Introduction: Navigating the Global Market for microfiber microsuede

In the rapidly evolving textile market, sourcing high-quality microfiber microsuede presents both opportunities and challenges for B2B buyers. As businesses seek durable and aesthetically pleasing materials for upholstery and fashion, understanding the nuances of microfiber microsuede becomes critical. This guide delves into the diverse types of microfiber microsuede, their applications across various industries, and essential factors for supplier vetting, ensuring that international buyers can make informed decisions.

From the vibrant markets of Africa and South America to the sophisticated sectors in the Middle East and Europe, the demand for cost-effective and versatile fabric solutions is on the rise. This comprehensive resource not only highlights the advantages of microfiber microsuede—such as its superior stain resistance, ease of maintenance, and luxurious feel—but also addresses potential pitfalls in sourcing. By equipping buyers with insights into pricing strategies, quality assessments, and supplier reliability, this guide empowers stakeholders to navigate the complexities of the global market confidently.

Whether you’re a furniture manufacturer in Brazil or a fashion retailer in Vietnam, understanding the dynamics of microfiber microsuede will enhance your purchasing strategy, ultimately leading to smarter investments and improved product offerings.

Table Of Contents

- Top 6 Microfiber Microsuede Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for microfiber microsuede

- Understanding microfiber microsuede Types and Variations

- Key Industrial Applications of microfiber microsuede

- 3 Common User Pain Points for ‘microfiber microsuede’ & Their Solutions

- Strategic Material Selection Guide for microfiber microsuede

- In-depth Look: Manufacturing Processes and Quality Assurance for microfiber microsuede

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber microsuede’

- Comprehensive Cost and Pricing Analysis for microfiber microsuede Sourcing

- Alternatives Analysis: Comparing microfiber microsuede With Other Solutions

- Essential Technical Properties and Trade Terminology for microfiber microsuede

- Navigating Market Dynamics and Sourcing Trends in the microfiber microsuede Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of microfiber microsuede

- Strategic Sourcing Conclusion and Outlook for microfiber microsuede

- Important Disclaimer & Terms of Use

Understanding microfiber microsuede Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Microsuede | Soft, suede-like texture; durable polyester | Upholstery, automotive interiors, fashion | Pros: Affordable, easy to clean, versatile. Cons: May wear faster than higher-end options. |

| Performance Microsuede | Enhanced stain and water resistance; heavier weight | High-traffic furniture, hospitality | Pros: Highly durable, excellent for busy environments. Cons: Higher cost compared to standard. |

| Eco-friendly Microsuede | Made from recycled materials; sustainable production | Eco-conscious brands, high-end upholstery | Pros: Sustainable, appealing to green consumers. Cons: May be limited in color options. |

| Microfiber Blend | Combination of microfiber and other synthetic fibers | Apparel, cleaning products, home textiles | Pros: Soft, lightweight, versatile. Cons: Performance can vary based on blend ratios. |

| Faux Suede Microsuede | Mimics genuine suede; luxurious appearance | Fashion accessories, premium home furnishings | Pros: Looks and feels like real suede, easy maintenance. Cons: Lacks the unique texture of real suede. |

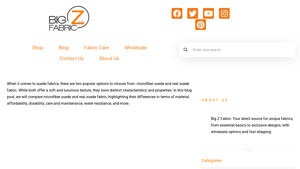

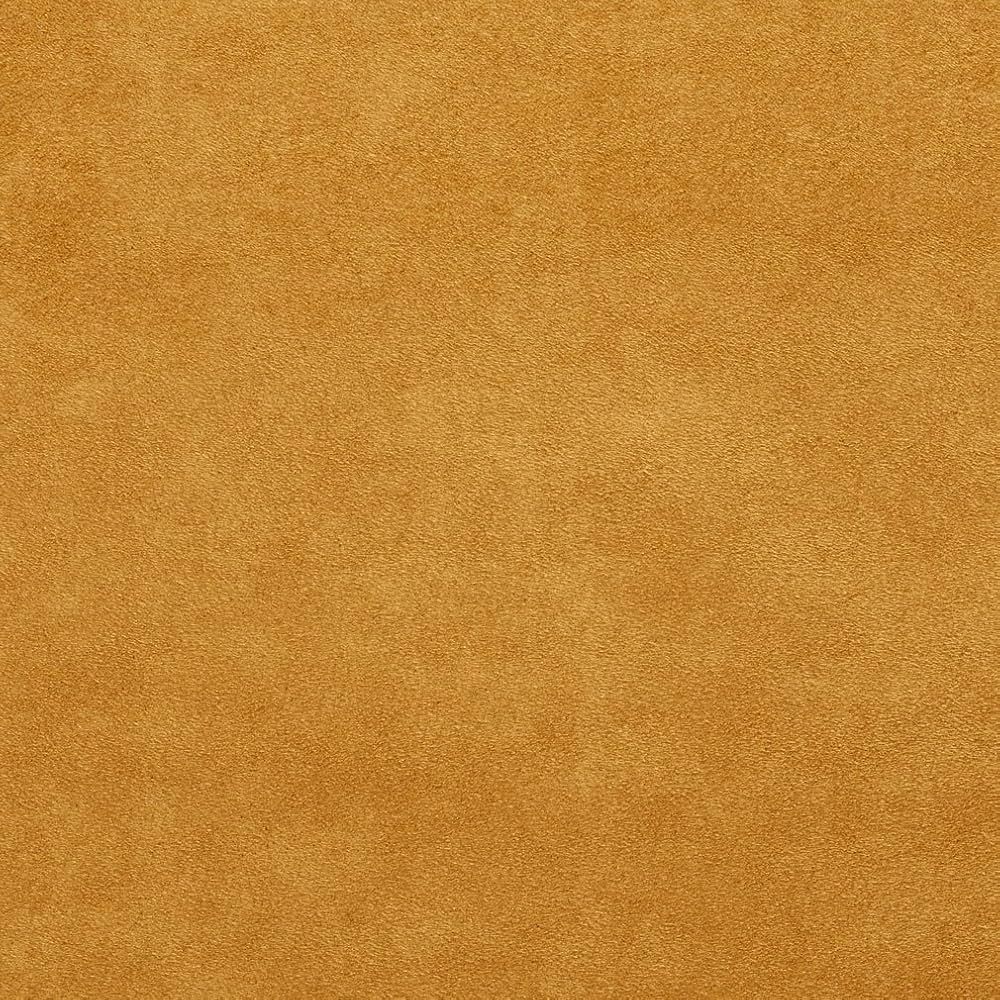

What are the Characteristics of Standard Microsuede?

Standard microsuede is a popular choice in the B2B sector due to its balance of affordability and durability. Composed primarily of tightly woven polyester fibers, it offers a soft, suede-like texture that appeals to various industries, including upholstery and automotive. This type is particularly suitable for furniture and fashion applications, providing an elegant appearance without the high maintenance associated with genuine suede. Buyers should consider its performance in high-traffic areas, as it may show signs of wear more quickly than higher-end fabrics.

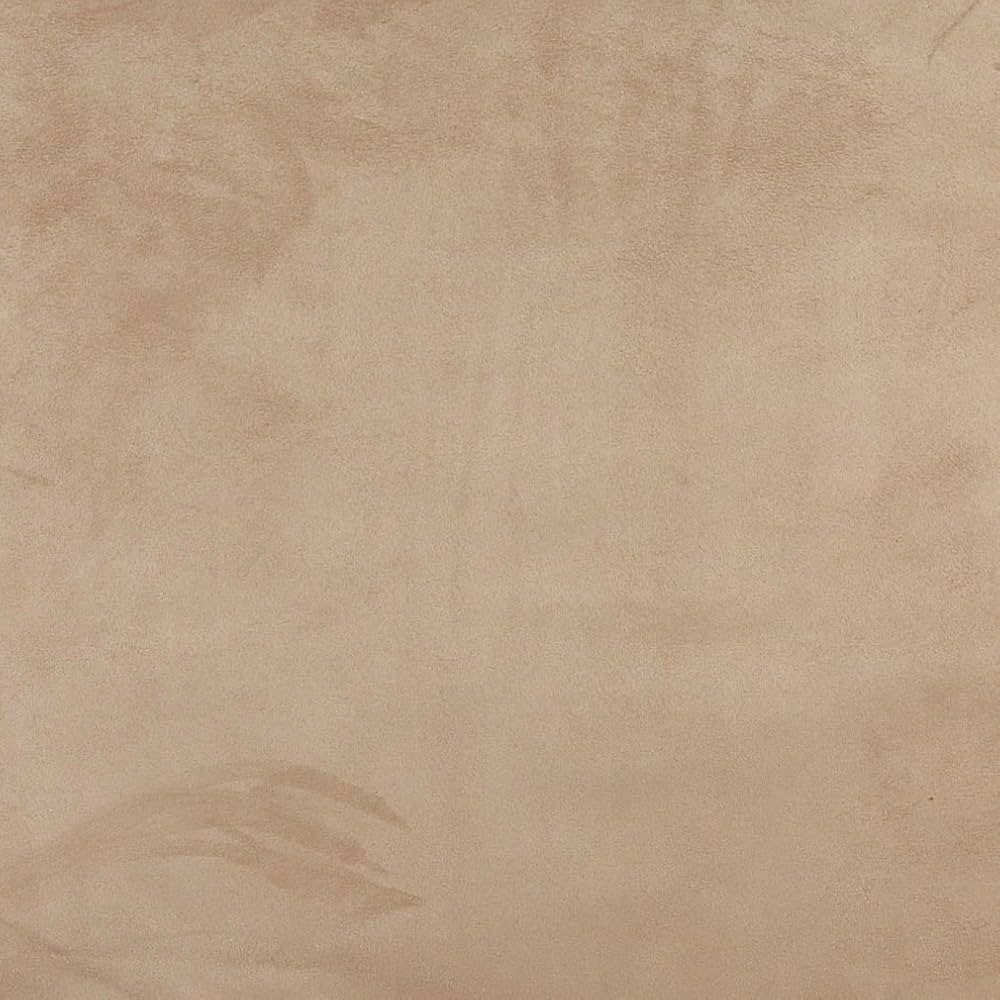

How Does Performance Microsuede Differ from Standard Options?

Performance microsuede is engineered for enhanced durability, featuring improved stain and water resistance. This heavier-weight fabric is ideal for high-traffic environments such as hospitality venues and family-oriented furniture. B2B buyers seeking long-lasting materials for commercial applications will find performance microsuede advantageous. However, the cost is typically higher than standard microsuede, which may impact budget considerations for larger projects. The investment can be justified by its longevity and reduced maintenance needs.

What Makes Eco-friendly Microsuede Attractive to B2B Buyers?

Eco-friendly microsuede is crafted from recycled materials and produced through sustainable practices, making it an attractive option for brands aiming to reduce their environmental footprint. This type appeals to eco-conscious consumers and businesses looking to align with sustainable practices. While it may offer fewer color choices compared to traditional microsuede, its unique selling proposition can enhance brand reputation and customer loyalty. B2B buyers should consider the growing market demand for sustainable products when evaluating this option.

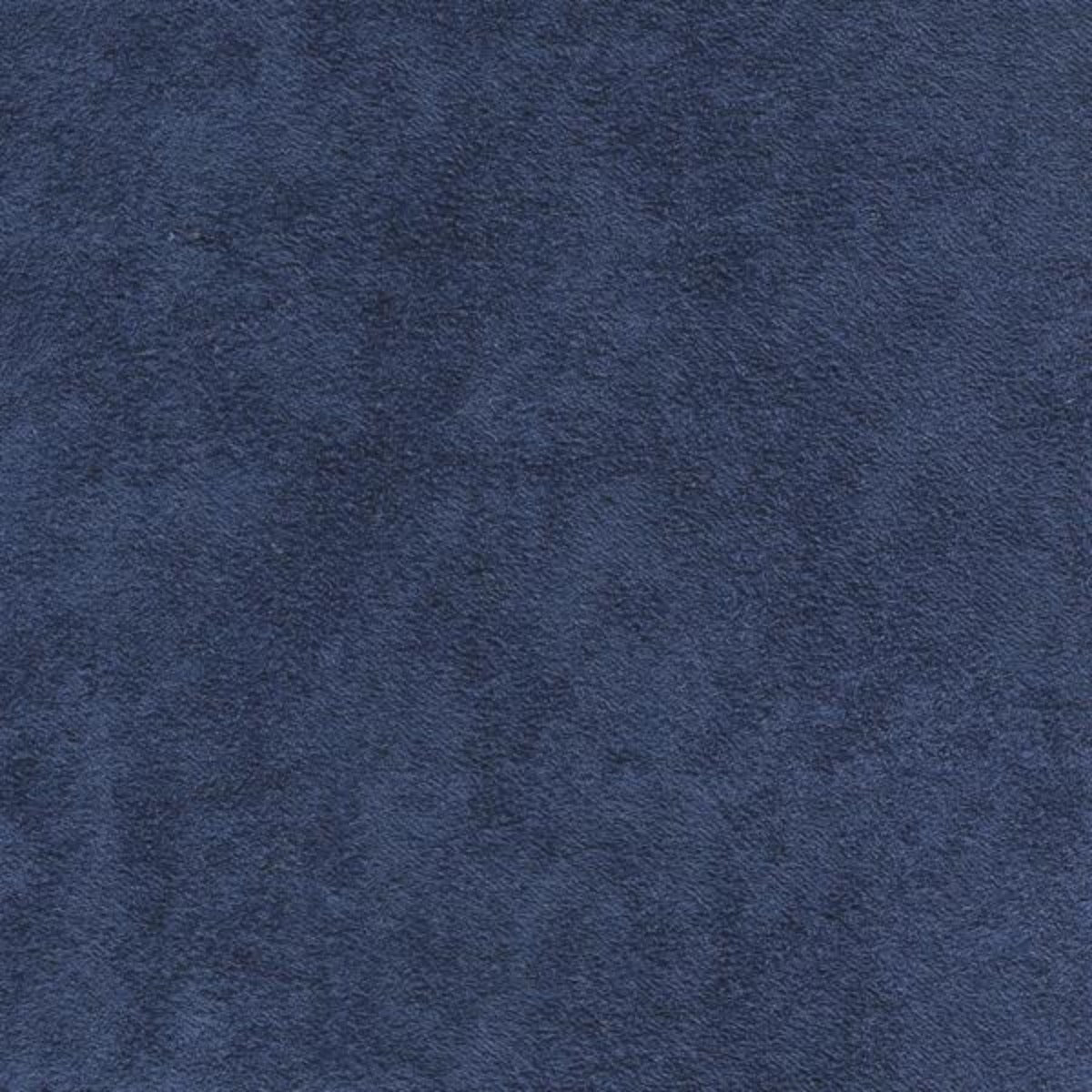

How Do Microfiber Blends Enhance Versatility?

Microfiber blends incorporate other synthetic fibers to enhance the fabric’s properties, resulting in a lightweight and soft material suitable for various applications. This versatility makes it ideal for apparel, cleaning products, and home textiles. B2B buyers should assess the blend ratios, as the performance can vary significantly based on the composition. While these blends may not offer the same luxurious feel as pure microsuede, their adaptability can meet diverse market needs and price points.

Why Choose Faux Suede Microsuede for Fashion and Furnishings?

Faux suede microsuede mimics the luxurious appearance of genuine suede while providing the benefits of easy maintenance and durability. This fabric is particularly popular in the fashion industry and high-end home furnishings, appealing to consumers seeking elegance without the associated upkeep of real suede. B2B buyers should consider the aesthetic appeal and market demand for faux suede, as it offers a cost-effective alternative to genuine materials. However, the unique texture of real suede remains unmatched, which may influence consumer preferences in certain segments.

Key Industrial Applications of microfiber microsuede

| Industry/Sector | Specific Application of microfiber microsuede | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Durable, stain-resistant fabric that enhances longevity | Quality of fabric, availability of colors and textures, compliance with safety standards |

| Automotive | Interior car upholstery | Lightweight, easy to clean, enhances aesthetic appeal | Compatibility with automotive standards, fire resistance, color fastness |

| Home Textiles | Bedding and cushions | Soft texture that is hypoallergenic and easy to maintain | Certifications for hypoallergenic properties, durability against wear and tear |

| Fashion Industry | Clothing and accessories | Cost-effective alternative to leather with a luxurious feel | Trend alignment, fabric weight, and breathability |

| Cleaning Industry | Cleaning cloths and mops | Superior dirt-trapping capabilities, reusable and eco-friendly | Fiber composition, cleaning efficiency, and sustainability certifications |

How is Microfiber Microsuede Used in Furniture Manufacturing?

In the furniture manufacturing sector, microfiber microsuede is primarily used for upholstery on sofas and chairs. Its durability and stain resistance make it an ideal choice for high-traffic areas, ensuring that furniture retains its aesthetic appeal over time. This fabric’s ability to mimic the luxurious feel of natural suede while being easier to maintain is particularly attractive for manufacturers targeting family-oriented markets. Buyers should consider the quality of the fabric, the variety of available colors and textures, and compliance with safety standards to ensure that the end product meets consumer expectations.

What Role Does Microfiber Microsuede Play in Automotive Interiors?

In the automotive industry, microfiber microsuede is widely utilized for interior car upholstery, including seats, headliners, and door panels. Its lightweight nature contributes to overall vehicle efficiency, while its easy-to-clean properties are vital for maintaining a pristine interior. Additionally, the fabric enhances the aesthetic appeal of vehicles, aligning with consumer preferences for luxury. When sourcing for this application, businesses must ensure compatibility with automotive standards, such as fire resistance and color fastness, to meet regulatory requirements and consumer safety.

How is Microfiber Microsuede Beneficial in Home Textiles?

Microfiber microsuede is increasingly popular in the home textiles industry for applications such as bedding and cushions. Its soft texture is hypoallergenic, making it suitable for sensitive individuals, while its durability ensures that products withstand regular use. The ease of maintenance is another critical factor, as consumers seek fabrics that remain looking new with minimal effort. Buyers should focus on certifications for hypoallergenic properties and durability against wear and tear when selecting suppliers to guarantee quality and consumer satisfaction.

Illustrative image related to microfiber microsuede

Why is Microfiber Microsuede Important in the Fashion Industry?

In the fashion industry, microfiber microsuede serves as a cost-effective alternative to leather for clothing and accessories. It offers a luxurious appearance without the associated environmental concerns of animal products. The fabric’s versatility allows designers to create a variety of styles, appealing to eco-conscious consumers. When sourcing for fashion applications, it is essential to consider trend alignment, the weight of the fabric, and breathability to ensure that products meet market demands and consumer preferences.

How Does Microfiber Microsuede Enhance Cleaning Products?

The cleaning industry leverages microfiber microsuede in the production of cleaning cloths and mops due to its superior dirt-trapping capabilities. This fabric is reusable and eco-friendly, appealing to businesses looking to promote sustainability. Its ability to trap dust and dirt without the need for chemical sprays makes it a preferred choice for both commercial and residential cleaning applications. When sourcing, companies should prioritize fiber composition, cleaning efficiency, and sustainability certifications to align with environmental goals and consumer expectations.

3 Common User Pain Points for ‘microfiber microsuede’ & Their Solutions

Scenario 1: The Challenge of Durability in High-Traffic Areas

The Problem: B2B buyers in the furniture and upholstery sector often face the challenge of selecting materials that can withstand heavy use, particularly in commercial settings like hotels, restaurants, and family-friendly establishments. Microfiber microsuede, while known for its durability, can still wear down over time if not properly sourced or specified. Buyers may find that some lower-quality options begin to show signs of wear, pilling, or fading much sooner than expected, leading to increased replacement costs and dissatisfied customers.

The Solution: To ensure longevity and performance in high-traffic areas, it’s crucial to specify high-quality microfiber microsuede with a robust denier rating (the measurement of fiber thickness). A denier rating of 300 or above is typically more durable and resistant to wear. Additionally, buyers should inquire about the fabric’s abrasion resistance, which is rated using the Martindale test. Fabrics that score above 30,000 rubs are generally suitable for commercial use. Establish relationships with reputable suppliers who can provide detailed specifications and samples for testing. Regularly reviewing performance metrics and gathering feedback from end-users can also help in refining material choices for future projects.

Scenario 2: Managing Stain Resistance for Diverse Applications

The Problem: In sectors like hospitality or family-oriented retail, buyers often encounter the issue of maintaining the appearance of furniture and upholstery in environments prone to spills and stains. While microfiber microsuede is celebrated for its stain resistance, not all variants perform equally. Buyers may find that certain finishes are less effective against specific types of stains, leading to increased maintenance efforts and potential customer dissatisfaction.

The Solution: To combat this issue, B2B buyers should prioritize sourcing microfiber microsuede that is treated with advanced stain-repellent technologies. Look for products that incorporate Teflon or similar coatings, which can significantly enhance stain resistance. Furthermore, establishing a clear cleaning protocol for end-users is essential. Providing detailed care instructions, including recommended cleaning agents and techniques, can empower users to effectively maintain the fabric. Offering training sessions or workshops on proper cleaning and maintenance can also increase customer satisfaction and reduce the likelihood of damage due to improper care.

Scenario 3: Balancing Cost and Quality in Material Selection

The Problem: One common challenge faced by international B2B buyers is striking the right balance between cost and quality when sourcing microfiber microsuede. Many buyers are tempted to opt for the lowest-priced options, which can lead to subpar performance and increased long-term costs due to replacements and repairs. This is particularly crucial in regions where budget constraints are prevalent, such as in emerging markets in Africa and South America.

The Solution: To navigate this dilemma, buyers should adopt a value-based sourcing strategy rather than a purely cost-driven one. Begin by conducting a thorough cost-benefit analysis, factoring in not just the initial purchase price but also the total cost of ownership, including maintenance and replacement cycles. Engage with suppliers who can provide transparent pricing structures and demonstrate the long-term value of their products through warranties or performance guarantees. It may also be beneficial to establish a tiered pricing model based on quantity or commitment, allowing for better negotiation leverage while ensuring quality. Collaborating with suppliers who understand regional market dynamics can also lead to more tailored solutions that meet both budgetary and quality requirements.

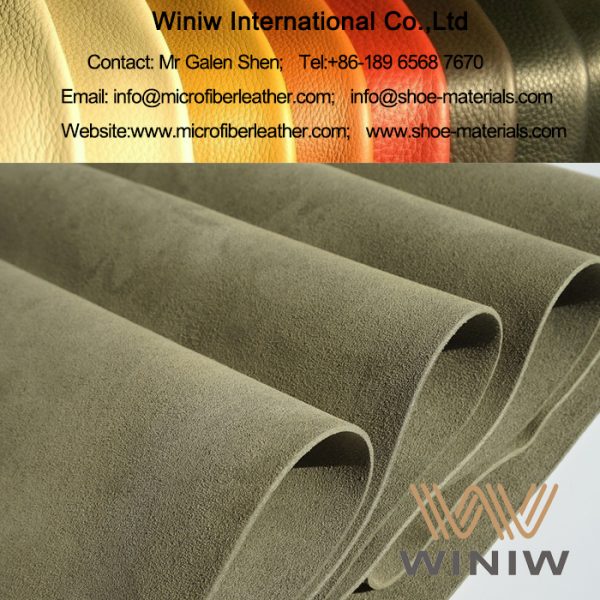

Illustrative image related to microfiber microsuede

Strategic Material Selection Guide for microfiber microsuede

What Are the Key Properties of Microfiber Microsuede Materials?

Microfiber microsuede is primarily made from synthetic fibers, predominantly polyester and nylon, which contribute to its unique properties. The fibers are woven tightly to create a soft, suede-like texture that mimics genuine suede while offering enhanced durability and stain resistance. This material excels in applications requiring comfort and aesthetics, such as upholstery, clothing, and accessories.

What Are the Pros and Cons of Using Polyester-Based Microfiber Microsuede?

Key Properties: Polyester microfiber microsuede has excellent tensile strength, making it resistant to wear and tear. It also offers good breathability and moisture-wicking capabilities, which are beneficial in upholstery applications.

Pros: The primary advantages include its affordability compared to natural suede, ease of maintenance, and hypoallergenic properties. It is also water-resistant, making it suitable for high-traffic areas and environments with children or pets.

Cons: While durable, polyester microsuede can be less resistant to high temperatures than other materials, potentially leading to melting or deformation if exposed to excessive heat. Additionally, its synthetic nature may not appeal to buyers seeking eco-friendly options.

How Does Nylon-Based Microfiber Microsuede Compare?

Key Properties: Nylon microfiber microsuede is known for its superior strength and elasticity, providing excellent durability under pressure and resistance to abrasion.

Pros: This material is highly resilient, making it suitable for applications requiring a longer lifespan. It also offers a luxurious feel and can be dyed in various colors, enhancing its aesthetic appeal.

Cons: The main drawback is its higher cost compared to polyester options, which may deter budget-conscious buyers. Furthermore, nylon can be prone to static electricity, which may complicate its use in certain environments.

What Are the Specific Considerations for B2B Buyers in Different Regions?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider local compliance and standards when selecting microfiber microsuede materials. For instance, adherence to ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) standards may be crucial for ensuring product quality and safety. Additionally, regional preferences for material sustainability and eco-friendliness are increasingly influencing purchasing decisions. Buyers should also be aware of logistical considerations, such as shipping costs and tariffs, which can impact overall pricing.

Summary Table of Material Selection for Microfiber Microsuede

| 素材 | Typical Use Case for microfiber microsuede | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester Microfiber | Upholstery, clothing, accessories | Affordable and easy to maintain | Less heat resistant | 低い |

| Nylon Microfiber | High-end furniture, automotive interiors | Superior durability and elasticity | Higher cost and static issues | Med |

| Blended Microfiber | Sportswear, cleaning products | Versatile and moisture-wicking | Potentially less durable than pure | Med |

| Eco-Friendly Microfiber | Sustainable fashion and upholstery | Appeals to environmentally conscious buyers | May have higher production costs | 高い |

This guide provides a comprehensive overview of the strategic material selection for microfiber microsuede, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

Illustrative image related to microfiber microsuede

In-depth Look: Manufacturing Processes and Quality Assurance for microfiber microsuede

What Are the Key Stages in the Manufacturing Process of Microfiber Microsuede?

The manufacturing process of microfiber microsuede involves several critical stages that ensure the creation of a high-quality product suitable for various applications, including upholstery, clothing, and cleaning products. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

1. Material Preparation: How Are Raw Materials Selected and Processed?

The foundation of microfiber microsuede is its raw materials, primarily polyester and nylon. These synthetic fibers are chosen for their durability, softness, and stain resistance. The manufacturing process begins with sourcing high-quality raw materials from reputable suppliers, ensuring compliance with international environmental and safety standards.

Once sourced, the materials undergo initial processing, which includes cutting and treating the fibers to enhance their properties. This may involve processes such as splitting, where the fibers are divided into finer strands to achieve the desired texture. The preparation phase is crucial as it sets the stage for the quality of the final product.

2. Forming: What Techniques Are Used to Create the Fabric?

After material preparation, the next step is forming the fabric. This stage typically involves weaving or knitting the prepared fibers. In the case of microfiber microsuede, the fibers are woven tightly together to create a dense, suede-like texture.

One common technique used in this process is the “microfiber weaving” method, which ensures that the fibers are closely packed, enhancing the fabric’s durability and softness. This tight weaving not only contributes to the tactile quality of the microsuede but also improves its resistance to wear and staining.

Illustrative image related to microfiber microsuede

3. Assembly: How Is Microfiber Microsuede Processed for End Use?

Once the fabric is formed, it undergoes assembly, which may include cutting, sewing, or laminating the fabric into finished products such as upholstery covers, clothing, or cleaning cloths. The assembly process often involves automated machinery for precision cutting and stitching, ensuring consistency in product quality.

Quality control checkpoints are integrated into the assembly phase to monitor the fabric’s integrity and appearance. Any defects identified during this stage can be corrected before the product reaches the market, thereby minimizing waste and maximizing customer satisfaction.

4. Finishing: What Treatments Enhance the Properties of Microfiber Microsuede?

The finishing stage is where microfiber microsuede is treated to enhance its desirable properties. This may include applying coatings for additional water and stain resistance, dyeing the fabric for color consistency, and conducting brushing or shearing processes to achieve the desired texture.

Finishing techniques can vary based on the intended use of the fabric. For example, upholstery-grade microsuede may undergo more rigorous finishing processes to ensure durability against heavy usage, while fabrics intended for fashion applications may focus more on aesthetic qualities.

What Quality Assurance Measures Are Implemented in Microfiber Microsuede Production?

Quality assurance (QA) is paramount in the manufacturing of microfiber microsuede, especially given the global market’s demand for consistent quality and compliance with international standards.

1. Which International Standards Should Buyers Look For?

B2B buyers should ensure that suppliers adhere to recognized international quality standards, such as ISO 9001, which focuses on quality management systems. Compliance with such standards indicates that the manufacturer has established procedures for maintaining quality throughout the production process.

Additionally, industry-specific certifications, such as CE marking for products sold in Europe or the American API (American Petroleum Institute) standards for cleaning products, may be relevant depending on the end-use application of the microfiber microsuede. Verification of these certifications can provide buyers with confidence in the supplier’s commitment to quality.

2. What Are the Key Quality Control Checkpoints During Production?

Quality control in microfiber microsuede manufacturing typically involves several checkpoints, including:

Illustrative image related to microfiber microsuede

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. Suppliers must provide documentation and testing results for the fibers to ensure they meet required standards.

-

In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor the weaving, assembly, and finishing processes. This ensures that any deviations from quality standards are identified and addressed promptly.

-

Final Quality Control (FQC): Once the products are completed, a final inspection is performed to assess the overall quality and consistency of the finished goods. This step may involve physical tests, such as abrasion resistance and colorfastness, to confirm that the products meet established specifications.

3. How Can Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following verification methods:

-

Audits: Conducting regular audits of the supplier’s manufacturing facility can provide insights into their quality control processes and adherence to standards. Auditors can assess the effectiveness of the QA measures in place and identify areas for improvement.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the frequency and outcomes of quality checks throughout the production process. These reports should include data on defect rates, testing methods, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These services can conduct random sampling and testing of products to verify compliance with specified standards.

What Are the Unique QC Considerations for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances when sourcing microfiber microsuede.

1. Navigating Regional Regulations and Standards

Different regions may have unique regulations governing the use of synthetic fabrics. For example, the European Union has stringent regulations regarding chemical safety (REACH) that impact the types of dyes and treatments used in fabric production. Buyers must ensure that their suppliers comply with these regulations to avoid potential legal issues.

2. Understanding Supply Chain Risks

International supply chains can present risks related to quality consistency, especially when sourcing from multiple regions. Buyers should assess the reliability of their suppliers, including their ability to maintain quality across different production batches. Establishing long-term relationships with reputable suppliers can mitigate these risks and ensure a stable supply of high-quality microfiber microsuede.

Illustrative image related to microfiber microsuede

3. Cultural and Language Barriers

Cultural differences and language barriers can impact communication regarding quality expectations. Buyers should establish clear channels of communication with suppliers to convey their quality requirements effectively. Utilizing bilingual representatives or translators can facilitate smoother interactions and ensure that quality standards are clearly understood and met.

In conclusion, understanding the manufacturing processes and quality assurance measures for microfiber microsuede is essential for B2B buyers. By focusing on the key stages of production, international standards, and effective verification methods, buyers can make informed decisions and establish successful partnerships with suppliers in this competitive market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber microsuede’

はじめに

Sourcing microfiber microsuede for your business requires a strategic approach to ensure you obtain quality materials that meet your specific needs. This guide provides a practical step-by-step checklist to help B2B buyers navigate the procurement process efficiently, ensuring that you select the right suppliers and products.

Step 1: Define Your Technical Specifications

Clearly outline the characteristics you need for microfiber microsuede. This includes factors such as weight, thickness, texture, and color. Specific technical specifications help in communicating your requirements to potential suppliers, ensuring they can meet your needs effectively.

- Consider the intended use: upholstery, clothing, or other applications.

- Determine the required durability and stain resistance based on your target market.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Utilize online platforms, trade shows, and industry connections to compile a list of potential vendors. This step is critical to ensure you partner with reputable companies that can deliver quality products.

Illustrative image related to microfiber microsuede

- Look for suppliers with positive reviews and testimonials.

- Check their experience in producing microfiber microsuede and their capacity to fulfill your order volume.

Step 3: Evaluate Supplier Certifications

Verify that suppliers hold relevant industry certifications. Certifications can indicate compliance with safety, quality, and environmental standards. This step helps mitigate risks associated with sourcing from unverified suppliers.

- Look for certifications such as ISO 9001 for quality management or Oeko-Tex for textile safety.

- Ensure they follow sustainable practices, which can be a selling point in your market.

Step 4: Request Samples for Testing

Always request samples before making bulk purchases. Testing samples allows you to assess the quality, feel, and performance of the microfiber microsuede. This step is essential to ensure that the materials meet your specifications and expectations.

- Evaluate the samples for texture, durability, and ease of cleaning.

- Consider how the fabric performs under various conditions, especially if it’s intended for high-traffic areas.

Step 5: Analyze Pricing and Terms

Compare pricing structures among suppliers while considering the total cost of ownership. Look beyond just the price per yard; evaluate shipping costs, payment terms, and any additional fees. This analysis helps you identify the most cost-effective options without compromising quality.

- Inquire about bulk discounts or loyalty programs.

- Understand the terms of delivery and lead times to ensure they align with your project timelines.

Step 6: Review Contract Terms

Carefully review the contract terms before finalizing your order. Ensure that all aspects, including pricing, delivery schedules, and quality assurance measures, are clearly stated. This protects your interests and sets clear expectations for both parties.

- Look for clauses related to returns, warranties, and quality disputes.

- Ensure there is a clear communication channel for addressing potential issues post-purchase.

Step 7: Establish a Long-Term Relationship

Consider establishing a long-term relationship with your chosen supplier. Building a partnership can lead to better pricing, priority service, and tailored solutions for your business needs. Strong relationships often yield more favorable terms and improved collaboration over time.

- Stay in regular contact to discuss new developments and product innovations.

- Provide feedback to help suppliers improve their offerings and service quality.

By following this checklist, you can streamline your sourcing process for microfiber microsuede, ensuring that you make informed decisions that benefit your business in the long run.

Comprehensive Cost and Pricing Analysis for microfiber microsuede Sourcing

What Are the Key Cost Components in Sourcing Microfiber Microsuede?

Understanding the cost structure of microfiber microsuede is crucial for international B2B buyers. The main components that contribute to the overall cost include:

Illustrative image related to microfiber microsuede

-

Materials: The primary cost driver is the raw materials used in producing microfiber microsuede. The quality of polyester or nylon fibers significantly impacts the price. Higher-grade materials, which offer better durability and stain resistance, may command a premium.

-

Labor: Labor costs can vary based on the region of production. For instance, labor costs in Southeast Asia might be lower compared to Europe or North America. Additionally, skilled labor for specialized tasks such as weaving and finishing can influence overall pricing.

-

Manufacturing Overhead: This encompasses the costs associated with factory operations, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, which can be passed on to buyers.

-

Tooling: Initial setup costs for machinery and tools are essential, especially for custom designs or unique specifications. These costs may be amortized over larger production runs, impacting the unit price.

-

Quality Control (QC): Ensuring that the microfiber microsuede meets specified standards incurs costs related to testing and inspection. Rigorous QC processes may slightly increase the price but are crucial for maintaining product integrity.

-

Logistics: Shipping costs can vary widely based on the origin of the materials, destination, and chosen Incoterms. Freight charges, customs duties, and insurance can significantly affect the total landed cost.

-

Margin: Suppliers typically include a profit margin that reflects their business strategy and market conditions. Understanding the margin can help buyers gauge the competitiveness of pricing.

How Do Price Influencers Affect Microfiber Microsuede Pricing?

Several factors can influence the pricing of microfiber microsuede, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often result in lower per-unit costs. Buyers should negotiate MOQs to ensure they are not overcommitting to quantities that may lead to excess inventory.

-

Specifications and Customization: Custom designs, colors, or finishes can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., eco-friendly, hypoallergenic) may incur additional costs. Buyers should assess whether the benefits justify the price difference.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Established suppliers with a track record of quality may charge more but could provide better assurance against defects.

-

Incoterms: The choice of Incoterms can impact the total cost. Buyers should consider who is responsible for shipping, insurance, and duties to avoid unforeseen expenses.

What Are Effective Buyer Tips for Negotiating Microfiber Microsuede Prices?

International B2B buyers can enhance their purchasing strategies by considering the following tips:

-

Negotiation: Approach negotiations with clear objectives. Understanding your supplier’s cost structure can provide leverage in discussions. Aim for a win-win situation where both parties feel satisfied with the agreement.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the initial price. Factors such as durability, maintenance, and potential replacement costs should be considered to ascertain the overall value.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import taxes, and tariffs that can impact the final cost. Establishing a local presence or using local suppliers can mitigate some of these challenges.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including reviews, certifications, and previous client experiences. This will help ensure that you are partnering with a reputable manufacturer.

Disclaimer for Indicative Prices

While this analysis provides valuable insights into the cost structure and pricing dynamics of microfiber microsuede, actual prices may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek multiple quotes and conduct a comprehensive evaluation before making purchasing decisions.

Alternatives Analysis: Comparing microfiber microsuede With Other Solutions

Understanding Alternatives to Microfiber Microsuede

When considering materials for upholstery and other applications, it’s crucial to evaluate alternatives to microfiber microsuede. Each option has distinct characteristics that can affect performance, cost, and maintenance, particularly in B2B contexts where durability and usability are paramount. This section explores viable alternatives to microfiber microsuede, providing B2B buyers with the insights needed to make informed decisions.

Comparison Table

| Comparison Aspect | Microfiber Microsuede | フェイクレザー | Natural Cotton |

|---|---|---|---|

| Performance | Highly durable, stain-resistant, mimics suede feel | Durable, water-resistant, looks like leather | Breathable, soft, less durable than synthetic options |

| Cost | Mid-range pricing | Generally affordable | Variable, often lower than synthetics |

| Ease of Implementation | Easy to cut and sew, widely available | Similar to traditional leather in handling | Requires more care in cutting and sewing |

| Maintenance | Easy to clean, machine washable | Wipe clean, resistant to stains | Machine washable, but more prone to wrinkles |

| Best Use Case | Upholstery for furniture and décor | High-end furniture, automotive interiors | Casual wear, home textiles, eco-friendly products |

Detailed Breakdown of Alternatives

フェイクレザー

Faux leather, also known as synthetic leather, is a popular alternative that offers an appealing aesthetic similar to genuine leather. It is generally more affordable than genuine leather and provides good durability and water resistance. However, while faux leather is easy to clean, it may not have the same breathability as natural materials, which can lead to discomfort in warmer climates. Its versatility makes it suitable for a range of applications, including furniture and automotive interiors, but it may not perform as well under heavy wear compared to microfiber microsuede.

Natural Cotton

Natural cotton is a classic upholstery option known for its softness and breathability. It is favored for its eco-friendliness and comfort, making it an excellent choice for casual wear and home textiles. However, cotton is less durable than synthetic options and can be prone to stains and wrinkling, requiring more maintenance over time. While it can be machine washed, it may not withstand the same level of wear and tear as microfiber microsuede, especially in high-traffic areas or environments where spills are common.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate fabric for your B2B needs, consider factors such as durability, maintenance, and cost. Microfiber microsuede stands out for its combination of luxurious feel, easy care, and resistance to stains, making it ideal for high-traffic environments and family settings. Conversely, if your application prioritizes aesthetics and eco-friendliness, natural cotton may be more suitable, while faux leather can be a cost-effective alternative for those seeking a leather-like appearance. Ultimately, the best choice will align with your specific application requirements, budget constraints, and maintenance capabilities, ensuring that you make a sound investment for your business.

Illustrative image related to microfiber microsuede

Essential Technical Properties and Trade Terminology for microfiber microsuede

What Are the Key Technical Properties of Microfiber Microsuede?

When considering microfiber microsuede for B2B applications, understanding its technical properties is crucial for informed decision-making. Here are some essential specifications:

1. Material Composition

Microfiber microsuede is primarily composed of synthetic fibers, typically a blend of polyester and nylon. The precise composition can influence attributes such as softness, durability, and stain resistance. For buyers, knowing the material grade helps assess the fabric’s suitability for specific applications, such as upholstery or fashion.

2. Weight and Denier

Denier is a unit of measurement that indicates the thickness of the fibers in the fabric. A lower denier indicates finer fibers, which can contribute to a softer feel but may also affect durability. For example, a microsuede with a denier of 80-100 is generally considered lightweight and suitable for clothing, while a denier of 200+ may be preferred for upholstery. Understanding weight specifications aids buyers in matching the product to its intended use.

3. Tear Strength

Tear strength measures how well the fabric can withstand tearing forces. This property is vital for applications in high-traffic areas or products subject to frequent use. A higher tear strength value ensures longevity, making it an essential consideration for B2B buyers looking for durable materials for furniture or automotive applications.

Illustrative image related to microfiber microsuede

4. Stain Resistance

While microfiber microsuede is naturally resistant to stains due to its tightly woven fibers, some manufacturers enhance this property with additional treatments. Buyers should inquire about the level of stain resistance and whether the fabric can be easily cleaned, as this will affect maintenance costs and product lifespan.

5. Water Repellency

Water repellency is another important property, especially for applications in outdoor furniture or environments prone to spills. Fabrics treated for water resistance can prolong the life of the product, making it a desirable feature for buyers who prioritize durability and ease of care.

6. Abrasion Resistance

This property indicates how well the fabric can withstand friction and wear over time. Fabrics with high abrasion resistance are ideal for upholstery in commercial settings where heavy use is expected. Understanding this specification helps businesses select the right material for their specific environments.

Illustrative image related to microfiber microsuede

What Common Trade Terms Should B2B Buyers Know When Sourcing Microfiber Microsuede?

When engaging in procurement, familiarity with industry terminology can streamline communication and negotiations. Here are key trade terms relevant to microfiber microsuede:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that may be marketed by another manufacturer. In the context of microfiber microsuede, an OEM might create custom fabric solutions for specific brands. Understanding OEM relationships can help buyers identify potential partnerships and streamline sourcing.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of product a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management, as it directly impacts purchasing decisions and supply chain planning.

3. RFQ (Request for Quotation)

An RFQ is a formal document that solicits price quotes from suppliers for specific products or services. When sourcing microfiber microsuede, submitting an RFQ can help buyers compare pricing, terms, and conditions across different suppliers, facilitating better negotiation outcomes.

Illustrative image related to microfiber microsuede

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in global trade. Understanding Incoterms is crucial for B2B transactions involving microfiber microsuede, as they specify who bears the costs and risks during shipping, which can significantly affect overall pricing.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses that rely on timely deliveries, understanding lead times associated with different suppliers can help manage inventory and production schedules effectively.

6. Customs Duties and Tariffs

These are taxes imposed on imported goods. B2B buyers should be aware of any customs duties and tariffs that may apply to microfiber microsuede, as these can influence the overall cost of procurement and affect pricing strategies in different markets.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions when sourcing microfiber microsuede, ensuring they select the right products for their needs while navigating international trade complexities effectively.

Navigating Market Dynamics and Sourcing Trends in the microfiber microsuede Sector

What Are the Global Market Dynamics and Key Trends in the Microfiber Microsuede Sector?

The microfiber microsuede market is experiencing significant growth driven by several global factors. Increasing consumer demand for versatile and affordable upholstery materials is propelling this trend. The durability, ease of maintenance, and aesthetic appeal of microsuede make it an attractive option for manufacturers in various sectors, including furniture, automotive, and fashion. Notably, the rise in online retail platforms has facilitated access to diverse suppliers, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe, including Brazil and Vietnam.

Emerging technologies, such as automation and AI-driven supply chain management, are reshaping sourcing strategies. Companies are increasingly utilizing digital platforms for real-time inventory tracking and supplier evaluation, which enhances efficiency and reduces lead times. The demand for customization is also on the rise, with B2B buyers seeking unique textures and colors to differentiate their offerings. Furthermore, the trend toward eco-friendly and sustainable materials is prompting suppliers to innovate, leading to the development of biodegradable microsuede options and recycled fibers.

How Does Sustainability and Ethical Sourcing Impact the Microfiber Microsuede Sector?

Sustainability has become a pivotal consideration in the microfiber microsuede sector. As environmental concerns grow, both consumers and businesses are prioritizing eco-friendly materials. The production of microfiber microsuede can have significant environmental impacts, including water pollution and resource depletion. Therefore, B2B buyers are increasingly seeking suppliers who adhere to ethical sourcing practices and demonstrate a commitment to reducing their carbon footprint.

Illustrative image related to microfiber microsuede

Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® are becoming essential in the sourcing process. These certifications assure buyers that the materials used are sustainably sourced and free from harmful substances. Companies are also exploring the use of recycled polyester in the manufacturing of microsuede, which not only minimizes waste but also appeals to environmentally conscious consumers.

Additionally, transparency in supply chains is gaining traction. Buyers are demanding detailed information about the sourcing and production processes to ensure that their suppliers uphold ethical standards. By aligning with suppliers who prioritize sustainability, B2B buyers can enhance their brand reputation and meet the growing consumer demand for responsible products.

What is the Historical Context of Microfiber Microsuede in the B2B Market?

The evolution of microfiber microsuede can be traced back to the late 20th century when advancements in textile technology enabled the creation of synthetic fabrics. Initially, microsuede was developed as a cost-effective alternative to genuine suede, providing similar aesthetics while offering superior durability and stain resistance. Over the years, its applications have expanded beyond upholstery into sectors such as automotive interiors, fashion, and home textiles.

As environmental awareness grew, the microfiber microsuede industry adapted, leading to innovations in sustainable practices and materials. Today, it stands as a testament to the balance between functionality and ecological responsibility, making it a preferred choice for B2B buyers looking to invest in high-quality, sustainable upholstery solutions.

In summary, the microfiber microsuede sector is at a pivotal point, characterized by dynamic market trends, a strong focus on sustainability, and a rich historical backdrop that continues to shape its future. As B2B buyers navigate these developments, aligning with innovative suppliers will be crucial for staying competitive in this evolving landscape.

Illustrative image related to microfiber microsuede

Frequently Asked Questions (FAQs) for B2B Buyers of microfiber microsuede

1. How do I choose the right supplier for microfiber microsuede?

Selecting the right supplier is crucial for ensuring quality and reliability. Start by researching potential suppliers’ backgrounds, focusing on their experience in the industry and client testimonials. Request samples to assess the quality of the microfiber microsuede. It’s also beneficial to verify their production capabilities, certifications, and adherence to international quality standards. Additionally, consider their communication responsiveness and willingness to accommodate your specific needs, which can indicate their customer service level.

2. What are the minimum order quantities (MOQs) for microfiber microsuede?

MOQs can vary significantly between suppliers and are often influenced by factors such as fabric type, customization options, and production capacity. Generally, MOQs for microfiber microsuede can range from 100 to 1,000 meters. When negotiating with suppliers, clarify your needs upfront and inquire about flexibility in order sizes, especially if you are testing the market or require smaller batches for specific projects. Understanding the MOQ can help you manage inventory and cash flow effectively.

3. What customization options are available for microfiber microsuede?

Most suppliers offer various customization options, including color, texture, and finish. You can request specific dye lots or patterns that align with your brand’s identity. Some manufacturers may also provide options for eco-friendly or hypoallergenic treatments. When discussing customization, ensure that you communicate your requirements clearly and ask for sample swatches to evaluate the final product. This can enhance your offerings and cater to niche markets.

4. How do I ensure quality assurance (QA) in my microfiber microsuede orders?

Implementing a robust QA process is essential to maintain product quality. Start by establishing clear specifications and standards for the microfiber microsuede you require. Work with your supplier to conduct pre-production and in-line inspections to catch any defects early. Additionally, consider third-party quality audits, especially for international shipments. Regular communication with your supplier about your quality expectations can foster a strong partnership and minimize issues down the line.

Illustrative image related to microfiber microsuede

5. What payment terms should I expect when sourcing microfiber microsuede?

Payment terms can vary based on the supplier’s policies and your business relationship. Common terms include a deposit upon order confirmation, with the balance due before shipment. Some suppliers may offer net payment terms, allowing you to pay after receiving the goods. It’s advisable to discuss and negotiate payment terms upfront to ensure they align with your cash flow needs. Always consider the risks involved and opt for secure payment methods to protect your investment.

6. What are the logistics considerations when importing microfiber microsuede?

Logistics plays a vital role in the timely delivery of your microfiber microsuede. Consider factors such as shipping methods (air vs. sea), customs clearance processes, and potential tariffs or duties applicable in your country. Collaborate with logistics providers experienced in handling textile imports to navigate these complexities smoothly. Additionally, ensure that your supplier is aware of your logistics requirements to avoid delays and misunderstandings during the shipping process.

7. How do I handle potential issues with microfiber microsuede quality upon receipt?

In case of quality discrepancies upon receipt, first document the issues with photographs and detailed descriptions. Review the purchase agreement to understand the terms related to defects or non-conformities. Contact your supplier immediately to discuss the issues and seek a resolution, which may include replacements, refunds, or discounts. Establishing a clear returns policy with your supplier beforehand can streamline this process and help maintain a good business relationship.

8. What are the best practices for storing microfiber microsuede?

Proper storage of microfiber microsuede is essential to maintain its quality and appearance. Store the fabric in a cool, dry environment away from direct sunlight to prevent fading and deterioration. Avoid folding or compressing the fabric for long periods, as this may cause creases. Instead, roll the fabric or store it flat to preserve its texture. Regularly check the storage area for moisture or pests to ensure the longevity of your microfiber microsuede inventory.

Top 6 Microfiber Microsuede Manufacturers & Suppliers List

1. Fabric Warehouse – MicroSuede Upholstery Fabrics

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: MicroSuede Fabrics for Upholstery

– Types Available: By the Yard, Remnants

– Total Colors: 13 (Beige, Black, Blue, Brown, Gold, Gray, Green, Ivory, Khaki, Orange, Pink, Purple, Red, Silver, Tan)

– Upholstery Fabric Weights: Extra Heavy Weight (16), Heavy Weight (35), Lightweight (5), Medium/Heavyweight (2), Medium Weight (53)

– Drapery Fabric Weights: Heavy Weight (39), Light Weight (1), Medium We…

2. Folio Fabrics – Dotson Cobalt

Domain: foliofabrics.com

Registered: 2013 (12 years)

Introduction: Microfiber & Microsuede Fabric Collection: Ideal for upholstery, drapery, and decorative accents. Features a soft, luxurious feel with durability and easy care. Plush textures create an inviting ambiance. Key products include: 1. Dotson Cobalt – $40/yard 2. Davis Cream – $44/yard 3. Camaro Oat – $38/yard 4. Hartford Pewter – $46/yard 5. Dotson Slate – $40/yard 6. Dotson Onyx – $40/yard 7. Lydia Ro…

3. Hunker – Microfiber Fabrics

Domain: hunker.com

Registered: 2001 (24 years)

Introduction: Microfiber is an umbrella term for synthetic fabrics made from polyester, nylon, or a combination, known for being durable, comfortable, stain-resistant, and easy to clean. Microsuede is a type of microfiber that resembles real suede but is less expensive, softer, more durable, and more stain-resistant. Microsuede is available in a wide range of colors. Care instructions for microsuede include: do…

4. KOVI Fabrics – Microfiber Upholstery Fabric

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Microfiber Upholstery Fabric from KOVI Fabrics offers a wide selection of soft, durable, and cleanable fabrics suitable for various home design projects. Key features include:

– Made from synthetic materials like polyester or nylon.

– Available in strong neutrals and bold colors.

– Timeless residential fabric, ideal for furniture, curtains, and throw pillows.

– Easy to clean and maintain, often ma…

5. Big Z Fabric – Microfiber Suede vs Real Suede

Domain: blog.bigzfabric.com

Registered: 2010 (15 years)

Introduction: Microfiber Suede: Crafted from synthetic fibers like polyester or nylon; affordable; durable; easy to clean and maintain; better water resistance; hypoallergenic. Real Suede Fabric: Derived from the inner layer of animal hides (cows, sheep, goats); luxurious appearance; more expensive; durable but requires careful maintenance; sensitive to water; develops a patina over time.

6. BuyFabrics – Microsuede Fabric by the Yard

Domain: buyfabrics.com

Registered: 2001 (24 years)

Introduction: Microsuede fabric available for purchase by the yard at discount prices. Variety of colors and styles for upholstery and apparel. Key features include:

– Fiber Content: Polyester, Polyester-Lycra, Polyester-Spandex

– Suitable for: Activewear, Apparel, Blouses, Costumes, Crafts, Dancewear, Dresses, Home Decor, Jackets, Outerwear, Shirts, Slacks, Suits, Upholstery

– Weight Options: Light, Light-Medi…

Strategic Sourcing Conclusion and Outlook for microfiber microsuede

As the demand for high-quality, durable fabrics continues to rise, microfiber microsuede emerges as a compelling choice for international B2B buyers. Its unique combination of affordability, stain resistance, and ease of maintenance makes it an ideal material for various applications, from furniture upholstery to fashion accessories. Companies seeking to optimize their supply chains should prioritize strategic sourcing to ensure access to reliable suppliers who can provide consistent quality and competitive pricing.

Investing in microfiber microsuede not only enhances product offerings but also aligns with consumer preferences for sustainable and low-maintenance materials. This fabric’s versatility allows businesses to cater to diverse markets, particularly in regions like Africa, South America, the Middle East, and Europe, where the demand for innovative upholstery solutions is growing rapidly.

Looking ahead, companies should leverage market insights and trends to inform their sourcing strategies, ensuring they remain competitive. By fostering strong partnerships with suppliers, businesses can secure a sustainable future in the microfiber microsuede market. Now is the time for B2B buyers to take action—explore new sourcing avenues and embrace the potential of microfiber microsuede to elevate your product line and meet evolving consumer needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.