Introduction: Navigating the Global Market for alcantara headliner material

In today’s competitive automotive and interior design markets, sourcing high-quality alcantara headliner material poses a significant challenge for international B2B buyers. With a diverse array of suppliers and products available, it can be daunting to navigate the intricacies of material specifications, quality assurance, and cost-effectiveness. This guide aims to demystify the process of procuring alcantara headliner material, offering insights into its various types, applications, and essential supplier vetting criteria.

Throughout this comprehensive resource, we will explore the unique characteristics of alcantara, such as its durability, ease of maintenance, and aesthetic appeal, which make it an ideal choice for headliners in automotive and luxury interiors. Additionally, we will provide actionable strategies for evaluating suppliers, understanding pricing structures, and assessing the overall value of your investments. By the end of this guide, B2B buyers from regions including Africa, South America, the Middle East, and Europe—such as Nigeria and Vietnam—will be equipped with the knowledge necessary to make informed purchasing decisions.

Empowering your business with the right materials can enhance product offerings and customer satisfaction, ultimately leading to greater success in the global marketplace. This guide serves as a strategic tool, ensuring that you not only find the right alcantara headliner material but also build lasting partnerships with reliable suppliers.

Table Of Contents

- Top 6 Alcantara Headliner Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara headliner material

- Understanding alcantara headliner material Types and Variations

- Key Industrial Applications of alcantara headliner material

- 3 Common User Pain Points for ‘alcantara headliner material’ & Their Solutions

- Strategic Material Selection Guide for alcantara headliner material

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara headliner material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara headliner material’

- Comprehensive Cost and Pricing Analysis for alcantara headliner material Sourcing

- Alternatives Analysis: Comparing alcantara headliner material With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara headliner material

- Navigating Market Dynamics and Sourcing Trends in the alcantara headliner material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara headliner material

- Strategic Sourcing Conclusion and Outlook for alcantara headliner material

- Important Disclaimer & Terms of Use

Understanding alcantara headliner material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

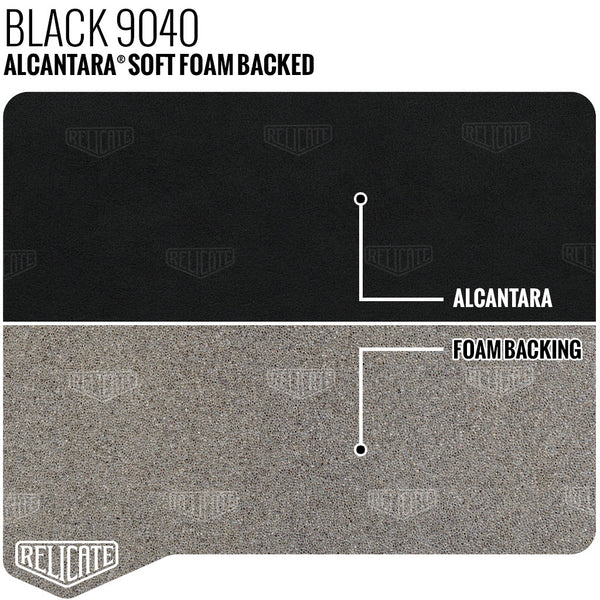

| Alcantara Soft Foam Backed | 2mm foam backing, single layer construction | Automotive headliners, interior panels | Pros: Durable, easy to clean; Cons: Higher cost than non-foam options. |

| Alcantara Unbacked | Lightweight, no foam backing, more flexible | Custom upholstery, fashion accessories | Pros: Lightweight, versatile; Cons: Less durable, may require additional adhesive. |

| Alcantara Performance | Enhanced resistance to wear, UV protection, and colorfastness | High-end automotive, luxury interiors | Pros: Long-lasting, maintains appearance; Cons: Premium pricing. |

| Alcantara Eco-Friendly | Made from recycled materials, sustainable production methods | Eco-conscious brands, green initiatives | Pros: Sustainable, unique selling point; Cons: Limited color options. |

| Alcantara Faux Suede | Synthetic alternative to traditional suede, budget-friendly | Entry-level automotive, budget designs | Pros: Cost-effective, decent aesthetics; Cons: Inferior durability compared to genuine Alcantara. |

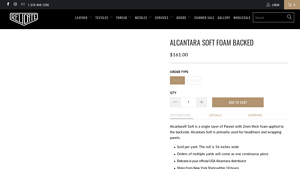

What Are the Key Features of Alcantara Soft Foam Backed Material?

Alcantara Soft Foam Backed is characterized by its 2mm foam backing, providing both comfort and durability. This type is primarily utilized in automotive applications for headliners and interior panels. Its composition allows for easy cleaning and maintenance, making it ideal for environments where aesthetics and functionality are crucial. B2B buyers should consider its higher price point compared to non-foam options, but the investment often pays off in terms of longevity and performance.

How Does Alcantara Unbacked Differ from Other Variants?

Alcantara Unbacked is recognized for its lightweight and flexible nature, which makes it suitable for custom upholstery projects and fashion accessories. This variant lacks foam backing, allowing for greater versatility in applications but also requiring careful handling and adhesive application. B2B buyers should weigh the benefits of flexibility against potential durability issues, particularly in high-traffic areas.

What Makes Alcantara Performance Ideal for Luxury Applications?

Alcantara Performance is engineered for enhanced wear resistance and UV protection, making it a top choice for high-end automotive interiors and luxury applications. This variant maintains its appearance over time, ensuring that investments in premium vehicles remain visually appealing. While the pricing is on the higher side, the return on investment is evident in its durability and aesthetic longevity, appealing to brands focused on quality.

Why Choose Alcantara Eco-Friendly for Sustainable Initiatives?

Alcantara Eco-Friendly is produced using recycled materials and sustainable methods, catering to businesses that prioritize environmental responsibility. This variant offers a unique selling point for eco-conscious brands, although it may come with a limited color palette. B2B buyers looking to align with green initiatives will find this option attractive, provided they can accommodate the potential constraints in design options.

How Does Alcantara Faux Suede Compare in Terms of Cost?

Alcantara Faux Suede presents a budget-friendly alternative to traditional Alcantara materials, making it suitable for entry-level automotive applications and budget-conscious designs. While it offers decent aesthetics, it falls short in durability compared to genuine Alcantara options. Buyers should consider their target market and application needs, balancing cost against the potential for wear and tear in high-use environments.

Key Industrial Applications of alcantara headliner material

| Industry/Sector | Specific Application of alcantara headliner material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior headliners for luxury vehicles | Enhances aesthetic appeal and perceived value | Ensure high-quality foam backing for durability |

| Aviation | Cabin interiors in commercial aircraft | Lightweight yet durable, improves passenger comfort | Compliance with aviation safety standards |

| Furniture | Upholstery for high-end furniture | Provides a luxurious feel and easy maintenance | Color matching and texture consistency are crucial |

| Sports Equipment | Custom padding and interior for sporting goods | Offers superior grip and durability under stress | Evaluate wear resistance and cleaning ease |

| Fashion Industry | Accessories and apparel detailing | Adds a premium look and tactile experience | Source from reputable suppliers to ensure authenticity |

How is Alcantara Headliner Material Used in the Automotive Sector?

In the automotive industry, alcantara headliner material is predominantly utilized for luxury vehicle interiors. It is favored for its aesthetic appeal, providing a sophisticated finish that enhances the overall value of the vehicle. Alcantara’s lightweight nature contributes to better fuel efficiency, while its sound-absorbing properties improve cabin acoustics. International B2B buyers must prioritize sourcing high-quality foam-backed variants to ensure durability and ease of installation, particularly in regions with varying climates like Africa and South America, where temperature fluctuations can impact material performance.

What Role Does Alcantara Play in Aviation Interiors?

In aviation, alcantara headliner material is used extensively in the interiors of commercial aircraft. Its lightweight properties help reduce overall aircraft weight, contributing to fuel efficiency while maintaining high durability standards. The material is also easy to clean and maintain, which is crucial for meeting strict hygiene regulations in the aviation industry. B2B buyers in this sector should focus on sourcing materials that comply with aviation safety standards, ensuring that they can withstand the rigors of frequent use and high passenger traffic.

How is Alcantara Beneficial in High-End Furniture Upholstery?

The furniture industry leverages alcantara headliner material for high-end upholstery applications, where a luxurious feel and visual appeal are paramount. Its soft texture and variety of colors allow designers to create bespoke pieces that stand out in the market. Additionally, alcantara is easy to clean, making it suitable for both residential and commercial furniture settings. Buyers should consider sourcing from reputable suppliers to guarantee color consistency and material authenticity, especially in regions like Europe and the Middle East where design standards are particularly high.

In What Ways Does Alcantara Enhance Sports Equipment?

Alcantara is increasingly used in the sports equipment sector, particularly for custom padding and interior linings. Its superior grip and durability under stress make it an ideal choice for items such as golf clubs, tennis rackets, and automotive racing gear. The material’s resistance to wear and ease of maintenance are significant advantages for manufacturers. B2B buyers should evaluate the wear resistance of the materials sourced, ensuring they meet the rigorous demands of athletes and sports enthusiasts in markets across South America and Africa.

How is Alcantara Used in the Fashion Industry?

In the fashion industry, alcantara headliner material is employed for accessories and apparel detailing, where a premium look is essential. Designers appreciate its versatility, as it can be used in a wide range of applications from handbags to footwear. The tactile experience it provides enhances the overall appeal of fashion items. When sourcing alcantara for this sector, buyers must ensure they are acquiring authentic materials from reputable suppliers to maintain brand integrity and meet consumer expectations across diverse markets, including Europe and the Middle East.

3 Common User Pain Points for ‘alcantara headliner material’ & Their Solutions

Scenario 1: Sourcing High-Quality Alcantara Headliner Material

The Problem: One of the primary challenges B2B buyers face when sourcing Alcantara headliner material is ensuring the quality and authenticity of the fabric. With numerous suppliers offering variations, distinguishing between genuine Alcantara and lower-quality imitations can be difficult. Buyers often encounter discrepancies in texture, durability, and color matching, which can lead to dissatisfaction and increased costs if the material does not meet specific project requirements.

The Solution: To effectively source high-quality Alcantara headliner material, buyers should focus on established distributors known for providing genuine products. Engage with suppliers that offer samples, allowing for a tactile assessment of the fabric before committing to a bulk purchase. Additionally, utilize resources like the EZMatch Swatch Scanner to ensure accurate color matching. When placing orders, specify the required characteristics such as thickness and foam backing to align with project specifications. Buyers should also consider the long-term relationships with suppliers who can provide consistent quality over time, ensuring reliability in future projects.

Scenario 2: Ensuring Correct Installation and Adhesion of Alcantara Headliner Material

The Problem: Another significant pain point for B2B buyers is the proper installation of Alcantara headliner material. Inadequate adhesion can lead to sagging or peeling, which compromises the aesthetic appeal and functionality of the headliner. Many buyers, especially those new to working with Alcantara, may not be familiar with the best practices for installation, leading to wasted materials and time.

The Solution: To ensure proper installation, it is crucial to use the right adhesive specifically designed for foam-backed Alcantara. Recommended options include high-quality spray adhesives or trim adhesives, such as those from 3M, which provide a strong bond between the fabric and the substrate. Before applying the adhesive, ensure that both surfaces are clean and free from dust or grease to facilitate optimal adhesion. For buyers unfamiliar with upholstery techniques, it may be beneficial to consult with experienced professionals or consider hiring a specialist for complex installations. Providing training or resources for installation teams can also minimize errors and improve overall project outcomes.

Illustrative image related to alcantara headliner material

Scenario 3: Managing Expectations for Durability and Maintenance of Alcantara Headliner Material

The Problem: Buyers often have unrealistic expectations regarding the durability and maintenance of Alcantara headliner material. While it is known for its luxurious feel and aesthetic appeal, improper care can lead to premature wear, discoloration, and damage. Buyers may also face challenges in communicating the correct care instructions to their clients, leading to dissatisfaction down the line.

The Solution: To manage expectations effectively, it is essential to provide clear and detailed care instructions along with the Alcantara headliner material. Educate clients on the proper cleaning techniques, emphasizing the importance of using non-abrasive cleaners and soft brushes to maintain the fabric’s integrity. Additionally, inform them about the inherent characteristics of Alcantara, such as its resistance to fading and ease of cleaning compared to traditional fabrics. Buyers should also consider offering maintenance services or products to clients, which can enhance customer satisfaction and prolong the lifespan of the headliner material. Regular follow-ups to check on the condition of the Alcantara can foster strong client relationships and encourage repeat business.

Strategic Material Selection Guide for alcantara headliner material

What Are the Key Properties of Alcantara Headliner Materials?

When selecting Alcantara headliner materials, several options are available, each with unique properties and performance characteristics. Understanding these materials is crucial for B2B buyers looking to make informed purchasing decisions.

Alcantara Soft Foam-Backed Material

Alcantara Soft is a synthetic suede composed of 68% polyester and 32% polyurethane, featuring a foam backing that enhances its performance for headliner applications. The foam provides additional insulation and sound-dampening properties, making it suitable for automotive interiors.

Pros: The material is highly durable, with a wear resistance rating of over 30,000 cycles, making it ideal for high-traffic areas. It is also easy to clean and maintain, which is essential for automotive applications. The foam backing ensures better adhesion to surfaces, reducing the likelihood of peeling or damage.

Cons: The primary drawback is the cost, as Alcantara Soft is more expensive than traditional fabrics. Additionally, its manufacturing complexity may lead to longer lead times for orders, which could be a consideration for buyers needing quick turnaround times.

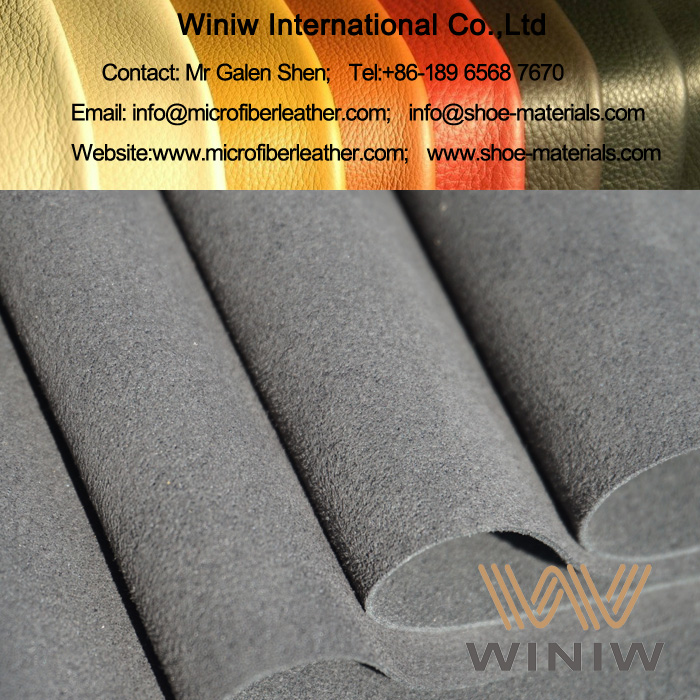

Alcantara Unbacked Material

Unbacked Alcantara is another option, primarily used in applications where the backing is provided by the substrate it adheres to. This material retains the luxurious feel and aesthetic appeal of Alcantara while being lighter.

Pros: Its lighter weight can contribute to overall vehicle weight reduction, which is beneficial for fuel efficiency. It also offers a high level of customization in terms of color and texture.

Cons: The lack of a foam backing means it may not provide the same level of sound insulation or durability as foam-backed options. Additionally, it may require more careful handling during installation to avoid damage.

Alcantara with Alternative Backing Materials

Some manufacturers offer Alcantara with alternative backing materials, such as non-woven fabrics or other synthetic substrates. These options can vary widely in terms of performance and cost.

Pros: Depending on the backing material, these alternatives can provide varying degrees of strength, flexibility, and cost-effectiveness. They may also offer different aesthetic qualities, appealing to diverse market preferences.

Cons: The performance can be inconsistent, and buyers may need to conduct thorough testing to ensure suitability for their specific applications. The variability in quality can also lead to challenges in maintaining consistent manufacturing standards.

What Should International B2B Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several factors when sourcing Alcantara headliner materials. Compliance with local regulations and standards, such as ASTM, DIN, or JIS, is critical to ensure product safety and performance. Additionally, regional preferences may influence material selection, with some markets favoring specific colors, textures, or eco-friendly options. Buyers should also consider logistics and shipping times, as longer lead times can impact project timelines.

Summary Table of Alcantara Headliner Materials

| 素材 | Typical Use Case for alcantara headliner material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara Soft Foam-Backed | Automotive headliners, wrapping panels | High durability and sound insulation | Higher cost and longer lead times | 高い |

| Alcantara Unbacked | Lightweight applications, custom interiors | Lightweight and customizable | Less sound insulation and potential for damage | Medium |

| Alcantara with Alternative Backing | Diverse applications across various industries | Potential for cost savings and aesthetic variety | Inconsistent performance and quality variability | Medium to High |

This guide provides a comprehensive overview of the strategic material selection for Alcantara headliner materials, equipping B2B buyers with the insights necessary to make informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara headliner material

What are the Key Stages in the Manufacturing Process of Alcantara Headliner Material?

The manufacturing process for Alcantara headliner material involves several critical stages, each designed to ensure high quality and durability. Understanding these stages can help B2B buyers make informed purchasing decisions.

Illustrative image related to alcantara headliner material

Material Preparation

The journey of Alcantara begins with the selection of raw materials. The primary components are polyester and polyurethane, typically comprising 68% and 32% of the final product, respectively. These materials are sourced from suppliers who meet stringent quality standards. After sourcing, the raw materials undergo a thorough cleaning process to eliminate any contaminants that could affect the final product’s quality.

Forming the Material

Once the raw materials are prepared, they are mixed and processed to create a uniform blend. This blend is then subjected to a spinning process, which forms a non-woven fabric. The resulting fabric is soft, lightweight, and has the desired tactile properties. For Alcantara headliner materials, a foam backing is applied. This foam not only enhances the tactile feel but also provides additional insulation and sound-dampening properties, crucial for automotive applications.

Assembly

After forming, the material is cut into specified dimensions based on customer requirements. This stage often involves precision cutting machines to ensure consistency and minimize waste. The foam-backed Alcantara is typically sold in rolls, making it easier for buyers to order large quantities. The assembly process may also include additional treatments to enhance durability, such as water-repellent or UV-resistant coatings.

Finishing Touches

The final stage in manufacturing Alcantara headliner material involves quality checks and finishing processes. This can include dyeing for color consistency and applying surface treatments for added functionality. The finished product is rolled and prepared for shipping, ensuring it meets the specified dimensions and quality standards.

Illustrative image related to alcantara headliner material

What Quality Control Measures are Essential for Alcantara Headliner Material?

Quality control (QC) is integral to the manufacturing process of Alcantara headliner material. Ensuring that the final product meets international standards can significantly impact customer satisfaction and brand reputation.

What International Standards Should B2B Buyers Look for?

Buyers should prioritize suppliers that adhere to international quality management standards, such as ISO 9001. This certification indicates that the manufacturer has a systematic approach to managing quality across all stages of production. Additionally, industry-specific certifications, such as CE marking in Europe, ensure that the materials comply with health, safety, and environmental protection standards.

What are the Key QC Checkpoints in the Manufacturing Process?

Quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This phase verifies the quality of raw materials before production begins. Suppliers must provide documentation proving that their materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, samples are taken at various points to ensure that the processes are producing materials that meet quality standards. This includes checking for consistency in thickness, color, and texture.

-

Final Quality Control (FQC): After the product is completed, a final inspection ensures that the material meets all specifications. This includes testing for durability, wear resistance, and color fastness.

What Common Testing Methods are Used in Quality Assurance?

The following testing methods are commonly employed to ensure the quality of Alcantara headliner materials:

Illustrative image related to alcantara headliner material

-

Martindale Abrasion Test: This method assesses the wear resistance of the fabric. A high number of cycles (over 30,000) indicates that the material can withstand significant wear.

-

Light Fastness Testing: Using the Xenotest Beta method, manufacturers test the material’s resistance to fading under UV light. A minimum rating of 3 on the Grey Scale is ideal.

-

Cohesion Testing: This test measures the adhesive properties of the foam backing, ensuring that it adheres properly to the Alcantara material.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial.

What Steps Can Buyers Take for Verification?

-

Conduct Audits: Buyers should conduct on-site audits of potential suppliers to assess their manufacturing processes and quality control measures. This firsthand evaluation can reveal much about a supplier’s commitment to quality.

-

Request QC Reports: Suppliers should be able to provide documentation detailing their quality control measures and results from recent tests. This transparency is a good indicator of reliability.

-

Utilize Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of the supplier’s quality control processes. This is particularly important for buyers unfamiliar with local suppliers.

What are the QC and Certification Nuances for International Buyers?

International B2B buyers must navigate various certification and quality control nuances when sourcing Alcantara headliner materials.

What Should Buyers Consider?

-

Regional Certifications: Different regions may have specific requirements. For instance, CE marking is essential for products sold within the European Union, while other regions may have their own standards.

-

Cultural and Language Barriers: Communication can pose challenges. Buyers should ensure that they understand the supplier’s quality control processes and certifications, which may require translation services or local representation.

-

Logistical Considerations: Transportation and storage conditions can impact material quality. Buyers should discuss these aspects with suppliers to ensure that the materials arrive in optimal condition.

In conclusion, understanding the manufacturing processes and quality assurance measures for Alcantara headliner materials is essential for B2B buyers. By focusing on quality control standards and verification methods, buyers can make informed decisions, ensuring they source high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara headliner material’

はじめに

This practical sourcing guide aims to assist B2B buyers in procuring Alcantara headliner material, a premium fabric known for its durability and aesthetic appeal. With a focus on high-quality applications in automotive and interior design, following this checklist will help you make informed decisions that align with your business needs and customer expectations.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the Alcantara headliner material you intend to purchase. Consider factors such as thickness, weight, and backing type (foam-backed is essential for headliners). Clear specifications help in comparing different suppliers and ensuring that the material meets performance standards for your intended application.

- Thickness: Aim for materials with a thickness of at least 3 mm for adequate durability.

- Weight: Look for a unit weight of around 270 gm² or more to ensure quality.

Step 2: Research Reliable Suppliers

Identify suppliers with a strong reputation in the market. Look for distributors who specialize in Alcantara products and have a history of serving clients in your region. A reliable supplier is crucial for maintaining consistent quality and supply chains.

- Check Reviews: Utilize platforms like industry forums and social media to gauge customer feedback.

- Verify Experience: Prioritize suppliers who have extensive experience in the automotive or upholstery sectors.

Step 3: Request Samples

Before placing a bulk order, request samples of the Alcantara material you are considering. This step allows you to assess the texture, color, and overall quality firsthand, ensuring it aligns with your expectations and project requirements.

- Limitations: Be aware that many suppliers may limit the number of samples you can request to manage costs.

- Color Matching: Use physical samples to confirm color accuracy, as digital representations may vary.

Step 4: Evaluate Supplier Certifications

Ensure that your chosen suppliers adhere to industry standards and possess relevant certifications. Certifications can indicate the quality and sustainability of the materials, which is increasingly important for buyers focused on ethical sourcing.

Illustrative image related to alcantara headliner material

- Sustainability: Look for certifications that demonstrate environmentally friendly practices in the manufacturing process.

- 品質保証: Suppliers should provide quality assurance certifications to confirm the material meets specified standards.

Step 5: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery schedules. Establishing clear agreements upfront can prevent misunderstandings later and ensure that you receive the best value for your investment.

- Volume Discounts: Inquire about bulk purchasing options to reduce costs.

- Shipping Terms: Confirm shipping times and costs, especially if you are sourcing internationally.

Step 6: Confirm Production and Delivery Timelines

Once you have finalized your order, confirm the production and delivery timelines with your supplier. Understanding these timelines is crucial for planning your projects and ensuring that you meet your deadlines.

- Lead Times: Ask for estimated lead times, especially if you’re sourcing from different regions such as Africa, South America, or Europe.

- Contingency Plans: Discuss potential delays and how they would be handled to mitigate risks.

Step 7: Establish a Quality Control Process

Implement a quality control process to inspect the Alcantara material upon delivery. This step is vital to ensure that the product meets your specifications and is free from defects, thus safeguarding your project’s integrity.

- Inspection Criteria: Develop a checklist based on your initial specifications to evaluate the delivered material.

- Feedback Loop: Maintain open communication with your supplier for addressing any quality concerns swiftly.

By following this step-by-step checklist, B2B buyers can streamline the sourcing process for Alcantara headliner material, ensuring high-quality outcomes that meet industry demands.

Comprehensive Cost and Pricing Analysis for alcantara headliner material Sourcing

Understanding the cost structure and pricing analysis for Alcantara headliner material is crucial for international B2B buyers seeking to source this high-quality product. This section delves into the various cost components, price influencers, and strategic tips for effective negotiation and purchasing, particularly for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Alcantara Headliner Material?

The cost of Alcantara headliner material encompasses several components:

-

Materials: The primary cost driver is the raw material itself, which typically includes a blend of polyester and polyurethane. The quality of these materials significantly impacts the final price.

-

Labor: Labor costs associated with manufacturing, cutting, and finishing the Alcantara fabric must also be considered. Skilled labor is often required to ensure high-quality production standards.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Initial setup costs for manufacturing tooling can be substantial, especially if customization is required. This investment is spread over the production volume.

-

Quality Control (QC): Ensuring that the product meets quality standards involves additional costs for testing and inspection. Certifications like ISO can add to these expenses but are crucial for maintaining product integrity.

-

Logistics: The cost of transporting the finished products to the buyer’s location, including packaging and shipping fees, is a significant factor, particularly for international shipments.

-

Margin: Suppliers will add a profit margin on top of the combined costs, which can vary based on market conditions and competition.

How Do Volume and Specifications Influence Pricing?

Volume and minimum order quantities (MOQ) play a pivotal role in determining the price per unit. Typically, larger orders will yield lower per-unit costs due to economies of scale. Custom specifications, such as unique colors or finishes, can also affect pricing. Buyers should be aware that customization may require higher initial investments and longer lead times.

What Buyer Tips Can Help in Negotiating Better Prices?

-

Negotiate Based on Volume: Leverage bulk purchasing to negotiate better rates. Suppliers are often willing to offer discounts for larger orders, which can significantly reduce costs.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the long-term value of the material, including durability, maintenance, and potential replacement costs. Alcantara, known for its longevity and ease of cleaning, may offer better TCO compared to cheaper alternatives.

-

Understand Pricing Nuances for International Markets: Different regions may have varying cost structures due to labor, tariffs, and shipping expenses. For instance, sourcing from a supplier in Europe may incur higher logistics costs when shipping to Africa compared to a local supplier.

-

Familiarize Yourself with Incoterms: Understanding shipping terms can help you anticipate additional costs associated with delivery. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly influence your total cost.

What Are the Pricing Trends for Alcantara Headliner Material?

As of late 2023, pricing for Alcantara headliner material typically ranges from $161 per yard for foam-backed variants. However, prices can fluctuate based on supply chain dynamics, material availability, and global market trends. It’s essential for buyers to keep abreast of these trends and seek quotes from multiple suppliers to ensure competitive pricing.

Illustrative image related to alcantara headliner material

Conclusion

Navigating the cost and pricing landscape of Alcantara headliner material requires a comprehensive understanding of various cost components and market influences. By employing strategic negotiation techniques and being mindful of total cost implications, international B2B buyers can secure favorable terms and high-quality materials suited to their needs. Always remember to obtain indicative pricing from multiple sources to make informed decisions.

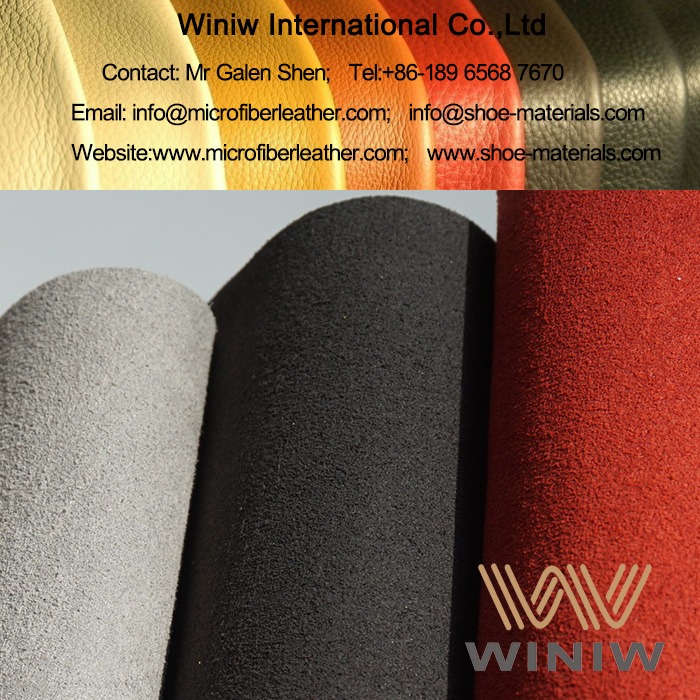

Alternatives Analysis: Comparing alcantara headliner material With Other Solutions

Exploring Alternative Solutions to Alcantara Headliner Material

When selecting materials for automotive interiors, particularly headliners, it’s crucial to evaluate alternatives to Alcantara headliner material. While Alcantara is renowned for its luxurious feel and durability, other options may offer competitive advantages in terms of cost, performance, or specific use cases. This analysis will provide insights into two viable alternatives: synthetic suede and leather.

| Comparison Aspect | Alcantara Headliner Material | Synthetic Suede | Leather |

|---|---|---|---|

| Performance | High durability, stain-resistant, excellent grip | Good durability, less grip than Alcantara | Very durable, natural aesthetics, high grip |

| Cost | $161 per yard | $50-$100 per yard | $100-$300 per yard |

| Ease of Implementation | Requires specialized adhesive and skills | Easier to install, can be stapled or glued | More complex installation, requires skilled labor |

| Maintenance | Easy to clean, machine washable | Easy to clean, stain-resistant | Requires conditioning, prone to scratches |

| Best Use Case | Luxury automotive interiors, high-end vehicles | Budget-friendly applications, general upholstery | High-end luxury vehicles, classic restorations |

Pros and Cons of Synthetic Suede as an Alternative to Alcantara

Synthetic suede is a popular alternative that mimics the look and feel of Alcantara but at a lower cost. It typically ranges from $50 to $100 per yard, making it a budget-friendly option for projects that require a soft touch without the premium price tag. While synthetic suede offers good durability and is easy to maintain, it does not provide the same level of grip or luxurious feel that Alcantara does. Additionally, the installation process is generally simpler, which can save time and labor costs.

Evaluating Leather as a Headliner Material Alternative

Leather is another alternative that stands out for its durability and natural aesthetics. Priced between $100 and $300 per yard, leather offers a premium appearance that can elevate the interior of any vehicle. It is highly durable and provides a unique tactile experience. However, leather installation is more complex and often requires skilled labor, which can increase overall project costs. Maintenance involves regular conditioning to prevent drying and cracking, which adds to the long-term upkeep compared to Alcantara.

Conclusion: Choosing the Right Material for Your Needs

For B2B buyers, the choice of headliner material hinges on various factors including budget, desired aesthetic, and installation capabilities. Alcantara remains an excellent choice for luxury applications where durability and a high-end feel are paramount. However, synthetic suede offers a cost-effective solution for projects where budget constraints are significant, while leather provides a classic touch for high-end restorations. Understanding these alternatives allows buyers to make informed decisions that align with their specific project requirements and market demands.

Essential Technical Properties and Trade Terminology for alcantara headliner material

What Are the Key Technical Properties of Alcantara Headliner Material?

Alcantara headliner material is known for its unique blend of aesthetics and functionality, making it a preferred choice in various industries, particularly automotive. Understanding its technical properties is crucial for B2B buyers looking to make informed purchasing decisions.

1. Thickness

The thickness of Alcantara headliner material typically ranges from 3.0 mm to 5.0 mm. This property is critical as it affects the material’s durability and ease of installation. A thicker material provides better sound insulation and resistance to wear, which is particularly important in high-use areas like vehicle interiors.

2. Unit Weight

Unit weight is measured in grams per square meter (gm²) and generally starts at around 270 gm² for Alcantara. This specification is vital for logistics and shipping, as it affects freight costs and handling. A lighter material may reduce shipping expenses, but it could compromise durability and performance.

Illustrative image related to alcantara headliner material

3. Breaking Load

The breaking load, defined by UNI EN 29073-3 standards, measures the force required to break the material both lengthwise and transversally. Alcantara generally has a breaking load of ≥ 225 N (lengthwise) and ≥ 175 N (transversally). This property is essential for assessing the material’s strength and suitability for applications that experience stress or strain.

4. Wear Resistance

Wear resistance is quantified using the Martindale test, which measures the number of cycles the fabric can withstand before showing significant wear. Alcantara typically achieves ≥ 30,000 cycles, making it an excellent choice for high-traffic areas. This durability translates to lower replacement costs and better long-term value for businesses.

5. Color Fastness

Color fastness is measured through various tests, including Xenotest Beta for light exposure and rubbing tests for both dry and wet conditions. Alcantara’s performance in these tests ensures that colors remain vibrant over time, an important factor for aesthetic consistency in automotive and interior applications.

What Are Common Trade Terms Related to Alcantara Headliner Material?

Understanding trade terminology is equally important for B2B buyers when sourcing Alcantara headliner material. Here are several key terms that are commonly used in the industry:

Illustrative image related to alcantara headliner material

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are purchased by another company and sold under the latter’s brand name. In the context of Alcantara, understanding whether a supplier is an OEM can help buyers ensure they are getting genuine materials that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For Alcantara, MOQs can vary significantly based on the supplier and the specific material. Understanding MOQ is crucial for budget planning and inventory management, particularly for smaller businesses.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. In the case of Alcantara headliner materials, submitting an RFQ can help buyers receive competitive pricing and terms from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping costs, insurance, and risk management, especially when importing Alcantara materials from overseas.

5. Lead Time

Lead time refers to the amount of time it takes for an order to be fulfilled once it is placed. Knowing the lead time for Alcantara headliner materials is essential for project planning and ensuring timely delivery, particularly in industries like automotive where schedules can be tight.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the purchasing process for Alcantara headliner materials more effectively, ensuring they select the best options for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the alcantara headliner material Sector

What Are the Current Market Dynamics and Key Trends for Alcantara Headliner Material?

The alcantara headliner material market is currently experiencing robust growth driven by several global factors. The increasing demand for luxury automotive interiors, especially in emerging markets such as Africa and South America, is a significant driver. As consumers become more discerning about vehicle aesthetics and comfort, manufacturers are turning to alcantara for its premium feel and durability. In regions like Europe and the Middle East, where luxury car manufacturers are prevalent, the shift toward lightweight and sustainable materials is accelerating the adoption of alcantara.

Technological advancements in sourcing and manufacturing processes are also influencing market dynamics. B2B buyers are increasingly leveraging digital platforms for procurement, making it easier to compare prices, quality, and supplier reliability. The rise of e-commerce in the textile sector allows international buyers to access a wider range of products, including custom alcantara options tailored to specific applications. Additionally, innovations in foam backing technologies enhance the performance characteristics of alcantara, making it more suitable for a variety of applications beyond just headliners, such as automotive upholstery and fashion accessories.

How Is Sustainability and Ethical Sourcing Influencing Alcantara Headliner Material Procurement?

Sustainability is becoming a cornerstone of procurement strategies for alcantara headliner materials. The environmental impact of sourcing practices is under increasing scrutiny, with buyers seeking suppliers who adhere to ethical and sustainable practices. Alcantara, as a synthetic material composed primarily of polyester and polyurethane, presents opportunities for eco-friendly production methods.

B2B buyers are advised to look for suppliers that offer environmentally certified products, such as those with ISO certifications or those that comply with the Global Organic Textile Standard (GOTS). The focus on recycling and waste reduction in the manufacturing process is also crucial, as it not only lessens the ecological footprint but can also enhance brand reputation. Furthermore, consumers in emerging markets are increasingly favoring brands that demonstrate a commitment to sustainability, making it essential for international buyers to align their sourcing strategies with these values.

What Is the Brief Evolution and History of Alcantara Headliner Materials?

Alcantara was developed in the late 1970s in Italy and has since evolved into a preferred material in various high-end applications, including automotive interiors. Initially created as a substitute for leather, it quickly gained popularity due to its luxurious feel and durability. Its unique composition allows for easy maintenance and a variety of design options, making it suitable for both automotive and fashion industries.

Over the years, the material has undergone significant advancements, particularly in terms of performance and sustainability. The introduction of foam-backed versions has enhanced its application in headliners, ensuring better adhesion and comfort. As the automotive industry increasingly emphasizes lightweight and eco-friendly materials, alcantara is positioned to play a pivotal role in the future of vehicle interiors, catering to the needs of both manufacturers and consumers alike.

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara headliner material

-

How do I choose the right Alcantara headliner material for my project?

Choosing the right Alcantara headliner material involves considering the specific requirements of your project, such as thickness, color, and backing type. Alcantara comes in various compositions; for headliners, foam-backed options are preferred for better adhesion and durability. Always request samples to assess texture and color accuracy before placing a bulk order. Additionally, ensure the supplier provides detailed specifications, including wear resistance and maintenance guidelines, to meet your project’s needs. -

What is the best way to ensure quality when sourcing Alcantara headliner material?

To ensure quality, start by vetting suppliers thoroughly. Look for reputable manufacturers or distributors with positive reviews and a track record in the industry. Request certifications and test results that confirm the material’s durability, such as Martindale tests for wear resistance. Additionally, consider visiting the supplier’s facility if possible, or use third-party quality assurance services to inspect materials before shipment. Establishing a long-term relationship with a reliable supplier can also facilitate better quality control. -

What are the minimum order quantities (MOQ) for Alcantara headliner materials?

Minimum order quantities for Alcantara headliner materials can vary significantly by supplier. Typically, MOQs range from 10 to 50 yards, depending on the supplier’s policies and the type of material ordered. It’s advisable to communicate your needs directly with potential suppliers, as some may offer flexibility on MOQs for first-time buyers or larger ongoing contracts. Additionally, consider consolidating orders with other materials to meet MOQ requirements more efficiently. -

What payment terms should I expect when purchasing Alcantara headliner materials internationally?

Payment terms for international purchases of Alcantara headliner materials can differ based on supplier policies and your negotiation. Common terms include upfront payment, deposits (typically 30-50%), and payment upon delivery. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect both parties. Discussing payment terms upfront can help avoid misunderstandings and ensure a smooth transaction process. -

How can I customize Alcantara headliner materials for my specific needs?

Customization options for Alcantara headliner materials may include selecting specific colors, patterns, and textures. Some suppliers offer bespoke solutions tailored to your specifications, including custom foam backing or unique finishes. To initiate the customization process, provide detailed requirements and, if possible, reference existing samples. Collaborating closely with the supplier’s design team can also facilitate achieving the desired outcome while ensuring the material meets functional requirements. -

What logistics considerations should I be aware of when importing Alcantara materials?

When importing Alcantara materials, consider shipping costs, customs duties, and lead times. It’s essential to partner with a logistics provider experienced in handling fabric imports, as they can help navigate the complexities of international shipping and customs clearance. Additionally, ensure that your supplier provides all necessary documentation for a smooth import process. Establishing a clear timeline and understanding potential delays can help manage expectations and prevent disruptions. -

What are the common challenges faced when sourcing Alcantara headliner material internationally?

Common challenges include language barriers, varying quality standards, and shipping delays. It’s crucial to have clear communication with suppliers and possibly engage a local representative who understands the market. Quality assurance can also be a concern, so it’s advisable to request samples and certifications. Additionally, fluctuating exchange rates can impact costs, so consider negotiating prices in stable currencies to mitigate financial risks. -

How can I ensure compliance with international regulations when sourcing Alcantara materials?

To ensure compliance, familiarize yourself with both your country’s import regulations and the supplier’s country standards. This includes understanding safety and environmental regulations related to synthetic materials. Request documentation from suppliers that prove compliance with international quality standards, such as ISO certifications. Consulting with a legal expert in international trade can also provide guidance on navigating complex regulations and ensuring that all materials meet necessary compliance criteria.

Top 6 Alcantara Headliner Material Manufacturers & Suppliers List

1. Alcantara – Soft Foam Backed

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: {“name”: “Alcantara Soft Foam Backed”, “price”: “$161.00”, “description”: “Alcantara Soft is a single layer of Pannel with 2mm thick foam applied to the backside. Primarily used for headliners and wrapping panels. Sold per yard. The roll is 56 inches wide. Orders of multiple yards will come as one continuous piece.”, “specifications”: {“thickness”: “≥ 3.0 mm”, “unit_weight”: “UNI EN 29073-1 ≥ 270 …

2. DLT Corporation – Alcantara Soft

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: Alcantara Soft is a foam-backed, Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Available colors include Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black, Deep Black, Raw Amber, Dark Brown, Brombeer,…

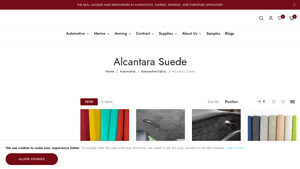

3. Keyston Bros – Alcantara Suede Automotive Fabric

Domain: keystonbros.com

Registered: 1997 (28 years)

Introduction: Alcantara Suede – Automotive Fabric. Product options include Alcantara Cover, Alcantara Soft, Alcantara Pannel, Alcantara EXO, Alcantara Pannel MB-4 Perf, and Alcantara Pannel S-2000 Perf. Pricing requires login to view. Features include various roll sizes, cleaning codes, abrasion ratings, and UFAC class specifications.

4. BMW E90 – Fabric vs Alcantara Headliners

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the comparison between fabric and Alcantara headliners for the BMW E90. Key points include: 1. Alcantara is considered by some to look better than fabric, but opinions vary on whether the aesthetic difference justifies the higher cost. 2. One user mentioned spending $120 on materials and glues for a DIY headliner project. 3. Concerns were raised about the overall loo…

5. Alcantara – Auto Panel Deep Black 9040

Domain: autointeriorspecialists.com

Registered: 2019 (6 years)

Introduction: [{‘name’: ‘Alcantara Auto Panel Deep Black 9040’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel Charcoal Black 9002’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel Dark Grey 9052’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel Slate Grey 2957’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel Red 4996’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel 9002 Soft’, ‘price’: 157}, {‘name’: ‘Alcantara Auto …

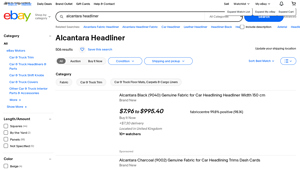

6. Alcantara – Headliner Fabric

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Alcantara Headliner available in various sizes and colors. Key features include:

– Material: Alcantara (159 items), Suede (2 items)

– Suitable for: Car upholstery, quilting, outdoor use, crafts, apparel, motorcycle upholstery

– Width options: 46 – 59″ (45 items), 60″ (111 items)

– Color options: Beige (4), Black (32), Blue (5), Brown (8), Gray (64), Green (4), Multicolor (1), Orange (4), Red (…

Strategic Sourcing Conclusion and Outlook for alcantara headliner material

In the evolving landscape of automotive and interior design, strategic sourcing of Alcantara headliner material emerges as a crucial differentiator for international B2B buyers. The unique attributes of Alcantara, including its durability, ease of maintenance, and aesthetic appeal, position it as a premium choice compared to traditional materials. By leveraging established suppliers and understanding the specifications—such as foam backing and fabric weight—buyers can ensure they acquire high-quality products that meet their specific needs.

Moreover, fostering relationships with reliable distributors can enhance supply chain efficiency, allowing for quicker delivery times and the possibility of bulk purchasing discounts. As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for sophisticated materials like Alcantara is likely to rise.

Looking ahead, businesses should prioritize partnerships with suppliers that offer not only the product but also expertise in application and installation. This proactive approach will not only streamline procurement processes but also elevate the overall quality of finished products. Engage with trusted sources today to secure your competitive advantage in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to alcantara headliner material

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.