Introduction: Navigating the Global Market for chinese leather sewing machine

Navigating the global market for Chinese leather sewing machines presents unique challenges for international B2B buyers, particularly those seeking reliable and efficient solutions for leatherwork. Sourcing high-quality equipment that meets specific production needs while balancing cost and functionality can be daunting, especially when dealing with products that often require significant setup and modification. This guide aims to demystify the process by providing a comprehensive overview of the various types of Chinese leather sewing machines available, their applications across different industries, and critical insights into supplier vetting.

In this guide, you will explore the nuances of selecting the right leather sewing machine, understanding the intricacies of their designs, and recognizing the potential for enhancements through customization. Additionally, we will delve into cost considerations, ensuring you can make budget-conscious decisions without compromising on quality. By equipping international buyers from Africa, South America, the Middle East, and Europe—particularly in regions like Germany and Vietnam—with actionable insights, this guide empowers you to navigate the complexities of the market confidently. Whether you’re a seasoned manufacturer or a newcomer to leather production, this resource is designed to facilitate informed purchasing decisions that align with your operational goals.

Table Of Contents

- Top 3 Chinese Leather Sewing Machine Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for chinese leather sewing machine

- Understanding chinese leather sewing machine Types and Variations

- Key Industrial Applications of chinese leather sewing machine

- 3 Common User Pain Points for ‘chinese leather sewing machine’ & Their Solutions

- Strategic Material Selection Guide for chinese leather sewing machine

- In-depth Look: Manufacturing Processes and Quality Assurance for chinese leather sewing machine

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘chinese leather sewing machine’

- Comprehensive Cost and Pricing Analysis for chinese leather sewing machine Sourcing

- Alternatives Analysis: Comparing chinese leather sewing machine With Other Solutions

- Essential Technical Properties and Trade Terminology for chinese leather sewing machine

- Navigating Market Dynamics and Sourcing Trends in the chinese leather sewing machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of chinese leather sewing machine

- Strategic Sourcing Conclusion and Outlook for chinese leather sewing machine

- Important Disclaimer & Terms of Use

Understanding chinese leather sewing machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Patcher | Compact design, manual operation, ideal for thick materials | Holster making, bag repairs | Pros: Cost-effective, versatile for small jobs. Cons: Requires tuning and modifications for optimal performance. |

| Walking Foot Machine | Equipped with a walking foot mechanism for thick layers | Upholstery, leather goods manufacturing | Pros: Excellent for multiple layers, consistent stitch quality. Cons: Higher initial investment, may need maintenance. |

| Industrial Leather Machine | Heavy-duty construction, motorized operation | Mass production of leather products | Pros: High speed, durable for continuous use. Cons: Bulky, requires significant space and power supply. |

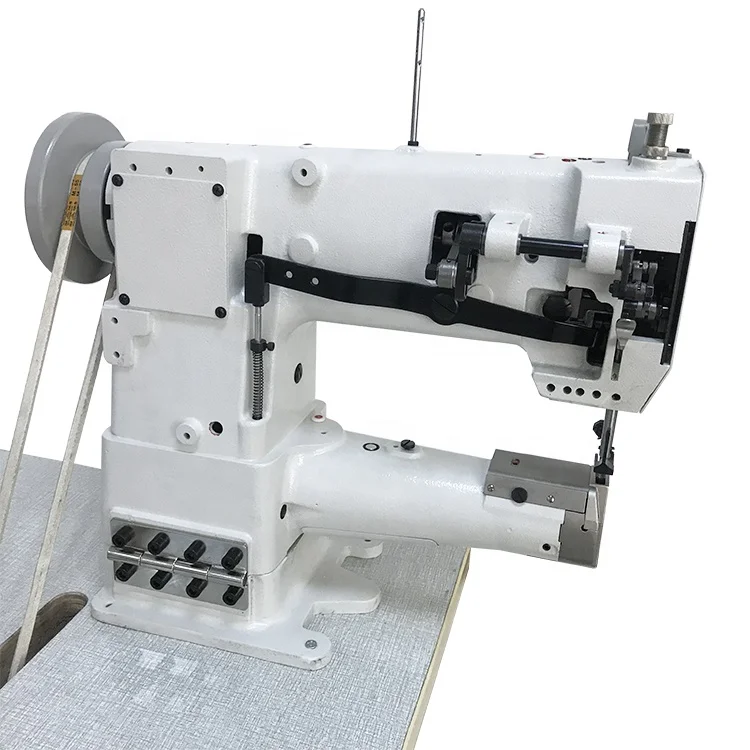

| Cylinder Bed Machine | Cylindrical arm design for hard-to-reach areas | Shoe manufacturing, gear repairs | Pros: Allows for intricate stitching in tight spaces. Cons: Limited to specific applications, may have a steep learning curve. |

| Flatbed Sewing Machine | Flat work surface, versatile for various materials | General leather crafting, garment making | Pros: User-friendly, suitable for a range of projects. Cons: Not ideal for thick layers or complex designs. |

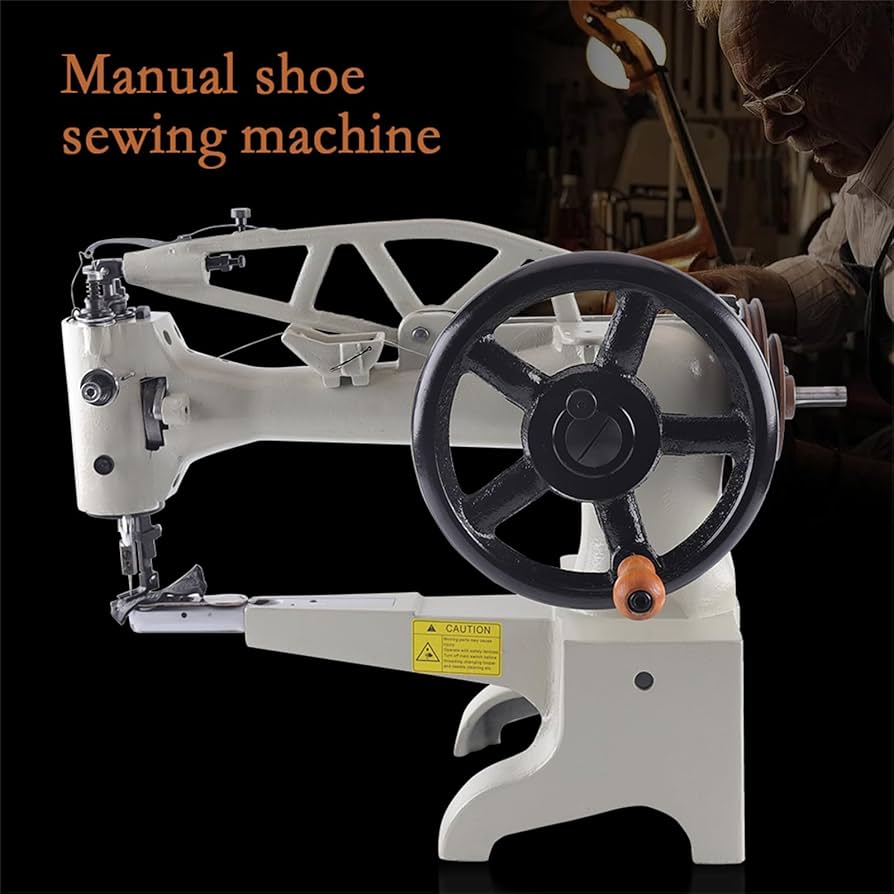

What are the Characteristics of Leather Patcher Machines?

Leather patcher machines are designed for small-scale leather projects, making them ideal for businesses focusing on repairs or custom work. Their compact design allows for easy maneuverability, particularly in tight spaces. However, these machines often require initial tuning and modifications to achieve optimal performance. B2B buyers should consider their specific needs, as the machine’s low cost can be appealing for startups or small workshops.

How Do Walking Foot Machines Benefit B2B Operations?

Walking foot machines are characterized by their ability to handle multiple layers of leather with ease. This makes them particularly suitable for upholstery and the production of leather goods, where consistent stitch quality is paramount. While they come with a higher initial investment, the durability and efficiency of these machines can lead to significant time savings in production. Businesses should weigh the upfront costs against long-term productivity gains.

What Makes Industrial Leather Machines a Good Investment?

Industrial leather machines are built for heavy-duty use and are often motorized for high-speed operation. They are ideal for mass production environments where efficiency and durability are crucial. While they require a larger workspace and a stable power supply, their capability to handle continuous use without compromising quality makes them a strong choice for larger manufacturers. B2B buyers should assess their production volume needs when considering this type of machine.

Why Choose Cylinder Bed Machines for Specific Applications?

Cylinder bed machines feature a unique design that allows for stitching in hard-to-reach areas, making them essential for shoe manufacturing and other specialized tasks. Their ability to maneuver in tight spaces can significantly enhance productivity for specific applications. However, businesses should be aware of the learning curve associated with operating these machines and ensure they have the necessary training or support.

What are the Advantages of Flatbed Sewing Machines?

Flatbed sewing machines provide a versatile platform suitable for a wide range of leather crafting projects. Their user-friendly design makes them accessible for beginners and experienced operators alike. While they excel in general leather crafting and garment making, they may not be the best choice for thicker materials or complex stitching patterns. B2B buyers should consider the types of projects they frequently undertake to determine if a flatbed machine meets their needs.

Key Industrial Applications of chinese leather sewing machine

| Industry/Sector | Specific Application of Chinese Leather Sewing Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Sewing shoes and boots | High durability and customization of footwear products | Assess machine compatibility with various leather types |

| Leather Goods Production | Crafting bags, wallets, and belts | Efficient production of high-quality leather goods | Ensure machine adaptability for different leather thicknesses |

| Upholstery & Furniture | Sewing leather upholstery for furniture | Enhanced aesthetics and durability of furniture items | Evaluate machine speed and stitch quality |

| Automotive Industry | Assembling leather interiors for vehicles | Improved product quality and luxury appeal in vehicles | Verify machine capabilities for heavy-duty leather |

| Sports Equipment | Manufacturing leather sports gear (e.g., gloves) | Increased performance and durability of sports products | Check for machine versatility in handling diverse materials |

How is a Chinese Leather Sewing Machine Used in Footwear Manufacturing?

In footwear manufacturing, Chinese leather sewing machines are primarily used for assembling shoes and boots. These machines provide the necessary strength and precision required for stitching leather, ensuring that the final products are durable and aesthetically pleasing. They allow for customization, enabling manufacturers to create unique designs that cater to different consumer preferences. Buyers in this sector must ensure that the machines can handle various leather thicknesses and types to meet production demands.

What Role Do Chinese Leather Sewing Machines Play in Leather Goods Production?

Chinese leather sewing machines are essential in the leather goods production industry, particularly for crafting items like bags, wallets, and belts. These machines facilitate efficient stitching, which is crucial for maintaining the quality and integrity of leather products. The ability to produce high-quality goods quickly can significantly enhance a company’s competitive edge. International buyers should consider the adaptability of these machines to different leather textures and thicknesses to ensure optimal performance.

Illustrative image related to chinese leather sewing machine

How Are Chinese Leather Sewing Machines Utilized in Upholstery and Furniture?

In the upholstery and furniture sector, Chinese leather sewing machines are used to stitch leather materials for sofas, chairs, and other furniture items. The precision and quality of stitching contribute to the overall aesthetics and durability of the furniture. Companies looking to invest in these machines should evaluate their speed and stitch quality, as these factors directly impact production efficiency and customer satisfaction.

What Benefits Do Chinese Leather Sewing Machines Offer to the Automotive Industry?

The automotive industry utilizes Chinese leather sewing machines for assembling leather interiors in vehicles, such as seats and dashboards. These machines enhance the luxury appeal and overall quality of vehicles, making them more attractive to consumers. For businesses in this sector, it’s crucial to verify that the machines can handle heavy-duty leather and provide consistent stitch quality, as these factors are vital for meeting industry standards.

How Are Chinese Leather Sewing Machines Applied in Sports Equipment Manufacturing?

In the sports equipment industry, Chinese leather sewing machines are used to manufacture items like gloves and protective gear. These machines provide the durability and performance required for high-quality sports products. Buyers in this sector should focus on the versatility of the machines, ensuring they can accommodate various materials and thicknesses, which is essential for producing reliable and effective sports equipment.

3 Common User Pain Points for ‘chinese leather sewing machine’ & Their Solutions

Scenario 1: Quality Control Issues with Chinese Leather Sewing Machines

The Problem: B2B buyers often encounter challenges with the quality of Chinese leather sewing machines. Many machines arrive with poor assembly, unrefined components, and inconsistent performance, which can lead to delays in production and increased operational costs. This issue is particularly pressing for businesses that rely on high-quality stitching for leather goods, as inconsistent machinery can result in product defects and customer dissatisfaction.

The Solution: To mitigate quality control issues, buyers should prioritize sourcing machines from reputable manufacturers with established quality assurance processes. Conducting thorough due diligence is essential. Request samples or conduct factory visits if feasible, and seek references from other buyers in similar industries. Additionally, investing in machines that allow for customization or upgrades can enhance their longevity and performance. Implementing a regular maintenance schedule for the machines can also address minor issues before they escalate, ensuring consistent output quality.

Scenario 2: Difficulty in Operating and Tuning the Machines

The Problem: Many international buyers find that Chinese leather sewing machines, while affordable, often require significant tuning and adjustment before they can be used effectively. New users, especially those unfamiliar with sewing machinery, may struggle to set up the machine properly or optimize it for specific leather types, leading to frustration and wasted materials.

The Solution: To overcome operational challenges, it is advisable to invest in training sessions for staff before the machines are put into regular use. Manufacturers often provide instructional videos and manuals that can be invaluable for understanding machine setup and operation. Additionally, joining online forums or communities focused on leather crafting can provide access to a wealth of knowledge and troubleshooting tips from experienced users. For buyers, considering machines with a user-friendly design and readily available customer support can streamline the learning curve and enhance productivity.

Scenario 3: Limited Versatility for Diverse Leather Projects

The Problem: B2B buyers may find that certain models of Chinese leather sewing machines are not versatile enough for a range of leather projects. This limitation can be particularly challenging for businesses that handle various leather types, thicknesses, and styles, leading to the need for multiple machines or additional investments in equipment.

The Solution: To ensure versatility, buyers should look for machines that offer adjustable settings for different leather types and thicknesses. Features such as multiple stitch patterns, adjustable foot pressure, and free-arm capabilities can significantly enhance the machine’s adaptability. It’s also beneficial to consult with suppliers about the machine’s specifications and recommended usage scenarios. Consideration of additional attachments and upgrades can further expand the machine’s functionality. Investing in a robust machine that can handle a wide range of projects not only saves costs in the long term but also enhances operational efficiency and adaptability to market demands.

Illustrative image related to chinese leather sewing machine

Strategic Material Selection Guide for chinese leather sewing machine

What Are the Key Materials Used in Chinese Leather Sewing Machines?

Chinese leather sewing machines often utilize a variety of materials that significantly influence their performance and durability. Understanding these materials can help international B2B buyers make informed decisions when sourcing these machines.

How Does Steel Impact Performance in Leather Sewing Machines?

Steel is a primary material used in the construction of the frames and components of leather sewing machines. Its high tensile strength offers excellent durability and resistance to wear, making it ideal for heavy-duty applications. Steel components can withstand high pressure and temperature variations, ensuring consistent performance during prolonged use.

Pros and Cons: The advantages of steel include its robustness and longevity, which reduce the need for frequent replacements. However, it can be susceptible to corrosion if not properly treated, which can be a concern in humid environments. Additionally, the manufacturing complexity can increase costs due to the need for precise machining.

Impact on Application: Steel’s compatibility with various sewing tasks is significant, as it can handle heavy leather and thick fabrics without bending or breaking. For buyers in regions with high humidity, such as parts of Africa and South America, selecting machines with corrosion-resistant coatings is advisable.

What Role Does Aluminum Play in Chinese Leather Sewing Machines?

Aluminum is frequently used in the manufacturing of lighter components such as the machine body and some internal parts. Its lightweight nature makes machines easier to handle and transport, which is beneficial for small-scale operations and workshops.

Pros and Cons: The main advantage of aluminum is its resistance to corrosion and lower weight, making it suitable for mobile applications. However, it has a lower tensile strength compared to steel, which may limit its use in high-stress areas. The manufacturing process for aluminum can be less complex, potentially lowering costs.

Impact on Application: Aluminum components are particularly advantageous for sewing machines intended for lighter fabrics or applications requiring portability. Buyers from Europe, especially Germany, may prefer aluminum for its recyclability and environmental sustainability.

Why Is Plastic Used in Some Components of Leather Sewing Machines?

Plastic is often utilized for non-structural components such as knobs, covers, and some internal parts. Its versatility and low cost make it an attractive option for manufacturers looking to reduce overall production costs.

Pros and Cons: The key advantages of plastic include its lightweight nature and resistance to corrosion. However, plastics may not withstand high temperatures or heavy loads, which can limit their application in critical areas. The manufacturing complexity is generally low, allowing for quick production.

Impact on Application: While plastic components can reduce the overall weight of the machine, they may not be suitable for heavy-duty sewing tasks. Buyers should assess the specific applications intended for the machine to ensure that plastic components will meet their needs.

How Does Cast Iron Contribute to the Durability of Sewing Machines?

Cast iron is sometimes used in the base and frame of leather sewing machines due to its excellent vibration-damping properties. This material helps maintain stability during operation, which is crucial for precision sewing.

Pros and Cons: The main advantage of cast iron is its durability and ability to absorb vibrations, enhancing sewing accuracy. However, it is heavy and can be prone to rust if not properly maintained. The manufacturing process can be complex and costly due to the need for casting and finishing.

Impact on Application: Cast iron bases are particularly beneficial for machines designed for industrial applications, where stability is paramount. Buyers in the Middle East, where heavy machinery is common, may find cast iron bases appealing for their robustness.

Summary Table of Material Selection for Chinese Leather Sewing Machines

| 素材 | Typical Use Case for chinese leather sewing machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High durability and wear resistance | Susceptible to corrosion without treatment | 高い |

| Aluminum | Machine body and lightweight components | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Plastic | Non-structural components (knobs, covers) | Versatile and cost-effective | Limited temperature and load resistance | 低い |

| Cast Iron | Base and frame for stability | Excellent vibration damping | Heavy and prone to rust | Medium |

This material selection guide provides a comprehensive overview for international B2B buyers, enabling them to select the most suitable leather sewing machines based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for chinese leather sewing machine

What Are the Main Stages in the Manufacturing Process of Chinese Leather Sewing Machines?

The manufacturing process of Chinese leather sewing machines involves several key stages that ensure the machines are functional, durable, and cost-effective. Understanding these stages helps B2B buyers assess the quality and reliability of the products they are considering.

Material Preparation: What Raw Materials Are Used?

The first stage in manufacturing involves sourcing quality raw materials, primarily metals and plastics. High-grade cast iron or aluminum is often used for the machine body to ensure stability and durability. Steel is typically utilized for the moving parts, which must withstand significant wear and tear. Additionally, components like bearings and thread guides are sourced from reputable suppliers to guarantee reliability. The selection of materials is crucial, as they directly impact the machine’s performance and longevity.

Forming: How Are Components Shaped and Molded?

After material preparation, the next stage is forming, where raw materials are shaped into specific components. This typically involves machining processes such as turning, milling, and grinding. CNC (Computer Numerical Control) machines are commonly employed for precision in creating parts like the needle bar, presser foot, and feed dog. For plastic components, injection molding techniques are often used, ensuring consistency and quality in the finished parts. This stage is critical, as precise dimensions are necessary for the assembly of the sewing machine.

Assembly: What Techniques Are Employed for Assembly?

The assembly stage combines all individual components into a complete sewing machine. Skilled technicians typically perform this task, ensuring that each part fits correctly and operates smoothly. During assembly, techniques such as manual fitting and alignment are employed, along with the use of jigs and fixtures to maintain accuracy. Quality control measures, such as visual inspections and functional tests, are integrated throughout this process to identify any defects or misalignments early on.

Finishing: How Is the Final Product Prepared for Market?

The finishing stage involves several processes aimed at enhancing the machine’s aesthetics and functionality. Surface treatments, such as painting or powder coating, are applied to protect the metal parts from corrosion and improve their appearance. Additionally, final assembly checks are conducted to ensure that all components function as intended. This stage may also include packaging, where machines are carefully packed to prevent damage during shipping, particularly for international deliveries.

How Is Quality Assurance Implemented in the Production of Leather Sewing Machines?

Quality assurance (QA) is a critical aspect of the manufacturing process for leather sewing machines. It involves systematic checks and balances to ensure that products meet international standards and customer expectations.

What International Standards Apply to Leather Sewing Machines?

Many Chinese manufacturers adhere to international quality standards such as ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 helps ensure that the manufacturing process is consistently monitored and improved. Additionally, certifications such as CE (Conformité Européenne) are essential for selling products in European markets, indicating that the machines meet EU safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process to catch defects and ensure product reliability. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival at the factory. Suppliers must provide certifications and reports to verify the quality of materials.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of components being produced. This includes dimensional checks and functional tests at various stages.

-

Final Quality Control (FQC): Once the assembly is complete, a thorough inspection is conducted. This includes testing the machine’s performance, ensuring all parts function correctly, and verifying that the final product meets specifications.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers can take several steps to verify the quality control practices of potential suppliers:

-

Conduct Audits: Buyers can request to conduct on-site audits of manufacturing facilities. This allows them to assess the quality management systems in place and observe production processes firsthand.

-

Review Quality Reports: Suppliers should provide detailed quality reports that outline their testing methods and results. Buyers should look for consistency in testing results and adherence to international standards.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can add an extra layer of assurance. These inspectors can evaluate the production process, quality control measures, and the final product before shipment.

What Are the Specific Quality Control and Certification Nuances for B2B Buyers?

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, B2B buyers should be aware of specific quality control and certification nuances:

-

Regional Certifications: Different regions may have unique certification requirements. For instance, machinery sold in the EU must comply with CE marking, while products in the United States might need to meet ANSI (American National Standards Institute) standards.

-

Cultural Differences in Quality Expectations: Buyers should consider cultural factors that might influence quality perceptions. For instance, what is deemed acceptable in one region may not meet the standards of another.

-

Language Barriers: Documentation related to quality control and certifications may not always be available in English or the buyer’s primary language. Buyers should ensure they can access accurate translations to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance practices associated with Chinese leather sewing machines, B2B buyers can make informed decisions, ensuring they procure reliable and high-quality products for their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chinese leather sewing machine’

In the ever-evolving landscape of leather crafting, sourcing the right Chinese leather sewing machine is critical for efficiency and quality. This guide serves as a practical checklist to help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the first step in sourcing a sewing machine that meets your needs. Consider the types of leather you will be working with, the thickness of the materials, and the specific stitching techniques required. This clarity will help you filter out machines that do not align with your operational needs.

- Material Compatibility: Ensure the machine can handle the specific leather types (e.g., full-grain, top-grain).

- Stitching Type: Identify whether you need a straight stitch, zigzag, or decorative stitch.

Step 2: Research Supplier Reputation

Supplier reputation plays a vital role in ensuring product quality and reliability. Look for manufacturers with a proven track record in producing leather sewing machines, particularly those that cater to international markets. Reviews and testimonials from other businesses in your industry can provide valuable insights.

- Online Reviews: Check platforms like Alibaba or trade forums for user feedback.

- Industry References: Request references from suppliers and verify their credibility through other buyers.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to thoroughly vet potential suppliers. Request detailed company profiles, including their manufacturing capabilities, certifications, and any relevant case studies. This will help you gauge their reliability and industry experience.

Illustrative image related to chinese leather sewing machine

- Certifications: Verify if the supplier holds quality certifications such as ISO 9001.

- 生産能力: Ensure they can meet your order volume and timeline requirements.

Step 4: Inspect Machine Features and Specifications

When evaluating different models, pay close attention to their features and specifications. Machines vary significantly in terms of motor power, speed, and additional functionalities. Understanding these aspects will help you choose a machine that enhances your production efficiency.

- Motor Type: Look for machines with servo motors for better control and energy efficiency.

- Ease of Use: Assess features like adjustable speed and automatic tension settings.

Step 5: Request Samples and Demonstrations

Before finalizing your purchase, request samples of the machines in operation. This is crucial to assess the machine’s performance and suitability for your specific leather types and projects. A hands-on demonstration can also clarify operational ease and maintenance requirements.

- Sample Stitches: Ask to see the stitching quality on materials similar to what you’ll be using.

- Demo Sessions: If possible, attend a live demonstration to evaluate machine handling.

Step 6: Negotiate Terms and Conditions

Negotiating favorable terms and conditions is essential for a successful purchase. Discuss payment terms, warranty, after-sales support, and return policies with your chosen supplier. Clear agreements can mitigate potential risks and ensure a smooth procurement process.

Illustrative image related to chinese leather sewing machine

- Payment Options: Explore flexible payment terms that suit your cash flow.

- Warranty Coverage: Understand what is covered under warranty and for how long.

Step 7: Plan for After-Sales Support and Maintenance

Finally, ensure that the supplier offers adequate after-sales support and maintenance options. This is vital for minimizing downtime and ensuring the longevity of your sewing machine. Discuss technical support availability and the ease of obtaining replacement parts.

- Technical Assistance: Confirm if the supplier provides troubleshooting support.

- Parts Availability: Check the accessibility of spare parts to avoid future disruptions.

By following this checklist, you can confidently source a Chinese leather sewing machine that aligns with your business needs and enhances your production capabilities.

Comprehensive Cost and Pricing Analysis for chinese leather sewing machine Sourcing

What Are the Key Cost Components in Sourcing Chinese Leather Sewing Machines?

When sourcing Chinese leather sewing machines, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The quality of materials used in manufacturing significantly influences costs. Basic models may use lower-grade metals and plastics, while higher-end machines incorporate durable components such as stainless steel and high-performance motors. Buyers should assess the material specifications to gauge durability and performance.

-

Labor: Labor costs in China are generally lower than in Western countries, but this can vary by region and factory. Skilled labor for assembly and quality checks can increase the price, especially for machines that require precision engineering.

-

Manufacturing Overhead: This encompasses expenses related to factory operation, including utilities, maintenance, and administrative costs. Efficient factories often pass on savings to buyers, making it essential to evaluate the supplier’s operational efficiency.

-

Tooling: The initial investment in tooling for specialized or custom machines can be substantial. Buyers should inquire about these costs, particularly if they require specific customizations.

-

Quality Control (QC): Ensuring quality in production is crucial, particularly for machines intended for heavy-duty use. Additional QC measures may incur extra costs, but they can prevent future issues and enhance the machine’s reliability.

-

Logistics: Shipping costs can vary significantly based on the Incoterms agreed upon. Factors such as distance, shipping method (air vs. sea), and insurance will affect the total logistics cost.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary depending on competition and market demand. Understanding this margin can help in negotiations.

How Do Price Influencers Impact Sourcing Decisions for Chinese Leather Sewing Machines?

Several factors can influence the pricing of leather sewing machines, and recognizing these can help buyers make informed decisions:

-

Volume/MOQ: Suppliers often offer better pricing for larger orders due to economies of scale. Establishing a minimum order quantity (MOQ) can help buyers negotiate favorable terms.

-

Specifications and Customization: Customized machines will generally cost more than standard models. Buyers should carefully consider their needs and whether customization is essential to their operations.

-

Material Quality and Certifications: Machines with higher quality materials and recognized certifications (e.g., ISO standards) may command a premium price. However, investing in certified machines can lead to lower maintenance costs and longer lifespans.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers with a track record of quality may charge more but can provide better customer support and warranty options.

-

Incoterms: Different shipping terms can alter the total cost. Understanding whether costs include shipping, duties, and insurance is crucial for accurate budgeting.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

To maximize cost efficiency when sourcing Chinese leather sewing machines, consider the following tips:

-

Leverage Volume Discounts: If your business anticipates ongoing needs, negotiate bulk pricing. Suppliers are often willing to lower prices for large orders, which can lead to substantial savings.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, spare parts availability, and operational costs. A cheaper machine may lead to higher TCO if it requires frequent repairs.

-

Be Prepared to Walk Away: Establish a budget and be firm about it. If a supplier is unwilling to meet your price or terms, exploring alternatives can often yield better results.

-

Understand Market Trends: Staying informed about market fluctuations, tariffs, and trade policies can provide leverage during negotiations. Knowledge of the current economic climate helps in assessing whether a supplier’s pricing is competitive.

-

Build Relationships with Suppliers: A good relationship can lead to better negotiation outcomes. Suppliers may offer favorable terms or priority service to long-term partners.

Conclusion

Sourcing Chinese leather sewing machines involves navigating a complex landscape of costs and pricing influences. By understanding the components of cost, recognizing price influencers, and employing effective negotiation strategies, international B2B buyers can make informed decisions that enhance their procurement processes. Always remember to assess the total cost of ownership to ensure long-term value in your investment.

Alternatives Analysis: Comparing chinese leather sewing machine With Other Solutions

Introduction to Alternatives in Leather Sewing Solutions

When considering the purchase of a leather sewing machine, particularly a Chinese model, it is essential to evaluate alternative solutions that may better meet specific business needs. Different technologies and methodologies can offer varying levels of performance, cost-effectiveness, and usability. This analysis will provide a comparative overview of the Chinese leather sewing machine against two viable alternatives: industrial walking foot sewing machines and manual leather stitching tools.

Illustrative image related to chinese leather sewing machine

Comparison Table

| Comparison Aspect | Chinese Leather Sewing Machine | Industrial Walking Foot Sewing Machine | Manual Leather Stitching Tools |

|---|---|---|---|

| Performance | Basic, suitable for light to medium leather | High, ideal for heavy leather and intricate designs | Variable, depends on user skill |

| Cost | Low (approximately $150) | Moderate to high (around $800 – $3,000) | Low (approximately $50 – $200) |

| Ease of Implementation | Requires setup and tinkering | Ready to use out of the box | Simple, but requires manual labor |

| Maintenance | High (frequent adjustments needed) | Moderate (occasional servicing) | Low (minimal upkeep) |

| Best Use Case | Hobbyist projects, light leather work | Professional leather crafting, production | DIY projects, small repairs |

Detailed Breakdown of Alternatives

Industrial Walking Foot Sewing Machine

Industrial walking foot sewing machines are designed for professional leatherwork, offering superior performance for heavy materials. They feature an advanced feeding mechanism that allows for smooth sewing of multiple layers, making them ideal for crafting bags, footwear, and upholstery. However, the initial investment can be substantial, often ranging from $800 to $3,000. These machines are generally ready to use with minimal setup, but they do require regular maintenance and servicing to ensure optimal performance. For businesses focused on high-volume production and complex leather goods, this alternative provides the best reliability and output quality.

Manual Leather Stitching Tools

Manual leather stitching tools, such as hand needles and awls, are the most cost-effective solutions for leatherwork, with prices ranging from $50 to $200. These tools offer a high degree of control and craftsmanship, allowing artisans to create unique, custom designs. However, the performance is highly dependent on the user’s skill level and can be time-consuming, especially for larger projects. Maintenance is minimal, as these tools require little upkeep beyond basic cleaning. For businesses looking to produce bespoke items or engage in small repair tasks, manual stitching tools can be an excellent choice, balancing cost with craftsmanship.

Conclusion: Choosing the Right Leather Sewing Solution

For B2B buyers in the leather crafting industry, selecting the right sewing solution hinges on understanding specific operational needs and budget constraints. If your business requires high-volume production and the ability to work with heavy materials, investing in an industrial walking foot sewing machine is advisable despite the higher upfront cost. Alternatively, for hobbyists or small businesses focusing on custom projects, a Chinese leather sewing machine or manual stitching tools may suffice, providing flexibility and lower costs. Ultimately, the choice should align with your production goals, the types of leather goods you intend to create, and your long-term business strategy.

Essential Technical Properties and Trade Terminology for chinese leather sewing machine

What Are the Key Technical Properties of Chinese Leather Sewing Machines?

When evaluating Chinese leather sewing machines for B2B procurement, understanding their technical specifications is crucial for making informed decisions. Here are several essential properties to consider:

-

Material Grade

The construction material of the sewing machine significantly affects its durability and performance. Common materials include high-grade steel for the frame and aluminum for certain components. A higher material grade translates to better resistance against wear and tear, essential for businesses that require machines to operate continuously and efficiently. Buyers should prioritize machines made from robust materials that can handle heavy leather and prolonged usage. -

Sewing Speed

Measured in stitches per minute (SPM), sewing speed is a vital specification for productivity. Machines typically range from 500 to 3,000 SPM. A higher sewing speed can increase output, allowing businesses to meet larger orders or tight deadlines. However, it is also essential to balance speed with precision, especially when dealing with intricate leatherwork. -

Needle Size Compatibility

Different leather projects require various needle sizes, typically ranging from 70 to 160 (metric). Compatibility with a range of needle sizes allows for versatility in stitching different types of leather, from lightweight to heavy-duty materials. Businesses should ensure that the sewing machine can accommodate the needles required for their specific applications. -

Motor Type and Power

The type of motor—whether servo or clutch—affects the machine’s efficiency and control. Servo motors are generally preferred for their quiet operation and precise speed control, making them suitable for delicate stitching. The power rating, usually expressed in watts, also determines the machine’s ability to handle thick materials. A powerful motor ensures consistent performance, particularly for high-volume production settings. -

Tension Adjustment Mechanism

Proper thread tension is crucial for achieving high-quality seams in leatherwork. A good machine will offer an adjustable tension mechanism that allows operators to fine-tune the tension according to the material thickness and type. This feature is essential for businesses focused on delivering professional-grade products.

What Are Common Trade Terms Used in the Leather Sewing Machine Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B sector. Here are some common trade terms related to Chinese leather sewing machines:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are branded by another company. In the context of leather sewing machines, understanding OEM relationships can help buyers source parts and machines that meet specific quality standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of products that a supplier is willing to sell. For B2B buyers, knowing the MOQ can help in budgeting and inventory management. It’s crucial for negotiating terms with suppliers, especially when looking to order customized machines. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific goods or services. Utilizing RFQs can help businesses obtain competitive pricing and terms, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs and liabilities, which can impact the total cost of procurement. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is crucial for planning production schedules and managing inventory. In the leather sewing machine market, longer lead times may be associated with custom orders or high-demand periods. -

Warranty and Service Agreement

These terms outline the manufacturer’s commitment to repair or replace defective products and the conditions under which these services are provided. A solid warranty and service agreement can provide peace of mind for buyers, ensuring that they are covered in case of machine malfunctions or defects.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing Chinese leather sewing machines, ensuring they meet their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the chinese leather sewing machine Sector

What Are the Current Market Dynamics and Key Trends in the Chinese Leather Sewing Machine Sector?

The Chinese leather sewing machine market is witnessing significant growth, driven by increasing demand for leather goods across various sectors, including fashion, automotive, and furniture. The expansion of e-commerce and globalization has opened doors for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe. Buyers are increasingly looking for cost-effective solutions without compromising quality, making Chinese manufacturers a popular choice due to their competitive pricing and diverse product offerings.

Key trends shaping this market include the integration of advanced technologies such as automation and digitalization in manufacturing processes. Manufacturers are focusing on enhancing the functionality of sewing machines, incorporating features like servo motors for precise control and reduced noise. Additionally, there is a growing emphasis on customization, allowing buyers to tailor machines to their specific needs. Sustainability is also becoming a priority, with companies seeking eco-friendly materials and practices in their production processes.

Furthermore, international buyers must navigate varying regulations and quality standards across different regions. Understanding local market demands and preferences is crucial for successful sourcing. As more businesses aim for rapid turnaround times and flexibility, establishing strong relationships with reliable suppliers in China can significantly enhance operational efficiency and reduce lead times.

How Can Sustainability and Ethical Sourcing Impact B2B Purchasing Decisions in the Leather Sewing Machine Sector?

In the context of leather sewing machines, sustainability and ethical sourcing have become critical considerations for B2B buyers. The environmental impact of leather production, including resource consumption and waste generation, has prompted a shift towards more sustainable practices. Manufacturers are increasingly adopting greener technologies and materials to minimize their ecological footprint. This includes using synthetic leathers, recycled materials, and eco-friendly production processes.

Ethical supply chains are also gaining traction, with buyers seeking vendors who comply with labor standards and fair trade practices. Certifications like ISO 14001 for environmental management and OEKO-TEX for sustainable textiles are becoming essential for suppliers aiming to attract conscientious buyers. By prioritizing vendors with these certifications, businesses can ensure that their sourcing aligns with their corporate social responsibility goals.

Moreover, the demand for transparency in supply chains is influencing purchasing decisions. Buyers are increasingly interested in knowing the origin of materials and the production methods employed. This trend is not only driven by consumer demand for sustainable products but also by the potential for enhanced brand reputation and customer loyalty.

What Is the Historical Context of Chinese Leather Sewing Machines Relevant to B2B Buyers?

The evolution of Chinese leather sewing machines can be traced back to traditional craftsmanship, which has gradually integrated modern manufacturing techniques. Initially, these machines were designed for basic leatherworking tasks, often characterized by simplicity and durability. Over time, advancements in technology have transformed these machines into sophisticated tools capable of handling intricate designs and various leather types.

Illustrative image related to chinese leather sewing machine

The introduction of automated features and enhanced precision has positioned Chinese manufacturers as competitive players in the global market. This transformation aligns with the rise of the leather goods industry, which has seen exponential growth over the past few decades. For B2B buyers, understanding the historical context can provide valuable insights into the reliability and evolution of the machines they are considering, as well as the potential for future innovations.

In summary, as the Chinese leather sewing machine sector continues to evolve, international buyers must stay informed about market trends, prioritize sustainability, and appreciate the historical significance of these machines to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of chinese leather sewing machine

-

1. How do I solve issues with the performance of a Chinese leather sewing machine?

To address performance issues with a Chinese leather sewing machine, it is essential to conduct a thorough inspection upon delivery. Check for loose parts, misalignments, and ensure that all components are clean and free from casting sand or debris. Regular maintenance, such as oiling moving parts and adjusting tension settings, can enhance performance. Additionally, consider watching instructional videos or consulting user forums for specific tuning tips. In some cases, upgrading components, like the motor or adding bearings, can significantly improve the machine’s functionality. -

2. What is the best type of leather sewing machine for thick leather projects?

For thick leather projects, a walking foot or heavy-duty leather sewing machine is recommended. These machines are designed to handle multiple layers of heavy material, providing better feed and stitch quality. Models specifically designed for cobblers or industrial applications may offer the durability and power needed for such tasks. It’s also beneficial to ensure the machine has adjustable pressure feet and stitch length settings, allowing for versatility in various leather applications. -

3. How can I vet suppliers of Chinese leather sewing machines for quality assurance?

To vet suppliers effectively, start by researching their reputation through online reviews and testimonials from previous customers. Request samples of their machines to assess quality firsthand. Inquire about their manufacturing processes, certifications, and warranties offered on their products. Establishing clear communication regarding your quality expectations and conducting a factory visit, if possible, can also provide insights into their operational standards and commitment to quality. -

4. What customization options are available for Chinese leather sewing machines?

Many suppliers offer customization options for leather sewing machines, including modifications to the machine’s specifications, color, and additional features like specialized presser feet or motors. Discuss your specific needs with potential suppliers to determine what customization can be accommodated. Be sure to clarify any associated costs and lead times for customized orders, as these can vary significantly. -

5. What is the typical minimum order quantity (MOQ) for purchasing leather sewing machines?

The MOQ for leather sewing machines can vary widely among suppliers, often ranging from 1 to 100 units. Factors influencing MOQ include the supplier’s production capacity, machine type, and your negotiation with them. When sourcing, it’s crucial to communicate your intended purchase volume and explore options for smaller initial orders, especially if you are testing the market or establishing a new product line. -

6. What payment terms should I expect when ordering from Chinese suppliers?

Payment terms when ordering from Chinese suppliers typically include options such as a 30% deposit with the balance due before shipment, or payment through letters of credit. Some suppliers may also offer more flexible terms for larger orders. It’s important to clarify payment methods accepted, such as bank transfers or online payment platforms, and ensure that all terms are documented in the purchase agreement to avoid misunderstandings. -

7. How can I manage logistics and shipping when importing sewing machines from China?

To effectively manage logistics and shipping, partner with a reliable freight forwarder who can handle customs clearance and transportation logistics. Discuss shipping options, including sea or air freight, based on your budget and urgency. Ensure you understand the Incoterms (International Commercial Terms) that define the responsibilities of both buyer and seller. Additionally, confirm that the supplier provides necessary shipping documentation, including the bill of lading and commercial invoice. -

8. What quality assurance measures should I implement when receiving sewing machines?

Upon receiving your shipment, conduct a comprehensive inspection of each machine. Check for any visible damages and ensure all components are included as per your order. Test the machines for functionality and performance to confirm they meet your specifications. Establish a return policy with the supplier in case of defects or discrepancies. Keeping detailed records of inspections can also help in future negotiations or claims.

Top 3 Chinese Leather Sewing Machine Manufacturers & Suppliers List

1. Cheap Chinese Sewing Machine – Key Product

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Cheap Chinese sewing machine available on Amazon for $120, features an aluminum body. Discussion includes comparison with cast iron body regarding stability and flex. Primarily intended for hobby use, suitable for functional items like knife sheaths. Concerns raised about the machine’s performance, fit and finish, and the amount of thread the bobbin can hold compared to older domestic machines. Al…

2. Hobby Machinist – Chinese Leather Patcher

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: This company, Hobby Machinist – Chinese Leather Patcher, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. SINGER – Sewing Machines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Chinese Sewing Machines available on eBay include various brands and models such as Unbranded, SINGER, and Union Special. The price range for these machines varies from under $35 to over $350, with new items numbering 303 and used items 22. The machines are categorized under sewing machines and sergers, with options for industrial sewing machines and parts. Shipping options include free delivery a…

Strategic Sourcing Conclusion and Outlook for chinese leather sewing machine

In the competitive landscape of leather goods manufacturing, strategic sourcing of Chinese leather sewing machines offers significant advantages for international B2B buyers. These machines, often positioned as cost-effective solutions, require a keen understanding of their capabilities and potential limitations. While they may need some initial setup and tuning, the value they provide—especially in terms of versatility for thick leather projects—cannot be understated.

Illustrative image related to chinese leather sewing machine

Buyers should consider the long-term benefits of integrating these machines into their production lines, including the potential for customization and adaptation. The ability to refine and enhance these machines can transform a basic tool into a powerhouse for innovative designs. Furthermore, the market demand for high-quality leather products continues to grow, presenting an opportunity for businesses to leverage these machines to meet evolving consumer preferences.

As you explore your sourcing options, remember that investing in quality machinery is investing in the future of your business. Embrace the potential of Chinese leather sewing machines to enhance your production capabilities and stay ahead of the competition. For those in Africa, South America, the Middle East, and Europe, now is the time to act—evaluate your needs, research suppliers, and secure the machines that will drive your success in the leather industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.