Introduction: Navigating the Global Market for leather grades

In the complex world of international trade, sourcing high-quality leather grades presents a significant challenge for B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. Understanding the nuances of leather grading—ranging from full-grain to bonded leather—can make a substantial difference in product durability, aesthetic appeal, and overall value. This guide aims to demystify the various types of leather, their applications across industries, and the critical factors to consider when selecting suppliers.

By providing a detailed analysis of leather grades, including their unique properties and potential uses, this guide empowers international buyers to make informed purchasing decisions. It also addresses key considerations such as supplier vetting processes, cost implications, and market trends, ensuring that your procurement strategy is both effective and competitive. Whether you’re based in bustling markets like Vietnam or Nigeria, or navigating the intricacies of European trade, understanding leather grades is essential for maintaining product quality and enhancing customer satisfaction. This comprehensive resource will equip you with the insights necessary to confidently navigate the global leather market, ultimately leading to more successful and profitable sourcing outcomes.

Table Of Contents

- Top 8 Leather Grades Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather grades

- Understanding leather grades Types and Variations

- Key Industrial Applications of leather grades

- 3 Common User Pain Points for ‘leather grades’ & Their Solutions

- Strategic Material Selection Guide for leather grades

- In-depth Look: Manufacturing Processes and Quality Assurance for leather grades

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather grades’

- Comprehensive Cost and Pricing Analysis for leather grades Sourcing

- Alternatives Analysis: Comparing leather grades With Other Solutions

- Essential Technical Properties and Trade Terminology for leather grades

- Navigating Market Dynamics and Sourcing Trends in the leather grades Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather grades

- Strategic Sourcing Conclusion and Outlook for leather grades

- Important Disclaimer & Terms of Use

Understanding leather grades Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

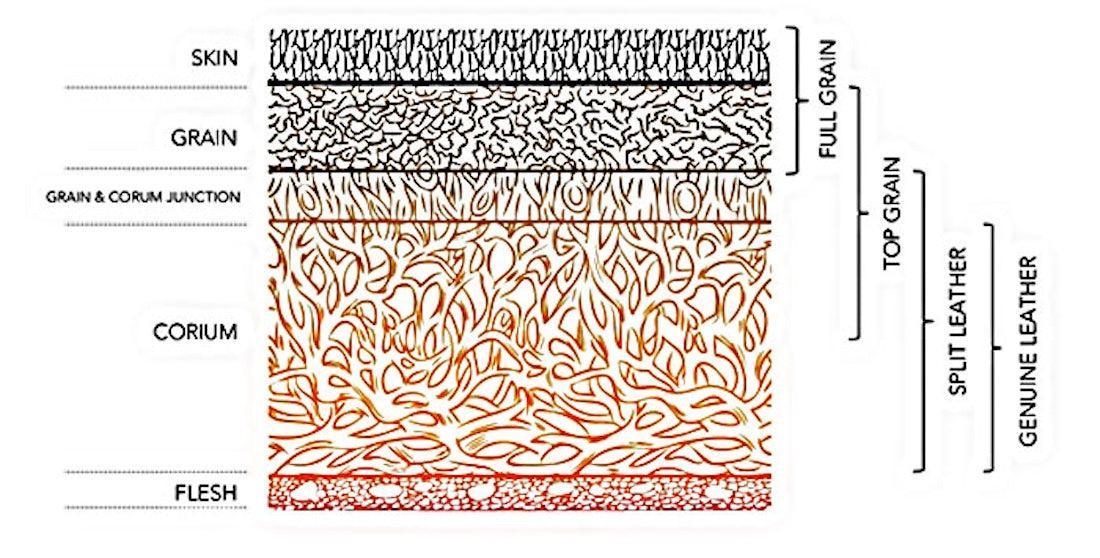

| Full-Grain Leather | Retains the natural grain, high durability, develops patina | Luxury goods, high-end furniture, accessories | Pros: Long-lasting, unique appearance. Cons: Higher cost. |

| Top-Grain Leather | Sanded for a uniform look, slightly less durable than full-grain | Fashion items, handbags, upholstery | Pros: Attractive finish, easier to clean. Cons: Less breathable than full-grain. |

| Split-Grain Leather | Lacks natural grain, often soft and pliable | Suede products, affordable fashion items | Pros: Cost-effective, soft texture. Cons: Less durable, prone to wear. |

| Genuine Leather | Made from lower-quality layers, heavily processed | Budget-friendly products, mass-produced items | Pros: Affordable, widely available. Cons: Lacks durability and natural appearance. |

| Bonded Leather | Composed of leather scraps and synthetic materials | Inexpensive furniture, low-cost accessories | Pros: Very affordable. Cons: Poor durability, often peels or cracks. |

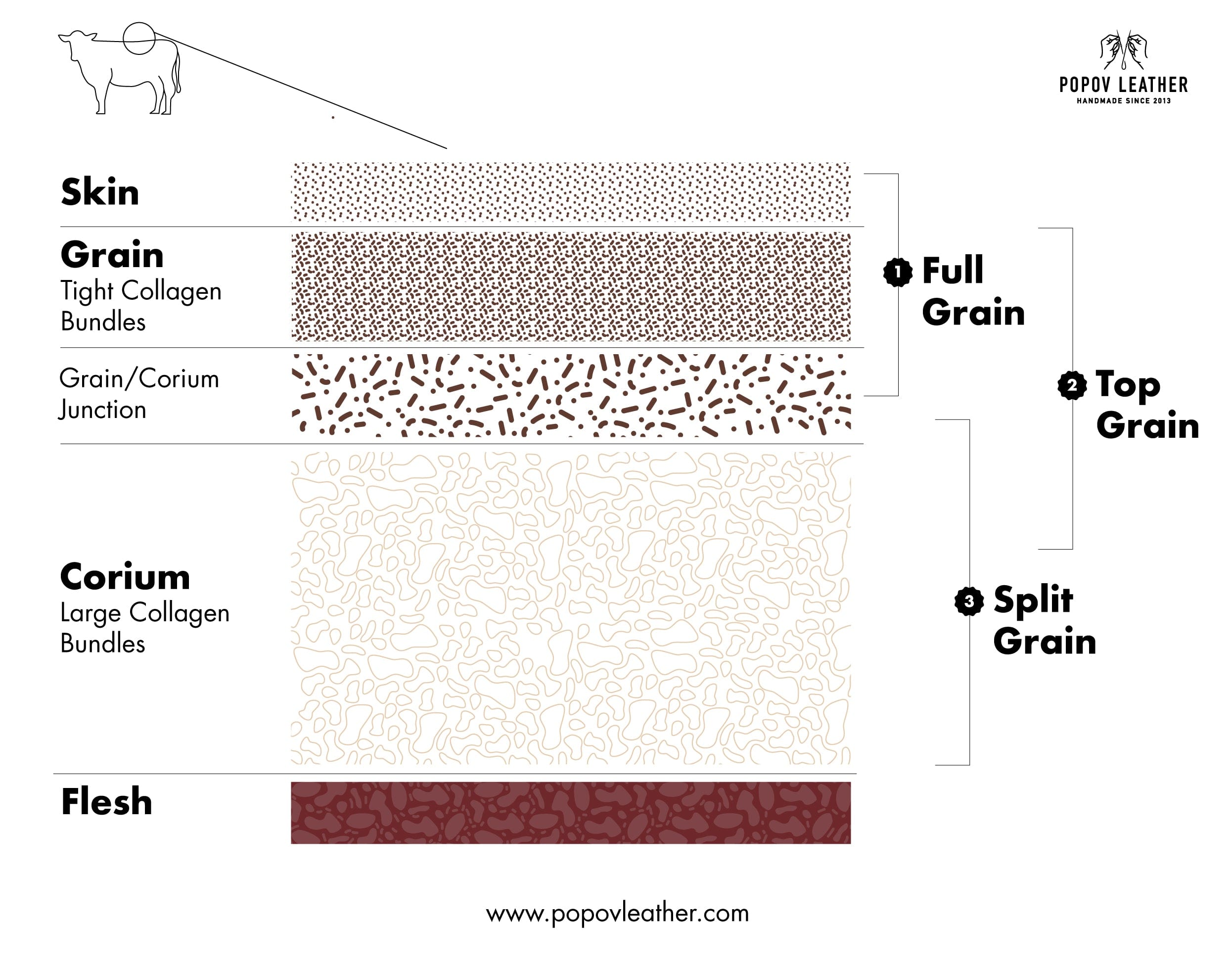

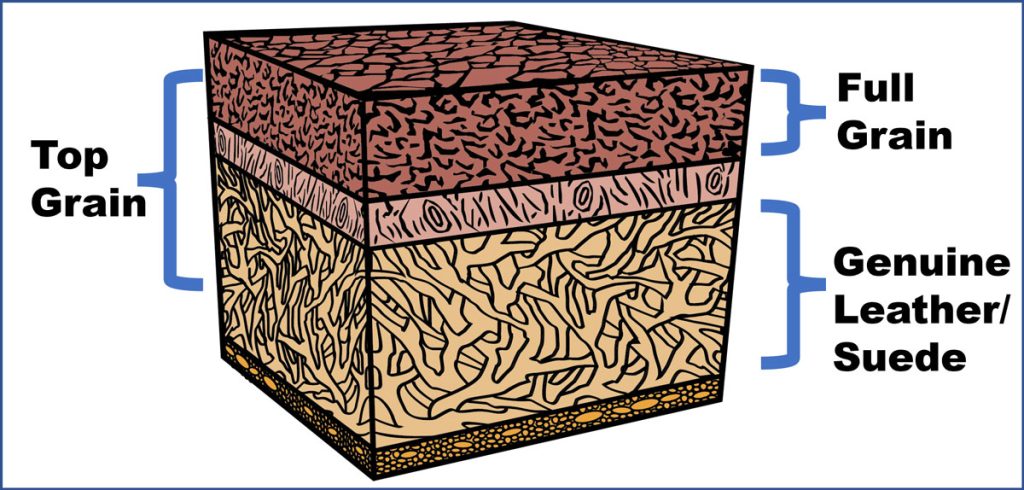

What are the Characteristics of Full-Grain Leather?

Full-grain leather is the highest quality leather available, made from the top layer of the hide, retaining its natural grain and imperfections. This type of leather is highly durable and develops a rich patina over time, making it ideal for luxury goods and high-end furniture. B2B buyers should consider full-grain leather for products that demand longevity and aesthetic appeal, as it can command a higher price but offers excellent value over its lifespan.

How Does Top-Grain Leather Differ from Full-Grain?

Top-grain leather is sanded and treated for a smoother finish compared to full-grain leather. While it still offers good durability, it is less breathable and may not develop the same rich patina. This type is commonly used in fashion items and upholstery where a polished look is desired. Buyers should weigh the benefits of a uniform appearance against the potential for reduced longevity when considering top-grain leather for their products.

What are the Benefits of Split-Grain Leather?

Split-grain leather is created from the lower layers of the hide and is known for its softness and pliability, often used in suede applications. It is a cost-effective option for manufacturers looking to produce affordable fashion items and accessories. However, its lack of durability compared to higher-grade leathers means buyers should consider the intended use and lifespan of the product before choosing split-grain leather.

Why is Genuine Leather Considered Lower Quality?

Genuine leather is derived from the bottom layers of the hide and is heavily processed, resulting in a product that lacks the natural characteristics of higher-quality leathers. While it is an affordable option for mass-produced items, it does not offer the same durability or aesthetic appeal. B2B buyers should be cautious when selecting genuine leather, as it may not meet expectations for longevity or quality in more demanding applications.

What Should Buyers Know About Bonded Leather?

Bonded leather is a composite material made from leather scraps combined with synthetic materials, resulting in a product that is low-cost but also low-quality. It is often used in inexpensive furniture and accessories. Buyers should be aware that while bonded leather is affordable, it typically does not withstand wear and tear, making it unsuitable for products requiring durability. Understanding these limitations is crucial for B2B buyers looking to balance cost and quality.

Key Industrial Applications of leather grades

| Industry/Sector | Specific Application of leather grades | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery and interior components | Enhances vehicle aesthetics and durability | Ensure compliance with industry regulations and standards for safety and quality. |

| Fashion & Apparel | High-end bags, jackets, and footwear | Provides luxury feel and long-lasting products | Source from reputable tanneries with sustainable practices and quality certifications. |

| Furniture | Sofas, chairs, and decorative items | Increases product lifespan and customer satisfaction | Focus on full-grain and top-grain leathers for durability; consider maintenance requirements. |

| Sports Equipment | Protective gear and accessories | Offers durability and comfort for athletes | Assess performance characteristics and ensure materials meet safety standards. |

| Industrial Goods | Workwear and safety gear | Provides protection and comfort in harsh environments | Look for abrasion-resistant leathers with certifications for industrial use. |

How is Leather Used in the Automotive Industry?

In the automotive sector, leather grades are crucial for upholstery and interior components. High-quality leather, such as full-grain or top-grain, is preferred for its durability and luxurious appearance, enhancing the vehicle’s overall aesthetic appeal. International buyers should ensure that the leather meets industry regulations regarding safety and emissions, as well as consider the environmental impact of sourcing practices. Properly sourced leather can significantly elevate the perceived value of the vehicle, fostering customer loyalty.

What Role Does Leather Play in Fashion and Apparel?

In the fashion industry, leather grades are pivotal for creating high-end bags, jackets, and footwear. Full-grain leather is often favored for its unique texture and ability to develop a rich patina over time, adding character to fashion items. B2B buyers from regions like Africa and Europe should prioritize suppliers that adhere to sustainable practices and offer quality certifications to ensure the longevity and appeal of their products. This not only enhances brand reputation but also meets the growing consumer demand for ethically sourced materials.

Why is Leather Important for Furniture?

In the furniture sector, leather grades are essential for producing sofas, chairs, and decorative items. High-quality leather contributes to the durability and comfort of furniture, making it a preferred choice for luxury and high-end markets. International buyers should focus on full-grain and top-grain leathers, which offer superior resistance to wear and tear. Additionally, understanding the maintenance requirements of different leather types is crucial for ensuring long-term customer satisfaction and reducing return rates.

How is Leather Utilized in Sports Equipment?

Leather grades play a significant role in sports equipment, particularly in protective gear and accessories. Full-grain leather is often used for its durability and ability to provide comfort during physical activities. B2B buyers need to assess the performance characteristics of the leather, ensuring it meets safety standards relevant to sports. This focus on quality not only enhances the safety of athletes but also contributes to a brand’s reputation for reliability and performance.

Illustrative image related to leather grades

What are the Applications of Leather in Industrial Goods?

In the industrial sector, leather is commonly used for workwear and safety gear. The durability and protective qualities of high-grade leather make it an ideal choice for harsh working environments. Buyers should prioritize abrasion-resistant leathers that have certifications for industrial use, ensuring compliance with safety standards. By sourcing high-quality leather, businesses can improve employee safety and satisfaction, ultimately reducing costs associated with workplace injuries and enhancing overall productivity.

3 Common User Pain Points for ‘leather grades’ & Their Solutions

Scenario 1: Navigating the Complexity of Leather Grades

The Problem:

International B2B buyers often face confusion when it comes to understanding the various grades of leather. For instance, a buyer from Nigeria looking to source leather for high-end furniture may find themselves overwhelmed by terms like “full-grain,” “top-grain,” and “bonded leather.” This lack of clarity can lead to miscommunication with suppliers, resulting in the procurement of inferior-quality leather that does not meet the desired specifications. Such mistakes can harm their reputation and result in significant financial losses, especially when working on high-stakes projects that require premium materials.

The Solution:

To effectively navigate the complexity of leather grades, buyers should invest time in educating themselves about the characteristics and applications of each type of leather. One actionable step is to create a detailed specification document that outlines the desired leather grade, including the intended use, durability requirements, and aesthetic preferences. This document can serve as a reference point during discussions with suppliers. Additionally, buyers should request samples from potential vendors and conduct a comparative analysis to evaluate the quality firsthand. Establishing a relationship with trusted suppliers who can provide clear labeling and documentation of leather grades will further ensure that the materials meet the buyer’s standards.

Scenario 2: Ensuring Durability and Longevity in Leather Products

The Problem:

A buyer from South America seeking leather for luxury handbags may encounter issues with durability and longevity. Many suppliers might offer “genuine leather” as a cost-effective option, but this grade often falls short in terms of strength and wear resistance. When these products fail prematurely, it not only affects customer satisfaction but also leads to costly returns and repairs, damaging the brand’s reputation in a competitive market.

The Solution:

To ensure that leather products withstand the test of time, buyers should prioritize sourcing full-grain or top-grain leather. These grades provide superior durability and develop an appealing patina over time. Buyers can ask suppliers for information on the tanning process and the leather’s thickness, as thicker hides typically offer better durability. Additionally, implementing a quality assurance process that includes rigorous testing for wear and tear can help identify any potential issues before products reach the market. Collaborating with manufacturers who have a strong track record in leather craftsmanship will also enhance the chances of securing high-quality materials.

Illustrative image related to leather grades

Scenario 3: Avoiding Misleading Marketing Claims in Leather Products

The Problem:

In the Middle East, a buyer for a retail chain may struggle with misleading marketing claims regarding leather grades. Suppliers often label products as “genuine leather” to make them appear more desirable, but the reality is that this type of leather is typically of lower quality. Such discrepancies can lead to customer dissatisfaction and negative reviews, which are particularly damaging in the age of social media where word-of-mouth can significantly impact sales.

The Solution:

To combat misleading marketing claims, buyers should adopt a proactive approach in verifying the authenticity of leather grades. This can be accomplished by demanding transparency from suppliers, including detailed product descriptions and certificates of authenticity. Establishing a checklist of key characteristics for each leather grade can also aid in making informed purchasing decisions. Furthermore, buyers should educate their sales teams about the differences between leather grades so they can effectively communicate the value of higher-quality options to customers. This not only enhances customer trust but also positions the retail chain as a knowledgeable and reliable source for quality leather products.

Strategic Material Selection Guide for leather grades

What Are the Key Properties of Different Leather Grades for B2B Applications?

When selecting leather grades for various applications, it’s crucial to understand the key properties of each type. The most common grades—full-grain, top-grain, split-grain, genuine, and bonded leather—each come with distinct characteristics that can affect product performance, durability, and suitability for specific uses.

Illustrative image related to leather grades

How Does Full-Grain Leather Perform in Various Applications?

Full-grain leather is renowned for its durability and natural aesthetics, retaining the hide’s original grain and imperfections. This type of leather is highly breathable and develops a rich patina over time, making it ideal for high-end products like luxury handbags and furniture. Its temperature and pressure resistance are excellent, allowing it to withstand daily wear and tear without compromising its structural integrity.

Pros: Exceptional durability, natural beauty, and moisture resistance.

Cons: Higher cost and longer manufacturing time due to the need for careful processing.

Impact on Application: Suitable for premium goods where longevity and aesthetic appeal are paramount.

Considerations for International Buyers: Compliance with international quality standards (e.g., ASTM) is essential, particularly in markets like Europe where consumers expect high-quality materials.

What Advantages Does Top-Grain Leather Offer for B2B Buyers?

Top-grain leather is slightly processed, offering a more uniform appearance while maintaining decent durability. It is sanded and treated, which makes it less prone to staining and easier to clean compared to full-grain leather. This makes it a popular choice for items that require a balance between aesthetics and practicality, such as automotive interiors and office furniture.

Pros: Easier maintenance, good durability, and visually appealing.

Cons: Less breathable than full-grain and may not develop a patina as beautifully.

Impact on Application: Well-suited for environments where spills and stains are common.

Considerations for International Buyers: Buyers should ensure that the top-grain leather meets local regulations for chemical treatments, especially in markets with strict environmental standards.

Illustrative image related to leather grades

How Does Split-Grain Leather Compare for Versatile Uses?

Split-grain leather, often used for suede, is derived from the lower layers of the hide and lacks the natural grain. While it is softer and more pliable, it is less durable than full-grain and top-grain leathers. This type is commonly used in fashion accessories and home décor items.

Pros: Soft texture and flexibility, often more affordable.

Cons: Lower durability and more susceptible to staining and wear.

Impact on Application: Ideal for products where comfort and aesthetics are prioritized over longevity.

Considerations for International Buyers: Split-grain leather may not meet the same durability standards as higher grades, so buyers should evaluate its suitability for their specific applications.

What Should Buyers Know About Genuine and Bonded Leather?

Genuine leather is made from the lower layers of the hide and is heavily processed, making it a lower-quality option. Bonded leather, on the other hand, is an amalgamation of leather scraps and synthetic materials, often used in lower-end products. While both are budget-friendly, they lack the durability and aesthetic appeal of higher grades.

Pros: Cost-effective and widely available.

Cons: Poor durability, prone to cracking and peeling over time.

Impact on Application: Best for low-cost items where longevity is not a concern.

Considerations for International Buyers: Buyers should be cautious of misleading marketing claims and ensure that products labeled as “genuine” or “bonded” meet their quality expectations.

Summary of Leather Grades for B2B Buyers

| Material | Typical Use Case for leather grades | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury handbags, high-end furniture | Exceptional durability and aesthetics | Higher cost and longer processing | High |

| Top-Grain Leather | Automotive interiors, office furniture | Easier maintenance and good durability | Less breathable than full-grain | Medium |

| Split-Grain Leather | Fashion accessories, home décor | Soft texture and flexibility | Lower durability and prone to stains | Low |

| Genuine Leather | Low-end bags, wallets | Cost-effective | Poor durability and aesthetic appeal | Low |

| Bonded Leather | Inexpensive furniture, low-cost goods | Budget-friendly | Lacks durability and quality | Low |

This guide provides a strategic overview for B2B buyers in diverse markets, helping them make informed decisions when selecting leather grades for their products. Understanding the properties, pros and cons, and compliance considerations will lead to better purchasing choices and improved product offerings.

Illustrative image related to leather grades

In-depth Look: Manufacturing Processes and Quality Assurance for leather grades

What Are the Key Stages in the Leather Manufacturing Process?

The manufacturing process for leather involves several key stages that transform raw hides into finished leather goods. Understanding these stages is crucial for B2B buyers looking to source high-quality leather products.

1. Material Preparation: How Are Hides Processed?

The journey begins with sourcing high-quality hides, primarily from cattle, which are selected for their thickness and quality. The hides undergo a curing process to prevent decay, typically using salt or chemicals. After curing, the hides are soaked in water to remove salt and dirt, followed by a process called liming, which uses lime to remove hair and other unwanted materials. This step is crucial in preparing the hide for splitting.

2. Forming: What Techniques Are Used to Shape Leather?

Once the hides are prepared, they are split into various grades. The splitting process separates the hide into top-grain and split-grain leather. Top-grain leather retains the outer layer, which contains the natural grain and features of the hide, while split-grain leather, often used for suede, is derived from the inner layers. After splitting, the leather is dyed and treated, which can involve processes such as tanning. Vegetable tanning, chrome tanning, and synthetic tanning are common methods that impart different characteristics to the leather, influencing its durability, flexibility, and appearance.

3. Assembly: How Are Leather Products Constructed?

In the assembly phase, the leather is cut into specific shapes and sizes based on the final product design. This is often done using precision cutting tools to ensure consistency. Skilled craftsmen or automated machines stitch the pieces together, utilizing techniques such as saddle stitching for durability. Additional components like zippers, buttons, and linings are integrated into the products at this stage.

Illustrative image related to leather grades

4. Finishing: What Final Touches Are Added?

The finishing process involves applying surface treatments to enhance the leather’s appearance and durability. This can include buffing, polishing, and applying protective coatings. Finishing techniques can vary widely depending on the desired look, from matte to glossy. The final product is then inspected for defects before being packaged for shipment.

What Quality Assurance Measures Are Crucial for Leather Products?

Quality assurance is a critical aspect of leather manufacturing, ensuring that products meet international standards and consumer expectations. Understanding these measures can help B2B buyers make informed decisions when sourcing leather goods.

1. What Are the Relevant International Standards?

B2B buyers should be aware of international quality standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with this standard indicates that a supplier consistently meets customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking for products sold in Europe and API (American Petroleum Institute) standards for leather used in specific industrial applications may also apply.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) in leather manufacturing typically involves multiple checkpoints:

-

Incoming Quality Control (IQC): This initial inspection occurs when raw materials arrive at the manufacturing facility. It ensures that hides meet specified quality standards before processing begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are conducted to monitor quality. This includes verifying that tanning, dyeing, and stitching meet established criteria.

-

Final Quality Control (FQC): Before products are packaged, a thorough inspection is performed. This includes checking for defects, ensuring that measurements align with specifications, and confirming that finishing processes are completed satisfactorily.

3. What Common Testing Methods Are Used in Leather Quality Assurance?

Testing methods for leather products include:

- Physical Tests: Assessing tensile strength, tear resistance, and abrasion resistance to ensure durability.

- Chemical Tests: Evaluating the leather for harmful substances, including heavy metals and formaldehyde, which are essential for compliance with safety regulations.

- Aesthetic Tests: Checking color consistency, grain quality, and overall appearance.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier QC practices is essential.

1. What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality control reports and audit results from potential suppliers. These documents should outline the supplier’s compliance with international standards and detail their internal QC processes. Regular third-party audits can provide additional assurance of a supplier’s commitment to maintaining quality.

Illustrative image related to leather grades

2. How Can Third-Party Inspection Services Enhance Buyer Confidence?

Engaging third-party inspection services can offer an independent assessment of product quality before shipment. Inspectors will conduct a thorough examination based on predefined criteria, including visual inspections and testing for compliance with specifications. This step can mitigate risks associated with sourcing from international suppliers.

What Are the QC Nuances for International B2B Buyers?

International buyers must navigate various regulations and standards that may differ by region. For instance, leather products exported to Europe must comply with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations, which restrict hazardous substances. Buyers should familiarize themselves with these regulations and ensure that their suppliers are compliant.

Additionally, cultural differences in business practices can impact quality expectations. Establishing clear communication channels and setting explicit quality requirements from the outset can help bridge these gaps and ensure a successful sourcing relationship.

By understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they procure high-quality leather products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather grades’

Introduction

Navigating the leather procurement process can be complex, particularly when it comes to understanding leather grades. This checklist serves as a practical guide for B2B buyers seeking to source quality leather products. By following these steps, buyers can ensure they select the right leather grade that aligns with their project requirements and quality expectations.

Illustrative image related to leather grades

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your specific requirements for leather grades. Consider factors such as the intended use of the leather (e.g., upholstery, accessories, garments), desired durability, and aesthetic characteristics. This clarity will help you communicate effectively with suppliers and ensure they understand your needs.

- Key Considerations:

- Types of leather required (full-grain, top-grain, etc.)

- Thickness and finish preferences

- Expected lifecycle and durability requirements

Step 2: Research Leather Grades Thoroughly

Understanding the various leather grades is crucial for making informed purchasing decisions. Familiarize yourself with the characteristics of full-grain, top-grain, genuine, split, and bonded leather. Each grade has distinct qualities that affect performance, appearance, and price.

- Essential Insights:

- Full-grain leather offers the highest durability and patina development.

- Genuine leather, while marketed as real leather, is of lower quality and may not meet long-term expectations.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your leather specifications. Look for companies with a solid reputation in the leather industry, focusing on those that align with your geographical sourcing preferences, especially if you’re targeting markets in Africa, South America, or Europe.

- What to Look For:

- Supplier certifications and industry affiliations

- Customer testimonials and case studies

- Capabilities in producing specific leather grades

Step 4: Request Samples for Quality Assessment

Before finalizing your order, request samples of the leather grades you are considering. This will allow you to evaluate the leather’s texture, finish, and overall quality firsthand. Pay attention to the leather’s feel, appearance, and how it responds to bending and stretching.

- Sampling Tips:

- Compare samples across different grades to understand their unique qualities.

- Check for uniformity and any visible defects that could indicate poor quality.

Step 5: Verify Compliance with Industry Standards

Ensure that the leather being sourced complies with international standards and regulations, especially concerning environmental impact and animal welfare. This step is critical not only for legal compliance but also for maintaining ethical sourcing practices.

- Compliance Checks:

- Look for certifications like ISO or Leather Working Group standards.

- Inquire about the tanning processes used and their environmental impact.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate terms that align with your business needs. Discuss pricing, delivery timelines, minimum order quantities, and return policies. Clear agreements will help mitigate risks and ensure smooth transactions.

- Negotiation Focus:

- Ensure transparency in pricing to avoid hidden costs.

- Establish clear timelines for delivery to meet production schedules.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the leather received against your original specifications. This proactive approach will help you catch any discrepancies early and maintain the quality standards of your final products.

- Quality Control Measures:

- Conduct inspections upon receipt of the leather.

- Set up a feedback loop with suppliers to address any quality issues promptly.

By following this step-by-step checklist, B2B buyers can confidently navigate the complexities of sourcing leather grades, ensuring they make informed decisions that enhance their product offerings.

Comprehensive Cost and Pricing Analysis for leather grades Sourcing

What Are the Key Cost Components in Sourcing Leather Grades?

When sourcing leather grades for B2B transactions, understanding the cost structure is essential. The primary cost components include:

Illustrative image related to leather grades

-

Materials: The type of leather grade significantly influences material costs. Full-grain leather, known for its durability and aesthetic appeal, commands a higher price compared to lower grades like bonded leather. The quality of the raw hides used directly impacts the final cost.

-

Labor: Skilled labor is required for processing high-quality leather. The complexity of tasks such as tanning, dyeing, and finishing adds to labor costs. Regions with a rich tradition of leather craftsmanship may have higher labor costs, reflecting the skill level and quality of workmanship.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. High-quality leather production often requires advanced machinery and technology, which can elevate overhead expenses.

-

Tooling: Custom tooling for specific leather products can be a significant investment. This includes molds and cutting dies that are tailored for unique product designs. The initial cost can be high, but it can lead to efficiencies in production once set up.

-

Quality Control (QC): Ensuring that leather products meet industry standards and client specifications involves rigorous quality control processes. This adds to the overall cost but is essential for maintaining product integrity, especially when dealing with high-end markets.

-

Logistics: Transportation costs vary based on the source of the leather and the destination market. International shipping, customs duties, and insurance can add considerable expenses, particularly for buyers in Africa, South America, and the Middle East.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. The margin can vary based on the supplier’s reputation, market demand, and the competitive landscape.

How Do Price Influencers Affect Leather Grades?

Several factors influence pricing in the leather market:

-

Volume/MOQ: Bulk orders usually lead to better pricing. Suppliers are more inclined to offer discounts for larger quantities, which can reduce the cost per unit significantly.

-

Specifications and Customization: Custom orders that require specific leather grades or unique finishes can drive up costs. Standardized products are typically less expensive due to streamlined production processes.

-

Material Quality and Certifications: Leather with certifications (e.g., eco-friendly tanning processes) may be priced higher due to the additional costs associated with compliance and quality assurance. Buyers should weigh the benefits of such certifications against their budget.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can affect pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: The terms of shipment can impact total costs. Buyers should be aware of which party is responsible for shipping, insurance, and tariffs, as these can significantly affect the final price.

What Buyer Tips Can Help Negotiate Better Pricing?

For international B2B buyers, particularly from regions like Africa and South America, understanding the nuances of leather pricing can lead to cost efficiencies:

-

Negotiate Wisely: Leverage volume purchases and long-term relationships to negotiate better terms. Building rapport with suppliers can lead to favorable pricing and priority service.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term value of leather products. Higher-quality leather may incur a higher initial cost but offers better durability and lower replacement rates.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations in leather prices. Demand can rise during certain times of the year, affecting availability and pricing.

-

Do Your Research: Stay informed about market trends and competitor pricing. Understanding the broader market landscape can provide leverage in negotiations.

Disclaimer on Indicative Prices

Prices for leather grades can vary widely based on quality, sourcing location, and market conditions. It is advisable for buyers to obtain quotations from multiple suppliers and conduct thorough due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing leather grades With Other Solutions

When evaluating leather grades, B2B buyers should consider viable alternatives that can meet similar needs while offering different benefits. Understanding these alternatives is crucial for making informed purchasing decisions, especially in international markets like Africa, South America, the Middle East, and Europe. This analysis will compare leather grades with synthetic leather and waxed canvas, two popular alternatives that provide distinctive advantages and disadvantages.

| Comparison Aspect | Leather Grades | Synthetic Leather | Waxed Canvas |

|---|---|---|---|

| Performance | Highly durable; develops patina; breathable | Good durability; less breathable; can mimic leather appearance | Durable; water-resistant; breathable |

| Cost | Varies by grade; generally higher for full-grain | Typically lower than high-quality leather | Generally affordable; budget-friendly |

| Ease of Implementation | Requires skilled craftsmanship; can be complex | Easy to produce; widely available | Simple to manufacture; versatile |

| Maintenance | Requires regular conditioning and care | Low maintenance; easy to clean | Needs occasional re-waxing for water resistance |

| Best Use Case | High-end products, luxury goods, durable fashion | Fashion accessories, upholstery, budget-friendly items | Outdoor gear, bags, durable work products |

What Are the Advantages and Disadvantages of Synthetic Leather?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to traditional leather. Its primary advantage lies in affordability and ease of maintenance; it does not require conditioning and can be wiped clean easily. However, synthetic leather typically lacks the breathability and aging characteristics of genuine leather. It may not develop the same patina over time, which can be a significant drawback for products aimed at high-end markets.

How Does Waxed Canvas Compare to Leather Grades?

Waxed canvas is a durable fabric treated with wax to repel water, making it an excellent choice for outdoor applications. It is generally more affordable than high-quality leather and offers good breathability and weight. However, it does not provide the same level of luxury or durability as full-grain leather and may require re-waxing over time to maintain its water-resistant properties. Waxed canvas is ideal for products like backpacks and outdoor gear, where functionality is prioritized over aesthetics.

Illustrative image related to leather grades

Conclusion: Which Option Should B2B Buyers Choose?

When selecting the right material, B2B buyers should consider their specific needs, target market, and product application. For high-end, luxury products that require durability and aesthetic appeal, investing in full-grain leather is often justified despite its higher cost. On the other hand, if budget constraints or lower maintenance are critical factors, synthetic leather or waxed canvas may be more suitable. Ultimately, the choice should align with the brand’s positioning and the expectations of the end consumer.

Essential Technical Properties and Trade Terminology for leather grades

What Are the Critical Technical Properties of Leather Grades?

Understanding the essential technical properties of leather grades is vital for B2B buyers, particularly those sourcing leather goods for diverse applications. Here are some key specifications that every buyer should be familiar with:

1. Material Grade

Material grade refers to the classification of leather based on its quality, which directly affects durability and aesthetics. Common grades include full-grain, top-grain, split-grain, genuine, and bonded leather. Full-grain leather is the highest quality, offering superior strength and a natural look, while bonded leather is the lowest grade, often lacking the characteristics associated with genuine leather. Knowing these grades helps buyers make informed decisions that align with their product quality expectations and pricing strategies.

2. Thickness (mm)

The thickness of leather is a crucial property that impacts its use and performance. Thicker leather (e.g., 3-4 mm) is often used for heavy-duty applications like belts and upholstery, while thinner leather (e.g., 1-2 mm) is preferred for lighter goods like wallets and bags. Understanding the thickness required for specific applications can help buyers ensure that the leather will perform adequately under expected conditions.

Illustrative image related to leather grades

3. Tensile Strength

Tensile strength measures how much force leather can withstand before breaking. This property is particularly important for products that undergo significant stress, such as straps and belts. High tensile strength indicates durability and longevity, which are critical factors for B2B buyers looking for reliable materials that minimize returns and enhance customer satisfaction.

4. Water Resistance

Water resistance is a property that indicates how well leather can repel moisture. Full-grain leather typically has natural oils that enhance its resistance, while top-grain leather may be treated for additional protection. For buyers in regions with high humidity or frequent rain, selecting water-resistant leather is essential to ensure product longevity and maintain customer satisfaction.

5. Grain Structure

The grain structure of leather affects its texture and appearance. Full-grain leather retains the natural grain of the hide, showcasing unique patterns and imperfections, while top-grain leather is sanded to create a smoother finish. Understanding grain structure is essential for buyers looking to market their products based on aesthetics or tactile qualities.

What Are Common Trade Terms in the Leather Industry?

Familiarizing yourself with industry-specific jargon is critical for effective communication and negotiation in the leather market. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the leather industry, this could mean companies that create leather goods under another brand’s label. Understanding OEM relationships can help buyers navigate partnerships and quality assurance processes.

Illustrative image related to leather grades

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory and cash flow effectively. This term is crucial when negotiating with suppliers, as it can significantly impact purchasing decisions and overall project budgets.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing for specific products or services. Crafting a clear RFQ helps ensure that suppliers provide accurate quotes, facilitating better comparison and decision-making. It is a standard practice in B2B transactions that can streamline procurement processes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers to manage shipping costs and liability effectively.

5. Lead Time

Lead time refers to the time taken from placing an order until the goods are delivered. In the leather industry, lead times can vary based on material availability and production schedules. Being aware of lead times helps buyers plan their inventory and meet customer demand without interruptions.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies, leading to better product quality and supplier relationships in the leather industry.

Illustrative image related to leather grades

Navigating Market Dynamics and Sourcing Trends in the leather grades Sector

What Are the Current Market Dynamics and Key Trends in the Leather Grades Sector?

The global leather market is witnessing significant evolution, influenced by various factors, including consumer preferences, technological advancements, and sustainability concerns. Key drivers include the rising demand for high-quality leather products across sectors such as fashion, automotive, and furniture, particularly in emerging markets like Africa, South America, and the Middle East. As buyers increasingly seek authenticity and durability, full-grain and top-grain leathers are gaining popularity, pushing manufacturers to prioritize quality over quantity.

Emerging B2B technologies are reshaping sourcing practices, with digital platforms enabling better transparency and traceability in the supply chain. Buyers are leveraging e-commerce platforms and B2B marketplaces to connect directly with tanneries and suppliers, facilitating quicker and more efficient transactions. Moreover, advancements in artificial intelligence and data analytics are allowing businesses to forecast trends and manage inventory more effectively, which is crucial in a fluctuating market.

International buyers, especially from regions like Vietnam and Nigeria, are also adapting to market dynamics by focusing on quality assurance and supplier reliability. As competition intensifies, understanding the nuances of leather grades and their applications becomes essential for making informed purchasing decisions. This strategic approach not only enhances product offerings but also strengthens supplier relationships, ensuring a competitive edge in a global marketplace.

How Is Sustainability and Ethical Sourcing Reshaping the Leather Grades Market?

Sustainability has become a cornerstone of the leather industry, driven by growing consumer awareness regarding environmental impacts. Traditional leather production processes often involve significant water usage and chemical treatments, raising concerns about their ecological footprint. Consequently, ethical sourcing practices are gaining traction, with buyers increasingly prioritizing suppliers that adhere to sustainable methods.

The importance of ethical supply chains cannot be overstated. International buyers are urged to seek out tanneries that implement environmentally friendly practices, such as using vegetable-based tanning agents and minimizing waste. Certifications like the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) serve as benchmarks, assuring buyers that the leather products they purchase are produced sustainably.

Illustrative image related to leather grades

Additionally, innovative alternatives such as plant-based leathers and recycled materials are emerging, offering eco-conscious options without compromising on quality. For B2B buyers, investing in sustainable leather grades not only meets market demand but also enhances brand reputation, potentially leading to increased customer loyalty and competitive advantage.

What Is the Historical Context of Leather Grades in B2B Sourcing?

The evolution of leather grading can be traced back centuries, rooted in the necessity for durable and functional materials. Initially, leather was graded based on its source and processing techniques, with full-grain and top-grain being recognized for their superior quality. Over time, as industrialization took hold, mass production introduced lower-quality leather grades such as genuine and bonded leather, which catered to the demand for affordable goods.

In the B2B context, understanding the historical significance of leather grades is vital for contemporary buyers. The shift towards quality-centric purchasing has prompted a resurgence of interest in traditional leather craftsmanship. By appreciating the historical context, B2B buyers can make more informed decisions that align with modern consumer expectations for quality, sustainability, and ethical sourcing. This awareness fosters stronger partnerships with suppliers who share similar values, ultimately enhancing the overall value chain in the leather industry.

Frequently Asked Questions (FAQs) for B2B Buyers of leather grades

-

How do I ensure I’m purchasing high-quality leather for my business needs?

To ensure you’re purchasing high-quality leather, always request detailed product specifications from your suppliers. Look for certifications that indicate the leather’s grade, such as full-grain or top-grain, and ask for samples to assess texture and durability. Conducting a “fire test” can also help; real leather will resist burning while synthetic materials will char quickly. Additionally, evaluate the supplier’s reputation and history in the industry to confirm they deliver quality products consistently. -

What is the best leather grade for manufacturing durable goods?

The best leather grade for manufacturing durable goods is full-grain leather. This type retains the natural grain of the hide, making it extremely robust and resistant to wear. It also develops a unique patina over time, enhancing its aesthetic appeal. For products requiring a slightly more uniform appearance, top-grain leather is also a solid option, providing a balance between durability and visual appeal. -

How can I effectively vet leather suppliers in international markets?

Vetting leather suppliers involves several steps. Start by researching their reputation through online reviews, industry forums, and trade associations. Request references from previous clients and verify their production capabilities. It’s also essential to inspect their facilities, either virtually or in person, to assess their quality control processes. Additionally, ensure they comply with international standards for leather production to avoid issues with quality and sustainability. -

What customization options should I consider when sourcing leather?

Customization options can greatly enhance the value of your leather products. Consider factors such as color, texture, and thickness, which can all be tailored to meet your specific needs. Some suppliers may also offer embossing, tooling, or dyeing services. Be sure to communicate your requirements clearly and confirm the supplier’s ability to meet these needs within your timeline and budget constraints. -

What are typical minimum order quantities (MOQs) for leather products?

Minimum order quantities (MOQs) for leather products can vary significantly based on the supplier and the type of leather. Generally, MOQs can range from 50 to 500 units for standard items. For custom orders, MOQs may be higher due to the increased production costs involved. It’s advisable to discuss MOQs upfront with potential suppliers to ensure they align with your business needs. -

What payment terms are common in international leather transactions?

Common payment terms in international leather transactions include a deposit upfront, often ranging from 30% to 50%, with the balance due upon delivery or before shipping. Letters of credit are also frequently used to secure transactions, providing assurance to both parties. Be sure to negotiate terms that are favorable and ensure they are clearly outlined in your contract to avoid disputes later. -

How can I ensure quality assurance (QA) for leather products?

To ensure quality assurance (QA) for leather products, establish a comprehensive inspection process. This should include pre-production samples, in-process checks, and final inspections before shipping. Collaborate with your supplier to create a QA checklist that covers aspects such as leather grade, stitching quality, and finishing details. Consider hiring third-party inspection services if necessary to maintain quality standards. -

What logistics considerations should I keep in mind when importing leather?

When importing leather, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder experienced in handling leather imports to navigate potential tariffs and compliance issues. Additionally, account for the climate during transport, as extreme temperatures can affect leather quality. Lastly, maintain clear communication with your supplier about shipping schedules to ensure timely delivery.

Top 8 Leather Grades Manufacturers & Suppliers List

1. Popov Leather – Leather Quality Chart

Domain: popovleather.com

Registered: 2013 (12 years)

Introduction: Leather Quality Chart: Decoding the World of Leather Grades – Popov Leather®\n\n1. Leather Grades: \n – Top Grain Leather (includes Full Grain and Corrected Grain) \n – Full Grain Leather \n – Corrected Grain Leather \n – Split Grain Leather (sometimes called “Genuine Leather”) \n – Bonded Leather \n\n2. Full Grain Leather Characteristics: \n – Common Uses: Higher-end products …

2. Leather Grades – Understanding Full Grain and Top Grain

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Grades of leather such as Full Grain, Top Grain, Genuine, and Bonded leather are not recognized as real grades of leather by any authoritative body. Full Grain leather refers to leather that has not been altered on the outermost layer, preserving its natural character. Top Grain leather is technically a type of Full Grain leather, as it refers to the top layer split from a hide, but often involves…

3. Leather Edge Paint – Leather Grades Explained

Domain: blog.leatheredgepaint.com

Registered: 2014 (11 years)

Introduction: 5 Leather Grades: 1. Full Grain Leather: Complete grain intact, most durable, lasts longer, includes vegetable tanned and distressed leather. 2. Top Grain Leather: Second highest quality, thinner, more workable, sanded surface, smooth feel, used in high-end products. 3. Split Grain Leather: Lacks grain, includes suede, soft linings, less durable, porous surface. 4. Genuine Leather: Marketing term,…

4. Weaver Leather Supply – Leather Grades Explained

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Leather grades are categorized as A, B, or C based on the number of defects present. Grade A allows for 1-2 small defects in prime areas and 3-4 in non-prime areas. Grade B can have 3-4 defects in prime areas, 6-12 inches of damage or waste, and small holes in non-prime areas. Grade C allows for more than 12 inches of damage or waste and color variation. Weaver Leather Supply uses a tannery run (T…

5. American Leather – Types of Leather

Domain: americanleather.com

Registered: 1997 (28 years)

Introduction: Types of Leather: 1. Full Grain: Highest quality leather, retains natural textures and imperfections, ideal for luxury furniture. 2. Corrected Leather: Undergoes treatments to smooth surface, may lose natural beauty. 3. Top Grain: Can be misleading; does not always mean full grain. 4. Split Leather: Derived from the fibrous part of the hide, less durable. 5. Bonded Leather: Made from scraps, cost-…

6. Billy Tannery – Types of Leather

Domain: billytannery.co.uk

Registered: 2016 (9 years)

Introduction: Types of Leather: 1. Full Grain Leather – Highest quality, retains natural state, durable, unique marks, improves with age. 2. Top Grain Leather – Sanded for uniform look, softer finish, less durable. 3. Genuine Leather – Corrected-grain, thinner, weaker, used in cheaper goods. 4. Split Leather – Uses corium section, fragile, low life expectancy. 5. Bonded Leather – Made from scraps mixed with bin…

7. Overland – Leather Types

Domain: overland.com

Registered: 1997 (28 years)

Introduction: Leather Types: Cowhide, Bison, Deerskin, Goatskin, Lambskin, Calfskin. Cowhide: Strong, thick, durable, water- and dirt-resistant. Bison: Strong, durable, distinctive pebbled grain. Deerskin: Soft, lightweight, contours to form. Goatskin: Softer than cowhide, durable, smooth, characteristic pebble grain. Lambskin: Extremely soft, lightweight, flattering drape. Calfskin: Strong, durable, supple, sm…

8. Dalgado – Understanding Leather Grades

Domain: dalgado.de

Introduction: The leather industry is complex and often misleading. Understanding leather grades is essential for making informed purchases. Key leather grades include: 1. Full-grain leather: Top layer, unprocessed, durable, develops patina, maintains natural blemishes, considered premium. 2. Top-grain leather: Sanded and buffed, enhances workability, uniformity, greater stain resistance, slightly less durable….

Strategic Sourcing Conclusion and Outlook for leather grades

As the leather industry evolves, understanding the nuances of leather grades is essential for international B2B buyers. Each grade, from full-grain to bonded leather, carries distinct characteristics that impact durability, aesthetics, and pricing. By strategically sourcing high-quality leather, buyers can ensure they are investing in products that not only meet but exceed customer expectations, resulting in enhanced brand reputation and customer loyalty.

Buyers from Africa, South America, the Middle East, and Europe must prioritize partnerships with reputable tanneries that prioritize quality and sustainability. This proactive approach not only mitigates risks associated with inferior products but also aligns with the growing consumer demand for ethically sourced materials.

Looking ahead, the demand for premium leather is poised to rise, driven by trends favoring sustainability and craftsmanship. As you navigate this dynamic landscape, remain informed and adaptable to leverage opportunities that arise. Engage with suppliers who can provide transparency about their sourcing practices and product quality. By doing so, you position your business for success in a competitive market, ensuring your offerings resonate with discerning consumers worldwide. Embrace the future of leather sourcing—quality today leads to loyalty tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to leather grades

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.