Introduction: Navigating the Global Market for how to make leather darker

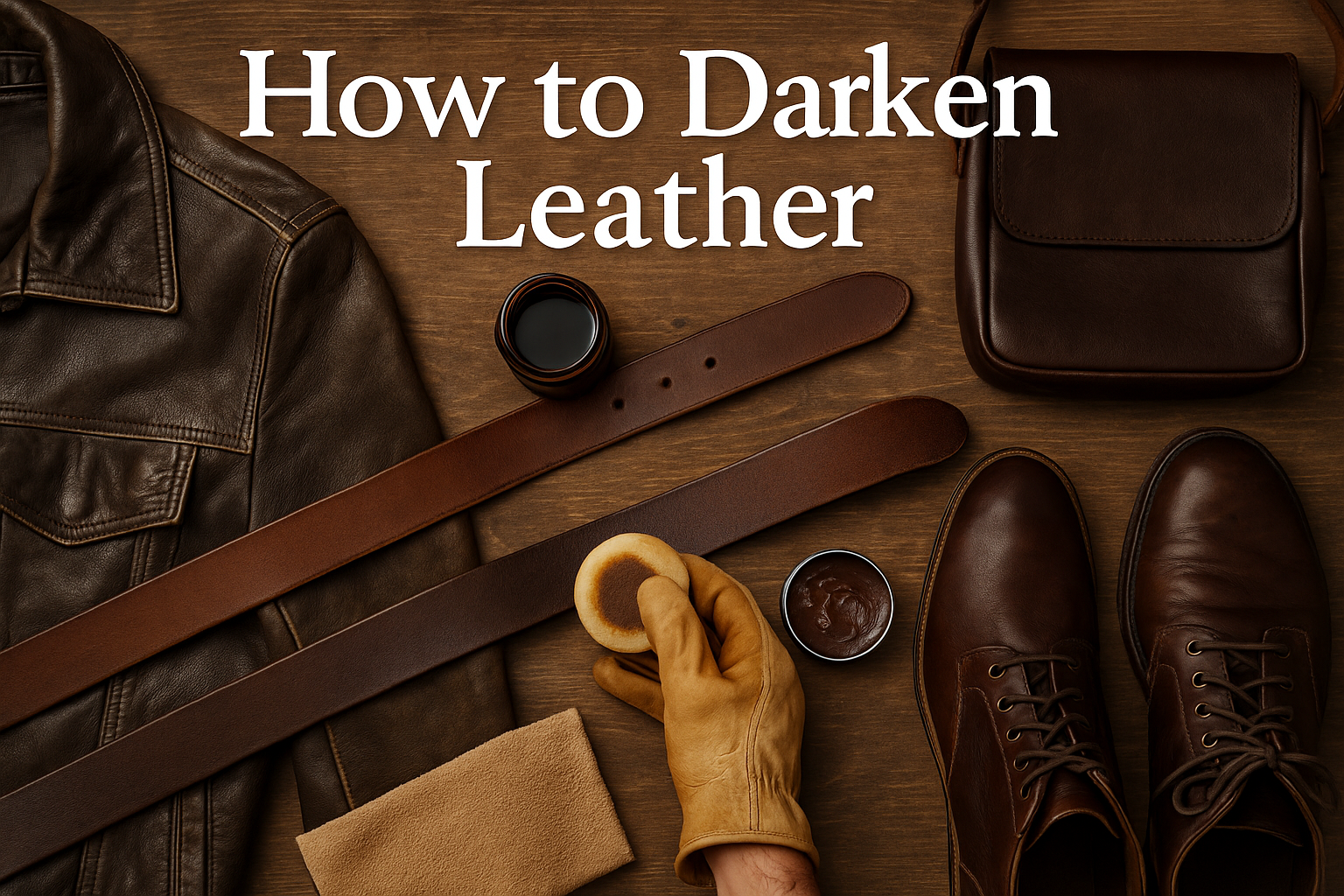

In the competitive landscape of leather goods, many businesses face the challenge of sourcing effective methods to darken leather without compromising its quality. Understanding how to make leather darker not only enhances the aesthetic appeal of products but also serves practical purposes, such as improving durability and protecting against wear. This comprehensive guide explores various techniques, including the use of oils, dyes, and conditioning agents, tailored specifically for international B2B buyers from Africa, South America, the Middle East, and Europe, including markets like Germany and Saudi Arabia.

Throughout this guide, we provide insights into different types of darkening agents, their applications, and best practices for implementation. Buyers will learn how to vet suppliers effectively, ensuring they source high-quality materials that meet their specific needs. Additionally, we address cost considerations, enabling informed purchasing decisions that balance quality with budget constraints.

By equipping businesses with the knowledge needed to navigate the complexities of leather darkening, this guide empowers decision-makers to enhance their product offerings, satisfy customer demands, and maintain a competitive edge in the global market. Whether you’re a manufacturer, retailer, or artisan, understanding these processes will enable you to elevate your leather products while meeting the diverse preferences of your international clientele.

Table Of Contents

- Top 4 How To Make Leather Darker Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make leather darker

- Understanding how to make leather darker Types and Variations

- Key Industrial Applications of how to make leather darker

- 3 Common User Pain Points for ‘how to make leather darker’ & Their Solutions

- Strategic Material Selection Guide for how to make leather darker

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather darker

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather darker’

- Comprehensive Cost and Pricing Analysis for how to make leather darker Sourcing

- Alternatives Analysis: Comparing how to make leather darker With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make leather darker

- Navigating Market Dynamics and Sourcing Trends in the how to make leather darker Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather darker

- Strategic Sourcing Conclusion and Outlook for how to make leather darker

- Important Disclaimer & Terms of Use

Understanding how to make leather darker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Oils | Derived from plants or animals, nourishing leather | Footwear, upholstery, leather goods | Pros: Enhances flexibility, rehydrates leather. Cons: Can leave residue, may require multiple applications. |

| Leather Dyes | Alcohol-based, penetrates deeply for color change | Fashion, accessories, custom leather | Pros: Provides vibrant color, customizable. Cons: Can dry out leather, requires careful application. |

| Cream Conditioners | Emulsified products that moisturize and color | High-end leather goods, furniture | Pros: Restores shine, protects leather. Cons: May not achieve as dark a tone as oils or dyes. |

| Beeswax | Natural wax that provides a waterproof finish | Outdoor gear, footwear | Pros: Excellent for water resistance, enhances durability. Cons: Can be difficult to apply evenly. |

| Mink Oil | Animal fat that conditions and darkens leather | Boots, rugged leather goods | Pros: Softens leather, adds protection. Cons: Can darken too much if over-applied. |

What Are the Characteristics of Natural Oils for Darkening Leather?

Natural oils, such as coconut oil and mink oil, are popular choices for darkening leather due to their nourishing properties. These oils penetrate the leather, enhancing its flexibility while providing a rich, darker tone. Suitable for a variety of applications, including footwear and upholstery, natural oils can rejuvenate aging leather goods. Buyers should consider the oil type based on the intended use, as some oils may leave residues or require additional cleaning steps.

How Do Leather Dyes Differ in Application and Effect?

Leather dyes are primarily alcohol-based and designed to penetrate deeply into the leather fibers, resulting in a significant color change. They are especially useful in fashion and custom leather applications where vibrant colors are desired. However, due to their drying properties, they can lead to leather degradation over time. B2B buyers should ensure that the dye is suitable for the type of leather being treated and be prepared for a more meticulous application process to achieve even coloring.

Why Are Cream Conditioners a Good Option for Leather Maintenance?

Cream conditioners combine moisturizing agents with pigments to restore both color and shine to leather products. Ideal for high-end leather goods and furniture, these products offer a balanced approach to maintaining leather’s appearance without overly darkening it. While they may not achieve the same depth of color as oils or dyes, their ease of application and protective benefits make them a practical choice for businesses looking to maintain their leather inventory. Buyers should evaluate the specific needs of their products to determine if a cream conditioner meets their requirements.

What Benefits Does Beeswax Provide for Leather?

Beeswax serves as a natural barrier against water and environmental damage, making it an excellent option for outdoor gear and footwear. When applied, it darkens leather while enhancing its durability. However, the application can be tricky, as achieving an even coat requires skill and care. B2B buyers should consider the specific environmental conditions their leather products will face to determine if beeswax is a suitable protective measure.

How Does Mink Oil Contribute to Leather Longevity?

Mink oil is a powerful conditioning agent that not only darkens leather but also maintains its suppleness and strength. Particularly beneficial for rugged leather goods like boots, it provides a layer of protection against moisture and wear. However, caution is needed with application, as excessive use can lead to an overly darkened appearance. B2B buyers should assess their leather types and use cases to effectively leverage mink oil’s benefits while avoiding potential drawbacks.

Key Industrial Applications of how to make leather darker

| Industry/Sector | Specific Application of how to make leather darker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Darkening leather jackets and accessories | Enhanced aesthetic appeal and marketability | Quality of dyes and oils, compliance with environmental standards |

| Furniture Manufacturing | Darkening leather upholstery for furniture | Improved durability and consumer satisfaction | Sourcing from eco-friendly suppliers, consistency in color |

| Automotive Industry | Darkening leather interiors in vehicles | Increased luxury appeal and resale value | Compatibility with automotive materials, UV resistance |

| Footwear Production | Darkening leather shoes and boots | Enhanced durability and fashion appeal | Sourcing natural oils and dyes, ensuring water resistance |

| Leather Goods Retailers | Darkening leather bags and wallets | Improved product lifecycle and customer loyalty | Authenticity of materials, ethical sourcing practices |

How is Darkening Leather Applied in the Fashion and Apparel Industry?

In the fashion and apparel sector, darkening leather is vital for enhancing the aesthetic appeal of products like jackets and accessories. Brands often seek deeper, richer tones to attract discerning consumers who value style and craftsmanship. The process not only revitalizes the leather but can also help mask imperfections, thereby increasing the overall marketability of the products. Buyers in this industry must prioritize high-quality dyes and oils that comply with environmental standards, ensuring that their products meet consumer expectations for sustainability.

What Role Does Darkening Leather Play in Furniture Manufacturing?

In the furniture manufacturing industry, darkening leather upholstery is essential for creating luxurious and durable seating options. A darker finish can enhance the richness of the leather, making it more appealing to consumers looking for premium quality. Additionally, this process can improve the leather’s resistance to wear and tear, extending the product’s lifespan. For B2B buyers, sourcing from eco-friendly suppliers is crucial, as is ensuring consistency in color to meet design specifications across different furniture lines.

Illustrative image related to how to make leather darker

How Does Darkening Leather Enhance Automotive Interiors?

The automotive industry utilizes leather darkening techniques to elevate the interiors of vehicles, enhancing their luxury appeal. Darker leather not only contributes to a sophisticated aesthetic but can also increase the vehicle’s resale value by providing a more premium look and feel. Buyers in this sector must consider the compatibility of darkening agents with automotive materials, as well as their resistance to UV damage, to ensure long-lasting quality in vehicle interiors.

Why is Darkening Leather Important in Footwear Production?

In footwear production, darkening leather is a common practice to improve both the durability and visual appeal of shoes and boots. A darker finish can offer a more sophisticated look while also helping to conceal scuffs and scratches that occur during wear. B2B buyers should focus on sourcing natural oils and dyes that provide water resistance, as this is essential for maintaining the integrity of footwear in various climates, particularly in regions like Africa and South America where weather conditions can vary significantly.

How Do Retailers Benefit from Darkening Leather in Goods?

Leather goods retailers often darken leather bags and wallets to enhance their appeal and longevity. A darker tone can add a touch of elegance, making products more attractive to potential buyers. Furthermore, this process can help improve the product lifecycle by providing additional protection against wear. For international buyers, ensuring the authenticity and ethical sourcing of materials is paramount, as consumers increasingly seek transparency in the production process, especially in markets across Europe and the Middle East.

3 Common User Pain Points for ‘how to make leather darker’ & Their Solutions

Scenario 1: Inconsistent Darkening Results Across Different Leather Types

The Problem: B2B buyers often encounter the challenge of inconsistent results when attempting to darken leather products made from various types of hides. For instance, full-grain leather may absorb oils differently compared to corrected-grain leather or synthetic alternatives. This inconsistency can lead to dissatisfaction among customers, as the final product may not meet their expectations in terms of color depth and uniformity. Additionally, some buyers may not be fully aware of the specific requirements for treating different leather types, leading to confusion and potential waste of resources.

Illustrative image related to how to make leather darker

The Solution: To tackle this issue, it’s essential to conduct a thorough assessment of the leather type before applying any darkening techniques. Buyers should source high-quality leather samples and conduct small-scale tests using various oils and dyes tailored to the specific leather type. For instance, natural oils like mink oil work best on full-grain leather, while alcohol-based dyes may be more effective on unfinished leather. Providing detailed guidelines for each leather type, including recommended products and application techniques, can significantly enhance the predictability of results. Collaborating with suppliers who offer comprehensive product information and support can also help ensure that buyers can achieve consistent, satisfactory outcomes.

Scenario 2: Over-Application Leading to Damage or Stiffness

The Problem: One of the prevalent issues B2B buyers face is the risk of over-application when darkening leather, which can lead to damage or an undesirable stiff texture. This often occurs when users are eager to achieve a darker shade quickly and apply too much product, whether it be oil or dye. Over-saturation can not only affect the appearance of the leather but also compromise its flexibility and comfort, ultimately impacting the usability of the final product.

The Solution: A practical approach to preventing over-application is to implement a systematic, step-by-step application process. Buyers should start by applying a small amount of product—about a teaspoon of oil or dye—using a soft cloth. Emphasizing the importance of even application in small circular motions can help avoid streaks and blotches. Additionally, it is crucial to educate users on the drying time required for each application; allowing the leather to dry completely before assessing the final color can prevent the urge to apply more product prematurely. Providing training sessions or instructional materials can enhance user confidence and ensure better adherence to recommended practices.

Scenario 3: Lack of Knowledge About Eco-Friendly Darkening Options

The Problem: As sustainability becomes a priority in the leather industry, many B2B buyers struggle to find eco-friendly options for darkening leather. Traditional dyes and oils may contain harmful chemicals that not only pose risks to the environment but may also conflict with consumer preferences for natural and safe materials. This lack of knowledge can hinder the ability to meet market demands for sustainable products, ultimately affecting sales and brand reputation.

The Solution: To address this pain point, buyers should actively seek out suppliers who specialize in eco-friendly leather treatment products. These may include plant-based oils like coconut or jojoba oil, which are not only effective at darkening but also safe for the environment. Encouraging collaboration with manufacturers who prioritize sustainable practices can open up opportunities for sourcing innovative, natural darkening solutions. Additionally, providing training on the benefits and application methods of these eco-friendly products can empower buyers to confidently market their sustainable leather goods, aligning with consumer trends and enhancing their competitive edge in the market.

Illustrative image related to how to make leather darker

Strategic Material Selection Guide for how to make leather darker

What Are the Key Materials for Darkening Leather?

When it comes to darkening leather, several materials can be employed, each with its unique properties and implications for performance, cost, and application. Understanding these materials is essential for B2B buyers looking to make informed decisions in regions such as Africa, South America, the Middle East, and Europe.

How Do Natural Oils Impact Leather Darkening?

Natural oils, such as mink oil and neatsfoot oil, are popular choices for darkening leather due to their conditioning properties. Mink oil, derived from the fat of minks, not only darkens leather but also enhances its flexibility and durability. It provides a protective layer against moisture and environmental factors. Neatsfoot oil, made from cattle hooves, is effective for quick fixes and rehydrating leather but should be used sparingly to avoid deterioration.

Pros: These oils are relatively easy to apply and are generally cost-effective. They improve the leather’s appearance while providing conditioning benefits.

Cons: Over-application can lead to a greasy finish or deterioration over time. Additionally, the darkening effect may vary based on the leather type and initial color.

What Role Do Leather Dyes Play in Darkening Leather?

Leather dyes are alcohol-based solutions designed to penetrate the leather’s surface and alter its color. They are particularly effective on unfinished leather but can dry out the material if used excessively. Dyes offer a more uniform color change compared to oils but may require multiple applications for optimal results.

Pros: Dyes provide a wide range of color options and can achieve a significant darkening effect.

Cons: They can be more complex to apply evenly and may require additional conditioning after use to maintain leather integrity.

How Do Beeswax and Other Waxes Contribute to Leather Care?

Beeswax is a natural product that not only darkens leather but also enhances its water resistance. It can be mixed with oils to create a protective barrier that prevents moisture damage while providing a rich, dark finish. Other waxes, like carnauba wax, can also be used for similar purposes.

Pros: Waxes are durable and provide long-lasting protection. They are also relatively easy to apply and can be used in combination with oils for enhanced effects.

Cons: Waxes can create a surface layer that may require additional buffing to achieve a desired sheen. They may not penetrate as deeply as oils or dyes, potentially limiting their effectiveness in darkening.

Illustrative image related to how to make leather darker

What Are the Considerations for International B2B Buyers?

International buyers must consider compliance with local regulations and standards when selecting materials for darkening leather. For instance, European buyers may need to adhere to REACH regulations regarding chemical substances, while buyers in the Middle East may have specific preferences for natural products. Understanding the common standards, such as ASTM, DIN, or JIS, is crucial for ensuring product quality and safety.

Summary Table of Materials for Darkening Leather

| 素材 | Typical Use Case for how to make leather darker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Oils | Conditioning and darkening leather goods | Enhances flexibility and durability | Risk of over-application | 低い |

| Leather Dyes | Achieving uniform color change on leather | Wide range of color options | Can dry out leather if overused | Medium |

| Beeswax | Water-resistant darkening | Long-lasting protection | May require buffing for desired sheen | Medium |

| Synthetic Dyes | Industrial applications for leather products | Consistent results across batches | Potential environmental concerns | 高い |

This strategic material selection guide provides a comprehensive overview of the options available for darkening leather, highlighting the importance of understanding each material’s properties and implications for B2B buyers in diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather darker

What Are the Key Manufacturing Processes for Darkening Leather?

The process of darkening leather involves several key manufacturing stages that ensure quality and consistency. The main stages include material preparation, forming, assembly, and finishing. Each stage utilizes specific techniques that can significantly influence the final product’s appearance and durability.

How Is Leather Prepared for Darkening?

Material Preparation is the initial step where the quality of leather is assessed. Full-grain leather is often preferred due to its durability and ability to absorb oils and dyes effectively. The leather is cleaned using specialized solutions to remove any dirt, grease, or old finishes that could interfere with the darkening process. This stage may also involve conditioning to ensure the leather is pliable and receptive to oils or dyes.

Illustrative image related to how to make leather darker

Forming involves cutting the leather into the desired shapes for products such as bags, jackets, or shoes. Precision in this stage is crucial, as it directly affects the leather’s ability to absorb darkening agents uniformly. Techniques such as laser cutting may be employed for intricate designs, ensuring minimal waste and high accuracy.

What Techniques Are Used in Darkening Leather?

How Are Oils and Dyes Applied to Leather?

The application of darkening agents can be executed using various methods, including:

- Brushing: A common technique for applying oils where a soft brush is used to ensure even coverage and penetration.

- Spraying: Suitable for large surfaces, spraying allows for a fine mist that can cover extensive areas without over-saturating the leather.

- Dipping: This method involves submerging the leather in a dye solution, providing a uniform color but requiring careful management to avoid excessive saturation.

Each method has its advantages and drawbacks, and the choice often depends on the product type and desired finish.

How Is Quality Control Implemented in Leather Darkening?

Quality Control (QC) is paramount in the leather darkening process to ensure that the final products meet international standards and customer expectations.

Which International Standards Apply to Leather Manufacturing?

Many B2B buyers are familiar with standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with such standards helps ensure that manufacturers follow best practices in production and QC. For specific leather goods, additional certifications like CE marking (for products sold in the European Economic Area) or API (American Petroleum Institute) may also be relevant, depending on the application.

What Are the Key QC Checkpoints in Leather Darkening?

Quality control checkpoints are established at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This is the first line of defense where raw materials are inspected for quality and compliance before production begins. This step is crucial for ensuring that only high-quality leather is used for darkening.

-

In-Process Quality Control (IPQC): During production, samples may be taken to assess the consistency of the darkening process. This includes checking for evenness of color and the leather’s responsiveness to oils or dyes.

-

Final Quality Control (FQC): After the darkening process is complete, a thorough inspection is conducted to ensure that the final product meets all specifications. This includes checking for color uniformity, texture, and any defects.

How Can B2B Buyers Verify Supplier Quality Control?

What Methods Can Be Used for Supplier Audits?

B2B buyers can verify supplier quality control through several methods:

-

Supplier Audits: Conducting regular audits allows buyers to assess the supplier’s compliance with quality standards and practices. This may include reviewing production processes, QC checkpoints, and documentation.

-

Inspection Reports: Requesting detailed inspection reports can provide insights into the QC measures implemented by the supplier. These reports should outline the findings from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s processes. These inspections can be especially beneficial for international buyers unfamiliar with local practices.

What Are the QC and Certification Nuances for International Buyers?

How Do Regional Differences Impact Quality Standards?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding regional differences in quality standards is vital. European buyers may prioritize CE certification, while Middle Eastern buyers might focus on compliance with local regulations.

Moreover, language barriers and cultural differences can influence how quality standards are interpreted and implemented. Buyers should ensure clear communication with suppliers regarding expectations and standards to avoid discrepancies.

Illustrative image related to how to make leather darker

What Should Buyers Look for in Supplier Certifications?

When assessing suppliers, buyers should look for:

- Certification Validity: Ensure that the certifications are current and relevant to the products being sourced.

- Reputation of Certifying Bodies: Certifications from recognized organizations add credibility to the supplier’s claims.

- Traceability of Materials: Understanding the source of leather and darkening agents can provide insights into the sustainability and ethical practices of the supplier.

Conclusion

The processes involved in darkening leather are intricate and require a combination of skilled craftsmanship and stringent quality control measures. By understanding the manufacturing stages, techniques used, and the importance of quality assurance, B2B buyers can make informed decisions when sourcing leather products. Ensuring compliance with international standards and verifying supplier practices will help maintain high-quality standards and foster successful business relationships across borders.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather darker’

はじめに

This sourcing guide aims to provide B2B buyers with a clear and actionable checklist for procuring the necessary materials and tools to effectively darken leather products. Whether you’re in the fashion, furniture, or automotive industry, understanding the steps involved in darkening leather can enhance product quality and customer satisfaction. This guide will help you navigate the procurement process with confidence.

Step 1: Identify Your Leather Type

Understanding the type of leather you are working with is critical. Different leathers, such as full-grain, top-grain, or bonded leather, respond uniquely to darkening methods. For example, full-grain leather absorbs oils better than bonded leather, which may require dyes instead of oils.

- Research leather types: Familiarize yourself with the properties of various leather types to ensure compatibility with your chosen darkening method.

- Assess the end-use: Consider how the leather will be used, as this may affect your choice of darkening product.

Step 2: Determine Your Desired Shade

Before sourcing materials, it’s essential to establish the specific shade of darkness you wish to achieve. This helps narrow down your options and ensures consistency across your product line.

- Consult color samples: Gather samples of the desired color for reference during the procurement process.

- Consider customer preferences: Engage with your customer base to understand their color preferences and trends in your target markets.

Step 3: Research Suitable Darkening Products

Once you have defined your leather type and desired shade, research various products available in the market, such as oils, dyes, and creams. Each product has unique properties that can impact the final result.

- Evaluate product effectiveness: Look for reviews or case studies that demonstrate the effectiveness of each product in achieving the desired results.

- Assess environmental impact: Consider eco-friendly options, especially if your target markets prioritize sustainable practices.

Step 4: Source Quality Suppliers

Identifying reliable suppliers is crucial for ensuring the quality of your darkening products. This step involves evaluating potential suppliers based on their reputation and product offerings.

- Request samples: Before placing a bulk order, request samples to test the effectiveness and compatibility of their products with your leather.

- Check certifications: Ensure suppliers adhere to industry standards and certifications, which can assure product quality and safety.

Step 5: Evaluate Application Methods

Understanding how to properly apply darkening products is essential for achieving the best results. Different methods may be recommended depending on the product used.

- Consult product instructions: Thoroughly review the manufacturer’s guidelines for application techniques and recommended tools.

- Train your team: Ensure that your team is well-trained in application techniques to minimize errors and achieve consistent results.

Step 6: Conduct Quality Control

After applying the darkening product, implement a quality control process to ensure the final product meets your standards. This step is vital for maintaining customer satisfaction and brand integrity.

- Establish testing protocols: Set up a routine for testing color consistency and durability of the darkened leather.

- Gather feedback: Solicit feedback from customers to improve future sourcing and application practices.

Step 7: Monitor Trends and Innovations

The leather darkening industry is continually evolving, with new products and techniques emerging regularly. Staying updated can provide a competitive edge.

- Attend industry trade shows: Participate in trade shows and workshops to discover the latest trends and innovations in leather care.

- Network with industry professionals: Build relationships with other professionals in the leather industry to share insights and experiences.

By following these steps, B2B buyers can confidently navigate the process of sourcing materials for darkening leather, ensuring high-quality results that meet market demands.

Illustrative image related to how to make leather darker

Comprehensive Cost and Pricing Analysis for how to make leather darker Sourcing

What Are the Key Cost Components for Darkening Leather?

When considering the cost structure for darkening leather, several key components come into play:

-

Materials: The primary materials include oils, dyes, and cleaning agents. Natural oils such as mink oil or neatsfoot oil are popular for darkening leather, while dyes may require additional chemicals for application. The cost of these materials can vary significantly based on quality, source, and type.

-

Labor: Labor costs can fluctuate based on the complexity of the darkening process. For instance, applying dyes may necessitate skilled labor for even application, while oil treatments can be performed more simply. Training and expertise are essential, particularly for high-end products that require a meticulous approach.

-

Manufacturing Overhead: Overhead costs encompass utilities, equipment maintenance, and facility expenses. These costs can impact the overall pricing, particularly for manufacturers with advanced machinery for dyeing or oiling processes.

-

Tooling: Special tools such as brushes, applicators, and drying racks may be necessary. The initial investment in these tools can be significant, especially for companies aiming to maintain high-quality standards.

-

Quality Control (QC): Implementing quality control measures to ensure consistent results adds to costs. This includes testing batches of leather for durability and colorfastness, which is vital for maintaining reputation and customer satisfaction.

-

Logistics: Shipping costs can vary widely based on the destination, particularly for international buyers. Factors such as distance, volume, and chosen Incoterms (e.g., FOB, CIF) will influence these logistics expenses.

-

Margin: The profit margin will depend on the market demand and competitive landscape. Suppliers often adjust margins based on customer relationships, volume orders, and negotiated contracts.

How Do Price Influencers Affect the Cost of Darkening Leather?

Several price influencers can affect the overall cost of darkening leather:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to reduced per-unit costs. Suppliers are more likely to offer discounts for larger quantities, which can be beneficial for buyers looking to stock up.

-

Specifications and Customization: Custom requests, such as specific shades or unique formulations, can increase costs. Buyers should be clear about their specifications to avoid unexpected pricing.

-

Material Quality and Certifications: Higher-quality materials and certified products (e.g., eco-friendly or organic) typically command higher prices. Buyers should assess whether these attributes align with their brand values and customer expectations.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more but offer better quality assurance, while newer suppliers might provide lower prices to gain market share.

What Tips Can Buyers Use for Cost-Efficiency in Sourcing Leather Darkening Solutions?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Always negotiate terms with suppliers. Discussing pricing, payment terms, and delivery schedules can yield better deals, especially for long-term partnerships.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider factors like durability, maintenance, and potential reapplication of oils or dyes over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import tariffs that can affect pricing. Understanding local market dynamics can also help in negotiating better terms.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and reliability can foster trust, often resulting in favorable deals.

Disclaimer on Pricing

Pricing for leather darkening solutions can vary widely based on the factors mentioned above. This analysis provides a general overview and should be used as a guideline. Always consult with specific suppliers for accurate quotes tailored to your needs.

Alternatives Analysis: Comparing how to make leather darker With Other Solutions

Exploring Alternatives for Darkening Leather: A Comparative Analysis

When it comes to enhancing the aesthetic appeal and durability of leather goods, various methods exist beyond traditional darkening techniques. As B2B buyers consider options for darkening leather, understanding alternative solutions can help in making informed decisions that align with their operational needs and product offerings.

Illustrative image related to how to make leather darker

Comparison Table

| Comparison Aspect | How To Make Leather Darker | Vegetable Tanning | Leather Dyeing |

|---|---|---|---|

| Performance | Provides a rich, natural finish while conditioning leather. | Enhances color depth and durability, but results can vary based on leather type. | Offers a wide range of color options, but can dry out leather if not applied properly. |

| Cost | Moderate cost for oils and creams, depending on quality. | Generally higher due to the natural materials and time-consuming process. | Variable; costs can range from low to high based on brand and quality. |

| Ease of Implementation | Simple DIY methods; requires minimal tools. | Requires skilled artisans for effective application. | Requires precision and technique, often best handled by professionals. |

| Maintenance | Low maintenance; reapplication as needed. | Moderate; periodic conditioning required to maintain quality. | High; may need frequent touch-ups and conditioning to prevent drying. |

| Best Use Case | Ideal for everyday leather goods needing revitalization. | Best for high-quality leather products that require a natural finish. | Suitable for creative projects where color customization is essential. |

Detailed Breakdown of Alternatives

What is Vegetable Tanning and How Does it Compare?

Vegetable tanning is a traditional method of leather treatment that uses tannins derived from plant sources. This method enhances the natural color of leather while providing durability and a unique finish. However, it can be more expensive and labor-intensive compared to simply applying oils. While vegetable-tanned leather can achieve deep, rich tones, the outcome is highly dependent on the type of leather used and the skill of the artisan. B2B buyers seeking premium, sustainable products may find this method aligns well with their brand values.

How Does Leather Dyeing Differ from Darkening Techniques?

Leather dyeing involves applying alcohol-based dyes that penetrate the leather fibers to change the color significantly. While this technique offers a broad spectrum of color options, it can lead to leather becoming dry and brittle over time if not treated with conditioning products post-application. Compared to darkening methods that enhance the leather’s natural oils, dyeing might require additional maintenance and care. For businesses focusing on custom-colored products, dyeing may be the preferred option, but the potential for damaging the leather should be carefully considered.

Conclusion: Choosing the Right Leather Darkening Solution

In selecting the most suitable method for darkening leather, B2B buyers must weigh the specific needs of their products against the characteristics of each alternative. Factors such as performance, cost, and maintenance are crucial in determining the best approach. For everyday leather goods that require a simple refresh, traditional darkening methods using oils may suffice. However, for high-quality items or custom projects, vegetable tanning or dyeing may provide the desired aesthetic and durability. Ultimately, understanding these alternatives will empower buyers to make decisions that enhance their product offerings and meet customer expectations.

Essential Technical Properties and Trade Terminology for how to make leather darker

What Are the Key Technical Properties for Darkening Leather?

Understanding the technical specifications when it comes to darkening leather is crucial for ensuring quality and consistency in the final product. Below are some essential properties that B2B buyers should consider:

1. Material Grade

Material grade refers to the quality of leather used, which significantly influences the darkening process. Full-grain leather, for example, retains the natural grain and imperfections, allowing it to absorb oils and dyes more effectively. Higher-grade leather will provide better results in terms of color richness and longevity, making it a vital consideration for businesses looking to enhance their leather products.

2. Color Fastness

Color fastness denotes the resistance of leather to fading or running when exposed to various conditions, such as light, moisture, and friction. This property is particularly important in B2B transactions as it ensures that the darker tones achieved through oils or dyes remain intact over time. Buyers should assess the color fastness ratings to ensure durability in their leather goods, especially for products intended for high-use environments.

3. Flexibility

Flexibility is a key property that affects the leather’s usability and comfort. The darkening process can sometimes alter this characteristic, depending on the oils or dyes used. For B2B buyers, ensuring that the leather retains its flexibility post-treatment is essential, especially for products like clothing or shoes that require movement and comfort.

4. Moisture Resistance

Moisture resistance is critical for leather products, particularly those exposed to varying climates. Darkening treatments should ideally enhance the leather’s ability to repel water, preventing damage and extending the lifespan of the product. Businesses should inquire about the moisture-resistant properties of the oils or dyes used, as this can impact customer satisfaction and product performance.

Illustrative image related to how to make leather darker

5. 耐久性

Durability refers to the leather’s ability to withstand wear and tear over time. The darkening process should not compromise this property; therefore, selecting high-quality oils or dyes that enhance rather than weaken the leather is crucial. Buyers must evaluate the long-term performance of darkened leather, ensuring that it meets their specific market demands.

What Are the Common Trade Terms in Leather Darkening Processes?

Familiarity with industry terminology is essential for effective communication and negotiation in the leather trade. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then marketed by another company under its brand name. In the context of leather goods, understanding OEM relationships can help buyers identify the source of their materials and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. This term is critical for B2B buyers to understand, as it can impact inventory costs and cash flow. Knowing the MOQ helps businesses plan their purchases more effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits quotes from suppliers for specific products or services. B2B buyers use RFQs to compare prices and terms from different vendors, making it a vital tool for cost-effective procurement in leather darkening processes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms helps B2B buyers navigate shipping, insurance, and risk management when sourcing leather products globally.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For businesses involved in leather darkening, understanding lead times is essential for planning production schedules and meeting customer demands.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their leather products and ensure successful transactions in the marketplace.

Navigating Market Dynamics and Sourcing Trends in the how to make leather darker Sector

What Are the Global Drivers Impacting the Leather Darkening Market?

The leather darkening market is influenced by several global drivers, including the growing demand for premium leather products across various sectors such as fashion, automotive, and furniture. International B2B buyers are increasingly seeking high-quality leather that not only meets aesthetic requirements but also offers durability and longevity. This demand is particularly strong in Europe and the Middle East, where leather goods are often seen as a status symbol. Moreover, advancements in technology have led to the development of innovative leather treatments that enhance the darkening process while ensuring the material’s integrity.

Illustrative image related to how to make leather darker

Emerging sourcing trends also indicate a shift towards customizable leather solutions. Buyers are looking for suppliers who can provide tailored options that meet specific color and texture preferences. The rise of e-commerce platforms has facilitated this trend by allowing buyers to connect directly with manufacturers and artisans worldwide. Additionally, there is an increasing focus on the use of natural and plant-based oils for darkening leather, driven by consumer preferences for eco-friendly products. This trend is gaining traction in regions like Africa and South America, where sustainable practices are becoming more prominent.

How Is Sustainability Reshaping the Leather Darkening Industry?

Sustainability and ethical sourcing are becoming central to the leather darkening sector. As global awareness of environmental issues grows, B2B buyers are placing a premium on sustainable practices throughout the supply chain. The leather industry, traditionally associated with significant environmental impacts due to chemical treatments and tanning processes, is undergoing a transformation. Companies are now prioritizing the use of environmentally friendly dyes and oils, which not only darken leather but also minimize ecological footprints.

Furthermore, certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining importance among buyers. These certifications assure buyers that the leather products they source adhere to rigorous environmental and ethical standards. The use of such certified materials not only enhances brand reputation but also appeals to a growing demographic of eco-conscious consumers. In this evolving landscape, establishing partnerships with suppliers who prioritize sustainability can yield competitive advantages in the marketplace.

What Is the Historical Context of Leather Darkening Techniques?

The techniques used to darken leather have evolved significantly over the centuries. Historically, natural oils and animal fats were the primary methods for achieving darker hues, reflecting the materials available at the time. As industrialization progressed, synthetic dyes emerged, offering a wider palette of colors but often at the expense of the leather’s natural properties.

In recent decades, there has been a resurgence of interest in traditional methods, as artisans and manufacturers alike recognize the benefits of natural treatments. This shift is not only about aesthetics but also about maintaining the leather’s flexibility and durability. The modern market now sees a blend of traditional and innovative methods, allowing for both rich colors and sustainable practices that cater to the demands of today’s discerning B2B buyers.

Illustrative image related to how to make leather darker

Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather darker

-

How do I solve the problem of uneven color when darkening leather?

To avoid uneven color when darkening leather, ensure that you prepare the surface properly by cleaning it thoroughly and allowing it to dry completely before application. Use a high-quality leather oil or dye, applying it in thin, even layers. Work in small sections and use circular motions for consistent coverage. After applying, allow it to dry fully, ideally overnight, before assessing the color. If necessary, a second coat can be applied for deeper color saturation. -

What is the best oil for darkening leather?

The best oil for darkening leather often depends on the specific type of leather and desired results. Mink oil is popular for its conditioning and protective properties, making it suitable for items like boots and outdoor gear. Neatsfoot oil is effective for quick fixes and restoring flexibility but should be used sparingly. For vegan options, coconut oil and beeswax provide good darkening effects, although they may leave a residue. Always test a small area first to ensure compatibility. -

What factors should I consider when sourcing leather darkening products internationally?

When sourcing leather darkening products, consider the supplier’s reputation, product quality, and compliance with international standards. Evaluate certifications, reviews, and case studies to ensure reliability. Additionally, assess the supplier’s ability to provide consistent supply and customization options to meet your specific needs. Understand local regulations regarding chemical usage, as these can vary significantly across regions, impacting your sourcing decisions. -

What are typical minimum order quantities (MOQ) for leather darkening products?

Minimum order quantities (MOQ) can vary widely based on the supplier and product type. Typically, MOQs range from 100 to 1,000 units for specialty items like leather oils and dyes. Some suppliers may offer lower MOQs for new clients or trial orders, while others may have higher requirements for bulk pricing. It’s essential to communicate your needs clearly to suppliers and inquire about flexible options, especially if you are testing a new product line. -

How can I vet suppliers for leather darkening products?

To vet suppliers effectively, start by conducting thorough research on their background, including years in business, product range, and customer testimonials. Request samples to assess product quality firsthand. Additionally, inquire about their production processes, sourcing of raw materials, and adherence to safety standards. Engaging in direct conversations or video calls can also help gauge their professionalism and responsiveness, ensuring that they align with your business values. -

What payment terms are common in international B2B transactions for leather products?

Common payment terms in international B2B transactions for leather products include options like Letter of Credit (LC), advance payment, and net 30 or net 60 days. Many suppliers prefer a partial upfront payment to secure the order, with the balance paid upon delivery or during shipping. It’s crucial to negotiate terms that protect both parties and to clarify any additional fees, such as shipping or customs duties, to avoid surprises. -

How should I handle quality assurance (QA) for leather darkening products?

Implementing a robust quality assurance (QA) process is essential when working with leather darkening products. Establish clear specifications for product quality, including color consistency, viscosity, and scent. Conduct regular inspections during production and upon receipt of goods to ensure compliance with your standards. Collaborating with suppliers on QA protocols can help mitigate risks and ensure that the final products meet your expectations. -

What logistics considerations should I keep in mind when importing leather products?

When importing leather products, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling leather goods to navigate the complexities of international shipping. Be aware of lead times for both production and shipping to avoid delays. Additionally, consider warehousing options if you need to manage inventory effectively upon arrival. Proper planning can streamline the import process and minimize costs.

Top 4 How To Make Leather Darker Manufacturers & Suppliers List

1. Reddit – Leather Care Essentials

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Leather dye, mink oil, Obenauf’s, beeswax, sunshine.

2. The Fedora Lounge – Darkening Medium Brown Leather

Domain: thefedoralounge.com

Registered: 2003 (22 years)

Introduction: The discussion revolves around methods to darken medium brown leather without using dye. Suggestions include: 1. Vaseline Petroleum Jelly – Apply outdoors on a sunny day, let it sit, then wipe off; may darken leather by one shade. 2. Neatsfoot Oil – Can cause leather to darken by a shade or two. 3. Mink Oil – Also has a color darkening effect. 4. Antique Stain – Wipe on, let sit, then wipe off; da…

3. Leatherworker – Neatsfoot Oil

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Neatsfoot oil, Extra Virgin Olive Oil, strong brewed coffee, walnut hulls

4. Leather Care – Neatsfoot Cream

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Leather Care – Neatsfoot Cream, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how to make leather darker

How Can Strategic Sourcing Enhance Leather Darkening Processes?

In summary, darkening leather is not merely an aesthetic choice; it also serves to enhance the material’s longevity and performance. By adopting a strategic sourcing approach, international B2B buyers can secure high-quality oils, dyes, and cleaning products that align with their specific needs, ensuring consistency and reliability in their leather care processes. Sourcing natural oils like mink and neatsfoot oil, or opting for specialized leather dyes, can provide superior results, allowing businesses to offer products that stand out in the marketplace.

Investing in quality materials and understanding the methods of application can significantly improve the durability and appeal of leather goods. For buyers in regions like Africa, South America, the Middle East, and Europe, establishing relationships with trusted suppliers can facilitate access to premium products, fostering innovation and sustainability in leather production.

As the global demand for high-quality leather goods continues to rise, now is the time to leverage strategic sourcing for a competitive edge. Engage with suppliers who prioritize quality and sustainability, and explore new methods to darken leather that will not only meet customer expectations but also enhance your brand’s reputation. Embrace these opportunities to position your business for success in an evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to how to make leather darker

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.