Introduction: Navigating the Global Market for custom leather dies

In the dynamic landscape of the global market for custom leather dies, B2B buyers often grapple with the challenge of sourcing high-quality, precision-engineered products that meet their specific manufacturing needs. Custom leather dies are essential tools for businesses involved in leather goods production, enabling the efficient cutting of intricate designs with minimal waste. However, navigating the various types, applications, and supplier options can be daunting, particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Brazil and Saudi Arabia.

This comprehensive guide aims to empower B2B buyers by elucidating the intricacies of custom leather dies. We will explore the different types of dies available, their specific applications across various industries, and the critical factors to consider when vetting suppliers. Additionally, we will provide insights into pricing structures, including the cost implications of intricate designs and necessary add-ons like hole punches. By equipping buyers with actionable information and best practices, this guide seeks to facilitate informed purchasing decisions, ensuring that businesses can optimize their production processes while maintaining product quality and cost-effectiveness.

Understanding these elements not only streamlines the sourcing process but also enhances the overall production efficiency, enabling companies to focus on craftsmanship and innovation in their leather goods offerings.

Table Of Contents

- Top 6 Custom Leather Dies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather dies

- Understanding custom leather dies Types and Variations

- Key Industrial Applications of custom leather dies

- 3 Common User Pain Points for ‘custom leather dies’ & Their Solutions

- Strategic Material Selection Guide for custom leather dies

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather dies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather dies’

- Comprehensive Cost and Pricing Analysis for custom leather dies Sourcing

- Alternatives Analysis: Comparing custom leather dies With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather dies

- Navigating Market Dynamics and Sourcing Trends in the custom leather dies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather dies

- Strategic Sourcing Conclusion and Outlook for custom leather dies

- Important Disclaimer & Terms of Use

Understanding custom leather dies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Rule Dies | Made of steel with a flat cutting edge, high precision. | Mass production of leather goods, crafts | Pros: High durability; Cons: May require heavy machinery. |

| Polycarbonate Dies | Lightweight and impact-resistant, suitable for intricate designs. | Small to medium production runs | Pros: Cost-effective; Cons: Less durable than steel. |

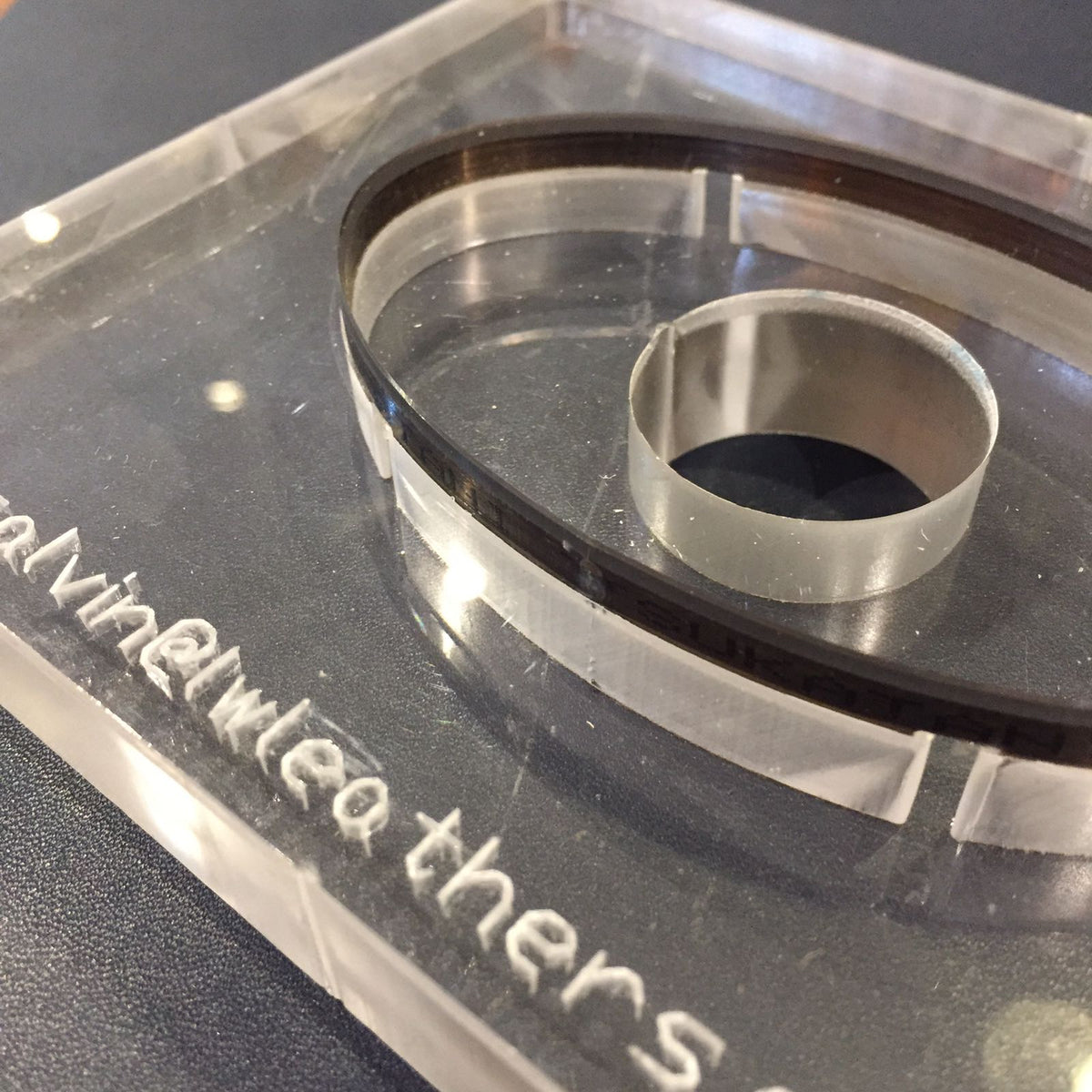

| Acrylic Mount Dies | Provides easy alignment, reducing material waste. | Custom shapes for various materials | Pros: Versatile; Cons: Limited cutting depth. |

| Clicker Dies | Designed for use with clicker presses, ideal for repetitive tasks. | High-volume production of leather items | Pros: Increases efficiency; Cons: Initial investment in machinery. |

| Custom Engraved Dies | Personalized designs with engraving options available. | Branding and unique product offerings | Pros: Enhances brand identity; Cons: Longer lead times. |

What are Steel Rule Dies and Their Suitability for B2B Buyers?

Steel rule dies are a staple in the leather cutting industry, characterized by their robust steel construction and flat cutting edge. These dies are particularly suitable for businesses engaged in mass production of leather goods, allowing for precise and consistent cuts across large batches. B2B buyers should consider the durability and longevity of steel rule dies, which can withstand extensive use. However, they may require specialized machinery, which could entail additional costs.

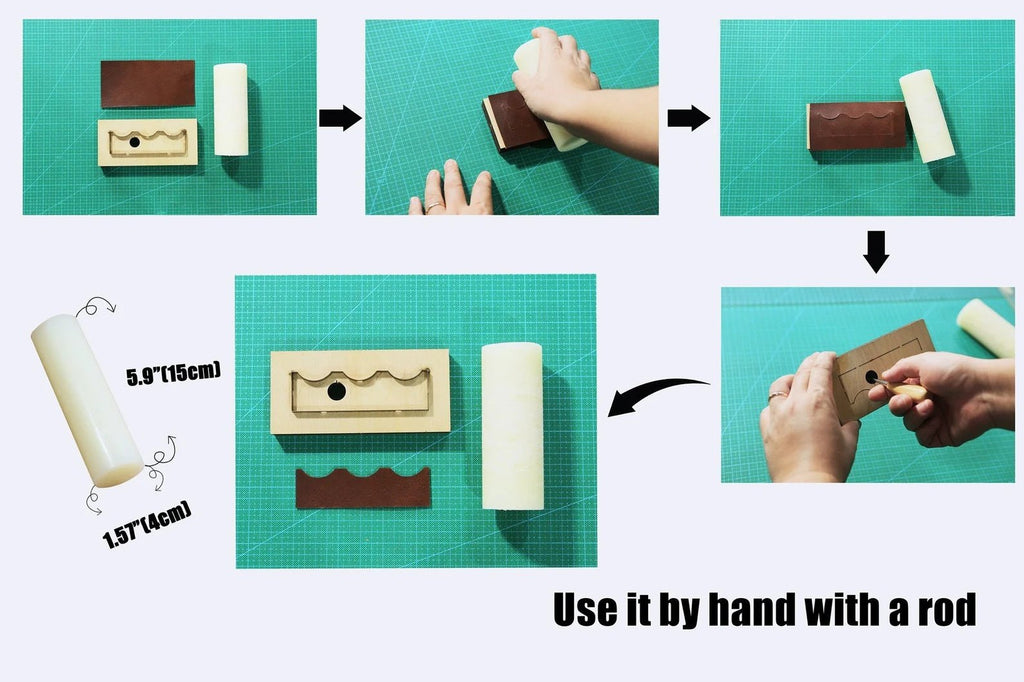

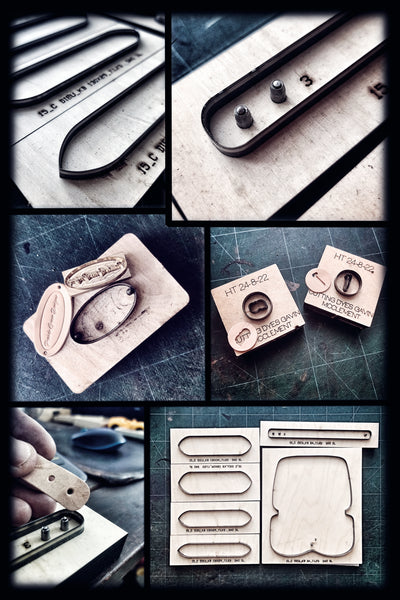

Illustrative image related to custom leather dies

How Do Polycarbonate Dies Compare in Performance and Use?

Polycarbonate dies are a lighter alternative to steel, designed for intricate shapes and smaller production runs. They are ideal for businesses that prioritize cost efficiency without sacrificing quality. B2B buyers can benefit from these dies when producing unique leather items or crafts in moderate quantities. The trade-off is that while they are cost-effective, polycarbonate dies may not offer the same level of durability as steel, necessitating careful consideration of their intended use.

Why Choose Acrylic Mount Dies for Custom Leather Projects?

Acrylic mount dies are notable for their ease of alignment, which significantly reduces material waste during cutting. This feature makes them particularly attractive for businesses focused on sustainability and cost reduction. They are versatile enough to cut various materials, including leather and paper, making them a valuable asset for creative projects. However, buyers should be aware of their limitations regarding cutting depth, which may not suit all production needs.

What Advantages Do Clicker Dies Offer for High-Volume Production?

Clicker dies are specially designed to work with clicker presses, making them essential for businesses that require high-volume leather cutting. The efficiency gained from using clicker dies can greatly enhance productivity, allowing companies to focus on craftsmanship and detail. While the initial investment in a clicker press can be significant, the long-term benefits in terms of time savings and consistency can justify the cost for B2B buyers.

How Can Custom Engraved Dies Enhance Branding for B2B Buyers?

Custom engraved dies allow businesses to incorporate unique designs and branding elements into their leather products. This personalization can elevate a brand’s identity and appeal to customers seeking distinctive items. However, B2B buyers should consider that custom engraved dies may have longer lead times and higher costs associated with the design process. Balancing these factors is crucial when deciding on the investment in custom engraving for product differentiation.

Illustrative image related to custom leather dies

Key Industrial Applications of custom leather dies

| Industry/Sector | Specific Application of custom leather dies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Cutting intricate patterns for garments and accessories | Enhances production efficiency and design precision | Material compatibility, lead times, and minimum order quantities |

| Automotive | Creating custom leather interiors for vehicles | Improves aesthetic appeal and customization options | Durability requirements, design complexity, and scale of production |

| Footwear Manufacturing | Producing shoe components and custom designs | Streamlines manufacturing processes and reduces labor costs | Tolerance levels, material thickness, and design intricacies |

| Craft and Hobby | DIY projects for leather goods | Enables personalization and creativity in product offerings | Support for custom designs, pricing, and turnaround times |

| Furniture and Upholstery | Fabricating leather components for furniture | Enhances quality and uniqueness in furniture design | Sourcing for eco-friendly materials, design specifications, and shipment options |

How Are Custom Leather Dies Utilized in the Fashion and Apparel Industry?

In the fashion and apparel sector, custom leather dies are essential for efficiently cutting intricate patterns used in garments and accessories. By using these dies, manufacturers can produce consistent and precise cuts, significantly reducing waste and production time. For international B2B buyers, it’s crucial to assess the compatibility of dies with various leather types and the lead times required for production, especially when sourcing from different regions like Africa or South America.

What Role Do Custom Leather Dies Play in Automotive Applications?

Custom leather dies are increasingly utilized in the automotive industry for creating bespoke leather interiors. These dies allow manufacturers to produce high-quality, aesthetically pleasing designs that enhance the overall appeal of vehicles. Buyers must consider the durability of the dies, as automotive interiors must withstand wear and tear. Additionally, understanding the design complexity and the scale of production required can help in negotiating better terms with suppliers.

How Are Custom Leather Dies Beneficial for Footwear Manufacturing?

In footwear manufacturing, custom leather dies streamline the production of shoe components, enabling manufacturers to create unique designs efficiently. This method reduces manual labor and enhances consistency across mass-produced items. For businesses in this sector, it’s vital to communicate specific tolerance levels and material thickness requirements to suppliers to ensure the dies meet the necessary standards for quality and performance.

Why Are Custom Leather Dies Important for Craft and Hobby Applications?

For DIY enthusiasts and hobbyists, custom leather dies facilitate the creation of personalized leather goods. These dies allow for intricate designs that cater to individual creativity, making it easier to produce unique items. Buyers in this space should focus on the support offered for custom designs, pricing structures, and turnaround times, as these factors can significantly affect project timelines and costs.

How Do Custom Leather Dies Enhance Furniture and Upholstery Production?

In the furniture and upholstery industry, custom leather dies are used to fabricate unique leather components that enhance product quality. These dies enable manufacturers to offer distinctive designs that cater to high-end markets. When sourcing, businesses should prioritize eco-friendly materials and clearly defined design specifications to align with consumer preferences and sustainability goals. Additionally, understanding shipment options can help manage logistics effectively.

Illustrative image related to custom leather dies

3 Common User Pain Points for ‘custom leather dies’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision with Custom Designs

The Problem: B2B buyers often struggle with ensuring precision in their custom leather dies, particularly when dealing with intricate designs. Many manufacturers may offer custom cutting dies, but inconsistencies in tolerances can lead to wasted materials and time. This can be especially frustrating for businesses that rely on high-quality outcomes to maintain customer satisfaction and brand integrity. For example, a leather goods manufacturer in Brazil might find that their custom die does not accurately reflect their design specifications, resulting in pieces that do not fit together properly, thus delaying production and increasing costs.

The Solution: To overcome this issue, buyers should prioritize sourcing manufacturers who provide clear specifications on tolerances and offer sample cuts before full production. When placing an order, it’s crucial to provide detailed design files in formats such as .ai or .pdf, as these formats allow for more accurate die creation. Additionally, requesting a prototype die can help assess the precision of the cut before committing to a larger order. Engaging in open communication with the manufacturer regarding design intricacies and tolerances can also help ensure that the final product meets expectations.

Scenario 2: High Costs Associated with Custom Leather Dies

The Problem: The financial burden of creating custom leather dies can be significant, particularly for smaller businesses or startups. Costs can escalate quickly due to factors like design complexity, material choices, and minimum order quantities. For instance, a startup in Saudi Arabia aiming to produce a unique line of leather accessories may find themselves faced with a minimum order requirement of 100 units, leading to an upfront investment that strains their budget.

Illustrative image related to custom leather dies

The Solution: To mitigate costs, buyers should consider collaborating with manufacturers that offer tiered pricing structures based on order volume. Additionally, exploring local suppliers can reduce shipping costs and lead times, making it easier for businesses to manage their budgets. Another effective strategy is to invest in dies that can be used for multiple products, thereby maximizing the return on investment. By carefully analyzing their design needs and exploring options for shared or pooled orders with other businesses, buyers can significantly reduce individual costs.

Scenario 3: Long Lead Times and Delays in Production

The Problem: Many B2B buyers face challenges with long lead times when ordering custom leather dies, which can disrupt their production schedules. For instance, a leather manufacturer in Europe may place an order for custom dies only to find that they are delayed by weeks, causing them to miss delivery deadlines for their clients. Such delays can not only affect cash flow but also damage relationships with customers who rely on timely deliveries.

The Solution: To address lead time issues, it’s essential for buyers to clearly communicate their timelines and urgency when placing orders. Establishing relationships with manufacturers known for their quick turnaround times can also be beneficial. For urgent projects, buyers should inquire about rush order options, understanding that these may come with additional costs. Additionally, maintaining a buffer stock of standard dies can help mitigate disruptions, allowing businesses to continue production while awaiting custom orders. Regular follow-ups during the production process can keep buyers informed about their order status and help manage expectations effectively.

Strategic Material Selection Guide for custom leather dies

What Are the Key Materials Used in Custom Leather Dies?

When selecting materials for custom leather dies, it’s essential to consider the specific properties and performance characteristics that align with your production needs. The choice of material can significantly impact the efficiency, durability, and cost-effectiveness of your leather cutting operations. Here, we analyze four common materials used in the manufacturing of custom leather dies.

How Does Steel Perform as a Material for Custom Leather Dies?

Steel is a prevalent choice for custom leather dies due to its strength and durability. It can withstand high pressure and temperature, making it suitable for various cutting applications. Steel dies are known for their longevity and can maintain sharp cutting edges over extended periods.

Pros: Steel dies offer exceptional durability and can handle intricate designs. They are also relatively easy to manufacture, making them a cost-effective option for larger production runs.

Cons: The initial cost of steel dies can be higher compared to other materials. Additionally, they may require more maintenance to prevent corrosion, especially in humid environments.

Impact on Application: Steel dies are compatible with a wide range of materials, including leather, paper, and synthetic fabrics, making them versatile for various industries.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards for manufacturing and safety. Understanding the specific corrosion resistance requirements based on climate can also influence material selection.

What Advantages Does Polycarbonate Offer for Leather Cutting Dies?

Polycarbonate is a high-impact plastic that is increasingly used for custom leather dies. It is lightweight yet incredibly strong, making it suitable for both manual and automated cutting processes.

Pros: One of the significant advantages of polycarbonate is its resistance to wear and tear, which can lead to lower replacement costs over time. Additionally, polycarbonate dies can be manufactured quickly, allowing for faster turnaround times.

Cons: While polycarbonate is durable, it may not be suitable for extremely intricate designs due to its limitations in maintaining sharp edges compared to steel. It can also be more expensive than traditional plastic options.

Illustrative image related to custom leather dies

Impact on Application: Polycarbonate is particularly effective for cutting softer materials, such as thin leather and fabric, making it ideal for fashion and accessory applications.

Considerations for International Buyers: Buyers from the Middle East should be aware of the specific temperature ranges that polycarbonate can withstand, as extreme heat can affect its performance. Compliance with international standards for plastics may also be relevant.

Why Choose Acrylic for Custom Leather Dies?

Acrylic is another material that is commonly used for custom leather dies, particularly for applications requiring precise alignment and visibility during the cutting process.

Pros: Acrylic mounts facilitate easy alignment of materials, which can significantly reduce waste during production. They are also lightweight and can be produced quickly.

Cons: Acrylic is less durable than steel and polycarbonate, making it less suitable for high-volume production runs. It can also be prone to scratching, which may affect the cutting quality over time.

Impact on Application: Acrylic dies are particularly effective for applications where visibility is essential, such as in design studios or educational settings.

Considerations for International Buyers: Buyers in Europe may need to consider the environmental impact of acrylic and its recyclability, as many regions are moving towards more sustainable materials.

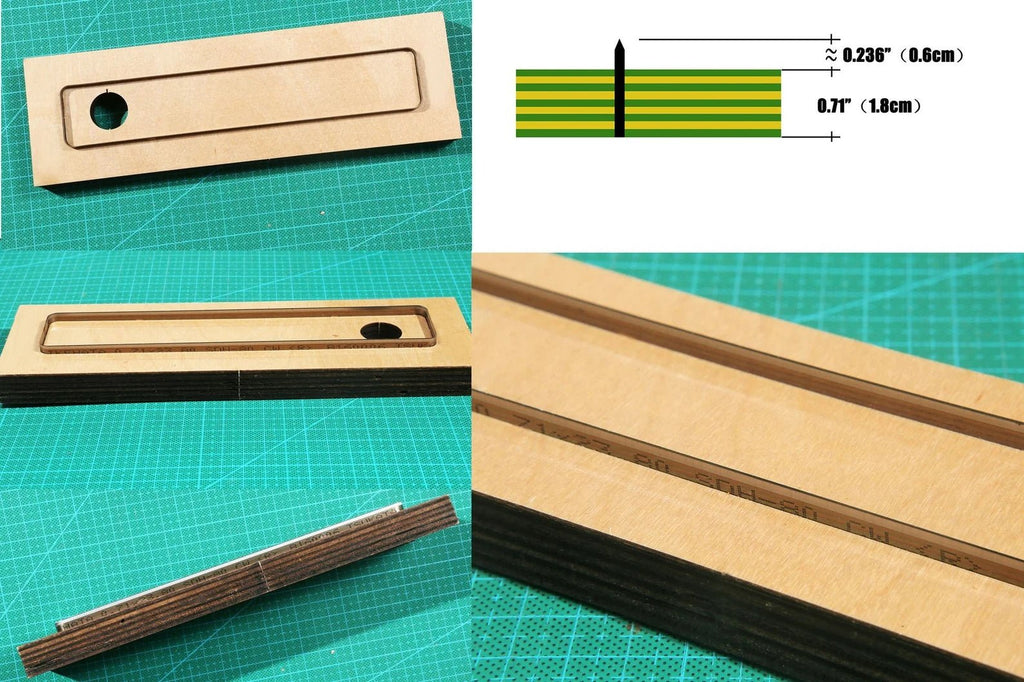

How Do Wood Dies Compare in Custom Leather Cutting?

Wood is sometimes used for custom leather dies, particularly in smaller-scale operations or for specific craft applications.

Illustrative image related to custom leather dies

Pros: Wood dies are often less expensive to produce and can be customized easily. They are suitable for simpler designs and are often favored in artisanal settings.

Cons: Wood is less durable than metal or plastic options and may not withstand the same level of pressure, leading to quicker wear. Additionally, they may not be suitable for high-volume production.

Impact on Application: Wood dies are best for small craft projects or educational purposes but are not recommended for mass production.

Illustrative image related to custom leather dies

Considerations for International Buyers: Buyers should ensure that the wood used complies with international sustainability standards, particularly in regions with strict environmental regulations.

Summary of Material Selection for Custom Leather Dies

| 素材 | Typical Use Case for custom leather dies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-volume production | Exceptional durability | Higher initial cost | 高い |

| Polycarbonate | Fashion accessories | Quick manufacturing | Limited for intricate designs | Medium |

| Acrylic | Design studios, educational settings | Easy alignment | Less durable, prone to scratching | Medium |

| Wood | Small craft projects | Cost-effective, easy customization | Not suitable for high pressure | 低い |

By considering these materials and their respective properties, B2B buyers can make informed decisions that align with their production needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather dies

What Are the Key Stages in the Manufacturing Process of Custom Leather Dies?

The manufacturing of custom leather dies involves several critical stages that ensure precision, quality, and functionality. Understanding these stages is crucial for B2B buyers looking to source high-quality leather cutting solutions.

Material Preparation: What Materials Are Used and How Are They Processed?

The process begins with selecting the right materials, which typically include steel for the die blades and acrylic or wood for the mounts. Steel is favored for its durability and ability to maintain sharp edges, while acrylic provides visibility and easy alignment for users.

Illustrative image related to custom leather dies

Once the materials are selected, they undergo preparation, which may include cutting to size, surface treatment, and hardening processes. These treatments enhance the material’s properties, such as wear resistance and cutting precision. For instance, heat treatment can be employed to harden steel, ensuring that it withstands the rigors of continuous use in cutting applications.

Forming: How Are Custom Designs Transformed into Functional Dies?

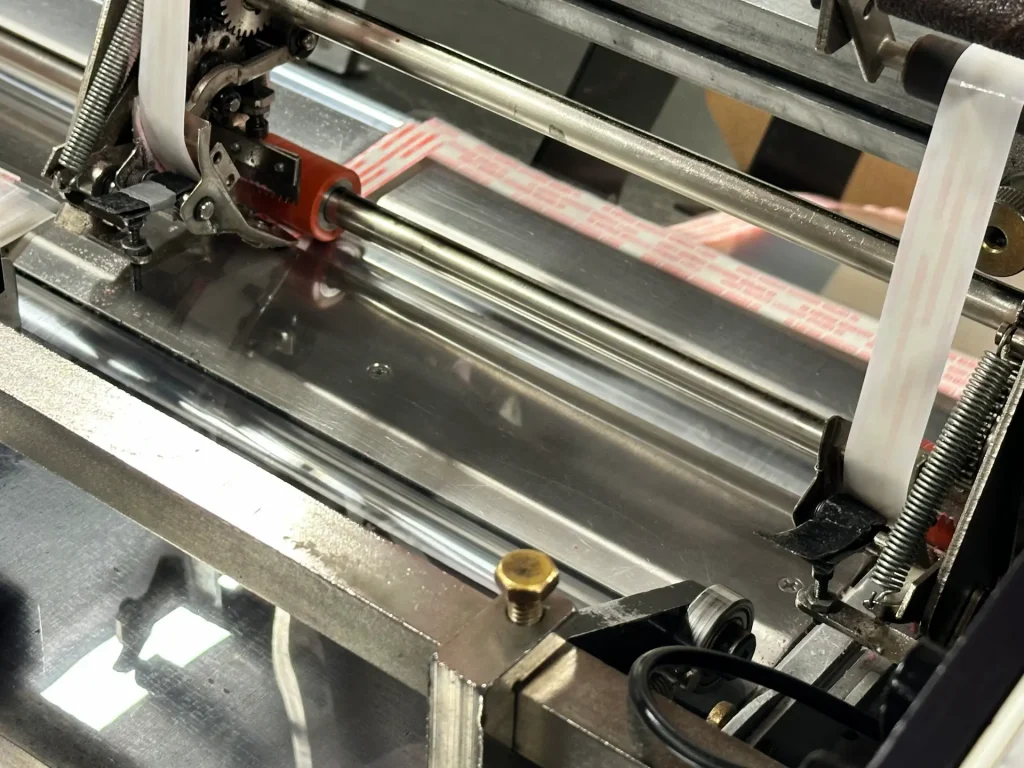

After preparation, the next stage is forming the die. This typically involves advanced techniques such as laser cutting or CNC (Computer Numerical Control) machining. These methods allow for intricate designs and high precision, which are essential for creating custom shapes that meet specific client requirements.

In the context of custom leather dies, forming involves crafting the blade shape according to the provided design files, which could be in formats like AI, PDF, or JPG. The accuracy of this stage is crucial; tolerances are often maintained within ±0.2mm to ensure effective cutting performance.

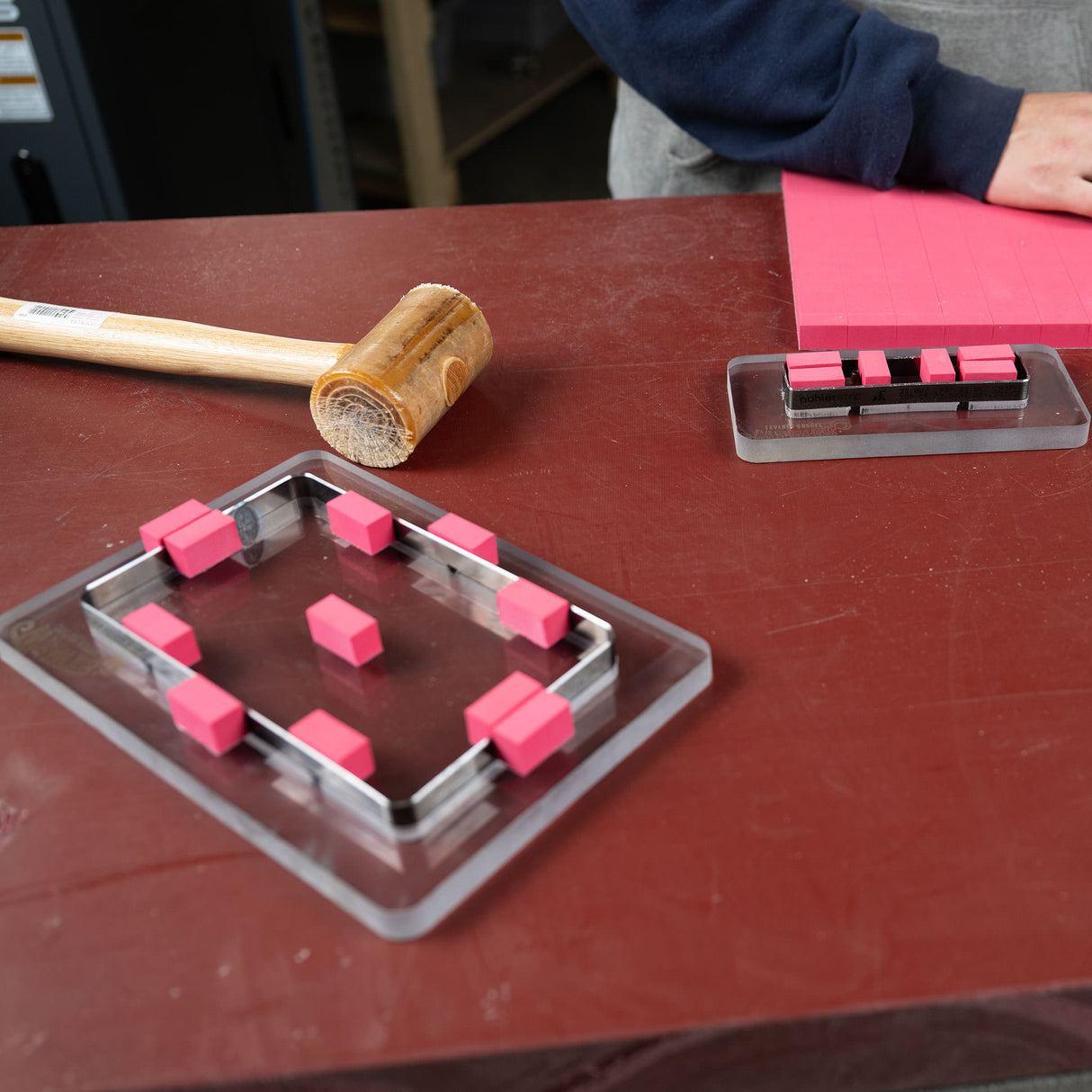

Assembly: What Steps Ensure the Die’s Integrity and Performance?

Once the components are formed, they are assembled into a complete die. This stage often includes attaching the cutting blades to the mounting material. Proper alignment is essential to minimize material waste during cutting. Many manufacturers utilize fixtures or jigs during assembly to maintain consistency and accuracy.

Quality checks are performed at this stage to ensure that all components fit together correctly and function as intended. Any discrepancies can lead to inefficient cutting processes, which can be costly for B2B buyers who rely on high-volume production.

Illustrative image related to custom leather dies

Finishing: How Is the Final Product Prepared for Delivery?

The final stage in the manufacturing process is finishing, which may involve polishing the edges, applying protective coatings, or engraving custom designs onto the die. These finishing touches not only enhance the aesthetic appeal but also improve the die’s functionality and longevity.

Once finished, the dies are carefully packaged to prevent damage during shipping. Manufacturers often use foam or custom boxes that ensure the blades are protected, safeguarding the investment of the buyer.

What Quality Assurance Practices Are Essential for Custom Leather Dies?

Quality assurance (QA) is a fundamental component of the manufacturing process, especially for custom leather dies. B2B buyers must ensure that their suppliers adhere to strict QA practices to guarantee product reliability and performance.

What International and Industry-Specific Standards Should Buyers Consider?

International standards such as ISO 9001, which focuses on quality management systems, are crucial for manufacturers of custom leather dies. Compliance with ISO standards signifies that the manufacturer has established processes to ensure consistent quality and customer satisfaction.

In addition to ISO 9001, industry-specific certifications, such as CE marking for products sold in Europe, can provide additional assurance regarding safety and performance. Buyers should inquire about these certifications when evaluating potential suppliers.

Illustrative image related to custom leather dies

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt. Ensuring that materials meet specified standards is critical, as defects at this stage can affect the entire production process.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to verify that the processes are being followed correctly and that the product is being made to specifications.

-

Final Quality Control (FQC): Before shipping, the finished product undergoes a thorough inspection to ensure it meets all quality and design specifications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should adopt a proactive approach to verifying supplier quality control. This can include:

-

Supplier Audits: Conducting regular audits of suppliers’ facilities to assess their adherence to quality standards and processes.

-

Requesting Quality Reports: Buyers can ask for documentation that details the quality control processes and results from their suppliers.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s capabilities and product quality.

What Nuances Should International Buyers Be Aware of Regarding QC?

International buyers, particularly from diverse markets such as Africa, South America, the Middle East, and Europe, should be aware of regional differences in quality standards and regulatory compliance. For instance, while CE marking is crucial in Europe, other regions may have different requirements that need to be met.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Buyers should establish clear lines of communication and set explicit quality expectations from the outset.

Conclusion

Understanding the manufacturing processes and quality assurance practices for custom leather dies is essential for B2B buyers seeking to invest in high-quality cutting solutions. By familiarizing themselves with the key stages of manufacturing, industry standards, and quality control practices, buyers can make informed decisions that ensure their projects meet the desired specifications and quality levels. This knowledge not only facilitates smoother transactions but also fosters long-term partnerships with reliable suppliers.

Illustrative image related to custom leather dies

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather dies’

In the competitive landscape of leather goods manufacturing, sourcing custom leather dies effectively is critical for ensuring product quality, consistency, and cost efficiency. This guide provides a systematic approach for B2B buyers aiming to procure these essential tools.

Step 1: Define Your Project Requirements

Clearly outline your project specifications, including the types of leather and the complexity of designs you need. This clarity helps suppliers provide accurate quotes and recommendations. Consider factors such as:

– Material Thickness: Ensure the die can handle the thickness of the leather you are using.

– Design Complexity: More intricate designs may require specialized dies, affecting cost and lead time.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the industry. Look for companies that specialize in custom leather dies and have a proven track record. Key points to investigate include:

– Experience and Expertise: Look for suppliers with years of experience in custom die manufacturing.

– Customer Reviews: Analyze testimonials and case studies from previous clients, especially those in your region.

Step 3: Evaluate Supplier Capabilities

Assess the manufacturing capabilities of potential suppliers to ensure they can meet your specifications. This includes understanding their production processes, technology, and materials used. Focus on:

– Precision Tolerance: Confirm the supplier can maintain the necessary precision for your designs (e.g., ±0.2mm).

– Customization Options: Check if they offer additional features like engraving or different mount materials.

Step 4: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the dies to evaluate their quality and performance. This step is vital to avoid costly mistakes later. Consider:

– Testing the Sample: Use the sample die on your materials to see how well it performs.

– Feedback Loop: Provide feedback to the supplier for any adjustments before the final production run.

Step 5: Understand Pricing Structures

Gain a clear understanding of the pricing structure to avoid unexpected costs. Custom dies can vary widely in price based on design complexity and production volume. Key pricing considerations include:

– Initial Costs vs. Long-term Value: While a higher upfront cost may seem daunting, investing in quality dies can lead to better efficiency and reduced waste over time.

– Additional Fees: Be aware of any extra charges for modifications, shipping, or rush orders.

Step 6: Confirm Lead Times and Shipping Options

Establish clear timelines for production and delivery to align with your project schedules. Delays can impact your overall production timeline. Important factors include:

– Standard vs. Rush Orders: Understand the typical lead time and what options are available for expedited orders.

– Shipping Methods: Evaluate shipping options that best suit your needs, considering cost and delivery speed.

Illustrative image related to custom leather dies

Step 7: Finalize Agreements and Contracts

Once you’ve selected a supplier, ensure that all terms are clearly documented in a contract. This protects both parties and clarifies expectations. Key elements to include are:

– Payment Terms: Specify payment schedules and accepted methods.

– Quality Assurance: Establish quality control measures and what recourse you have if the dies do not meet agreed-upon standards.

By following this checklist, B2B buyers can navigate the procurement process for custom leather dies with confidence, ensuring they select the right supplier and achieve optimal results for their leather goods projects.

Comprehensive Cost and Pricing Analysis for custom leather dies Sourcing

What Are the Key Cost Components in Custom Leather Dies Sourcing?

When sourcing custom leather dies, several cost components contribute to the overall expense. Understanding these can help buyers make informed decisions.

Illustrative image related to custom leather dies

-

Materials: The primary materials used in manufacturing custom leather dies include steel, polycarbonate, and acrylic. The choice of material directly influences the die’s durability and effectiveness. For instance, steel dies are typically more expensive but offer better longevity compared to polycarbonate options. Additionally, sourcing high-quality materials can incur higher upfront costs but may result in lower total costs over time due to reduced wear and tear.

-

Labor: Labor costs can vary significantly based on geographic location and the complexity of the die being produced. Skilled labor is required to create intricate designs, which may raise labor costs. For international buyers, consider the local labor market conditions of the supplier’s country, as this can impact pricing.

-

Manufacturing Overhead: This includes indirect costs associated with the production process, such as utilities, equipment depreciation, and facility maintenance. Suppliers may include these costs in their pricing, which can vary depending on the efficiency of their operations.

-

Tooling: Custom tooling is often necessary for unique die designs. This initial investment can be substantial, but it is crucial for achieving high precision and quality. Tooling costs may be amortized over larger production runs, making it more cost-effective for bulk orders.

-

Quality Control (QC): Implementing QC measures ensures the final product meets specified tolerances and standards. This may involve additional costs for inspection and testing. Buyers should inquire about the QC processes of potential suppliers to ensure they align with their quality expectations.

-

Logistics: Shipping costs, including freight and customs duties, can significantly affect the total cost of ownership. International buyers should consider the Incoterms agreed upon, as they determine who is responsible for shipping costs and risks during transport.

-

Margin: Supplier margins vary based on their business model, competition, and market demand. Understanding a supplier’s margin can provide insights into their pricing strategy and flexibility during negotiations.

How Do Price Influencers Affect Custom Leather Dies?

Several factors can influence the pricing of custom leather dies:

-

Volume/MOQ: Minimum order quantities (MOQs) can vary by supplier. Larger orders typically lead to lower per-unit costs, making it essential to assess your production needs upfront.

-

Specifications/Customization: Unique designs or additional features, such as engraving, can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Sourcing dies made from certified materials may incur additional costs but can provide assurance of quality and compliance with industry standards.

-

Supplier Factors: Supplier reputation, experience, and location play critical roles in pricing. Established suppliers with a track record of quality may charge more but offer greater reliability.

What Are the Best Practices for Negotiating Custom Leather Die Prices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings:

-

Research Market Rates: Understand the typical price range for the dies you require. This knowledge can empower you during negotiations.

-

Discuss Total Cost of Ownership: Emphasize the importance of long-term value rather than just initial costs. Highlight factors like durability and reduced waste to justify your pricing expectations.

-

Explore Multiple Suppliers: Obtain quotes from various suppliers to compare pricing and service offerings. This can help you identify the best value for your investment.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, favorable terms, and priority service.

Conclusion: What Should Buyers Keep in Mind About Pricing Nuances?

While indicative prices for custom leather dies can range from as low as $43 for simple designs to over $500 for intricate dies, these figures can fluctuate based on the factors discussed. Buyers should be aware that prices may differ significantly based on local market conditions, supplier capabilities, and shipping logistics. Engaging in thorough research and maintaining open communication with suppliers will enhance your sourcing experience and help you secure the best possible deal.

Alternatives Analysis: Comparing custom leather dies With Other Solutions

Exploring Alternatives to Custom Leather Dies for Leather Cutting Needs

When considering the best solutions for leather cutting, it’s essential to evaluate various methods available in the market. Custom leather dies are popular for their precision and adaptability, but alternatives exist that may better suit specific operational needs or budget constraints. This section compares custom leather dies against two viable alternatives: clicker presses and rotary cutting systems.

Illustrative image related to custom leather dies

Comparison Table

| Comparison Aspect | Custom Leather Dies | Clicker Presses | Rotary Cutting Systems |

|---|---|---|---|

| Performance | High precision, tailored designs | Excellent for mass production; consistent results | Moderate precision; suitable for complex shapes |

| Cost | Moderate to high ($100 – $500+) | High initial investment; cost-effective for high volume | Lower initial cost; ongoing material costs |

| Ease of Implementation | Requires design files; setup needed | Requires space and training; setup can be complex | User-friendly; minimal training needed |

| Maintenance | Low; durable with proper care | Moderate; requires regular upkeep | Low; simple maintenance procedures |

| Best Use Case | Custom, low to medium volume needs | High volume production; uniformity required | Crafting and prototyping; flexible designs |

Detailed Breakdown of Alternatives

What Are Clicker Presses and Their Advantages?

Clicker presses utilize steel or polycarbonate dies to cut leather with remarkable efficiency. They are particularly beneficial for businesses that require high-volume production, as they can significantly reduce cutting time while maintaining consistent quality. The initial cost of a clicker press can be high, but it pays off in the long run through labor savings and increased output. However, they do require ample workspace and operator training, which could be a barrier for smaller operations.

How Do Rotary Cutting Systems Compare?

Rotary cutting systems employ circular blades to cut through various materials, including leather. These systems are generally more affordable to set up and operate, making them appealing to small businesses or startups. They are user-friendly and require minimal training, allowing for quick adoption. However, they may lack the precision of custom dies and can struggle with intricate designs. As a result, rotary cutters are ideal for prototyping or crafting, where flexibility and speed are prioritized over precision.

Conclusion: Choosing the Right Solution for Your Leather Cutting Needs

Selecting the appropriate cutting solution depends on your business’s specific requirements, including production volume, design complexity, and budget constraints. Custom leather dies offer unparalleled precision for unique designs but may not be cost-effective for high-volume production. Clicker presses excel in mass production, while rotary cutting systems provide a balance between cost and ease of use. By assessing these factors, B2B buyers can make informed decisions that align with their operational goals and maximize efficiency in leather cutting processes.

Essential Technical Properties and Trade Terminology for custom leather dies

What Are the Key Technical Properties of Custom Leather Dies?

When sourcing custom leather dies, understanding their technical properties is crucial for ensuring quality, efficiency, and compatibility with your production processes. Here are some essential specifications that B2B buyers should consider:

Illustrative image related to custom leather dies

-

Material Grade

The material used in leather dies significantly affects durability and performance. Common materials include steel and polycarbonate. Steel dies are favored for their robustness and longevity, while polycarbonate offers a lighter alternative that is easier to handle. Selecting the right material can lead to cost-effective production and minimal wear over time. -

Tolerance

Tolerance refers to the allowable variation in die dimensions, typically expressed in millimeters (e.g., ±0.2mm). High precision is essential, especially for intricate designs, to ensure a perfect fit during the cutting process. Understanding tolerance levels helps buyers avoid costly errors in production and ensures that the final products meet quality standards. -

Cutting Depth

The effective cutting depth indicates the maximum thickness of material the die can cut through. For instance, a die with an effective cutting depth of 8.8mm can handle thicker leather and other materials. Knowing the cutting depth is vital for buyers to ensure that the dies can accommodate their specific material requirements. -

Mounting Options

Custom leather dies can come with various mounting options, such as acrylic mounts or wood bases. Acrylic mounts, for example, allow for precise alignment, reducing material waste during the cutting process. Choosing the right mounting option can enhance operational efficiency and improve the quality of the final product. -

Engraving Capabilities

Many manufacturers offer the option to add text or logos to the die through engraving. This feature is particularly beneficial for branding purposes and can be a valuable selling point in competitive markets. Understanding the engraving capabilities can help buyers enhance their product offerings and differentiate from competitors. -

Lead Time

The lead time for manufacturing and shipping custom leather dies can vary significantly among suppliers. Some companies offer expedited services, which can be critical for businesses needing quick turnaround times. Knowing the lead times helps buyers manage their production schedules effectively.

What Are Common Trade Terms Used in Custom Leather Die Procurement?

Familiarity with industry terminology can streamline communication and negotiations between buyers and suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the leather die industry, OEMs often create custom dies based on specific designs provided by clients, ensuring tailored solutions for their cutting needs. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. For custom leather dies, MOQs can vary based on design complexity and materials used. Understanding MOQs is crucial for buyers to assess whether a supplier aligns with their production volumes and budget. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. It typically includes details about the required products, including specifications and quantities. Submitting a well-prepared RFQ can lead to competitive pricing and better terms. -

Incoterms

These international commercial terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations in a transaction, such as who bears the risk during transit and who is responsible for import duties. -

Clicker Press

A clicker press is a machine used for cutting leather with dies. It ensures precision and efficiency, making it a popular choice for businesses engaged in mass production. Understanding the capabilities of a clicker press is essential for buyers planning to scale their operations. -

Die Set

A die set refers to a collection of dies designed to cut multiple shapes or components simultaneously. This feature can enhance productivity by reducing setup times and increasing output, making it a valuable consideration for B2B buyers looking to optimize their production processes.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring custom leather dies, ultimately enhancing their manufacturing efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the custom leather dies Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Dies Sector?

The custom leather dies market is experiencing significant growth, driven by the increasing demand for personalized leather goods across various industries, including fashion, automotive, and furniture. As global consumers lean towards bespoke products, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe are seeking reliable suppliers that can deliver high-quality, custom-designed leather dies efficiently. Key trends include the adoption of digital design technologies, which facilitate rapid prototyping and customization, allowing businesses to respond quickly to market demands. Additionally, the rise of e-commerce platforms has streamlined the sourcing process, enabling buyers to connect directly with manufacturers worldwide.

Emerging technologies such as laser cutting and automated die-making are enhancing production capabilities, reducing lead times, and minimizing waste. This shift towards technology-driven processes is particularly relevant for buyers looking to scale operations without compromising on quality. Furthermore, sustainability is becoming a critical factor, with buyers increasingly prioritizing suppliers who demonstrate environmental responsibility and ethical sourcing practices. The ability to provide transparent supply chain information is becoming a competitive advantage in the marketplace, influencing purchasing decisions among discerning B2B buyers.

Illustrative image related to custom leather dies

How Is Sustainability and Ethical Sourcing Impacting the Custom Leather Dies Market?

Sustainability and ethical sourcing are now paramount in the custom leather dies sector. The environmental impact of leather production, including water consumption, chemical usage, and waste generation, is prompting buyers to seek suppliers who adhere to sustainable practices. The demand for eco-friendly materials, such as vegetable-tanned leather and synthetic alternatives, is on the rise. B2B buyers are increasingly looking for manufacturers that offer certifications for sustainable practices, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification, which assures that the products are made with environmentally friendly methods.

Moreover, ethical supply chains are crucial for maintaining brand reputation and consumer trust. Buyers are encouraged to partner with suppliers who prioritize fair labor practices and transparency in their production processes. By aligning with such suppliers, businesses can not only fulfill their corporate social responsibility commitments but also cater to a growing consumer base that values sustainability. This shift towards ethical sourcing is not just a trend but a vital strategy for long-term business viability and success in the custom leather dies market.

How Has the Custom Leather Dies Market Evolved Over Time?

The evolution of the custom leather dies market reflects broader changes in manufacturing and consumer preferences. Historically, leather goods were produced using manual methods, which were labor-intensive and time-consuming. However, the introduction of steel rule dies and clicker presses revolutionized the industry, allowing for faster and more precise cutting of leather. As technology advanced, the development of computer-aided design (CAD) systems and laser cutting techniques further streamlined the production process, enabling manufacturers to create intricate designs with minimal waste.

In recent years, the demand for personalized and customized leather products has surged, prompting manufacturers to adapt their offerings to meet this need. The focus has shifted from mass production to small-batch, high-quality custom orders, catering to niche markets and individual consumer preferences. This evolution not only reflects changing consumer demands but also highlights the growing importance of agility and innovation in the custom leather dies sector. As the market continues to evolve, staying informed about technological advancements and consumer trends will be essential for B2B buyers looking to thrive in this dynamic landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather dies

-

How do I choose the right custom leather die for my business?

Selecting the appropriate custom leather die involves several considerations. First, assess the complexity of your design; intricate shapes may require more specialized dies. Evaluate the materials you intend to cut, as different dies perform better with specific thicknesses and types of leather or other materials. Also, consider the production scale—if you plan to produce in large quantities, investing in a high-quality die will ensure consistency and efficiency. Lastly, work with suppliers who can provide samples or prototypes to test before making a bulk order. -

What factors influence the cost of custom leather dies?

The cost of custom leather dies is influenced by multiple factors, including the complexity of the design, the materials used, and the size of the die. Intricate designs or larger dies typically come with higher costs. Additionally, features like hole punches or engraving can add to the overall price. It’s also essential to consider shipping and any potential import duties, especially when sourcing from international suppliers. Request quotes from multiple suppliers to find the best balance between quality and cost. -

What is the minimum order quantity (MOQ) for custom leather dies?

Minimum order quantities for custom leather dies can vary significantly among suppliers. While some may accept small orders for prototype or test runs, others might require a minimum of 100 pieces or more, particularly for mass production. When sourcing from international suppliers, ensure you clarify the MOQ upfront, as this can impact your production timeline and costs. Building a relationship with your supplier may also lead to more flexible terms over time. -

How can I ensure the quality of custom leather dies from international suppliers?

To ensure quality, conduct thorough research on potential suppliers. Look for reviews and testimonials from other businesses, and consider requesting samples of their previous work. Establish clear communication regarding your specifications and quality expectations. Additionally, if feasible, arrange for a factory visit or request third-party inspections before shipment. This proactive approach helps mitigate risks associated with international sourcing and ensures you receive a product that meets your standards. -

What payment terms should I expect when ordering custom leather dies?

Payment terms can vary widely depending on the supplier’s policies and your relationship with them. Many suppliers may require a partial upfront payment, typically between 30-50%, with the balance due upon completion or delivery. For larger orders, some suppliers might offer payment plans or credit terms after establishing a trusted relationship. Always clarify payment methods accepted (e.g., credit card, PayPal, bank transfer) and ensure that the terms are documented in your purchase agreement. -

What are the logistics and shipping options for custom leather dies?

When sourcing custom leather dies internationally, logistics play a crucial role in your supply chain. Most suppliers offer various shipping options, ranging from standard to express delivery services. Standard shipping may take longer but is often more economical, while express services can expedite delivery but at a higher cost. Factor in potential customs duties and tariffs, as these can affect overall delivery times and costs. Ensure your supplier provides tracking information to monitor shipment progress. -

How can I communicate my design specifications effectively to the supplier?

Effective communication of design specifications is key to obtaining the right custom leather die. Provide detailed drawings or digital files (AI, PDF, or high-resolution images) illustrating your design. Include measurements, material types, and any specific features such as engraving or hole punches. If you have a prototype or sample, sharing that can also be beneficial. Establishing a dialogue with your supplier allows for clarifications and adjustments, ensuring that the final product aligns with your expectations. -

What should I do if my custom leather die does not meet my expectations?

If your custom leather die fails to meet your expectations, promptly communicate your concerns to the supplier. Document the issues with clear descriptions and photos if possible. Many reputable suppliers will have policies in place for handling such discrepancies, including adjustments, replacements, or refunds. It’s crucial to address these matters quickly, as delays can affect your production schedule. Building a strong relationship with your supplier can also facilitate smoother resolutions in the future.

Top 6 Custom Leather Dies Manufacturers & Suppliers List

1. LW Leathers – Leather Die Cut with Acrylic Mount

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Leather Die Cut with Acrylic Mount”, “category”: “Leather Cutting and Paper Cutting”, “regular_price”: “US$138.00”, “sizes_available”: [“Up to 3×3 inch”, “Up to 4×4 inch”, “Up to 5×5 inch”, “Up to 6×6 inch”], “description”: “Custom made laser engraved leather die cut / steel rule die cut for cutting leather, paper, card stock, silicone, thin magnet, etc. Acrylic mount steel rule …

2. Weaver Leather Supply – Clicker Dies & Sets

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Clicker Dies & Sets from Weaver Leather Supply include a variety of steel and polycarbonate leather cutting dies designed for efficiency and precision in leather crafting. Key features include:

– High impact polycarbonate construction for durability and longevity.

– Customization options available for specific project needs.

– Ideal for mass production, saving time and ensuring consistency in c…

3. DM Leather Studio – Custom Leather Cutting Die

Domain: dmleatherstudio.com

Registered: 2017 (8 years)

Introduction: Custom leather cutting dies, Steel Die for cutting leather. Product Code: X09-LCD. Price: $2.00. Availability: Many in stock. Materials: wood, steel. Default height of the mold: 24mm (0.95in). Custom orders accepted for size adjustments and design modifications. Customers can send design files in various formats (.ai, .eps, .pdf, .jpg, .png) or sketches with dimensions. Packaging includes foam for…

4. Texas Custom Dies – Custom Die Cutting Services

Domain: usacuttingdie.com

Registered: 2009 (16 years)

Introduction: Texas Custom Dies offers custom die cutting services, including saddle dies, small key fobs, and coaster dies. They also provide die cutting services for customers without a press. The company emphasizes honesty, quality, and value in their die making.

5. Leather Stamp Maker – Custom Steel Cutting Dies

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Steel Leather Cutting Dies by Leather Stamp Maker, Made in the USA. All custom stamps ship next business day. Full Letter Sets include: trio of each letter A-Z, numbers 0-9, special characters (period, comma, at symbol, ampersand, hash, slash, dash, exclamation mark), four blank spacers, stamping handle, and a 4-inch holder, all packaged in a box. Mini Font Sets include: full set of 26 uppercase l…

6. Infinity Stamps – Custom Leather Roll Dies

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Custom Leather Roll Dies from Infinity Stamps, Inc. Made in the USA. Family owned for over 25 years. Available for various stamping applications including leather. Contact options include calling 818-576-1188 or filling out a contact form.

Strategic Sourcing Conclusion and Outlook for custom leather dies

Why is Strategic Sourcing Essential for Custom Leather Dies?

In the evolving landscape of custom leather dies, strategic sourcing emerges as a vital component for B2B buyers aiming to optimize their production processes. By leveraging suppliers that offer precision-engineered dies, businesses can significantly reduce material waste and enhance production efficiency. Customization options, such as specific shapes and sizes, allow companies to meet diverse market demands while maintaining high quality and consistency in their leather products.

How Can International Buyers Benefit from Custom Leather Dies?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, the ability to source custom leather dies can lead to competitive advantages. By investing in high-quality, tailored dies, businesses can streamline their operations, reduce labor costs, and improve turnaround times. Moreover, working with suppliers who understand local market needs and regulations can facilitate smoother transactions and enhance supply chain resilience.

What Should B2B Buyers Do Next?

As you consider your sourcing strategy, prioritize partnerships with reputable manufacturers who can deliver precision and reliability. Evaluate your design requirements and engage with suppliers who offer robust customization options. Embrace this opportunity to elevate your product offerings and drive business growth. The future of your leather crafting endeavors depends on the strategic choices you make today—seize the moment to innovate and lead in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather dies