Introduction: Navigating the Global Market for leather factory florence

In today’s competitive landscape, sourcing high-quality leather products from a reputable leather factory in Florence can present significant challenges for international B2B buyers. The quest for premium leather goods often involves navigating a complex web of suppliers, understanding various product types, and ensuring that the materials meet both aesthetic and functional requirements. This guide is designed to empower buyers by providing a comprehensive overview of the Florentine leather market, covering essential aspects such as product categories, manufacturing processes, supplier vetting strategies, and cost considerations.

Buyers from Africa, South America, the Middle East, and Europe—particularly nations like Saudi Arabia and Nigeria—will find actionable insights tailored to their unique needs. By understanding the rich tradition of leather craftsmanship in Florence, along with current market trends, businesses can make informed decisions that align with their brand values and customer expectations. Whether you are looking for bespoke leather jackets, handbags, or accessories, this guide equips you with the knowledge to select the right suppliers, negotiate favorable terms, and ultimately enhance your product offerings.

With a focus on quality assurance and sustainable sourcing, this resource aims to simplify the procurement process, ensuring that your business thrives in the global marketplace while benefiting from the unparalleled craftsmanship that Florence has to offer.

Table Of Contents

- Top 8 Leather Factory Florence Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather factory florence

- Understanding leather factory florence Types and Variations

- Key Industrial Applications of leather factory florence

- 3 Common User Pain Points for ‘leather factory florence’ & Their Solutions

- Strategic Material Selection Guide for leather factory florence

- In-depth Look: Manufacturing Processes and Quality Assurance for leather factory florence

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather factory florence’

- Comprehensive Cost and Pricing Analysis for leather factory florence Sourcing

- Alternatives Analysis: Comparing leather factory florence With Other Solutions

- Essential Technical Properties and Trade Terminology for leather factory florence

- Navigating Market Dynamics and Sourcing Trends in the leather factory florence Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather factory florence

- Strategic Sourcing Conclusion and Outlook for leather factory florence

- Important Disclaimer & Terms of Use

Understanding leather factory florence Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-End Fashion Leather | Artisan-crafted, premium materials, intricate detailing | Luxury fashion brands, bespoke retailers | Pros: Unique designs, high quality. Cons: Higher cost, longer lead times. |

| Eco-Friendly Leather | Sustainable sourcing, vegetable-tanned, biodegradable options | Green fashion brands, eco-conscious retailers | Pros: Market appeal, sustainability credentials. Cons: Limited color options, potential durability issues. |

| Custom Leather Goods | Tailored products to specific client specifications | Corporate gifting, promotional items | Pros: Personalization, brand alignment. Cons: Minimum order quantities, longer production times. |

| Functional Leather Accessories | Versatile designs, durable materials, practical functionality | Retailers, e-commerce platforms | Pros: Broad appeal, functional use. Cons: May lack unique branding, competitive pricing pressure. |

| Luxury Handbags & Luggage | Exclusive designs, premium craftsmanship, high-end branding | Luxury retailers, travel brands | Pros: High resale value, brand prestige. Cons: High investment, niche market. |

What are the Characteristics of High-End Fashion Leather?

High-end fashion leather is characterized by its artisan craftsmanship, which often involves meticulous attention to detail and the use of premium materials such as full-grain leather. This type of leather is typically used by luxury fashion brands and bespoke retailers seeking to create unique, stylish products that appeal to a discerning clientele. Buyers should consider the brand’s reputation, the quality of the materials used, and the artisans’ skill level when purchasing. While high-end leather products offer exclusivity and superior quality, they come with a higher price point and longer production times.

How Does Eco-Friendly Leather Stand Out?

Eco-friendly leather is distinguished by its sustainable sourcing practices and the use of natural tanning methods, such as vegetable tanning. This leather variant is increasingly popular among green fashion brands and eco-conscious retailers looking to appeal to environmentally aware consumers. When considering eco-friendly leather, buyers should assess the sourcing certifications and the environmental impact of the production processes. While this type of leather can enhance a brand’s sustainability credentials, it may offer fewer color options and can sometimes face durability challenges compared to conventional leather.

What Makes Custom Leather Goods a Viable Option for B2B Buyers?

Custom leather goods are tailored to meet specific client requirements, making them ideal for corporate gifting and promotional items. These products allow businesses to align their branding with unique designs that resonate with their target audience. Buyers should consider the minimum order quantities and the potential for longer production times when opting for custom leather. While the personalization aspect can significantly enhance brand recognition and customer loyalty, it may also require a larger upfront investment.

Illustrative image related to leather factory florence

Why are Functional Leather Accessories Important for Retailers?

Functional leather accessories are designed for versatility and practicality, making them suitable for a wide range of retail applications, including e-commerce platforms. These products often feature durable materials and designs that cater to everyday use, appealing to a broader market. Buyers should focus on the product’s functionality and overall design appeal when sourcing these items. Although functional leather accessories may lack the unique branding of high-end products, they can benefit from competitive pricing and high demand in the retail space.

How Do Luxury Handbags & Luggage Fit into the Market?

Luxury handbags and luggage are synonymous with exclusivity and premium craftsmanship, often featuring high-end branding and unique designs. This segment caters to luxury retailers and travel brands looking to offer products that enhance their brand prestige. Buyers should evaluate the craftsmanship, brand reputation, and potential resale value when considering these items. While luxury leather goods represent a significant investment, they also provide high return potential and cater to a niche market willing to pay for quality and exclusivity.

Key Industrial Applications of leather factory florence

| Industry/Sector | Specific Application of leather factory florence | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end leather clothing production | Offers unique, artisanal products that appeal to luxury markets | Quality of leather, craftsmanship, and customization options |

| Accessories and Handbags | Custom leather handbags and accessories | Differentiates brand offerings with exclusive designs | Lead times, minimum order quantities, and design capabilities |

| Automotive | Leather interiors for luxury vehicles | Enhances vehicle aesthetics and comfort, appealing to premium buyers | Material specifications, durability, and compliance with safety standards |

| Home Décor | Leather upholstery and decorative items | Elevates interior design with high-quality materials | Sourcing of sustainable materials and customization options |

| Footwear | Custom leather footwear production | Meets niche market demands for unique, high-quality shoes | Sizing standards, production timelines, and design flexibility |

How is Leather Factory Florence Integral to the Fashion and Apparel Industry?

Leather factory Florence specializes in high-end leather clothing production, catering to fashion brands seeking unique, artisanal products. This application is particularly advantageous for luxury labels aiming to differentiate themselves in a competitive market. International buyers must consider the quality of leather used, the level of craftsmanship, and the potential for customization. By sourcing from Florence, brands can offer exclusive designs that resonate with discerning consumers, particularly in markets across Europe, Africa, and the Middle East.

Illustrative image related to leather factory florence

What Role Does Leather Factory Florence Play in Handbag and Accessories Production?

The production of custom leather handbags and accessories is a key application for leather factory Florence. This sector benefits from the factory’s ability to create unique pieces that enhance brand identity. International B2B buyers should focus on lead times, minimum order quantities, and the factory’s design capabilities to ensure alignment with their brand strategies. Partnering with Florence-based manufacturers allows businesses to tap into the rich heritage of Italian craftsmanship while offering customers exclusive products that stand out in the market.

How Does Leather Factory Florence Enhance Luxury Automotive Interiors?

In the automotive industry, leather factory Florence provides high-quality leather for luxury vehicle interiors. This application enhances the aesthetic appeal and comfort of vehicles, making them more attractive to premium buyers. For international buyers, it is crucial to understand material specifications, durability, and compliance with safety standards. Collaborating with Florentine leather manufacturers allows automotive brands to elevate their offerings, catering to consumers who prioritize quality and luxury in their vehicles.

What Benefits Does Leather Factory Florence Provide for Home Décor?

Leather factory Florence also plays a significant role in the home décor sector by supplying leather for upholstery and decorative items. This application allows interior designers and homeowners to incorporate high-quality materials that elevate the overall design aesthetic. Buyers need to consider the sourcing of sustainable materials and customization options when collaborating with Florentine manufacturers. By leveraging the expertise of these artisans, businesses can create unique, luxurious spaces that resonate with upscale clientele.

Illustrative image related to leather factory florence

How is Leather Factory Florence Relevant to Footwear Production?

The production of custom leather footwear is another significant application of leather factory Florence. This sector meets the growing demand for unique, high-quality shoes, particularly in niche markets. International buyers must focus on sizing standards, production timelines, and design flexibility when sourcing from Florence. By partnering with skilled artisans, footwear brands can offer exclusive designs that appeal to consumers seeking individuality and craftsmanship in their footwear choices.

3 Common User Pain Points for ‘leather factory florence’ & Their Solutions

Scenario 1: Difficulty in Assessing Quality Before Purchase

The Problem: B2B buyers often struggle with evaluating the quality of leather products before making a purchase. Given the significance of high-quality leather in various applications—be it fashion, accessories, or furniture—many buyers find themselves uncertain about how to assess the craftsmanship and material integrity of products from a Florence leather factory. This uncertainty can lead to costly mistakes, such as investing in products that do not meet their standards or the expectations of their clientele.

The Solution: To mitigate this issue, buyers should consider arranging a visit to the leather factory in Florence. Many reputable factories, like AJ Leather and Pierotucci, offer guided tours where buyers can observe the production processes and interact with artisans. This hands-on experience allows buyers to assess the quality of materials, craftsmanship, and design firsthand. Furthermore, it’s advisable to request samples of various leather types and finished products prior to bulk orders. Engaging in direct communication with the manufacturers about their sourcing and production techniques can also provide deeper insights into the quality assurance processes they employ.

Illustrative image related to leather factory florence

Scenario 2: Navigating Complex Customization Requests

The Problem: As international B2B buyers, particularly from diverse regions like Africa or South America, the need for customized products can pose significant challenges. Buyers often face difficulties in articulating their specific requirements, which may lead to miscommunication and unsatisfactory outcomes. The intricacies of cultural preferences, design specifications, and materials can further complicate the customization process, resulting in delays and increased costs.

The Solution: To streamline the customization process, buyers should prepare a detailed brief that outlines their specific requirements. This should include design sketches, preferred materials, dimensions, and any additional features. Collaborating closely with the factory’s design team can enhance this process, as many Florentine leather factories have skilled artisans who can provide valuable input and suggestions based on their expertise. Additionally, leveraging technology—such as video calls or collaborative design software—can facilitate clearer communication. Establishing a timeline for revisions and approvals can help manage expectations and keep the project on track.

Scenario 3: Understanding Pricing Structures and Minimum Order Quantities

The Problem: B2B buyers often encounter confusion regarding pricing structures and minimum order quantities (MOQs) when sourcing leather products from Florence. The variation in pricing based on material choices, customization options, and order size can make it difficult for buyers to calculate total costs accurately. Additionally, some factories may impose high MOQs that do not align with the buyers’ needs, leading to either excess inventory or missed opportunities.

The Solution: To navigate these complexities, buyers should engage in upfront discussions with the leather factory regarding their pricing model and MOQ policies. It’s crucial to clearly communicate your budget constraints and order intentions from the outset. Requesting a detailed quote that breaks down costs associated with different materials and customization options can provide clarity. Some factories may offer flexible ordering options or discounts for larger orders, so it’s beneficial to inquire about any available promotional programs. Additionally, consider negotiating terms that allow for smaller initial orders with the possibility of scaling up in the future, which can reduce the financial risk while establishing a working relationship with the factory.

Strategic Material Selection Guide for leather factory florence

What Are the Key Properties of Common Leather Materials Used in Florence?

In the leather industry, particularly within the artisan workshops of Florence, the selection of materials is crucial for producing high-quality leather goods. Here, we analyze four common materials used in leather production: Nappa leather, Suede, Full-grain leather, and Split leather. Each material has distinct properties, advantages, and limitations that international B2B buyers must consider.

Illustrative image related to leather factory florence

Nappa Leather: A Luxurious Choice for High-End Products

Nappa leather is known for its softness and smooth texture, making it a popular choice for luxury products such as handbags and jackets. This material is typically made from lamb or kid skin, which provides excellent durability and resistance to wear. Nappa leather performs well under normal temperature and pressure conditions, making it suitable for everyday use.

Pros: The primary advantage of Nappa leather is its luxurious feel and aesthetic appeal, which enhances the marketability of products. It is also relatively easy to dye and finish, allowing for a wide range of color options.

Cons: However, Nappa leather can be susceptible to scratches and stains, requiring careful handling and maintenance. Its higher cost may also be a consideration for budget-conscious buyers.

Illustrative image related to leather factory florence

Impact on Application: Nappa leather is ideal for high-end fashion items, where appearance and tactile quality are paramount. Buyers should ensure compliance with international quality standards, particularly for luxury markets in Europe and the Middle East.

Suede: Versatile and Stylish but Requires Care

Suede, made from the inner layer of animal hides, offers a soft, velvety texture that is highly sought after in fashion. It provides good breathability, making it suitable for clothing and accessories. However, suede is less durable than other leather types and can be affected by moisture.

Pros: The aesthetic appeal of suede is significant, as it adds a unique texture to products. It is also lighter than full-grain leather, making it a popular choice for garments.

Cons: The main drawback is its vulnerability to water and stains, necessitating special care and treatment. This can complicate manufacturing processes and increase costs for buyers.

Impact on Application: Suede is commonly used in fashion apparel and accessories. Buyers from regions with high humidity, such as parts of Africa and South America, should consider the material’s limitations in wet conditions.

Full-Grain Leather: The Benchmark for Quality and Durability

Full-grain leather is considered the highest quality leather available. It retains the natural grain of the hide, providing exceptional durability and resistance to wear. This material can withstand significant pressure and is less prone to damage over time.

Pros: The primary advantage of full-grain leather is its longevity and ability to develop a rich patina, enhancing its appearance with age. It is also highly breathable and suitable for a wide range of products.

Cons: The cost of full-grain leather is typically high, which may deter some buyers. Additionally, its thickness can complicate certain manufacturing processes.

Illustrative image related to leather factory florence

Impact on Application: Full-grain leather is ideal for high-quality goods, such as luxury handbags and shoes. Buyers should ensure compliance with international leather standards, particularly for markets in Europe and the Middle East.

Split Leather: A Cost-Effective Alternative

Split leather is derived from the lower layers of the hide and is often used in more affordable products. While it lacks the durability of full-grain leather, it offers a good balance between cost and quality.

Pros: The main advantage of split leather is its affordability, making it accessible for a wider range of products. It is also easier to work with during the manufacturing process.

Cons: However, split leather is less durable and may not withstand heavy use as well as other types. It is also more prone to wear and tear.

Impact on Application: Split leather is suitable for budget-friendly items, such as casual bags and accessories. Buyers should consider the market demand in their regions, especially in price-sensitive markets in Africa and South America.

Illustrative image related to leather factory florence

Summary Table of Material Selection for Leather Factory Florence

| 素材 | Typical Use Case for leather factory florence | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| ナッパレザー | High-end handbags and jackets | Luxurious feel and aesthetic appeal | Susceptible to scratches and stains | 高い |

| スエード | Fashion apparel and accessories | Unique texture and lightweight | Vulnerable to water and stains | Medium |

| Full-Grain Leather | Luxury handbags and shoes | Exceptional durability and patina | High cost and manufacturing complexity | 高い |

| Split Leather | Budget-friendly bags and accessories | Affordability | Less durable and prone to wear | 低い |

This guide provides valuable insights for international B2B buyers looking to source leather materials from Florence, ensuring they make informed decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for leather factory florence

What Are the Key Stages in the Leather Manufacturing Process in Florence?

The leather manufacturing process in Florence is a meticulous blend of traditional craftsmanship and modern techniques, aimed at producing high-quality leather goods. The main stages of this process include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Leather Selected and Prepared?

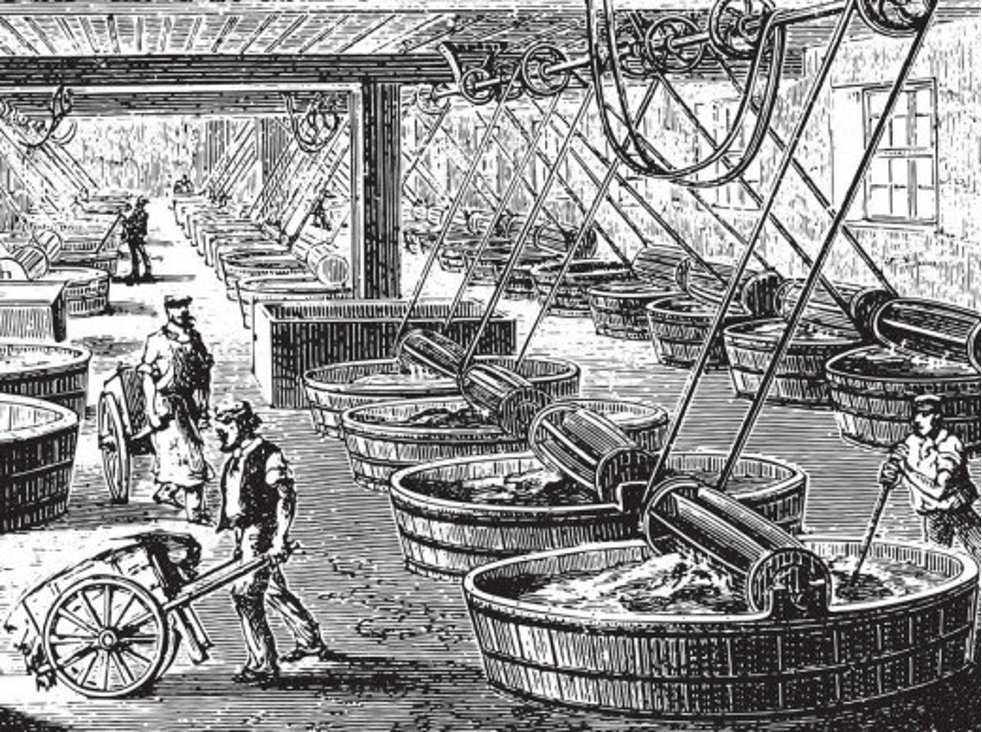

The first step in the manufacturing process involves selecting the appropriate type of leather, which can vary from cowhide to lambskin, depending on the desired end product. Artisans inspect raw hides for quality, checking for imperfections, thickness, and texture. Once selected, the leather undergoes a series of treatments, including tanning, which preserves the hide and enhances its durability. This stage often incorporates natural tanning agents, reflecting the Florentine commitment to sustainable practices.

Illustrative image related to leather factory florence

After tanning, the leather is conditioned and dyed. The dyeing process can be done using various methods, including aniline, semi-aniline, or pigmented finishes, each offering distinct aesthetic and tactile qualities. This careful selection and treatment ensure the leather not only meets aesthetic standards but also possesses the necessary durability for everyday use.

How Is Leather Formed into Products?

Once the leather is prepared, the next stage involves forming it into the desired shapes. This is where skilled artisans employ techniques such as hand cutting and pattern making. Precision is crucial in this phase, as accurate cuts and patterns significantly impact the final product’s quality.

After cutting, the leather pieces are often subjected to additional processes like embossing or perforating, which add character and functionality. The formation phase is not just about shaping; it also involves ensuring that the leather retains its natural characteristics while adapting to the product’s design requirements.

What Does the Assembly Process Look Like in Leather Production?

The assembly phase is where the magic happens. Artisans stitch together the pre-cut leather pieces, incorporating linings, zippers, and other components as necessary. Techniques such as saddle stitching and machine stitching are commonly used, with a preference for hand stitching in high-end products to ensure durability and a distinctive finish.

During assembly, quality control measures begin to take shape. Artisans continuously inspect their work, ensuring that seams are tight, and no material is wasted. This attention to detail is what sets Florentine leather products apart in the global market.

Illustrative image related to leather factory florence

How Is the Finishing Process Conducted to Ensure Quality?

Finishing is the final stage in the manufacturing process, where products receive their last touches. This may involve polishing, coating, or applying protective treatments to enhance durability and aesthetics. Finishing techniques can vary based on the product type, with handbags requiring a different approach than jackets, for instance.

Moreover, the finishing stage is critical for ensuring consistency across batches. Artisans often conduct tests to confirm that the leather’s finish meets the desired specifications, which can include water resistance, colorfastness, and surface texture.

What Quality Assurance Standards Should B2B Buyers Consider?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding quality assurance (QA) standards is essential. Many Florentine leather manufacturers adhere to internationally recognized standards, such as ISO 9001, which ensures that quality management systems are in place.

Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the product’s intended use. Buyers should inquire about these certifications to ensure compliance with their local regulations and expectations.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control in Florentine leather manufacturing typically encompasses several key checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival. Artisans assess the leather for quality, ensuring it meets the predetermined specifications before processing begins.

-

In-Process Quality Control (IPQC): As products are being assembled, continuous inspections are performed to catch any deviations from quality standards. This proactive approach minimizes defects and ensures that any issues are addressed promptly.

-

Final Quality Control (FQC): Once the product is completed, a thorough inspection is conducted. This includes checking for aesthetic imperfections, functionality (e.g., zippers, straps), and overall craftsmanship.

What Common Testing Methods Are Used in Quality Assurance?

Manufacturers often employ a variety of testing methods to ensure the quality of their leather products. Common tests include:

- Tensile Strength Testing: This assesses the leather’s durability and resistance to tearing.

- Water Resistance Testing: Essential for products exposed to moisture, this test ensures that the leather can withstand various environmental conditions.

- Colorfastness Testing: This evaluates the leather’s ability to retain its color when exposed to light or water.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in diverse markets, verifying a supplier’s quality control practices is crucial. Here are several actionable steps:

-

Conduct Audits: Schedule visits to the manufacturing facility to observe the production process and quality control practices firsthand. This not only provides insight into the operations but also builds trust.

-

Request Quality Reports: Ask suppliers for documentation that outlines their quality control measures, including inspection reports and testing results. This information can provide transparency about their practices.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. These inspectors can conduct audits and provide detailed reports on compliance with international standards.

What Are the Nuances of Quality Control for International Buyers?

When sourcing leather products from Florence, international buyers should be aware of specific nuances that may affect quality control:

-

Cultural Differences: Understanding the local craftsmanship and production methods can aid in setting realistic expectations regarding quality and delivery times.

-

Regulatory Compliance: Different countries have varied regulations concerning leather goods. Buyers must ensure that products meet both local and international standards to avoid compliance issues.

-

Sustainability Practices: Increasingly, buyers are considering suppliers’ environmental practices. Florentine manufacturers often emphasize sustainable sourcing and production methods, which can be a significant factor for buyers focused on ethical procurement.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing leather products from Florence, ensuring they receive goods that meet their quality expectations and market demands.

Illustrative image related to leather factory florence

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather factory florence’

はじめに

This guide serves as a practical sourcing checklist for international B2B buyers looking to procure high-quality leather products from factories in Florence, Italy. Known for its rich tradition of leather craftsmanship, Florence offers a unique blend of artisanal skill and innovative design. By following this checklist, buyers can ensure a successful procurement process that aligns with their business needs and quality standards.

Step 1: Identify Your Product Requirements

Begin by clearly defining what leather products you need, including specifications such as type, size, and quantity. This step is crucial as it helps narrow down potential suppliers who specialize in the products that meet your criteria. Consider the end-use of the leather goods and any specific features that might be required, such as waterproofing or specific color finishes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable leather factories in Florence. Utilize online resources, industry directories, and trade shows to compile a list of potential suppliers. Pay attention to their product offerings, production capabilities, and any certifications they may have, such as ISO or eco-friendly credentials. This foundational step will set the stage for further evaluations.

Illustrative image related to leather factory florence

Step 3: Evaluate Supplier Experience and Expertise

It’s vital to assess the experience and expertise of the suppliers you’re considering. Look for factories with a proven track record in producing similar leather products. Inquire about their years in business, notable projects, and partnerships with well-known brands. A supplier with substantial experience is likely to have better quality control and craftsmanship.

Step 4: Request Samples and Quality Assessments

Once you have shortlisted potential suppliers, request samples of their products. This is a critical step to evaluate the quality of leather, stitching, and overall craftsmanship. Assess the samples not only for aesthetic appeal but also for durability and functionality. Make sure to communicate your standards clearly to ensure the samples align with your expectations.

Step 5: Check Client References and Reviews

Before finalizing a supplier, check references and reviews from previous clients. Reach out to businesses that have worked with the factory to gain insights into their reliability, product quality, and customer service. This step helps mitigate risks by ensuring that the supplier has a history of meeting client expectations and resolving issues effectively.

Step 6: Understand Pricing and Payment Terms

Discuss pricing structures and payment terms with your shortlisted suppliers. It’s essential to understand not just the cost of the products but also any additional fees for shipping, handling, or customization. Ensure that payment terms are favorable and align with your financial processes. Transparency in pricing can prevent misunderstandings later in the procurement process.

Step 7: Negotiate Contracts and Delivery Terms

Once you’ve selected a supplier, negotiate the terms of your contract, including delivery timelines and quality guarantees. Clearly outline expectations regarding product delivery, potential penalties for delays, and quality assurance measures. A well-defined contract protects both parties and ensures a smoother transaction process.

Illustrative image related to leather factory florence

By following this checklist, B2B buyers can effectively navigate the procurement landscape of leather products in Florence, ensuring they partner with the right suppliers for their business needs.

Comprehensive Cost and Pricing Analysis for leather factory florence Sourcing

What Are the Key Cost Components for Sourcing from Leather Factories in Florence?

When considering sourcing from leather factories in Florence, understanding the cost structure is essential. The main components that contribute to the overall cost include:

-

Materials: The quality of leather significantly influences pricing. Florentine factories often use premium Italian leather, which is more expensive but offers superior durability and aesthetic appeal. The type of leather, whether it’s nappa, washed, or an artisan-crafted variant, can vary in cost.

-

Labor: Skilled artisans in Florence command higher wages due to their craftsmanship and expertise. Labor costs can account for a substantial portion of the overall pricing, especially for products that require intricate handwork.

-

Manufacturing Overhead: This includes costs associated with running the factory, such as utilities, rent, and administrative expenses. High-quality facilities that maintain a traditional craftsmanship ethos will have higher overhead costs.

-

Tooling: Investments in specialized tools and machinery for leather processing can add to the costs. Factories that emphasize artisanal techniques may have lower tooling costs but will incur higher labor expenses.

-

Quality Control (QC): Ensuring that products meet international quality standards often requires rigorous testing and inspection processes, contributing to the overall cost.

-

Logistics: Shipping costs can vary widely based on the destination and the chosen shipping method. International buyers should consider these costs when evaluating total expenses.

-

Margin: Factories typically build in a profit margin that reflects their brand value and market positioning. High-end brands may have more significant margins compared to mass-market producers.

How Do Price Influencers Affect Sourcing Costs from Leather Factories in Florence?

Several factors influence pricing beyond the basic cost components. Key influencers include:

-

Volume/MOQ (Minimum Order Quantity): Buying in larger quantities can lead to better pricing. Factories often offer discounts for bulk orders, making it essential for buyers to evaluate their purchasing capacity.

-

Specifications and Customization: Customized products, including unique designs or special features, generally incur higher costs. Buyers should balance the desire for customization with budget constraints.

-

Materials: The choice of leather and other materials can significantly impact pricing. Sourcing sustainable or certified materials may also increase costs but can enhance brand value.

-

Quality Certifications: Products that carry specific quality certifications may cost more due to the additional processes involved in meeting those standards.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established brands with a track record of quality may charge a premium.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial. Incoterms affect who bears costs and risks at different stages of the shipping process, impacting the overall price.

What Are Essential Buyer Tips for Negotiating Prices with Leather Factories in Florence?

When negotiating with leather factories in Florence, international buyers should keep several strategies in mind to maximize cost-efficiency:

-

Research and Compare: Conduct thorough market research to understand typical pricing structures. This knowledge will empower you during negotiations and help you identify fair pricing.

-

Focus on Total Cost of Ownership: Evaluate not just the upfront cost but the total cost of ownership, including durability and maintenance. High-quality leather may have a higher initial price but offers better longevity.

-

Negotiate Volume Discounts: Leverage your purchasing power by negotiating for lower prices based on order size. Discussing future orders can also be a strategy for securing better rates.

-

Be Aware of Pricing Nuances: Different markets may have varying expectations regarding pricing and quality. Buyers from Africa, South America, the Middle East, and Europe should understand local market conditions and customs, as these can influence negotiations.

-

Clarify Terms: Ensure clarity on payment terms, delivery schedules, and return policies. Misunderstandings in these areas can lead to unexpected costs.

Disclaimer on Indicative Prices

Prices for leather goods from factories in Florence can vary widely based on several factors, including the specifics mentioned above. It is advisable for buyers to request detailed quotes tailored to their unique needs and specifications to obtain accurate pricing.

Alternatives Analysis: Comparing leather factory florence With Other Solutions

Exploring Alternatives for Leather Production Solutions

In the dynamic world of leather production, B2B buyers have various options to consider when sourcing high-quality leather goods. While the artisanal craftsmanship found in leather factories in Florence, Italy, is renowned for its quality and heritage, other viable alternatives can meet diverse business needs. This analysis will compare ‘Leather Factory Florence’ with two alternative solutions: mass-produced leather goods from Asian manufacturers and the use of synthetic leather technologies.

Comparison Table

| Comparison Aspect | Leather Factory Florence | Mass-Produced Leather (Asia) | Synthetic Leather Technologies |

|---|---|---|---|

| Performance | High durability, artisan quality | Variable quality, often lower durability | Good durability, eco-friendly options |

| Cost | Higher price point due to craftsmanship | Lower cost due to mass production | Moderate cost, varies by brand |

| Ease of Implementation | Requires longer lead times for custom orders | Quick turnaround, readily available | Fast production, often customizable |

| Maintenance | Requires specific care to maintain quality | Generally low maintenance | Easy to clean, less care needed |

| Best Use Case | Luxury goods, bespoke items | Large-scale retail, budget-conscious consumers | Eco-conscious brands, fashion-forward products |

Detailed Breakdown of Alternatives

Mass-Produced Leather (Asia)

Mass production in countries like China and India offers a cost-effective solution for businesses looking to source leather goods at scale. The primary advantage of this alternative is the significantly lower price point, making it accessible for budget-conscious retailers. However, the quality can be inconsistent, with variability in durability and craftsmanship. Additionally, lead times are shorter, allowing for quicker market entry. On the downside, these products may lack the unique characteristics and artisanal touch that many consumers desire, particularly in the luxury segment.

Synthetic Leather Technologies

Synthetic leather, or faux leather, has gained traction as an eco-friendly alternative to traditional leather. Technologies such as polyurethane (PU) and polyvinyl chloride (PVC) provide a durable option that mimics the look and feel of real leather while often being easier to maintain. The cost is generally moderate, and production can be fast and flexible, catering to various design preferences. However, some purists argue that synthetic materials do not possess the same prestige or longevity as genuine leather. Furthermore, potential environmental concerns regarding the production processes of synthetic materials can deter eco-conscious brands.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the right leather production solution, B2B buyers must assess their specific needs and target market. For businesses focused on luxury and bespoke offerings, the artisanal quality of leather factories in Florence will likely be the best choice, despite higher costs and longer lead times. Conversely, companies aiming for mass-market appeal or those with budget constraints may find that mass-produced leather from Asia meets their requirements effectively. Lastly, brands emphasizing sustainability and modern aesthetics might lean towards synthetic leather technologies, balancing cost and environmental impact. Ultimately, understanding the unique advantages and limitations of each alternative will empower buyers to make informed decisions that align with their business objectives.

Illustrative image related to leather factory florence

Essential Technical Properties and Trade Terminology for leather factory florence

What Are the Key Technical Properties in Leather Manufacturing?

Understanding the technical properties of leather is crucial for B2B buyers engaging with leather factories in Florence. These properties not only determine the quality and durability of the products but also impact pricing, sourcing, and production timelines. Here are essential specifications to consider:

-

Material Grade

– Definition: Material grade refers to the classification of leather based on its quality, texture, and finish. Common grades include full-grain, top-grain, corrected grain, and bonded leather.

– B2B Importance: Higher grades like full-grain leather are more durable and age beautifully, making them ideal for high-end products. Buyers must align material grades with their target market expectations to ensure product satisfaction. -

Thickness

– Definition: Leather thickness is measured in millimeters and can significantly affect the feel and usability of the final product. Typical thickness ranges from 0.6mm for lighter garments to over 2mm for heavy-duty items.

– B2B Importance: The thickness impacts not only the durability but also the weight and drape of the leather. Buyers need to specify thickness based on the intended application to avoid issues with product performance. -

Finish Type

– Definition: The finish type refers to the treatment applied to the leather surface, such as aniline, semi-aniline, or pigmented finishes. Each type has distinct aesthetic and functional properties.

– B2B Importance: Different finishes offer various levels of protection and appearance. Understanding these can help buyers select products that meet their design and performance criteria while ensuring longevity. -

Tensile Strength

– Definition: This is the maximum amount of tensile (pulling) stress that a leather can withstand before breaking. It is typically measured in Newtons per millimeter.

– B2B Importance: High tensile strength is crucial for products like bags and jackets that require durability. Buyers should ensure that the tensile strength meets the functional requirements of their products, especially for heavy-duty applications. -

Color Fastness

– Definition: This property measures the resistance of leather to fading or running when exposed to light, water, or other environmental conditions.

– B2B Importance: Color fastness is vital for maintaining product aesthetics over time. Buyers must ensure that their chosen leather meets industry standards for color retention, especially for items exposed to sunlight or moisture.

What Trade Terms Should B2B Buyers Know in Leather Manufacturing?

Familiarity with industry jargon is essential for effective communication and negotiation with leather factories. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In leather, this often refers to factories that produce items for brands under their label.

– Relevance: Understanding OEM relationships helps buyers ensure that they are engaging with reputable manufacturers capable of producing high-quality goods. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell. This can vary widely depending on the manufacturer and the type of leather product.

– Relevance: Knowing the MOQ is crucial for budgeting and inventory management. Buyers should confirm this before placing orders to avoid excess costs or stock issues. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting pricing and details for specific products or services.

– Relevance: Submitting a well-defined RFQ can streamline the procurement process, ensuring that buyers receive accurate quotes and can compare offers effectively. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts.

– Relevance: Understanding Incoterms is essential for managing shipping logistics, costs, and risks associated with international transactions. Buyers should specify the applicable terms in their contracts to avoid misunderstandings. -

Private Label

– Definition: Private label refers to products manufactured by one company for sale under another company’s brand.

– Relevance: This is particularly relevant for buyers looking to create unique products under their brand name. It allows for customization while leveraging the manufacturer’s expertise.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they source quality leather products that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the leather factory florence Sector

What Are the Current Market Dynamics and Key Trends in the Leather Factory Florence Sector?

The leather industry in Florence, renowned for its artisanal craftsmanship, is experiencing significant transformations driven by global market dynamics. A surge in demand for high-quality leather goods is being fueled by rising disposable incomes in emerging markets, particularly in Africa, South America, and the Middle East. These regions are increasingly valuing luxury items, which has led to a spike in interest from international B2B buyers looking to import premium leather products.

Additionally, advancements in technology are reshaping sourcing practices. Digital platforms are becoming essential for connecting buyers with manufacturers, allowing for more streamlined communication and transaction processes. The rise of Industry 4.0, characterized by automation and data exchange in manufacturing technologies, is also influencing production efficiency and customization capabilities in leather factories. B2B buyers are now able to leverage these technologies to gain insights into production timelines, quality assurance, and inventory management, which are critical for maintaining competitive advantage in their markets.

Moreover, the trend towards personalization is gaining momentum, with buyers increasingly seeking bespoke products that reflect individual consumer preferences. This shift necessitates that manufacturers in Florence adapt their offerings and production processes to meet these evolving demands, thus creating opportunities for international partnerships.

Illustrative image related to leather factory florence

How Is Sustainability and Ethical Sourcing Impacting the Leather Factory Florence Sector?

Sustainability and ethical sourcing have become pivotal considerations for B2B buyers in the leather sector. The environmental impact of leather production, particularly in terms of water usage, chemical treatments, and waste generation, is under scrutiny. Consequently, many leather factories in Florence are adopting eco-friendly practices, such as utilizing vegetable-tanned leather and minimizing waste through innovative production techniques.

For international buyers, sourcing from manufacturers committed to sustainability not only aligns with growing consumer expectations but also enhances brand reputation. The demand for ‘green’ certifications, such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification, is on the rise. These certifications assure buyers that products are made using environmentally and socially responsible practices, thus facilitating compliance with stricter regulations in various markets.

Furthermore, ethical sourcing is becoming a key differentiator in the competitive landscape. B2B buyers are increasingly seeking partners who demonstrate transparency in their supply chains and who actively contribute to social responsibility initiatives. This trend is particularly relevant for buyers from regions like Europe and the Middle East, where consumer awareness and demand for ethical products are rapidly growing.

What Is the Historical Context of the Leather Factory Sector in Florence?

Florence’s leather industry has a rich history that dates back to the Renaissance when the city became a hub for artisans and skilled craftsmen. The combination of high-quality raw materials sourced from local livestock and innovative tanning techniques established Florence as a leader in leather production. Over the centuries, this tradition has evolved, blending historical craftsmanship with modern design and technology.

Illustrative image related to leather factory florence

Today, the legacy of Florentine artisanship continues to attract international B2B buyers who seek not only quality but also authenticity in their products. The city’s commitment to maintaining traditional methods while embracing innovation ensures that Florence remains at the forefront of the global leather industry. This historical foundation provides a competitive edge, allowing manufacturers to offer unique products that resonate with buyers looking for both luxury and heritage in their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of leather factory florence

-

How do I select the right leather supplier in Florence for my business needs?

Selecting the right leather supplier involves assessing several key factors. Start by researching the supplier’s reputation, experience, and expertise in the specific type of leather you need, whether it’s clothing, accessories, or custom designs. Review their product catalog and previous work to ensure quality and craftsmanship meet your standards. It’s also beneficial to request samples before making a bulk order. Establish direct communication to discuss your requirements, including customization options and lead times, to ensure they align with your business needs. -

What types of leather products can I source from factories in Florence?

Florentine leather factories offer a diverse range of products, including high-end clothing, handbags, wallets, belts, and accessories for both men and women. Many factories also specialize in custom leather goods tailored to specific designs and styles. Depending on your market demands, inquire about their capabilities for producing unique items or collections that resonate with your target audience. Assessing their catalog can provide insights into their craftsmanship and design versatility. -

What are the typical minimum order quantities (MOQs) for leather products?

Minimum order quantities can vary widely among leather manufacturers in Florence, typically ranging from 50 to 500 units per style, depending on the product and customization level. For custom designs, MOQs may be higher due to the setup costs involved in production. It’s advisable to discuss your needs directly with the supplier to negotiate terms that suit your business model. Some manufacturers may offer flexibility for first-time buyers or smaller businesses, so don’t hesitate to inquire. -

How can I ensure the quality of leather products when sourcing from Florence?

To ensure quality, start by visiting the factory if possible, or request a virtual tour to observe their production processes. Ask for samples of leather and finished products to evaluate craftsmanship, texture, and durability. Additionally, review certifications that indicate adherence to quality standards and ethical practices. Establishing a good relationship with your supplier can also facilitate open communication about quality expectations and any concerns that may arise. -

What payment terms are commonly offered by leather suppliers in Florence?

Payment terms can vary but typically include options such as upfront deposits ranging from 30% to 50%, with the balance due upon delivery or before shipment. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established relationships. It’s essential to clarify payment methods accepted, including wire transfers or credit terms, and to negotiate terms that align with your cash flow. Always ensure you have a formal agreement outlining payment conditions before proceeding. -

What is the process for customizing leather products through a Florence factory?

The customization process usually begins with a consultation where you discuss your design ideas, materials, and specific requirements with the supplier. Many factories offer design assistance, helping you refine your concepts into feasible products. Once the design is agreed upon, the factory will provide prototypes for your approval. After finalizing the design, they will proceed with production, keeping you updated on timelines and any adjustments needed during the manufacturing process. -

How do I handle logistics and shipping for leather products sourced from Florence?

Logistics can be managed effectively by coordinating with your supplier about shipping options. Most Florentine factories have established relationships with logistics providers and can assist in arranging shipping to your destination. Discussing shipping methods (air freight vs. sea freight) will depend on your urgency and budget. Ensure to factor in customs duties and taxes for international shipments. Establish a clear timeline for delivery and communicate any specific requirements you may have regarding packaging or handling. -

What should I consider regarding after-sales support from my leather supplier?

After-sales support is crucial for maintaining a good relationship with your supplier. Inquire about their policies on returns, repairs, or replacements for defective items. A reputable supplier should provide assistance in case of quality issues and offer guidance on leather care and maintenance. Establishing a clear channel of communication for after-sales support can help resolve any potential issues quickly, ensuring that your business operations remain smooth and customer satisfaction is maintained.

Top 8 Leather Factory Florence Manufacturers & Suppliers List

1. AJ Leather Factory – High-End Leather Clothing

Domain: ajleatherfactory.it

Registered: 2014 (11 years)

Introduction: AJ Leather Factory specializes in high-end leather clothing production in Florence, Italy, with over a decade of experience. They produce clothing for men and women, as well as handbags and craft accessories made from leather. Their products are characterized by original and refined features, top-quality materials, and high-level manufacturing, appealing to a demanding clientele. The collections i…

2. Pierotucci – Leather Factory Tours

Domain: pierotucci.com

Registered: 1998 (27 years)

Introduction: Free Guided Leather Factory Tour, Free shipping over 350 €, Ship to: USA, Available languages: English, Italian, Russian, Japanese, Spanish, Tour duration: Monday to Friday, 9 am – 5 pm, Location: Via Lungo L’Ema, 17 Bagno a Ripoli, Florence, Italy, Contact: +39 055 644645, Email: info@pierotucci.com, Customization options: Personalized monogramming, Leather care tips, Tax-free shopping available …

3. Peruzzi Firenze – Luxury Leather Products

Domain: peruzzifirenze.com

Registered: 2013 (12 years)

Introduction: Peruzzi Firenze offers a range of luxury leather products including leather jackets, bags, and accessories for both men and women. Key product categories include:

– Men’s Accessories: bags, belts, wallets, clothing, jackets, and coats.

– Women’s Accessories: bags & purses, wallets, belts, clothing, coats, and jackets.

– Luxury items include high fashion handbags and wallets made from Italian le…

4. Yelp – Best Leather Shops in Florence

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Leather Shops in Florence, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Peroni Firenze – Handcrafted Leather Goods

Domain: peronifirenze.com

Registered: 2016 (9 years)

Introduction: Pelletteria Peroni specializes in handcrafted leather goods made in Florence, Italy. Their product range includes bags (suitcases, briefcases, handbags, iPad holders), folders, travel cases, accessories (belts, necklaces, bracelets, business and credit card holders, coin cases, wallets, keychains, eyeglasses cases, pen cases), gift items, smokers’ articles, gaming articles, sporting goods, flasks,…

6. Florence Leather Factory – Handbags & Travel Bags

Domain: florenceleatherfactory.it

Registered: 2014 (11 years)

Introduction: Manufacturer of handbags, suitcases, and leather belts since the early 80s. Located in Tuscany, Italy. Products include various handbags (SKU: 5146, 5145, 5144, 5143, 5142, 5141, 5140, 5139, 5137, 5136, 5135, 5132), backpacks (SKU: 5138), travel bags (SKU: 5134), and shoulder bags (SKU: 5133). All items can be customized, including inner labels, tags, liners, and hot stamping. Products are made fr…

7. The Bridge – Handcrafted Bags

Domain: thebridgefirenze.com

Registered: 2023 (2 years)

Introduction: The Bridge offers a variety of handcrafted bags made in Italy, including crossbody bags, shopper bags, handbags, double function bags, bucket bags, mini bags, shoulder bags, hobo bags, carry-all bags, wristlets, and backpacks for women. For men, the collection includes crossbody bags, work bags, messenger bags, one handle briefcases, laptop bags, doctors bags, pouches, and wallets. The luggage sec…

8. Adam Leather Factory – Affordable Leather Goods

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Adam Leather Factory – Affordable Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather factory florence

In conclusion, strategic sourcing from leather factories in Florence offers international B2B buyers a unique opportunity to leverage the region’s renowned craftsmanship and high-quality materials. The integration of traditional artisan skills with modern innovations ensures that products not only meet but exceed global standards. Buyers from Africa, South America, the Middle East, and Europe can benefit from the rich history and expertise embedded in Florentine leather goods, making them ideal for luxury markets.

As the demand for ethically sourced, high-end leather products continues to rise, establishing partnerships with reputable manufacturers in Florence can enhance your product offerings and brand reputation. Engaging directly with these artisans provides insights into sustainable practices, customization options, and exclusive designs that can distinguish your business in a competitive landscape.

Looking ahead, the potential for growth in the leather sector remains robust. We encourage B2B buyers to explore strategic collaborations with Florentine leather factories, ensuring a supply chain that not only supports quality but also fosters innovation. Take the next step in elevating your product line by connecting with these esteemed artisans and experiencing firsthand the exceptional craftsmanship that Florence has to offer.

Illustrative image related to leather factory florence

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.