Introduction: Navigating the Global Market for custom leather engraving

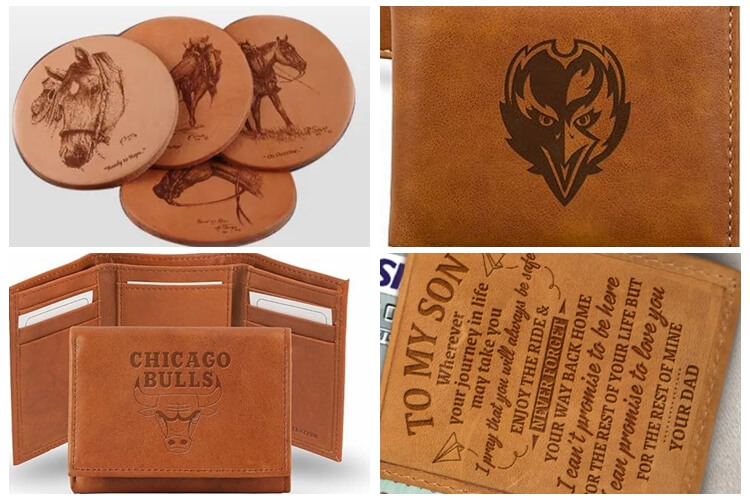

In the rapidly evolving landscape of international commerce, sourcing custom leather engraving services can be a daunting challenge for B2B buyers. With an increasing demand for personalized and high-quality leather products across markets in Africa, South America, the Middle East, and Europe, understanding the nuances of this craft becomes essential. Whether you are looking to enhance your brand identity through engraved promotional items or seeking unique, customized gifts for clients, navigating the complexities of custom leather engraving requires informed decision-making.

This comprehensive guide delves into the multifaceted world of custom leather engraving, covering various techniques such as laser engraving, embossing, and pyrography. It examines the diverse applications of engraved leather products, from corporate gifts to luxury fashion items, and offers insights into supplier vetting processes to ensure quality and reliability. Additionally, we provide a thorough analysis of cost considerations, enabling you to budget effectively while maximizing value.

By equipping international B2B buyers with the knowledge and resources to make informed purchasing decisions, this guide empowers you to successfully navigate the global market for custom leather engraving. With a focus on actionable insights and best practices, you will be well-prepared to engage with suppliers and capitalize on the unique opportunities that personalized leather products present for your business.

Table Of Contents

- Top 5 Custom Leather Engraving Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather engraving

- Understanding custom leather engraving Types and Variations

- Key Industrial Applications of custom leather engraving

- 3 Common User Pain Points for ‘custom leather engraving’ & Their Solutions

- Strategic Material Selection Guide for custom leather engraving

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather engraving

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather engraving’

- Comprehensive Cost and Pricing Analysis for custom leather engraving Sourcing

- Alternatives Analysis: Comparing custom leather engraving With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather engraving

- Navigating Market Dynamics and Sourcing Trends in the custom leather engraving Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather engraving

- Strategic Sourcing Conclusion and Outlook for custom leather engraving

- Important Disclaimer & Terms of Use

Understanding custom leather engraving Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Branding | Burns design into leather; creates a darker, sunken effect | Custom branding for products; promotional items | Pros: High visibility; unique aesthetic. Cons: Limited detail; potential for damage if not done carefully. |

| Laser Engraving | Uses focused laser to etch precise designs; minimal material loss | High-end personalization; intricate designs | Pros: High precision; versatile; suitable for complex designs. Cons: Requires specialized equipment; higher initial investment. |

| Embossing | Imprints design without removing material; retains leather grain | Mass production of decorative items; furniture | Pros: Efficient for large volumes; maintains leather texture. Cons: Less detail than engraving; potential wear over time. |

| Pyrography | Uses heated tools for detailed designs; manual process | Artisan goods; custom gifts | Pros: Unique artistry; customizable. Cons: Time-consuming; requires skill and experience. |

| Perforation | Creates holes to enhance design; improves breathability | Functional designs; custom patterns | Pros: Adds texture and visual interest. Cons: Not suitable for all leather types; labor-intensive. |

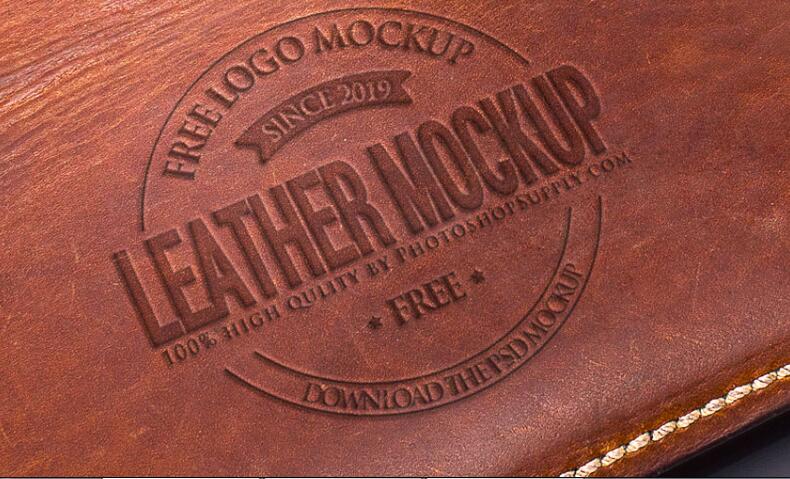

What Are the Characteristics of Branding in Custom Leather Engraving?

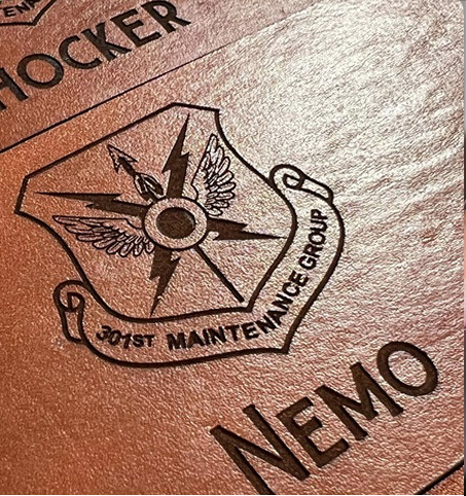

Branding is a traditional method where a heated metal object is pressed onto leather to create a distinct design. This technique is ideal for businesses looking to establish a strong brand identity through logos or unique markings on their products. It’s commonly used for promotional items, making it a popular choice among companies in retail and hospitality sectors. However, while branding offers high visibility, it may lack the intricate detail that other methods provide, and improper technique can damage the leather.

How Does Laser Engraving Stand Out for B2B Applications?

Laser engraving employs a focused beam of light to etch designs into leather with remarkable precision. This method is particularly advantageous for businesses requiring intricate patterns, such as detailed logos or artwork. Industries such as fashion, luxury goods, and personalized gifts frequently leverage laser engraving for its versatility and ability to produce high-quality results. While the initial investment in laser equipment can be significant, the precision and durability of the designs often justify the cost for B2B buyers.

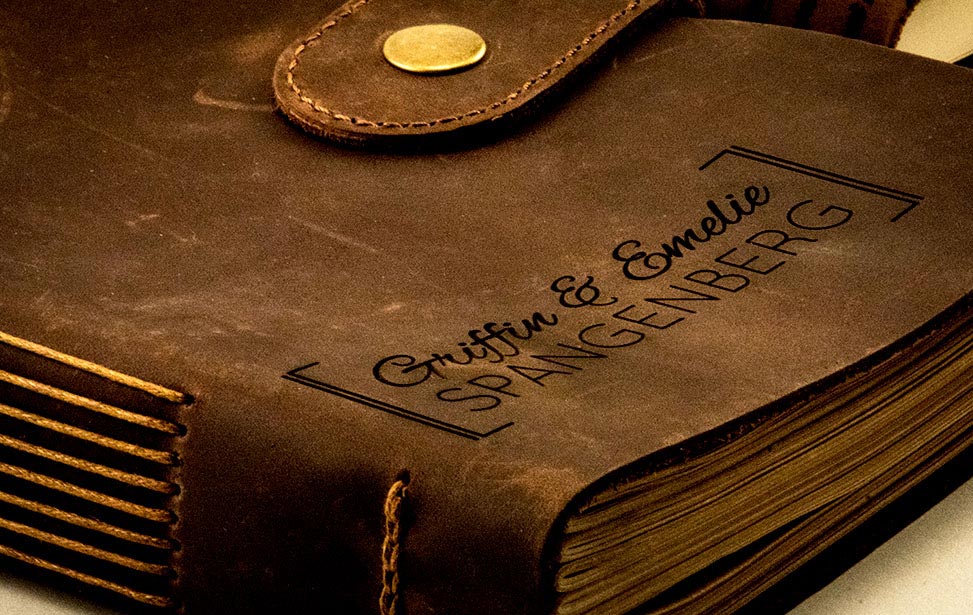

Illustrative image related to custom leather engraving

What Makes Embossing a Popular Choice for Mass Production?

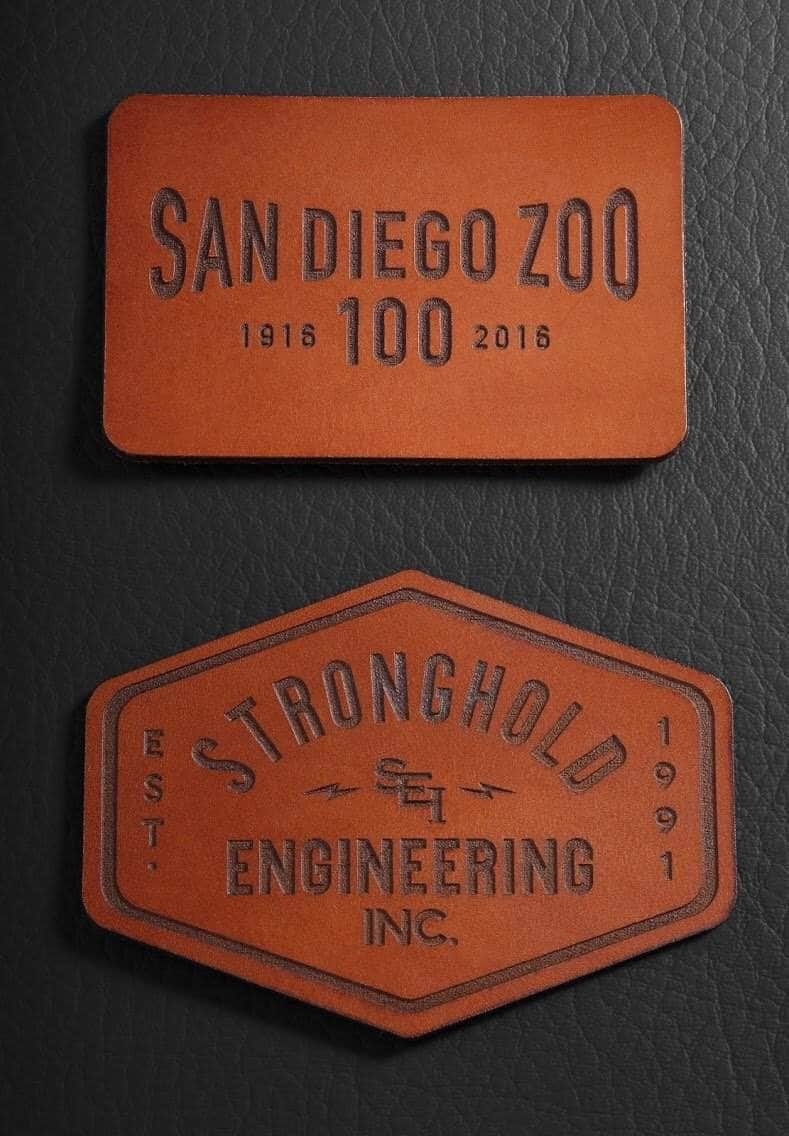

Embossing involves pressing a design into leather without removing material, which preserves the natural texture and grain of the leather. This technique is especially beneficial for manufacturers producing large quantities of decorative items, such as leather furniture or accessories, as it allows for efficient replication of designs. While embossing is effective for high-volume production, it may not achieve the same level of detail as other engraving methods, and the designs can wear over time if not properly maintained.

Why Consider Pyrography for Unique Artisan Goods?

Pyrography is a manual engraving method that uses heated tools to create detailed designs on leather. This technique is favored by artisans and small businesses looking to offer unique, handcrafted products. Pyrography allows for a high level of customization, appealing to customers seeking one-of-a-kind gifts or personalized items. However, the time-intensive nature of this method requires skilled artisans, which can limit scalability for larger B2B operations.

How Does Perforation Enhance Design and Functionality?

Perforation involves creating small holes in leather to enhance breathability and design aesthetics. This method can be strategically used to create patterns or improve the functionality of leather items, making it suitable for applications like footwear or custom bags. While perforation adds a unique visual element, it is typically more labor-intensive and is often executed using machinery for efficiency. Businesses considering this method should ensure that the leather type can withstand perforation without compromising structural integrity.

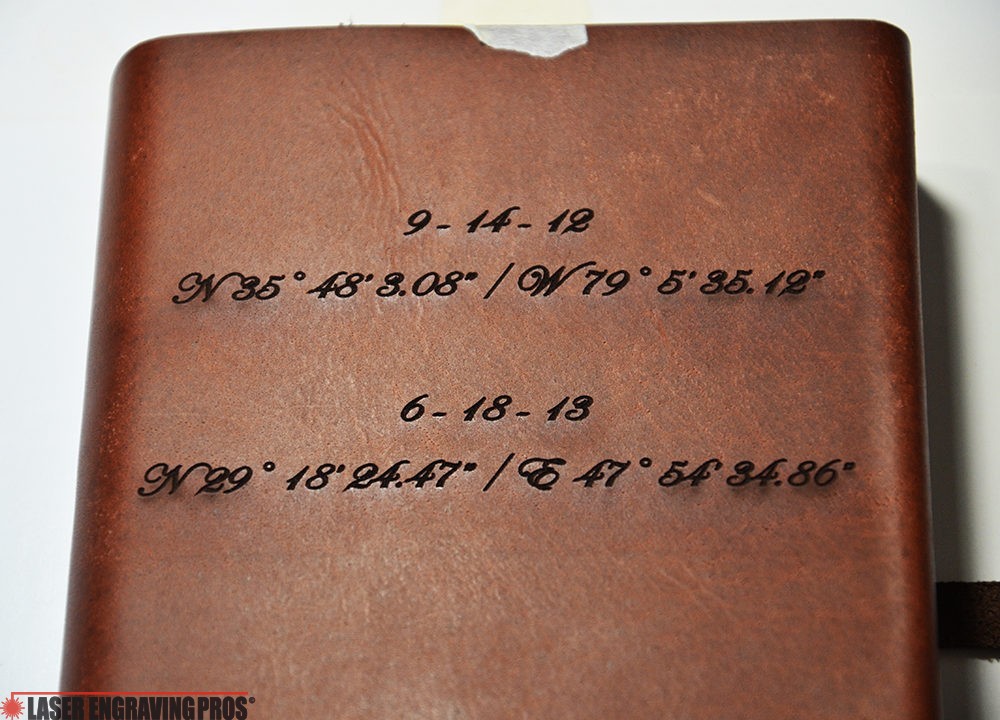

Illustrative image related to custom leather engraving

Key Industrial Applications of custom leather engraving

| Industry/Sector | Specific Application of Custom Leather Engraving | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Personalized handbags and wallets | Enhances brand identity and customer loyalty | Quality of leather, engraving precision, turnaround time |

| Corporate Gifts | Customized leather portfolios and notebooks | Strengthens client relationships through unique gifting | Volume discounts, customization options, shipping logistics |

| Automotive | Engraved leather interiors and accessories | Adds luxury appeal and personalization to vehicles | Material compatibility, design complexity, production scale |

| Hospitality | Customized leather menus and coasters | Elevates dining experience and brand image | Durability of leather, design adaptability, sourcing reliability |

| Sports & Recreation | Personalized sports gear and equipment | Boosts brand recognition and customer engagement | Production timelines, material sourcing, design flexibility |

How is Custom Leather Engraving Used in the Fashion & Accessories Industry?

In the fashion and accessories sector, custom leather engraving is employed to create personalized handbags and wallets that resonate with individual customer preferences. This personalization enhances brand identity and fosters customer loyalty, as consumers are increasingly seeking unique products that reflect their personal style. International buyers should consider the quality of leather and the precision of engraving techniques, as these factors significantly impact the final product’s appeal and durability.

What Role Does Custom Leather Engraving Play in Corporate Gifts?

Corporate gifting often incorporates customized leather portfolios and notebooks that can feature company logos or personalized messages. This strategy strengthens client relationships and enhances brand visibility, making gifts memorable and impactful. B2B buyers need to evaluate volume discounts, available customization options, and shipping logistics to ensure a seamless procurement process, especially when catering to diverse markets across Africa, South America, the Middle East, and Europe.

How Can Automotive Businesses Benefit from Custom Leather Engraving?

In the automotive industry, custom leather engraving is used for enhancing vehicle interiors and accessories, such as steering wheels and seats. This service adds a layer of luxury and personalization that appeals to discerning customers. Buyers must consider material compatibility, the complexity of designs, and the ability to scale production to meet demand, particularly when targeting international markets where preferences may vary significantly.

Why is Custom Leather Engraving Important in the Hospitality Sector?

Custom leather engraving is widely utilized in the hospitality industry for creating unique leather menus and coasters that elevate the dining experience. These engraved items not only enhance the brand image but also serve as conversation starters, adding a touch of sophistication to the establishment. Buyers should assess the durability of leather used, the adaptability of designs to various themes, and the reliability of sourcing to ensure consistency in quality.

How Does Custom Leather Engraving Enhance Sports & Recreation Products?

In the sports and recreation sector, personalized sports gear and equipment, such as engraved leather gloves or bags, significantly boost brand recognition and customer engagement. This personalization allows brands to connect with their audience on a deeper level, fostering loyalty. B2B buyers must focus on production timelines, material sourcing, and design flexibility to accommodate diverse customer needs and preferences, especially in international markets where trends may differ.

3 Common User Pain Points for ‘custom leather engraving’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Quality Across Orders

The Problem: For B2B buyers looking to source custom leather products, maintaining consistent quality across multiple orders can be a significant challenge. Variations in leather quality, engraving depth, and design execution can lead to discrepancies that may affect branding and customer satisfaction. Buyers may find that some items are beautifully engraved while others fall short of expectations, leading to frustration and potential loss of business.

The Solution: To ensure consistent quality, it is crucial to establish a solid partnership with a reliable leather engraving service that prioritizes quality control. Before placing bulk orders, conduct a small test batch to evaluate the engraving quality and material consistency. Clearly communicate your specifications, including the type of leather, desired engraving depth, and design details. Additionally, consider implementing a quality assurance checklist that the engraving service must follow for every order. This could include checks for leather type consistency, engraving precision, and overall finish. Regularly reviewing samples and providing feedback will help maintain high standards across all orders.

Scenario 2: Limited Customization Options for Unique Branding Needs

The Problem: Many B2B buyers face the issue of finding engraving services that can accommodate specific branding requirements. Off-the-shelf solutions may not provide the level of personalization needed to stand out in competitive markets. Buyers may struggle to find engraving techniques that align with their brand’s aesthetic or that can incorporate intricate designs and logos effectively.

The Solution: To overcome this limitation, engage with engraving services that specialize in customization and offer various engraving techniques. When approaching a vendor, provide detailed design files and specify the engraving method that best suits your brand identity—whether it be laser engraving for intricate designs or embossing for a classic look. Request samples of previous work that align with your vision to gauge the vendor’s capability. Additionally, consider leveraging digital mock-ups that allow you to visualize how your branding will appear on the leather before production. This proactive approach will ensure that the final product meets your unique branding needs.

Scenario 3: Long Lead Times Affecting Product Availability

The Problem: B2B buyers often experience long lead times when ordering custom leather engraved products, which can disrupt supply chains and affect customer satisfaction. This issue is particularly pronounced when working with vendors that have limited production capabilities or those that do not prioritize timely delivery.

The Solution: To mitigate lead time challenges, it is essential to partner with an engraving service that offers transparent timelines and flexible production capacities. Start by discussing your project timelines during the initial consultation, emphasizing the importance of timely delivery. Look for vendors that provide expedited services or have the capability to handle large orders efficiently. Additionally, consider establishing long-term contracts or agreements that prioritize your orders in exchange for volume commitments. This not only secures better lead times but also fosters a stronger relationship with the vendor, ultimately benefiting both parties. Regular communication and setting clear deadlines will further enhance the efficiency of the production process, ensuring that your supply chain remains uninterrupted.

Strategic Material Selection Guide for custom leather engraving

When considering custom leather engraving, the choice of material is crucial for achieving optimal results. This guide analyzes four common leather types used in the engraving process, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Full-Grain Leather for Engraving?

Full-grain leather is the highest quality leather available, retaining the natural grain and texture of the hide. It offers excellent durability and breathability, making it ideal for high-end products. This material can withstand significant temperature variations and pressure, which is essential during the engraving process.

Pros: Full-grain leather is highly resistant to wear and tear, making it suitable for products that require longevity, such as wallets and bags. Its natural appearance enhances the aesthetic appeal of engraved designs.

Cons: The cost of full-grain leather is relatively high compared to other types, which may affect pricing strategies for B2B buyers. Additionally, its thickness can complicate the engraving process, requiring specialized equipment.

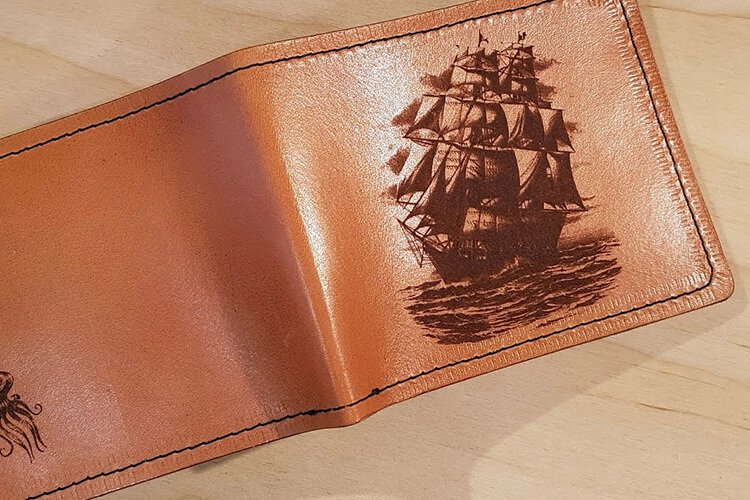

Illustrative image related to custom leather engraving

Impact on Application: Full-grain leather is compatible with various engraving techniques, including laser and branding, allowing for intricate designs. However, the engraving depth may vary based on the leather’s thickness.

How Does Top-Grain Leather Compare in Custom Leather Engraving?

Top-grain leather is slightly less durable than full-grain but is more affordable and easier to work with. It has been sanded and treated to remove imperfections, giving it a smoother finish.

Pros: The smooth surface of top-grain leather allows for detailed engraving and is more cost-effective, making it a popular choice for bulk orders. It is also more flexible, which can be advantageous for products requiring bending or shaping.

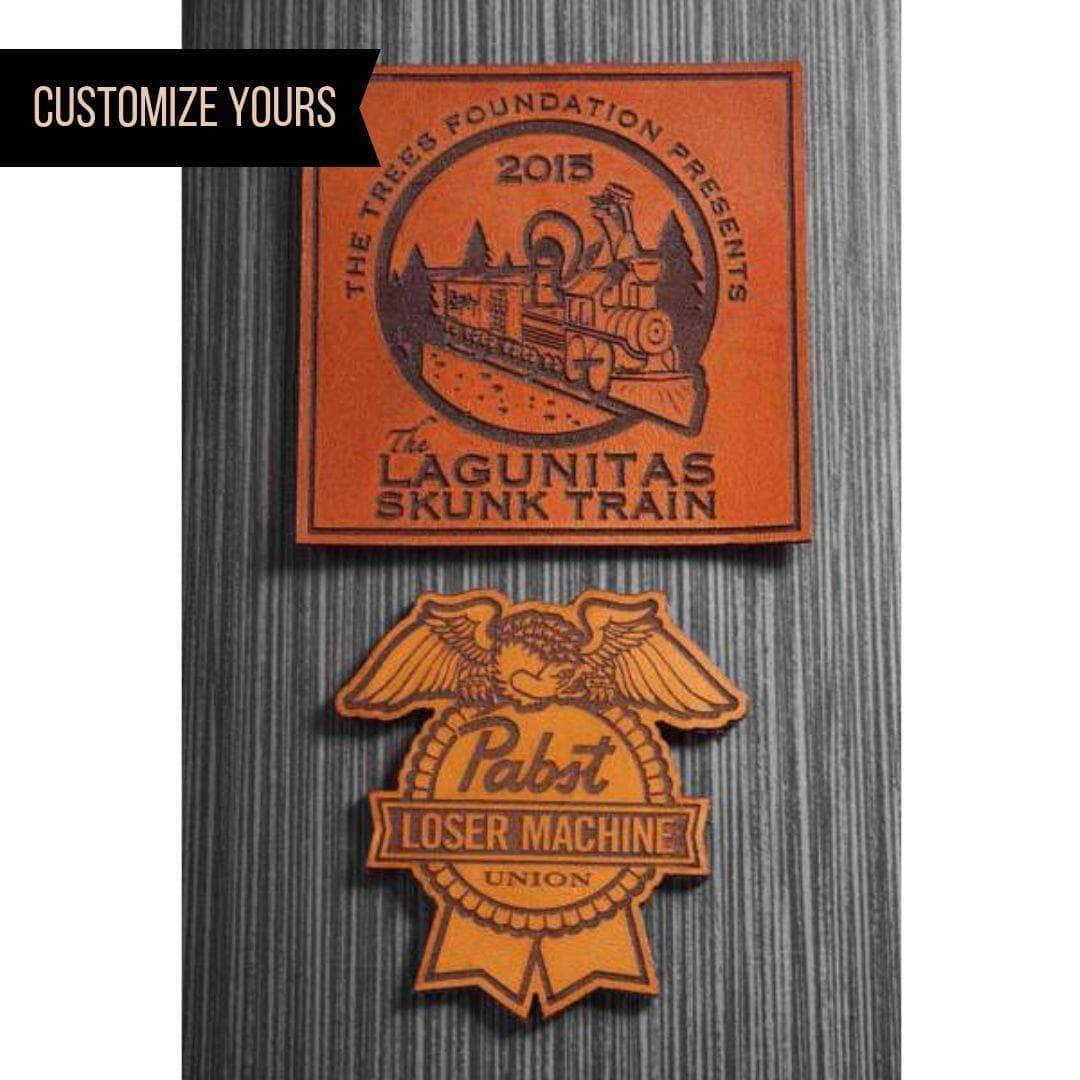

Illustrative image related to custom leather engraving

Cons: While top-grain leather is durable, it is not as resistant to scratches and wear as full-grain leather. This may limit its suitability for high-traffic items.

Impact on Application: Top-grain leather can be effectively engraved using laser techniques, but the results may not be as striking as those achieved with full-grain leather due to its treated surface.

What Are the Benefits and Limitations of Suede Leather in Engraving?

Suede leather, made from the underside of the hide, offers a unique texture and appearance. It is softer and more pliable than other leather types, making it an appealing option for certain applications.

Pros: Suede’s soft texture allows for unique engraving effects, creating a tactile experience. It is also lightweight, which can be beneficial for products like bags and accessories.

Cons: Suede is less durable than full-grain and top-grain leather, making it more susceptible to damage from moisture and stains. This limits its use in products that require high durability.

Impact on Application: Engraving on suede can yield beautiful results, but the process may require additional care to ensure the design remains intact over time. Suede is generally less suitable for heavy-duty applications.

How Does Bonded Leather Fit into the Custom Engraving Landscape?

Bonded leather is made from leather scraps and fibers that are bonded together with polyurethane or latex. It is often used as a more affordable alternative to genuine leather.

Pros: Bonded leather is cost-effective and can be produced in various colors and textures, making it appealing for promotional items and lower-cost products. It is also lightweight and easy to handle during the engraving process.

Cons: The durability of bonded leather is significantly lower than that of full-grain or top-grain leather. It is prone to peeling and may not withstand the test of time as well as natural leather.

Impact on Application: While bonded leather can be engraved, the results may not be as high-quality as those achieved with genuine leather. It is best suited for items that do not require long-term durability.

Summary Table of Material Selection for Custom Leather Engraving

| 素材 | Typical Use Case for custom leather engraving | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end wallets, bags, and accessories | Exceptional durability and aesthetics | High cost; requires specialized equipment | 高い |

| Top-Grain Leather | Mid-range bags, wallets, and apparel | Cost-effective; smooth surface for detail | Less durable than full-grain | Medium |

| Suede Leather | Fashion accessories, bags, and home decor | Unique texture and lightweight | Less durable; susceptible to stains | Medium |

| Bonded Leather | Promotional items, low-cost accessories | Affordable and versatile | Lower durability; prone to peeling | 低い |

This strategic material selection guide is designed to help international B2B buyers make informed decisions about custom leather engraving, considering the unique properties and applications of each material.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather engraving

What Are the Main Stages of Manufacturing Custom Leather Engraving?

The manufacturing process for custom leather engraving involves several critical stages that ensure quality and precision. These stages include material preparation, forming, assembly, and finishing. Each step is crucial in producing a high-quality final product that meets the expectations of international B2B buyers.

How Is Material Prepared for Custom Leather Engraving?

Material preparation begins with the selection of the leather type. Different types of leather, such as full-grain or vegetable-tanned leather, are chosen based on their suitability for engraving. The leather is then conditioned to achieve optimal moisture content, which enhances the engraving quality. This conditioning may involve soaking the leather in water to make it more pliable and receptive to engraving techniques.

Illustrative image related to custom leather engraving

Following conditioning, the leather is cut to size and inspected for any imperfections. This inspection is vital, as any flaws can affect the engraving quality. Buyers should ensure that their suppliers adhere to strict selection criteria to guarantee the best material is used.

What Techniques Are Employed in Custom Leather Engraving?

Several engraving techniques are employed in the manufacturing process, each offering unique advantages:

-

Laser Engraving: This method uses a focused beam of light to etch designs into the leather. It allows for high precision and intricate designs, making it the preferred choice for complex images and lettering.

-

Branding: This traditional method involves using a heated metal stamp to burn a design into the leather. While it creates a distinctive look, it requires careful handling to avoid damaging the material.

-

Embossing: This technique presses a design into the leather without removing material, allowing for a raised effect. It’s commonly used for creating logos and patterns on larger items.

-

Hand Engraving: Skilled artisans can use hand tools to carve designs into the leather. This method offers a personal touch but requires significant time and skill.

-

Perforation: This involves creating holes in the leather for decorative or functional purposes. It’s often used in conjunction with other techniques to enhance the design.

Each technique has its own set of equipment and operational requirements, which can vary significantly based on the scale of production.

How Is Quality Assurance Implemented in Custom Leather Engraving?

Quality assurance (QA) is essential in the custom leather engraving process to ensure that the final products meet international standards and buyer expectations. Key quality assurance measures include adherence to international standards such as ISO 9001 and industry-specific certifications like CE and API.

Illustrative image related to custom leather engraving

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. For leather, this includes checking for grain quality, thickness, and any defects.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to monitor equipment performance and engraving quality. This can include verifying the accuracy of laser settings and ensuring that branding irons are heated correctly.

-

Final Quality Control (FQC): Once the engraving process is complete, a final inspection is conducted. This includes checking for precision in the engraving, overall appearance, and adherence to any client-specific requirements.

What Testing Methods Are Commonly Used in Quality Control for Leather Engraving?

Testing methods in leather engraving quality control can vary based on the intended use of the product. Common methods include:

-

Visual Inspection: The most basic yet effective method, where trained personnel assess the quality of the engraving and overall product appearance.

-

Dimensional Testing: Using calipers and other measuring tools to ensure that the dimensions of the engraved product match specifications.

-

Durability Testing: Conducting wear and tear tests to determine how well the engraving holds up under various conditions, such as exposure to moisture or abrasion.

-

Adhesion Testing: For products that may have additional coatings or finishes, adhesion tests ensure that these layers bond effectively to the leather.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are effective methods to ensure that suppliers maintain high standards:

-

Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can help identify any gaps in compliance with international standards.

-

Requesting Reports: Suppliers should be willing to provide quality assurance reports, which include details about their QC processes, certifications, and any issues encountered during production.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These services can conduct random checks and report on compliance with specified standards.

-

Certifications: Verify that suppliers hold relevant certifications (ISO 9001, CE, etc.) and maintain up-to-date documentation. This can provide assurance that they adhere to recognized quality standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control and certification is critical. Different regions may have varying standards and regulations, which can affect product compliance. Buyers should be aware of:

Illustrative image related to custom leather engraving

-

Local Regulations: Familiarize themselves with the regulations in their specific markets (e.g., CE marking in Europe) to ensure that the products meet local compliance requirements.

-

Cultural Considerations: Different regions may have unique expectations regarding quality and craftsmanship. Understanding these cultural nuances can help buyers communicate effectively with suppliers.

-

Supply Chain Transparency: Ensuring transparency throughout the supply chain can help mitigate risks related to quality. Buyers should inquire about sourcing practices and traceability of materials used in manufacturing.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing custom leather engraving services, ensuring they receive products that meet their specifications and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather engraving’

はじめに

This guide serves as a comprehensive checklist for B2B buyers looking to procure custom leather engraving services. Understanding the nuances of this specialized service is crucial for ensuring high-quality results that meet your branding and personalization needs. By following these steps, you can streamline your sourcing process and establish reliable partnerships with suppliers.

Step 1: Define Your Technical Specifications

Clearly outline the specifics of your engraving requirements before reaching out to suppliers. This includes the type of leather, design complexity, and engraving method (e.g., laser, branding, or embossing). Providing detailed specifications helps suppliers understand your needs and ensures they can deliver the desired outcome.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom leather engraving. Look for companies with a strong portfolio and positive reviews from previous clients. Pay attention to their experience with international shipping, particularly if you are sourcing from different continents like Africa, South America, or Europe.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s essential to assess the capabilities of your shortlisted suppliers. Request samples of their previous work and inquire about their engraving techniques. Ensure they have the necessary equipment and expertise to handle your specific requirements, whether it’s intricate designs or bulk orders.

Step 4: Check Certifications and Compliance

Verify that the suppliers adhere to relevant industry standards and certifications. This is particularly important when sourcing leather products, as compliance with environmental and ethical standards can impact your brand’s reputation. Look for certifications related to leather sourcing and manufacturing practices.

Illustrative image related to custom leather engraving

Step 5: Inquire About Customization Options

Discuss customization options with your potential suppliers to ensure they can accommodate your branding needs. Ask about the flexibility of design changes, the possibility of incorporating logos, and their process for handling revisions. A supplier’s willingness to collaborate on design aspects can significantly enhance the personalization of your leather products.

Step 6: Understand Pricing Structures and Terms

Request detailed pricing information from your shortlisted suppliers, including any minimum order quantities and potential bulk discounts. Understanding the pricing model will help you gauge the overall cost-effectiveness of your sourcing decision. Be sure to clarify payment terms, lead times, and return policies to avoid any surprises later.

Step 7: Establish Communication Protocols

Effective communication is key to a successful partnership. Set clear expectations for communication frequency and preferred channels, whether via email, phone, or video conferencing. Establishing a reliable communication process helps in addressing any issues promptly and ensures that both parties are aligned throughout the project.

By following this step-by-step checklist, B2B buyers can effectively navigate the procurement process for custom leather engraving, ensuring they partner with the right suppliers who can deliver quality products tailored to their specific needs.

Illustrative image related to custom leather engraving

Comprehensive Cost and Pricing Analysis for custom leather engraving Sourcing

What Are the Key Cost Components in Custom Leather Engraving?

When sourcing custom leather engraving, understanding the breakdown of costs is crucial for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The choice of leather significantly impacts costs. Full-grain leather is the most expensive but offers durability and a premium look, while synthetic alternatives can be cheaper but may compromise quality. Additionally, the type of engraving—whether laser, branding, or embossing—can affect material requirements and costs.

-

Labor: Skilled labor is essential in the engraving process, especially for intricate designs. Labor costs vary based on geographic location, with skilled artisans in Europe potentially costing more than those in Asia or South America.

-

Manufacturing Overhead: This includes the costs of running machinery, utilities, and facility maintenance. Overhead can vary significantly based on the scale of production and the efficiency of the manufacturing process.

-

Tooling: The tools required for engraving—such as laser engravers, branding irons, and embossing plates—represent a significant upfront investment. The cost can be amortized over larger production volumes, making it essential to consider economies of scale.

-

Quality Control (QC): Ensuring the final product meets quality standards incurs additional costs. This may involve inspections, testing materials, and ensuring that the engraving aligns with specifications.

-

Logistics: Shipping costs can vary widely based on distance, volume, and chosen Incoterms. International buyers should factor in customs duties and potential delays in transit.

-

Margin: Finally, suppliers typically add a profit margin that can range from 15% to 50%, depending on market demand and competition.

How Do Price Influencers Affect Custom Leather Engraving Costs?

Several factors influence the pricing of custom leather engraving:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Larger orders often benefit from bulk discounts, while smaller orders may incur higher per-unit costs.

-

Specifications/Customization: The complexity of the design and the level of customization can increase costs. Simple logos may be less expensive to engrave compared to intricate patterns requiring more time and skill.

-

Materials: As previously mentioned, the choice of leather type and quality directly influences cost. High-quality, sustainably sourced leather may come at a premium.

-

Quality and Certifications: Buyers seeking certified materials (e.g., environmentally friendly or ethically sourced leather) may face higher costs but can leverage these certifications as a selling point in their markets.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers with a proven track record may charge more but offer better quality assurance.

-

Incoterms: Understanding shipping terms is vital. Choosing Incoterms like DDP (Delivered Duty Paid) can simplify logistics but may increase costs compared to FOB (Free On Board), where buyers assume more responsibility.

What Are Effective Buyer Tips for Negotiating Custom Leather Engraving Prices?

International B2B buyers should consider the following strategies to enhance cost-efficiency in sourcing custom leather engraving:

-

Negotiate Terms: Don’t hesitate to negotiate prices, especially for larger orders. Suppliers may be willing to adjust pricing to secure a long-term partnership.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and resale value of engraved items. A higher upfront cost for quality leather may yield savings in the long run.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, sourcing from suppliers in Brazil or Vietnam may offer cost advantages due to lower labor costs, but ensure that quality standards are met.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and more favorable terms. Frequent communication and timely payments can foster trust.

-

Stay Informed: Keep abreast of market trends and material costs. Fluctuations in leather prices due to supply chain issues can impact overall costs, making it essential to stay informed.

Disclaimer on Pricing

All pricing insights provided are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing custom leather engraving With Other Solutions

When considering custom leather engraving, it’s essential to explore alternative solutions that can achieve similar personalization and branding effects. Each method has unique advantages and drawbacks, which can significantly impact the decision-making process for B2B buyers. This analysis will compare custom leather engraving with two viable alternatives: embossing and screen printing.

| Comparison Aspect | Custom Leather Engraving | Embossing | Screen Printing |

|---|---|---|---|

| Performance | High precision, durable designs; ideal for intricate patterns. | Good for raised designs; less detail than engraving. | High-speed production; effective for colorful, large designs. |

| Cost | Moderate to high, depending on complexity and volume. | Generally lower for bulk orders; setup costs may vary. | Cost-effective for large quantities; low per-item cost. |

| Ease of Implementation | Requires specialized equipment; more complex setup. | Easier for large batches; manual embossing can be labor-intensive. | Simple setup, especially for large runs; quick to execute. |

| Maintenance | Low; engraved items generally require minimal upkeep. | Low; embossed items also need little maintenance. | Moderate; printed designs may fade or wear over time. |

| Best Use Case | Ideal for premium, personalized items like wallets and gifts. | Best for leather goods requiring a tactile finish, like bags. | Suitable for promotional items and mass production. |

What Are the Pros and Cons of Embossing as an Alternative to Leather Engraving?

Embossing is a popular method that creates raised designs on leather surfaces. One of its primary advantages is the cost-effectiveness for bulk orders. It allows for a distinct tactile quality that can enhance the overall appeal of leather products. However, embossing typically lacks the fine detail that custom engraving can achieve, making it less suitable for intricate designs or personalization. Additionally, while the setup for embossing can be simpler, manual processes may slow down production for smaller businesses.

How Does Screen Printing Compare to Custom Leather Engraving?

Screen printing is another alternative that excels in producing colorful designs quickly and efficiently. It is particularly effective for creating large runs of promotional items where vivid graphics are essential. The main advantage of screen printing is its cost-efficiency in mass production, allowing businesses to maintain low per-item costs. However, the durability of printed designs can be a drawback, as they may fade or wear over time, especially when subjected to regular use. Additionally, screen printing may not be suitable for high-end leather goods where a sophisticated appearance is paramount.

Conclusion: How Can B2B Buyers Select the Right Solution for Their Needs?

Choosing the right solution for leather personalization depends on various factors, including the desired aesthetic, budget constraints, and production volume. Custom leather engraving is ideal for businesses looking to offer premium, personalized products that require intricate designs. In contrast, embossing is more suitable for bulk production with a focus on tactile appeal, while screen printing is best for colorful, cost-effective promotional items. By assessing these alternatives against their specific needs, B2B buyers can make informed decisions that align with their branding and product strategies.

Illustrative image related to custom leather engraving

Essential Technical Properties and Trade Terminology for custom leather engraving

What Are the Key Technical Properties of Custom Leather Engraving?

Understanding the essential technical properties of custom leather engraving is critical for B2B buyers looking to invest in personalized leather products. Here are some key specifications to consider:

1. Material Grade

Material grade refers to the quality of leather used in the engraving process. Common grades include full-grain, top-grain, and corrected grain leather. Full-grain leather, being the highest quality, retains the natural grain and is more durable, making it ideal for intricate designs. B2B buyers should prioritize high-grade leather to ensure longevity and aesthetic appeal in engraved products.

2. Thickness

Leather thickness is measured in ounces or millimeters and significantly impacts the engraving process. Thicker leather can withstand deeper engravings without compromising structural integrity, while thinner leather may require lighter engraving techniques. Understanding the appropriate thickness for specific designs ensures optimal results and reduces the risk of damage during the engraving process.

3. Tolerance

Tolerance in leather engraving refers to the precision of the engraving process, which is critical for maintaining design integrity. A tighter tolerance means more precise engravings, which is essential for intricate patterns or logos. B2B buyers should inquire about the manufacturer’s tolerance levels to ensure that the end product meets their specifications, particularly for corporate branding.

Illustrative image related to custom leather engraving

4. Finish Type

The finish type of the leather affects the engraving outcome. Common finishes include aniline, semi-aniline, and pigmented. Aniline leathers allow for deeper engravings due to their porous nature, while pigmented leathers might require more careful handling to avoid damage. Buyers should choose a finish that complements their design requirements and consider how it will affect the overall appearance of the engraving.

5. Engraving Technique

Various engraving techniques, such as laser engraving, branding, and embossing, produce different effects on the leather. Each technique has its own set of specifications and results. For instance, laser engraving allows for intricate designs with high precision, while branding creates a more rustic look. Understanding these techniques helps buyers select the most suitable method for their needs.

What Are Common Trade Terms Used in the Custom Leather Engraving Industry?

Familiarity with industry jargon is essential for effective communication in the B2B leather engraving market. Here are several common terms:

Illustrative image related to custom leather engraving

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products based on another company’s specifications. In the context of custom leather engraving, an OEM may produce leather goods that require engraving as part of the design. This term is vital for buyers seeking partnerships with manufacturers who can meet their specific customization needs.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers because it directly affects inventory management and cost efficiency. Understanding MOQ helps businesses plan their purchasing strategy and negotiate better deals with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. In the leather engraving industry, buyers can use RFQs to compare offers from different manufacturers, ensuring they receive competitive pricing and favorable terms for their projects.

Illustrative image related to custom leather engraving

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for B2B buyers engaged in cross-border trade, as they determine aspects such as shipping costs, insurance, and risk transfer.

5. Customization Levels

This term refers to the extent to which products can be personalized. In leather engraving, customization can range from simple monograms to complex designs. Understanding customization levels helps buyers assess the capabilities of potential suppliers and select those who can meet their specific requirements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions in the custom leather engraving market, ensuring that their investments yield high-quality, personalized products.

Navigating Market Dynamics and Sourcing Trends in the custom leather engraving Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Engraving?

The custom leather engraving market is experiencing significant growth, driven by increasing consumer demand for personalized products and the rise of e-commerce platforms. Global drivers such as the growing trend of customization in fashion and lifestyle products are reshaping the landscape. Notably, regions like Africa, South America, the Middle East, and Europe are witnessing a surge in interest, with B2B buyers seeking unique, high-quality leather goods. This demand is further fueled by the expansion of online marketplaces, allowing artisans and manufacturers to reach a broader audience, including international buyers.

Emerging technologies, particularly laser engraving, are revolutionizing the sector by offering precision and versatility. This method not only enhances the quality of engravings but also allows for intricate designs that traditional methods struggle to achieve. Additionally, the integration of digital tools for design and customer engagement is becoming commonplace, enabling businesses to streamline their operations and improve customer experience.

Illustrative image related to custom leather engraving

Another notable trend is the shift towards bulk orders and corporate gifting. Businesses are increasingly looking to personalize items for brand promotion, leading to higher volume orders. This trend is especially pronounced among industries such as hospitality, retail, and corporate sectors, where bespoke leather goods serve as effective promotional tools.

How Is Sustainability and Ethical Sourcing Affecting Custom Leather Engraving?

As the demand for custom leather products rises, so does the importance of sustainability and ethical sourcing within the industry. Environmental concerns related to leather production, such as water consumption and chemical use, have led many B2B buyers to prioritize suppliers who adopt eco-friendly practices. Brands that utilize vegetable-tanned leather or other sustainable materials are becoming increasingly attractive to conscientious consumers and businesses alike.

Furthermore, ethical supply chains are gaining traction as consumers demand transparency regarding the origin of materials and the treatment of workers involved in production. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming crucial for businesses looking to establish credibility and trust with their customers. These certifications ensure that suppliers adhere to stringent environmental and social standards, offering peace of mind to B2B buyers.

Investing in sustainable practices not only benefits the environment but also enhances brand reputation. Companies that actively demonstrate their commitment to sustainability can differentiate themselves in a competitive marketplace, appealing to a growing segment of eco-conscious buyers across regions.

Illustrative image related to custom leather engraving

What Is the Brief Evolution and History of Custom Leather Engraving?

The art of leather engraving has a rich history, dating back centuries when artisans used rudimentary tools to create functional and decorative items. Initially, engraving was primarily a manual craft, with techniques such as hand carving and branding being common. As industrialization progressed, the introduction of machinery allowed for greater efficiency and precision, paving the way for modern engraving methods.

In recent decades, technological advancements, particularly in laser engraving, have transformed the industry. This evolution has enabled businesses to offer highly personalized products at scale, catering to the unique preferences of consumers. Today, custom leather engraving stands at the intersection of tradition and innovation, allowing B2B buyers to access a diverse range of products that reflect both craftsmanship and modern design sensibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather engraving

-

How do I select the right supplier for custom leather engraving?

Choosing the right supplier involves several steps. First, evaluate their portfolio to assess the quality and variety of their work. Look for suppliers with experience in your specific industry and the ability to handle custom requests. Request samples to ensure the engraving matches your expectations. Additionally, check customer reviews and ask for references to gauge their reliability. It’s also essential to confirm their capacity to meet your order volume and deadlines, particularly if you require bulk orders. -

What customization options are available for leather engraving?

Customization options for leather engraving can include various techniques such as laser engraving, branding, embossing, and pyrography. Each method offers different aesthetic effects and durability. You can also choose from a range of designs, including logos, monograms, and intricate patterns. Discuss your specific needs with the supplier to understand their capabilities and any limitations regarding size, color, and material compatibility. -

What are the minimum order quantities (MOQs) for custom leather engraving?

Minimum order quantities can vary significantly between suppliers. Some may have no minimum requirement, allowing you to order a single customized item, while others may set MOQs of 50 or more for cost-effectiveness. When sourcing, clarify the MOQ with potential suppliers to ensure it aligns with your purchasing needs. If you require smaller quantities, look for suppliers who specialize in bespoke items or are willing to accommodate smaller orders. -

What payment terms should I expect when ordering custom leather engraving?

Payment terms can vary by supplier and often depend on the size of your order and your business relationship. Common arrangements include upfront payments for new customers, partial payments, or net terms (e.g., 30 or 60 days). Always clarify payment methods accepted (credit card, bank transfer, etc.) and confirm any additional fees for international transactions. Establishing clear terms upfront can prevent misunderstandings and facilitate smoother transactions. -

How can I ensure quality assurance (QA) in custom leather engraving?

To ensure quality assurance, select suppliers who follow strict quality control processes. Request detailed specifications for how they inspect their work, including pre-production samples and final product inspections. It may also be beneficial to establish a clear return policy in case the products do not meet your standards. Consider arranging factory visits or third-party inspections, especially for large orders, to verify quality before shipment. -

What logistics considerations should I keep in mind for international shipping of engraved leather products?

When planning for international shipping, consider shipping times, costs, and customs regulations. It’s important to discuss with your supplier their shipping methods and whether they handle customs clearance. Additionally, confirm who is responsible for shipping costs and duties—this can vary based on Incoterms. Ensure that packaging is robust to protect your engraved items during transit, as leather can be sensitive to environmental conditions. -

How do I address potential issues with international suppliers?

Addressing issues with international suppliers involves clear communication and documentation. Always maintain records of agreements, specifications, and communications to resolve disputes effectively. If problems arise, such as delays or quality issues, contact your supplier promptly to discuss solutions. Establishing a good rapport and being proactive in communication can help mitigate misunderstandings and foster a productive partnership. -

What are the benefits of using custom leather engraving for branding?

Custom leather engraving is an effective branding tool as it offers a unique and high-quality finish that enhances the perceived value of your products. Personalized items can create a lasting impression and foster customer loyalty. Engraved logos or messages also serve as a subtle yet powerful marketing tool, promoting your brand every time the item is used. Additionally, leather’s durability means that engraved products can withstand time, ensuring your brand remains visible for years.

Top 5 Custom Leather Engraving Manufacturers & Suppliers List

1. ShopDaddy – Custom Leather Engraving

Domain: shopdaddy-studio.com

Registered: 2018 (7 years)

Introduction: {“title”:”Leather Engraving (for each item)”,”price”:”$1.00 USD”,”stock”:”364 items in stock”,”description”:”Custom order request for leather engraving. Upload your logo file in formats such as EPS, AI, PSD, PDF, or high-resolution JPG, PNG. Our manager will contact you to agree on the size and placement of your logo.”,”shipping_info”:”Delivery usually takes 7–10 business days. Express shipping av…

2. Spinneybeck – Custom Laser Engraving

Domain: spinneybeck.com

Registered: 1996 (29 years)

Introduction: {‘name’: ‘Custom Laser Engraving’, ‘maximum_size’: ‘2’-3” x 4’-0” (61 x 121.9 cm)’, ‘edge_tolerance’: ‘Laser engrave to within 3 mm of edge of material’, ‘leather_types’: ‘AD, AL, AQ, AU, BL, CA, CO, CV, DE, DL, DT, ES, ET, FE, FT, HT, LU, PT, RA, RU, SA, SL, VO, VP, VZ’, ‘leather_colors’: ‘Refer to Color Book for available colors’, ’embellishment_option’: ‘Painted’, ‘primary_uses’: ‘Magnetic Back…

3. Gravotech – LS100 & LS100EX Laser Engraving Solutions

Domain: gravotech.us

Registered: 2007 (18 years)

Introduction: Laser tables: LS100 (Small CO2 laser engraver, Marking area: 460 x 305 mm, Materials: Plastics, wood, glass, organic materials, painted surfaces, Applications: Personalization, creative, signage); LS100EX (Medium CO2 or Fiber laser engraving and cutting machine, Marking area: 610 x 305 mm, Materials: Plastics, wood, glass, organic materials, painted surfaces, metals, Applications: Personalization,…

4. Yelp – Best Leather Engraving

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Leather Engraving, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Lazer Designs – Custom Laser Plaques

Domain: lazerdesigns.com

Registered: 2002 (23 years)

Introduction: This company, Lazer Designs – Custom Laser Plaques, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for custom leather engraving

As businesses increasingly recognize the allure of custom leather engraving, strategic sourcing becomes essential for optimizing quality, cost, and delivery timelines. International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers who offer flexibility in order quantities and personalization options. This adaptability not only meets diverse market demands but also enhances customer satisfaction through unique, tailored products.

The value of investing in high-quality engraving techniques, whether through laser, branding, or embossing, cannot be overstated. These methods not only elevate product aesthetics but also ensure durability and a lasting impression, making them ideal for corporate gifting, promotional items, or luxury branding. Moreover, as sustainability becomes a focal point in global sourcing, partnering with suppliers who utilize eco-friendly materials and processes can significantly bolster your brand’s reputation.

Looking ahead, the custom leather engraving market is poised for growth, driven by the rising demand for personalized products. Now is the time for B2B buyers to explore innovative partnerships that can expand their offerings and enhance their competitive edge. Engage with suppliers who understand your vision and can deliver exceptional quality, ensuring your brand stands out in an increasingly crowded marketplace.

Illustrative image related to custom leather engraving

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather engraving