Introduction: Navigating the Global Market for squeegee towel

In today’s competitive landscape, sourcing high-quality squeegee towels presents a significant challenge for international B2B buyers. With a wide variety of options available, navigating the global market for these essential cleaning tools can be daunting. This guide aims to simplify the process by providing a comprehensive overview of squeegee towels, including their types, applications, and the best practices for supplier vetting. By addressing critical factors such as material quality, cost considerations, and shipping logistics, we empower businesses from Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Germany—to make informed purchasing decisions.

As you delve into this guide, you will discover the various applications of squeegee towels across industries, from window cleaning to automotive detailing. Understanding the specific needs of your business will enable you to select the right product that not only enhances operational efficiency but also ensures customer satisfaction. Additionally, we will highlight effective strategies for evaluating suppliers, ensuring that you partner with reputable manufacturers who meet your quality standards.

By the end of this guide, you will be equipped with the knowledge and insights necessary to navigate the complexities of the squeegee towel market confidently. Whether you are looking to bulk purchase or seeking specialized products, this resource will serve as your go-to reference for optimizing your procurement process.

Table Of Contents

- Top 8 Squeegee Towel Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for squeegee towel

- Understanding squeegee towel Types and Variations

- Key Industrial Applications of squeegee towel

- 3 Common User Pain Points for ‘squeegee towel’ & Their Solutions

- Strategic Material Selection Guide for squeegee towel

- In-depth Look: Manufacturing Processes and Quality Assurance for squeegee towel

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘squeegee towel’

- Comprehensive Cost and Pricing Analysis for squeegee towel Sourcing

- Alternatives Analysis: Comparing squeegee towel With Other Solutions

- Essential Technical Properties and Trade Terminology for squeegee towel

- Navigating Market Dynamics and Sourcing Trends in the squeegee towel Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of squeegee towel

- Strategic Sourcing Conclusion and Outlook for squeegee towel

- Important Disclaimer & Terms of Use

Understanding squeegee towel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microfiber Towels | Ultra-absorbent, lint-free, durable | Window cleaning, automotive detailing | Pros: High absorbency, reusable, quick-drying. Cons: May require specific care instructions to maintain longevity. |

| Waffle Weave Towels | Unique textured surface enhances absorption | Detailing vehicles, cleaning glass | Pros: Excellent for detailing, lightweight. Cons: Texture may trap dirt if not properly washed. |

| 合成セーム革 | Soft, leather-like feel, highly absorbent | Car washes, industrial applications | Pros: Durable, great for large surface areas. Cons: May not be as effective on smaller, intricate surfaces. |

| Terry Cloth Towels | Traditional cotton fabric, plush and absorbent | General cleaning, household applications | Pros: Soft, versatile, widely available. Cons: Can leave lint, slower drying time. |

| ZORB-IT Drying Cloths | Synthetic material designed for quick drying | Commercial cleaning, shower maintenance | Pros: Fast drying, effective on various surfaces. Cons: Higher initial cost compared to cotton options. |

What are Microfiber Towels and Why Are They Beneficial for B2B Buyers?

Microfiber towels are a staple in the cleaning industry due to their ultra-absorbent properties and ability to trap dirt and grime without leaving lint behind. Their durability makes them suitable for repeated use, significantly reducing costs over time. B2B buyers should consider the care instructions, as improper washing can diminish their effectiveness. These towels are ideal for window cleaning and automotive detailing, making them a versatile choice for businesses in these sectors.

How Do Waffle Weave Towels Enhance Cleaning Efficiency?

Waffle weave towels feature a unique textured surface that enhances their absorption capabilities, making them particularly effective for detailing tasks. Their lightweight design allows for easy handling, which is beneficial in high-paced environments like automotive detailing or window cleaning. B2B buyers should ensure that these towels are properly laundered to avoid dirt buildup in the texture, which can affect performance. They are an excellent choice for businesses looking to improve efficiency in cleaning processes.

Illustrative image related to squeegee towel

What Makes Synthetic Chamois a Reliable Choice for Large Surface Areas?

Synthetic chamois towels offer a soft, leather-like feel and are known for their exceptional absorbency, making them ideal for large surface areas such as cars and industrial equipment. Their durability translates to a longer lifespan, providing value for B2B buyers in sectors that require frequent cleaning. However, these towels may not be as effective on intricate surfaces, so businesses should consider their specific cleaning needs when selecting this type.

Why Choose Terry Cloth Towels for General Cleaning Needs?

Terry cloth towels are made from traditional cotton fabric, providing a plush texture that is gentle on surfaces. They are versatile and widely available, making them a go-to option for general cleaning tasks in both household and commercial settings. However, B2B buyers should be aware that terry cloth towels can leave lint and may have a slower drying time compared to synthetic alternatives. Their affordability makes them a practical choice for businesses with varied cleaning requirements.

How Do ZORB-IT Drying Cloths Stand Out in the Market?

ZORB-IT drying cloths are designed specifically for quick drying, making them an excellent choice for commercial cleaning applications, including shower maintenance. Their synthetic composition allows for effective drying on a variety of surfaces, which can be a significant advantage in high-demand environments. While they may come at a higher initial cost than cotton options, their efficiency and durability can lead to cost savings in the long run. B2B buyers should evaluate their cleaning frequency and needs to determine if the investment is worthwhile.

Key Industrial Applications of squeegee towel

| Industry/Sector | Specific Application of squeegee towel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Window Cleaning | Used for detailing after squeegeeing windows. | Reduces streaks and improves customer satisfaction. | Look for high absorbency and low lint production. |

| Automotive Detailing | Ideal for drying vehicles after washing. | Enhances finish quality and reduces drying time. | Ensure towels are soft and non-abrasive to prevent scratches. |

| Food & Beverage | Utilized in cleaning glass surfaces in restaurants. | Maintains hygiene and ensures customer safety. | Sourcing should focus on microfiber material for effective cleaning. |

| Manufacturing | Employed in cleaning machinery and surfaces. | Prevents contamination and ensures operational efficiency. | Consider durability and washability for repeated use. |

| Construction | Used to clean glass and tiled surfaces post-installation. | Ensures high-quality finishes and customer satisfaction. | Look for towels that are easy to carry and store on-site. |

How is the squeegee towel used in the window cleaning industry?

In the window cleaning sector, squeegee towels are essential for detailing after the main cleaning process. Once windows are squeegeed, these towels absorb any residual water and eliminate streaks, leading to a flawless finish. For international buyers, especially those in regions like Africa and the Middle East, sourcing towels that are highly absorbent and produce minimal lint is crucial, as these factors directly impact service quality and customer satisfaction.

What role does the squeegee towel play in automotive detailing?

Automotive detailers utilize squeegee towels to dry vehicles after washing, effectively enhancing the car’s shine and reducing drying time. The soft texture of these towels prevents scratches on sensitive surfaces, making them an invaluable tool in the detailing process. Buyers in Europe and South America should prioritize towels made from non-abrasive materials to ensure a pristine finish and protect vehicle integrity.

Illustrative image related to squeegee towel

How does the food and beverage industry benefit from squeegee towels?

In the food and beverage sector, squeegee towels are used for cleaning glass surfaces, such as windows and display cases, ensuring a hygienic environment for customers. Their microfiber construction is effective in removing smudges and contaminants without leaving lint behind. For B2B buyers in this industry, it’s important to source towels that meet health and safety standards while providing superior cleaning performance.

Why are squeegee towels important in manufacturing?

Manufacturers employ squeegee towels for cleaning machinery and surfaces to prevent contamination during production processes. These towels help maintain operational efficiency by ensuring that equipment and work areas are free from debris and moisture. Buyers in this sector should focus on towels that are durable and machine washable, allowing for repeated use without compromising quality.

How do squeegee towels enhance quality in construction?

In the construction industry, squeegee towels are used to clean glass and tiled surfaces post-installation, ensuring that the finished product meets quality standards. They help remove excess water and debris, which can affect the final appearance. For international buyers, especially in emerging markets, sourcing lightweight and portable towels that are easy to transport to job sites can enhance workflow efficiency and client satisfaction.

3 Common User Pain Points for ‘squeegee towel’ & Their Solutions

Scenario 1: Struggling with Lint Residue on Finished Surfaces

The Problem: One of the most common frustrations for B2B buyers, particularly those in the cleaning and maintenance sectors, is the presence of lint or fiber residue left behind by traditional cleaning towels after squeegeeing windows or surfaces. This issue is particularly significant in high-end environments such as hotels and luxury retail spaces, where the appearance of cleanliness is paramount. Buyers may find themselves in a cycle of re-cleaning surfaces, leading to increased labor costs and time inefficiencies.

The Solution: To address this challenge, B2B buyers should consider sourcing high-quality microfiber squeegee towels specifically designed to minimize lint. Look for towels with a tight weave and low pile, as these characteristics help in reducing lint transfer. For optimal performance, use these towels in conjunction with a proper cleaning technique: after squeegeeing, use the towel to buff any remaining moisture or streaks, ensuring that it is dry and free from debris. Investing in microfiber towels with proven durability and lint-free properties can significantly enhance cleaning efficiency and reduce rework time, ultimately improving overall service quality.

Scenario 2: Inconsistent Absorbency Leading to Inefficient Drying

The Problem: B2B buyers often encounter towels that do not perform consistently when it comes to absorbency, which can lead to streaks and water spots on glass and other surfaces. This inconsistency can stem from using towels that have been overused or improperly cared for, leading to a lack of effective moisture absorption. As a result, cleaning teams may experience frustration and decreased productivity, ultimately impacting customer satisfaction.

The Solution: To ensure consistent absorbency, it is crucial to invest in high-performance squeegee towels made from advanced microfiber materials. B2B buyers should prioritize towels that offer a waffle weave structure, as this design enhances moisture retention and speed of drying. Additionally, proper maintenance is key; towels should be laundered regularly in cold water without fabric softeners to maintain their absorbent properties. Educating cleaning staff on the importance of towel rotation and effective washing techniques can further mitigate issues related to absorbency, leading to a more efficient cleaning process.

Scenario 3: High Replacement Costs Due to Poor Durability

The Problem: For many B2B buyers, particularly those managing cleaning services, the frequent need to replace squeegee towels due to wear and tear can lead to significant ongoing expenses. Cheaper alternatives may initially seem appealing, but they often result in quicker degradation, requiring more frequent purchases. This not only strains budgets but also complicates inventory management and supplier relationships.

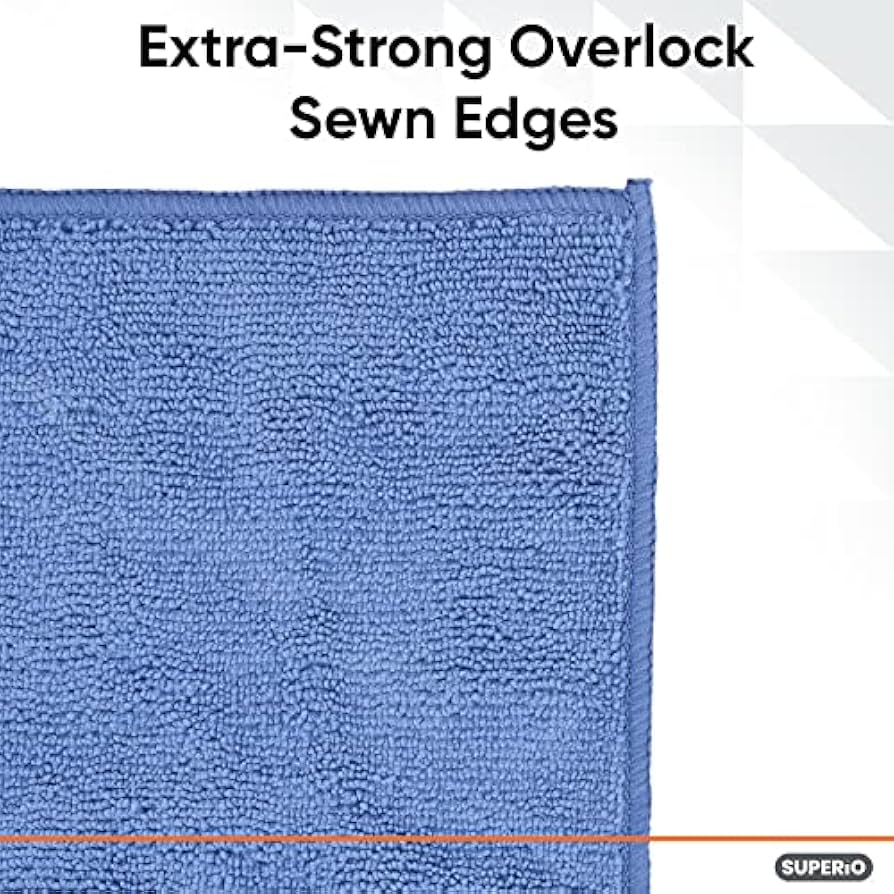

Illustrative image related to squeegee towel

The Solution: To combat high replacement costs, buyers should focus on sourcing squeegee towels that are specifically designed for durability and longevity. Look for options that boast reinforced edges and high-quality stitching, as these features enhance the lifespan of the towels. Conducting a cost analysis that factors in the total cost of ownership—including the price per use—can provide insight into the long-term value of investing in premium towels. Additionally, establishing relationships with reliable suppliers can lead to bulk purchasing discounts, further mitigating costs and ensuring a steady supply of high-quality towels that meet the demands of rigorous cleaning environments.

Strategic Material Selection Guide for squeegee towel

What Are the Key Materials Used in Squeegee Towels?

When selecting a squeegee towel, the choice of material significantly influences performance, durability, and overall effectiveness. Here, we analyze four common materials used in squeegee towels, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Microfiber Perform as a Material for Squeegee Towels?

Microfiber is a popular choice for squeegee towels due to its unique structure, which consists of ultra-fine fibers that create a high surface area for absorption. This material typically boasts excellent absorbency, allowing it to soak up water and cleaning solutions quickly. Microfiber towels are machine washable and can withstand multiple cleaning cycles without losing their effectiveness.

Pros: Microfiber towels are highly durable, lightweight, and effective at trapping dirt and grime. They are also cost-effective, making them suitable for bulk purchasing.

Cons: While generally resistant to wear, microfiber can be sensitive to high temperatures and harsh chemicals, which may degrade the fibers over time.

Impact on Application: Microfiber is compatible with various cleaning solutions, making it ideal for window cleaning, automotive detailing, and general-purpose cleaning.

Considerations for International Buyers: Microfiber towels should comply with international textile standards, such as ASTM D5034 for breaking strength. Buyers in regions like Europe may also prefer eco-friendly microfiber options that meet EU regulations on sustainability.

Illustrative image related to squeegee towel

What Advantages Do Cotton Towels Offer in Squeegee Applications?

Cotton towels are another common option, known for their softness and natural absorbency. They are often used in settings where gentle cleaning is required, such as in the automotive industry or delicate glass surfaces.

Pros: Cotton towels are biodegradable and can be produced at a relatively low cost. They are also highly absorbent and effective for polishing and buffing.

Cons: Cotton towels tend to wear out faster than synthetic options and may require more frequent replacement. They can also leave lint behind, which is not ideal for detailed cleaning tasks.

Impact on Application: Cotton towels are particularly effective in applications where absorbency is critical, but their linting can be a drawback in high-precision environments.

Considerations for International Buyers: Buyers should ensure that cotton towels meet relevant agricultural and textile standards, especially in regions like Africa and South America where organic cotton may be preferred.

How Do Synthetic Chamois Towels Compare for Squeegee Use?

Synthetic chamois towels are designed to mimic the properties of natural chamois leather, providing a unique combination of absorbency and quick-drying capabilities. These towels are often used in automotive and glass cleaning applications.

Pros: Synthetic chamois towels are highly absorbent and do not leave streaks or lint. They are also resistant to mold and mildew, making them suitable for humid environments.

Illustrative image related to squeegee towel

Cons: They can be more expensive than traditional cotton options and may require specific care instructions to maintain their properties.

Impact on Application: Their quick-drying nature makes synthetic chamois towels ideal for high-volume cleaning tasks, particularly in climates with high humidity.

Considerations for International Buyers: Ensure compliance with ASTM standards for synthetic materials, and consider preferences for eco-friendly options in markets like Germany.

Illustrative image related to squeegee towel

What Role Do Terry Cloth Towels Play in Squeegee Applications?

Terry cloth towels are characterized by their looped fibers, which provide excellent absorbency and softness. They are commonly used in both domestic and commercial cleaning applications.

Pros: Terry cloth towels are highly durable and can withstand extensive washing, making them suitable for repeated use. They are also versatile, serving multiple cleaning functions.

Cons: They can be bulkier and heavier than microfiber or synthetic options, which may affect usability in certain applications.

Impact on Application: Terry cloth is effective for drying and polishing surfaces, but its bulkiness may limit its effectiveness in tight spaces.

Considerations for International Buyers: Buyers should verify that terry cloth towels meet international textile standards, particularly in regions where quality assurance is critical.

Summary Table of Material Options for Squeegee Towels

| 素材 | Typical Use Case for squeegee towel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| マイクロファイバー | Window cleaning, automotive detailing | Highly absorbent, durable, lightweight | Sensitive to high temperatures and chemicals | Medium |

| Cotton | Polishing, general cleaning | Biodegradable, soft, highly absorbent | Can leave lint, wears out faster | 低い |

| 合成セーム革 | Automotive, glass cleaning | Quick-drying, streak-free, mold-resistant | More expensive, specific care required | 高い |

| Terry Cloth | Domestic and commercial cleaning | Durable, versatile, excellent absorbency | Bulkier, may limit effectiveness in tight spaces | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the different materials used for squeegee towels, enabling informed purchasing decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for squeegee towel

What Are the Key Stages in the Manufacturing Process of Squeegee Towels?

The production of squeegee towels involves several critical stages, each designed to ensure the final product meets high standards of quality and functionality. Understanding these stages can help B2B buyers make informed decisions when sourcing suppliers.

Material Preparation: What Materials Are Used in Squeegee Towel Manufacturing?

The primary materials for squeegee towels are microfiber and cotton, known for their absorbency and durability. Microfiber, made of polyester and polyamide, is favored for its ability to trap dirt and moisture effectively. The initial step in the manufacturing process involves sourcing high-quality fibers from reputable suppliers. This is crucial, as the quality of the raw material directly influences the towel’s performance and longevity.

How Are Squeegee Towels Formed and Assembled?

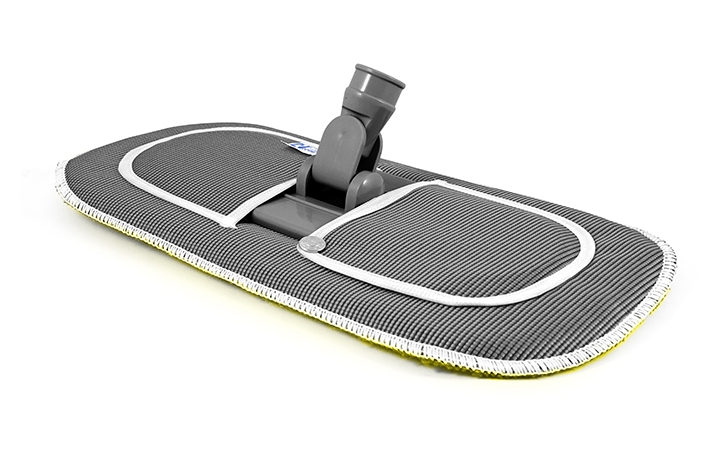

Once the materials are prepared, the next stage is forming and assembling the towels. This typically involves weaving or knitting the fibers into the desired texture. For squeegee towels, a waffle weave pattern is common, as it enhances absorbency and reduces lint. After weaving, the towels are cut to specified dimensions, usually around 22″ x 16″.

After cutting, towels undergo a stitching process to prevent fraying and ensure durability. This stage may also include the addition of labels or branding, which can be significant for B2B buyers looking for customized products.

What Finishing Techniques Are Employed for Squeegee Towels?

The finishing process enhances both the aesthetic and functional aspects of the towels. This may involve treatments to improve water repellency or to enhance softness. Towels are typically subjected to a quality check after finishing to ensure they meet the required specifications.

Moreover, the towels are washed and dried to remove any residual chemicals from the manufacturing process. This step not only ensures cleanliness but also helps set the fibers, enhancing absorbency and performance.

What Quality Assurance Practices Are Essential for Squeegee Towels?

Quality assurance (QA) is vital in the manufacturing of squeegee towels to ensure that each product meets international standards and customer expectations.

Which International Standards Should B2B Buyers Consider?

For squeegee towel manufacturers, adhering to international standards such as ISO 9001 is crucial. This standard focuses on quality management systems and ensures that products consistently meet customer and regulatory requirements. Additionally, other certifications like CE (Conformité Européenne) may be relevant for products sold in European markets, indicating compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated into various stages of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet predetermined specifications. B2B buyers should verify that suppliers conduct rigorous IQC to prevent defects in the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, samples are taken at various stages to monitor quality. This ensures that any issues can be identified and rectified before the towels reach the final inspection stage.

-

Final Quality Control (FQC): Before packaging, towels undergo a final inspection to check for defects, dimensional accuracy, and overall quality. Buyers should inquire about the FQC processes to ensure that only products meeting high standards are shipped.

How Can B2B Buyers Verify Supplier Quality Control Measures?

Verifying a supplier’s QC measures is essential for B2B buyers, especially when sourcing internationally. Here are some actionable strategies:

What Audit Processes Should Buyers Implement?

Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should establish a clear audit schedule, focusing on the supplier’s compliance with international standards and their internal QC processes.

How Can Buyers Utilize Reports and Documentation?

Requesting detailed QC reports from suppliers is another effective method. These reports should outline the results of IQC, IPQC, and FQC checks, providing transparency into the supplier’s commitment to quality. Buyers should also look for certificates of compliance with international standards, as these documents serve as proof of adherence to quality protocols.

Illustrative image related to squeegee towel

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can further validate the quality of the towels. These independent entities can conduct thorough checks at various stages of production, offering an unbiased assessment of the supplier’s capabilities. This is particularly important for buyers in regions like Africa, South America, and the Middle East, where local regulations may differ significantly from international standards.

What Nuances Should International B2B Buyers Be Aware Of Regarding Quality Control?

International buyers must navigate various nuances when sourcing squeegee towels. Cultural differences, regulatory requirements, and varying market expectations can impact quality standards.

How Do Regional Regulations Affect Quality Assurance?

For instance, buyers from Europe may have stricter requirements regarding textile safety and environmental impact compared to those in Africa or South America. Understanding these regional differences can help buyers set appropriate expectations and ensure compliance with local regulations.

What Role Does Communication Play in Ensuring Quality?

Effective communication with suppliers is crucial for ensuring that quality standards are met. B2B buyers should establish clear lines of communication to discuss specifications, quality expectations, and any concerns that may arise during the manufacturing process.

By thoroughly understanding the manufacturing processes and quality assurance practices for squeegee towels, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Illustrative image related to squeegee towel

Practical Sourcing Guide: A Step-by-Step Checklist for ‘squeegee towel’

In the competitive market of cleaning supplies, acquiring high-quality squeegee towels is essential for ensuring effective performance and customer satisfaction. This guide provides a step-by-step checklist for international B2B buyers to streamline the sourcing process, ensuring you select the best products for your needs.

Step 1: Identify Your Specific Needs

Understanding your unique requirements is the foundation of a successful sourcing strategy. Consider factors such as the intended use of the squeegee towels, whether for automotive detailing, window cleaning, or general housekeeping. Additionally, assess the volume you anticipate needing and any specific materials or features that may enhance performance, such as microfiber composition or absorbency levels.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that meet your criteria. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers and distributors. Pay attention to their experience in the field, product range, and customer reviews to ensure reliability and quality.

Step 3: Evaluate Supplier Certifications

Before finalizing any partnerships, verify that suppliers hold relevant certifications. This includes ISO certifications, environmental compliance (like REACH or RoHS), and any industry-specific standards. Certifications not only indicate product quality but also reflect the supplier’s commitment to best practices and safety regulations.

Step 4: Request Samples for Testing

Always request samples from shortlisted suppliers to assess the quality of their squeegee towels. Testing samples allows you to evaluate absorbency, lint-free performance, and durability. Use this opportunity to check how well the towels perform under various conditions, ensuring they meet your operational standards.

Step 5: Compare Pricing and Terms

Once you have evaluated product samples, compare pricing among different suppliers. Look beyond just the unit price; consider shipping costs, bulk purchase discounts, and payment terms. Ensure that the total cost aligns with your budget without compromising quality.

Step 6: Assess Customer Support and Communication

Effective communication and customer support are vital for a successful supplier relationship. Evaluate how promptly and transparently potential suppliers respond to inquiries. Strong customer service can facilitate smoother transactions and assist with any issues that may arise post-purchase.

Step 7: Finalize Contracts and Terms of Sale

Once you have selected a supplier, it’s time to negotiate and finalize contracts. Ensure all terms, including delivery schedules, payment terms, and return policies, are clearly defined. A well-documented agreement protects both parties and sets clear expectations for the business relationship.

By following this checklist, B2B buyers can confidently navigate the sourcing process for squeegee towels, ensuring they select the right products and partners to enhance their operations.

Comprehensive Cost and Pricing Analysis for squeegee towel Sourcing

What Are the Key Cost Components in Squeegee Towel Sourcing?

When sourcing squeegee towels, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. Common materials for squeegee towels include microfiber, cotton, and synthetic blends. Microfiber towels, known for their absorbency and durability, often command higher prices than basic cotton options.

-

Labor: Labor costs vary based on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but this can also affect quality. It’s essential to balance cost with the quality of workmanship.

-

Manufacturing Overhead: This encompasses the costs of running the production facility, including utilities, rent, and administrative expenses. Efficient production processes can help minimize these costs.

-

Tooling: Initial tooling costs can be significant, especially if custom designs or specifications are required. Buyers should inquire about tooling fees that may be applicable for unique orders.

-

Quality Control (QC): Implementing strict quality control measures ensures the towels meet required standards. However, this adds to the overall cost. Certifications for quality (e.g., ISO standards) can also influence pricing.

-

Logistics: Transportation costs, including shipping and handling, are critical, particularly for international buyers. The choice of shipping method (air vs. sea) can greatly affect delivery times and costs.

-

Margin: Suppliers will include their profit margin in the final price. Understanding typical industry margins can help buyers negotiate effectively.

How Do Price Influencers Affect Squeegee Towel Costs?

Several factors influence the pricing of squeegee towels, making it crucial for buyers to assess these before procurement:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract lower per-unit costs. Buyers should negotiate MOQs to optimize pricing, especially when dealing with multiple suppliers.

-

Specifications and Customization: Custom specifications (e.g., size, color, branding) can increase costs. Standardized products usually provide better pricing opportunities.

-

Material Quality and Certifications: Higher-quality materials and certifications (like eco-friendliness) can raise costs. Buyers should weigh the benefits of premium materials against budget constraints.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more due to their experience and quality assurance processes.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. They define responsibilities for shipping costs, insurance, and tariffs, which can significantly impact total costs.

What Tips Can Help International Buyers Optimize Costs for Squeegee Towels?

Navigating the squeegee towel market can be complex, especially for international buyers. Here are some actionable tips:

-

Negotiate Wisely: Always aim to negotiate prices, especially when placing large orders. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, shipping, handling, and potential waste or returns. A lower upfront cost may not always result in the best overall value.

-

Understand Pricing Nuances: Be aware of regional pricing differences and how local economies affect costs. For instance, sourcing from countries with favorable trade agreements may yield better pricing.

-

Evaluate Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and reliability. Regular communication and feedback can foster trust and collaboration.

-

Stay Informed on Market Trends: Keeping abreast of market trends, such as material innovations or changing demand, can help buyers make informed decisions and negotiate better deals.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and obtain multiple quotes to ensure the best pricing strategy for your business needs.

Alternatives Analysis: Comparing squeegee towel With Other Solutions

Exploring Alternatives to Squeegee Towels for Effective Cleaning Solutions

In the competitive landscape of cleaning solutions, businesses often seek alternatives to squeegee towels that can deliver similar or enhanced performance. Understanding these alternatives can help B2B buyers make informed decisions that align with their specific operational needs and budget constraints. Below, we compare squeegee towels with two viable alternatives: microfiber cloths and synthetic chamois.

| Comparison Aspect | Squeegee Towel | Microfiber Cloth | 合成セーム革 |

|---|---|---|---|

| Performance | Highly absorbent, effective for detailing and window cleaning | Excellent dirt and water absorption, versatile | Good absorption, but may leave streaks on glass |

| Cost | $6.29 per towel | $1.50 – $3.00 per cloth | $15.00 – $25.00 per chamois |

| Ease of Implementation | Easy to use; ideal for quick jobs | Simple to use; requires washing | Requires some practice for optimal use |

| Maintenance | Machine washable, durable | Machine washable, very durable | Hand wash recommended, less durable |

| Best Use Case | Window cleaning and detailing | General cleaning, dusting, and drying | Automotive drying and large surfaces |

Understanding the Pros and Cons of Microfiber Cloths

Microfiber cloths are made from synthetic fibers that are finer than human hair, making them highly effective for cleaning. They excel in absorbing moisture and picking up dirt, dust, and grime without the need for chemical cleaners. However, while they are relatively low-cost and easy to maintain, they can wear out over time and may require frequent washing to maintain their effectiveness. Microfiber cloths are versatile, making them suitable for various cleaning tasks beyond just windows, such as dusting and polishing surfaces.

Illustrative image related to squeegee towel

Evaluating Synthetic Chamois for Specialized Applications

Synthetic chamois, often used in automotive settings, are designed to absorb large volumes of water quickly. They are particularly effective for drying vehicles after washing, making them a favored choice among car detailers. However, they can be less effective for window cleaning as they may leave streaks if not used properly. Additionally, synthetic chamois can be more expensive than squeegee towels and require hand washing to maintain their quality, which may not be as convenient for high-volume cleaning operations.

Making the Right Choice for Your Cleaning Needs

When selecting the appropriate cleaning solution, B2B buyers should consider factors such as the specific cleaning tasks they encounter, budget constraints, and desired efficiency. Squeegee towels are an excellent choice for window cleaning and detailing due to their absorbent properties and ease of use. In contrast, microfiber cloths offer versatility for various cleaning applications at a lower cost, while synthetic chamois provide superior drying capabilities for automotive use but may require more maintenance. Ultimately, the right solution will depend on the unique demands of each business’s cleaning operations. By weighing these alternatives carefully, buyers can enhance their cleaning efficiency and effectiveness while optimizing their costs.

Essential Technical Properties and Trade Terminology for squeegee towel

What are the Key Technical Properties of Squeegee Towels?

Understanding the technical specifications of squeegee towels is essential for B2B buyers, particularly those operating in cleaning, automotive, or facility maintenance sectors. Here are several critical properties:

1. Material Composition

Squeegee towels are typically made from microfiber, which consists of synthetic fibers that are finer than human hair. This material is highly absorbent and effective at picking up dirt and moisture without leaving lint or streaks. For B2B buyers, selecting the right material ensures that the towels will meet performance expectations and durability requirements.

2. Weave Type

The weave of a squeegee towel, often a waffle or terry weave, significantly affects its absorbency and performance. A waffle weave allows for greater surface area, enhancing moisture absorption and making it ideal for detailing tasks after squeegeeing. Buyers should consider the weave type based on their specific cleaning applications to ensure optimal efficiency.

Illustrative image related to squeegee towel

3. Size Specifications

Squeegee towels come in various sizes, commonly around 22″ x 16″. The size impacts usability; larger towels can cover more surface area, while smaller ones are easier to handle. B2B buyers should choose sizes that align with their operational needs, as this can influence labor efficiency and productivity.

4. Durability Rating

Durability is a crucial factor, especially for businesses that require frequent laundering. High-quality squeegee towels can withstand multiple wash cycles without losing their effectiveness. Understanding the durability rating helps buyers assess the long-term value and cost-efficiency of their investment.

5. Absorbency Rate

The absorbency rate indicates how much moisture a towel can hold before becoming saturated. Towels with a higher absorbency rate are preferable for tasks that involve significant liquid, such as cleaning windows or surfaces. Buyers should evaluate this property to ensure they select towels that can handle their specific workload.

6. Care Instructions

Proper care instructions, such as recommended washing temperatures and drying methods, are vital for maintaining towel performance. Many microfiber towels can be washed in hot or cold water but should avoid fabric softeners that can diminish absorbency. Understanding care requirements helps businesses extend the lifespan of their towels.

Illustrative image related to squeegee towel

What are the Common Trade Terms Used in the Squeegee Towel Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several important terms:

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces products that are marketed under another brand’s name. In the context of squeegee towels, buyers may work with OEMs to obtain custom-branded products. Understanding OEM relationships can enhance branding strategies and product differentiation.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is a critical factor for B2B buyers as it can affect inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases according to their operational needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a standard business process wherein a buyer requests pricing and availability information from suppliers. For squeegee towels, submitting an RFQ allows businesses to compare offers from multiple suppliers, ensuring they secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping responsibilities, costs, and risks associated with importing squeegee towels.

Illustrative image related to squeegee towel

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to the delivery of goods. Understanding lead times is essential for B2B buyers to manage inventory levels and ensure timely availability of products for their operations.

6. SKU (Stock Keeping Unit)

A SKU is a unique identifier for each distinct product and service that can be purchased. In the context of squeegee towels, each variation (size, color, type) will have its own SKU. Recognizing SKUs is important for inventory tracking and management.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and enhance their purchasing strategies.

Navigating Market Dynamics and Sourcing Trends in the squeegee towel Sector

What Are the Current Market Dynamics and Key Trends in the Squeegee Towel Sector?

The global squeegee towel market is witnessing significant growth driven by several factors, including increased demand for cleaning solutions across various industries such as automotive, hospitality, and construction. The shift towards sustainability and eco-friendly products has also influenced the sourcing landscape, prompting manufacturers to explore innovative materials and production processes. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed purchasing decisions.

Emerging trends in technology are reshaping the squeegee towel sector, with advancements in materials science leading to the development of high-performance microfiber and synthetic options. These modern towels offer superior absorbency, durability, and ease of maintenance, which are essential features for businesses aiming to enhance operational efficiency. Furthermore, the rise of e-commerce platforms has expanded sourcing options, enabling buyers to access a broader range of products at competitive prices.

Illustrative image related to squeegee towel

Another key trend is the increasing focus on customization. B2B buyers are seeking tailored solutions that meet specific cleaning needs, allowing suppliers to differentiate themselves in a crowded market. As cleaning protocols evolve, especially post-pandemic, there is a growing emphasis on products that can be used effectively in diverse environments, from residential settings to industrial applications.

How Important Is Sustainability and Ethical Sourcing in the Squeegee Towel Market?

Sustainability and ethical sourcing have become paramount considerations for B2B buyers in the squeegee towel sector. The environmental impact of textile production, including water usage, chemical runoff, and waste generation, necessitates a shift towards more responsible practices. Buyers are increasingly prioritizing suppliers who can demonstrate a commitment to sustainable manufacturing processes, such as using recycled materials or implementing energy-efficient production methods.

Ethical supply chains are essential not only for compliance with regulatory standards but also for building brand reputation. Companies that source materials from certified suppliers often benefit from enhanced customer trust and loyalty. Certifications such as OEKO-TEX or GOTS (Global Organic Textile Standard) signify adherence to rigorous environmental and social criteria, providing buyers with confidence in the products they procure.

Moreover, the demand for ‘green’ products is on the rise, with consumers and businesses alike showing preference for items that contribute to environmental conservation. Squeegee towels made from sustainable materials, like organic cotton or recycled polyester, are increasingly favored, reflecting a broader trend towards eco-conscious purchasing. For B2B buyers, integrating sustainability into their sourcing strategy not only aligns with global trends but also positions their businesses as responsible corporate citizens.

What Is the Brief Evolution and History of Squeegee Towels?

The evolution of squeegee towels can be traced back to the broader development of cleaning textiles, which began with traditional cloth materials. In the early 20th century, cotton and linen were commonly used, but these fabrics often left lint and required frequent washing. The introduction of microfiber in the late 20th century marked a significant turning point, as these innovative materials provided superior absorbency and cleaning efficiency.

Illustrative image related to squeegee towel

As industries evolved, so did the design and functionality of squeegee towels. Manufacturers began to focus on specific applications, developing towels tailored for automotive detailing, window cleaning, and other specialized tasks. Today, the market is characterized by a diverse range of products that cater to various cleaning needs, underscored by advancements in material technology and sustainable practices. This history reflects a continual adaptation to consumer demands and environmental considerations, shaping the current landscape of the squeegee towel sector.

Frequently Asked Questions (FAQs) for B2B Buyers of squeegee towel

-

How do I ensure the quality of squeegee towels from suppliers?

To ensure the quality of squeegee towels, conduct thorough supplier vetting. Request samples to assess material quality, absorbency, and durability. Check for certifications like ISO or other relevant quality standards. It’s also beneficial to read customer reviews and ask for references from other B2B clients. Establish clear quality assurance protocols with your supplier, including specifications for materials and performance testing. -

What is the best material for squeegee towels in professional cleaning?

Microfiber is widely regarded as the best material for squeegee towels used in professional cleaning. Its unique weave allows for superior absorbency and lint-free performance, making it ideal for detailing and drying surfaces. Additionally, microfiber towels are lightweight, durable, and machine washable, which can lead to cost savings over time. Ensure that the towels you source have a high GSM (grams per square meter) for optimal effectiveness. -

How can I customize squeegee towels for my brand?

Customization options for squeegee towels often include printing your logo or selecting specific colors and sizes. Discuss your needs with potential suppliers to see what customization services they offer. Some manufacturers may require a minimum order quantity (MOQ) for customized products, so clarify this before placing an order. Providing your design files in the correct format will also facilitate the customization process. -

What are typical minimum order quantities (MOQs) for squeegee towels?

MOQs for squeegee towels can vary significantly based on the supplier and the type of customization. Generally, you can expect MOQs to range from 100 to 1,000 units for bulk orders. It’s essential to communicate your requirements with potential suppliers to negotiate MOQs that align with your business needs. Some suppliers may offer flexibility for first-time buyers or larger contracts. -

What payment terms should I expect when sourcing internationally?

International payment terms can vary widely among suppliers. Common options include letters of credit, wire transfers, and payment on delivery. It’s advisable to negotiate terms that provide security for both parties, such as partial payment upfront and the balance upon delivery. Ensure that you are aware of any additional fees related to currency exchange or transaction processing when dealing with international payments. -

How do logistics and shipping work for international orders of squeegee towels?

Logistics for international orders involve coordinating with freight forwarders for shipping, customs clearance, and local delivery. Discuss shipping methods with your supplier, as options may include air freight for faster delivery or sea freight for cost savings on larger orders. Be sure to account for lead times and potential delays, especially during peak shipping seasons. Understand your responsibilities for customs duties and taxes to avoid unexpected costs. -

What quality assurance measures should I implement when sourcing squeegee towels?

Implementing quality assurance measures involves setting clear expectations with suppliers regarding product specifications, conducting regular inspections, and requiring third-party testing if necessary. Create a checklist that includes parameters like absorbency, durability, and appearance. Periodic audits of the manufacturing process can also help ensure compliance with quality standards. Establish a return policy for defective products to protect your investment. -

How can I evaluate potential suppliers for squeegee towels?

Evaluating potential suppliers should involve assessing their production capabilities, quality control processes, and customer service. Request detailed product catalogs, company certifications, and references from other B2B clients. Consider visiting the supplier’s facility if possible, or utilize virtual tours to inspect their operations. Additionally, analyze their responsiveness to inquiries and willingness to accommodate your specific needs as indicators of their reliability.

Top 8 Squeegee Towel Manufacturers & Suppliers List

1. Window Magic Supply – Squeegee Life Towel

Domain: windowmagicsupply.com

Registered: 2017 (8 years)

Introduction: {‘name’: ‘Squeegee Life Towel’, ‘regular_price’: ‘$6.29’, ‘sale_price’: ‘$6.29’, ‘options’: [‘Single’, ’12 pack’], ’12_pack_price’: ‘$62.99’, ‘inventory_status’: ‘In stock, ready to ship’, ‘weight_single’: ‘113g’, ‘weight_12_pack’: ‘1361g’, ‘customer_reviews’: [{‘reviewer’: ‘Travis Turner’, ‘review’: ‘Towels of greatness. No lint, cuts laundry in half, wash in cold water and dry on low saves energ…

2. Carbrite – Professional Grade Microfiber Towel

Domain: carbrite.com

Registered: 1997 (28 years)

Introduction: This company, Carbrite – Professional Grade Microfiber Towel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Discount Car Care Products – Essential Car Care Supplies

Domain: discountcarcareproducts.com

Registered: 2014 (11 years)

Introduction: California “Style” Jelly Blade (Yellow) – Regular price $23.90\nCalifornia “Style” Water Blade – Regular price $20.50\nHuck Towels | 10 lb Box – Regular price $53.90\nMagna Shine Water Demon Drying Cloth – Regular price $19.95\nTerry Cloth Car Wash Towels, 20” x 20” (12 Pack) – Regular price $23.90\nUltra Plush 16″ x 16″ White Towel – Regular price $5.00\nZORB-IT™ Drying Cloth w/ Tube 17″ x 27″ – …

4. Microfiber Madness – Chipmunk Drying Towel

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: TRC Double Twistress drying towel; Chipmunk drying towel from Microfiber Madness; Metrovac blaster; EGO cordless leaf blower.

5. Window Cleaner – Detailing Towels

Domain: windowcleaner.com

Registered: 1998 (27 years)

Introduction: This company, Window Cleaner – Detailing Towels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. The Rag Company – Platinum Pluffle Microfiber Towel

Domain: houzz.com

Registered: 2006 (19 years)

Introduction: Platinum Pluffle microfiber towel, size 20″ x 40″, purchased from The Rag Company; comes in a 2 pack for $26.95; designed for easy and efficient drying of shower tile and glass; features soft, fluffy fibers with waffle-type pockets; allows for large swipes and easy handling; recommended for those with difficulty using a squeegee.

7. CleanTools – The Absorber® Drying Towel

Domain: cleantools.net

Registered: 2000 (25 years)

Introduction: The Absorber® is an ultra absorbent drying towel made of PVA (Poly Vinyl Alcohol) material, designed to outperform terrycloth towels and leather chamois. It features a uniform, sponge-like pore structure that enhances capillary action for superior drying capabilities. The towel measures 27 in. x 17 in. and is available in six colors: Tan, Blue, Aqua, Purple, Neon Yellow, Red, and a new Orange. It …

8. Autofiber – Waffle Weave Drying Towels

Domain: autofiber.com

Registered: 2003 (22 years)

Introduction: This company, Autofiber – Waffle Weave Drying Towels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for squeegee towel

What Are the Key Benefits of Strategic Sourcing for Squeegee Towels?

In the competitive landscape of B2B sourcing, the strategic acquisition of squeegee towels presents numerous advantages for international buyers. These towels, particularly those made from high-quality microfiber, offer exceptional absorbency and durability, making them an indispensable tool across various industries, from window cleaning to automotive care. By prioritizing strategic sourcing, businesses can ensure they not only secure the best pricing but also maintain a consistent supply chain that meets their operational demands.

How Can International Buyers Leverage Market Trends?

As markets in Africa, South America, the Middle East, and Europe evolve, international buyers must stay attuned to trends in material innovation and sustainability. Squeegee towels that emphasize eco-friendly production methods are gaining traction, appealing to a growing consumer base that values environmental responsibility. By aligning procurement strategies with these trends, companies can enhance their brand reputation and customer loyalty.

What’s Next for Your Squeegee Towel Procurement Strategy?

Looking ahead, now is the time for B2B buyers to reevaluate their sourcing strategies and consider partnerships with reputable suppliers that offer high-quality squeegee towels. Engaging in strategic sourcing not only streamlines operations but also positions your business for growth in a dynamic market. Invest in quality today to ensure your operational efficiency tomorrow. Embrace the opportunity to enhance your product offerings and drive customer satisfaction with superior squeegee towels.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.