Catalog

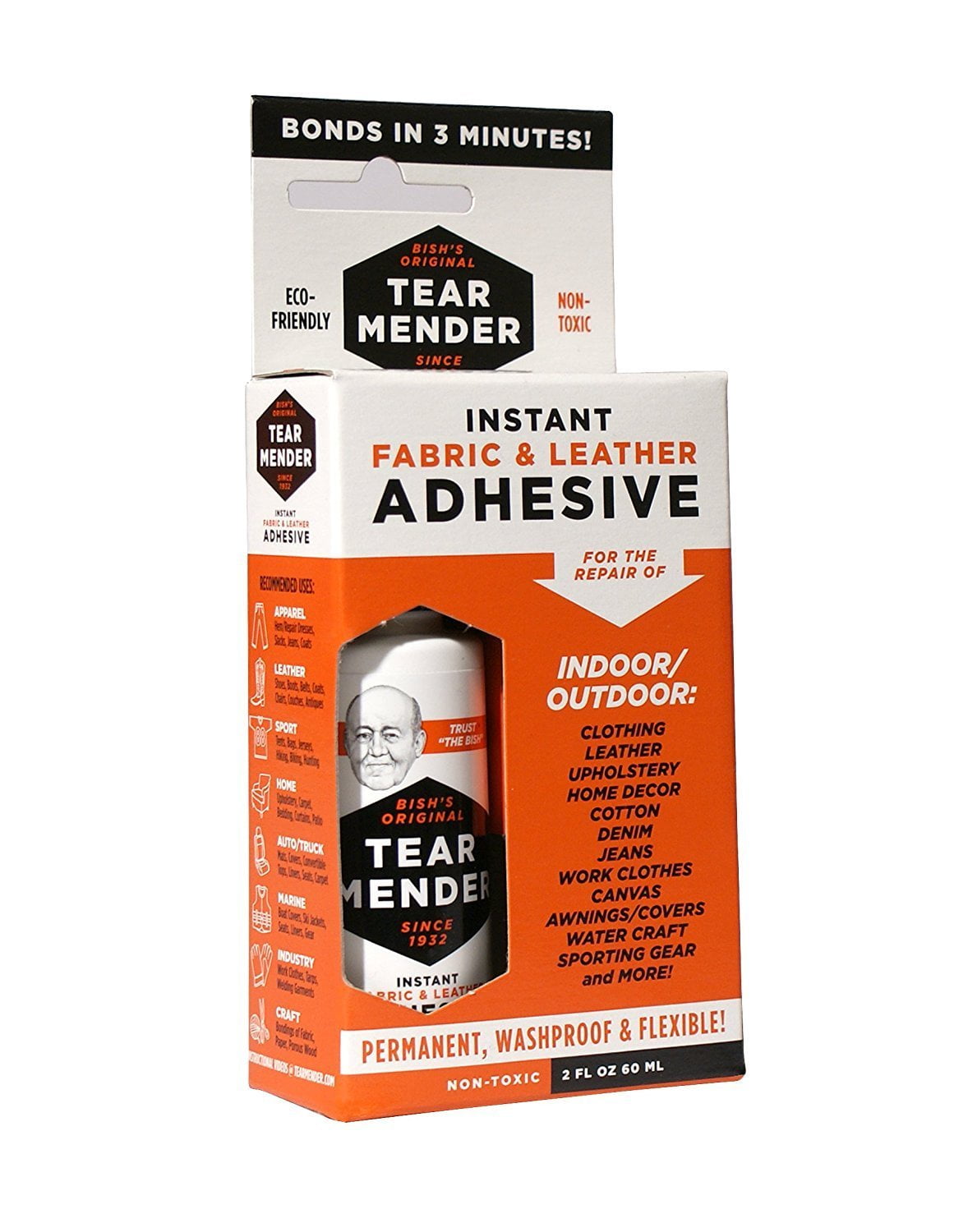

Material Insight: Tear Mender Instant Fabric And Leather Adhesive

B2B Product Guide: Tear Mender Instant Fabric and Leather Adhesive

Introduction to Tear Mender Instant Fabric and Leather Adhesive

Tear Mender Instant Fabric and Leather Adhesive is a high-performance bonding solution engineered for durability, speed, and reliability in industrial and commercial applications. Designed to address the growing demand for efficient repair and assembly of textiles and synthetic materials, this fast-acting adhesive delivers a strong, flexible bond that resists peeling, cracking, and wear. Ideal for use in upholstery, automotive interiors, fashion accessories, and performance gear, Tear Mender ensures long-lasting results with minimal application time.

The adhesive is formulated to work seamlessly with a variety of substrates, with exceptional performance on synthetic materials—particularly faux leather. Its solvent-free, low-odor composition supports eco-conscious manufacturing while meeting rigorous industry standards for strength and flexibility.

Why Faux Leather is the Best Choice for This Application

Faux leather—especially high-grade microfiber and PU-based variants—offers a sustainable, cost-effective, and highly durable alternative to genuine leather. When paired with Tear Mender Instant Adhesive, it delivers superior bonding performance due to the following advantages:

- Consistent surface texture that ensures uniform adhesive spread and strong adhesion

- Enhanced resistance to environmental stressors such as UV exposure, moisture, and temperature fluctuations

- Greater compatibility with modern bonding agents compared to treated or uneven genuine leather surfaces

- Ethical and eco-friendly profile, aligning with global sustainability goals in manufacturing

Faux leather’s engineered structure allows for predictable, long-term performance in high-stress applications, making it the ideal material for use with instant adhesives in both production and repair environments.

WINIWについて

WINIW is a trusted global leader in synthetic leather innovation, with over 20 years of experience in developing high-performance materials for diverse industrial applications. Specializing in microfiber and PU leather solutions, WINIW combines advanced technology, sustainable practices, and rigorous quality control to deliver products that meet the evolving needs of manufacturers worldwide.

Our expertise extends beyond material production—we provide comprehensive support in material selection, bonding optimization, and application engineering. Partnering with WINIW means access to durable, eco-conscious synthetic leather solutions designed to perform under real-world conditions and integrate seamlessly with advanced adhesives like Tear Mender.

Technical Performance & Standards

WINIW Tear Mender Instant Fabric & Leather Adhesive: Technical Product Guide for B2B Applications

WINIW Tear Mender Instant Fabric & Leather Adhesive is engineered specifically for industrial and commercial repair, manufacturing, and upholstery workflows demanding speed, strength, and compliance. This solvent-based adhesive delivers exceptional performance on synthetic and genuine leather, textiles, vinyl, and coated fabrics, providing a significant operational advantage over generic alternatives. Its formulation prioritizes efficiency, longevity, and adherence to stringent global regulatory standards, directly supporting your sustainability and quality management objectives.

Key Technical Advantages for Industrial Users:

- Cost-Effective Production & Repair: Significantly reduces labor time and material waste through instant grab and rapid handling strength (achieved in 30-60 seconds). Minimizes rework and costly downtime by ensuring reliable, permanent bonds on first application, optimizing throughput in high-volume settings like automotive trim, furniture manufacturing, and footwear repair.

- Superior Durability & Performance: Engineered for demanding applications with high peel strength (8-10 N/mm on standard synthetic leather substrates) and exceptional resistance to flexing, heat (up to 80°C continuous), moisture, and common solvents. Bonds remain flexible yet strong, preventing cracking or delamination under stress, extending product lifecycle and reducing warranty claims.

- Customizable Color Matching: Available in clear/translucent base or easily tinted with compatible pigments to precisely match a vast array of synthetic leather, fabric, and vinyl colors (Pantone® matching service available). Ensures seamless, invisible repairs and bonds critical for premium automotive interiors, high-end upholstery, and branded merchandise where aesthetic integrity is paramount.

- Full REACH Compliance: Formulated and rigorously tested to comply with EU REACH regulations (EC 1907/2006), including restrictions on SVHCs (Substances of Very High Concern). Documentation readily available, mitigating supply chain risks and ensuring market access for products destined for the European Union and other regions adopting similar standards.

- ISO 9001 Certified Manufacturing: Produced under WINIW’s robust Quality Management System, certified to ISO 9001:2015. This guarantees consistent batch-to-batch performance, stringent raw material control, traceability, and adherence to defined manufacturing protocols, providing reliability essential for your production planning and quality assurance.

Technical Specifications Overview:

| Property | 仕様 | Test Method (Typical) |

|---|---|---|

| Base Type | Solvent-Based | Visual Inspection |

| Primary Solvents | Aliphatic Hydrocarbons | GC-MS Analysis |

| Viscosity (25°C) | 800 – 1200 mPa·s | Brookfield RVT, Spindle #3 |

| Solid Content | 25% – 30% | ASTM D2876 |

| VOC Content | < 650 g/L (REACH Compliant) | EPA Method 24 |

| Open Time | 30 – 90 seconds | Tack Measurement |

| Handling Strength | Achieved in 30 – 60 seconds | Peel Test (Initial) |

| Full Cure Time | 12 – 18 hours (24h optimal) | ASTM D903 |

| Peel Strength | 8 – 10 N/mm (Synthetic Leather) | ISO 1421 |

| Heat Resistance | Up to 80°C continuous | Thermal Aging Test |

| Color Options | Clear, Translucent; Custom Tintable | Visual Comparison (Pantone®) |

| Primary Substrates | Synthetic Leather, Genuine Leather, Vinyl, Coated Fabrics, Textiles | Adhesion Testing |

| REACH Status | Compliant (No SVHCs above threshold) | Internal & 3rd Party Testing |

| ISO 9001 Certified | Yes (Manufacturing Process) | Certificate on File |

Application Note: For optimal results on synthetic leather and coated substrates, ensure surfaces are clean, dry, and free of oils or release agents. Apply a thin, even layer to both surfaces, allow 30-60 seconds for solvent flash-off (until tacky), then press firmly together. Clamping or pressure application is recommended during initial set. Always conduct adhesion and color compatibility tests on specific substrates prior to full-scale use. Store in a cool, dry place below 30°C. WINIW provides detailed technical data sheets (TDS) and safety data sheets (SDS) upon request for integration into your quality and safety protocols.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather – Performance and Sustainability Comparison

In the evolving landscape of material selection for fashion, automotive, and furniture industries, synthetic leather continues to gain traction as a viable alternative to real leather. This guide compares Real Leather with synthetic leather bonded using Tear Mender Instant Fabric and Leather Adhesive, focusing on cost, durability, and environmental impact to support informed B2B decision-making.

Overview of Materials

-

Real Leather: Sourced from animal hides (primarily bovine), real leather is known for its natural grain, breathability, and aging characteristics. It requires extensive tanning and finishing processes, contributing to higher costs and environmental concerns.

-

Synthetic Leather with Tear Mender Adhesive: High-performance synthetic leather (e.g., PU or microfiber-based) laminated or repaired using Tear Mender Instant Fabric and Leather Adhesive offers strong bonding, flexibility, and resistance to wear. This combination supports rapid production cycles and repair applications, especially in industrial and upholstery settings.

Key Advantages of Synthetic Leather with Adhesive Bonding

- Faster production turnaround due to simplified lamination and repair processes

- Consistent texture and thickness across batches, enhancing manufacturing precision

- Lower material waste during cutting and sewing

- Suitable for vegan and cruelty-free product lines

- Repair-friendly; minor damages can be fixed quickly using adhesives like Tear Mender

Performance and Sustainability Comparison

| カテゴリー | Real Leather | Synthetic Leather + Tear Mender Adhesive |

|---|---|---|

| Cost | High (raw material and labor-intensive processing) | Moderate to low (scalable production, less waste) |

| 耐久性 | High (ages well, develops patina; susceptible to moisture and UV degradation) | High (resistant to abrasion, fading, and moisture; bond strength up to 85% of original material with proper application) |

| Eco-Friendliness | Moderate to low (high water/energy use, chemical tanning, CO₂ footprint) | Moderate (depends on base material; PU leather has lower biodegradability but newer bio-based synthetics improve sustainability; adhesive is water-based and low-VOC) |

Considerations for B2B Buyers

- Cost Efficiency: Synthetic leather systems offer significant savings in material and labor, particularly for high-volume production.

- Durability in Use: While real leather excels in long-term aging, synthetic leather with strong adhesive bonding performs reliably in commercial environments such as public seating, automotive interiors, and workwear.

- Sustainability Goals: Brands prioritizing circularity and reduced environmental impact may favor advanced synthetic leathers made from recycled or bio-based polymers, especially when combined with low-impact adhesives like Tear Mender.

Conclusion

For B2B manufacturers seeking a balance between performance, cost, and sustainability, synthetic leather bonded with high-quality adhesives presents a compelling alternative to real leather. With ongoing innovations in eco-friendly materials and bonding technologies, synthetic solutions align well with modern ethical and environmental standards—without compromising on durability or aesthetic appeal.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered Manufacturing Excellence

WINIW stands at the forefront of sustainable synthetic leather production through vertically integrated manufacturing capabilities. Our 100,000 sqm state-of-the-art facility in China operates under stringent environmental protocols, enabling end-to-end control from raw material sourcing to finished goods. This scale ensures consistent supply chain resilience for global partners while minimizing ecological impact through closed-loop water systems and renewable energy integration.

Our competitive advantage is anchored in four pillars of operational strength:

- Advanced Production Capacity: A 100,000 sqm manufacturing complex featuring automated coating lines and digital printing systems, supporting annual output of 150+ million meters with flexible batch sizing for tier-1 brand demands.

- Dedicated R&D Innovation: 45+ material scientists and engineers continuously develop next-generation solutions, holding 37 patents for eco-friendly formulations (including 100% recycled PET and plant-based PU) and performance-enhancing textures.

- Certified Quality Assurance: Triple-stage QC protocols exceeding ISO 9001 standards, with in-house testing for abrasion resistance (50,000+ cycles), colorfastness (Grade 4+), and chemical compliance (OEKO-TEX® STANDARD 100, EU Ecolabel). Every batch undergoes traceability scanning.

- Global Regulatory Expertise: Direct export infrastructure serving 40+ countries, with full compliance documentation for EU REACH, US CPSIA, and California Proposition 65. 78% of shipments reach European and North American markets within 25 days.

This infrastructure delivers measurable value to B2B partners through reduced lead times, auditable sustainability credentials, and technical collaboration for custom performance specifications. WINIW’s factory ecosystem transforms synthetic leather from a commodity into a strategic asset for forward-thinking brands.

Contact Us for Samples

B2B Product Guide: Tear Mender Instant Fabric and Leather Adhesive

Tear Mender Instant Fabric and Leather Adhesive is a high-performance bonding solution engineered for industrial and commercial applications involving synthetic leather, textiles, and flexible substrates. Developed with precision and reliability in mind, this adhesive supports fast-paced manufacturing environments while maintaining strong, durable bonds that meet rigorous quality standards.

Ideal for use in automotive interiors, upholstery repair, footwear production, and furniture manufacturing, Tear Mender delivers instant adhesion with minimal curing time—maximizing efficiency and reducing downtime across production lines.

Key Features:

– Fast-acting formula ensures immediate bond strength

– Compatible with synthetic leather (including PU and PVC-based microfibers), natural leather, fabrics, and vinyl

– Flexible, waterproof bond resists cracking and peeling under stress

– Solvent-based chemistry for superior adhesion on low-surface-energy materials

– Heat and humidity resistant—ideal for global supply chains and diverse climates

– Designed for both manual and semi-automated application processes

Recommended Applications:

– Seam reinforcement in automotive and furniture upholstery

– Patch bonding for performance textiles and coated fabrics

– Repair and rework solutions in manufacturing facilities

– Footwear assembly, especially in synthetic upper-to-sole bonding

– Lamination of multi-layer material composites

Technical Specifications:

| Property | 仕様 |

|---|---|

| Bond Type | Permanent, flexible |

| Substrates | Synthetic leather, fabric, vinyl, natural leather |

| Viscosity | Medium (2,500–3,500 cP) |

| Open Time | 15–30 seconds |

| Full Cure Time | 24 hours |

| Storage Life | 12 months (unopened, 15–25°C) |

| Packaging Options | 1 oz, 4 oz, 8 oz bottles; bulk pails available |

Why Choose Tear Mender?

Manufacturers trust Tear Mender for its consistency, strength, and ease of integration into existing workflows. As part of WINIW’s commitment to sustainable innovation, this adhesive supports efficient material usage and reduces waste in production—aligning with eco-conscious manufacturing goals without compromising performance.

Free samples are available for qualified B2B partners to evaluate performance in real-world applications.

For product inquiries, technical data sheets, or to request a free sample:

Contact our Marketing Team at MKT88@MicrofiberLeather.com.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.