Introduction: Navigating the Global Market for leather belt making supplies

In today’s competitive landscape, international B2B buyers face the intricate challenge of sourcing high-quality leather belt making supplies that meet diverse market demands. With the rise of custom fashion trends and the growing popularity of leather goods, understanding the nuances of this market is essential. This comprehensive guide delves into the various types of leather, tools, and accessories vital for crafting premium belts. From selecting the best materials—such as veg-tanned or cowhide leather—to understanding the significance of hardware options like buckles and rivets, we aim to equip buyers with the knowledge necessary for informed decision-making.

Furthermore, we will explore the practical applications of these supplies across different industries, including fashion, outdoor gear, and bespoke accessories. The guide will also highlight effective strategies for vetting suppliers, ensuring that buyers can establish reliable partnerships in regions as diverse as Africa, South America, the Middle East, and Europe. By addressing cost considerations and potential sourcing pitfalls, this resource empowers businesses to streamline their procurement processes and ultimately enhance product offerings. With this actionable insight, buyers can navigate the global market confidently, securing the best leather belt making supplies to elevate their brands in a crowded marketplace.

Table Of Contents

- Top 4 Leather Belt Making Supplies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather belt making supplies

- Understanding leather belt making supplies Types and Variations

- Key Industrial Applications of leather belt making supplies

- 3 Common User Pain Points for ‘leather belt making supplies’ & Their Solutions

- Strategic Material Selection Guide for leather belt making supplies

- In-depth Look: Manufacturing Processes and Quality Assurance for leather belt making supplies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather belt making supplies’

- Comprehensive Cost and Pricing Analysis for leather belt making supplies Sourcing

- Alternatives Analysis: Comparing leather belt making supplies With Other Solutions

- Essential Technical Properties and Trade Terminology for leather belt making supplies

- Navigating Market Dynamics and Sourcing Trends in the leather belt making supplies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather belt making supplies

- Strategic Sourcing Conclusion and Outlook for leather belt making supplies

- Important Disclaimer & Terms of Use

Understanding leather belt making supplies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Strips | Available in various weights, finishes, and colors | Custom belt production, repairs, and crafting | Pros: Versatile, customizable; Cons: Quality varies by supplier. |

| Buckles | Diverse styles, materials, and sizes | Belt assembly, fashion accessories | Pros: Wide selection for customization; Cons: Sizing can be inconsistent. |

| Craft Templates | Reusable designs for consistent tooling patterns | Efficient design transfer for mass production | Pros: Saves time, ensures uniformity; Cons: Initial investment in templates. |

| Edge Finishing Supplies | Includes dyes, finishes, and tools for edges | Enhancing product durability and aesthetics | Pros: Improves product longevity; Cons: Requires skill for application. |

| Fasteners and Rivets | Various types for securing components | Assembly of belts and other leather goods | Pros: Ensures sturdiness; Cons: May require specific tools for installation. |

What are Leather Strips and How Are They Used in Belt Making?

Leather strips are essential materials in belt making, available in various weights, finishes, and colors. These strips can be made from cowhide or other leather types, and they come in pre-cut lengths suitable for different belt sizes. B2B buyers should consider the weight of the leather, as it affects the final product’s durability and flexibility. Additionally, sourcing from reputable suppliers ensures consistent quality, which is vital for maintaining brand standards.

How Do Buckles Contribute to Leather Belt Production?

Buckles are a critical component of leather belts, available in diverse styles, materials, and sizes to suit various market segments. B2B buyers must consider the compatibility of buckles with the leather strips they choose, as the size and style can significantly impact the overall design. Furthermore, sourcing buckles from manufacturers that offer customization options can enhance the uniqueness of the final product, catering to specific customer preferences.

Why Are Craft Templates Important for Efficient Production?

Craft templates are reusable tools designed to facilitate the transfer of intricate designs onto leather. These templates are particularly beneficial for businesses looking to streamline their production processes and maintain consistency across multiple products. For B2B buyers, investing in high-quality templates can reduce labor costs and improve the efficiency of design replication, making them a valuable asset in high-volume production settings.

What Role Do Edge Finishing Supplies Play in Belt Quality?

Edge finishing supplies, including dyes, finishes, and specialized tools, are vital for enhancing the durability and aesthetics of leather belts. Proper edge treatment not only prevents wear and tear but also adds a polished look to the product. B2B buyers should evaluate the compatibility of these supplies with their leather types and the skill level required for application, as this can influence both production timelines and end-user satisfaction.

How Do Fasteners and Rivets Ensure Belt Durability?

Fasteners and rivets are crucial for securing different components of leather belts, providing structural integrity and durability. These hardware elements come in various designs and materials, allowing for customization based on the belt’s intended use. When purchasing fasteners, B2B buyers should consider the specific installation requirements and whether their production processes can accommodate these components, as this can affect assembly efficiency and product quality.

Key Industrial Applications of leather belt making supplies

| Industry/Sector | Specific Application of leather belt making supplies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Production of high-quality leather belts | Enhances brand image with durable and stylish products | Sourcing premium leather, sustainable practices, and custom designs |

| Automotive | Leather belts for vehicle interiors | Improves aesthetic appeal and customer satisfaction | Compliance with automotive standards and durability requirements |

| Outdoor & Sports Gear | Leather belts for outdoor equipment | Provides reliability and functionality in rugged conditions | Weather resistance, thickness, and custom sizing options |

| Craft & Hobby | DIY leather belt-making kits | Encourages creativity and personalized product offerings | Variety in materials, tools, and instructional resources |

| E-commerce & Retail | Online sales of leather belt-making supplies | Expands market reach and boosts sales through diverse offerings | Efficient logistics, competitive pricing, and product variety |

How is Leather Belt Making Supplies Utilized in the Fashion & Apparel Industry?

In the fashion and apparel sector, leather belt making supplies are essential for producing high-quality belts that complement clothing lines. Businesses often seek durable materials that can withstand wear while maintaining aesthetic appeal. By sourcing premium leather and custom designs, brands can enhance their image and offer unique products. International buyers, especially from regions like Europe and Africa, should focus on the sustainability of their materials and the craftsmanship involved in the production process.

What Role Do Leather Belt Making Supplies Play in the Automotive Industry?

In the automotive industry, leather belts are integral to vehicle interiors, providing both function and style. Suppliers must ensure that the materials meet specific automotive standards for durability and resistance to wear. By utilizing high-grade leather and advanced manufacturing techniques, businesses can significantly improve customer satisfaction and vehicle aesthetics. Buyers should consider compliance with industry regulations and the availability of custom sizes to meet unique automotive designs.

How Are Leather Belt Making Supplies Applied in Outdoor & Sports Gear?

Outdoor and sports gear manufacturers leverage leather belt making supplies for creating reliable equipment, such as hiking packs and tool belts. These belts must withstand harsh environmental conditions while offering comfort and functionality. Companies in this sector should prioritize sourcing weather-resistant materials and consider the thickness of leather for different applications. Buyers from regions with diverse climates, like South America, should ensure that their products can endure extreme weather conditions.

Illustrative image related to leather belt making supplies

What Benefits Do DIY Leather Belt-Making Kits Offer in the Craft & Hobby Sector?

The craft and hobby sector utilizes leather belt making supplies by providing DIY kits that encourage creativity among enthusiasts. These kits typically include leather strips, buckles, and tools, allowing individuals to create personalized belts. Businesses can benefit by offering a variety of materials and instructional resources to cater to different skill levels. International buyers should focus on sourcing diverse materials and ensuring that kits are adaptable for various crafting techniques.

How Do E-commerce Platforms Benefit from Selling Leather Belt-Making Supplies?

E-commerce platforms have tapped into the growing demand for leather belt-making supplies, offering a wide range of products to cater to different customer needs. By providing competitive pricing and efficient logistics, these businesses can expand their market reach. It’s crucial for suppliers to offer a diverse product range, including various types of leather and crafting tools, to attract international buyers. Additionally, ensuring a seamless online shopping experience can significantly enhance customer satisfaction and repeat business.

3 Common User Pain Points for ‘leather belt making supplies’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Leather for Belt Production

The Problem:

Many B2B buyers in the leather industry face the challenge of sourcing high-quality leather suitable for belt making. This is particularly problematic for businesses in regions like Africa and South America, where local suppliers may not offer a consistent supply of premium leather. Inconsistent quality can lead to production delays, increased costs, and ultimately, customer dissatisfaction. Additionally, buyers might find it hard to verify the authenticity and quality of leather products when dealing with new suppliers, leading to significant risks in production quality.

The Solution:

To overcome this challenge, it is essential for buyers to establish relationships with reputable leather suppliers who specialize in belt-making materials. Conduct thorough research to identify suppliers with a proven track record of delivering quality products. Utilize industry networks and trade shows to connect with potential suppliers.

When placing orders, clearly specify the leather grades and characteristics required for your products—whether it be veg-tan, latigo, or embossed leather. Request samples before committing to larger orders to assess the leather’s quality firsthand. Furthermore, consider establishing long-term contracts with suppliers to ensure a consistent supply of quality leather, which can help stabilize pricing and delivery schedules, mitigating the risk of sudden shortages.

Scenario 2: Inconsistent Availability of Specialized Hardware

The Problem:

Buyers often struggle with the inconsistent availability of specialized hardware, such as buckles, rivets, and fasteners, which are crucial for the completion of leather belts. This inconsistency can lead to production bottlenecks, where manufacturers are unable to finish products on time due to missing components. This is especially true for businesses that rely on a diverse range of styles and customizations, as different designs may require unique hardware that is not always readily available.

The Solution:

To mitigate this issue, buyers should develop a comprehensive inventory management system that includes tracking the availability of essential hardware. Establish relationships with multiple suppliers to diversify sourcing options, ensuring that you have alternatives if one supplier faces shortages.

Illustrative image related to leather belt making supplies

Additionally, consider bulk purchasing or creating a stockpile of essential hardware items that are frequently used. This approach can help prevent delays in production caused by hardware shortages. Implementing just-in-time inventory systems can also optimize stock levels, balancing the costs of holding inventory against the need for timely production. Regularly review and update supplier lists to include those who can consistently meet your demand for specialized hardware.

Scenario 3: Challenges in Customization and Design Implementation

The Problem:

B2B buyers often face challenges when it comes to customization and design implementation for leather belts. Many manufacturers may lack the necessary tools or expertise to execute intricate designs, leading to subpar results that do not meet customer expectations. This is particularly problematic for businesses that cater to niche markets where unique designs are a selling point. Inadequate tooling or lack of skilled labor can significantly hinder the ability to deliver high-quality customized products.

The Solution:

Investing in the right tools and training for staff is crucial for overcoming this challenge. Buyers should consider sourcing high-quality acrylic templates and specialized tools, such as strap cutters and hole punchers, which can facilitate precise and consistent design execution.

Moreover, providing training sessions for employees on the use of these tools can enhance their skills, leading to better craftsmanship. Partnering with design experts or consultants who specialize in leatherwork can also provide valuable insights into effective customization techniques. By creating a collaborative environment where design ideas can be shared and refined, businesses can enhance their product offerings, ensuring that they meet the diverse needs of their customers. Additionally, exploring partnerships with local artisans can provide unique design insights and help elevate product quality.

Strategic Material Selection Guide for leather belt making supplies

What Are the Key Properties of Common Materials Used in Leather Belt Making Supplies?

When selecting materials for leather belt making, it is crucial to consider their properties, advantages, and limitations, particularly from a B2B perspective. This analysis focuses on four common materials: full-grain leather, top-grain leather, synthetic leather, and nylon webbing.

Illustrative image related to leather belt making supplies

Full-Grain Leather: The Premium Choice

Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain and imperfections, which contribute to its unique character. This material is highly durable and develops a beautiful patina over time.

Pros: Full-grain leather is exceptionally strong and resistant to wear and tear. Its natural breathability makes it comfortable for prolonged use, and it can withstand various environmental conditions.

Cons: The cost of full-grain leather is relatively high, which may not suit all budgets. It also requires specialized care to maintain its appearance, which can complicate manufacturing processes.

Illustrative image related to leather belt making supplies

Impact on Application: Full-grain leather is ideal for high-end belts that require a luxurious finish. Its compatibility with dyeing and finishing processes allows for customization, appealing to international markets that prioritize aesthetics.

Considerations for International Buyers: Compliance with international quality standards (e.g., ASTM, DIN) is essential. Buyers from regions like Africa and South America may prefer locally sourced materials to reduce costs and support local economies.

Top-Grain Leather: A Balanced Option

Top-grain leather is slightly less durable than full-grain but is still a popular choice for belt making. It is sanded and refinished to remove imperfections, resulting in a more uniform appearance.

Pros: This material is more affordable than full-grain leather while still offering good durability and a refined look. It is easier to work with due to its softer texture.

Cons: Top-grain leather is less breathable than full-grain, which may affect comfort over time. It is also more susceptible to scratches and damage.

Illustrative image related to leather belt making supplies

Impact on Application: Top-grain leather is suitable for mid-range products where a balance between cost and quality is desired. It can be dyed and embossed, providing versatility for various designs.

Considerations for International Buyers: Buyers should verify the sourcing and tanning processes to ensure compliance with environmental regulations. Preferences for specific finishes may vary by region, influencing purchasing decisions.

Synthetic Leather: The Cost-Effective Alternative

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is a popular alternative for budget-conscious manufacturers.

Pros: Synthetic leather is significantly cheaper than natural leather and is often easier to clean and maintain. It can mimic the appearance of leather while being more resistant to stains and moisture.

Cons: While durable, synthetic leather does not offer the same level of breathability or longevity as natural leather. It may also lack the unique character that many consumers seek.

Impact on Application: This material is suitable for mass-produced belts, particularly in markets where cost is a primary concern. It can be produced in various colors and textures, appealing to diverse consumer preferences.

Considerations for International Buyers: Buyers should be aware of the environmental impact of synthetic materials and seek suppliers that adhere to sustainability practices. Compliance with international standards for chemical safety is crucial.

Nylon Webbing: The Functional Choice

Nylon webbing is a strong, synthetic material often used in casual and functional belts, especially in outdoor and tactical applications.

Pros: Nylon webbing is lightweight, highly durable, and resistant to abrasion and moisture. It is also relatively inexpensive, making it a cost-effective option for bulk production.

Illustrative image related to leather belt making supplies

Cons: The aesthetic appeal of nylon webbing is limited compared to leather. It may not be suitable for formal or high-end applications.

Impact on Application: Ideal for utility belts, nylon webbing is compatible with various buckles and hardware, making it versatile for different uses.

Considerations for International Buyers: Buyers should consider the strength ratings and compatibility with local regulations for outdoor gear. The demand for functional products may vary across different regions.

Summary Table of Material Selection for Leather Belt Making Supplies

| 素材 | Typical Use Case for leather belt making supplies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end belts | Exceptional durability and aesthetics | High cost and maintenance complexity | 高い |

| Top-Grain Leather | Mid-range belts | Good balance of quality and affordability | Less durable than full-grain | Medium |

| Synthetic Leather | Budget-friendly mass production belts | Cost-effective and easy to maintain | Lacks breathability and character | 低い |

| Nylon Webbing | Utility and tactical belts | Lightweight and highly durable | Limited aesthetic appeal | 低い |

This analysis provides a comprehensive overview of the materials available for leather belt making, enabling international B2B buyers to make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for leather belt making supplies

What Are the Main Stages in the Manufacturing Process of Leather Belt Making Supplies?

The manufacturing process for leather belt making supplies is intricate and involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers, especially when sourcing high-quality products.

Material Preparation: What Is Involved?

The first step in the manufacturing process is material preparation. It begins with selecting high-quality leather, such as full-grain or vegetable-tanned leather, which is known for its durability and aesthetic appeal. Suppliers often inspect the hides for imperfections, as these can affect the final product’s quality.

Next, the leather is cut into strips of varying widths based on the intended use—ranging from lightweight to heavyweight options. This step may involve advanced cutting techniques, such as die-cutting or laser cutting, to ensure precision and minimize waste.

How Is the Forming Process Carried Out?

Once the leather is prepared, the forming process begins. This stage may include tooling, embossing, or dyeing the leather to achieve specific designs and colors. Tooling involves using specialized stamps or tools to create patterns or logos, while embossing adds texture that enhances the visual appeal of the belts.

Dyeing is another critical process where the leather is treated with various dyes to achieve the desired color. Natural and eco-friendly dyes are becoming increasingly popular due to rising consumer demand for sustainable products. This stage is crucial for ensuring that the leather not only looks good but also meets environmental standards.

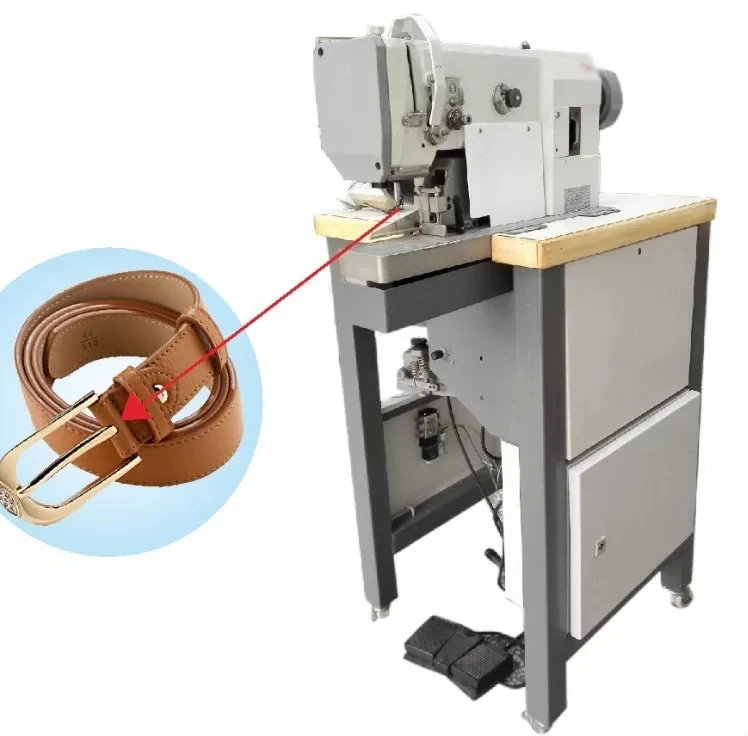

What Does the Assembly Stage Entail?

The assembly stage involves stitching the prepared leather strips together and attaching hardware, such as buckles and rivets. This step requires skilled craftsmanship to ensure that the components are securely fastened and that the overall design is aesthetically pleasing.

Illustrative image related to leather belt making supplies

Modern manufacturers may employ sewing machines for precision stitching, while others might use hand-stitching techniques for artisanal quality. The choice between machine and hand-stitching can influence the product’s price point and perceived value.

How Is the Finishing Process Conducted?

The final stage, finishing, involves applying protective coatings and finishes to enhance the leather’s durability and appearance. This may include edge finishing techniques to prevent fraying and applying conditioners to maintain the leather’s suppleness.

In addition, polishing and buffing may be performed to achieve a high-gloss finish. Quality assurance checks are typically implemented during this stage to ensure that the final product meets the required specifications.

What Quality Assurance Measures Are in Place for Leather Belt Manufacturing?

Quality assurance (QA) is integral to the leather belt manufacturing process, ensuring that products meet international and industry-specific standards. Understanding these measures helps B2B buyers make informed sourcing decisions.

Which International Standards Should Be Considered?

International standards like ISO 9001 play a pivotal role in establishing a quality management system (QMS) for manufacturers. This standard focuses on continuous improvement and customer satisfaction, ensuring that suppliers maintain high-quality production processes.

Illustrative image related to leather belt making supplies

For certain markets, compliance with CE marking and other industry-specific certifications may be necessary. This is particularly relevant for suppliers exporting to Europe, where safety and environmental impact are crucial considerations.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria. Any defects at this stage can lead to downstream quality issues.

-

In-Process Quality Control (IPQC): During production, regular checks are conducted to monitor the manufacturing process and identify defects early. This could include checking dimensions, stitching quality, and dye consistency.

-

Final Quality Control (FQC): At this stage, finished products undergo thorough inspection, including functionality tests and visual assessments to ensure they meet customer specifications.

What Common Testing Methods Are Used in QC?

Various testing methods are employed to assess the quality of leather belt making supplies. These may include:

-

Physical Tests: Assessing the tensile strength, flexibility, and abrasion resistance of the leather.

-

Chemical Tests: Ensuring that dyes and finishes do not contain harmful substances and comply with environmental regulations.

-

Visual Inspections: Checking for aesthetic defects such as discoloration, uneven stitching, or misalignment.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. There are several effective strategies to accomplish this.

Illustrative image related to leather belt making supplies

What Steps Can Buyers Take to Conduct Audits?

Conducting supplier audits is a proactive approach to assess a manufacturer’s quality assurance practices. Buyers can establish a checklist based on international standards and industry best practices, focusing on areas like production processes, equipment, and employee training.

Engaging third-party auditing services can provide an impartial assessment and enhance credibility. This is particularly important for buyers from regions with diverse regulatory frameworks, such as Africa, South America, the Middle East, and Europe.

How Important Are Quality Reports and Third-Party Inspections?

Requesting quality reports from suppliers is another effective way to gauge their QC capabilities. These reports should outline test results, production metrics, and compliance with relevant standards.

Third-party inspections can further bolster confidence in a supplier’s quality claims. Independent inspectors can verify that products adhere to specified quality criteria and provide buyers with detailed inspection reports.

What Are the Nuances of QC and Certification for International Buyers?

International buyers must navigate various nuances when dealing with QC and certification. Understanding the specific requirements for each region is critical, as standards may vary significantly.

For instance, buyers from Europe may prioritize CE certification, while those in Africa and South America may focus on different local standards. Additionally, cultural perceptions of quality can influence buyer expectations, making it essential for suppliers to adapt their quality assurance practices accordingly.

Conclusion

In conclusion, the manufacturing processes and quality assurance measures for leather belt making supplies are multifaceted. By understanding these aspects, international B2B buyers can make informed decisions that ensure they source high-quality products that meet their specifications and market demands. Investing time in assessing manufacturing processes and quality control measures will lead to more fruitful partnerships and greater customer satisfaction in the long run.

Illustrative image related to leather belt making supplies

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather belt making supplies’

To effectively source leather belt making supplies, B2B buyers must navigate a variety of components and considerations. This guide serves as a practical checklist to streamline the procurement process, ensuring that you secure high-quality materials and tools for your business needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to outline the specifications for your leather belt making supplies. This includes determining the type of leather (e.g., cowhide, veg-tan), thickness (lightweight, midweight, heavyweight), and any special treatments (e.g., dyed, embossed). Clear specifications help in communicating your needs to suppliers and ensure that the materials meet your production standards.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to identify potential suppliers who specialize in leather belt making materials. Look for suppliers with a solid reputation in the industry, as well as positive reviews from previous clients. Consider using online marketplaces, industry directories, and trade shows to gather a list of potential partners.

- Tip: Focus on suppliers that have experience serving businesses in your region, as they may better understand local market demands and regulations.

Step 3: Evaluate Supplier Certifications and Compliance

It’s crucial to verify the certifications and compliance of potential suppliers, especially regarding quality standards and ethical sourcing practices. Check for certifications such as ISO for quality management systems or Leather Working Group (LWG) certifications, which indicate sustainable practices.

- Why it matters: Ensuring compliance not only guarantees product quality but also enhances your brand reputation by aligning with ethical sourcing initiatives.

Step 4: Request Samples for Quality Assessment

Before making large orders, request samples of the leather and other materials you intend to use. This will allow you to assess the quality, texture, and durability firsthand. Pay close attention to how the leather holds up during practical tests, such as dyeing or tooling.

- Tip: Analyze the color consistency and any imperfections to ensure the materials meet your standards.

Step 5: Compare Pricing and Terms of Sale

Once you have a shortlist of suppliers, compare their pricing structures, payment terms, and shipping options. Be sure to consider the total cost of ownership, which includes shipping fees, import duties, and any potential tariffs that may apply, especially if sourcing internationally.

- Key considerations: Look for bulk order discounts and flexible payment terms that can improve your cash flow.

Step 6: Establish Clear Communication Channels

Effective communication is vital for successful procurement. Establish clear channels for discussing orders, changes, and any potential issues with your suppliers. Regular communication can prevent misunderstandings and foster a strong working relationship.

- Best practice: Set up regular check-ins or updates to stay aligned on order statuses and any evolving needs.

Step 7: Finalize Contracts and Agreements

Before proceeding with orders, ensure that all terms are clearly outlined in a contract. This should include delivery timelines, return policies, and warranty information. A well-structured agreement protects both parties and ensures accountability.

- Important: Always consult with legal experts if you’re unsure about contractual terms, especially when dealing with international suppliers.

By following these steps, B2B buyers can navigate the complexities of sourcing leather belt making supplies efficiently, ensuring they procure high-quality materials that meet their business needs.

Comprehensive Cost and Pricing Analysis for leather belt making supplies Sourcing

What Are the Key Cost Components for Leather Belt Making Supplies?

When sourcing leather belt making supplies, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: Leather types significantly influence pricing. For instance, vegetable-tanned leather is often more expensive due to its quality and dyeing process. Other materials such as buckles, clips, and rivets also add to the overall cost. Buyers should evaluate the quality of materials, as premium options can lead to higher initial expenses but may reduce long-term replacement costs.

-

Labor: Labor costs can vary widely based on the region and the complexity of the belt-making process. In countries with lower labor costs, such as Vietnam, buyers may find more competitive pricing. However, it’s essential to consider the skill level required for craftsmanship, as highly skilled labor may command a premium.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Overhead can vary by supplier and should be factored into the total cost when comparing quotes.

-

Tooling: Initial tooling costs for custom designs can be significant. Suppliers may charge for custom molds or dies, which can be amortized over larger production runs.

-

Quality Control (QC): Ensuring product quality is vital, especially for international markets. Implementing robust QC processes can add to costs but is essential for maintaining standards and reducing returns.

-

Logistics: Shipping costs are a significant consideration, particularly for international buyers. Factors such as distance, shipping method, and customs duties can greatly influence the overall expenditure.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding market norms for margins can help buyers negotiate better deals.

How Do Price Influencers Affect Leather Belt Making Supplies?

Several price influencers affect the cost of leather belt making supplies.

-

Volume/MOQ: The minimum order quantity (MOQ) often dictates pricing. Larger orders generally attract better pricing due to economies of scale.

-

Specifications/Customization: Custom designs or specific dimensions can lead to higher costs. Buyers should clearly outline requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Leather quality and certifications (like eco-friendly or ethical sourcing) can also impact pricing. Premium materials will typically increase costs but may be worth the investment for brand reputation.

-

Supplier Factors: The supplier’s reputation, location, and relationship with buyers can influence price. Long-standing relationships often lead to better pricing and terms.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for clarifying responsibilities regarding shipping, insurance, and tariffs, which can affect total costs.

What Are Effective Buyer Tips for Sourcing Leather Belt Making Supplies?

International B2B buyers should adopt strategic approaches for cost-effective sourcing:

-

Negotiation: Always negotiate terms with suppliers. Leverage volume purchases or long-term contracts for better pricing.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just upfront costs. Consider long-term savings from quality materials and efficient logistics.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Africa or South America may offer lower prices due to local market conditions.

-

Research Suppliers: Conduct thorough due diligence on suppliers to ensure they meet quality and service expectations. This can prevent costly mistakes.

-

Flexibility with Specifications: If possible, be flexible with specifications to take advantage of existing inventory or lower-cost alternatives.

Buyers should keep in mind that prices can fluctuate based on market conditions, demand, and geopolitical factors, making it essential to stay informed and adaptable in sourcing strategies.

Alternatives Analysis: Comparing leather belt making supplies With Other Solutions

Introduction to Alternatives in Leather Belt Making

In the leather industry, the choice of materials and methods for producing leather belts is crucial for ensuring quality, durability, and aesthetic appeal. While traditional leather belt making supplies are widely used, it’s beneficial to explore alternative solutions that may offer different advantages. This analysis will compare leather belt making supplies with synthetic belt materials and pre-manufactured belts, providing insights into their respective benefits and limitations.

Comparison Table

| Comparison Aspect | Leather Belt Making Supplies | Synthetic Belt Materials | Pre-Manufactured Belts |

|---|---|---|---|

| Performance | High durability; customizable styles | Moderate durability; often less breathable | Consistent quality; limited customization |

| Cost | Variable; can be higher for premium leather | Generally lower due to mass production | Moderate; often includes branding premiums |

| Ease of Implementation | Requires skill and tools; time-consuming | Simple to work with; minimal tools needed | Ready to use; no setup required |

| Maintenance | Requires care and conditioning | Low maintenance; easy to clean | Minimal; depends on material quality |

| Best Use Case | Custom, high-end products; artisans | Cost-effective production; everyday use | Bulk sales; retail environments |

Detailed Breakdown of Alternatives

Synthetic Belt Materials

Synthetic materials, such as polyurethane or nylon, have become popular alternatives to traditional leather. They offer the advantage of being lightweight, often waterproof, and resistant to staining. These materials can be produced at a lower cost, making them appealing for mass production. However, while synthetic belts can mimic the appearance of leather, they often lack the breathability and longevity associated with genuine leather. For businesses focused on affordability and quick production times, synthetic materials present a viable option, albeit with some compromises in aesthetics and durability.

Pre-Manufactured Belts

Pre-manufactured belts represent a convenient solution for businesses looking to streamline their operations. These belts are ready to sell, allowing retailers to minimize inventory costs and eliminate the need for in-house production. The quality of pre-manufactured belts can vary, but they typically offer consistent sizing and design, catering well to high-volume sales. However, the downside is the lack of customization; businesses may find it challenging to differentiate their products in a competitive market. Pre-manufactured belts are best suited for companies aiming for efficiency and volume rather than unique craftsmanship.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate solution for leather belt production, B2B buyers must consider their specific needs and market positioning. Leather belt making supplies are ideal for businesses that prioritize craftsmanship, quality, and customization, catering to niche markets that value artisanal products. Conversely, synthetic materials may be more suitable for those focused on cost-efficiency and everyday wear, while pre-manufactured belts can serve businesses that require quick turnaround and uniformity. Ultimately, the choice should align with the target audience, production capabilities, and long-term business goals to ensure optimal satisfaction and profitability.

Essential Technical Properties and Trade Terminology for leather belt making supplies

What Are the Key Technical Properties of Leather Belt Making Supplies?

When sourcing leather belt making supplies, understanding the essential technical properties is crucial for ensuring product quality and performance. Here are some critical specifications that B2B buyers should consider:

-

Material Grade: Leather is categorized into various grades, such as full-grain, top-grain, and genuine leather. Full-grain leather, for instance, retains the natural grain and is the most durable and high-quality option. This property is vital for buyers looking to produce premium products that stand the test of time.

-

Weight (Oz): The weight of leather is measured in ounces (oz), indicating its thickness and sturdiness. Lightweight leather (less than 4 oz) is suitable for items like casual belts, while heavyweight leather (over 8 oz) is ideal for heavy-duty applications. Buyers should match the leather weight to the intended use to ensure functionality and durability.

-

Tanning Process: The method used to tan leather (e.g., vegetable tanning, chrome tanning) affects its characteristics, such as flexibility, color retention, and environmental impact. Buyers should be aware of the tanning process to align with their sustainability goals and product requirements.

-

Finish Type: The finish applied to leather can vary widely, including matte, glossy, or embossed. The finish not only affects aesthetics but also impacts durability and maintenance. Understanding finish types helps buyers ensure that the final product meets customer expectations and market trends.

-

Tolerance Levels: Tolerance levels refer to the permissible variation in the dimensions of leather strips or components. Maintaining strict tolerances is essential for ensuring that all parts fit together seamlessly during production. This specification is especially important for manufacturers who rely on precision to create high-quality belts.

-

Color Fastness: This property indicates how well the dye used on leather holds up against washing, rubbing, and exposure to light. High color fastness is critical for ensuring that belts retain their appearance over time, which is a key factor in customer satisfaction and brand reputation.

What Are Common Trade Terms in the Leather Belt Industry?

Navigating the terminology in the leather belt making industry can be daunting. Here are some common trade terms that B2B buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable partners for sourcing high-quality components.

-

MOQ (Minimum Order Quantity): MOQ represents the smallest quantity a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory effectively and minimize costs while ensuring they meet production needs.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers requesting pricing and terms for specific products. This process is crucial for obtaining competitive pricing and understanding supplier capabilities.

-

Incoterms (International Commercial Terms): These terms define the responsibilities of buyers and sellers in international shipping, covering aspects like delivery, risk, and cost. Familiarity with Incoterms helps buyers negotiate better shipping arrangements and clarify their obligations in international transactions.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is vital for planning production schedules and ensuring timely delivery to customers.

-

Sustainability Certifications: Certifications like Leather Working Group (LWG) or Global Organic Textile Standard (GOTS) indicate that the leather products meet certain environmental and ethical standards. Buyers increasingly seek these certifications to align with consumer demands for sustainable products.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions that enhance their supply chain efficiency and product quality in the leather belt making industry.

Navigating Market Dynamics and Sourcing Trends in the leather belt making supplies Sector

What Are the Key Trends Influencing the Leather Belt Making Supplies Market?

The leather belt making supplies market is experiencing significant growth driven by several global factors. The increasing demand for personalized and high-quality leather products is one of the primary drivers. As consumers prioritize fashion and durability, businesses are adapting by sourcing superior materials, such as premium cowhide and eco-friendly alternatives. Additionally, the integration of technology in the sourcing process is reshaping how B2B buyers operate. Online platforms are becoming essential for international procurement, allowing buyers from regions like Africa, South America, the Middle East, and Europe to access a wider variety of products and suppliers.

Illustrative image related to leather belt making supplies

Emerging trends also include the rise of automation in manufacturing processes. This is not only improving efficiency but also enabling more intricate designs and customizations in leather belts. Furthermore, sustainability is becoming a focal point in sourcing decisions, with buyers increasingly looking for suppliers who adhere to ethical practices. As consumers demand transparency, businesses must be prepared to provide information about their supply chains.

How Does Sustainability and Ethical Sourcing Impact the Leather Belt Making Supplies Sector?

Sustainability and ethical sourcing are paramount in the leather belt making supplies sector. The environmental impact of leather production has led to a growing emphasis on responsible sourcing practices. Buyers are increasingly seeking suppliers that utilize environmentally friendly tanning processes and materials. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) have gained importance, as they help buyers identify sustainable and ethically sourced leather.

Furthermore, the shift towards eco-conscious products is influencing consumer preferences across markets. As international buyers, particularly from regions like Africa and South America, become more attuned to these values, they are likely to favor suppliers who prioritize sustainability. This trend not only enhances brand reputation but also aligns with global efforts to reduce carbon footprints and promote ethical labor practices in the leather industry.

What Is the Historical Context Behind the Leather Belt Making Supplies Industry?

The leather belt making supplies industry has a rich history that dates back centuries, rooted in traditional craftsmanship and artisanal techniques. Historically, leather was a prized material due to its durability and versatility, leading to the creation of various leather goods, including belts. The industrial revolution marked a significant turning point, as mass production techniques emerged, allowing for more affordable and accessible leather products.

In recent decades, the industry has evolved significantly with technological advancements, shifting from purely artisanal methods to incorporating modern manufacturing practices. This evolution has opened new avenues for B2B buyers, enabling them to access a broader range of products and suppliers. The focus on quality and design has remained constant, but today’s market is increasingly influenced by sustainability and ethical considerations, shaping the future of leather belt making supplies.

Illustrative image related to leather belt making supplies

Frequently Asked Questions (FAQs) for B2B Buyers of leather belt making supplies

-

How do I choose the right leather for belt making?

Choosing the right leather for belt making depends on several factors, including the intended use, desired aesthetics, and durability requirements. Vegetable-tanned leather is popular for its natural look and ability to develop a rich patina over time, making it ideal for high-quality belts. For more rugged applications, consider chrome-tanned leather, which offers enhanced flexibility and water resistance. Always request samples from suppliers to assess texture, weight, and color before making bulk purchases. -

What are the best tools and supplies for making leather belts?

Essential tools for leather belt making include a cutting mat, rotary cutter or knife, hole punch set, and edge finishing tools. Additionally, consider investing in quality buckles, rivets, and dyeing supplies to enhance the final product. Acrylic templates can also streamline the cutting process, ensuring consistent sizing. When sourcing these supplies, look for suppliers who provide comprehensive kits to simplify the purchasing process. -

What is the minimum order quantity (MOQ) for leather belt supplies?

Minimum order quantities (MOQ) can vary significantly between suppliers and product types. Typically, MOQs for leather hides range from 5 to 20 hides, while smaller components like buckles and rivets may have lower MOQs. Always clarify the MOQ with your supplier before placing an order, as some may offer flexibility based on your business needs or the type of product being sourced. -

How can I ensure the quality of leather supplies from international suppliers?

To ensure the quality of leather supplies, conduct thorough vetting of potential suppliers. Request product samples to evaluate the leather’s texture, smell, and durability. Additionally, check for certifications that indicate adherence to industry standards, such as ISO or environmental sustainability practices. Building a relationship with suppliers who have a proven track record can also enhance trust in product quality. -

What payment terms are typically offered by suppliers in the leather industry?

Payment terms can vary widely based on the supplier and your negotiation power. Common terms include full payment upfront, a deposit with the balance due upon shipment, or net terms (30, 60, or 90 days). For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risk. Always clarify payment terms before finalizing orders to avoid misunderstandings. -

How can I customize leather belts to meet my brand’s needs?

Customization options for leather belts often include embossing, dyeing, and unique buckle designs. Many suppliers offer services to personalize products with logos or specific color schemes. When seeking customization, provide clear specifications and examples of desired outcomes to ensure alignment with your brand’s vision. Discuss lead times for custom orders, as they may differ from standard production timelines. -

What logistics considerations should I keep in mind when importing leather supplies?

When importing leather supplies, consider shipping methods, customs regulations, and import duties. Collaborate with suppliers experienced in international shipping to streamline logistics. It’s crucial to understand the shipping timelines and any potential delays at customs. Additionally, factor in the costs associated with logistics to ensure they align with your budget and pricing strategy for the end products. -

How do I handle quality assurance (QA) for leather products?

Implementing a robust quality assurance process is essential for maintaining product standards. Establish clear QA criteria before production begins, including specifications for leather quality, stitching, and finishing. Conduct regular inspections during the manufacturing process and upon receipt of goods. Consider third-party QA services if you’re sourcing from regions with varying quality standards to ensure compliance with your specifications.

Top 4 Leather Belt Making Supplies Manufacturers & Suppliers List

1. Tandy Leather – Belt Making Essentials

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Belt Making Essentials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Weaver Leather Supply – Leather Belt Making Kits & Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Leather Belt Making Kits & Supplies – Weaver Leather Supply includes various types of leather such as ChahinLeather®, Hermann Oak® Veg Tan, Natural Veg Tan, Dyed, Chrome Tanned, and Water Buffalo Leather. The collection features leather cuts like double shoulders, backs, bends, panels, half sides, fringes, sides, whole hides, bellies, and belt blanks. Textures available include top grain, pebbled,…

3. Buckleguy – Premium Leather Straps

Domain: buckleguy.com

Registered: 2002 (23 years)

Introduction: Leather Straps available in various types and colors, including Crocodile, Hermann Oak, Horween, Newbury Leathers, Sedgwick, and Wickett & Craig. Weights range from 8/10oz to 10/12oz. Lengths are typically 55″ to 60″. Bulk discounts available: 5% off for 10-49 items, 10% off for 50 or more. Popular options include Russet, Chestnut, Brown, Black, Mustard, Buck Brown, Tan, Dark Brown, and Natural co…

4. Makers Leather Supply – Premium Veg Tan Belt Blanks

Domain: makersleathersupply.com

Registered: 2012 (13 years)

Introduction: Belt Blanks and Belt Supplies include various leather products such as Texas Oak Veg Tanned Shoulders, Imported Belt Blanks, Premium Veg Tan Belt Blanks/Straps, English Bridle/Harness Leather Straps, English Bridle Project Box Straps, El Matador Belt Liners, Russet Straps, and Veg Tanned Imported Sides. Products are available in different colors including Blacks & Grays, Browns & Tans, and Reds & …

Strategic Sourcing Conclusion and Outlook for leather belt making supplies

In conclusion, strategic sourcing for leather belt making supplies is essential for businesses aiming to enhance product quality and streamline operations. By leveraging a diverse range of materials—from premium veg-tanned leather to specialized hardware—buyers can create unique offerings that resonate with consumer demands across various markets. Understanding regional preferences, such as the growing interest in sustainable materials in Europe and the Middle East, allows for tailored sourcing strategies that maximize competitiveness.

Moreover, maintaining strong relationships with reliable suppliers ensures not only a steady supply chain but also access to innovative products and technologies that can elevate your brand. As the global market continues to evolve, businesses must remain agile, adapting to trends such as customization and eco-friendliness.

Looking ahead, international B2B buyers from regions such as Africa, South America, and Asia should actively engage with suppliers who can provide not just materials but also insights into market trends and consumer behavior. Embrace this opportunity to enhance your sourcing strategy and position your business for sustainable growth in the leather goods sector. Your next step is to explore partnerships that can propel your offerings into new markets and elevate your brand’s presence on the global stage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to leather belt making supplies

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.