook for custom printed leather

In navigating the evolving landscape of custom printed leather, strategic sourcing emerges as a pivotal element for international B2B buyers. The advancements in digital printing technology have transformed the possibilities within this sector, allowing for high-quality, customizable products that cater to diverse market demands. Buyers should prioritize suppliers that offer a variety of leather types, including vegan options, to meet consumer preferences across regions.

Furthermore, understanding the unique characteristics of different leathers—such as Nappa, suede, and specialty vegan materials—can enhance product offerings and differentiate brands in competitive markets. Establishing strong relationships with reliable suppliers not only ensures consistent quality but also facilitates faster turnaround times, crucial for responding to market trends.

As we look to the future, the potential for innovation in custom printed leather remains vast. Buyers from Africa, South America, the Middle East, and Europe are encouraged to leverage this opportunity by integrating unique designs and sustainable practices into their sourcing strategies. Embrace the future of custom printed leather—connect with suppliers today to explore how tailored solutions can elevate your brand’s offerings and meet the growing demand for personalized products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.