Introduction: Navigating the Global Market for alcantara suede

In the ever-evolving landscape of textiles, sourcing high-quality Alcantara suede presents both opportunities and challenges for B2B buyers. As a versatile synthetic material prized for its durability and aesthetic appeal, Alcantara is increasingly favored in industries such as automotive, fashion, and interior design. However, navigating the complexities of sourcing this premium fabric—whether for luxury car interiors in Saudi Arabia or high-end upholstery in Brazil—can be daunting. This guide aims to demystify the global market for Alcantara suede by providing actionable insights into various types, applications, and supplier vetting processes.

Buyers will gain a comprehensive understanding of Alcantara’s unique properties, including its sustainability credentials and maintenance requirements, enabling them to make informed purchasing decisions. We will explore the cost factors associated with Alcantara, helping you budget effectively while ensuring you receive a product that meets your quality standards. Additionally, our guide will delve into the critical aspects of supplier evaluation, ensuring that you partner with reputable manufacturers who adhere to the highest industry standards.

Empowering international B2B buyers from Africa, South America, the Middle East, and Europe, this guide equips you with the knowledge and resources needed to confidently navigate the Alcantara suede market. Whether you are looking to enhance your product offerings or secure a reliable source of this innovative material, our insights will pave the way for successful procurement strategies.

Table Of Contents

- Top 4 Alcantara Suede Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara suede

- Understanding alcantara suede Types and Variations

- Key Industrial Applications of alcantara suede

- 3 Common User Pain Points for ‘alcantara suede’ & Their Solutions

- Strategic Material Selection Guide for alcantara suede

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara suede

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara suede’

- Comprehensive Cost and Pricing Analysis for alcantara suede Sourcing

- Alternatives Analysis: Comparing alcantara suede With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara suede

- Navigating Market Dynamics and Sourcing Trends in the alcantara suede Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara suede

- Strategic Sourcing Conclusion and Outlook for alcantara suede

- Important Disclaimer & Terms of Use

Understanding alcantara suede Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alcantara | Classic suede-like texture; available in diverse colors | Automotive interiors, luxury goods | Pros: Soft, durable, customizable. Cons: Can wear over time if not maintained. |

| Alcantara EXO | Enhanced thickness and durability; water-resistant | Outdoor furniture, automotive | Pros: High durability, water-resistant. Cons: Heavier than standard Alcantara. |

| Alcantara Multi-layer | Multi-layer structure for added comfort and support | High-end seating, fashion items | Pros: Superior comfort, luxurious feel. Cons: Higher cost, may require specific cleaning methods. |

| Alcantara Eco | Eco-friendly production; made from recycled materials | Sustainable product lines, fashion | Pros: Sustainable, vegan-friendly. Cons: May have limited color options. |

| Alcantara Sport | Textured surface for improved grip and performance | Sports cars, performance gear | Pros: Excellent grip, lightweight. Cons: Prone to wear in high-contact areas. |

What are the Characteristics of Standard Alcantara?

Standard Alcantara is the quintessential suede-like fabric, known for its soft texture and wide range of color options. It is primarily used in automotive interiors and luxury goods, offering a premium look and feel. B2B buyers should consider its aesthetic appeal and versatility, but also be aware of the potential for wear over time, especially in high-traffic areas. Regular maintenance can mitigate these issues, making it a reliable choice for various applications.

How Does Alcantara EXO Stand Out in Durability?

Alcantara EXO is designed with enhanced thickness and durability, making it suitable for outdoor furniture and automotive applications. Its water-resistant properties provide added functionality, ensuring longevity even in challenging environments. B2B buyers should evaluate the trade-off between weight and durability; while it is heavier than standard Alcantara, its resilience makes it ideal for demanding uses. This type is particularly appealing for businesses focused on outdoor or high-traffic settings.

What Makes Multi-layer Alcantara Ideal for Comfort?

Alcantara Multi-layer features a sophisticated construction that enhances comfort and support, making it a preferred choice for high-end seating and fashion items. This type offers a luxurious feel that elevates the user experience, which is crucial for businesses in the luxury market. However, buyers should be prepared for a higher cost and specific cleaning requirements. Its premium nature can justify the investment, particularly for brands aiming to deliver exceptional comfort.

Why Choose Alcantara Eco for Sustainable Products?

Alcantara Eco is produced using recycled materials, aligning with the growing demand for sustainable products in the market. This type appeals to businesses looking to enhance their eco-friendly product lines, particularly in fashion and lifestyle sectors. While it may offer fewer color options, the benefits of being vegan-friendly and sustainable make it a compelling choice for environmentally conscious brands. B2B buyers should assess how this aligns with their corporate values and target audience preferences.

How Does Alcantara Sport Enhance Performance?

Alcantara Sport is engineered for improved grip and performance, making it a popular choice in sports cars and performance gear. Its textured surface provides excellent handling, which is essential for high-performance applications. Buyers should consider its suitability for high-contact areas, as it may show wear more quickly than other types. Nonetheless, its lightweight nature and superior performance characteristics can significantly enhance the appeal of sports-related products, making it an attractive option for manufacturers in that sector.

Key Industrial Applications of alcantara suede

| Industry/Sector | Specific Application of alcantara suede | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for seats and dashboards | Enhances luxury appeal, provides superior grip | Ensure compliance with automotive standards; consider flame retardant options. |

| Fashion & Apparel | High-end clothing and accessories | Offers a premium look and feel, lightweight | Look for sustainable sourcing; verify color and texture consistency. |

| Interior Design | Furniture upholstery | Adds a touch of elegance and durability | Assess stain resistance and ease of cleaning; ensure colorfastness. |

| Electronics | Device covers and accessories | Provides a soft touch and premium aesthetic | Evaluate durability against wear and tear; consider customization options. |

| Sports Equipment | Gear and apparel for athletes | Improves grip and comfort, lightweight | Check for moisture-wicking properties; assess performance under stress. |

How is Alcantara Suede Used in the Automotive Industry?

In the automotive sector, Alcantara suede is primarily used for upholstery in high-end vehicles, covering seats, dashboards, and steering wheels. Its unique texture not only enhances the aesthetic appeal but also offers superior grip, which is crucial for performance vehicles. International buyers must ensure that the material meets specific automotive safety and environmental standards, including flame retardant properties. Additionally, sourcing Alcantara from reputable manufacturers guarantees authenticity and compliance with industry regulations.

What Role Does Alcantara Suede Play in Fashion and Apparel?

Alcantara suede has carved a niche in the fashion industry, where it is used in high-end clothing and accessories. Its luxurious appearance and lightweight nature make it an attractive option for designers looking to elevate their products. For B2B buyers, especially in emerging markets like Brazil and Saudi Arabia, it’s essential to focus on sustainable sourcing practices and verify the consistency of colors and textures to maintain brand integrity. Collaborating with established suppliers can also facilitate access to exclusive designs and limited editions.

How is Alcantara Suede Utilized in Interior Design?

In interior design, Alcantara suede is favored for furniture upholstery due to its elegance and durability. It provides an upscale look while being easy to maintain, making it ideal for both residential and commercial applications. Buyers should consider the fabric’s stain resistance and cleaning ease, especially in high-traffic areas. Furthermore, ensuring colorfastness is crucial for maintaining the desired aesthetic over time. Sourcing from trusted manufacturers will enhance the project’s quality and longevity.

Why Choose Alcantara Suede for Electronics?

Alcantara suede is increasingly used in electronics, particularly for device covers and accessories. It offers a soft touch that enhances user experience while providing a premium aesthetic. For international B2B buyers, evaluating the material’s durability against wear and tear is essential, as is the availability of customization options to meet specific branding needs. Ensuring that the supplier can provide consistent quality is vital for maintaining product reputation in a competitive market.

How is Alcantara Suede Applied in Sports Equipment?

In the sports equipment industry, Alcantara suede is utilized in gear and apparel, where it enhances grip and comfort for athletes. Its lightweight nature and moisture-wicking properties make it suitable for high-performance applications. Buyers should assess the material’s performance under stress to ensure it meets the rigorous demands of athletic use. Establishing relationships with suppliers who understand the specific requirements of sports applications can lead to better product outcomes and innovations.

3 Common User Pain Points for ‘alcantara suede’ & Their Solutions

Scenario 1: Sourcing Quality Alcantara Suede for High-End Projects

The Problem:

B2B buyers often struggle to find suppliers that provide high-quality Alcantara suede that meets their exact specifications. This is particularly critical for industries like automotive and luxury fashion, where the material’s texture, durability, and aesthetic qualities can significantly impact the end product. The challenge is compounded by the presence of non-genuine alternatives that may not deliver the same performance or visual appeal, leading to potential dissatisfaction from clients and end-users.

The Solution:

To ensure the procurement of genuine Alcantara suede, buyers should establish relationships with reputable suppliers who are authorized distributors of Alcantara S.p.A. Conduct thorough research to verify the authenticity of the material by checking for certifications and sourcing information. When placing an order, specify the exact requirements regarding thickness, color, and texture. For instance, if your project demands a specific weight or thickness (such as 1.0-1.3 mm for backed Alcantara), clearly communicate this to your supplier. Additionally, consider requesting a sample before committing to larger orders to assess the material’s quality firsthand. By taking these steps, buyers can mitigate risks and ensure they receive the superior material necessary for their projects.

Scenario 2: Maintaining Alcantara Suede in High-Traffic Areas

The Problem:

One common pain point for B2B buyers is the maintenance of Alcantara suede in high-traffic environments, such as vehicle interiors or public seating areas. Over time, Alcantara can absorb oils and dirt, leading to visible wear and a decline in its appealing texture. This can result in costly replacements or repairs and can damage the brand’s reputation for quality if the material looks worn out prematurely.

The Solution:

To maintain the integrity of Alcantara suede in high-traffic areas, implement a proactive cleaning and care regimen. Regularly scheduled cleaning should involve using gentle, pH-balanced cleaning solutions specifically designed for Alcantara. Utilize soft brushes and microfiber cloths to avoid damaging the material’s nap. Educate your staff on proper cleaning techniques to ensure consistency. Additionally, consider applying a protective coating that is compatible with Alcantara to create a barrier against dirt and oils. Investing in these maintenance practices not only prolongs the life of the material but also enhances customer satisfaction by maintaining a pristine appearance.

Scenario 3: Addressing the Perceived Value of Alcantara Suede

The Problem:

B2B buyers often encounter skepticism from clients regarding the value of Alcantara suede compared to traditional leather or other materials. This skepticism can be especially pronounced in markets where natural materials are prized for their heritage and authenticity. Buyers may find it challenging to justify the premium price of Alcantara, especially in competitive bids where cost is a significant factor.

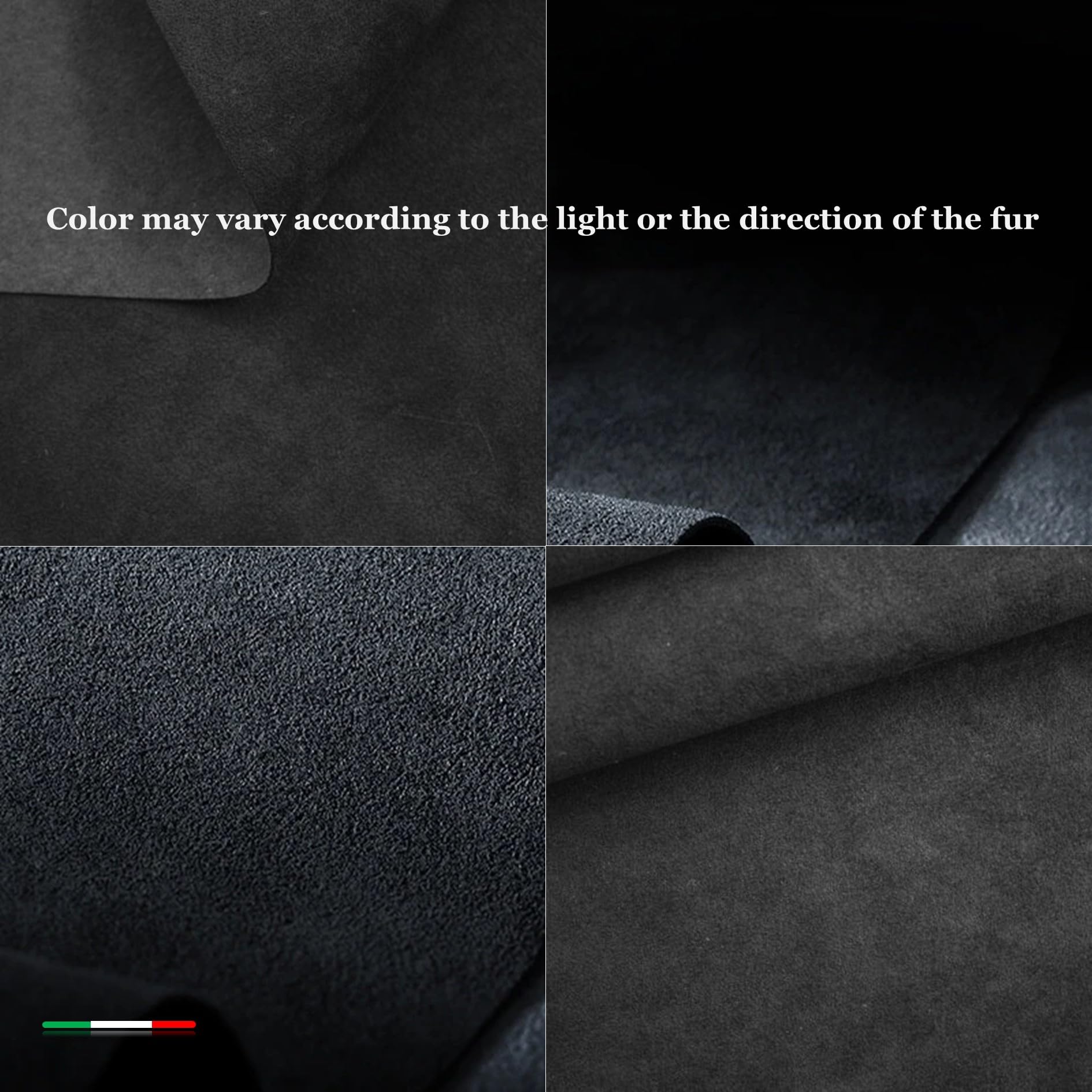

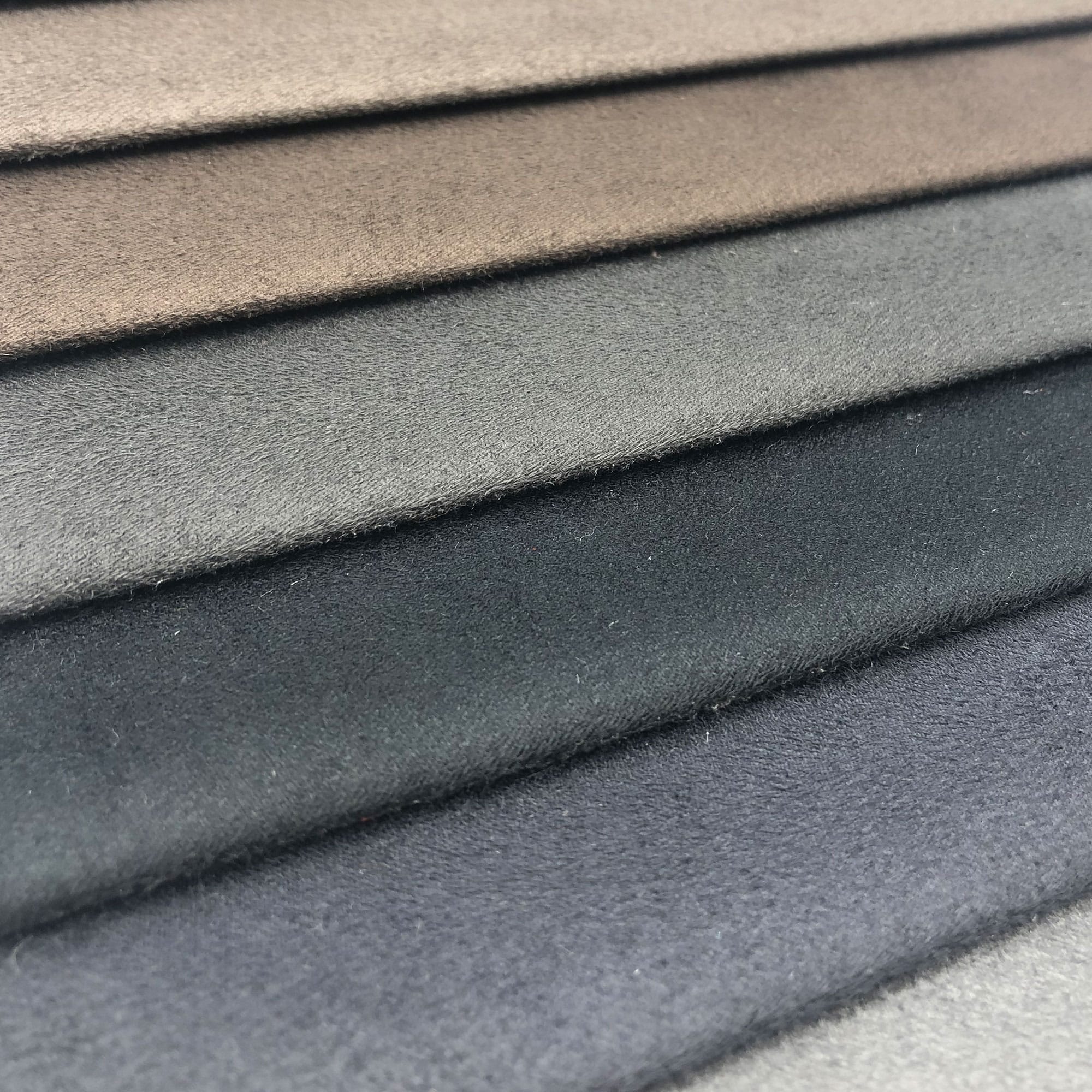

Illustrative image related to alcantara suede

The Solution:

To effectively communicate the value of Alcantara suede, buyers should focus on its unique benefits, including durability, versatility, and sustainability. Prepare a compelling presentation that highlights how Alcantara is not only a high-performance material but also a sustainable option, as it is produced without animal products and can be recycled. Share case studies or testimonials from reputable brands that have successfully used Alcantara in their products, showcasing the material’s aesthetic appeal and superior performance in demanding applications. Additionally, consider offering side-by-side comparisons that illustrate the long-term cost savings associated with Alcantara’s durability versus traditional leather. By educating clients on the multifaceted advantages of Alcantara, buyers can enhance its perceived value and strengthen their negotiating position.

Strategic Material Selection Guide for alcantara suede

What Are the Key Materials Used in Alcantara Suede Production?

Alcantara suede, a synthetic textile known for its luxurious feel and versatility, is primarily composed of a blend of polyester and polyurethane. However, various materials can impact its performance and application in different industries. Below, we analyze several common materials related to Alcantara suede from a B2B perspective, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

What Are the Key Properties of Polyester in Alcantara Suede?

Polyester is a primary component of Alcantara suede, contributing significantly to its durability and aesthetic appeal. This synthetic fiber is known for its excellent resistance to stretching and shrinking, making it ideal for applications that require stability under varying conditions. Polyester also boasts good moisture-wicking properties, which help maintain comfort in automotive and fashion applications.

Pros: Polyester is cost-effective and widely available, making it a popular choice for manufacturers. It also offers good color retention and is resistant to mildew and abrasion.

Cons: While durable, polyester can be less breathable than natural fibers, which may affect comfort in certain applications. Additionally, its environmental impact is a concern, as it is derived from petroleum-based sources.

Impact on Application: Polyester’s properties allow Alcantara suede to be used in automotive interiors, fashion, and upholstery, where durability and aesthetic appeal are essential.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM for textile performance. In regions like Europe, there is a growing demand for sustainable materials, prompting manufacturers to seek eco-friendly alternatives.

How Does Polyurethane Enhance Alcantara Suede?

Polyurethane is another critical component of Alcantara suede, providing a soft, suede-like texture that mimics natural leather. It enhances the material’s flexibility and resilience, allowing it to withstand wear and tear in high-traffic areas.

Illustrative image related to alcantara suede

Pros: Polyurethane is known for its excellent abrasion resistance and can be engineered to be flame-retardant, making it suitable for automotive and aviation applications. Its soft texture also adds to the premium feel of Alcantara.

Cons: The production of polyurethane can involve complex manufacturing processes, which may increase costs. Additionally, while it is a synthetic material, it may not appeal to consumers looking for natural products.

Impact on Application: Polyurethane’s properties make Alcantara suede an ideal choice for luxury automotive interiors, furniture, and fashion accessories, where a high-end look and feel are desired.

Considerations for International Buyers: Compliance with fire safety standards is crucial in regions like the Middle East, where regulations may be stricter. Buyers should also consider the sourcing of materials to align with sustainability goals.

What Role Does Nylon Play in Alcantara Suede?

Nylon is sometimes blended with Alcantara suede to enhance its strength and resilience. This synthetic polymer offers high tensile strength and excellent resistance to abrasion, making it suitable for demanding applications.

Pros: The addition of nylon can significantly improve the durability of Alcantara suede, making it ideal for high-wear areas such as automotive seats and upholstery. It also provides good elasticity, allowing the material to maintain its shape over time.

Cons: Nylon can be more expensive than polyester, potentially impacting the overall cost of the final product. Additionally, its environmental footprint is a concern, as it is also derived from petroleum.

Impact on Application: Nylon-enhanced Alcantara suede is particularly useful in automotive and industrial applications where durability is paramount.

Illustrative image related to alcantara suede

Considerations for International Buyers: Buyers should evaluate the cost-benefit ratio of using nylon in their products, especially in markets where price sensitivity is high, such as in parts of Africa and South America.

Summary Table of Material Analysis

| Material | Typical Use Case for alcantara suede | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Automotive interiors, upholstery | Cost-effective and durable | Less breathable than natural fibers | Medium |

| Polyurethane | Luxury automotive, fashion accessories | Soft texture, flame-retardant | Complex manufacturing processes | High |

| Nylon | High-wear upholstery, automotive | Excellent durability and elasticity | Higher cost compared to polyester | Medium to High |

This analysis provides a comprehensive overview of the materials commonly associated with Alcantara suede, offering valuable insights for B2B buyers seeking to make informed decisions in their sourcing strategies.

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara suede

What Are the Key Stages in the Manufacturing Process of Alcantara Suede?

The manufacturing of Alcantara suede is a sophisticated process that combines cutting-edge technology with artisanal craftsmanship. The production involves several key stages, each crucial for ensuring the material’s premium quality and performance.

Illustrative image related to alcantara suede

Material Preparation: How Are Raw Materials Sourced and Processed?

The primary ingredients for Alcantara suede are polyester and polyurethane, which are sourced from reputable suppliers to ensure consistent quality. The production begins with the careful selection of these raw materials, which are then subjected to rigorous quality control checks to verify their specifications.

Once the raw materials are confirmed, they undergo a series of treatments to enhance their properties. This includes the polymerization process, where the polyester and polyurethane are blended to create a synthetic fiber that mimics the softness and appearance of natural suede. This stage is critical, as it lays the foundation for the durability and aesthetic qualities of the final product.

How Is Alcantara Formed into Its Final Fabric Structure?

After material preparation, the next step is forming the Alcantara fabric. This process involves spinning the treated fibers into yarn, which is then woven or non-woven into sheets of fabric. The non-woven technique is particularly popular for Alcantara, as it allows for a more uniform texture and better performance characteristics.

The fabric is then coated with a polyurethane layer, enhancing its durability and making it more resistant to wear and tear. This step is essential for ensuring that the Alcantara can withstand the rigors of various applications, from automotive interiors to high-end fashion products.

What Are the Finishing Techniques Applied to Alcantara Suede?

Finishing techniques play a pivotal role in the overall quality and appeal of Alcantara. Once the fabric is formed, it undergoes several treatments to achieve the desired softness, color, and texture. These finishing processes may include dyeing, embossing, and applying protective coatings to enhance resistance to stains and fading.

Illustrative image related to alcantara suede

The dyeing process is particularly important for meeting the aesthetic demands of various industries. Alcantara is available in a wide array of colors and textures, allowing for customization according to client specifications. Protective coatings are applied to ensure that the fabric retains its appearance over time, even in high-use environments.

What International Quality Standards Are Applicable to Alcantara Suede?

Quality assurance is paramount in the production of Alcantara suede. To ensure that the final product meets both consumer expectations and regulatory requirements, manufacturers adhere to several international standards.

Which ISO Standards Are Relevant for Quality Assurance?

ISO 9001 is one of the most recognized quality management standards globally. It provides a framework for consistent quality across production processes. Manufacturers of Alcantara suede often pursue ISO 9001 certification to demonstrate their commitment to quality and customer satisfaction.

In addition to ISO 9001, there may be other industry-specific certifications relevant to Alcantara production. For example, the CE marking indicates compliance with European health, safety, and environmental protection standards, which can be crucial for B2B buyers in Europe.

Illustrative image related to alcantara suede

What Are the Key Quality Control Checkpoints in Alcantara Manufacturing?

To ensure the highest quality, manufacturers implement several quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials before they enter the production line. The goal is to verify that all materials meet predefined standards and specifications.

-

In-Process Quality Control (IPQC): During manufacturing, various tests are conducted to monitor the quality of the product in real-time. This may include checks on fabric thickness, color consistency, and texture.

-

Final Quality Control (FQC): Once production is complete, finished products undergo a final inspection to ensure they meet all quality standards before being shipped to clients.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential for ensuring product reliability.

What Auditing Procedures Should Buyers Consider?

Conducting supplier audits can provide valuable insights into a manufacturer’s quality control practices. Buyers should consider the following:

-

On-Site Inspections: Regular visits to the manufacturing facility can help buyers assess the production environment, quality control processes, and adherence to international standards.

-

Requesting Quality Reports: Buyers should ask for quality reports that detail the results of IQC, IPQC, and FQC checks. These documents can reveal the consistency and reliability of the supplier’s quality assurance measures.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be particularly beneficial for buyers who may not have the resources to conduct thorough audits themselves.

What Are the Quality Control and Certification Nuances for International Buyers?

Navigating the complexities of international trade can present unique challenges for B2B buyers. Understanding the nuances of quality control and certification can help mitigate risks associated with sourcing Alcantara suede.

Illustrative image related to alcantara suede

How Do Cultural and Regulatory Differences Impact Quality Standards?

Buyers from different regions may encounter variations in quality expectations and regulatory requirements. For instance, while European markets may prioritize environmental sustainability and compliance with CE regulations, buyers in other regions might focus more on durability and performance.

Understanding these cultural and regulatory differences is crucial for making informed purchasing decisions. Buyers should communicate openly with suppliers to clarify quality expectations and ensure that all products meet local regulatory standards.

What Should Buyers Know About Sustainability Certifications?

Sustainability is becoming increasingly important in the textile industry. Buyers should inquire about any sustainability certifications that a supplier holds, such as Global Organic Textile Standard (GOTS) or OEKO-TEX certification. These certifications can provide assurance that the Alcantara suede is produced with minimal environmental impact and adheres to ethical labor practices.

Illustrative image related to alcantara suede

By understanding the manufacturing processes, quality assurance measures, and certification nuances, B2B buyers can make informed decisions when sourcing Alcantara suede, ensuring they receive a product that meets their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara suede’

To facilitate your procurement of Alcantara suede, this guide outlines a step-by-step checklist designed specifically for B2B buyers. Following this checklist will ensure you make informed decisions, ultimately leading to a successful purchase.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for Alcantara suede. This includes dimensions, thickness, and specific applications (e.g., automotive interiors, fashion, or furniture). Knowing these details helps streamline your search and ensures that the materials you procure meet your project needs.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to identify reputable suppliers specializing in Alcantara suede. Look for companies with a strong track record, positive reviews, and relevant industry experience. Utilize platforms like trade shows, industry directories, and online marketplaces to compile a list of potential suppliers.

- Consider Global Reach: Suppliers with international shipping capabilities can help you avoid logistical issues, especially if you are sourcing from regions like Africa or South America.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; consider reaching out to existing customers for first-hand feedback.

- Check Certifications: Ensure that the supplier complies with industry standards and sustainability practices, as Alcantara is often marketed as an eco-friendly alternative.

Step 4: Request Samples for Quality Assessment

Once you have narrowed down potential suppliers, request samples of Alcantara suede to assess the quality firsthand. This step is vital, as it allows you to evaluate the texture, durability, and color consistency.

- Test Durability: Consider performing basic wear tests on the samples to see how they hold up under typical usage conditions.

Step 5: Negotiate Pricing and Terms

With quality samples in hand, engage in negotiations with your chosen supplier. Discuss pricing, minimum order quantities, and payment terms. Be transparent about your budget and any constraints to foster a collaborative relationship.

- Explore Bulk Discounts: If you plan to make large orders, inquire about volume discounts or loyalty programs that could reduce costs.

Step 6: Review Shipping and Logistics Options

Before finalizing your order, clarify the shipping methods and logistics involved. Discuss lead times, shipping costs, and delivery timelines to ensure they align with your project schedule.

- Understand Customs Regulations: If sourcing internationally, familiarize yourself with any customs regulations or import duties that may apply to Alcantara suede.

Step 7: Establish a Clear Communication Channel

After placing your order, maintain open lines of communication with your supplier. Regular updates on production status, shipping details, and any potential issues can help prevent misunderstandings and delays.

- Utilize Technology: Consider using project management tools to track progress and maintain documentation of all communications for future reference.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing Alcantara suede, ensuring they obtain high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for alcantara suede Sourcing

What Are the Key Cost Components in Alcantara Suede Sourcing?

When sourcing Alcantara suede, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: Alcantara is a synthetic textile made from a proprietary blend of polyester and polyurethane. The price per foot can range from approximately $55, depending on quality and supplier. Genuine Alcantara, made in Italy, typically commands higher prices due to its brand value and quality assurance.

-

Labor: Labor costs will vary based on the location of production. Regions with lower labor costs may reduce overall sourcing expenses, but this can also affect quality. It’s essential to balance cost with the expertise required for handling and processing Alcantara.

-

Manufacturing Overhead: This includes costs related to the production facility, utilities, and equipment maintenance. A well-managed facility ensures higher quality and efficiency, impacting the overall cost.

-

Tooling: If custom designs or specifications are required, tooling costs can add significantly to the initial investment. This is particularly relevant for buyers looking for unique textures or colors.

-

Quality Control (QC): Ensuring the quality of Alcantara is vital, especially for high-end applications in automotive or fashion industries. QC measures can incur additional costs but are necessary to maintain product integrity.

-

Logistics: Transportation costs will vary based on the supplier’s location and the buyer’s destination. International shipping involves customs duties, taxes, and potential tariffs, which can add complexity and cost.

-

Margin: Suppliers will typically include a margin that reflects their operational costs and desired profit. This margin can vary widely based on the supplier’s reputation and market demand.

How Do Price Influencers Affect Alcantara Suede Costs?

Several factors can influence the pricing of Alcantara suede, and understanding these can help buyers negotiate better deals:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing discounts. Suppliers may set a MOQ, which can affect initial sourcing costs.

-

Specifications and Customization: Custom colors, patterns, or finishes may increase the price. Buyers should clearly communicate their needs to avoid unexpected costs.

-

Material Quality and Certifications: Genuine Alcantara with certifications for sustainability and performance may be priced higher. Buyers should verify the authenticity to ensure they receive the expected quality.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers might offer better quality assurance, but at a premium.

-

Incoterms: Understanding shipping terms (like FOB, CIF, etc.) is crucial for calculating total costs. These terms dictate who bears responsibility for shipping, insurance, and tariffs, influencing the overall price.

What Are the Essential Buyer Tips for Cost-Efficiency in Alcantara Sourcing?

To optimize costs when sourcing Alcantara suede, international buyers should consider the following strategies:

Illustrative image related to alcantara suede

-

Negotiate Pricing: Always negotiate with suppliers. Leverage volume purchases or long-term contracts to secure better rates.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider long-term costs associated with maintenance, durability, and potential waste. Alcantara’s longevity can make it more cost-effective than cheaper alternatives.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, import duties, and local taxes can significantly affect pricing. Buyers in regions like Africa, South America, the Middle East, and Europe should account for these factors when budgeting.

-

Research Local Suppliers: In addition to international suppliers, exploring local options can reduce logistics costs and lead to better pricing through lower shipping expenses.

Disclaimer on Indicative Pricing

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct thorough research and request quotes from multiple suppliers to ensure competitive pricing and best value.

Alternatives Analysis: Comparing alcantara suede With Other Solutions

The quest for high-quality materials in various applications often leads buyers to consider alternatives that can meet similar performance standards. Alcantara suede, a synthetic textile renowned for its luxurious feel and versatility, is frequently compared to other materials in the market. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Alcantara Suede | UltraSuede | MicroSuede |

|---|---|---|---|

| Performance | Excellent grip, durable, flame retardant | Comparable softness, durable, but less grip | Soft texture, good durability, but less premium feel |

| Cost | $55 per linear foot | Generally lower cost | Similar to UltraSuede |

| Ease of Implementation | Easy to cut and sew, versatile | Easy to work with | Easy to work with |

| Maintenance | Requires gentle cleaning | Similar maintenance needs | Easy maintenance, machine washable |

| Best Use Case | Automotive, luxury interiors | Fashion, upholstery | General upholstery, fashion |

What is UltraSuede and How Does it Compare?

UltraSuede is a synthetic fabric that mimics the appearance and feel of suede. It is widely used in fashion and upholstery due to its luxurious look and ease of maintenance. The primary advantage of UltraSuede is its affordability compared to Alcantara, making it an attractive option for budget-conscious buyers. However, it may not offer the same level of grip or performance as Alcantara, particularly in high-stress applications like automotive interiors where durability and safety are paramount.

How Does MicroSuede Stack Up?

MicroSuede is another alternative that offers a soft texture and good durability. It is often used in everyday applications, including clothing and furniture. While MicroSuede is easy to maintain and can be machine washed, it lacks the premium feel and the performance characteristics associated with Alcantara. This can make it less desirable for high-end applications where aesthetic and tactile qualities are critical. Additionally, MicroSuede may not provide the same level of heat resistance or flame retardancy that Alcantara offers, making it less suitable for automotive or industrial uses.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting between Alcantara suede and its alternatives, B2B buyers should carefully assess their specific requirements, such as performance criteria, budget constraints, and the intended application. Alcantara stands out for its superior performance and luxury appeal, making it ideal for high-end automotive and design projects. In contrast, options like UltraSuede and MicroSuede may offer cost-effective solutions for less demanding applications. Ultimately, understanding the unique attributes and limitations of each material will empower buyers to make choices that align with their operational needs and brand values.

Essential Technical Properties and Trade Terminology for alcantara suede

What Are the Key Technical Properties of Alcantara Suede?

Alcantara suede, known for its luxurious feel and versatile applications, possesses several critical technical properties that are vital for B2B buyers to understand. Here are some of the most important specifications:

-

Material Composition: Alcantara is a synthetic suede-like fabric made from a blend of polyester and polyurethane. This unique composition allows it to mimic the aesthetic qualities of natural suede while offering enhanced durability and ease of maintenance. For B2B buyers, understanding the material composition is essential for evaluating the performance and suitability of Alcantara for various applications, from automotive interiors to fashion.

-

Thickness Specifications: Alcantara comes in various thicknesses, typically ranging from 0.83 mm to 1.3 mm. The unbacked thickness is approximately 0.83 mm to 1.0 mm, while the backed thickness ranges from 1.0 mm to 1.3 mm. These measurements are crucial for manufacturers and designers who need to ensure that the fabric meets specific design and structural requirements, especially in high-stress environments like automotive or furniture upholstery.

-

Width of the Fabric: Alcantara is usually available in widths of 56 inches (142 cm) or greater. This specification is significant for B2B buyers as it affects the amount of fabric needed for large-scale projects, helping in budgeting and minimizing waste during production.

-

Durability and Wear Resistance: Alcantara is recognized for its durability and ability to withstand wear and tear better than traditional leather. This property is particularly important in industries where high traffic and frequent use are expected, such as automotive or hospitality. Buyers must consider this feature to ensure long-term satisfaction and performance in their applications.

-

Flame Retardancy: The ability to make Alcantara flame retardant is a critical property for applications in automotive and aviation sectors. This specification ensures that the material complies with safety regulations, providing peace of mind to B2B buyers focused on safety standards.

What Are Common Trade Terminology Terms Related to Alcantara Suede?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B sector. Here are several key terms commonly used in relation to Alcantara suede:

Illustrative image related to alcantara suede

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of Alcantara, OEMs may utilize this fabric in their products, such as automotive interiors. Understanding OEM relationships is vital for B2B buyers to establish partnerships and streamline supply chains.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For Alcantara suede, this is an important consideration for businesses looking to manage inventory and costs effectively. Buyers should negotiate MOQs to align with their project requirements while ensuring supplier compliance.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. When procuring Alcantara, an RFQ allows buyers to compare pricing and terms from various suppliers, facilitating informed decision-making.

-

Incoterms (International Commercial Terms): These are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping, risk, and insurance responsibilities when importing Alcantara from manufacturers abroad.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the product. For Alcantara suede, understanding lead times is crucial for project planning and ensuring timely delivery, especially in industries with tight deadlines.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing Alcantara suede, enhancing their overall procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the alcantara suede Sector

What Are the Current Market Dynamics and Key Trends in the Alcantara Suede Sector?

The Alcantara suede market is witnessing a transformative phase driven by several global factors. As an innovative synthetic material, Alcantara has gained traction in various sectors, particularly automotive, fashion, and interior design. One key trend is the growing preference for lightweight, durable materials that enhance performance without compromising aesthetics. This is particularly pertinent for automotive manufacturers in regions like Europe and the Middle East, where performance and luxury are paramount. Furthermore, as digital transformation reshapes B2B sourcing, technologies such as e-commerce platforms and supply chain management software are becoming essential for international buyers to streamline procurement processes.

Emerging markets in Africa and South America are also becoming increasingly significant for Alcantara suppliers. These regions are experiencing a rise in demand for high-quality materials in their burgeoning automotive and fashion industries. Buyers in these markets are looking for reliable suppliers who can provide both small and bulk orders, as seen in offerings like Alcantara sold by the linear foot. This flexibility caters to both small designers and large-scale manufacturers, making it crucial for suppliers to adopt scalable production methods.

Additionally, sustainability is becoming a pivotal factor influencing purchasing decisions. As B2B buyers prioritize eco-friendly materials, Alcantara’s commitment to sustainable practices positions it favorably in the global market. The ability to source Alcantara that meets strict environmental and ethical standards will be a decisive factor for buyers across continents.

How Important Is Sustainability and Ethical Sourcing in the Alcantara Suede Sector?

Sustainability and ethical sourcing are no longer optional in the Alcantara suede sector; they are essential components of a successful B2B strategy. The environmental impact of materials used in production is under increasing scrutiny from consumers and regulatory bodies alike. Alcantara’s manufacturing process emphasizes sustainability, utilizing eco-friendly practices that minimize waste and energy consumption. This commitment not only mitigates environmental risks but also aligns with the values of modern consumers and businesses alike.

Illustrative image related to alcantara suede

Moreover, ethical supply chains are vital for maintaining brand integrity and trust. B2B buyers are increasingly seeking suppliers who can demonstrate compliance with environmental regulations and social responsibility standards. Certifications like OEKO-TEX or Global Organic Textile Standard (GOTS) can serve as valuable indicators of a supplier’s commitment to sustainable practices. This focus on “green” certifications is particularly pertinent for international buyers in regions like Europe and North America, where sustainability is a key purchasing criterion.

In addition to the environmental aspects, the shift towards vegan and cruelty-free products has also gained momentum. Alcantara’s synthetic nature allows it to be marketed as an animal-friendly alternative to traditional leather, appealing to a broader audience. For B2B buyers, sourcing Alcantara that is both high-quality and ethically produced offers a competitive advantage in a market increasingly driven by sustainability.

What Is the Historical Context of Alcantara Suede in the B2B Landscape?

Alcantara suede, a synthetic textile developed in the 1970s, has its roots in innovative material science. Originally created by a Japanese chemist, it was later manufactured by Alcantara S.p.A., an Italian company known for its commitment to quality and sustainability. Over the decades, Alcantara has established itself as a leading choice for luxury brands, particularly in the automotive industry, where it has been used extensively in high-end vehicles. Its unique combination of aesthetics and performance has made it synonymous with premium quality.

Illustrative image related to alcantara suede

The evolution of Alcantara has been marked by a continuous dialogue with the creative industries, leading to its adoption in various applications beyond automotive, including fashion, furniture, and consumer electronics. As B2B buyers today navigate an increasingly complex market, understanding the historical significance of Alcantara can provide valuable insights into its enduring appeal and potential for future applications. This historical context is particularly relevant for international buyers looking to leverage the material’s unique properties to enhance their product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara suede

-

How do I ensure the quality of Alcantara suede before placing a bulk order?

To ensure the quality of Alcantara suede, request samples from potential suppliers. Evaluate the texture, thickness, and color consistency. Additionally, inquire about the manufacturing process and certifications, such as ISO or sustainability credentials. Establish a quality assurance protocol that includes third-party inspections before shipment. This can help mitigate risks associated with defects and ensure that the material meets your specifications. -

What are the minimum order quantities (MOQs) for Alcantara suede?

Minimum order quantities for Alcantara suede can vary significantly depending on the supplier. Typically, MOQs range from 10 to 50 linear yards, depending on the supplier’s production capabilities and your specific requirements. It’s advisable to communicate your needs clearly and negotiate MOQs based on your project scale. Some suppliers may offer flexibility for first-time buyers or bulk orders. -

What payment terms should I expect when sourcing Alcantara suede internationally?

Payment terms for international purchases of Alcantara suede often include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may request a deposit of 30-50% upfront, with the balance due before shipment. It’s essential to clarify payment terms during negotiations to ensure both parties are aligned. Always consider using secure payment methods to protect your investment. -

What customization options are available for Alcantara suede?

Customization options for Alcantara suede can include color selection, thickness, and texture variations. Some suppliers may offer printing or embossing services to create unique patterns or branding. It’s essential to communicate your design specifications early in the process and verify whether the supplier can meet your customization needs within your timeline and budget. -

How can I vet suppliers of Alcantara suede for reliability?

To vet suppliers effectively, research their reputation through online reviews, industry forums, and references from previous clients. Verify their certifications and compliance with industry standards. Conduct virtual or in-person visits to their facilities if feasible, and assess their production capabilities. Establish clear communication channels to ensure responsiveness and transparency throughout the sourcing process. -

What logistics considerations should I keep in mind when importing Alcantara suede?

When importing Alcantara suede, consider shipping methods, customs duties, and lead times. Collaborate with logistics providers experienced in handling textiles to ensure timely delivery. Be aware of import regulations in your country, including any tariffs that may apply. Clear communication with your supplier regarding shipping terms (e.g., FOB, CIF) can help manage expectations and costs effectively. -

What are the best practices for maintaining Alcantara suede in commercial applications?

To maintain Alcantara suede, implement regular cleaning protocols using gentle cleaning solutions and soft brushes. Avoid harsh chemicals that can damage the fabric. Encourage users to keep the material dry and free from oils and dirt to prolong its lifespan. Establish a periodic inspection schedule to assess wear and tear, allowing for timely maintenance or replacement as necessary. -

How does Alcantara suede compare to other upholstery materials in terms of sustainability?

Alcantara suede is known for its eco-friendly attributes, as it is produced without animal products and is often made from recycled materials. In comparison to traditional leather, Alcantara has a lower environmental impact due to its synthetic composition and sustainable manufacturing practices. When sourcing Alcantara, inquire about the supplier’s commitment to sustainability and any certifications that support their environmental initiatives.

Top 4 Alcantara Suede Manufacturers & Suppliers List

1. Relicate – Alcantara by the Linear Foot

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Alcantara by the Linear Foot – Price: $55.00; Available Colors: 9040 Black (Unbacked, Backed, Perforated, Starlite Perforated, Multilayer), 9002 Anthracite (Unbacked, Backed), 9052 Dark Charcoal (Unbacked), 2957 Chic Grey (Unbacked), 2934 Silver Grey (Unbacked, Backed), 4978 Pearl Grey (Backed), 1452 Lemon Yellow (Unbacked), 2969 Mango (Unbacked), 4996 Goya (Unbacked, Backed), 2916 Rubin (Unbacked…

2. Alcantara – Versatile Sustainable Material

Domain: alcantara.com

Registered: 1996 (29 years)

Introduction: Alcantara is a 100% Italian brand known for its versatility and commitment to sustainability. It combines aesthetics and performance, making it suitable for various applications in art, design, fashion, luxury, and automotive industries. The material is characterized by its emotional feel, technological innovation, and endless possibilities for customization. Alcantara has a strong presence in glo…

3. Carwow – Alcantara Upholstery

Domain: carwow.co.uk

Registered: 2011 (14 years)

Introduction: Alcantara is a synthetic textile made from a blend of polyester and polyurethane, developed in the 1970s by a Japanese chemist and manufactured by the Italian company Alcantara. It is commonly used in car interiors for upholstery on seats, dashboards, arm rests, door cards, transmission tunnels, sun visors, and headliners. Pros include better grip than leather or plastic, flame retardant propertie…

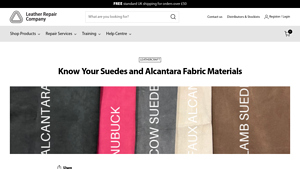

4. Leather Repair Company – Leather Care & Restoration Services

Domain: leatherrepaircompany.com

Registered: 2007 (18 years)

Introduction: Leather Repair Company offers various products and services related to leather care and restoration. Key product categories include: 1. Leather Cleaning & Stain Removal 2. Leather Protection 3. Leather Repairs (Holes, Rips, Scratches, Scuffs, Burns) 4. Leather Colour Restoration and Recolouring 5. Applicators & Accessories 6. Care & Restoration Kits 7. Sneakers/Trainers Care & Customisation Additi…

Strategic Sourcing Conclusion and Outlook for alcantara suede

As the global demand for high-quality materials like Alcantara suede continues to rise, strategic sourcing becomes paramount for international B2B buyers. This synthetic textile, renowned for its versatility and premium aesthetics, offers distinct advantages across various industries, particularly in automotive, fashion, and interior design. Its unique properties—such as superior grip, durability, and a luxurious feel—make it an attractive alternative to traditional materials.

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing Alcantara is essential. Engaging with reputable suppliers ensures access to genuine products that meet quality standards and sustainability criteria. Moreover, leveraging the flexibility of purchasing Alcantara by the linear foot enables businesses to tailor their orders according to specific project needs, minimizing waste and optimizing inventory management.

Looking ahead, the increasing emphasis on sustainable materials and innovative applications will likely drive further interest in Alcantara suede. We encourage B2B buyers to explore partnerships with trusted manufacturers and distributors to stay ahead of trends and capitalize on the growing market for this exceptional fabric. Embrace the potential of Alcantara to elevate your offerings and differentiate your brand in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to alcantara suede

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.