Introduction: Navigating the Global Market for pu sofa leather

In the competitive landscape of global furniture sourcing, finding high-quality PU sofa leather can be a challenging endeavor for international B2B buyers. As the demand for stylish yet affordable upholstery grows, understanding the nuances of PU leather becomes crucial for making informed purchasing decisions. This guide offers a comprehensive exploration of PU sofa leather, covering essential topics such as the different types available, their diverse applications, effective supplier vetting strategies, and cost considerations.

By delving into these aspects, buyers from regions like Africa, South America, the Middle East, and Europe—including markets such as Saudi Arabia and Germany—will gain valuable insights into optimizing their sourcing strategies. The guide aims to empower decision-makers by equipping them with the knowledge needed to navigate the complexities of the PU leather market effectively. Whether you’re looking to furnish commercial spaces or upscale residential environments, understanding the characteristics and benefits of PU leather will enable you to make choices that align with your budget and aesthetic goals.

Join us as we unravel the potential of PU sofa leather, ensuring that your purchasing decisions not only meet quality standards but also resonate with market trends and consumer preferences.

Table Of Contents

- Top 5 Pu Sofa Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pu sofa leather

- Understanding pu sofa leather Types and Variations

- Key Industrial Applications of pu sofa leather

- 3 Common User Pain Points for ‘pu sofa leather’ & Their Solutions

- Strategic Material Selection Guide for pu sofa leather

- In-depth Look: Manufacturing Processes and Quality Assurance for pu sofa leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu sofa leather’

- Comprehensive Cost and Pricing Analysis for pu sofa leather Sourcing

- Alternatives Analysis: Comparing pu sofa leather With Other Solutions

- Essential Technical Properties and Trade Terminology for pu sofa leather

- Navigating Market Dynamics and Sourcing Trends in the pu sofa leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pu sofa leather

- Strategic Sourcing Conclusion and Outlook for pu sofa leather

- Important Disclaimer & Terms of Use

Understanding pu sofa leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PU Leather | Synthetic, smooth finish, affordable | Residential furniture, budget retail | Pros: Cost-effective, easy maintenance. Cons: Less durable than high-end options. |

| PU Leather Match | Combination of PU leather and real leather | Mid-range furniture, upscale showrooms | Pros: Luxury look at lower cost. Cons: Limited durability in high-use areas. |

| Bonded PU Leather | Made from leather scraps mixed with PU | Budget furniture, temporary solutions | Pros: Eco-friendly, budget-friendly. Cons: Prone to peeling, less durable. |

| PVC Leather | Stiffer texture, lower cost, less breathable | Budget-friendly options, automotive | Pros: Very affordable. Cons: Lacks comfort and durability compared to PU leather. |

| Vegan PU Leather | Fully synthetic, marketed as animal-friendly | Eco-conscious brands, modern furniture | Pros: Ethical choice, versatile. Cons: Can vary in quality. |

What Are the Characteristics of Standard PU Leather?

Standard PU leather is a widely used synthetic material characterized by its smooth finish and affordability. Its primary applications include residential furniture and budget retail settings, making it an attractive option for manufacturers looking to provide cost-effective solutions. Buyers should consider its ease of maintenance and lower price point, but they should also be aware that it may not withstand heavy use as well as higher-end leather options.

How Does PU Leather Match Differentiate Itself?

PU leather match is a hybrid upholstery material that combines PU leather with real leather in high-contact areas. This type is primarily used in mid-range furniture and upscale showrooms, where the appearance of luxury is essential without the associated high costs. While it provides a more luxurious look at a fraction of the price, businesses should note that its durability may be limited in high-use environments, necessitating careful consideration of the intended application.

What Makes Bonded PU Leather a Unique Option?

Bonded PU leather is produced from leather scraps mixed with polyurethane, offering an eco-friendly alternative for budget-conscious buyers. Its applications often include budget furniture and temporary solutions. While it is cost-effective and environmentally friendly, businesses should be cautious of its durability, as it is prone to peeling and may not hold up well over time compared to other PU leather types.

Why Choose PVC Leather Over Other Options?

PVC leather, often regarded as a budget-friendly alternative, features a stiffer texture and is less breathable than PU leather. It is commonly found in budget-friendly furniture and automotive applications. While its low cost is appealing, buyers should consider that it lacks the comfort and durability provided by PU leather, making it a less desirable choice for high-quality furniture.

What Are the Benefits of Vegan PU Leather?

Vegan PU leather is a fully synthetic material marketed as an ethical choice for consumers. It is widely used by eco-conscious brands and in modern furniture designs. While it offers versatility and aligns with ethical purchasing trends, the quality can vary significantly among manufacturers, making it essential for B2B buyers to evaluate specific products carefully to ensure they meet their standards.

Key Industrial Applications of pu sofa leather

| Industry/Sector | Specific Application of PU Sofa Leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Cost-effective alternative to real leather, appealing to budget-conscious consumers. | Ensure durability and resistance to wear; verify supplier certifications. |

| Hospitality | Furnishings for hotels and restaurants | Enhances aesthetic appeal while being easy to maintain and clean. | Look for fire-retardant materials; consider local climate impacts on material performance. |

| Automotive | Interior seating and upholstery for vehicles | Provides a luxurious look at a fraction of the cost of real leather. | Check for compliance with automotive standards; evaluate long-term durability against wear and tear. |

| Office Furniture | Chairs and lounge areas in corporate settings | Offers a professional appearance while being easy to maintain. | Assess for ergonomic comfort; ensure compliance with corporate sustainability policies. |

| Retail Displays | Upholstered furniture for showrooms and displays | Attracts customers with a stylish look while being budget-friendly. | Consider customization options; verify availability of various colors and textures. |

How is PU Sofa Leather Used in Furniture Manufacturing?

In the furniture manufacturing industry, PU sofa leather is widely used for upholstering sofas and chairs. This material provides a cost-effective alternative to genuine leather, making it accessible for budget-conscious consumers. Manufacturers benefit from its durability and ease of cleaning, which are essential for products expected to endure regular use. International buyers, particularly from regions like Africa and South America, should prioritize sourcing from suppliers that demonstrate quality and compliance with industry standards to ensure longevity and satisfaction.

What Role Does PU Leather Play in the Hospitality Sector?

In the hospitality sector, PU leather is frequently employed in the furnishings of hotels and restaurants. Its aesthetic appeal enhances the ambiance while offering practicality through easy maintenance and cleaning. This is particularly important in high-traffic areas where spills and stains are common. Buyers in the Middle East and Europe should consider sourcing PU leather that meets fire safety regulations and is suitable for local climate conditions to ensure durability and compliance with safety standards.

Why is PU Leather Preferred in Automotive Applications?

The automotive industry utilizes PU sofa leather for interior seating and upholstery due to its luxurious appearance at a fraction of the cost of real leather. It provides a comfortable and appealing look while being more resistant to spills and stains compared to traditional materials. When sourcing PU leather for automotive applications, buyers must ensure that the material complies with industry regulations and standards for durability and safety, especially in regions like Germany, where automotive quality is paramount.

How is PU Sofa Leather Beneficial for Office Furniture?

In the office furniture sector, PU leather is commonly used for chairs and lounge areas, offering a professional appearance that enhances workplace aesthetics. Its low maintenance requirements are particularly appealing for businesses looking to maintain a polished look without incurring high cleaning costs. Buyers should evaluate the ergonomic features of PU leather office furniture and ensure it aligns with corporate sustainability policies, especially in markets where eco-friendly practices are increasingly prioritized.

What Advantages Does PU Leather Offer for Retail Displays?

PU leather is also utilized in retail displays, where upholstered furniture plays a crucial role in attracting customers. Its stylish appearance combined with affordability allows retailers to create visually appealing environments without overspending. When sourcing PU leather for retail applications, businesses should consider customization options to align with branding and verify the availability of diverse colors and textures to appeal to their target market effectively.

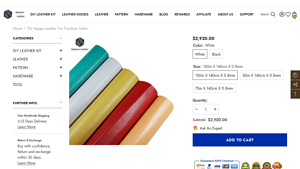

Illustrative image related to pu sofa leather

3 Common User Pain Points for ‘pu sofa leather’ & Their Solutions

Scenario 1: Navigating Quality Concerns in PU Leather Procurement

The Problem: One of the most significant challenges B2B buyers face when sourcing PU leather sofas is the inconsistency in quality. Different suppliers may offer products that vary drastically in durability, finish, and overall feel. This inconsistency can lead to dissatisfaction among end-users, especially in commercial settings where the sofas are expected to endure heavy use. Buyers may struggle to ascertain which suppliers provide high-quality PU leather that meets their standards, risking investments in subpar products that could damage their reputation.

The Solution: To address quality concerns, B2B buyers should establish clear criteria for evaluating suppliers. Request samples of the PU leather from potential suppliers to conduct physical assessments. Evaluate the texture, weight, and durability, and consider conducting stress tests to assess how the material holds up under typical usage conditions. Additionally, buyers should request certifications or third-party quality assessments that validate the material’s performance claims. Building relationships with reliable suppliers who have a proven track record in delivering consistent quality can further mitigate risks.

Scenario 2: Understanding Maintenance and Longevity of PU Leather Sofas

The Problem: Many buyers underestimate the maintenance requirements of PU leather sofas, leading to premature wear and tear. This oversight is particularly problematic in environments such as hotels, offices, or healthcare facilities, where furniture is subject to high usage. Without proper care, PU leather can develop cracks or stains, which not only affect the aesthetic appeal but also necessitate costly replacements.

The Solution: Buyers should prioritize educating their staff on the specific maintenance needs of PU leather. Create a maintenance guide that includes recommended cleaning solutions, techniques, and frequency of care. Opt for products specifically designed for synthetic materials to avoid damaging the finish. Incorporating protective measures, such as using coasters and avoiding direct sunlight, can significantly enhance the lifespan of PU leather sofas. For businesses, consider offering training sessions for employees on furniture care, ensuring that everyone understands how to maintain the quality and appearance of the sofas over time.

Illustrative image related to pu sofa leather

Scenario 3: Aligning Design with Market Trends and Consumer Preferences

The Problem: In a rapidly changing market, staying aligned with design trends while sourcing PU leather sofas can be a challenge. Buyers often find themselves torn between selecting timeless designs and incorporating trendy aesthetics that appeal to consumers. Misalignment with current trends can lead to stagnant inventory, negatively impacting sales and profitability.

The Solution: To effectively navigate design trends, B2B buyers should engage in market research and trend analysis regularly. Leverage insights from industry reports, trade shows, and social media to stay updated on emerging styles and consumer preferences. Collaborate with designers to create a versatile product line that can adapt to shifting trends without compromising quality. Consider using customizable options that allow end-users to select colors, textures, and styles that resonate with their clientele. This not only enhances the appeal of the PU leather sofas but also positions your business as responsive and in tune with market demands.

Strategic Material Selection Guide for pu sofa leather

What Are the Key Materials Used in PU Sofa Leather Production?

When selecting materials for PU sofa leather, it is essential to understand the various components that contribute to its performance, durability, and overall suitability for different applications. Here, we analyze four common materials used in PU leather production, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Polyurethane Coating?

Polyurethane (PU) is a synthetic polymer that serves as the primary coating for PU leather. Its key properties include high flexibility, abrasion resistance, and excellent water resistance. PU can withstand a range of temperatures, making it suitable for various climates, from the humid conditions of South America to the arid environments of the Middle East.

Pros: PU is cost-effective compared to genuine leather and offers a similar aesthetic appeal. It is also easy to clean and maintain, which is particularly advantageous for commercial applications where heavy use is expected.

Illustrative image related to pu sofa leather

Cons: While PU is durable, it may not match the longevity of high-grade leather. Over time, it can show signs of wear, especially in high-contact areas.

Impact on Application: PU’s water resistance makes it ideal for environments where spills are common, such as cafes or family homes.

Considerations for International Buyers: Compliance with standards such as ASTM or DIN is crucial, particularly in Europe, where regulations on material safety and environmental impact are stringent. Buyers from regions like Africa and the Middle East may prioritize cost and maintenance over compliance.

How Does Polyester Fabric Contribute to PU Leather?

Polyester is often used as the backing fabric for PU leather. It provides structural integrity and enhances the overall durability of the material. Polyester is resistant to shrinking and stretching, ensuring that the PU leather maintains its shape over time.

Illustrative image related to pu sofa leather

Pros: The combination of PU and polyester results in a lightweight material that is easy to handle and transport. It is also less expensive than natural fibers.

Cons: Polyester may not be as breathable as natural fibers, which can lead to discomfort in warm climates.

Impact on Application: This material is particularly suitable for upholstered furniture that requires regular cleaning, as polyester is stain-resistant.

Considerations for International Buyers: Buyers should consider the local climate when selecting polyester-backed PU leather, as breathability can affect customer satisfaction in warmer regions.

What Role Does Cotton Play in PU Leather?

Cotton is sometimes used as an alternative backing material for PU leather. It offers a softer feel and is biodegradable, appealing to environmentally conscious consumers.

Pros: Cotton’s natural fibers provide a breathable option that enhances comfort, making it suitable for residential applications.

Cons: Cotton is less durable than polyester and may be more susceptible to wear and tear in high-traffic areas.

Impact on Application: Cotton-backed PU leather is ideal for residential sofas and chairs where comfort is a priority over extreme durability.

Considerations for International Buyers: Buyers in Europe may favor cotton for its sustainability, while those in regions with harsher climates may prioritize durability over environmental factors.

How Does PVC Compare to PU in Sofa Leather Applications?

Polyvinyl chloride (PVC) is another synthetic alternative to PU leather. While it is often cheaper, it lacks some of the desirable properties of PU.

Pros: PVC is highly affordable and offers a wide range of colors and textures, making it appealing for budget-conscious buyers.

Cons: It is less flexible and breathable than PU, which can lead to cracking and peeling over time.

Impact on Application: PVC is suitable for low-cost furniture but may not withstand heavy use as effectively as PU leather.

Considerations for International Buyers: Buyers should be cautious about the long-term performance of PVC, especially in regions where quality is prioritized over cost.

Summary of Material Selection for PU Sofa Leather

| Material | Typical Use Case for PU Sofa Leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Commercial and residential sofas | High water resistance and easy maintenance | Less durable than genuine leather | Medium |

| Polyester Fabric | Upholstered furniture | Lightweight and cost-effective | Less breathable than natural fibers | Low |

| Cotton | Residential sofas and chairs | Soft feel and biodegradable | Less durable in high-traffic areas | Medium |

| Polyvinyl Chloride (PVC) | Budget furniture | Highly affordable | Prone to cracking and peeling | Low |

This guide serves as a comprehensive overview for international B2B buyers, ensuring informed decisions in selecting materials for PU sofa leather that align with market demands and regional preferences.

Illustrative image related to pu sofa leather

In-depth Look: Manufacturing Processes and Quality Assurance for pu sofa leather

What Are the Main Stages of the Manufacturing Process for PU Sofa Leather?

The manufacturing process of PU sofa leather involves several critical stages, each designed to ensure the final product meets quality and durability standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is PU Leather Made?

The first step in creating PU sofa leather is the preparation of materials. PU leather is synthesized from a backing fabric, usually cotton or polyester, which is coated with a layer of polyurethane. This process begins with the selection of high-quality fabric that will provide both strength and flexibility.

The polyurethane is then applied to the fabric using various techniques such as roller coating or spraying, depending on the desired texture and finish. The material is subsequently embossed to replicate the grain and feel of genuine leather, enhancing its aesthetic appeal.

Forming: What Techniques Are Used to Shape PU Sofa Leather?

Once the material is prepared, the next stage involves forming. This process includes cutting the PU leather into specific shapes and sizes that will be used for different components of the sofa, such as the cushions, armrests, and backrests. Advanced cutting technologies, such as laser cutting, are often employed to achieve precise shapes and reduce waste.

Illustrative image related to pu sofa leather

After cutting, the pieces are often subjected to a pre-assembly inspection to ensure they meet design specifications. This initial quality check is crucial for minimizing errors in later stages of the production process.

Assembly: How Are PU Sofas Constructed?

The assembly stage involves stitching the cut pieces of PU leather together to form the sofa. This process requires skilled labor to ensure the seams are strong and aesthetically pleasing. High-quality stitching techniques, such as double stitching, are commonly used to enhance durability.

In addition to stitching, various components such as frames, springs, and cushioning materials are incorporated during assembly. The choice of frame materials (e.g., hardwood or metal) can significantly impact the sofa’s overall strength and longevity.

Illustrative image related to pu sofa leather

Finishing: What Are the Final Touches for PU Sofa Leather?

The final stage of the manufacturing process is finishing, which includes applying protective coatings to enhance the PU leather’s durability and resistance to stains and spills. This step may also involve additional treatments to improve the material’s feel and appearance.

Quality assurance checks are performed at this stage to ensure that the final product meets the required specifications. This may include visual inspections and tactile assessments to confirm the quality of the PU leather.

What Quality Assurance Standards Are Relevant for PU Sofa Leather?

Quality assurance is critical in the manufacturing of PU sofa leather, as it ensures that the end product meets industry standards and customer expectations. International standards such as ISO 9001 are widely recognized and provide a framework for quality management systems.

Which International Standards Should B2B Buyers Consider?

B2B buyers should look for suppliers who adhere to relevant international standards, including:

-

ISO 9001: This standard focuses on quality management systems and ensures that manufacturers have processes in place to consistently produce products that meet customer and regulatory requirements.

-

CE Marking: This indicates that the product complies with European health, safety, and environmental protection standards. It is essential for buyers in Europe, including Germany, who seek assurance of product quality.

-

API Standards: While more common in the oil and gas industry, some manufacturers of PU leather may adhere to API standards to ensure material integrity and performance.

What Are the Common Quality Control Checkpoints?

Quality control (QC) is an integral part of the manufacturing process, with several checkpoints designed to catch any defects early on. These include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified quality standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are performed at various stages to monitor production quality. This may include inspections of stitching quality and material integrity.

-

Final Quality Control (FQC): Once the sofa is fully assembled, a final inspection is conducted to assess the overall quality, appearance, and functionality of the product. Any defects identified at this stage can be addressed before shipping.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for B2B buyers, particularly those sourcing from international markets. Here are several actionable steps to ensure supplier credibility:

What Audits and Reports Should Buyers Request?

-

Supplier Audits: Requesting a comprehensive audit report can provide insights into the supplier’s quality management systems and adherence to international standards.

-

Quality Control Reports: Suppliers should provide detailed QC reports that outline inspection results, testing methods, and any corrective actions taken in response to identified issues.

How Can Third-Party Inspections Enhance Confidence?

Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. These inspections often include:

-

Factory Audits: Conducting a factory audit can help buyers assess the supplier’s manufacturing capabilities and compliance with quality standards.

-

Product Inspections: Pre-shipment inspections can verify that the products meet agreed-upon specifications before they leave the factory.

What Nuances Should International B2B Buyers Be Aware Of?

International B2B buyers should be aware of specific nuances when dealing with suppliers from different regions. For example, quality standards and practices may vary significantly between countries. Buyers should familiarize themselves with local regulations and standards applicable to PU leather products in their target markets.

In regions such as Africa, South America, and the Middle East, establishing strong relationships with suppliers can be beneficial. Effective communication regarding quality expectations and standards can help mitigate misunderstandings and ensure that the final products meet buyer specifications.

Illustrative image related to pu sofa leather

By understanding the manufacturing processes and quality assurance practices associated with PU sofa leather, B2B buyers can make informed decisions when selecting suppliers and ensure they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu sofa leather’

In the competitive world of furniture manufacturing, sourcing PU leather for sofas requires a systematic approach to ensure quality, cost-effectiveness, and supplier reliability. This checklist will guide B2B buyers through the essential steps to successfully procure PU leather for their projects, tailored specifically for international markets.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for the PU leather you require. This includes details such as thickness, texture, color options, and intended use (e.g., residential or commercial).

– Why It’s Important: Precise specifications help in narrowing down suppliers who can meet your needs, ensuring that the final product aligns with your quality standards and market expectations.

Step 2: Research and Identify Potential Suppliers

Compile a list of potential suppliers that specialize in PU leather. Utilize online directories, trade shows, and industry recommendations to find reputable manufacturers.

– What to Look For: Focus on suppliers with a strong market presence and positive reviews from other B2B clients. Check their website for product catalogs and certifications that demonstrate compliance with international quality standards.

Step 3: Request Samples for Quality Assessment

Once you have identified potential suppliers, request samples of their PU leather products. This allows you to evaluate the texture, durability, and overall quality firsthand.

– Importance of This Step: Assessing samples helps you make informed decisions and ensures that the material meets your specifications before placing a bulk order.

Illustrative image related to pu sofa leather

Step 4: Verify Supplier Certifications

Ensure that your shortlisted suppliers possess the necessary certifications that indicate compliance with industry standards, such as ISO or other quality management systems.

– Why Verification Matters: Certifications provide assurance that the supplier adheres to quality control practices and environmental regulations, which is crucial for maintaining your brand’s reputation.

Step 5: Evaluate Pricing and Payment Terms

Analyze the pricing structures offered by different suppliers and understand their payment terms. Consider factors such as minimum order quantities, shipping costs, and potential discounts for bulk purchases.

– Key Considerations: Balancing cost with quality is vital; the lowest price may not always equate to the best value. Ensure that payment terms are aligned with your cash flow management.

Step 6: Negotiate Terms and Conditions

Before finalizing your order, engage in negotiations regarding delivery timelines, warranty terms, and after-sales support. Clear agreements help in setting expectations and mitigating potential disputes.

– Focus Areas: Pay attention to lead times, return policies, and support for product issues, as these can significantly impact your operational efficiency.

Step 7: Establish a Communication Plan

Once you select a supplier, establish a clear communication plan to ensure ongoing collaboration. Regular updates on production, shipping, and any potential issues are crucial for maintaining a smooth supply chain.

– Importance of Communication: A proactive communication strategy helps in addressing challenges quickly and fosters a strong supplier relationship, which can lead to better service and flexibility in future transactions.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for PU leather sofas, ensuring they partner with the right suppliers to meet their business needs effectively.

Comprehensive Cost and Pricing Analysis for pu sofa leather Sourcing

What Are the Key Cost Components for Sourcing PU Sofa Leather?

When evaluating the costs associated with sourcing PU sofa leather, several key components come into play. The first is materials, which predominantly include the PU leather itself, a backing fabric (typically cotton or polyester), and any additional treatments for durability and aesthetics. Material costs can vary significantly based on quality and supplier relationships.

Next, labor costs encompass the wages paid to workers involved in cutting, sewing, and assembling the sofas. This can vary by region, with countries like Germany and Saudi Arabia generally having higher labor costs compared to some South American and African nations. Additionally, manufacturing overhead such as utilities, rent, and equipment maintenance contributes to the overall cost.

Tooling expenses for specialized machinery used in producing PU leather furniture must also be considered. While these costs are often amortized over a large number of units, they can significantly impact the initial pricing of smaller orders. Quality Control (QC) is another essential component; implementing rigorous QC processes ensures that the final product meets standards, which can incur additional costs.

Lastly, logistics involves shipping and handling, which can vary based on the distance to the buyer’s location and chosen shipping methods. This is especially pertinent for international buyers, where tariffs and import duties may further influence costs.

Illustrative image related to pu sofa leather

How Do Pricing Influencers Affect PU Sofa Leather Sourcing?

Several factors influence the pricing of PU sofa leather, particularly for international B2B buyers. Volume and Minimum Order Quantity (MOQ) are critical; larger orders generally lead to lower per-unit costs due to economies of scale. Custom specifications can also impact pricing; bespoke designs or unique color options typically incur additional charges.

Materials and their quality play a significant role in pricing. Higher-grade PU leather with certifications (e.g., eco-friendly standards) may cost more but can justify a higher retail price. Supplier factors, such as reputation and reliability, also influence costs; established suppliers may charge a premium for consistent quality and service.

Additionally, Incoterms—the international shipping agreements—can significantly affect overall costs. Buyers should be aware of whether they are responsible for shipping and insurance or if the supplier covers these expenses. Understanding these terms is crucial for accurate cost assessments.

What Are the Best Tips for Buyers Negotiating PU Sofa Leather Prices?

For B2B buyers, effective negotiation strategies can lead to significant cost savings. Start by researching market prices to establish a baseline and leverage this information in discussions with suppliers. Highlighting potential for larger orders can also encourage suppliers to offer better pricing or additional benefits.

Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes ongoing maintenance, durability, and potential resale value. For instance, investing in higher-quality PU leather may result in lower replacement costs over time.

Buyers in regions like Africa and South America should also be mindful of the pricing nuances associated with local economic conditions, such as currency fluctuations and import regulations. Establishing long-term relationships with suppliers can also lead to better terms and pricing over time.

Conclusion: Navigating the Complexities of PU Sofa Leather Sourcing

In conclusion, understanding the comprehensive cost structure and pricing influencers related to PU sofa leather is vital for international B2B buyers. By being informed about the various cost components and employing strategic negotiation tactics, buyers can effectively navigate the complexities of sourcing PU sofa leather while maximizing value and minimizing costs.

Disclaimer: The prices and cost components mentioned in this analysis are indicative and can vary based on market conditions, supplier relationships, and specific project requirements.

Alternatives Analysis: Comparing pu sofa leather With Other Solutions

Exploring Alternative Upholstery Solutions to PU Sofa Leather

In the competitive landscape of furniture manufacturing and retail, selecting the right upholstery material is crucial for meeting customer demands while managing costs. PU leather has gained popularity due to its affordability and ease of maintenance, but there are several alternatives worth considering. This analysis will compare PU sofa leather against PVC leather and bonded leather, providing insights that can aid B2B buyers in making informed decisions.

Illustrative image related to pu sofa leather

| Comparison Aspect | PU Sofa Leather | PVC Leather | Bonded Leather |

|---|---|---|---|

| Performance | Durable and water-resistant | Less durable, prone to cracking | Poor durability, can peel |

| Cost | Moderate | Low | Moderate to high |

| Ease of Implementation | Simple to manufacture | Easy to work with | Requires careful handling |

| Maintenance | Low maintenance, easy to clean | Low maintenance, but can stain | High maintenance, prone to wear |

| Best Use Case | Residential and commercial use | Budget-friendly furniture | Low-cost luxury alternatives |

What Are the Advantages and Disadvantages of PVC Leather?

PVC leather, or vinyl leather, is known for its cost-effectiveness and wide availability. It is often used in low-budget furniture and commercial settings where durability is less critical. While PVC is easy to clean and maintain, it lacks the softness and breathability of PU leather. Over time, PVC leather can become stiff and may crack, especially in high-traffic environments. This makes it less suitable for long-term residential use but a viable option for temporary solutions or budget constraints.

How Does Bonded Leather Compare to PU Leather?

Bonded leather is a blend of genuine leather scraps and polyurethane, designed to provide a more affordable alternative to full-grain leather. While it offers some aesthetic appeal, its performance is often lacking. Bonded leather tends to peel and wear out more quickly than PU leather, making it a less durable option. It is suitable for low-cost luxury items, but buyers should be cautious about its longevity and maintenance requirements. In contrast, PU leather offers better durability and ease of cleaning, making it a more practical choice for both residential and commercial applications.

Conclusion: How Should B2B Buyers Choose the Right Upholstery Material?

When selecting the right upholstery for your furniture products, consider the specific needs of your target market. PU leather stands out for its balance of durability, affordability, and low maintenance, making it suitable for a wide range of applications. In contrast, PVC leather may serve well in budget-conscious scenarios, while bonded leather might appeal to those seeking a temporary luxury aesthetic. Ultimately, understanding your customer base and their expectations will guide you in choosing the most appropriate solution for your business needs, ensuring both satisfaction and profitability.

Essential Technical Properties and Trade Terminology for pu sofa leather

What Are the Key Technical Properties of PU Sofa Leather?

When sourcing PU sofa leather, understanding its technical properties is essential for making informed purchasing decisions. Here are the critical specifications you should consider:

1. Material Composition

PU leather, or polyurethane leather, is composed of a backing fabric—typically cotton or polyester—coated with a layer of polyurethane. This synthetic composition allows PU leather to mimic the appearance of genuine leather while being more affordable. For B2B buyers, knowing the material composition is crucial for assessing durability and maintenance requirements.

2. Thickness

The thickness of PU leather typically ranges from 0.8 to 1.5 mm. A thicker material often indicates greater durability and resistance to wear and tear, making it suitable for high-traffic environments such as offices or commercial spaces. Understanding thickness helps buyers evaluate the longevity of the product and its suitability for specific applications.

3. Weight Capacity

PU leather sofas often have specified weight capacities, commonly ranging from 600 to 800 pounds for three-seat models. This specification is essential for buyers, especially in commercial settings, as it ensures the furniture can accommodate multiple users without compromising safety or stability.

4. Flame Retardancy

Many PU leather products come with flame-retardant properties, which are vital for commercial applications, particularly in hospitality and public spaces. This property not only enhances safety but may also be a regulatory requirement in certain markets, making it a critical consideration for B2B buyers.

Illustrative image related to pu sofa leather

5. Maintenance and Cleaning

PU leather is recognized for its easy maintenance, typically requiring just a damp cloth for cleaning. This property is especially appealing for B2B buyers looking for furniture solutions that minimize upkeep costs and time, making it a practical choice for busy environments.

What Are the Common Trade Terminologies Used in PU Sofa Leather Transactions?

Understanding industry jargon can streamline negotiations and ensure clarity in communications. Here are some essential terms related to PU sofa leather:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are branded by another firm. In the context of PU leather, this may involve manufacturers who create PU leather sofas for retailers under various brand names. Buyers should be aware of OEM relationships to understand quality assurance and brand reputation.

Illustrative image related to pu sofa leather

2. MOQ (Minimum Order Quantity)

MOQ is the minimum amount of product a supplier is willing to sell. For PU leather sofas, MOQs can vary widely depending on the manufacturer. Understanding MOQs is critical for B2B buyers to ensure they meet order requirements while managing inventory effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit pricing and terms from suppliers. In the PU leather market, submitting an RFQ can help businesses compare offers from different manufacturers and negotiate better terms, thereby optimizing purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth logistics when importing PU leather products.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. In the context of PU leather sofas, understanding lead times is crucial for B2B buyers to manage project timelines and ensure that products arrive when needed, particularly for commercial projects with strict deadlines.

By familiarizing yourself with these technical properties and trade terminologies, you can navigate the PU leather market more effectively, ensuring that your sourcing decisions align with your business needs and objectives.

Navigating Market Dynamics and Sourcing Trends in the pu sofa leather Sector

What Are the Current Market Dynamics and Key Trends in the PU Sofa Leather Sector?

The PU sofa leather market is experiencing significant growth, driven by factors such as rising disposable incomes, urbanization, and evolving consumer preferences for affordable yet stylish furniture. In regions like Africa and South America, where the demand for cost-effective furniture solutions is surging, PU leather is increasingly favored due to its lower price point compared to genuine leather. Additionally, the Middle East and Europe, particularly countries like Saudi Arabia and Germany, are witnessing a shift towards modern, minimalist designs that incorporate PU leather for its aesthetic appeal and versatility.

Emerging technologies are also shaping sourcing trends in the PU sofa leather sector. The integration of e-commerce platforms is facilitating easier access for international buyers, enabling them to compare products, prices, and suppliers from various regions. Moreover, advancements in manufacturing processes are enhancing the quality of PU leather, making it a more attractive option for high-traffic environments such as commercial spaces and offices. Buyers are now more informed and demand transparency in the sourcing process, leading to an increased focus on sustainable and ethical practices within the supply chain.

How Important Is Sustainability and Ethical Sourcing in the PU Sofa Leather Industry?

Sustainability and ethical sourcing have become paramount in the PU sofa leather sector, reflecting broader consumer values and regulatory pressures. The environmental impact of synthetic materials, including PU leather, is a growing concern among B2B buyers. Companies are increasingly seeking suppliers that adhere to sustainable practices, such as using eco-friendly production methods and materials. This shift is particularly relevant in Europe and North America, where stringent regulations and consumer demand for sustainability are pushing manufacturers to adopt greener alternatives.

Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® Standard 100 are becoming essential for suppliers aiming to appeal to environmentally-conscious buyers. These certifications assure buyers that the materials used in PU leather production meet specific ecological and safety standards. Additionally, the use of recycled materials in production processes is gaining traction, offering a sustainable alternative that aligns with the global push towards circular economies. B2B buyers are advised to prioritize suppliers who can demonstrate their commitment to ethical sourcing, not only to meet regulatory requirements but also to enhance their brand reputation in a competitive marketplace.

What Is the Evolution of PU Leather and Its Relevance to B2B Buyers?

PU leather, or polyurethane leather, has evolved significantly since its introduction in the mid-20th century as a synthetic alternative to traditional leather. Initially developed to provide a cost-effective solution for upholstery, PU leather has undergone various enhancements in durability, texture, and aesthetics, making it a viable option for modern furniture design.

Today, PU leather is not only popular in residential settings but also extensively used in commercial applications, from office furniture to automotive interiors. Its versatility and ease of maintenance make it an attractive choice for B2B buyers looking to balance quality with affordability. The evolution of PU leather reflects a broader trend towards innovation in materials, catering to the diverse needs of global markets while addressing consumer demands for sustainable and ethical options. Understanding this evolution is crucial for B2B buyers as they navigate their sourcing decisions in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of pu sofa leather

-

How do I determine the quality of PU leather when sourcing sofas?

To assess the quality of PU leather, consider the thickness of the material and the backing fabric used. High-quality PU leather typically has a thicker layer of polyurethane and a sturdy backing made from cotton or polyester. Request samples from suppliers to evaluate texture, durability, and resistance to wear. Additionally, inquire about the manufacturing process and certifications, such as those for sustainability or non-toxic materials, which can indicate a higher standard of quality. -

What are the benefits of sourcing PU leather sofas for my business?

Sourcing PU leather sofas offers several advantages, including cost-effectiveness and ease of maintenance. PU leather is significantly more affordable than genuine leather, making it an attractive option for budget-conscious buyers. It is also easier to clean and maintain, offering durability suitable for high-traffic environments. This material’s versatility allows for a wide range of designs, appealing to diverse customer preferences in various markets. -

What customization options are available when sourcing PU leather sofas?

Most manufacturers provide customization options such as color, size, and design features to meet specific market demands. You can choose from various shades, finishes, and patterns to align with your brand identity. Additionally, inquire about custom dimensions or configurations to cater to unique space requirements. Ensure to communicate your needs clearly during the negotiation process to secure tailored products that resonate with your target audience. -

What are the minimum order quantities (MOQ) for PU leather sofas?

Minimum order quantities for PU leather sofas can vary widely based on the supplier and the complexity of the order. Typically, MOQs can range from 50 to 500 units. When negotiating, consider your inventory needs and market demand to determine a suitable MOQ. Some suppliers may offer flexible terms for first-time buyers or larger orders, so it’s beneficial to discuss your specific situation to explore potential options. -

How can I effectively vet suppliers of PU leather sofas?

To vet suppliers, start by reviewing their reputation and experience in the industry. Check for customer reviews, testimonials, and case studies. Conduct background checks to confirm business legitimacy and adherence to quality standards. Request references from past clients and inquire about their experiences. Additionally, consider visiting manufacturing facilities if possible, as this can provide insight into their production processes and quality control measures. -

What payment terms should I expect when sourcing PU leather sofas internationally?

Payment terms can vary by supplier and region but typically include options such as advance payment, letters of credit, or payment on delivery. Most suppliers require a deposit (often 30% of the total cost) upfront, with the remaining balance due before shipment. It’s essential to negotiate terms that align with your cash flow and risk management strategies. Ensure that all payment details are clearly outlined in the contract to prevent misunderstandings. -

What quality assurance measures should be in place for PU leather sofas?

Quality assurance (QA) measures for PU leather sofas should include thorough inspections at various production stages. Suppliers should conduct tests for durability, colorfastness, and resistance to wear and tear. Request documentation of QA processes, such as inspection reports and compliance with international standards. Consider implementing your own QA checks upon receipt of goods to ensure that products meet your specifications and quality expectations. -

How do I handle logistics and shipping for PU leather sofas?

Logistics for shipping PU leather sofas involve coordinating with freight forwarders and understanding customs regulations in your destination country. Discuss shipping options with your supplier, including shipping methods (air, sea, or land) and estimated delivery times. Ensure you are aware of import duties and taxes that may apply. It’s advisable to have a reliable logistics partner who can manage the complexities of international shipping, ensuring timely and safe delivery of your products.

Top 5 Pu Sofa Leather Manufacturers & Suppliers List

1. COLAMY – 95” PU Leather Sofa

Domain: colamyhome.com

Registered: 2022 (3 years)

Introduction: {“name”:”COLAMY 95” PU Leather Sofa”,”style”:”Modern & Cozy”,”price”:”$1,399.99″,”warranty”:”1 Year Warranty”,”money_back_guarantee”:”30-Day Money-Back Guarantee”,”shipping”:”Free Standard Shipping on All orders”,”additional_info”:”This oversized item requires truck delivery with an additional in-home handling fee (varies by location).”,”color_options”:[“Brown”,”Brown Auburn”,”Chocolate”,”Wolf Gr…

2. Yorkshire Fabric Shop – PU Leather

Domain: yorkshirefabricshop.com

Registered: 2014 (11 years)

Introduction: PU leather is a synthetic leather made from thermoplastic polymers, often used in furniture and shoes. It is considered vegan, does not absorb water, is easy to clean, and does not dry out over time. PU leather sofas are durable, resistant to cracking and fading, and are economical compared to genuine leather. They are available in various colors and styles, making them suitable for different pref…

3. Macy’s – Polyester Polyurethane Chair

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Option 1: Macy’s Polyester Polyurethane – Price: ~$5000, Features: 2 cupholders per chair, functional design, liked by the user for comfort and appearance. Option 2: Top Grain Leather – Price: ~$5000, Features: sold by an independent dealer, praised for quality and comfort by AVS Forum members, single cupholder per seat, bland design, tested in person by the user.

4. A2Z Furniture – Faux Leather Sofas

Domain: thea2zfurniture.com

Registered: 2013 (12 years)

Introduction: Discover Comfort & Style with Our Faux Leather Sofas. Extensive range of designs, colours, and sizes including 2 seater, 3 seater, and modular designs. Available in various colours: brown, tan, black leather, and faux leather. Corner sofa options with side change and size adjustment. Assembly assistance available.

5. Babylon Leather – DIY Bag Kits

Domain: babylonleather.com

Registered: 2021 (4 years)

Introduction: This company, Babylon Leather – DIY Bag Kits, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for pu sofa leather

In the evolving landscape of furniture sourcing, PU leather stands out as a strategic choice for B2B buyers looking to balance quality, cost, and sustainability. This synthetic material not only mimics the aesthetic appeal of genuine leather but also offers superior durability and ease of maintenance, making it ideal for both residential and commercial applications. The affordability of PU leather allows businesses to offer competitive pricing while meeting diverse consumer demands, particularly in growing markets across Africa, South America, the Middle East, and Europe.

As international buyers navigate sourcing options, understanding the nuances of PU leather can enhance product offerings and customer satisfaction. The flexibility in design, coupled with its vegan-friendly status, positions PU leather as a versatile alternative that aligns with modern consumer preferences for ethical purchasing.

Looking ahead, strategic sourcing of PU leather can significantly enhance your product portfolio, enabling you to cater to a wider audience. Embrace this opportunity to innovate and differentiate your offerings in the marketplace. Connect with reliable suppliers and explore the potential of PU leather to elevate your business’s competitive edge. Now is the time to take action and integrate this valuable material into your sourcing strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.