Introduction: Navigating the Global Market for leather fabric material

In today’s competitive landscape, sourcing high-quality leather fabric material poses a significant challenge for B2B buyers across the globe. Whether you’re looking for durable upholstery for luxury furniture or stylish accessories that stand out in the market, understanding the nuances of leather sourcing is crucial. This guide delves deep into the various types of leather fabrics, their diverse applications, and the intricacies of supplier vetting processes.

International buyers from Africa, South America, the Middle East, and Europe—especially in countries like Germany and Brazil—will find actionable insights tailored to their unique needs. We will explore key factors influencing costs, from material quality and processing methods to market trends and regional sourcing opportunities. Additionally, the guide highlights best practices for establishing reliable supplier relationships that ensure consistent quality and timely delivery.

By equipping you with comprehensive knowledge and strategic recommendations, this guide empowers informed purchasing decisions, helping you navigate the complexities of the leather fabric market effectively. Whether you are a seasoned buyer or new to the industry, the insights shared here will enhance your procurement strategy and ultimately lead to successful business outcomes.

Table Of Contents

- Top 6 Leather Fabric Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather fabric material

- Understanding leather fabric material Types and Variations

- Key Industrial Applications of leather fabric material

- 3 Common User Pain Points for ‘leather fabric material’ & Their Solutions

- Strategic Material Selection Guide for leather fabric material

- In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric material’

- Comprehensive Cost and Pricing Analysis for leather fabric material Sourcing

- Alternatives Analysis: Comparing leather fabric material With Other Solutions

- Essential Technical Properties and Trade Terminology for leather fabric material

- Navigating Market Dynamics and Sourcing Trends in the leather fabric material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric material

- Strategic Sourcing Conclusion and Outlook for leather fabric material

- Important Disclaimer & Terms of Use

Understanding leather fabric material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

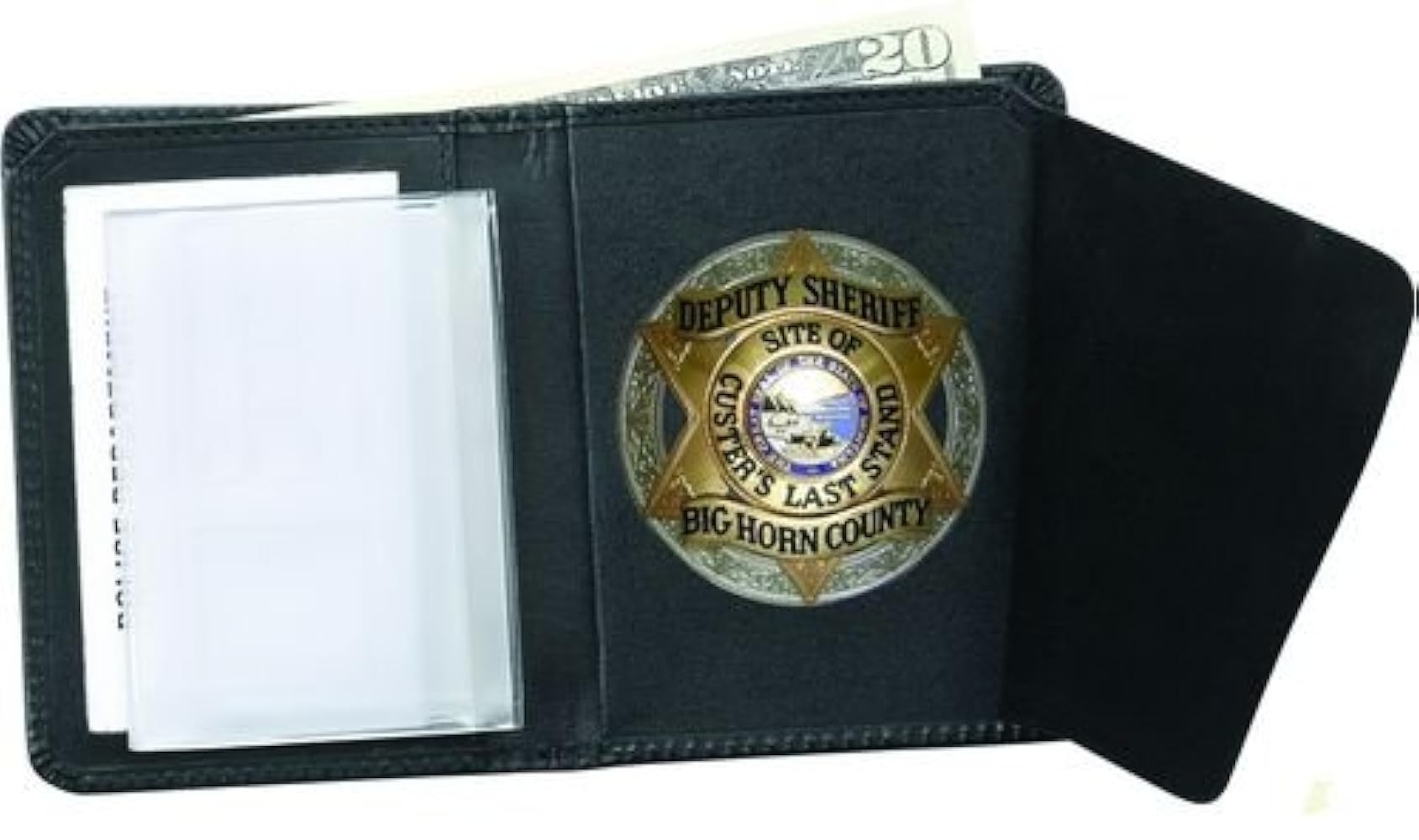

| Full-Grain Leather | Retains natural grain, highly durable | High-end furniture, luxury apparel, automotive | Pros: Exceptional durability, develops a patina. Cons: Higher cost, requires maintenance. |

| Top-Grain Leather | Sanded to remove imperfections, more uniform | Fashion accessories, upholstery, wallets | Pros: Softer than full-grain, easier to work with. Cons: Less durable than full-grain. |

| Suede | Soft, napped finish, less durable | Apparel, footwear, upholstery | Pros: Luxurious feel, lightweight. Cons: Prone to stains, requires special care. |

| Nubuck | Sanded top layer of full-grain leather | High-end footwear, jackets, furniture | Pros: Soft texture, water-resistant options. Cons: More expensive, sensitive to scratches. |

| Faux Leather | Synthetic alternative, varied textures | Budget-friendly apparel, furniture, automotive | Pros: Cost-effective, animal-friendly. Cons: Less durable, may not have the same aesthetic appeal. |

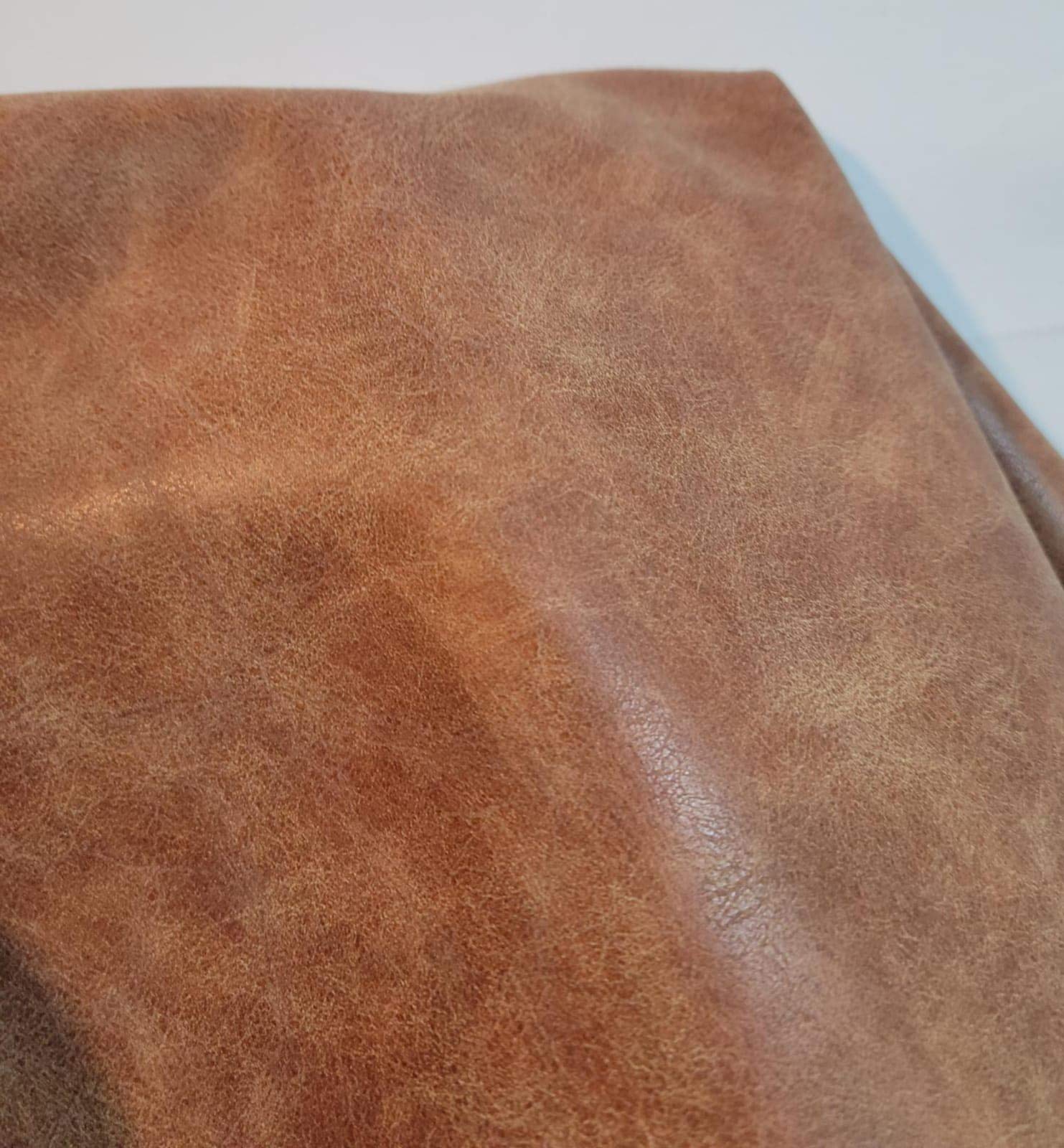

What are the characteristics and suitability of Full-Grain Leather for B2B applications?

Full-grain leather is considered the highest quality leather due to its natural grain and durability. It retains the original texture and imperfections of the animal hide, which gives it a unique character. This type is suitable for high-end furniture, luxury apparel, and automotive interiors, as it ages beautifully and develops a rich patina over time. B2B buyers should consider the long-term investment aspect, as while full-grain leather has a higher upfront cost, its longevity and durability can lead to cost savings in maintenance and replacement.

How does Top-Grain Leather compare for B2B buyers?

Top-grain leather is the second-highest quality, characterized by a sanded surface that offers a more uniform appearance. It is softer and more pliable than full-grain leather, making it ideal for fashion accessories, upholstery, and wallets. B2B buyers may find it appealing due to its balance of quality and price, as it is generally more affordable than full-grain while still providing a luxurious look and feel. However, it is important to note that it may not be as durable, making it less suitable for heavy-duty applications.

Why is Suede a popular choice for certain applications?

Suede features a soft, napped finish and is primarily derived from the underside of animal hides. It is often used in apparel, footwear, and upholstery, providing a luxurious and lightweight option. B2B buyers should be aware that while suede offers a unique aesthetic, it is less durable and more prone to staining compared to other leather types. Thus, it is best suited for fashion items or low-traffic applications where the luxurious feel can be prioritized over durability.

Illustrative image related to leather fabric material

What makes Nubuck a premium option for specialized products?

Nubuck leather is created by sanding the outer layer of full-grain leather, resulting in a soft, velvety texture. It is commonly used in high-end footwear, jackets, and furniture. Nubuck can be treated to be water-resistant, which enhances its appeal for outdoor and fashion applications. B2B buyers should consider its premium price point and the need for careful handling, as it can be more susceptible to scratches and stains compared to other leather types.

How does Faux Leather serve budget-conscious buyers?

Faux leather, a synthetic alternative, offers a variety of textures and finishes that mimic traditional leather. It is particularly popular in budget-friendly apparel, furniture, and automotive applications. For B2B buyers, faux leather presents a cost-effective option without compromising aesthetic appeal. However, it is essential to consider that while it is animal-friendly and easy to clean, faux leather generally lacks the durability and longevity of genuine leather products, making it less suitable for high-wear applications.

Key Industrial Applications of leather fabric material

| Industry/Sector | Specific Application of leather fabric material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | High-end clothing, jackets, and accessories | Enhances brand prestige and customer loyalty | Sourcing sustainable leather; ensuring compliance with local regulations regarding animal welfare. |

| Automotive | Upholstery for car interiors | Durability and aesthetic appeal; high resale value | Assessing material resistance to wear and tear; customization options for color and texture. |

| Furniture & Interiors | Upholstery for sofas, chairs, and décor items | Long-lasting quality; easy maintenance | Evaluating fire resistance and stain-proof treatments; ensuring ethical sourcing practices. |

| Sports Equipment | Production of sports gear like gloves and balls | Performance enhancement; brand differentiation | Seeking lightweight yet durable options; adherence to international sports standards. |

| Footwear | Manufacturing of shoes and boots | Comfort and longevity; premium market positioning | Understanding regional preferences for style and fit; ensuring waterproofing and breathability features. |

How is Leather Fabric Material Used in the Fashion & Apparel Industry?

In the fashion and apparel industry, leather fabric is extensively used for crafting high-end clothing, jackets, and accessories. Its unique texture and luxurious appearance enhance brand prestige, attracting discerning customers willing to pay a premium. Buyers in this sector must prioritize sourcing sustainable leather options, as consumers increasingly demand ethical practices. Compliance with local regulations regarding animal welfare is crucial, particularly for international buyers from regions like Europe, where standards may vary significantly.

Illustrative image related to leather fabric material

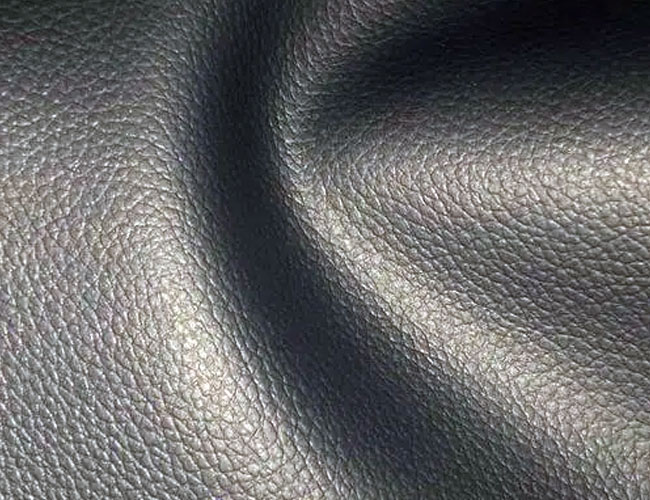

What Role Does Leather Fabric Play in Automotive Upholstery?

Leather fabric is a popular choice for automotive upholstery, providing both durability and aesthetic appeal. It elevates the overall look of car interiors while offering a comfortable experience for passengers. Additionally, vehicles with leather interiors often command higher resale values. When sourcing leather for automotive applications, businesses should focus on material resistance to wear and tear, as well as customization options that align with consumer preferences for color and texture.

How is Leather Fabric Utilized in Furniture and Interior Design?

In the furniture and interiors sector, leather fabric is favored for upholstery on sofas, chairs, and decorative items due to its long-lasting quality and ease of maintenance. The fabric’s ability to resist wear makes it ideal for high-traffic areas. Buyers must evaluate the fire resistance and stain-proof treatments of the leather, especially in commercial settings. Additionally, businesses should ensure ethical sourcing practices to align with consumer expectations for responsible manufacturing.

What is the Importance of Leather in Sports Equipment Production?

Leather fabric is integral to the production of sports equipment, such as gloves and balls, due to its performance-enhancing qualities. It provides the necessary grip and durability required for high-impact activities, helping brands differentiate their products in a competitive market. Buyers should seek lightweight yet durable options that meet international sports standards, ensuring that the products can withstand rigorous use. Understanding regional preferences for equipment design is also essential for successful sourcing.

How is Leather Fabric Applied in Footwear Manufacturing?

In footwear manufacturing, leather is a preferred material for creating shoes and boots that offer both comfort and longevity. Its natural properties allow for breathability while providing a premium feel that appeals to consumers. When sourcing leather for footwear, businesses need to comprehend regional preferences regarding style and fit, as these can differ significantly across markets. Additionally, ensuring that the leather has waterproofing and breathability features can enhance product performance and customer satisfaction.

3 Common User Pain Points for ‘leather fabric material’ & Their Solutions

Scenario 1: Sourcing Quality Leather Fabric Amidst Inconsistent Standards

The Problem: B2B buyers often struggle to find reliable sources for leather fabric that meet their quality standards. With varying grading systems and quality assessments, it becomes challenging to ensure that the leather they purchase is durable and suitable for their specific applications, such as upholstery or fashion. This inconsistency can lead to wasted investments in subpar materials that do not meet customer expectations or industry standards.

The Solution: To mitigate this issue, buyers should establish a robust vendor evaluation process that includes sampling and testing before placing bulk orders. Collaborate with suppliers who provide detailed information on the tanning process, material composition, and quality certifications. Request physical samples to assess texture, durability, and finish before finalizing your supplier. Additionally, it can be beneficial to develop long-term relationships with a select group of trusted suppliers who can consistently deliver high-quality leather. Consider implementing a quality assurance protocol that includes periodic audits of your suppliers to ensure they adhere to agreed-upon standards.

Scenario 2: Navigating Environmental Concerns in Leather Production

The Problem: As global awareness of environmental issues grows, B2B buyers face pressure to source leather materials that are sustainably produced. Traditional tanning processes can involve toxic chemicals that are harmful to the environment. This can lead to reputational risks for businesses that do not prioritize sustainable sourcing, especially in markets that increasingly demand eco-friendly products.

The Solution: To address this challenge, buyers should prioritize sourcing leather from suppliers who use environmentally friendly tanning processes, such as vegetable tanning or chrome-free methods. Engage with suppliers who can provide transparency in their production processes and certifications that demonstrate their commitment to sustainability. Additionally, consider leveraging alternative materials, such as bio-based or synthetic leathers, which can offer similar aesthetics and functionality without the environmental impact. By promoting and using sustainable leather options, businesses can not only meet regulatory requirements but also enhance their brand image and appeal to environmentally-conscious consumers.

Scenario 3: Overcoming Misconceptions About Leather Maintenance

The Problem: Many buyers, particularly those new to working with leather, may have misconceptions regarding the maintenance and care of leather products. These misunderstandings can lead to improper usage, resulting in premature wear and tear of the leather, impacting the overall quality and longevity of the products made from it.

The Solution: It is crucial to provide comprehensive education and resources on leather care and maintenance to your teams and end-users. Develop training materials that outline best practices for cleaning, conditioning, and protecting leather products. Collaborate with suppliers to distribute care kits that include the right cleaning agents and tools. Additionally, consider offering workshops or webinars that demonstrate proper leather maintenance techniques. By investing in education, you not only prolong the life of your leather products but also enhance customer satisfaction and loyalty, ultimately driving repeat business.

Strategic Material Selection Guide for leather fabric material

What Are the Key Properties of Different Leather Fabric Materials?

When selecting leather fabric materials for various applications, it’s crucial to understand the properties and performance characteristics of each type. Here, we analyze four common materials: genuine leather, synthetic leather, suede, and nubuck. Each material has unique properties that influence its suitability for specific applications, especially in international markets.

Genuine Leather: What Are Its Advantages and Limitations?

Genuine leather, sourced from animal hides, is known for its durability and natural aesthetic appeal. It offers excellent temperature regulation, making it suitable for apparel and upholstery. Its resistance to wear and tear is a significant advantage, particularly in high-traffic applications like furniture and automotive interiors.

However, genuine leather can be expensive and requires careful maintenance to prevent damage from moisture and UV exposure. Additionally, compliance with animal welfare regulations and environmental standards can pose challenges for international buyers, particularly in regions with strict regulations like Europe.

Synthetic Leather: How Does It Compare to Genuine Leather?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to genuine leather. It is lightweight, easy to clean, and resistant to stains, making it ideal for various applications, including fashion and automotive upholstery. Synthetic leather also tends to have better water resistance compared to genuine leather.

On the downside, synthetic leather may not offer the same level of breathability and durability as genuine leather. Additionally, international buyers should be aware of the environmental impact of synthetic materials, as some may not comply with sustainability standards.

Illustrative image related to leather fabric material

Suede: What Are Its Unique Characteristics?

Suede, a type of leather with a napped finish, is celebrated for its softness and luxurious feel. It is commonly used in fashion items such as jackets, shoes, and accessories. Suede provides a unique aesthetic that appeals to high-end markets.

However, suede is less durable than genuine leather and is more susceptible to stains and water damage. Buyers must consider the specific care requirements and potential limitations in outdoor applications. For international buyers, understanding the market demand for suede products in their region is essential, as preferences can vary significantly.

Nubuck: What Should Buyers Know About This Material?

Nubuck is similar to suede but is made from the outer layer of the hide, giving it a more robust structure. It offers a luxurious appearance and is often used in premium products such as high-end footwear and furniture. Nubuck is known for its durability and resistance to wear.

Despite its advantages, nubuck requires special care to maintain its appearance and is vulnerable to staining. International buyers should be aware of the specific cleaning and maintenance products required for nubuck, as well as any regional preferences for this material.

Summary Table of Leather Fabric Materials

| Material | Typical Use Case for leather fabric material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end apparel, furniture upholstery | Exceptional durability and aesthetics | High cost, requires maintenance | High |

| Synthetic Leather | Fashion accessories, automotive interiors | Cost-effective, easy to clean | Less breathable, environmental concerns | Medium |

| Suede | Fashion items, luxury accessories | Soft texture and luxurious feel | Less durable, susceptible to stains | Medium |

| Nubuck | Premium footwear, upscale furniture | Luxurious appearance and durability | Requires special care, vulnerable to staining | High |

This guide provides a comprehensive overview of various leather fabric materials, highlighting their properties, advantages, and limitations. Understanding these factors is essential for international B2B buyers aiming to make informed decisions that align with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric material

What Are the Main Stages in the Manufacturing Process of Leather Fabric Material?

The manufacturing of leather fabric material involves several critical stages that ensure the final product meets the desired quality and functionality. Here’s a breakdown of these stages:

-

Material Preparation

This initial stage involves sourcing raw animal hides or synthetic alternatives. The selection of high-quality hides is crucial, as it directly affects the final product’s durability and appearance. The hides undergo a cleaning process to remove any impurities, followed by soaking to restore moisture. For synthetic leather, the raw materials are often made from polyurethane or polyvinyl chloride (PVC), which are selected based on the end use. -

Tanning

Tanning is the process that converts raw hides into leather, making them durable and less susceptible to decomposition. There are several tanning methods, including chrome tanning, vegetable tanning, and synthetic tanning. Chrome tanning is the most common due to its efficiency and ability to produce soft leather quickly. In contrast, vegetable tanning, which uses natural tannins from plants, results in a firmer, more environmentally friendly product. Each method imparts distinct characteristics to the leather, influencing factors such as color, texture, and flexibility. -

Forming

After tanning, the leather is shaped into the desired form. This may involve cutting the leather into specific patterns for garments, upholstery, or accessories. Advanced techniques like die-cutting and laser cutting are often employed to achieve precision in these shapes. For synthetic leather, this stage may also include applying coatings or finishes to enhance aesthetics and performance, such as adding a texture or color. -

Finishing

The finishing stage enhances the leather’s appearance and performance characteristics. This may include processes such as dyeing, coating, and polishing. Finishing treatments can make leather water-resistant, UV-resistant, or impart specific textures. The final appearance can range from matte to high-gloss, depending on the intended application. Quality control during this stage is essential to ensure uniformity and adherence to color standards.

What Quality Assurance Practices Are Essential for Leather Fabric Material?

Quality assurance in leather manufacturing is paramount to ensure that the final products meet international standards and customer expectations. Here are key practices and standards relevant to the leather industry:

-

International Standards and Certifications

Compliance with international quality standards, such as ISO 9001, ensures systematic management of quality throughout the production process. This standard focuses on continuous improvement and customer satisfaction. Additionally, certain leather products may require compliance with specific industry standards, such as CE marking for European markets, which signifies that the product meets health, safety, and environmental protection standards. -

Quality Control Checkpoints

Quality control is integral at various stages of the manufacturing process. The typical checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the specified criteria. Any non-conforming materials are rejected or returned.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and identify defects early. This can include checking the tanning process, verifying the thickness of the leather, and ensuring correct dye application.

-

Final Quality Control (FQC): Before shipping, a comprehensive final inspection is performed. This includes checking for defects, consistency in color and texture, and overall finish quality. Samples may be tested for durability, flexibility, and resistance to wear and tear.

- Common Testing Methods for Leather Fabric

To ensure that leather products meet quality standards, various testing methods are employed, including:

- Physical Tests: These evaluate the leather’s tensile strength, tear resistance, and abrasion resistance.

- Chemical Tests: These assess the leather’s pH levels, color fastness, and the presence of harmful substances, ensuring compliance with regulations like REACH in the EU.

- Environmental Tests: These determine the leather’s resistance to environmental factors such as moisture and UV exposure.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those sourcing leather fabric from international suppliers, verifying quality control practices is crucial to ensuring product reliability. Here are actionable steps buyers can take:

-

Conduct Supplier Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards. Buyers should look for suppliers who maintain transparent practices and are willing to share audit results. -

Request Quality Assurance Documentation

Suppliers should provide documentation that details their quality assurance processes, including records of inspections and test results. This documentation can help buyers understand how quality is maintained throughout the manufacturing process. -

Engage Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These services can conduct on-site inspections and testing, ensuring that products meet specified standards before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances in quality control and certification that may affect their sourcing decisions. For instance:

Illustrative image related to leather fabric material

-

Regional Compliance Requirements

Different regions may have varying standards for leather products. For example, European buyers must ensure compliance with CE marking, while buyers in the Middle East may focus on standards set by local authorities. Understanding these regional requirements can prevent costly compliance issues. -

Cultural and Economic Factors

Economic conditions in sourcing countries may affect quality control practices. Buyers should consider the local industry’s maturity and the supplier’s reputation in the market. Engaging with local trade associations can provide additional insights into reliable suppliers. -

Sustainability and Ethical Sourcing

Increasingly, buyers are prioritizing sustainability in their sourcing decisions. Suppliers who can demonstrate adherence to sustainable practices, such as eco-friendly tanning processes and ethical sourcing of raw materials, may provide a competitive advantage.

By understanding the manufacturing processes and quality assurance practices involved in leather fabric production, B2B buyers can make informed decisions, ensuring that they source high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric material’

Introduction

Sourcing high-quality leather fabric material is essential for businesses in various industries, including fashion, upholstery, and automotive. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select the right suppliers and products that meet your business needs.

Step 1: Define Your Technical Specifications

Before starting your search for leather fabric, clearly outline your technical requirements. Consider factors such as thickness, texture, finish, and color.

– Application-specific needs: Identify the intended use—apparel, upholstery, or accessories—as this will influence your specifications.

– Regulatory compliance: Ensure that your specifications align with any industry regulations, such as sustainability standards or safety requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in leather fabric. Look for companies with a strong market presence and positive customer feedback.

– Industry reputation: Utilize online platforms, trade fairs, and industry publications to gather information about suppliers.

– Geographic considerations: Factor in suppliers’ locations, especially if you are sourcing from regions like Africa or South America, as logistics can impact lead times and costs.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is crucial in ensuring product quality and compliance with industry standards. Check for certifications like ISO or environmental credentials.

– Quality assurance: Certifications can indicate adherence to quality management systems, which is vital for maintaining product consistency.

– Sustainability focus: Look for suppliers committed to environmentally friendly practices, as this can enhance your brand’s reputation.

Step 4: Request Samples for Quality Assessment

Always request samples before placing a bulk order. Evaluating physical samples allows you to assess the leather’s quality, texture, and durability firsthand.

– Testing durability: Check for resistance to wear and tear, as well as water resistance if applicable to your use case.

– Color matching: Ensure the sample matches your desired color specifications to avoid discrepancies in the final product.

Step 5: Negotiate Pricing and Terms

Once you have narrowed down your suppliers, engage in negotiations to secure favorable pricing and terms.

– Volume discounts: Discuss bulk purchasing options, as many suppliers offer discounts for larger orders.

– Payment terms: Clarify payment methods and terms, ensuring they align with your cash flow requirements.

Illustrative image related to leather fabric material

Step 6: Establish Clear Communication Channels

Effective communication with your supplier is key to a successful partnership. Set up clear channels for ongoing dialogue throughout the sourcing process.

– Regular updates: Schedule periodic check-ins to discuss production timelines and address any concerns.

– Cultural sensitivity: Be aware of cultural differences in communication styles, especially when working with international suppliers.

Step 7: Finalize Your Order and Confirm Delivery

After finalizing terms and specifications, place your order and confirm delivery timelines. Ensure all details are documented to avoid misunderstandings.

– Documentation: Request written confirmation of your order, including specifications and delivery dates.

– Logistics planning: Coordinate shipping and handling to ensure timely delivery, factoring in potential customs delays for international shipments.

By following these steps, B2B buyers can streamline their sourcing process for leather fabric material, ensuring they obtain high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for leather fabric material Sourcing

What Are the Key Cost Components in Leather Fabric Material Sourcing?

When sourcing leather fabric material, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of raw leather or synthetic alternatives represents a significant portion of the overall expense. Factors such as sourcing location and quality impact pricing. For instance, high-quality, full-grain leather is generally more expensive than lower-grade options.

-

Labor: Labor costs can vary significantly based on the manufacturing region. Countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality. Skilled artisans are essential for crafting premium leather goods, which can increase labor costs.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, equipment maintenance, and facility costs. High-quality manufacturers tend to have higher overhead due to advanced machinery and better working conditions.

-

Tooling: Custom tooling for leather goods can add to costs, especially for specialized designs or intricate patterns. This upfront investment is crucial for ensuring that the final product meets specific buyer requirements.

-

Quality Control (QC): Implementing stringent QC measures is vital to ensure that the leather meets industry standards and buyer specifications. Effective QC processes, while adding to costs, can prevent costly returns and dissatisfaction.

-

Logistics: Shipping costs, including freight charges and insurance, can vary based on the supplier’s location and chosen Incoterms. Buyers should consider the logistics involved in transporting leather from the manufacturer to their location, as this can significantly affect the total cost.

-

Margin: Suppliers typically add a profit margin to cover their expenses and risks. Understanding the margin expectations can provide insight into negotiation opportunities.

How Do Price Influencers Affect Leather Fabric Sourcing Costs?

Various factors can influence the pricing of leather fabric materials, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to better pricing due to economies of scale. Buyers should assess their needs to negotiate favorable terms based on their purchasing capacity.

-

Specifications and Customization: Custom designs or specific finishes can increase costs. Buyers should weigh the benefits of customization against potential price hikes.

-

Material Quality and Certifications: Leather sourced from reputable suppliers with certifications (e.g., eco-friendly practices) may command higher prices. However, these investments often translate into better durability and marketability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer higher quality but at a premium. Conducting due diligence can help in selecting the right partner.

-

Incoterms: Understanding Incoterms is essential for determining who bears the costs and risks during shipping. This knowledge can prevent unexpected expenses and facilitate smoother transactions.

What Are Effective Buyer Tips for Negotiating Leather Fabric Prices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings. Here are key strategies:

-

Research and Compare: Conduct thorough market research to understand average prices and competitors. This knowledge equips buyers to negotiate more effectively.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with quality, durability, and maintenance. Investing in higher-quality leather may reduce TCO over time.

-

Be Clear on Specifications: Clearly outline specifications and expectations to avoid miscommunication, which can lead to unexpected costs.

-

Leverage Relationships: Building strong relationships with suppliers can facilitate better pricing and terms. Regular communication and trust can lead to more favorable negotiations.

-

Flexibility in Terms: Being open to various payment and delivery terms can enhance negotiation leverage. For instance, agreeing to larger orders or longer lead times may yield discounts.

Conclusion: Why Understanding Pricing Nuances is Crucial for International Buyers

Navigating the complexities of leather fabric material sourcing requires a comprehensive understanding of cost structures and pricing influences. By being well-informed and strategic in negotiations, international buyers can optimize their sourcing efforts, ensuring they obtain high-quality materials at competitive prices. Always keep in mind that prices may vary significantly based on numerous factors, so obtaining multiple quotes and assessing the total cost of ownership will be invaluable in making informed purchasing decisions.

Alternatives Analysis: Comparing leather fabric material With Other Solutions

Exploring Alternatives to Leather Fabric Material

In the competitive landscape of material sourcing, international B2B buyers often seek alternatives to leather fabric that can deliver similar functionality, aesthetics, and durability. This analysis compares leather fabric material against two viable alternatives: synthetic leather (often referred to as vegan leather) and high-performance textiles like polyester. Each option presents unique advantages and challenges that can influence decision-making in various industries, including fashion, automotive, and furniture.

| Comparison Aspect | Leather Fabric Material | Synthetic Leather (Vegan Leather) | High-Performance Textiles (Polyester) |

|---|---|---|---|

| Performance | Durable, breathable, and thermal-regulating; ages well with time | Water-resistant, often less durable than leather; can vary in quality | Highly durable, resistant to wear and tear; moisture-wicking capabilities |

| Cost | Generally higher due to sourcing and processing of animal skins | Typically lower than genuine leather, but varies by brand | Usually lower cost, especially for bulk purchases |

| Ease of Implementation | Requires specialized skills for cutting and sewing | Easier to handle; can be cut and sewn like traditional fabrics | Simple to work with; can be mass-produced easily |

| Maintenance | Requires regular conditioning and care; can be prone to staining | Low maintenance; easy to clean and often stain-resistant | Easy to maintain; machine washable and quick-drying |

| Best Use Case | High-end fashion, luxury upholstery, durable accessories | Fashion items, casual wear, and budget-friendly products | Activewear, outdoor gear, and furniture |

Pros and Cons of Synthetic Leather

Synthetic leather, or vegan leather, is crafted from various materials, including polyurethane and PVC. One of its significant advantages is its lower cost compared to genuine leather, making it a popular choice for budget-conscious brands. Additionally, synthetic leather is often easier to maintain, requiring less care and being more resistant to stains. However, it typically lacks the same durability and luxurious feel as leather, which may impact its suitability for high-end applications.

Pros and Cons of High-Performance Textiles

High-performance textiles, such as polyester, offer exceptional durability and resistance to wear and tear, making them ideal for activewear and outdoor gear. These materials can be engineered to be moisture-wicking and quick-drying, providing excellent functionality in various environments. The cost-effectiveness of polyester is also a significant benefit, especially for bulk orders. However, it may not deliver the same aesthetic appeal and tactile experience as leather, which can be a disadvantage in luxury markets.

Illustrative image related to leather fabric material

How to Choose the Right Material for Your Business Needs

When selecting between leather fabric material and its alternatives, B2B buyers should consider their target market and specific application requirements. For luxury products that demand durability and aesthetic appeal, leather remains a top choice. Conversely, if cost and ease of maintenance are primary concerns, synthetic leather or high-performance textiles may be more suitable. Understanding the unique properties and market positioning of each material will empower businesses to make informed decisions that align with their brand values and consumer expectations.

Essential Technical Properties and Trade Terminology for leather fabric material

What Are the Key Technical Properties of Leather Fabric Material for B2B Buyers?

Understanding the essential technical properties of leather fabric is crucial for B2B buyers looking to make informed purchasing decisions. Here are several critical specifications to consider:

1. Material Grade

Material grade refers to the classification of leather based on its quality and source. Grades typically range from full-grain, which retains the natural surface and imperfections of the hide, to corrected-grain leather, which has been sanded and treated to remove blemishes. B2B buyers should prioritize higher grades for applications requiring durability and aesthetics, such as luxury goods or high-performance upholstery.

Illustrative image related to leather fabric material

2. Tolerance

Tolerance in leather manufacturing indicates the acceptable variations in thickness, width, and other dimensions of the fabric. Precise tolerances are vital for ensuring consistent quality and fit in production. For example, a tolerance of ±1mm in thickness can significantly affect the end product’s performance and appearance. B2B buyers must ensure their suppliers adhere to strict tolerances to minimize waste and rework.

3. Treatment and Finish

The treatment and finish of leather refer to the processes applied to enhance its properties, such as water resistance, flame retardance, or UV protection. For instance, leather can be treated to be water-repellent, making it suitable for outdoor applications. Buyers should clarify the type of treatment used, as this can impact both functionality and pricing.

4. Grain Pattern

The grain pattern of leather affects its texture, appearance, and usability. Common patterns include smooth, pebbled, and embossed. Each pattern has different applications; for example, smooth leather is often used in high-end fashion, while pebbled leather is favored for durability in luggage and accessories. Understanding grain patterns helps buyers select the right leather for their specific needs.

5. Weight

Weight, measured in ounces per square yard, directly impacts the leather’s application. Lighter weights are suitable for garments, while heavier weights are preferred for upholstery and industrial applications. Buyers should consider the intended use of the leather to select the appropriate weight, balancing durability and flexibility.

6. Breathability

Breathability refers to the leather’s ability to allow moisture and air to pass through. This property is essential for garments and footwear, where comfort is a priority. Leather with good breathability can prevent overheating and moisture buildup, enhancing user experience. B2B buyers should inquire about breathability ratings when sourcing leather for apparel.

Illustrative image related to leather fabric material

What Are Common Trade Terms Used in the Leather Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the leather fabric market. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end products. In the leather industry, this term is relevant when discussing custom leather goods designed for brands looking to outsource production. Understanding OEM relationships can help buyers identify reliable manufacturing partners.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. This term is essential for buyers looking to compare costs across multiple suppliers. Crafting a detailed RFQ can lead to more accurate and competitive pricing.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers involved in cross-border trade, as they clarify liability and costs associated with logistics.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. This term is critical for B2B buyers planning production schedules. Understanding lead times helps businesses align their supply chains effectively and avoid disruptions.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing leather fabric, ensuring they meet their quality, cost, and delivery requirements.

Navigating Market Dynamics and Sourcing Trends in the leather fabric material Sector

What Are the Current Market Dynamics and Key Trends in the Leather Fabric Sector?

The leather fabric material market is experiencing a transformative phase driven by various global factors. The demand for high-quality leather in sectors such as fashion, automotive, and furniture is consistently increasing, particularly in emerging markets across Africa, South America, the Middle East, and Europe. This demand is fueled by a rising middle class with disposable income and a growing preference for luxury goods. Additionally, the integration of advanced technologies, such as AI and IoT, in the manufacturing process is enhancing quality control and production efficiency, making it easier for international B2B buyers to source leather products that meet their specific needs.

Emerging trends also highlight a shift towards customization and personalization. Buyers are increasingly seeking unique leather products tailored to their specifications, which is facilitated by advancements in digital printing and on-demand manufacturing. Moreover, the rise of e-commerce platforms has made sourcing more accessible, allowing businesses to connect with suppliers globally while benefiting from competitive pricing. This dynamic landscape requires B2B buyers to stay informed about market fluctuations, consumer preferences, and the technological innovations shaping the leather fabric sector.

Illustrative image related to leather fabric material

How Is Sustainability Influencing Leather Fabric Sourcing in B2B Markets?

Sustainability and ethical sourcing have become paramount in the leather fabric sector, reflecting the growing consumer awareness regarding environmental impact. Traditional leather production is often criticized for its resource-intensive processes and ecological footprint. Consequently, B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices, such as using vegetable tanning methods, which minimize harmful chemicals, and sourcing from farms that adhere to ethical treatment of livestock.

The importance of certifications cannot be overstated. Green certifications, such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification, signal a commitment to sustainability and ethical sourcing. Buyers seeking to enhance their brand reputation and align with consumer values should consider partnerships with suppliers holding these certifications. By doing so, they not only support environmentally friendly practices but also tap into a growing market segment that values sustainability, thereby enhancing their competitive edge.

What Is the Historical Context of Leather Fabric in the B2B Landscape?

The history of leather fabric dates back thousands of years, with its use initially stemming from the need for durable clothing and shelter. Over time, leather became synonymous with luxury, evolving into a symbol of status and sophistication across various cultures. In the B2B context, leather has consistently been a sought-after material for high-end products, from bespoke footwear to premium automotive interiors.

The industrial revolution marked a significant turning point, introducing mechanized tanning processes that increased production capacity and accessibility. Today, the leather market has diversified significantly, with the emergence of synthetic alternatives and eco-friendly materials challenging traditional leather. However, genuine leather remains a staple due to its unique properties, durability, and aesthetic appeal, ensuring its continued relevance in the B2B sector. Understanding this evolution aids international buyers in making informed sourcing decisions that align with current market demands and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric material

-

How do I select the right leather fabric for my business needs?

When choosing leather fabric, consider the application and desired characteristics. Different types of leather, such as full-grain, top-grain, and bonded leather, offer varying durability, aesthetics, and cost. Assess the texture, thickness, and finish of the leather to ensure it meets your product requirements. Additionally, inquire about the tanning process, as this affects the leather’s environmental impact and longevity. Finally, request samples to evaluate the quality and feel before making a bulk purchase. -

What are the key factors to consider when vetting leather suppliers?

When vetting suppliers, prioritize their reputation, production capabilities, and compliance with international quality standards. Research their experience in the leather industry and seek reviews or testimonials from previous clients. Ensure they provide transparency regarding sourcing practices, tanning processes, and environmental certifications. Additionally, assess their capacity for customization and flexibility in order quantities, as well as their responsiveness to inquiries, which is crucial for building a reliable partnership. -

What are the typical minimum order quantities (MOQs) for leather fabric?

Minimum order quantities for leather fabric can vary significantly depending on the supplier and the type of leather. Generally, MOQs range from 50 to 500 yards for standard materials, but custom orders may require higher quantities. It’s essential to communicate your specific needs with potential suppliers to determine their MOQs and negotiate terms that align with your business model. Smaller businesses may benefit from suppliers who offer flexibility or bulk purchasing options to optimize inventory management. -

What payment terms should I expect when purchasing leather fabric internationally?

Payment terms for international leather fabric purchases typically include options like upfront payment, partial payment, or credit terms, depending on the supplier’s policies. Common methods of payment include wire transfers, letters of credit, or online payment platforms. Discuss and negotiate these terms upfront to establish a clear understanding and avoid any complications during the transaction. Additionally, consider using an escrow service for larger orders to ensure funds are released only upon successful delivery. -

How can I ensure quality assurance (QA) when sourcing leather fabric?

To ensure quality assurance, establish a clear set of specifications and standards for the leather you are sourcing. Request samples before placing bulk orders, and consider third-party inspections to verify the quality and compliance with your requirements. Communicate your expectations regarding defects, color matching, and texture consistency. Additionally, inquire about the supplier’s QA processes and certifications, which can provide further assurance of their commitment to quality. -

What logistics should I consider when importing leather fabric?

When importing leather fabric, consider the shipping methods, lead times, and customs regulations applicable to your region. Choose between air freight for faster delivery or sea freight for cost efficiency, depending on your urgency and budget. Ensure that the supplier provides all necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate customs clearance. Finally, factor in additional costs such as tariffs, taxes, and insurance to calculate the total landed cost of the fabric. -

What are the environmental considerations in sourcing leather fabric?

Environmental considerations are crucial in sourcing leather fabric. Look for suppliers that practice sustainable sourcing and adhere to eco-friendly tanning processes, such as vegetable tanning, which minimizes harmful chemicals. Certifications like the Leather Working Group (LWG) can indicate a supplier’s commitment to environmental responsibility. Additionally, inquire about waste management practices and the supplier’s overall carbon footprint to align your sourcing decisions with sustainable business practices. -

How can I customize leather fabric to meet my specific needs?

Customization options for leather fabric can include variations in color, texture, thickness, and finish. Many suppliers offer bespoke services, allowing you to create unique designs tailored to your brand. When discussing customization, provide detailed specifications and samples of desired qualities. Be aware that customization may require longer lead times and higher MOQs, so plan accordingly. Establish a collaborative relationship with your supplier to ensure the final product aligns with your vision and requirements.

Top 6 Leather Fabric Material Manufacturers & Suppliers List

1. Fabric Wholesale Direct – Leather Fabrics

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Leather Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Mood Fabrics – Genuine Leather by the Yard

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: Buy Leather Fabric by the Yard | Genuine Leather Material

3. Rub ‘n Restore® – Leather Restoration Solutions

Domain: rubnrestore.com

Registered: 2010 (15 years)

Introduction: Different types of leather include:

1. Full Grain Leather: Finest quality, fully intact hide, absorbent, can be aniline or semi-aniline, safe for Rub ‘n Restore®.

2. Top Grain Leather: Second best grade, sanded or buffed for uniform appearance, repels liquids, often thinner and more flexible.

3. Aniline & Semi-Aniline Leather: Full or top grain, marbled appearance, absorbent, prone to stains, req…

4. Fabric Warehouse – Faux Leather Upholstery Fabric

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Faux Leather Upholstery Fabric available by the yard. Common names include faux leather, pleather, vegan leather, synthetic leather, and simulated leather. Patterns available include ostrich, peacock, snake, crocodile, alligator, and cow. Fabric width is 54 inches. Ideal for upholstery due to durability. Suitable for stools, benches, and armchairs. Marine vinyl fabric also available for boat resto…

5. Decorative Fabrics Direct – Faux Leather Upholstery Vinyl

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Faux Leather Upholstery Vinyl Fabrics available in various colors including Black, Gray, Blue, Turquoise, Aqua, Brown, Beige, Green, Orange, Coral, Purple, Red, Pink, White, Yellow, and Gold. Prices range from $14.95 to $35.95 per yard. Fabrics are in stock with varying yardage available for each color. Brands include Naugahyde, Omnova, and others. Specific products listed include Landers Black, L…

6. Diffen – Fabric Comparison

Domain: diffen.com

Registered: 2007 (18 years)

Introduction: {“Comparison”: {“Fabric”: {“Material”: “Cloth”,”Durability”: “Less durable”,”Cost”: “Less expensive”,”Colors”: “More variety”,”Washable”: “Yes”,”Animal friendly”: “Scratch-resistant, but tends to trap pet hair and dander”,”Care”: “Hard to clean”,”Breathable”: “Depends on material”,”Biodegradable”: “Usually yes; depends on material”,”Common Uses”: “Couches and seat covers”,”Environmental / Ethical …

Strategic Sourcing Conclusion and Outlook for leather fabric material

As the global demand for leather fabric continues to rise, strategic sourcing emerges as a critical component for international B2B buyers. Understanding the diverse applications of leather—from fashion apparel to automotive upholstery—allows businesses to tap into various markets effectively. With the increasing focus on sustainability, sourcing from ethical suppliers who prioritize eco-friendly practices can enhance brand reputation and consumer trust.

Illustrative image related to leather fabric material

Investing in quality leather fabric not only ensures durability and aesthetic appeal but also positions companies competitively in their respective industries. Buyers from Africa, South America, the Middle East, and Europe must consider local market trends and consumer preferences when making procurement decisions. By leveraging insights into regional demands and supplier capabilities, businesses can optimize their supply chains and enhance product offerings.

Looking ahead, the leather fabric market presents significant opportunities for growth. We encourage international B2B buyers to engage with reliable suppliers, explore innovative material options, and stay informed about industry advancements. Embrace the potential of strategic sourcing to drive your business forward in this evolving landscape. Take action today to secure your position in the competitive leather fabric market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.