Introduction: Navigating the Global Market for what is alcantara material

In an increasingly competitive global market, sourcing high-quality materials like Alcantara is essential for manufacturers and designers looking to enhance their product offerings. Alcantara, a premium synthetic textile renowned for its suede-like appearance and superior durability, presents unique advantages and challenges that B2B buyers must navigate. This comprehensive guide serves as your go-to resource, providing an in-depth analysis of Alcantara material, including its types, applications across various industries, supplier vetting processes, and cost considerations.

International buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Nigeria and Saudi Arabia—stand to gain significant insights from this guide. The intricacies of sourcing Alcantara can be daunting, especially when balancing quality, cost, and supplier reliability. Our expert insights will empower you to make informed purchasing decisions, ensuring you select the right suppliers and negotiate favorable terms.

By understanding the properties and applications of Alcantara, you can leverage its benefits to create luxurious, high-performance products that appeal to discerning consumers. Whether you are outfitting automotive interiors, crafting bespoke furniture, or exploring fashion applications, this guide equips you with the knowledge to excel in your procurement strategy. Embrace the opportunity to elevate your offerings with Alcantara and navigate the complexities of the global market with confidence.

Table Of Contents

- Top 6 What Is Alcantara Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is alcantara material

- Understanding what is alcantara material Types and Variations

- Key Industrial Applications of what is alcantara material

- 3 Common User Pain Points for ‘what is alcantara material’ & Their Solutions

- Strategic Material Selection Guide for what is alcantara material

- In-depth Look: Manufacturing Processes and Quality Assurance for what is alcantara material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is alcantara material’

- Comprehensive Cost and Pricing Analysis for what is alcantara material Sourcing

- Alternatives Analysis: Comparing what is alcantara material With Other Solutions

- Essential Technical Properties and Trade Terminology for what is alcantara material

- Navigating Market Dynamics and Sourcing Trends in the what is alcantara material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is alcantara material

- Strategic Sourcing Conclusion and Outlook for what is alcantara material

- Important Disclaimer & Terms of Use

Understanding what is alcantara material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Classic | Standard suede-like finish, high durability | Automotive interiors, luxury furnishings | Pros: Premium feel, durable. Cons: Requires regular maintenance. |

| Alcantara Racing | Enhanced grip, flame retardant properties | Motorsports, performance vehicles | Pros: Superior grip, lightweight. Cons: Can wear quickly under heavy use. |

| Alcantara Eco | Made from recycled materials, eco-friendly production | Sustainable automotive brands | Pros: Environmentally friendly, vegan. Cons: May have a higher cost. |

| Alcantara Soft | Softer texture, plush feel | High-end automotive seats, luxury goods | Pros: Luxurious feel, aesthetic appeal. Cons: More prone to wear and tear. |

| Alcantara Tech | Embedded technology for smart functionalities | High-tech automotive applications | Pros: Innovative features, versatile. Cons: Complexity in sourcing and integration. |

What Are the Characteristics of Alcantara Classic?

Alcantara Classic is the most widely recognized variant of Alcantara, featuring a standard suede-like finish that offers a premium aesthetic. With a composition of 68% polyester and 32% polyurethane, it is highly durable and resistant to wear. This material is commonly used in automotive interiors, luxury furniture, and high-end fashion accessories. Buyers should consider the need for regular maintenance, as it can absorb oils and dirt, potentially leading to a loss of its soft texture over time.

How Does Alcantara Racing Enhance Performance?

Alcantara Racing is specifically designed for motorsports applications, offering enhanced grip and flame retardant properties. This version is ideal for steering wheels, gear levers, and seats in performance vehicles, where safety and control are paramount. While it provides significant advantages in terms of grip and weight reduction, it can wear down more quickly in high-stress environments. B2B buyers in the automotive sector should weigh the performance benefits against the potential for increased maintenance.

What Makes Alcantara Eco a Sustainable Choice?

Alcantara Eco is a sustainable variant made from recycled materials, appealing to environmentally conscious brands. This type is increasingly popular among automotive manufacturers looking to enhance their sustainability credentials. Its eco-friendly production processes do come with a higher price point, which is a critical consideration for B2B buyers. Brands can leverage Alcantara Eco to align with consumer demand for sustainable products while maintaining a luxurious image.

Why Choose Alcantara Soft for Luxury Interiors?

Alcantara Soft features a plush texture that offers an elevated tactile experience, making it particularly suitable for high-end automotive seats and luxury goods. This variant is designed to provide a luxurious feel that enhances the overall aesthetic of any application. However, it is more susceptible to wear and tear than other types, which may be a concern for B2B buyers focused on long-term durability. Buyers should consider the balance between luxury and practicality when selecting this material.

How Does Alcantara Tech Integrate Innovation?

Alcantara Tech incorporates embedded technology, making it suitable for high-tech automotive applications. This innovative variant can include features such as touch-sensitive controls or integrated sensors, enhancing the functionality of vehicle interiors. While it offers exciting possibilities for modern automotive designs, sourcing and integrating Alcantara Tech may present challenges for manufacturers. B2B buyers should assess their technological needs and capabilities when considering this advanced material.

Key Industrial Applications of what is alcantara material

| Industry/Sector | Specific Application of what is alcantara material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for seats and interiors | Enhances luxury appeal, provides better grip, and is lightweight | Ensure compliance with safety standards and durability tests |

| Aviation | Cabin interiors and seating | Offers a premium feel, lightweight, and fire-retardant properties | Certification for aviation use and maintenance guidelines |

| Furniture Design | Upholstery for high-end furniture | Provides an upscale aesthetic and durability | Consider colorfastness and stain resistance properties |

| Fashion and Accessories | Luxury bags and apparel | Appeals to eco-conscious consumers and offers a soft texture | Sourcing for sustainability and compatibility with designs |

| Marine Industry | Boat interiors and seating | Water-resistant, durable, and easy to clean | Ensure UV resistance and compliance with marine regulations |

How is Alcantara Material Used in the Automotive Sector?

In the automotive industry, Alcantara is predominantly used for upholstery in seats, dashboards, and door panels. Its unique properties, such as enhanced grip and a matte finish, make it ideal for high-performance vehicles where driver control is paramount. The material’s lightweight nature contributes to overall vehicle efficiency, appealing to manufacturers focused on performance. International buyers should ensure that their sourcing aligns with safety standards and durability requirements specific to their regions, particularly in environments with extreme weather conditions.

What Role Does Alcantara Play in Aviation Interiors?

In aviation, Alcantara is utilized for cabin interiors, including seating and paneling, where aesthetics and safety are critical. The material’s fire-retardant properties make it suitable for commercial and private aircraft, enhancing both luxury and safety. Its lightweight characteristic is advantageous for fuel efficiency. Buyers in this sector must prioritize suppliers who can provide certified materials that meet stringent aviation safety regulations, along with maintenance support to ensure longevity.

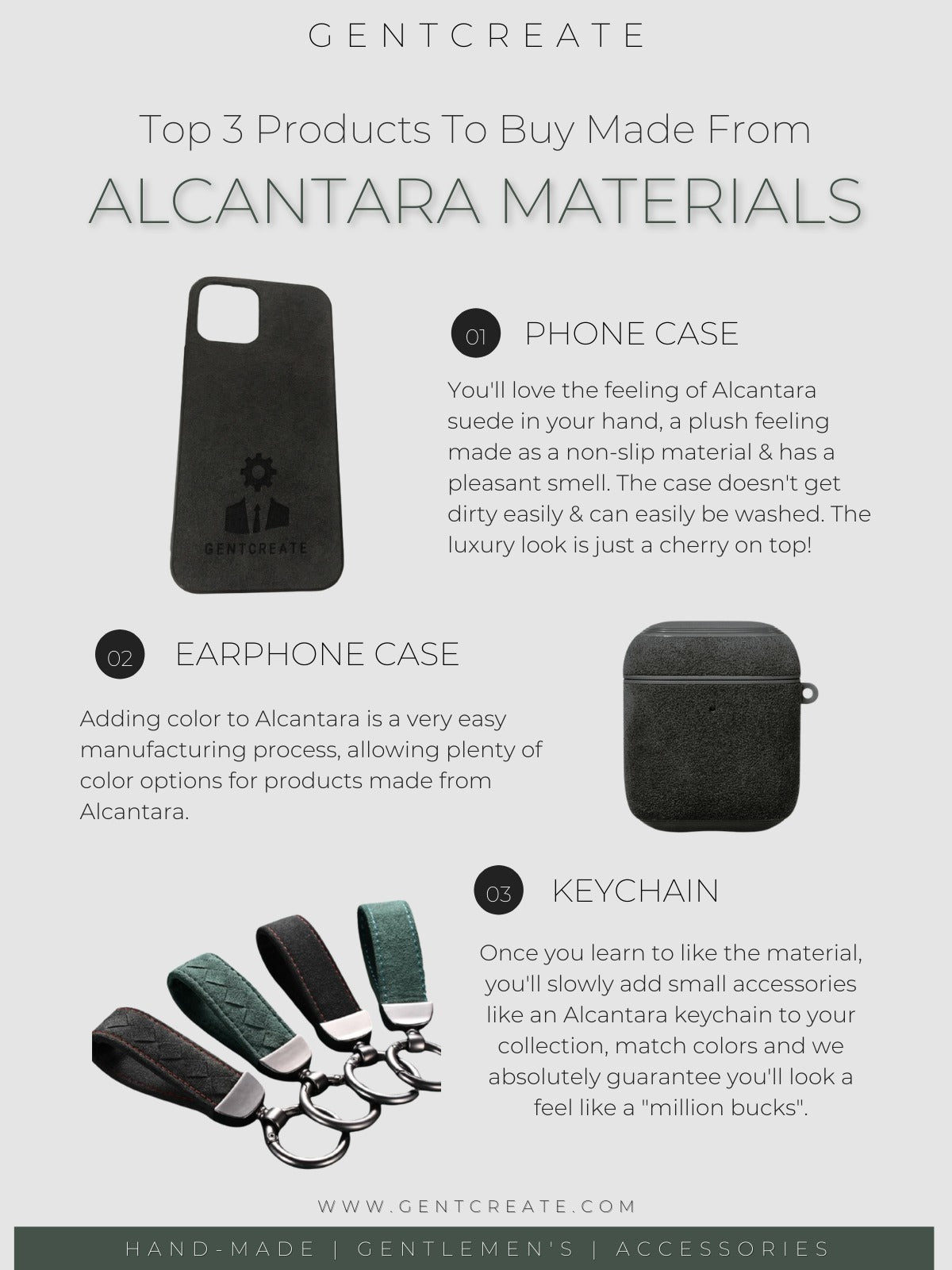

Illustrative image related to what is alcantara material

Why is Alcantara Preferred in High-End Furniture Design?

The furniture design industry leverages Alcantara for high-end upholstery due to its luxurious appearance and durability. It is used in items such as sofas, chairs, and decorative elements, appealing to customers seeking premium quality. The fabric is resistant to wear and tear, making it suitable for both residential and commercial applications. Buyers should consider the material’s colorfastness and stain resistance, especially in regions with high humidity or temperature fluctuations, to ensure longevity and aesthetic appeal.

How is Alcantara Impacting Fashion and Accessories?

In fashion, Alcantara is increasingly used in luxury bags, shoes, and apparel, appealing to eco-conscious consumers due to its vegan-friendly nature. The soft texture and unique look of Alcantara add a premium touch to products, enhancing brand value. For B2B buyers in this sector, sourcing should focus on sustainability practices and compatibility with design specifications, ensuring that the material meets both aesthetic and functional demands.

What Advantages Does Alcantara Offer in the Marine Industry?

In the marine sector, Alcantara is used for boat interiors and seating, providing a water-resistant and durable option that withstands harsh marine environments. Its easy-to-clean surface is particularly advantageous for maintaining a pristine appearance. Buyers in this industry must ensure that the material is UV resistant to prevent fading and deterioration caused by prolonged sun exposure. Compliance with marine safety regulations is also crucial for successful sourcing.

Illustrative image related to what is alcantara material

3 Common User Pain Points for ‘what is alcantara material’ & Their Solutions

Scenario 1: Understanding Alcantara’s Durability for High-Traffic Areas

The Problem: B2B buyers often face uncertainty regarding the durability of Alcantara when used in high-traffic areas, such as automotive interiors or office furniture. Given that Alcantara is frequently chosen for its aesthetic appeal and premium feel, companies may worry about its longevity, especially in environments where it will be subjected to regular wear and tear. Concerns about how quickly the material will show signs of wear, such as flattening of the nap or staining, can deter businesses from making a commitment to this fabric.

The Solution: To mitigate concerns regarding durability, buyers should conduct thorough due diligence before selecting Alcantara for their projects. Start by sourcing samples from reputable manufacturers and conducting stress tests to evaluate how the fabric performs under real-world conditions. Additionally, inquire about the specific grades of Alcantara available, as some may offer enhanced durability features designed for high-use applications. Implementing a regular maintenance schedule that includes brushing and gentle cleaning can also help maintain the fabric’s appearance and prolong its life. Educate end-users on the importance of care, as this can significantly enhance the material’s longevity and visual appeal.

Scenario 2: Cleaning and Maintenance Challenges with Alcantara

The Problem: Many B2B buyers are apprehensive about the maintenance requirements associated with Alcantara, particularly regarding cleaning. The fear of damaging the fabric during the cleaning process can lead to hesitation in choosing Alcantara for projects. Buyers may also struggle with finding the right cleaning products and techniques that won’t harm the material, which can result in costly mistakes and dissatisfaction from end-users.

Illustrative image related to what is alcantara material

The Solution: To address cleaning and maintenance concerns, businesses should invest in training for personnel responsible for the upkeep of Alcantara surfaces. Providing detailed cleaning guidelines that specify appropriate cleaning agents, tools, and techniques can empower staff to maintain the fabric without damage. For example, using a soft brush or vacuum to remove dust, followed by occasional wiping with a damp cloth, can keep Alcantara looking fresh. Additionally, consider partnering with professional cleaning services that specialize in Alcantara to ensure that maintenance is performed correctly. Including care instructions with product deliveries can also enhance customer satisfaction and confidence in choosing Alcantara.

Scenario 3: Cost Comparison and Budgeting for Alcantara in B2B Projects

The Problem: When considering Alcantara for projects, B2B buyers often grapple with budget constraints and the perception that Alcantara is prohibitively expensive compared to alternative materials. This can lead to second-guessing the decision to include Alcantara in product offerings or interior designs, especially in markets where cost sensitivity is high. Buyers may fear that the initial investment will not yield a sufficient return, leading to potential losses.

The Solution: Buyers should approach budgeting for Alcantara with a comprehensive cost-benefit analysis. Highlight the long-term value of using Alcantara, such as its durability, aesthetic appeal, and ease of maintenance, which can ultimately reduce replacement costs and enhance brand image. Furthermore, consider negotiating bulk purchasing agreements with suppliers to lower the per-unit cost, making Alcantara more accessible for larger projects. It can also be beneficial to conduct market research to demonstrate how Alcantara can elevate product offerings and attract a higher-end clientele, thereby justifying the investment. By framing Alcantara as a premium choice that can lead to increased sales and customer satisfaction, buyers can make informed decisions that align with their financial goals.

Strategic Material Selection Guide for what is alcantara material

What Are the Key Properties of Alcantara Material Compared to Other Fabrics?

When considering Alcantara material for various applications, it is essential to evaluate it against other common materials such as leather, suede, and synthetic textiles. Each of these materials has unique properties that can significantly influence their performance, durability, and suitability for specific applications.

How Does Alcantara Compare to Leather?

Key Properties: Leather is known for its high durability and natural aesthetic appeal. It offers excellent temperature resistance and can withstand significant wear and tear. However, it is heavier than Alcantara and can become slippery when wet.

Illustrative image related to what is alcantara material

Pros & Cons: Leather provides a premium feel and is often associated with luxury. However, it requires regular maintenance to prevent cracking and drying out. Alcantara, on the other hand, is lighter and offers better grip, especially in high-performance environments. Its vegan-friendly nature is an additional advantage, particularly for markets where animal welfare is a concern.

Impact on Application: In automotive interiors, leather is often preferred for its classic look, while Alcantara is favored for its performance characteristics, such as grip and moisture resistance.

Considerations for International Buyers: Compliance with animal welfare standards is crucial in regions like Europe, where regulations are stringent. Additionally, buyers should consider the availability of cleaning products compatible with Alcantara in their local markets.

Illustrative image related to what is alcantara material

What Are the Advantages of Using Suede Over Alcantara?

Key Properties: Suede is softer than Alcantara and provides a luxurious feel. However, it is less durable and more susceptible to staining and wear.

Pros & Cons: While suede offers a rich texture, it requires extensive care and is not as resistant to moisture. Alcantara, with its synthetic composition, is designed to withstand more rigorous conditions and is easier to clean.

Impact on Application: Suede is often used in high-end fashion and luxury items, while Alcantara is more commonly found in automotive and performance applications due to its durability.

Considerations for International Buyers: Buyers in regions with higher humidity levels, such as parts of South America and the Middle East, may find Alcantara’s moisture-resistant properties particularly beneficial compared to traditional suede.

How Does Synthetic Textile Compare to Alcantara?

Key Properties: Synthetic textiles can vary widely in quality and performance. However, Alcantara stands out due to its specific blend of polyester and polyurethane, which provides a unique combination of softness and durability.

Illustrative image related to what is alcantara material

Pros & Cons: While many synthetic textiles can be cost-effective, they often lack the premium feel and aesthetic of Alcantara. The latter is designed to mimic the look of suede while offering superior resistance to wear.

Impact on Application: Synthetic textiles are used in a wide range of applications, from clothing to upholstery. Alcantara is specifically tailored for high-performance environments, making it a preferred choice for automotive interiors.

Considerations for International Buyers: Buyers should ensure that any synthetic alternatives meet local standards such as ASTM or DIN, particularly in regions with strict regulations like Europe.

Summary Table of Material Comparisons

| Material | Typical Use Case for what is alcantara material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara | Automotive interiors, luxury upholstery | Lightweight, durable, vegan-friendly | Can wear over time, requires care | High |

| Leather | Luxury vehicles, high-end fashion | Premium feel, durable | Heavy, slippery when wet | High |

| Suede | Fashion items, luxury accessories | Soft texture, luxurious appearance | Less durable, stains easily | Medium |

| Synthetic Textile | General upholstery, clothing | Cost-effective, versatile | Varies in quality, less premium feel | Low to Medium |

This analysis provides a comprehensive overview of Alcantara and its comparison with other materials, emphasizing key properties and considerations for international B2B buyers. Understanding these factors will assist in making informed decisions tailored to specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for what is alcantara material

What Are the Main Stages of Alcantara Material Manufacturing?

The manufacturing of Alcantara material involves several critical stages, each meticulously designed to ensure the final product meets the high standards expected by industries such as automotive, fashion, and interior design. Understanding these stages can empower B2B buyers to make informed decisions when sourcing this premium textile.

Illustrative image related to what is alcantara material

How Is Material Prepared for Alcantara Production?

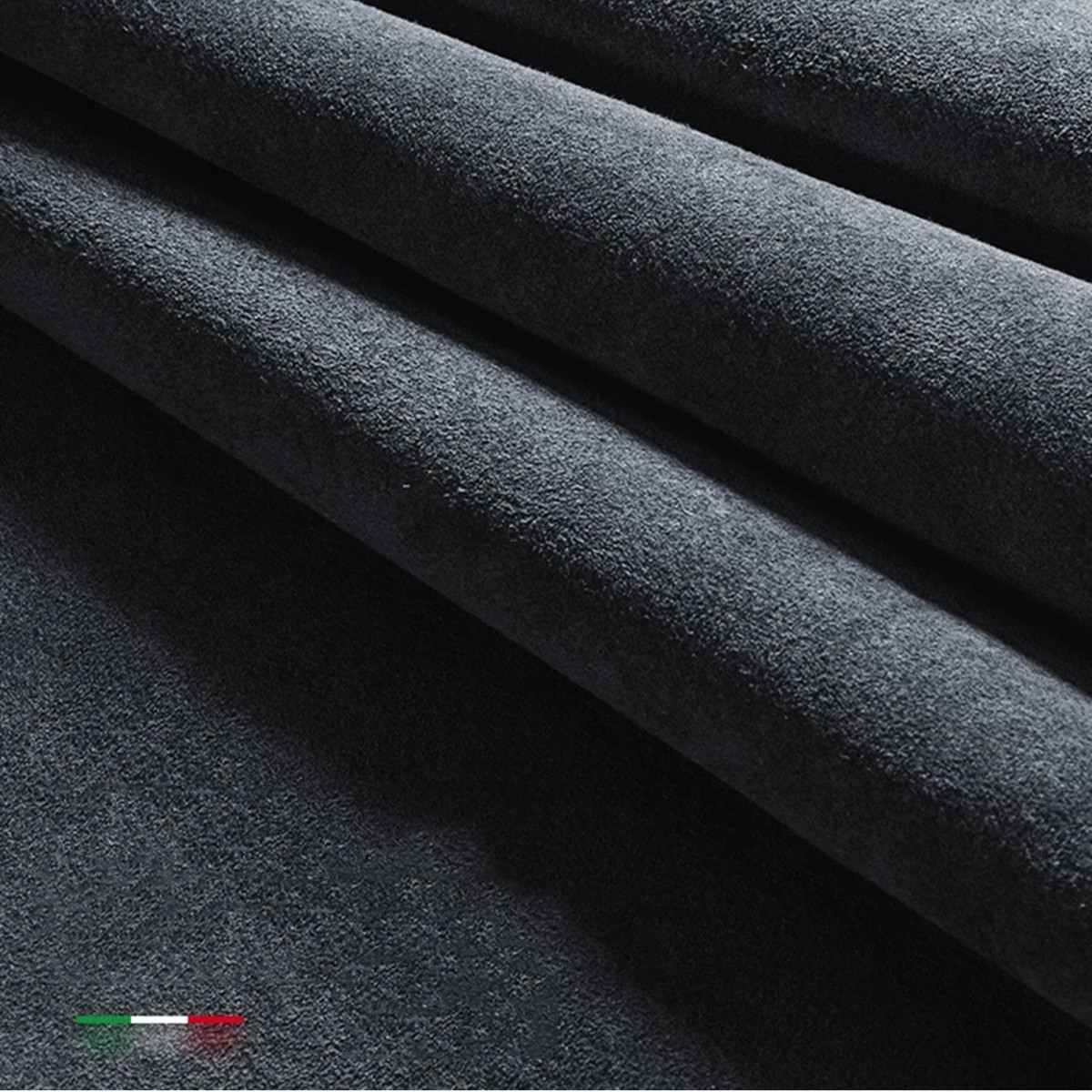

The first stage in the manufacturing process is material preparation, which involves sourcing and blending raw materials. Alcantara is primarily composed of 68% polyester and 32% polyurethane. These synthetic fibers are carefully selected to ensure consistency in quality. The blending process employs advanced techniques such as polymerization, where the polyester and polyurethane are chemically combined to create a homogenous mixture. This mixture is then extruded into fibers, which are subsequently cut to the desired length for further processing.

What Techniques Are Used in Forming Alcantara?

Once the fibers are prepared, the next step is forming, which includes several key techniques. Needle punching is a widely used method where the fibers are mechanically entangled through a process that creates a dense, durable fabric. This technique not only increases the material’s strength but also provides the soft, suede-like texture that Alcantara is renowned for. Additionally, the fabric undergoes a buffing process to enhance its softness and visual appeal, giving it the luxurious finish that is highly sought after in high-end applications.

How Is Alcantara Finished for Quality and Aesthetic Appeal?

Finishing is the final stage before Alcantara is ready for market. This stage involves dyeing the fabric to achieve the desired color and applying treatments to enhance properties such as water resistance and flame retardance. The finishing process can also include surface treatments to improve durability and ease of cleaning, which are essential features for automotive applications. These treatments ensure that Alcantara not only looks good but also performs well under various conditions, further solidifying its position as a premium material.

What Quality Assurance Standards Are Relevant for Alcantara?

Quality assurance (QA) is a pivotal aspect of Alcantara manufacturing, ensuring that the final product meets both industry standards and customer expectations. B2B buyers should familiarize themselves with the relevant international and industry-specific standards that govern Alcantara production.

Illustrative image related to what is alcantara material

Which International Standards Apply to Alcantara Quality Assurance?

The primary international standard relevant to Alcantara manufacturing is ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer adheres to best practices in quality management, focusing on continuous improvement and customer satisfaction. Additionally, certification under CE (Conformité Européenne) standards may be applicable, especially for products sold within the European Union, ensuring that they meet health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Alcantara Production?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the manufacturing process, ensuring that each stage adheres to quality benchmarks.

- Final Quality Control (FQC): After finishing, a comprehensive inspection is performed to evaluate the final product against predefined quality criteria, including visual appearance, texture, and performance characteristics.

These QC checkpoints are essential for maintaining the integrity of Alcantara, ensuring that only products that meet rigorous standards reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial in establishing a reliable supply chain.

Illustrative image related to what is alcantara material

What Methods Can Buyers Use to Assess Supplier Quality?

Buyers can adopt several strategies to evaluate supplier quality control:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and compliance with international standards firsthand.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC practices, including test results and compliance certifications.

- Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices and product quality.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers must be aware of specific nuances that can affect quality control. For instance, cultural differences in manufacturing practices and varying regulatory environments can influence the quality and compliance of products. Buyers should also consider the logistical challenges involved in transporting materials across borders, which may impact product integrity. Establishing clear communication channels and expectations regarding quality can help mitigate these risks and ensure a successful partnership.

Conclusion

Understanding the manufacturing processes and quality assurance measures for Alcantara material is essential for B2B buyers seeking to source this premium fabric. By familiarizing themselves with the stages of production, relevant quality standards, and verification methods, buyers can make informed decisions that enhance their supply chain and product offerings. As the demand for high-quality materials continues to grow across various industries, being well-versed in these aspects will provide a competitive edge in the marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is alcantara material’

Introduction

This guide serves as a practical checklist for B2B buyers interested in procuring Alcantara material. As a synthetic textile known for its aesthetic appeal and functional benefits, understanding its sourcing requirements is essential for making informed purchasing decisions. This checklist will help you navigate the complexities of sourcing Alcantara effectively.

Illustrative image related to what is alcantara material

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for your project. Alcantara comes in various colors, textures, and weights, each suited for different applications, such as automotive interiors, fashion, or furniture upholstery.

– Considerations: Determine the intended use of the Alcantara, whether for high-performance applications or luxury finishes, as this will influence your specifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in Alcantara material. Look for manufacturers with a solid reputation and experience in producing high-quality synthetic textiles.

– Key Actions: Utilize industry directories, attend trade shows, and leverage professional networks to gather a list of suppliers.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify the certifications and quality standards of your shortlisted suppliers. This step is crucial to ensure that the Alcantara meets industry regulations and sustainability criteria.

– What to Look For: Check for certifications such as OEKO-TEX® Standard 100 or ISO 14001, which indicate compliance with environmental and safety standards.

Step 4: Request Samples for Quality Assessment

Once you have identified potential suppliers, request samples of their Alcantara material. Evaluating physical samples allows you to assess the texture, color accuracy, and overall quality.

– Evaluation Criteria: Pay attention to the fabric’s durability, softness, and how it responds to light and wear. This hands-on assessment will help you gauge whether the material meets your specifications.

Step 5: Understand Pricing Structures

Engage suppliers in discussions about their pricing models for Alcantara. Pricing can vary significantly based on factors such as order volume, customization, and shipping.

– Negotiation Points: Inquire about bulk discounts, shipping costs, and lead times. Understanding the full cost will enable you to budget effectively and avoid unexpected expenses.

Step 6: Assess After-Sales Support and Warranty

Before finalizing your procurement, evaluate the after-sales support and warranty options provided by the supplier. A reliable supplier should offer guidance on care and maintenance, especially given Alcantara’s specific cleaning requirements.

– Important Considerations: Confirm the availability of customer support for troubleshooting and any warranty terms that cover defects or issues arising from normal use.

Step 7: Finalize Contracts with Clear Terms

Once you have chosen a supplier, draft a contract that outlines all agreed-upon terms, including delivery schedules, payment terms, and quality assurance protocols. Clear contracts help prevent misunderstandings and ensure accountability.

– Key Elements: Include clauses related to quality checks, returns, and dispute resolution to safeguard your interests throughout the sourcing process.

By following this checklist, B2B buyers can effectively source Alcantara material, ensuring they receive a product that meets their needs while maintaining quality and compliance standards.

Comprehensive Cost and Pricing Analysis for what is alcantara material Sourcing

What Are the Cost Components Involved in Sourcing Alcantara Material?

When evaluating the cost structure for sourcing Alcantara, several components come into play. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: Alcantara is composed of 68% polyester and 32% polyurethane, both of which are synthetic materials. The cost of these raw materials can fluctuate based on global oil prices and availability. Additionally, suppliers may offer different grades of Alcantara, which can impact pricing.

-

Labor: Labor costs in the manufacturing process can vary by region. Countries with lower labor costs may provide more competitive pricing, while regions with stringent labor laws may incur higher expenses.

-

Manufacturing Overhead: This encompasses the costs associated with running production facilities, including utilities, rent, and equipment maintenance. Manufacturers in countries with advanced technology may have higher overhead due to the investment in machinery and automation.

-

Tooling: Custom tooling for specific applications can add to the initial investment required for Alcantara production. This cost is particularly relevant for manufacturers creating bespoke designs or specialized products.

-

Quality Control (QC): Ensuring the integrity and quality of Alcantara involves rigorous testing and inspection processes. These costs, while necessary for maintaining high standards, can add to the overall expense.

-

Logistics: Transportation costs can vary significantly based on the distance between the supplier and the buyer, as well as the chosen method of shipping. International buyers must also consider tariffs and customs duties, which can affect the total cost.

-

Margin: Suppliers typically include a margin in their pricing to account for risk, market conditions, and profit. The margin can vary based on the supplier’s market positioning and the competitiveness of their offerings.

What Influences the Pricing of Alcantara Material?

Several factors influence the pricing of Alcantara, particularly for international B2B buyers.

-

Volume/MOQ: Minimum order quantities (MOQs) can dictate pricing. Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize their purchasing strategy.

-

Specifications and Customization: Custom designs or specific color requirements can increase costs. Buyers should clearly define their specifications to receive accurate pricing.

-

Materials and Quality Certifications: Higher-quality Alcantara or those with specific certifications (e.g., eco-friendly production) may command premium prices. Buyers should assess their quality needs versus budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more, but they often provide better service and reliability.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect the final cost. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears the costs and risks at different stages of shipping.

What Tips Should Buyers Consider for Cost-Efficiency?

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage your purchasing power to negotiate better terms.

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with Alcantara, including maintenance and cleaning requirements, to understand the true cost beyond the initial purchase price.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and shipping costs, which can significantly impact the final price. Building relationships with local suppliers in regions like Africa and the Middle East can also provide cost advantages.

-

Market Research: Conduct thorough market research to compare prices across different suppliers and regions. This diligence can lead to better procurement decisions.

Disclaimer on Indicative Prices

Prices for Alcantara can vary widely based on the aforementioned factors. Buyers should consult directly with suppliers for the most accurate and current pricing tailored to their specific needs and conditions.

Alternatives Analysis: Comparing what is alcantara material With Other Solutions

Exploring Alternatives to Alcantara Material

When considering materials for automotive interiors and other high-end applications, it’s crucial to evaluate not only the benefits of Alcantara but also viable alternatives. Each material has distinct characteristics that can influence decisions based on performance, cost, maintenance, and suitability for specific applications. Below, we compare Alcantara with two prominent alternatives: genuine leather and UltraSuede.

| Comparison Aspect | What Is Alcantara Material | Genuine Leather | UltraSuede |

|---|---|---|---|

| Performance | High grip, moisture-resistant, soft texture | Durable, luxurious feel, high maintenance | Soft, suede-like finish, good grip |

| Cost | Comparable to leather, generally between $1,000 – $3,000 | Typically more expensive, ranging from $1,500 – $5,000+ | Often lower cost than Alcantara, varies by brand |

| Ease of Implementation | Requires specific cutting and sewing techniques, lightweight | Standard upholstery processes | Similar to Alcantara, but can be easier to work with |

| Maintenance | Regular cleaning needed, sensitive to oils and dirt | Requires conditioning and cleaning, can stain | Easier to clean, often machine washable |

| Best Use Case | Luxury automotive interiors, furniture, fashion | High-end luxury vehicles, bespoke furniture | Budget-friendly luxury applications, automotive interiors |

What Are the Pros and Cons of Genuine Leather as an Alternative to Alcantara?

Genuine leather is renowned for its durability and timeless appeal, often regarded as the benchmark for luxury materials. It offers a rich texture and aesthetic that many consumers desire, making it a popular choice in high-end automotive markets. However, leather requires significant maintenance to keep it looking its best, including regular conditioning to prevent cracking and staining. Additionally, it is generally more expensive than Alcantara, which can be a concern for budget-conscious buyers. Its environmental impact is also a consideration, as it involves animal byproducts and often requires chemical treatments.

How Does UltraSuede Compare to Alcantara in Terms of Performance and Cost?

UltraSuede is a synthetic alternative that mimics the look and feel of Alcantara while often being more cost-effective. It provides a soft texture and is generally easier to clean, making it a practical choice for consumers who prioritize low maintenance. However, while UltraSuede offers a similar aesthetic, it may not provide the same level of grip and moisture resistance that Alcantara boasts. This can be a disadvantage in high-performance applications, such as racing or luxury vehicles where functionality is paramount. Furthermore, the brand’s reputation can vary, affecting perceived value and market positioning.

Illustrative image related to what is alcantara material

Conclusion: How Should B2B Buyers Choose the Right Material for Their Needs?

Selecting the right material for automotive interiors or other applications depends on a variety of factors, including budget, desired aesthetics, and maintenance capabilities. Alcantara stands out for its premium feel and performance, particularly in environments where grip and moisture resistance are crucial. However, alternatives like genuine leather and UltraSuede also offer unique advantages that may align better with specific needs or budget constraints. B2B buyers should evaluate the long-term implications of their choices, considering both initial costs and maintenance over time to ensure they invest in a solution that best fits their operational requirements.

Essential Technical Properties and Trade Terminology for what is alcantara material

What Are the Key Technical Properties of Alcantara Material?

What is the Material Composition of Alcantara?

Alcantara is a synthetic textile made from a proprietary blend of 68% polyester and 32% polyurethane. This unique composition gives Alcantara its suede-like appearance while ensuring durability and resistance to wear. For B2B buyers, understanding the material composition is crucial as it affects the performance, maintenance, and overall cost of the fabric. The synthetic nature of Alcantara also means it is a vegan-friendly alternative to leather, appealing to environmentally conscious consumers.

How Does Alcantara Perform in Terms of Durability?

Alcantara is known for its high durability, making it suitable for various applications, especially in automotive interiors. It is more resistant to abrasion and moisture than traditional suede and offers superior grip, which is particularly beneficial in high-performance environments. For businesses, investing in Alcantara can lead to lower replacement costs over time due to its longevity, making it a cost-effective option in the long run.

What Are the Maintenance Requirements for Alcantara?

One of the critical aspects of Alcantara is its maintenance needs. While it is easier to clean than leather, it still requires regular upkeep to maintain its aesthetic appeal. B2B buyers should be aware that cleaning methods typically involve gentle solutions and specialized brushes to avoid damaging the fabric. Understanding these maintenance requirements can influence purchasing decisions, particularly for industries where ease of cleaning is paramount, such as automotive or hospitality.

What is the Flame Resistance of Alcantara?

Alcantara can be treated to be flame-retardant, making it a safe choice for applications in environments where fire safety is a concern. This property is particularly relevant for industries like automotive, aviation, and public transportation. B2B buyers must consider flame resistance as a critical specification when selecting materials for projects where safety regulations are stringent.

What is the Weight of Alcantara Compared to Other Materials?

Alcantara is lightweight, which is advantageous in applications where reducing overall weight is essential, such as in automotive design. Its lighter nature does not compromise its strength, making it an ideal choice for manufacturers looking to enhance fuel efficiency without sacrificing quality. Buyers should assess the weight specifications of materials to ensure compliance with performance standards in their respective industries.

What Are Common Trade Terms Associated with Alcantara Material?

What Does OEM Mean in the Context of Alcantara?

OEM stands for Original Equipment Manufacturer. In the context of Alcantara, it refers to companies that use Alcantara in their products, such as automotive manufacturers. Understanding OEM relationships is vital for B2B buyers as it can influence supply chain dynamics and product quality assurance.

What is MOQ and Why is it Important for Alcantara Purchases?

MOQ, or Minimum Order Quantity, represents the smallest number of units a supplier is willing to sell. For Alcantara, MOQs can vary significantly based on the supplier and specific product lines. B2B buyers should be aware of MOQs when planning purchases to ensure they meet supplier requirements and avoid overstocking or stockouts.

What is an RFQ and How Does it Relate to Alcantara Procurement?

RFQ stands for Request for Quotation. This is a formal process where buyers solicit price quotes from suppliers. For Alcantara, issuing an RFQ allows businesses to compare costs, understand lead times, and negotiate terms effectively. It’s an essential step in ensuring competitive pricing and sourcing the best quality materials.

What Are Incoterms and Why Are They Relevant for Alcantara Shipping?

Incoterms, or International Commercial Terms, are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. For Alcantara, understanding Incoterms is crucial for B2B buyers, as they dictate shipping costs, insurance, and risk management during the transportation of goods. Proper comprehension of these terms can significantly affect budgeting and logistics planning.

What Does Lead Time Mean for Alcantara Orders?

Lead time refers to the time taken from placing an order until the product is delivered. In the context of Alcantara, lead times can vary based on production schedules, material availability, and shipping logistics. B2B buyers should factor in lead times when planning projects to ensure timely delivery and avoid disruptions in their supply chain.

Navigating Market Dynamics and Sourcing Trends in the what is alcantara material Sector

What Are the Global Drivers Influencing Alcantara Material Sourcing?

The Alcantara material sector is experiencing a significant shift driven by various global factors. The rising demand for high-performance automotive interiors, particularly in luxury and sports cars, is a primary driver. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking materials that not only enhance aesthetics but also improve functionality. Alcantara’s unique properties, such as its grip, durability, and lightweight nature, make it an appealing choice for manufacturers aiming to differentiate their products in competitive markets.

Emerging trends in technology and sourcing are also reshaping the market. Digital platforms and e-commerce have made it easier for manufacturers to source Alcantara and other synthetic textiles globally. B2B buyers are leveraging these platforms to compare suppliers, negotiate prices, and ensure timely delivery. Additionally, the increasing importance of customization in automotive interiors is driving demand for Alcantara, as it can be easily dyed and finished to match specific design requirements.

Moreover, the growing trend towards sustainability in manufacturing is influencing sourcing decisions. Buyers are more inclined to partner with suppliers who can demonstrate eco-friendly practices in their production processes, particularly in the sourcing of raw materials. As a result, the Alcantara market is likely to see a rise in suppliers who prioritize sustainable practices, aligning with the values of today’s conscientious consumers.

How Is Sustainability Shaping Alcantara Material Supply Chains?

Sustainability and ethical sourcing are becoming paramount in the Alcantara material sector. The production process of Alcantara involves synthetic fibers, primarily polyester and polyurethane, which raises concerns regarding environmental impact. However, Alcantara S.p.A. has made strides to mitigate these issues by implementing eco-friendly production methods. They focus on reducing waste, recycling materials, and minimizing water usage, which appeals to B2B buyers looking for sustainable options.

Ethical supply chains are also critical for fostering trust and loyalty among international buyers. Companies are increasingly seeking suppliers who can provide transparency regarding their sourcing practices and labor conditions. Certifications such as OEKO-TEX® and Global Recycled Standard (GRS) are becoming essential for manufacturers aiming to validate their sustainability claims. These certifications not only assure buyers of the environmental integrity of the materials but also enhance brand reputation in a market where consumers are becoming more eco-conscious.

Additionally, as Alcantara is a vegan-friendly product, it caters to the growing market segment that prioritizes animal welfare. This aspect further strengthens its appeal among B2B buyers who are committed to ethical sourcing and sustainability in their supply chains.

Illustrative image related to what is alcantara material

What Is the Historical Context of Alcantara Material in B2B Markets?

Alcantara was developed in the 1970s by Japanese chemist Miyoshi Okamoto and has been manufactured by the Italian company Alcantara S.p.A. since then. Initially, it was primarily used in high-end automotive interiors, quickly establishing itself as a luxury material due to its unique characteristics, including a soft texture and superior grip. Over the years, Alcantara has transitioned from being exclusive to performance vehicles to becoming a favored choice in mainstream automotive applications, offering a blend of luxury and practicality.

The evolution of Alcantara reflects broader trends in the textile industry, where synthetic materials are increasingly replacing natural fibers due to their versatility and performance advantages. This transition has led to a significant expansion in the availability of Alcantara, making it accessible to a wider range of manufacturers and B2B buyers across various sectors, including fashion and interior design. As the market continues to evolve, Alcantara’s reputation as a premium, sustainable, and functional material positions it well for future growth in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of what is alcantara material

-

How do I clean Alcantara material effectively?

Cleaning Alcantara requires a gentle approach to maintain its texture and appearance. Start by vacuuming or brushing the surface to remove loose dirt. For deeper cleaning, use a damp, soft cloth to wipe the material, ensuring not to saturate it. If stains persist, consider a mild, pH-neutral cleaner specifically designed for Alcantara. Always refer to the manufacturer’s guidelines for the best practices and recommended products to avoid damaging the fabric. -

What are the advantages of using Alcantara in automotive interiors?

Alcantara offers several benefits for automotive interiors, including its superior grip compared to leather, which enhances safety in high-performance vehicles. Its matte finish reduces glare, making it ideal for dashboards and steering wheels. Additionally, Alcantara is lightweight, flame-retardant, and does not involve animal products, making it a vegan-friendly option. These qualities contribute to its growing popularity among manufacturers aiming to create luxurious yet practical vehicle interiors. -

What factors should I consider when sourcing Alcantara suppliers?

When sourcing Alcantara suppliers, prioritize their reputation and experience in the industry. Verify their certifications and compliance with international standards to ensure product quality and ethical practices. Request samples to evaluate the fabric’s texture and durability. Additionally, consider the supplier’s ability to meet your customization needs, minimum order quantities (MOQ), and delivery timelines to ensure they align with your project requirements. -

What are typical minimum order quantities (MOQ) for Alcantara?

Minimum order quantities for Alcantara can vary significantly based on the supplier and the specific product line. Generally, MOQs range from a few meters to several hundred meters for bulk orders. It’s advisable to discuss your project needs with potential suppliers to negotiate favorable terms. Understanding the MOQ is crucial for budgeting and ensuring you have enough material for your production needs. -

How do I assess the quality of Alcantara before making a purchase?

To assess the quality of Alcantara, request physical samples from suppliers to evaluate texture, weight, and color consistency. Check for certifications that indicate compliance with environmental and safety standards, such as OEKO-TEX or ISO certifications. Additionally, inquire about the production process, including the ratio of polyester to polyurethane, as this impacts durability and performance. Conducting these assessments helps ensure you receive a product that meets your expectations. -

What payment terms are common when buying Alcantara?

Payment terms for Alcantara purchases typically include options like upfront payment, partial payment upon order confirmation, and the balance due before shipment. Some suppliers may offer credit terms based on your business relationship and order size. It’s essential to clarify payment methods, such as bank transfers or letters of credit, and to negotiate terms that suit your cash flow needs while ensuring security for both parties. -

What logistics considerations should I keep in mind when importing Alcantara?

When importing Alcantara, consider shipping methods, transit times, and customs regulations specific to your region. Ensure that your supplier can accommodate your preferred shipping options, whether air freight for faster delivery or sea freight for cost-effectiveness. Verify that all necessary documentation, such as invoices and certificates of origin, is in order to facilitate a smooth customs clearance process, preventing delays or additional costs. -

Can Alcantara be customized for specific projects?

Yes, Alcantara can be customized in terms of color, texture, and pattern to suit specific project requirements. Many suppliers offer a range of colors and finishes, allowing businesses to create unique designs. Discuss your customization needs with potential suppliers, including any specific applications or aesthetic considerations. Keep in mind that custom orders may require larger MOQs and longer lead times, so plan accordingly to ensure timely delivery for your projects.

Top 6 What Is Alcantara Material Manufacturers & Suppliers List

1. Alcantara – Synthetic Suede Upholstery

Domain: carwow.co.uk

Registered: 2011 (14 years)

Introduction: Alcantara is a synthetic suede-like fabric made from a blend of polyester and polyurethane, developed in the 1970s by a Japanese chemist and manufactured by the Italian company Alcantara. It is used in car interiors for upholstery on seats, dashboards, arm rests, door cards, transmission tunnels, sun visors, and headliners. Pros include better grip than leather or plastic, flame retardant properti…

2. Alcantara – Synthetic Suede Material

Domain: motortrend.com

Registered: 1998 (27 years)

Introduction: Alcantara is a synthetic suedelike material invented in the early 1970s by Miyoshi Okamoto, made up of 68% polyester and 32% non-fibrous polyurethane. It is produced in Italy by Alcantara S.p.A. The fabric is commonly used in high-end automobile interiors and aftermarket parts, often as a luxury alternative to leather. Alcantara has a matte finish that reduces glare and provides a less slippery su…

3. Alcantara – Innovative Material Solutions

Domain: alcantara.com

Registered: 1996 (29 years)

Introduction: Alcantara is a 100% Italian brand known for its unique and exclusive technology, making it a cutting-edge material suitable for covering any shape or surface. Key features include:

– Elegant and soft to the touch

– Durable and easy to care for

– Versatile in aesthetic form

– Resistant to light and heat

– Breathable, warm in winter and cool in summer

– Low maintenance, can be washed and irone…

4. Alcantara – Luxury Automotive Material

Domain: tt-blogs.dealerfire.com

Registered: 2004 (21 years)

Introduction: Alcantara is a synthetic material similar to suede, composed of approximately 68% polyester and 32% polyurethane. It is designed to be resistant to staining and is used in luxury and performance vehicles, including Lamborghini models. Alcantara is produced by Alcantara SPA in Italy and is known for its luxurious feel, achieved through a proprietary manufacturing process involving needle punching, …

5. GentCreate – Alcantara Luxury Material

Domain: gentcreate.com

Registered: 2020 (5 years)

Introduction: Alcantara is a synthetic material known for its luxurious feel and versatility in fashion. It is made from a blend of polyester and polyurethane, offering durability and a soft texture. Alcantara is often used in high-end fashion items, accessories, and automotive interiors due to its aesthetic appeal and functionality. The material is also environmentally friendly, being produced with a focus on …

6. Leather Repair Company – Leather Care Solutions

Domain: leatherrepaircompany.com

Registered: 2007 (18 years)

Introduction: Leather Repair Company offers various products and services related to leather care and restoration. Key offerings include: 1. Leather Cleaning & Stain Removal 2. Leather Protection 3. Leather Repairs (Holes, Rips, Scratches, Scuffs, Burns) 4. Leather Colour Restoration and Recolouring 5. Applicators & Accessories 6. Care & Restoration Kits 7. Sneakers/Trainers Care & Customisation 8. Repair Servi…

Strategic Sourcing Conclusion and Outlook for what is alcantara material

Alcantara is a versatile and appealing synthetic textile that offers significant advantages for automotive interiors and various other applications. Its unique blend of polyester and polyurethane results in a material that is both lightweight and durable, making it a popular choice among high-end manufacturers. The non-slip, matte finish enhances both safety and aesthetic appeal, providing a luxurious touch without the ethical concerns associated with animal-derived materials.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the sourcing and application of Alcantara can lead to competitive advantages. Its growing popularity in mainstream automotive markets indicates a shift in consumer preferences towards sustainable and low-maintenance materials. Strategic sourcing of Alcantara not only aligns with these trends but also positions businesses to meet rising demand for premium, eco-friendly products.

Looking ahead, now is the time to explore partnerships with reputable suppliers of Alcantara. By investing in this innovative material, companies can elevate their product offerings while appealing to a broader customer base. Embrace the opportunity to enhance your brand with Alcantara, and stay ahead of market trends by integrating sustainable solutions into your sourcing strategies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to what is alcantara material