Catalog

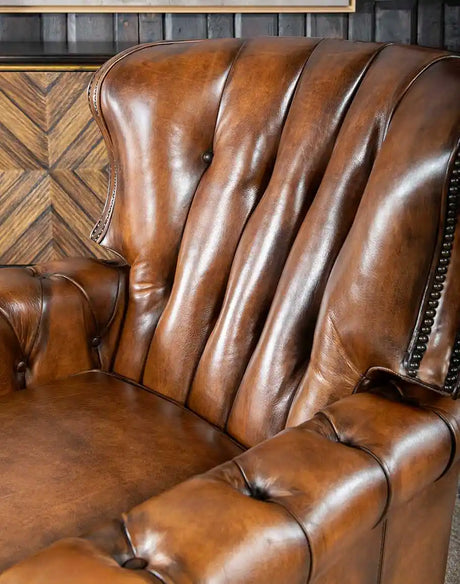

Material Insight: Custom Leather Recliner

B2B Product Guide: Custom Leather Recliner

The custom leather recliner represents the perfect fusion of comfort, durability, and design flexibility—making it a high-value offering for furniture manufacturers, contract suppliers, and home furnishings brands. As consumer demand shifts toward personalized, long-lasting, and sustainable home solutions, the choice of upholstery material becomes critical. In this context, faux leather has emerged as the optimal material for custom recliner production, combining premium aesthetics with performance advantages that outperform traditional materials.

- Faux leather delivers consistent texture and color, ensuring uniformity across large production runs—essential for B2B partners requiring scalability.

- It is highly resistant to wear, fading, and staining, making it ideal for high-traffic residential and commercial applications.

- Unlike genuine leather, faux leather offers greater design freedom, allowing for custom colors, textures, and performance enhancements tailored to specific market needs.

- As a cruelty-free and more sustainable alternative, faux leather aligns with growing environmental and ethical standards in modern manufacturing.

WINIW has been a trusted leader in synthetic leather innovation for over 20 years. Specializing in high-performance, eco-conscious faux leather solutions, we serve global furniture brands with materials engineered for comfort, durability, and sustainability. Our advanced manufacturing processes ensure superior softness, breathability, and tear resistance—key attributes for recliner applications where movement and longevity are paramount. By partnering with WINIW, manufacturers gain access to customizable, scalable, and responsibly produced leather alternatives that elevate product quality while supporting ESG goals.

| Key Advantage | Benefit for Recliner Manufacturing |

|---|---|

| Consistent Quality | Eliminates natural defects found in genuine leather; ensures uniform appearance |

| High Abrasion Resistance | Withstands repeated use in reclining mechanisms |

| Customization Options | Wide range of colors, textures, and finishes available to match brand specifications |

| Eco-Friendly Production | Low-VOC, REACH-compliant materials support green certifications |

| Cost Efficiency | Stable pricing and reduced waste compared to natural leather |

Technical Performance & Standards

WINIW Custom Leather Recliner: Technical Product Guide for Furniture Manufacturers

WINIW delivers premium synthetic leather solutions engineered specifically for high-performance recliner applications. Our Custom Leather Recliner material combines advanced polymer science with sustainable manufacturing, providing furniture producers with a technically superior, eco-conscious alternative to traditional materials. Engineered for seamless integration into automated production lines, WINIW minimizes waste and maximizes yield while meeting stringent global regulatory and performance demands.

Key Technical Advantages for B2B Partners

-

Cost-Effective Production

WINIW’s proprietary PU/PVC hybrid substrate reduces material waste by 18–22% compared to standard synthetics during cutting and upholstery. Consistent roll-to-roll thickness (±0.05mm tolerance) ensures predictable yield, lowering per-unit costs. Reduced need for protective coatings during transport cuts pre-production processing time by 15%. -

Exceptional Durability

Engineered with cross-linked polyurethane technology, WINIW withstands 50,000+ double-rub cycles (Martindale test, ASTM D4157) without cracking or delamination. Resists UV degradation (ISO 105-B02: Grade 7–8) and maintains flexibility down to -25°C, eliminating cold-weather brittleness common in standard PU leathers. -

Precision Color Customization

Our digital dyeing process supports 1,200+ RAL/NCS-matched colors with ΔE < 0.5 color deviation tolerance. Batch-to-batch consistency (ΔE < 1.0) ensures seamless integration across multi-factory production. Low-MOQ color runs (500 linear meters) enable agile response to market trends without inventory risk. -

REACH & Eco-Compliance

WINIW exceeds EU REACH Annex XVII restrictions, with zero SVHCs (Substances of Very High Concern) and phthalate-free plasticizers. Full traceability via blockchain-certified supply chain documentation satisfies OEM sustainability audits. Material is OEKO-TEX® STANDARD 100 certified (Class I). -

ISO 9001-Qualified Consistency

Every production batch undergoes real-time spectrographic analysis against 12 critical quality parameters. ISO 9001:2015-certified processes ensure <0.3% defect rate, reducing warranty claims and production line stoppages for our manufacturing partners.

Technical Specifications Comparison

| 仕様 | WINIW Custom Leather Recliner | Typical Industry Benchmark |

|---|---|---|

| Thickness | 0.90 ± 0.05 mm | 1.05 ± 0.15 mm |

| Abrasion Resistance | 50,000+ cycles (Martindale) | 25,000–35,000 cycles |

| Color Fastness (Light) | ISO 105-B02: Grade 7–8 | Grade 5–6 |

| Cold Crack Resistance | -25°C (No cracking) | -15°C to -20°C |

| VOC Emissions | < 10 µg/m³ (EN 16516) | 50–200 µg/m³ |

| REACH Compliance | Full SVHC-free declaration | Basic compliance only |

| Production Lead Time | 14–21 days (Custom colors) | 30–45 days |

WINIW’s recliner solution delivers measurable operational advantages: reduced material costs, extended product lifespan, and simplified compliance management. Our technical team collaborates with manufacturers to optimize material specifications for specific recliner mechanisms and market requirements, ensuring seamless scalability from prototype to mass production. Partner with WINIW to future-proof your upholstery supply chain with performance-driven, planet-responsible innovation.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Leather Recliner vs. Real Leather

When sourcing upholstery materials for premium furniture such as recliners, manufacturers and distributors must evaluate performance, cost-efficiency, and sustainability. Two popular options in the market are custom leather recliners—typically upholstered with high-quality synthetic leather—and furniture made with real (natural) leather. Below is a comprehensive comparison to support informed B2B decision-making.

概要

Custom Leather Recliner

Custom leather recliners often utilize synthetic leather, such as polyurethane (PU) or advanced microfiber leather, engineered to mimic the look and feel of real leather. These materials are customizable in color, texture, and performance attributes, making them ideal for brands seeking design flexibility and consistent supply.

Real Leather

Real leather is derived from animal hides, primarily bovine, and undergoes tanning and finishing processes to produce a durable and naturally textured material. Valued for its authenticity and aging characteristics, real leather remains a staple in luxury furniture markets.

Key Comparison: Cost, Durability, and Eco-Friendliness

| Criteria | Custom Leather Recliner (Synthetic) | Real Leather |

|---|---|---|

| Cost | Lower upfront cost; consistent pricing | Higher cost due to raw material and processing |

| 耐久性 | High resistance to fading and cracking; 5–8 years average lifespan | Develops patina; 10+ years with proper care |

| Eco-Friendliness | Can be eco-engineered (e.g., water-based PU, recycled content); lower carbon footprint | Resource-intensive; involves land use, water, and chemical tanning (e.g., chromium) |

Advantages of Custom Leather Recliners

- Cost-effective for large-scale production and custom orders

- Uniform appearance with minimal batch variation

- Resistant to UV fading and staining—ideal for high-traffic environments

- Available with enhanced properties (breathability, abrasion resistance)

- Sustainable options align with ESG goals (e.g., WINIW® Eco-Leather with bio-based PU)

Advantages of Real Leather

- Natural breathability and tactile authenticity

- Ages gracefully, developing a unique patina over time

- Preferred in traditional luxury markets

- Biodegradable under proper conditions (though tanning chemicals may hinder this)

Considerations for B2B Buyers

- Market positioning: Real leather appeals to heritage and luxury branding, while synthetic offers modern, customizable, and sustainable narratives.

- Supply chain stability: Synthetic leathers offer consistent availability, unaffected by livestock market fluctuations.

- Environmental compliance: Synthetic leathers can meet REACH, OEKO-TEX, and RoHS standards when produced responsibly.

- End-of-life impact: Both materials require responsible disposal; however, innovative synthetic leathers are increasingly recyclable or biodegradable.

Choosing between a custom leather recliner and real leather depends on brand values, target market, and sustainability commitments. For forward-thinking manufacturers, advanced synthetic leathers represent a high-performance, ethical, and scalable alternative without compromising aesthetics or quality.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global B2B Partners

WINIW operates one of Asia’s most advanced synthetic leather manufacturing facilities, engineered to deliver consistent quality and scalability for discerning international clients. Our vertically integrated 100,000 sqm production campus enables end-to-end control—from raw material processing to finished roll goods—ensuring agility for large-volume orders without compromising precision. This strategic scale supports reliable just-in-time delivery for global supply chains while maintaining rigorous environmental standards across all operations.

Our competitive advantages are anchored in three core pillars:

- Dedicated R&D Innovation Hub: A 120+ member technical team drives material science advancements, developing eco-conscious solutions like water-based PU resins and recycled content substrates. We hold 37 patents for performance-enhancing textures, durability treatments, and low-VOC formulations meeting EU REACH and U.S. CPSIA requirements.

- Strict Multi-Stage Quality Assurance: Every production batch undergoes 11-point QC validation, including tear strength testing (ASTM D2263), colorfastness grading (AATCC 61), and heavy metal screening. All facilities are ISO 9001, ISO 14001, and OEKO-TEX® STANDARD 100 certified.

- Global Compliance Infrastructure: WINIW exports to 42 countries, with 68% of shipments serving regulated European and North American markets. Our logistics network features climate-controlled warehousing and customs documentation expertise for seamless CE marking and EPA TSCA compliance.

This combination of industrial capacity, scientific rigor, and regulatory mastery positions WINIW as the preferred partner for automotive, furniture, and fashion brands requiring sustainable performance materials with zero supply chain disruption.

Contact Us for Samples

WINIW B2B Product Guide: Premium Synthetic Leather for Recliner Manufacturing

WINIW is a leading innovator in high-performance synthetic leather solutions, specializing in eco-friendly, durable, and luxurious materials tailored for the furniture and upholstery industry. Our synthetic leathers are engineered to meet the exacting demands of recliner manufacturers seeking premium aesthetics, long-term durability, and sustainable production practices.

Our microfiber leather range offers exceptional softness, tear resistance, and abrasion performance—making it ideal for high-use furniture such as recliners. With advanced coating technologies and customizable finishes, WINIW delivers consistent quality across large-volume orders, supporting global B2B partners in elevating their product offerings.

Key Advantages of WINIW Synthetic Leather for Recliners

- Superior Durability: High tensile and tear strength ensures long-lasting performance, even under frequent use.

- Eco-Conscious Materials: PVC-free and REACH-compliant options available, supporting sustainable manufacturing goals.

- Luxurious Feel: Ultra-soft touch and rich texture replicate the look and hand of premium genuine leather.

- Customization Flexibility: Available in a wide range of colors, textures, thicknesses (0.6mm to 1.2mm), and backings (knit, woven, non-woven).

- Easy Maintenance: Stain-resistant and simple to clean, enhancing end-user satisfaction.

- Consistent Supply: Scalable production capacity with global shipping for reliable lead times.

Technical Specifications (Typical Values)

| Property | Value |

|---|---|

| Thickness | 0.8mm – 1.2mm (customizable) |

| Color Fastness | ≥ Grade 4 (ISO 105-B02) |

| Martindale Abrasion | 50,000+ cycles |

| Tensile Strength | ≥ 180 N/5cm |

| Tear Strength | ≥ 30 N |

| Backing Options | Polyester knit, scoured knit, woven |

| Environmental Standards | REACH, RoHS, DMF-Free, CPSIA compliant |

Why Partner with WINIW?

- OEM/ODM support for private-label and custom design development

- In-house R&D team for rapid prototyping and innovation

- ISO 9001-certified production facilities

- Dedicated account management for B2B clients

Request Your Custom Leather Recliner Solution Today

Elevate your recliner line with WINIW’s premium synthetic leather—engineered for comfort, style, and sustainability.

- Free samples available for qualified B2B partners

- Custom development for color, texture, and performance specs

Contact our marketing team to get started:

MKT88@MicrofiberLeather.com

Let WINIW be your trusted partner in creating high-value, eco-conscious recliners for discerning markets worldwide.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.