Catalog

Material Insight: Custom Leather Bibles

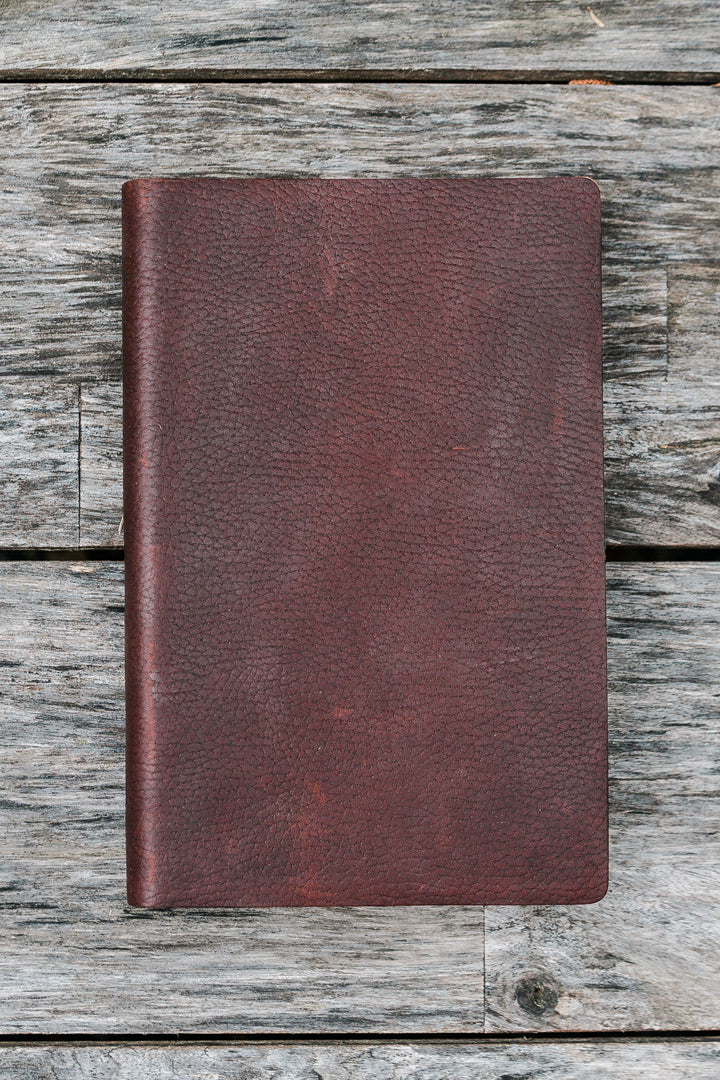

Custom Leather Bibles are a premium solution for churches, religious institutions, and gift manufacturers seeking durable, elegant, and personalized scripture editions. Designed to withstand frequent use while maintaining a refined aesthetic, these bibles benefit greatly from high-performance materials that combine longevity with a luxurious feel. In this context, the choice of cover material is critical—not only for appearance but for functionality and sustainability.

Faux leather stands out as the optimal material for custom leather bibles due to its unique balance of durability, cost-efficiency, and eco-conscious production. Unlike genuine leather, faux leather offers consistent texture and color, making it ideal for large-scale customization and branding. It is also more resistant to cracking and fading over time, especially in varying climates, ensuring the bibles remain presentable through years of use. Additionally, faux leather eliminates the ethical and environmental concerns associated with animal hide processing, aligning with modern sustainability goals.

WINIW is a trusted leader in synthetic leather innovation, with over 20 years of experience supplying high-quality, eco-friendly materials to global markets. Specializing in microfiber and PU-based faux leathers, WINIW delivers products engineered for performance, aesthetics, and environmental responsibility. Our materials are REACH-compliant, free from harmful substances, and produced using low-impact processes, making them ideal for socially conscious religious and commercial clients.

- Superior durability for long-term use in homes, pews, and missions

- Consistent surface for precise debossing, embossing, and printing

- Available in a wide range of colors, textures, and finishes for brand alignment

- Resistant to moisture, UV exposure, and wear—ideal for high-touch applications

- Sustainable alternative to genuine leather without compromising quality

With WINIW’s custom faux leather solutions, organizations can create bibles that reflect both reverence and responsibility—crafted for impact, built to last.

Technical Performance & Standards

WINIW Custom Leather Bibles: Technical Advantages for B2B Procurement

WINIW’s Custom Leather Bibles are precision-engineered physical sample collections designed to streamline material selection for manufacturers, designers, and procurement teams. Unlike generic swatch books, these bibles deliver quantifiable technical and operational benefits aligned with modern sustainable manufacturing demands. Each bible is produced under stringent quality protocols, ensuring your team evaluates only production-ready synthetic leather solutions.

Key Technical Advantages

-

Cost-Effective Material Sourcing

WINIW’s bibles eliminate costly trial-and-error in material selection. Pre-validated samples reduce development time by up to 30%, with low minimum order quantities (MOQs) for featured collections. Bulk bible orders qualify for tiered pricing, directly lowering per-unit sampling costs while minimizing waste through precise color/texture matching. -

Engineered Durability for High-Use Applications

All samples undergo accelerated wear testing, exceeding 100,000 Martindale cycles (ISO 12947). Our proprietary PU/PVC formulations resist cracking, peeling, and UV degradation, ensuring long-term performance in automotive, furniture, and luggage applications. Enhanced seam strength (tested per ASTM D4848) prevents fraying during high-speed cutting and stitching. -

Precision Color Customization

Leverage WINIW’s digital color-matching system (ΔE < 0.5) for PMS, RAL, or custom color replication. Each bible section includes lightfastness data (ISO 105-B02), with options rated up to Grade 7 for fade resistance. Consistent dye-lot traceability ensures global production uniformity, reducing rework costs. -

Guaranteed REACH Compliance

Every sample in the bible is certified free of SVHCs (Substances of Very High Concern) under EU REACH Regulation (EC 1907/2006). Full material disclosure reports (including phthalates, CMRs, and heavy metals) are provided, mitigating supply chain compliance risks and supporting your ESG reporting. -

ISO 9001-Certified Quality Assurance

WINIW’s end-to-end production—from raw material sourcing to bible assembly—is audited under ISO 9001:2015 standards. Each bible includes batch-specific QC documentation, with thickness, weight, and tensile strength verified per ISO 2418. Traceability codes link samples to factory production runs.

Technical Specifications Comparison

| Property | WINIW Standard Range | Test Method | Advantage vs. Industry Average |

|---|---|---|---|

| Thickness | 0.6mm – 1.8mm | ISO 2418 | ±0.05mm tolerance (vs. ±0.15mm) |

| Weight | 280g/m² – 650g/m² | ISO 2286-2 | 15% lighter at equivalent strength |

| Martindale Abrasion | 50,000 – 150,000 cycles | ISO 12947 | 2x durability in heavy-use categories |

| Color Fastness (Light) | Grade 5 – 7 | ISO 105-B02 | 30% higher UV resistance |

| Tensile Strength | 18 – 35 MPa | ISO 17683 | Optimized for automated cutting |

| REACH SVHC Status | 100% Compliant | EC 1907/2006 | Full disclosure documentation |

| Customization Lead Time | 10 – 15 business days | Internal QA | 40% faster than standard industry |

WINIW’s Custom Leather Bibles transform material selection from a logistical hurdle into a strategic advantage. By integrating eco-performance (Bluesign®-approved processes), regulatory certainty, and engineering-grade consistency, we empower your product development cycle with zero compromise on sustainability or durability. Request a technical dossier and sample bible to validate specifications against your application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather for Custom Bible Covers

When manufacturing custom leather bibles for religious institutions, gift retailers, or corporate branding, material selection is a critical decision. Two primary options dominate the market: real leather and synthetic leather (specifically premium PU leather, such as WINIW’s eco-friendly solutions). While both offer distinctive aesthetics and functional benefits, their differences in cost, durability, and environmental impact can significantly influence purchasing decisions.

Key Considerations for Material Selection

- Cost Efficiency: Synthetic leather typically offers a lower upfront cost compared to real leather, making it ideal for bulk production and budget-conscious clients.

- 耐久性: Real leather is naturally long-lasting but requires maintenance; synthetic leather has improved significantly in wear resistance and is often more consistent in quality.

- Eco-Friendliness: Real leather involves resource-intensive tanning processes and ethical concerns. High-quality synthetic leathers, especially those made with sustainable practices, offer a lower carbon footprint and reduced environmental impact.

- Customization: Synthetic leather allows for greater flexibility in color, texture, and branding options, including embossing, laser engraving, and digital printing.

- Ethical Sourcing: Synthetic leather eliminates the use of animal products, aligning with growing demand for cruelty-free and vegan-compliant materials.

The following table compares synthetic leather (custom leather bibles using premium PU) and real leather across three core business evaluation metrics:

| Criteria | Synthetic Leather (WINIW PU) | Real Leather |

|---|---|---|

| Cost | Lower cost per unit; ideal for large orders | Higher cost due to raw material and processing |

| 耐久性 | High abrasion resistance; consistent finish; resistant to fading and cracking | Naturally durable but prone to drying, cracking, and staining without maintenance |

| Eco-Friendliness | Low environmental impact; recyclable options available; no animal sourcing | High water and energy usage; chemical tanning byproducts; animal-derived |

Conclusion

For B2B manufacturers and distributors of custom leather bibles, synthetic leather presents a competitive, sustainable, and cost-effective alternative to real leather. With advancements in material science, modern synthetic leathers replicate the premium look and feel of real leather while offering enhanced consistency, customization, and environmental responsibility. WINIW’s eco-conscious synthetic leather solutions support ethical production goals without compromising on quality or aesthetics—making them a strategic choice for forward-thinking brands.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global Partners

WINIW operates one of the most advanced and sustainable synthetic leather manufacturing facilities in Asia, engineered to meet the rigorous demands of international B2B clients. Our vertically integrated 100,000 sqm factory in China is purpose-built for precision, scalability, and environmental responsibility, serving as the cornerstone of our global supply chain.

Key strengths underpinning our production capabilities include:

- Advanced R&D Infrastructure: A dedicated team of 50+ material scientists and engineers continuously innovates within our on-site laboratories, developing next-generation eco-friendly substrates and coatings, including water-based PU and recycled-content solutions compliant with EU REACH and CPSIA standards.

- Strict Quality Control Systems: Multi-stage QC protocols are enforced from raw material inspection to finished roll, featuring automated defect detection, physical property testing (abrasion, colorfastness, peel strength), and batch traceability. All processes adhere to ISO 9001 and IATF 16949 certifications.

- Global Compliance & Logistics: Decades of export experience ensure seamless delivery to Europe and North America, with full documentation for customs clearance, adherence to Lacey Act requirements, and carbon-neutral shipping options. Our facility maintains annual third-party audits for chemical safety (ZDHC MRSL compliance) and social responsibility (BSCI).

This combination of scale, technical expertise, and uncompromising quality enables WINIW to deliver consistent, sustainable synthetic leather solutions that meet the exacting specifications of automotive, furniture, and fashion brands worldwide. Partner with us for reliable, eco-conscious manufacturing at global scale.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Leather for B2B Applications

WINIW is a leading manufacturer of high-performance, eco-friendly microfiber leather engineered specifically for industrial and commercial use. Our synthetic leather solutions combine durability, sustainability, and design flexibility to meet the evolving needs of global B2B clients across furniture, automotive, fashion, and specialty product sectors.

Our advanced production technology ensures consistent quality, superior abrasion resistance, and customizable textures and finishes—offering a responsible alternative to genuine leather without compromising on performance or aesthetics.

Key Advantages of WINIW Microfiber Leather

- Eco-Friendly Composition: Made from polyurethane and ultra-fine fibers, our leather is free from hazardous substances and aligns with REACH, RoHS, and OEKO-TEX® standards.

- High Durability: Exceptional tensile strength, tear resistance, and color fastness ensure long-term performance in demanding environments.

- Customization Options: Tailor thickness (0.6mm–2.0mm), weight, texture (Nubuck, Suede, Grain), and color to match your product specifications.

- Water and Stain Resistant: Ideal for high-traffic applications where cleanliness and maintenance are critical.

- Cost-Effective: Stable pricing and reduced waste compared to natural leather, with consistent roll-to-roll quality.

- Sustainable Supply Chain: Low-emission manufacturing process and recyclable packaging support corporate ESG goals.

Common B2B Applications

- Upholstery for office, hospitality, and residential furniture

- Automotive and transportation interiors (seats, dashboards, door panels)

- Luggage, handbags, and fashion accessories

- Safety gear and workwear

- Specialty covers and protective casings

Technical Specifications (Standard Grade)

| Property | 仕様 |

|---|---|

| Thickness Range | 0.6 mm – 2.0 mm |

| Weight per Square Meter | 280 g/m² – 500 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale test) |

| Color Fastness | >Grade 4 (Xenon arc light exposure) |

| Cold Crack Resistance | Passes -20°C bend test |

| 环保认证 | REACH, OEKO-TEX® STANDARD 100, RoHS |

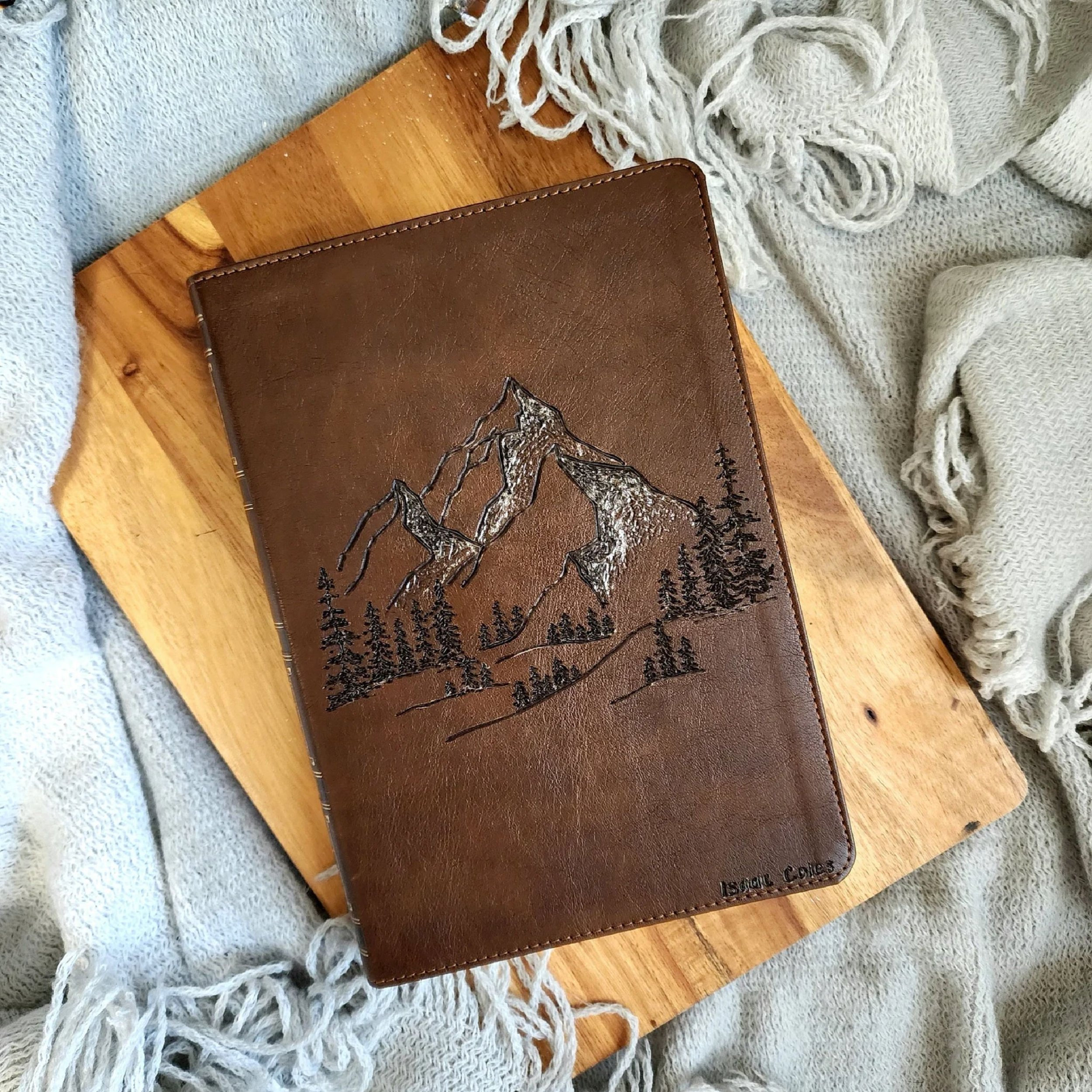

Request Your Custom Leather Bible

We offer custom leather bibles—personalized sample books featuring your selected textures, colors, and technical data—to streamline your material selection process and accelerate product development.

- Showcase WINIW options tailored to your industry needs

- Include branding and product codes upon request

- Ideal for internal review, client presentations, and design teams

Free samples available upon request.

For inquiries and to request your custom leather bible, contact:

MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.