Catalog

Material Insight: Custom Leather Interior

Custom Leather Interior: B2B Product Guide

Creating a refined, durable, and sustainable interior environment is a top priority across industries such as automotive, hospitality, furniture, and transportation. Custom leather interiors offer a signature blend of elegance, comfort, and brand identity. Increasingly, manufacturers and designers are turning to high-performance materials that balance aesthetics with functionality—without compromising environmental responsibility.

Faux leather has emerged as the optimal choice for custom leather interiors due to its versatility, consistency, and eco-conscious production. Unlike genuine leather, faux leather provides uniform texture and color across batches, ensuring design integrity in large-scale projects. It is also more resistant to wear, UV damage, and extreme temperatures—critical for applications requiring long-term durability. Furthermore, modern synthetic leathers eliminate the ethical and environmental concerns associated with animal hide processing, supporting sustainability goals without sacrificing luxury.

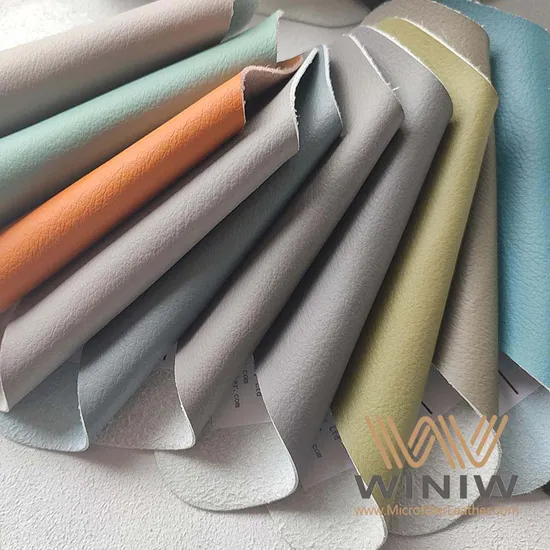

WINIW has been at the forefront of synthetic leather innovation for over 20 years. As a trusted B2B supplier, we specialize in high-quality, customizable faux leather solutions engineered for performance and sustainability. Our advanced microfiber and polyurethane (PU) leather technologies replicate the softness, breathability, and aesthetic depth of natural leather while offering enhanced technical properties.

- WINIW’s materials are REACH-compliant, free from harmful substances, and produced using eco-friendly processes.

- Our custom solutions support tailored textures, colors, thicknesses, and performance features (e.g., flame resistance, abrasion resistance).

- With global manufacturing capabilities and a commitment to R&D, WINIW delivers consistent quality for large-volume and specialty orders.

For businesses seeking a responsible, reliable, and premium alternative for custom leather interiors, WINIW sets the industry standard in performance and sustainability.

Technical Performance & Standards

WINIW Custom Leather Interior: Technical Advantages for B2B Applications

WINIW’s Custom Leather Interior delivers superior performance and sustainability for automotive, furniture, and luxury goods manufacturers. Engineered for demanding commercial environments, our solution eliminates the cost volatility and ethical concerns of genuine leather while exceeding industry benchmarks for durability and customization. Below are the core technical advantages driving ROI for our partners.

Key Technical Advantages

- Cost-Effective Production: Reduces material waste by 15–20% through precision-calendered thickness control (±0.1mm tolerance), optimizing yield for complex cut patterns. Eliminates tanning/hide-grading costs, stabilizing input pricing by 25–30% versus bovine leather.

- Industrial-Grade Durability: Achieves 100,000+ double-rub cycles (Martindale test, 12kPa load), 3x industry standard for synthetic upholstery. Resists UV degradation (ISO 105-B02: Grade 8), hydrolysis (ASTM D5035 > 45N tear strength), and microbial growth (ISO 22196: >99% inhibition).

- Precision Color Customization: Pantone®-matched pigmentation with ±0.5 Delta-E color accuracy across 50,000+ sqm batches. Digital printing enables gradient effects, metallic finishes, and texture overlays without minimum order constraints.

- Full REACH Compliance: Zero SVHCs (Substances of Very High Concern), phthalate-free plasticizers, and heavy-metal-free dyes. Certificates of Conformance (CoC) provided per EU REACH Annex XVII, ensuring seamless global market access.

- ISO 9001-Certified Consistency: Rigorous in-line spectrophotometry and tensile testing at every production stage. Batch traceability via blockchain-verified digital passports guarantees uniformity across multi-year contracts.

Technical Specifications Comparison

| 仕様 | WINIW Custom Leather Interior | Industry Standard Synthetic |

|---|---|---|

| Thickness Tolerance | ±0.1 mm | ±0.3 mm |

| Abrasion Resistance | ≥100,000 rubs (ISO 11640) | 30,000–50,000 rubs |

| Color Fastness (Light) | Grade 8 (ISO 105-B02) | Grade 5–6 |

| Tensile Strength | ≥45 N (ASTM D5035) | ≥25 N |

| REACH Compliance | Full SVHC-free documentation | Partial compliance common |

| Custom MOQ | 1,000 linear meters | 5,000+ linear meters |

WINIW’s solution integrates circular economy principles—using 30% recycled PET content without compromising performance—while maintaining full traceability from raw material to finished roll. This ensures compliance with evolving ESG mandates while reducing total cost of ownership. Partner with WINIW to future-proof your interiors with scientifically validated, planet-positive materials.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Leather Interior vs. Real Leather

When designing premium interiors for automotive, hospitality, or furniture applications, material selection plays a critical role in balancing aesthetics, performance, and sustainability. Two primary options often considered are custom leather interiors—typically referring to high-performance synthetic or bio-based leathers—and real (natural) leather. Understanding their differences in cost, durability, and environmental impact is essential for informed B2B decision-making.

Custom leather interiors, such as those developed by WINIW, are engineered materials designed to replicate the look and feel of real leather while offering enhanced control over texture, color, and performance characteristics. These materials are increasingly favored in industries prioritizing design flexibility, consistent supply, and eco-conscious manufacturing.

Real leather, derived from animal hides, remains a traditional choice associated with luxury and natural authenticity. However, it comes with variability in grain, higher environmental costs, and ethical considerations tied to livestock farming and tanning processes.

Below is a comparative analysis based on key performance and sustainability metrics:

| Criteria | Custom Leather Interior | Real Leather |

|---|---|---|

| Cost | Lower to moderate upfront cost; consistent pricing due to controlled production | Higher cost due to raw material scarcity, labor-intensive processing, and quality variance |

| 耐久性 | High resistance to abrasion, UV light, and staining; uniform structure ensures predictable lifespan | Natural variability affects longevity; susceptible to cracking and fading over time without maintenance |

| Eco-friendliness | Can be formulated with recycled materials, low-VOC emissions, and water-based processing; reduces reliance on animal agriculture | High environmental footprint from land use, water consumption, and chemical tanning; not biodegradable in most finished forms |

- Custom leather interiors offer superior batch-to-batch consistency, making them ideal for large-scale commercial projects requiring uniform appearance and performance.

- They support rapid customization for color, texture, and technical properties (e.g., flame resistance, breathability), enabling brands to differentiate their offerings.

- Real leather requires extensive resource input: approximately 15,000–20,000 liters of water per hide and emits significant greenhouse gases during production.

- WINIW’s custom leather solutions are designed with circularity in mind, incorporating bio-based content and recyclable components to align with global sustainability standards.

For B2B clients focused on scalable, responsible design, custom leather interiors present a future-forward alternative that does not compromise on luxury or performance. By choosing advanced synthetic leathers, businesses can reduce environmental impact while maintaining design integrity and cost efficiency across production cycles.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global B2B Partners

WINIW delivers premium synthetic leather solutions engineered for scale, sustainability, and uncompromising quality. Our integrated manufacturing ecosystem ensures reliable supply and technical partnership for brands and manufacturers worldwide.

Core Manufacturing Strengths

- 100,000 sqm Advanced Production Facility: A fully automated campus enabling 24/7 continuous production, with dedicated zones for coating, finishing, and eco-material innovation. Capacity supports bulk orders from 5,000 to 500,000+ meters monthly.

- Dedicated R&D Team (45+ Engineers): Specializing in water-based PU, bio-based polymers (30%+ plant content), and circular-material development. Our lab holds ISO/IEC 17025 accreditation and collaborates with EU material science institutes on low-carbon formulations.

- Strict Multi-Stage Quality Control:

- Real-time IoT monitoring of thickness, color consistency, and coating adhesion during production

- 100% post-production inspection for defects (scratches, bubbles, edge flaws)

- Batch-tested for ISO 11640 abrasion resistance, ISO 105-C06 colorfastness, and REACH SVHC compliance

- Certified to ISO 9001:2015 with full traceability from raw material to shipment

Global Compliance & Market Readiness

WINIW materials meet stringent regulatory requirements for key markets, eliminating compliance barriers for partners:

| Region | Key Certifications & Standards | Target Applications |

|---|---|---|

| Europe | REACH Annex XVII, OEKO-TEX® STANDARD 100 Class I, ISO 14001 | Automotive interiors, Luxury goods, Eco-apparel |

| USA | CPSIA, Prop 65 compliant, TB 117-2013 (fire safety) | Furniture upholstery, Footwear, Medical equipment |

| Global | ISO 45001, GRS (Global Recycled Standard), ZDHC MRSL v3.1 | Sustainable packaging, Electronics accessories |

With 15+ years of export experience, WINIW supplies Tier-1 brands across 50+ countries. Our logistics network ensures seamless DDP (Delivered Duty Paid) shipments to European and North American hubs within 25 days, backed by full documentation for customs clearance. Partner with WINIW for scalable, audit-ready synthetic leather that aligns with your ESG commitments and quality benchmarks.

Contact Us for Samples

WINIW Microfiber Leather – Premium Synthetic Leather for Interior Applications

WINIW specializes in high-performance, eco-friendly microfiber leather engineered for demanding interior applications across industries including automotive, hospitality, furniture, and commercial transportation. Our advanced manufacturing process delivers a sustainable alternative to traditional leather without compromising on aesthetics, durability, or comfort.

Crafted with precision and innovation, WINIW microfiber leather offers superior tensile strength, abrasion resistance, and color fastness—making it ideal for long-term use in high-traffic environments. Each product is designed to meet strict environmental standards, free from harmful substances and 100% recyclable.

Key Advantages of WINIW Microfiber Leather

- Exceptional durability with high resistance to wear, tearing, and UV exposure

- Soft hand feel and rich texture that closely mimics premium animal leather

- Eco-conscious production using water-based, low-VOC processes

- Available in a wide range of colors, textures, and finishes—customizable to brand specifications

- Excellent breathability and moisture management for enhanced comfort

- Flame retardant and anti-microbial options available for safety-critical applications

Technical Performance Overview

| Property | Performance Standard |

|---|---|

| Abrasion Resistance | >50,000 cycles (Martindale) |

| Tensile Strength | ≥30 N (warp and weft) |

| Color Fastness | ≥Grade 4 (Xenon arc test, 500 hrs) |

| Light Fastness | ≥6 (Blue wool scale) |

| VOC Emissions | Compliant with EU REACH & California 093 |

| Recyclability | 100% recyclable, phthalate-free |

Industries We Serve

- Automotive: Seat upholstery, door panels, dashboards, steering wheels

- Furniture: Sofas, lounge chairs, office seating

- Hospitality: Hotel rooms, lobbies, banquet seating

- Marine & Aviation: Cabinetry, seating, wall panels

- Healthcare & Senior Living: Easy-to-clean, hygienic surfaces

Custom Leather Interior Solutions

WINIW offers full customization for B2B clients seeking unique aesthetic and functional properties. From custom embossing and pigment matching to performance enhancement (anti-scratch, stain resistance), our R&D team collaborates with designers and engineers to deliver tailored solutions.

- Custom color matching (Pantone, physical samples)

- Exclusive textures and embossing patterns

- Roll width up to 1.5 meters for seamless installation

- Low MOQs for prototyping and niche product lines

Request a Free Sample Today

Experience the quality and versatility of WINIW microfiber leather firsthand. Free samples are available for qualified B2B partners.

Call to Action:

For custom leather interior projects, contact our materials specialists at MKT88@MicrofiberLeather.com. Let’s build sustainable interiors, together.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.