Introduction: Navigating the Global Market for how to make a leather handbag

In the competitive landscape of the leather goods market, understanding how to make a leather handbag is crucial for B2B buyers aiming to meet diverse customer needs. Sourcing high-quality materials and skilled craftsmanship can be a daunting challenge, particularly for businesses operating in dynamic regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide addresses key aspects of the leather handbag production process, from design concepts and material selection to supplier vetting and cost considerations.

By navigating through the intricacies of handbag creation, international buyers will gain insights into various styles, applications, and market trends, empowering them to make informed purchasing decisions that align with their business objectives. Whether you are looking to source artisanal pieces or mass-produced items, understanding these elements is essential for establishing a successful supply chain.

This guide is specifically tailored to help you identify reliable suppliers, evaluate the quality of materials, and optimize your sourcing strategy to enhance your product offerings. With actionable insights and expert tips, you can confidently approach the leather handbag market, ensuring that your business stands out in an increasingly competitive global arena.

Table Of Contents

- Top 2 How To Make A Leather Handbag Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather handbag

- Understanding how to make a leather handbag Types and Variations

- Key Industrial Applications of how to make a leather handbag

- 3 Common User Pain Points for ‘how to make a leather handbag’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather handbag

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather handbag

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather handbag’

- Comprehensive Cost and Pricing Analysis for how to make a leather handbag Sourcing

- Alternatives Analysis: Comparing how to make a leather handbag With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather handbag

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather handbag Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather handbag

- Strategic Sourcing Conclusion and Outlook for how to make a leather handbag

- Important Disclaimer & Terms of Use

Understanding how to make a leather handbag Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tote Bags | Open-top design, large capacity, often unstructured | Retail, promotional items, everyday use | Pros: Versatile, easy to customize. Cons: Less secure. |

| Crossbody Bags | Adjustable strap, worn across the body, compact | Fashion retail, travel, urban lifestyle | Pros: Hands-free convenience, stylish. Cons: Limited storage. |

| Messenger Bags | Flap closure, padded compartments, designed for easy access | Tech accessories, school, professional use | Pros: Functional for carrying devices, organized. Cons: Bulkier than other types. |

| Clutches | Small, handheld, often formal or evening wear | Events, parties, luxury retail | Pros: Elegant, great for branding. Cons: Limited space for essentials. |

| Backpacks | Two shoulder straps, designed for weight distribution | Education, travel, outdoor activities | Pros: Comfortable for heavy loads, practical. Cons: Less formal appearance. |

What Are the Key Characteristics of Tote Bags and Their B2B Suitability?

Tote bags are characterized by their open-top design and large capacity, making them ideal for carrying a variety of items. Their unstructured shape allows for easy customization, appealing to retailers looking for promotional items or everyday use. B2B buyers should consider the material quality and printing options for branding purposes, as these factors can significantly impact the bag’s durability and visual appeal.

How Do Crossbody Bags Cater to Specific Market Needs?

Crossbody bags feature adjustable straps and a compact design, making them perfect for urban consumers and travelers. They offer hands-free convenience, which is a significant selling point for retailers targeting a younger demographic. When purchasing, B2B buyers should assess the style, material, and functionality to ensure the bags meet the lifestyle needs of their customers.

What Makes Messenger Bags a Preferred Choice for Professionals?

Messenger bags are designed with a flap closure and padded compartments, making them suitable for carrying laptops and other devices. They are popular in the tech accessory market and among professionals who value organization and accessibility. B2B buyers should focus on the quality of zippers, padding, and overall construction to ensure the bags provide adequate protection for electronic devices.

Why Are Clutches Important for Luxury and Event Markets?

Clutches are small, handheld bags often associated with formal or evening events. Their elegant design makes them a favorite in luxury retail, providing excellent branding opportunities for businesses targeting upscale clients. B2B buyers should evaluate the materials used and the potential for custom designs, as these factors can enhance the perceived value of the product.

How Do Backpacks Address Diverse Consumer Needs?

Backpacks are designed with two shoulder straps, allowing for comfortable weight distribution, making them ideal for education, travel, and outdoor activities. Their practicality appeals to a broad audience, but B2B buyers should consider the balance between style and functionality. The choice of materials and features like water resistance can significantly influence purchasing decisions, especially in competitive markets.

Key Industrial Applications of how to make a leather handbag

| Industry/Sector | Specific Application of how to make a leather handbag | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom leather handbag production for boutiques | Unique offerings that enhance brand identity and customer loyalty | Sourcing quality leather, skilled artisans, and sustainable practices |

| Corporate Gifting | Leather handbags as corporate gifts | Strengthens client relationships and promotes brand image | Need for personalized designs and branding options |

| E-commerce | Online sales of handcrafted leather handbags | Expands market reach and caters to niche customer segments | Reliable supply chain logistics and quality assurance |

| Export and Trade | Exporting leather handbags to international markets | Access to diverse markets and increased revenue streams | Compliance with international trade regulations and quality certifications |

| Luxury Goods | High-end bespoke leather handbags | Attracts affluent customers and enhances luxury brand perception | Focus on premium materials and craftsmanship standards |

How is ‘how to make a leather handbag’ applied in the fashion retail industry?

In the fashion retail sector, the ability to produce custom leather handbags allows boutiques to differentiate themselves in a competitive market. By offering unique designs, retailers can attract a loyal customer base that values exclusivity. For international buyers, especially in regions like Europe and the Middle East, sourcing high-quality leather and skilled artisans is crucial. Additionally, understanding local fashion trends can guide design choices, ensuring that products resonate with target markets.

What role does leather handbag production play in corporate gifting?

Leather handbags serve as sophisticated corporate gifts, helping companies strengthen client relationships and enhance their brand image. Businesses can offer personalized designs that incorporate company logos, making these gifts memorable and impactful. For B2B buyers, particularly in Africa and South America, sourcing from reputable manufacturers who can guarantee quality and timely delivery is essential. Additionally, understanding cultural preferences in gifting can influence the choice of designs and materials.

How does the e-commerce sector benefit from leather handbag production?

E-commerce platforms can leverage the production of handcrafted leather handbags to tap into niche markets and expand their customer base. By offering unique, high-quality products online, businesses can attract discerning consumers seeking authenticity and craftsmanship. For international buyers, ensuring a reliable supply chain and maintaining quality assurance throughout the production process is vital. E-commerce businesses must also consider local regulations and payment systems when targeting diverse markets.

What are the implications of leather handbag exportation for international trade?

Exporting leather handbags to international markets presents opportunities for increased revenue and market diversification. Businesses can capitalize on growing demand for luxury and artisanal products across regions like Europe and Asia. However, B2B buyers need to navigate complex trade regulations, ensuring compliance with international standards. Establishing partnerships with reliable logistics providers is also critical to managing shipping and delivery efficiently.

How do luxury brands utilize leather handbag craftsmanship?

Luxury goods brands often focus on high-end bespoke leather handbags, which cater to affluent customers seeking exclusivity and superior quality. This craftsmanship enhances the brand’s perception and justifies premium pricing. For B2B buyers, particularly in affluent markets, sourcing premium materials and maintaining rigorous craftsmanship standards are paramount. Understanding the nuances of luxury consumer behavior can also guide marketing and sales strategies, ensuring alignment with brand values and customer expectations.

3 Common User Pain Points for ‘how to make a leather handbag’ & Their Solutions

Scenario 1: Navigating Material Sourcing Challenges

The Problem:

B2B buyers often struggle with sourcing high-quality leather that meets both aesthetic and functional requirements for handbag production. In regions like Africa and South America, where local leather quality can vary significantly, buyers may find it difficult to establish reliable suppliers who offer consistent quality and pricing. Additionally, the lack of transparency in the supply chain can lead to unexpected costs and delays, impacting production timelines and overall profitability.

The Solution:

To overcome these challenges, buyers should prioritize establishing strong relationships with vetted suppliers who specialize in leather. Conducting thorough market research to identify reputable tanneries is essential. Attend trade shows and industry events to meet potential suppliers in person, allowing for better negotiation of terms and a clearer understanding of product offerings. It’s also beneficial to request samples from multiple suppliers before committing to large orders. Consider diversifying your supplier base to mitigate risks associated with any single source. Implementing a quality control process, where samples are tested for durability and appearance, can further ensure that the leather used meets your specifications.

Scenario 2: Overcoming Design and Prototyping Limitations

The Problem:

Many B2B buyers face difficulties in transitioning from design concepts to actual prototypes. This is particularly true for those new to leather craftsmanship, where the intricacies of design can lead to misalignments in expectations versus reality. Buyers often lack the necessary tools or expertise to create prototypes that effectively represent their design vision, resulting in wasted resources and time.

The Solution:

Investing in professional design software can streamline the design process. Programs like Adobe Illustrator or CAD applications specifically for leather goods allow for precise pattern drafting and adjustments. Once designs are finalized, create a series of prototypes using less expensive materials, such as canvas or synthetic leather, to test functionality and aesthetic appeal. This iterative prototyping approach minimizes costs while allowing for adjustments based on feedback. Additionally, partnering with experienced artisans or workshops can provide invaluable insights into practical design considerations, ensuring that the final product not only looks good but also performs well in real-world conditions.

Scenario 3: Ensuring Compliance and Ethical Standards

The Problem:

In today’s market, there is an increasing demand for ethically sourced materials and compliance with environmental regulations. B2B buyers must navigate the complexities of sourcing leather that not only meets quality standards but also adheres to ethical practices, particularly in regions where animal welfare and environmental concerns are prominent. Failure to address these issues can lead to reputational damage and loss of customer trust.

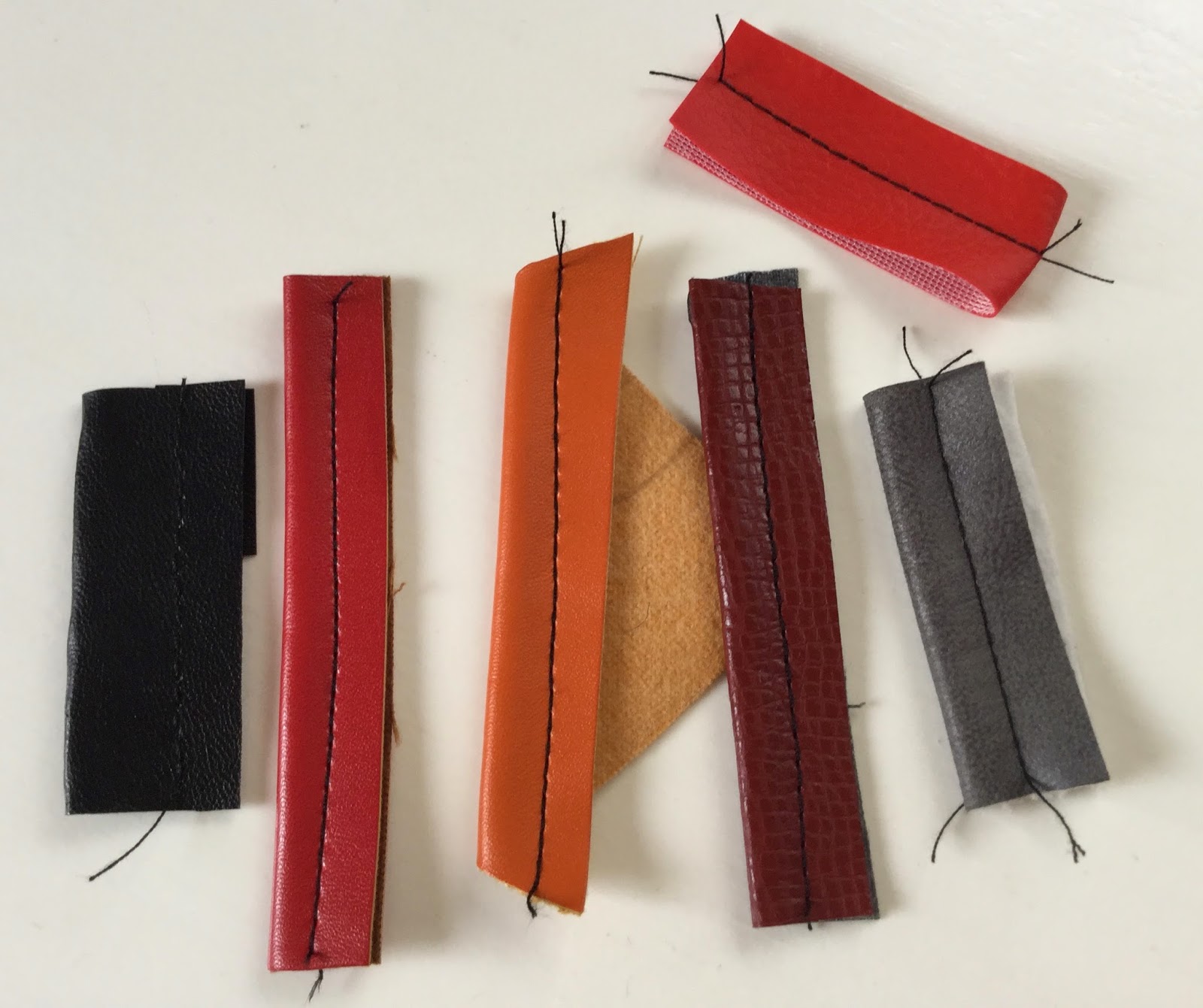

Illustrative image related to how to make a leather handbag

The Solution:

To ensure compliance with ethical standards, buyers should seek out suppliers who are certified by recognized organizations that promote sustainable practices in leather production. Certifications such as the Leather Working Group (LWG) can provide assurance regarding the environmental impact of the tanning process. Additionally, consider implementing a supplier audit system that evaluates the ethical practices of potential partners. Engaging with suppliers about their sourcing practices and transparency can also foster a culture of accountability. Educating your team on sustainability trends within the leather industry can further enhance your brand’s reputation, attracting environmentally conscious consumers and partners. By prioritizing ethical sourcing, businesses not only comply with regulations but also position themselves as leaders in responsible fashion.

Strategic Material Selection Guide for how to make a leather handbag

What Are the Key Materials for Making a Leather Handbag?

When selecting materials for leather handbags, international B2B buyers must consider various factors, including durability, cost, and manufacturing complexity. Here, we analyze four common materials used in leather handbag production: full-grain leather, top-grain leather, synthetic leather (PU), and canvas.

How Does Full-Grain Leather Perform in Handbag Manufacturing?

Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain, making it highly durable and resistant to wear. This material is known for its ability to develop a patina over time, enhancing its aesthetic appeal.

Illustrative image related to how to make a leather handbag

Pros: Full-grain leather is exceptionally durable, offers excellent resistance to moisture and temperature changes, and is easy to maintain with proper conditioning. It is ideal for luxury handbags that require longevity.

Cons: The cost of full-grain leather is high, which may not be suitable for budget-conscious manufacturers. Additionally, it requires skilled craftsmanship to work with, increasing manufacturing complexity.

Impact on Application: Full-grain leather is compatible with high-end fashion markets, appealing to consumers looking for premium products.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prioritize sustainability and ethical sourcing, necessitating compliance with standards such as REACH or ISO 14001.

What Are the Advantages of Top-Grain Leather?

Top-grain leather is slightly less durable than full-grain but is more affordable. It is sanded and treated to remove imperfections, resulting in a smoother finish.

Pros: This material is more cost-effective and easier to work with than full-grain leather, making it suitable for mid-range handbags. It also offers good resistance to stains and moisture.

Cons: While top-grain leather is durable, it is not as resilient as full-grain. It may also require more frequent conditioning to maintain its appearance.

Impact on Application: Top-grain leather is well-suited for everyday handbags that require a balance between style and functionality.

Considerations for International Buyers: Buyers in South America and Africa may find top-grain leather appealing for its affordability, but they should ensure compliance with local regulations regarding leather treatment chemicals.

How Does Synthetic Leather (PU) Compare?

Polyurethane (PU) leather is a popular alternative to genuine leather, made from a synthetic polymer. It mimics the look and feel of leather while being more affordable.

Pros: PU leather is lightweight, easy to clean, and resistant to water and stains. It offers a wide range of colors and textures, making it versatile for various designs.

Cons: While PU leather is durable, it does not have the same longevity as genuine leather. It can wear down over time and may not appeal to consumers seeking luxury products.

Impact on Application: PU leather is suitable for budget-friendly handbags and appeals to environmentally conscious consumers, as it can be produced with less environmental impact.

Illustrative image related to how to make a leather handbag

Considerations for International Buyers: Buyers from regions like Africa may appreciate the lower cost and availability of PU leather but should verify compliance with environmental standards such as ISO 14001.

What Role Does Canvas Play in Handbag Production?

Canvas is a sturdy fabric made from cotton or a cotton blend, often used in casual handbags. It is known for its durability and resistance to wear.

Pros: Canvas is highly affordable and easy to print on, allowing for unique designs. It is also lightweight and can be treated for additional water resistance.

Cons: Canvas lacks the luxurious feel of leather and may not appeal to high-end markets. It is also less resistant to environmental factors compared to leather.

Impact on Application: Canvas is ideal for casual or eco-friendly handbags, appealing to younger consumers or those seeking sustainable options.

Considerations for International Buyers: Buyers in Europe may favor canvas for its sustainability, but they should consider the local market’s preference for materials.

Summary Table of Material Selection for Leather Handbags

| Material | Typical Use Case for how to make a leather handbag | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury handbags | Exceptional durability | High cost and manufacturing complexity | High |

| Top-Grain Leather | Mid-range handbags | Cost-effective and easy to work with | Less durable than full-grain | Medium |

| Synthetic Leather (PU) | Budget-friendly handbags | Lightweight and easy to clean | Less longevity compared to leather | Low |

| Canvas | Casual handbags | Affordable and unique design options | Lacks luxury appeal | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing materials for leather handbag production.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather handbag

What Are the Main Stages in the Manufacturing Process of Leather Handbags?

The manufacturing process of leather handbags is intricate, involving several key stages that ensure a high-quality final product. Understanding these stages is essential for B2B buyers looking to partner with suppliers capable of delivering superior craftsmanship.

Illustrative image related to how to make a leather handbag

Material Preparation: How Is Quality Leather Selected?

The first step in the manufacturing process is the selection and preparation of leather. High-quality leather is sourced from reputable tanneries, with considerations for texture, durability, and aesthetic appeal. Buyers should look for suppliers that conduct thorough inspections of their leather, ensuring it meets specific criteria such as grain consistency and absence of defects.

Once the leather is sourced, it undergoes preparation processes like cutting and dyeing. The leather is cut into predetermined shapes based on the design specifications, which can be achieved through both manual and automated cutting techniques. Dyeing processes may involve natural or synthetic dyes, and it is crucial that these processes comply with international environmental standards.

How Is the Forming Process Conducted for Leather Handbags?

After the leather has been prepared, the next stage is forming. This involves shaping the leather into the desired structure of the handbag. Key techniques include:

- Molding: Leather can be molded into specific shapes using heat and moisture, ensuring it retains its form.

- Stitching: This is a critical step where the pieces of leather are sewn together. Using high-quality thread and appropriate stitching techniques, such as saddle stitching, ensures durability. Automated sewing machines may be employed for efficiency, but skilled artisans often perform intricate hand-stitching for premium products.

What Does the Assembly Process Look Like in Leather Handbag Manufacturing?

The assembly stage combines all the formed components into a finished handbag. This typically involves:

- Attaching Hardware: Zippers, clasps, and other accessories are affixed to the handbag at this stage. Suppliers should use high-quality hardware that can withstand wear and tear.

- Incorporating Linings and Pockets: The interior of the handbag is often lined with fabric or leather, and pockets are added for functionality. Attention to detail in this stage is crucial, as it affects the overall usability of the handbag.

How Are Finishing Touches Applied to Ensure Quality in Leather Handbags?

Finishing is the final stage of the manufacturing process and is essential for enhancing the handbag’s aesthetic and functional qualities. This includes:

- Edge Finishing: The edges of the leather are beveled and polished to prevent fraying and provide a clean look.

- Conditioning and Protecting: A high-quality leather conditioner is applied to nourish and protect the leather from damage. This step is vital for extending the handbag’s lifespan.

What International Standards and Quality Assurance Measures Should B2B Buyers Consider?

Quality assurance in leather handbag manufacturing is paramount, especially for international B2B buyers. Adhering to recognized standards ensures that products meet consumer expectations and regulatory requirements.

Which International Standards Are Relevant for Leather Handbag Manufacturers?

ISO 9001 is a widely recognized standard for quality management systems, applicable across various industries, including leather goods. Compliance with this standard indicates that a manufacturer has established effective processes to ensure consistent quality.

Additionally, industry-specific certifications, such as CE marking in Europe, may be relevant, particularly for handbags that incorporate electronic components or require safety compliance. Buyers should inquire about these certifications when vetting suppliers.

What Quality Control Checkpoints Are Commonly Used in Leather Handbag Manufacturing?

Quality control (QC) checkpoints are critical for maintaining high standards throughout the manufacturing process. Common checkpoints include:

Illustrative image related to how to make a leather handbag

- Incoming Quality Control (IQC): This involves inspecting materials and components upon arrival at the manufacturing facility to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): This ongoing inspection occurs during the manufacturing stages to catch defects early. It includes checks on stitching quality, alignment, and hardware functionality.

- Final Quality Control (FQC): Before shipment, finished handbags undergo a comprehensive inspection to ensure they meet design specifications and quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive measures to verify the quality control practices of potential suppliers. Here are actionable steps:

- Conduct Audits: Regular audits of suppliers can help assess their adherence to quality standards and manufacturing processes. Buyers should consider on-site audits to evaluate the production environment directly.

- Request Quality Reports: Suppliers should provide detailed QC reports, documenting inspections and testing results. This transparency helps buyers understand the quality of the products they are purchasing.

- Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control practices. These services can conduct random inspections before shipment, ensuring that products meet the required standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have varying regulations and consumer expectations.

Buyers should also be aware of potential challenges related to import/export regulations, customs inspections, and adherence to local laws regarding materials and labor practices. Establishing clear communication channels with suppliers and understanding local market demands can enhance the quality assurance process.

Conclusion: Why Is Comprehensive Quality Assurance Essential for Leather Handbags?

In the competitive landscape of leather handbag manufacturing, comprehensive quality assurance is not just an option; it is a necessity. B2B buyers must prioritize suppliers who adhere to international standards, implement robust quality control measures, and demonstrate a commitment to excellence throughout the manufacturing process. By doing so, they can ensure that they are investing in products that meet market expectations and stand the test of time.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather handbag’

To assist B2B buyers in procuring the necessary resources and knowledge to successfully create leather handbags, this guide provides a clear, actionable checklist. Each step ensures that the process is efficient, cost-effective, and tailored to the specific needs of buyers across various regions.

Step 1: Define Your Target Market and Bag Specifications

Understanding your target market is essential before initiating the production process. Consider factors such as demographics, preferences, and regional trends. Specify the type of handbag you aim to produce—whether it’s a tote, backpack, or clutch—along with size, functionality, and design elements that will appeal to your audience.

Step 2: Source Quality Leather and Materials

Quality materials are crucial for creating a durable and appealing handbag. Research various types of leather, such as full-grain, top-grain, or suede, and their suitability for your design. Identify suppliers that provide samples to assess texture, color, and durability, ensuring they meet your quality standards.

- Tip: Look for suppliers with sustainability certifications or ethical sourcing practices, as these factors can enhance your brand’s reputation.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to conduct a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions. This vetting process helps ensure that the supplier can meet your production timelines and quality expectations.

Illustrative image related to how to make a leather handbag

- Key Consideration: Assess the supplier’s capacity to handle your order volume and their ability to provide consistent quality.

Step 4: Review Technical Specifications and Compliance

Ensure that the materials and processes used by your suppliers comply with relevant international standards and regulations. This includes safety standards for materials and labor practices. Verification of compliance helps to mitigate risks associated with legal issues and enhances product credibility.

Step 5: Prototype Development and Testing

Create prototypes of your handbag designs to evaluate functionality and aesthetics. Work closely with your suppliers to refine the prototype based on feedback. Testing various designs allows you to identify potential improvements before full-scale production, saving time and resources in the long run.

- Action Item: Gather feedback from potential customers or focus groups to ensure the design meets market needs.

Step 6: Establish Supply Chain Logistics

Plan your logistics for sourcing materials, production, and distribution. Determine the most efficient shipping methods and timelines, especially considering international trade complexities. Establishing a reliable supply chain is critical for maintaining production schedules and meeting customer demands.

- Consideration: Factor in customs regulations and tariffs that may affect your costs and delivery times.

Step 7: Implement Quality Control Measures

Quality control is essential throughout the production process. Develop a checklist for inspections at various stages—raw materials, production, and final products. Consistent quality checks not only enhance customer satisfaction but also protect your brand’s reputation.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing and producing leather handbags effectively, ensuring a successful outcome in their business ventures.

Comprehensive Cost and Pricing Analysis for how to make a leather handbag Sourcing

What Are the Key Cost Components in Leather Handbag Manufacturing?

When sourcing leather handbags, understanding the comprehensive cost structure is crucial for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of leather significantly impacts costs. High-quality leather, such as full-grain or top-grain, commands a premium price. Additionally, hardware (zippers, buckles) and lining materials should be factored into the total material cost.

-

Labor: Skilled labor is essential for crafting quality leather handbags. Labor costs vary by region, with countries offering lower wages potentially reducing overall expenses. However, it’s vital to balance cost savings with the skill level required for intricate designs.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Overhead costs can fluctuate based on the production scale and facility location.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. These costs cover the creation of molds or cutting dies necessary for specific handbag shapes.

-

Quality Control (QC): Implementing a robust QC process ensures that the handbags meet quality standards. This adds to the overall cost but is essential for maintaining a reputable brand image.

-

Logistics: Shipping costs can vary widely based on the distance from the manufacturer to the buyer, the shipping method, and the volume of the order. Incoterms will define the responsibilities of each party in the shipping process, influencing logistics costs.

-

Margin: Finally, the margin that suppliers add to their costs will affect the final price. This varies based on market demand and competition.

How Do Price Influencers Impact Leather Handbag Sourcing?

Several price influencers can affect the overall cost of leather handbags:

-

Volume/MOQ: Minimum order quantities (MOQs) can lead to price breaks. Larger orders typically result in lower per-unit costs due to economies of scale.

-

Specifications/Customization: Customized handbags with unique designs or specific features may incur additional charges. Buyers should clarify these costs upfront.

-

Materials: The choice of leather and hardware can significantly affect pricing. Sustainable or ethically sourced materials may come at a premium.

-

Quality/Certifications: Handbags that meet specific quality certifications or standards may cost more. Buyers should assess whether these certifications align with their brand values.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better quality and reliability.

What Buyer Tips Can Help Negotiate Better Prices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the following tips can enhance negotiation and sourcing outcomes:

-

Negotiate Based on Volume: Leverage larger order sizes to negotiate better pricing. Suppliers are often willing to reduce costs for bulk purchases.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with quality, durability, and potential returns. A higher upfront cost may lead to lower TCO if the product lasts longer.

-

Understand Pricing Nuances: Be aware of regional pricing differences. Factors such as local labor costs, material availability, and import duties can affect pricing.

-

Use Incoterms Wisely: Familiarize yourself with Incoterms to clarify shipping responsibilities and costs. This understanding can prevent unexpected expenses in the logistics phase.

Disclaimer for Indicative Prices

It’s essential to note that prices can fluctuate based on market conditions, supplier negotiations, and specific project requirements. Therefore, B2B buyers should seek detailed quotes from multiple suppliers to ensure competitive pricing and avoid unexpected costs.

Illustrative image related to how to make a leather handbag

Alternatives Analysis: Comparing how to make a leather handbag With Other Solutions

Introduction to Alternatives in Leather Handbag Production

In the competitive world of fashion and accessories, B2B buyers must assess various methods for producing leather handbags. While traditional craftsmanship offers unique benefits, alternative approaches can also meet market demands. Understanding these alternatives allows businesses to make informed decisions that align with their operational goals, budget constraints, and customer preferences.

Comparison Table of Leather Handbag Production Methods

| Comparison Aspect | How To Make A Leather Handbag | Alternative 1: Synthetic Leather Handbag Production | Alternative 2: Mass-Produced Handbags |

|---|---|---|---|

| Performance | High durability, premium feel | Good durability, often water-resistant | Variable quality, depends on supplier |

| Cost | Higher due to material and labor | Generally lower due to cheaper materials | Low cost due to economies of scale |

| Ease of Implementation | Requires skilled labor and craftsmanship | Easier to implement with less specialized skills | Streamlined process, less manual labor |

| Maintenance | Requires care and upkeep | Low maintenance; easy to clean | Varies by material, generally low |

| Best Use Case | High-end market, custom orders | Mid-range market, eco-conscious consumers | Mass-market, budget-conscious buyers |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Synthetic Leather Handbag Production?

Synthetic leather, also known as faux leather, provides a viable alternative to traditional leather. It offers a more affordable solution without compromising on durability, making it appealing for mid-range products. Additionally, synthetic materials are often easier to clean and maintain, which can enhance customer satisfaction. However, some consumers may perceive synthetic leather as less luxurious, which could limit its appeal in high-end markets.

How Does Mass-Produced Handbag Production Compare?

Mass-produced handbags are designed for rapid manufacturing and distribution, making them an attractive option for businesses targeting budget-conscious consumers. The streamlined production process reduces costs significantly, enabling companies to offer competitive pricing. However, the variability in quality can lead to customer dissatisfaction, especially if the handbags do not meet the expectations set by branding. Furthermore, mass production often lacks the unique, artisanal touch that bespoke leather handbags provide, which may alienate niche markets seeking exclusivity.

Conclusion: How Can B2B Buyers Choose the Right Handbag Production Method?

Choosing the right method for producing leather handbags depends on various factors, including target market, budget, and desired brand positioning. For businesses aiming for high-quality, luxury offerings, traditional leather craftsmanship remains unmatched in performance and customer appeal. Conversely, companies targeting the mid-range or budget markets may find synthetic leather or mass production more aligned with their financial and operational goals. Ultimately, B2B buyers should evaluate their specific needs and market demands to select the most suitable handbag production method.

Illustrative image related to how to make a leather handbag

Essential Technical Properties and Trade Terminology for how to make a leather handbag

What Are the Key Technical Properties to Consider When Making a Leather Handbag?

When manufacturing leather handbags, several critical technical properties should be taken into account to ensure quality, durability, and market competitiveness.

1. Material Grade

Material grade refers to the quality of leather used in handbag production. Leather can be classified into various grades, such as full-grain, top-grain, corrected grain, and bonded leather. Full-grain leather is the highest quality, retaining the natural texture and breathability, while bonded leather is the lowest, often made from scraps. Understanding material grades is essential for B2B buyers as it directly affects product pricing, durability, and customer satisfaction.

2. Tolerance

Tolerance in handbag manufacturing indicates the allowable deviation from specified dimensions and design features. For instance, a tolerance of ±2mm on the dimensions of a handbag ensures that slight variations during cutting and stitching will not compromise the overall design. Adhering to specified tolerances is crucial for maintaining product consistency, which is vital for brand reputation and customer trust.

3. Stitch Density

Stitch density refers to the number of stitches per inch (SPI) in the seams of a handbag. A higher stitch density typically results in a more durable and aesthetically pleasing product. For example, a handbag designed for everyday use may require a stitch density of 8-10 SPI, while luxury handbags might feature 12-15 SPI. B2B buyers must understand stitch density as it influences both production costs and the perceived value of the handbag.

4. Finish Type

The finish type of leather can significantly affect its appearance and durability. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather has a natural look but is more susceptible to stains, while pigmented leather offers greater protection but may lack some natural characteristics. Buyers should consider finish types based on target markets and customer preferences to ensure product alignment with brand positioning.

5. Weight

The weight of the leather used in handbag construction is another critical property. Different weights (measured in ounces per square foot) can affect the handbag’s functionality and comfort. A heavier leather may provide more durability, whereas lighter leather can enhance portability. Understanding weight specifications helps buyers select products that meet the functional requirements of their target consumers.

What Are Common Trade Terms in Leather Handbag Manufacturing?

Navigating the leather handbag industry involves familiarizing oneself with specific trade terminology that is essential for effective communication and decision-making.

Illustrative image related to how to make a leather handbag

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the designs and specifications provided by another company. In the leather handbag industry, OEM partnerships can facilitate access to specialized manufacturing capabilities and reduce time-to-market for new designs. Understanding OEM relationships can help B2B buyers leverage manufacturing efficiencies and enhance their product offerings.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For leather handbags, MOQs can vary widely based on materials and complexity of design. Buyers need to be aware of MOQs to manage inventory effectively and ensure that they can meet market demands without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. In the context of leather handbags, an RFQ allows buyers to gather pricing information based on their design specifications, helping them make informed purchasing decisions. This process is vital for cost management and budgeting in B2B transactions.

Illustrative image related to how to make a leather handbag

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping, insurance, and risk transfer. Familiarity with Incoterms is crucial for B2B buyers involved in global supply chains, as they help mitigate misunderstandings and ensure smooth logistics.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their product offerings and improve their competitiveness in the leather handbag market.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather handbag Sector

What Are the Key Market Trends Influencing the Leather Handbag Sector?

The leather handbag market is experiencing a dynamic shift driven by several global factors. Firstly, the increasing demand for luxury and artisanal products is compelling manufacturers to innovate and elevate their craftsmanship. Countries in Africa and South America are emerging as new hubs for leather production, leveraging their rich animal husbandry traditions and unique tanning methods. Additionally, the digital transformation is reshaping sourcing strategies; B2B buyers are increasingly utilizing e-commerce platforms and digital marketplaces to connect with suppliers, streamlining procurement processes.

Emerging technologies like 3D printing and AI-driven design tools are revolutionizing product development, enabling rapid prototyping and customization. This trend is particularly advantageous for international buyers looking to cater to niche markets, as they can quickly adapt to changing consumer preferences. Furthermore, the rise of social media as a marketing tool is enabling brands to engage directly with consumers, fostering brand loyalty and allowing for targeted marketing strategies.

How Is Sustainability Shaping B2B Leather Handbag Sourcing?

Sustainability is now a critical consideration in the leather handbag sector, influencing sourcing decisions across the globe. B2B buyers are increasingly aware of the environmental impact of leather production, including water consumption and chemical pollution associated with traditional tanning processes. Consequently, there is a significant push towards ethical sourcing practices. Buyers are seeking suppliers who adhere to sustainable practices, such as vegetable tanning and the use of recycled materials, which not only minimize environmental harm but also appeal to eco-conscious consumers.

Certifications such as the Leather Working Group (LWG) certification are becoming essential for suppliers aiming to establish credibility in the market. These certifications assure buyers that the leather products they source are produced in environmentally responsible ways. Additionally, many manufacturers are investing in traceability technologies, allowing buyers to verify the origins of their materials, thereby enhancing transparency in the supply chain. This shift towards sustainability is not merely a trend but a fundamental change that is reshaping the competitive landscape of the leather handbag industry.

What Is the Historical Context of Leather Handbag Production?

The art of leather handbag making dates back centuries, with origins rooted in ancient civilizations that recognized leather’s durability and aesthetic appeal. Initially, leather was primarily used for functional items such as pouches and armor. Over time, the craft evolved into a form of artistic expression, with artisans developing intricate designs and techniques that are still revered today.

During the 19th and 20th centuries, the industrial revolution transformed leather production, introducing machinery that increased efficiency and scale. However, this also led to a decline in artisanal craftsmanship. In recent years, there has been a resurgence of interest in handmade leather goods, driven by consumer desire for unique, high-quality products. This evolution reflects a broader trend in the B2B market, where buyers are increasingly valuing craftsmanship and sustainability alongside traditional production methods. Understanding this historical context can provide valuable insights for B2B buyers looking to navigate the complexities of the modern leather handbag market.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather handbag

-

How do I source high-quality leather for handbag production?

To source high-quality leather, start by identifying reputable suppliers known for their craftsmanship. Look for tanneries with certifications that ensure ethical and sustainable practices, as well as durability and quality. Request samples to evaluate texture, grain, and color. It’s beneficial to attend leather trade shows or expos to meet suppliers in person and establish relationships. Additionally, leverage online platforms that specialize in leather goods to compare offerings and gather reviews from other buyers. -

What are the essential tools for making leather handbags?

The essential tools for leather handbag production include a rotary cutter or leather knife for cutting, leather punches for creating holes, needles and strong thread for stitching, and hardware such as zippers and buckles. It’s also advisable to have edge tools for finishing and leather conditioners to maintain the product’s quality. Investing in high-quality tools will improve efficiency and the final product’s durability. Consider purchasing toolkits specifically designed for leathercraft to ensure you have all necessary items. -

How do I ensure the durability of my leather handbags?

To ensure durability, select high-quality leather that suits the intended use of the handbag. Use proper stitching techniques, such as saddle stitching, which provides strength. Reinforce stress points with additional stitching or rivets. Regularly apply leather conditioner to protect against wear and tear. Conduct quality assurance checks at each stage of production to identify and rectify potential weaknesses before the final product is delivered. -

What factors should I consider when customizing leather handbags for clients?

When customizing leather handbags, consider the client’s target market, preferences, and usage requirements. Discuss design elements such as color, size, and hardware options. Be open to suggestions from the client to ensure the final product meets their vision. It’s crucial to establish a clear communication channel for revisions and approvals. Additionally, provide prototypes for client feedback before mass production to avoid costly mistakes. -

What are the typical minimum order quantities (MOQs) for leather handbags?

Minimum order quantities for leather handbags can vary significantly depending on the supplier and the complexity of the design. Generally, MOQs can range from 50 to 500 units. Smaller artisans may offer lower MOQs for custom designs, while larger manufacturers often require higher quantities to justify production costs. Always clarify MOQs during initial discussions to ensure they align with your business needs and budget. -

How do I vet suppliers for leather handbag production?

To vet suppliers, start by researching their reputation through online reviews and industry references. Request a portfolio showcasing their previous work, focusing on quality and design consistency. Evaluate their production capacity, turnaround times, and compliance with international standards. It’s advisable to conduct factory visits or audits if possible. Establishing a trial order can also help assess their reliability before committing to larger contracts. -

What payment terms should I negotiate with suppliers?

When negotiating payment terms, aim for a balance that protects both parties. Common practices include a deposit upfront (20-50%) with the balance due upon completion or delivery. Consider using escrow services to ensure funds are released only after satisfactory delivery. Discuss payment methods, such as bank transfers or letters of credit, to safeguard against fraud. Clear agreements on payment timelines can prevent misunderstandings and ensure a smooth transaction. -

What logistics considerations are important for shipping leather handbags internationally?

When shipping internationally, consider customs regulations, import duties, and taxes in the destination country. Choose reliable freight forwarders experienced in handling leather goods to navigate shipping complexities. Ensure proper packaging to prevent damage during transit. Additionally, familiarize yourself with lead times and track shipments to avoid delays. It’s also wise to have insurance for high-value orders to mitigate potential losses during transportation.

Top 2 How To Make A Leather Handbag Manufacturers & Suppliers List

1. Leatherworker – Drawstring Bag by Jean Luc Parisot

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: The bag is a drawstring bag designed by Jean Luc Parisot. It features a tooled panel stitched around the front and back, with a base that rests on the ground and a front closure flap. The design includes straps connected to the main body and a D-Ring for attachment. The bag’s usability is noted to be somewhat impractical due to the multiple steps required to open and close it.

2. Babylon Leather – DIY Purse Kit

Domain: thethingswellmake.com

Registered: 2013 (12 years)

Introduction: DIY leather purse kit from Babylon Leather, suitable for beginners. Includes various strips and larger pieces of leather, metal rings, plastic cording, tapestry needles, strong waxed white thread, snips for cutting thread, and binder clips. Pre-cut stitching holes on leather edges for easy assembly. Video tutorials provided for step-by-step guidance. Uses saddle stitch for sewing. Requires a light…

Strategic Sourcing Conclusion and Outlook for how to make a leather handbag

In conclusion, the journey of creating a leather handbag is not just an artistic endeavor but also a strategic business opportunity. By focusing on key elements such as design, material selection, and prototyping, B2B buyers can enhance their product offerings and meet consumer demands effectively. Sourcing high-quality leather and durable hardware is crucial for ensuring longevity and customer satisfaction, which can lead to repeat business and referrals.

Illustrative image related to how to make a leather handbag

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the potential for growth in the leather goods market is significant. Understanding local trends and consumer preferences can inform better sourcing decisions, ensuring that products resonate with target markets.

As you explore partnerships with suppliers, consider leveraging technology for efficient sourcing and inventory management. By embracing innovation and quality craftsmanship, you can position your brand as a leader in the leather handbag industry. Take the next step in your strategic sourcing journey—invest in quality, embrace creativity, and respond to market demands with agility. Your vision for leather handbags can redefine style and functionality in a competitive global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how to make a leather handbag