Introduction: Navigating the Global Market for pvc garments

In the dynamic landscape of the global fashion industry, sourcing high-quality PVC garments presents both opportunities and challenges for B2B buyers. The increasing demand for versatile, durable, and visually striking PVC clothing—ranging from elegant dresses to functional outerwear—requires careful consideration of various factors such as material quality, supplier reliability, and cost-effectiveness. This guide aims to illuminate the complex world of PVC garments by providing actionable insights into the types of products available, their applications across different markets, and effective supplier vetting strategies.

Navigating the PVC garments market can be daunting, especially for international buyers from diverse regions like Africa, South America, the Middle East, and Europe, including key markets such as Germany and Saudi Arabia. Understanding local consumer preferences and regulatory requirements is essential for making informed purchasing decisions. This comprehensive guide empowers B2B buyers by offering detailed information on sourcing practices, potential cost implications, and the latest trends in PVC fashion.

By equipping buyers with the knowledge to identify reputable suppliers and assess product quality, this resource aims to streamline the procurement process. Whether you are looking to expand your product line or enter new markets, this guide serves as your roadmap to successfully navigating the intricate world of PVC garments.

Table Of Contents

- Top 2 Pvc Garments Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pvc garments

- Understanding pvc garments Types and Variations

- Key Industrial Applications of pvc garments

- 3 Common User Pain Points for ‘pvc garments’ & Their Solutions

- Strategic Material Selection Guide for pvc garments

- In-depth Look: Manufacturing Processes and Quality Assurance for pvc garments

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc garments’

- Comprehensive Cost and Pricing Analysis for pvc garments Sourcing

- Alternatives Analysis: Comparing pvc garments With Other Solutions

- Essential Technical Properties and Trade Terminology for pvc garments

- Navigating Market Dynamics and Sourcing Trends in the pvc garments Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pvc garments

- Strategic Sourcing Conclusion and Outlook for pvc garments

- Important Disclaimer & Terms of Use

Understanding pvc garments Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Catsuits/Jumpsuits | Full-body coverage, often form-fitting | Costumes, fashion shows, performance wear | Pros: Eye-catching, versatile; Cons: Sizing can be tricky. |

| Corsets | Structured design emphasizing waist reduction | Lingerie, fashion, theatrical costumes | Pros: Enhances silhouette; Cons: May require fitting adjustments. |

| Clear PVC Clothing | Transparent material showcasing the body underneath | Fashion, cosplay, promotional events | Pros: Unique aesthetic; Cons: Limited in modesty and warmth. |

| Holographic PVC | Shimmering, reflective surface with color variations | Fashion, special events, performance costumes | Pros: Visually striking; Cons: Can be heavier and less breathable. |

| Accessories (Gloves, Collars) | Complementary pieces to main garments | Fashion, cosplay, costume design | Pros: Easy to pair; Cons: May require additional sourcing for complete outfits. |

What Are the Characteristics and Suitability of Catsuits and Jumpsuits in PVC Garments?

Catsuits and jumpsuits made from PVC are designed for full-body coverage and are often form-fitting, accentuating the wearer’s silhouette. These garments are particularly popular in the costume and fashion industries, where they are used for theatrical performances, fashion shows, and themed events. When purchasing, B2B buyers should consider the fit and flexibility of the material, as well as the potential for customization in terms of colors and designs to suit various branding needs.

How Do Corsets Made from PVC Stand Out for B2B Buyers?

Corsets crafted from PVC are structured garments that emphasize waist reduction and create a defined hourglass figure. They are frequently used in lingerie lines, fashion collections, and theatrical productions. B2B buyers should take into account the sizing and fitting requirements, as these garments often need to be tailored to ensure comfort and effectiveness. Additionally, the ability to offer varied styles and embellishments can enhance marketability.

Why is Clear PVC Clothing a Unique Option for Fashion and Events?

Clear PVC clothing is notable for its transparency, allowing the wearer’s body to be showcased while maintaining a stylish appearance. This type of garment is particularly suitable for fashion-forward brands, cosplay events, and promotional activities where visibility is key. B2B buyers must evaluate the garment’s comfort, breathability, and how it aligns with current fashion trends to ensure it meets consumer demands.

What Makes Holographic PVC an Eye-Catching Choice for Special Events?

Holographic PVC garments feature a shimmering, reflective surface that changes color with light, making them visually striking. These garments are ideal for fashion shows, special events, and performances where standout aesthetics are crucial. When sourcing holographic PVC, B2B buyers should consider the weight of the material and its breathability, as heavier fabrics may not be suitable for all climates or occasions.

How Do Accessories Enhance PVC Garment Offerings in B2B Markets?

PVC accessories such as gloves and collars serve as complementary pieces that can elevate the overall appeal of main garments. They are widely used in fashion, cosplay, and costume design, providing versatility and ease of pairing with various outfits. Buyers should focus on the quality and design of these accessories, as well as their ability to integrate seamlessly with existing product lines, ensuring they enhance the marketability of the overall collection.

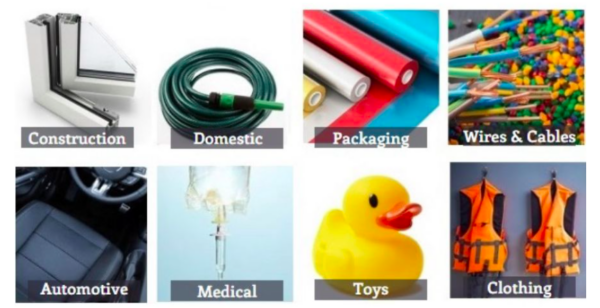

Key Industrial Applications of pvc garments

| Industry/Sector | Specific Application of PVC Garments | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Medical Protective Clothing | Ensures hygiene and safety in medical environments | Compliance with health regulations, durability, ease of cleaning |

| Food Processing | Waterproof and Stain-Resistant Uniforms | Maintains cleanliness and prevents cross-contamination | Food safety certifications, resistance to chemicals, comfort |

| Fashion and Entertainment | Costumes and Theatrical Attire | Enhances visual appeal and creativity in performances | Customization options, availability of diverse styles, fabric quality |

| Automotive | Protective Gear for Manufacturing and Repair | Offers safety and durability in hazardous environments | Compliance with safety standards, heat resistance, flexibility |

| Construction | Heavy-Duty Workwear and Safety Gear | Protects workers in challenging environments | ANSI/OSHA compliance, waterproofing, breathability |

How are PVC Garments Used in the Healthcare Sector?

In healthcare, PVC garments are primarily utilized for medical protective clothing, such as gowns and aprons. These garments provide a barrier against contaminants, ensuring hygiene and safety for healthcare professionals and patients. The durability of PVC allows for repeated use, while its waterproof properties protect against spills and bodily fluids. International buyers must consider compliance with local health regulations, the ease of cleaning, and the garment’s resistance to chemicals when sourcing these products.

What Role Do PVC Garments Play in Food Processing?

In the food processing industry, PVC garments are essential for creating waterproof and stain-resistant uniforms for workers. These garments help maintain cleanliness and prevent cross-contamination, which is critical for food safety. Buyers should prioritize sourcing uniforms that meet food safety certifications, offer resistance to chemicals, and ensure comfort for workers who may be on their feet for extended periods. This focus on functionality not only supports employee safety but also enhances overall operational efficiency.

How Are PVC Garments Used in Fashion and Entertainment?

PVC garments have found a significant niche in the fashion and entertainment sectors, particularly for costumes and theatrical attire. Their striking appearance and versatility allow designers to create visually captivating outfits that stand out on stage or at events. When sourcing these garments, international buyers should look for customization options to align with specific themes or branding, as well as diverse styles and high-quality fabrics that ensure comfort and durability during performances.

What Are the Applications of PVC Garments in the Automotive Industry?

In the automotive sector, PVC garments are used as protective gear for workers involved in manufacturing and repair processes. These garments are designed to withstand harsh conditions, offering safety and durability in environments where exposure to chemicals and sharp objects is common. Buyers in this industry must ensure that the garments comply with safety standards, are heat resistant, and provide the necessary flexibility for movement. This focus on protective gear is vital for maintaining a safe workplace.

How Are PVC Garments Beneficial in Construction?

The construction industry benefits significantly from heavy-duty PVC workwear and safety gear. These garments protect workers from harsh weather conditions and physical hazards on job sites. When sourcing PVC garments for construction, buyers should prioritize ANSI/OSHA compliance to ensure worker safety, along with features like waterproofing and breathability to enhance comfort during long hours of work. This approach not only safeguards workers but also contributes to improved productivity on site.

Illustrative image related to pvc garments

3 Common User Pain Points for ‘pvc garments’ & Their Solutions

Scenario 1: Sourcing Quality PVC Garments in Diverse Markets

The Problem: B2B buyers often struggle to find high-quality PVC garments that meet both aesthetic and durability standards. This is particularly challenging in international markets where material quality can vary significantly. Buyers may encounter suppliers who offer subpar products that do not withstand usage or fail to meet safety regulations. This can lead to product returns, damaged reputations, and financial losses, especially for businesses in industries like fashion, events, or protective apparel.

The Solution: To effectively source quality PVC garments, buyers should prioritize establishing relationships with reputable manufacturers who have a track record in the industry. Conduct thorough research by requesting samples to evaluate material quality, stitching, and overall construction. Additionally, buyers should inquire about the manufacturer’s adherence to international safety standards and certifications. Using platforms that facilitate B2B trade, such as Alibaba or Global Sources, can provide access to verified suppliers. Regular communication with suppliers regarding production processes and quality control measures can help ensure that the garments meet the desired specifications. Engaging in trade shows or industry expos is also beneficial for firsthand assessment and building direct connections with manufacturers.

Scenario 2: Navigating PVC Care and Maintenance Challenges

The Problem: Many buyers are unaware of the specific care requirements for PVC garments, leading to premature wear or damage. For example, improper cleaning methods can result in discoloration or loss of flexibility, which diminishes the garment’s appeal and functionality. This is especially problematic for businesses that rely on PVC for high-performance applications, such as in theater costumes or specialty fashion lines.

The Solution: To address this challenge, B2B buyers should provide comprehensive care instructions to end-users. This includes recommending gentle cleaning agents and specific washing techniques, such as hand washing with mild soap and air drying away from direct sunlight. Buyers can create informational materials or guides that accompany products to educate users on proper maintenance. Additionally, sourcing PVC garments that come with protective coatings can enhance durability and ease of cleaning. Buyers may also consider establishing partnerships with cleaning services that specialize in PVC to offer as an added value to their clients.

Scenario 3: Managing Sizing and Fit Issues for Diverse Audiences

The Problem: Sizing inconsistencies can be a significant pain point for B2B buyers of PVC garments, especially when catering to diverse markets with varying body types. Many suppliers may not provide accurate sizing charts or may have garments that do not conform to standard measurements. This can lead to customer dissatisfaction, increased return rates, and potential loss of business.

The Solution: To mitigate sizing issues, buyers should work with manufacturers who offer customizable sizing options or flexible return policies. When placing bulk orders, it’s advisable to request a size run sample to assess fit before committing to larger quantities. Buyers can also invest in data analytics tools to analyze customer feedback on sizing to make informed decisions about future orders. Furthermore, providing a detailed sizing guide that includes measurements for each style, along with a fit predictor tool on the company’s website, can help customers select the correct size. Consider implementing a “try before you buy” program, allowing retailers to test garments before finalizing orders, thus reducing the risk of sizing-related returns.

Strategic Material Selection Guide for pvc garments

When selecting materials for PVC garments, various factors come into play, especially for international B2B buyers. Understanding the properties, advantages, and limitations of different materials can significantly influence product performance and market acceptance. Below, we analyze four common materials used in PVC garments, focusing on their key properties, pros and cons, application impacts, and specific considerations for buyers from diverse regions.

What Are the Key Properties of PVC Fabric?

PVC (Polyvinyl Chloride) is a widely used synthetic material known for its versatility and durability. It is resistant to moisture, chemicals, and UV light, making it suitable for various applications, including fashion and protective clothing. PVC garments can be manufactured in various thicknesses and finishes, providing flexibility in design and functionality.

How Do Different PVC Variants Compare?

-

Clear PVC

– Key Properties: Offers transparency while maintaining durability and flexibility. It can withstand moderate temperatures and is resistant to water and UV rays.

– Pros: Ideal for fashion-forward designs, allows for creative layering, and is easy to clean. It is lightweight and cost-effective.

– Cons: Less resistant to abrasion compared to thicker PVC options, which may limit its use in high-wear applications.

– Impact on Application: Suitable for costumes, fashion accessories, and protective gear. However, it may not be ideal for heavy-duty use.

– Considerations for Buyers: Compliance with safety standards is crucial, especially in regions like Europe where regulations on materials are stringent. -

Holographic PVC

– Key Properties: Features a reflective surface that creates a visual effect. It retains the durability of standard PVC while adding aesthetic appeal.

– Pros: Highly attractive for fashion garments, especially in cosplay and performance wear. It is durable and resistant to fading.

– Cons: More expensive than standard PVC and may require specialized manufacturing techniques.

– Impact on Application: Primarily used in fashion and costume design, it may not be suitable for industrial applications.

– Considerations for Buyers: Buyers should ensure that the holographic finish complies with local regulations regarding chemical safety and environmental impact. -

Matte PVC

– Key Properties: Offers a non-reflective finish that is soft to the touch. It has good resistance to wear and tear while maintaining flexibility.

– Pros: Provides a sophisticated look and is less prone to showing fingerprints or smudges. It is versatile for various garment types.

– Cons: May not be as visually striking as glossy options, which could affect market appeal in certain segments.

– Impact on Application: Suitable for everyday wear and functional garments, including outerwear and fashion items.

– Considerations for Buyers: Ensure that matte PVC meets the required fire safety standards, especially in regions with strict regulations. -

Faux Leather PVC

– Key Properties: Mimics the appearance of genuine leather while offering the benefits of PVC, such as water resistance and easy maintenance.

– Pros: Durable and cost-effective alternative to leather. It is available in various textures and colors, appealing to a broad market.

– Cons: Can be less breathable than natural leather, which may affect comfort in warmer climates.

– Impact on Application: Commonly used in jackets, skirts, and accessories, it is suitable for both fashion and functional applications.

– Considerations for Buyers: Important to verify that faux leather PVC complies with international standards for phthalates and other harmful substances.

Summary Table of Material Selection for PVC Garments

| Material | Typical Use Case for PVC Garments | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clear PVC | Costumes, fashion accessories | Lightweight and easy to clean | Less abrasion-resistant | Low |

| Holographic PVC | Fashion, cosplay | Visually striking and durable | Higher manufacturing costs | High |

| Matte PVC | Everyday wear, functional garments | Sophisticated look, smudge-resistant | Less visually appealing | Medium |

| Faux Leather PVC | Jackets, skirts, accessories | Cost-effective leather alternative | Less breathability | Medium |

This analysis provides B2B buyers with a clear understanding of the various materials available for PVC garments, helping them make informed decisions based on performance, cost, and compliance with regional standards.

Illustrative image related to pvc garments

In-depth Look: Manufacturing Processes and Quality Assurance for pvc garments

What Are the Main Stages of Manufacturing PVC Garments?

The manufacturing process of PVC garments encompasses several critical stages, each essential for ensuring the final product meets quality and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for PVC Garment Production?

The first step involves selecting high-quality PVC materials. Suppliers typically provide various grades of PVC, which may vary in thickness, color, and finish (e.g., matte, glossy, holographic). This selection is vital as it influences the garment’s durability and aesthetic appeal. After selection, the materials undergo cutting to specific dimensions required for the intended designs. Advanced cutting techniques, including die-cutting and laser cutting, ensure precision and reduce waste.

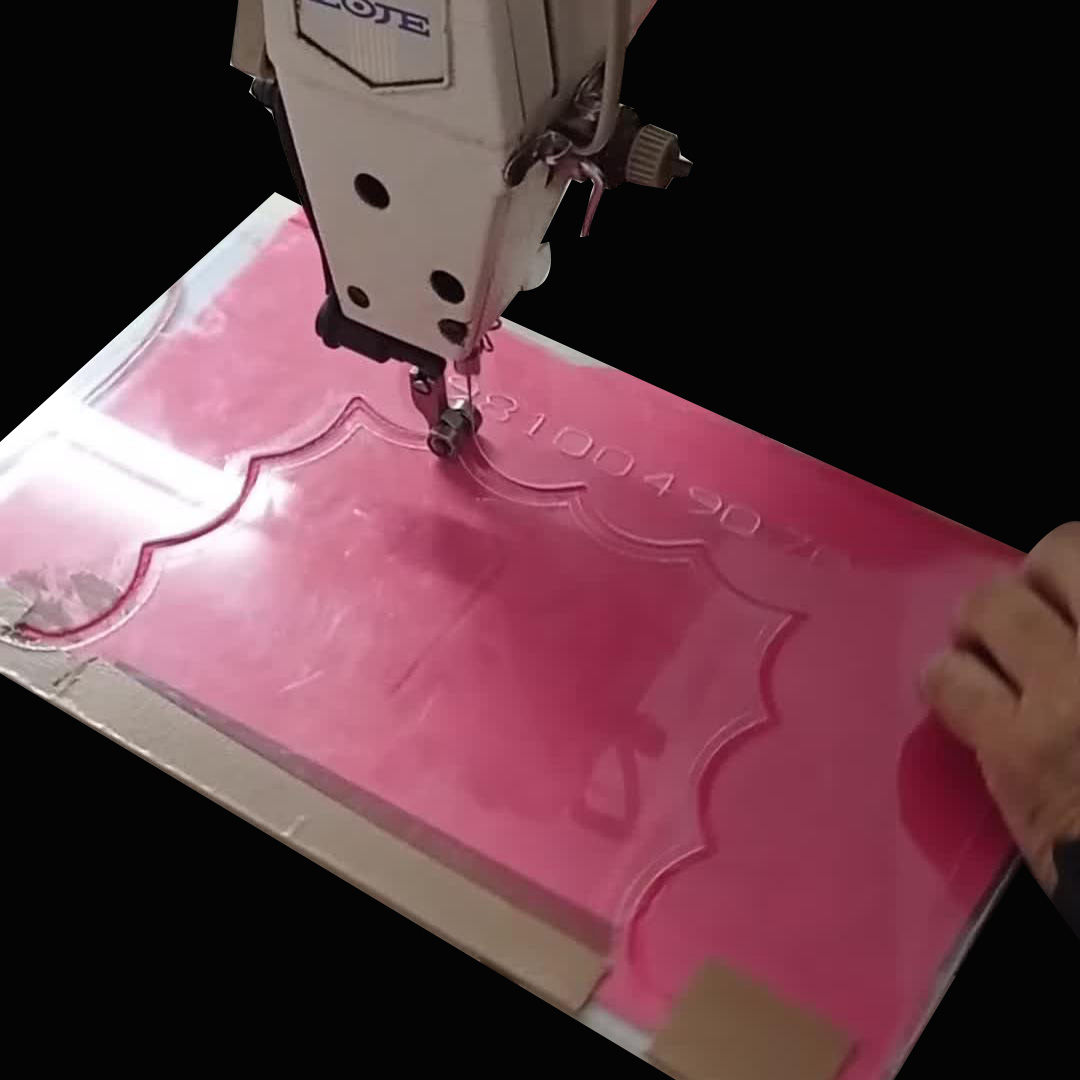

What Techniques Are Used in Forming PVC Garments?

Once the materials are prepared, the forming stage begins. This process often employs techniques such as heat sealing, welding, or stitching, depending on the garment type. Heat sealing involves fusing two pieces of PVC together through heat, providing a waterproof seam ideal for outdoor or protective wear. Alternatively, welding offers a robust bond for heavier garments, while stitching may be used for lighter items, allowing for more flexibility in design.

How Are PVC Garments Assembled?

The assembly stage involves bringing together the various components of the garment. This includes attaching straps, zippers, and other accessories. Quality craftsmanship is crucial during assembly, as any defects can lead to functional issues or aesthetic flaws. Skilled labor is often combined with automated processes to enhance efficiency while maintaining quality. Attention to detail in this stage ensures that the final product not only fits well but also meets the intended use specifications.

What Finishing Touches Are Applied to PVC Garments?

Finishing processes add the final touches to PVC garments. This stage may involve cleaning, polishing, and applying protective coatings to enhance durability and appearance. Additionally, labels and care instructions are affixed to the garments. Quality checks during the finishing stage ensure that all items are consistent in quality and free from defects, ready for packaging and shipping.

How is Quality Assurance Implemented in PVC Garment Manufacturing?

Quality assurance (QA) is an integral aspect of PVC garment manufacturing, designed to ensure that products meet both international standards and specific client requirements.

What International Standards Guide PVC Garment Quality?

Manufacturers often adhere to international quality standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards assures buyers that the manufacturer has processes in place to consistently produce quality products. Additionally, industry-specific standards like CE marking for European markets and API standards for protective clothing can apply depending on the garment’s intended use.

What Are the Key Quality Control Checkpoints in PVC Garment Production?

Quality control (QC) checkpoints are established at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Quality checks during the manufacturing process are crucial for identifying defects early. This can include visual inspections and functional testing of components.

- Final Quality Control (FQC): The last step involves a thorough inspection of finished garments to ensure they meet all quality standards before shipping.

Which Testing Methods Are Commonly Used for PVC Garments?

Testing methods for PVC garments typically include physical tests for tensile strength, elasticity, and tear resistance. Chemical tests may also be performed to ensure that the PVC complies with safety regulations, particularly regarding harmful substances. Additionally, water resistance and durability tests are conducted to evaluate performance under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying the quality control measures of their suppliers.

What Are Effective Strategies for Conducting Supplier Audits?

Conducting audits is an effective way to assess a supplier’s manufacturing processes and quality assurance practices. Buyers should consider on-site visits to evaluate the manufacturing environment, equipment, and workforce. This firsthand observation can provide valuable insights into the supplier’s commitment to quality.

How Can Buyers Leverage Reports and Third-Party Inspections?

Buyers should request detailed QC reports from suppliers, which should outline inspection results and compliance with international standards. Engaging third-party inspection agencies can also add an extra layer of assurance. These agencies can perform independent evaluations of the manufacturing processes and final products, ensuring adherence to quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is critical.

Illustrative image related to pvc garments

How Do Regional Regulations Impact Quality Standards?

Different regions may have specific regulations affecting quality standards for PVC garments. For example, European markets may require compliance with additional safety standards, while Middle Eastern countries might have different requirements for protective clothing. Buyers must be aware of these regulations to ensure that their products meet local compliance.

What Are the Challenges of Sourcing PVC Garments Internationally?

Sourcing PVC garments internationally can present challenges, including language barriers, cultural differences, and varying quality expectations. Buyers should establish clear communication channels and detailed specifications to mitigate these challenges. Building strong relationships with suppliers can also facilitate smoother transactions and enhance quality assurance processes.

Conclusion

Understanding the manufacturing processes and quality assurance practices for PVC garments is essential for B2B buyers looking to make informed purchasing decisions. By familiarizing themselves with the stages of production, quality control checkpoints, and verification methods, buyers can ensure they source high-quality products that meet their specific needs and comply with international standards. This comprehensive approach not only enhances the quality of the final products but also fosters long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc garments’

This guide serves as a comprehensive checklist for B2B buyers looking to source PVC garments effectively. By following these steps, you can ensure a smooth procurement process that meets your business needs and quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical to ensure that the PVC garments meet your intended use. Consider factors such as the type of PVC (e.g., clear, holographic), garment styles (e.g., tops, dresses, accessories), and any specific functional requirements, such as waterproofing or stretchability. This clarity will help you communicate your needs effectively to suppliers and avoid potential misunderstandings.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify suppliers that specialize in PVC garments. Utilize platforms like trade directories, industry-specific forums, and trade shows to compile a list of potential vendors. Focus on suppliers with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe, to ensure they understand local market demands.

Step 3: Evaluate Supplier Capabilities and Product Quality

Before making a decision, assess the capabilities of your shortlisted suppliers. Request product samples to evaluate the quality of the PVC garments, including texture, durability, and finish. Additionally, inquire about their production processes to ensure they adhere to international quality standards, as this can significantly impact the longevity and appeal of your products.

Step 4: Verify Compliance with Industry Standards

Ensure that your suppliers comply with relevant industry standards and regulations, particularly regarding material safety and environmental impact. Request certifications, such as ISO or OEKO-TEX, which demonstrate adherence to quality and safety benchmarks. This step is vital for safeguarding your brand’s reputation and ensuring your products are safe for consumers.

Step 5: Discuss Pricing and Payment Terms

Engage in transparent discussions about pricing structures and payment terms with your chosen suppliers. Understand the pricing breakdown, including production costs, shipping fees, and any potential tariffs. Establish clear payment terms, such as deposits or credit arrangements, to maintain financial control and reduce risks associated with procurement.

Step 6: Establish a Communication Protocol

Effective communication is key to a successful sourcing relationship. Set up a communication protocol that outlines how and when you will interact with your suppliers. Regular updates and feedback can help mitigate issues early and ensure that production timelines are met.

Illustrative image related to pvc garments

Step 7: Plan for Logistics and Distribution

Finally, consider the logistics involved in transporting the PVC garments from the supplier to your business location. Evaluate shipping options, customs requirements, and potential delays. A well-planned logistics strategy will help ensure timely delivery and minimize disruptions to your supply chain.

By following this checklist, B2B buyers can streamline their procurement process for PVC garments, ensuring they secure high-quality products that meet their business needs efficiently.

Comprehensive Cost and Pricing Analysis for pvc garments Sourcing

What Are the Key Cost Components in PVC Garment Sourcing?

When sourcing PVC garments, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

-

Materials: The cost of PVC fabric varies significantly based on quality and specifications, such as thickness, finish, and color. For instance, high-gloss or holographic PVC may carry a premium price compared to standard options. Buyers should also consider the sourcing location, as prices can fluctuate based on regional supply and demand.

-

Labor: Labor costs depend on the complexity of the garment design and the skill level required. Regions with lower labor costs, such as certain parts of South America and Africa, may offer competitive pricing. However, this can be offset by potential quality concerns if the manufacturing processes are not up to standard.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities, rent, and equipment maintenance. Efficient production processes can help reduce these costs, leading to better pricing for buyers.

-

Tooling: Custom designs often require specific tooling, which can be a significant upfront investment. Buyers should assess whether the tooling costs can be amortized over multiple orders to optimize the total cost.

-

Quality Control (QC): Ensuring that garments meet quality standards is essential, especially for international shipments. QC processes add to the overall cost but are critical in maintaining brand reputation.

-

Logistics: Shipping costs can vary based on the Incoterms agreed upon, the mode of transport, and the shipping distance. Buyers should factor in duties, tariffs, and potential delays, especially when importing from regions like Asia to Europe or the Americas.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards can help buyers negotiate better deals without compromising on quality.

What Influences Pricing in PVC Garments?

Several factors can influence the pricing of PVC garments, making it crucial for buyers to be aware of these nuances to achieve the best deal.

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Larger orders often lead to reduced unit costs due to economies of scale. Buyers should evaluate their needs carefully to find the right balance.

-

Specifications and Customization: Customized garments, such as those requiring unique designs or additional features, typically incur higher costs. Buyers should clearly communicate their specifications to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly or safety standards) may come at a premium. Buyers should weigh the benefits of these attributes against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms can greatly affect the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers anticipate additional costs.

How Can Buyers Negotiate Effectively for PVC Garments?

-

Conduct Market Research: Understanding current market prices and trends can empower buyers during negotiations. Gathering quotes from multiple suppliers can provide leverage.

-

Leverage Total Cost of Ownership (TCO): Rather than focusing solely on unit price, consider the TCO, which includes shipping, duties, and potential QC costs. A supplier with a slightly higher unit price may offer better overall value.

-

Be Clear About Requirements: Clear communication regarding garment specifications, timelines, and quality expectations minimizes misunderstandings and potential costs.

-

Build Long-Term Relationships: Establishing a solid relationship with suppliers can lead to better pricing and terms over time. Loyalty can foster goodwill and more favorable negotiation outcomes.

-

Understand Regional Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional economic conditions and how they affect pricing dynamics. This knowledge can enhance negotiation strategies and help in securing favorable terms.

In conclusion, sourcing PVC garments requires a comprehensive understanding of the cost structure and pricing influencers. By being informed and strategically negotiating, buyers can optimize their sourcing efforts and achieve favorable outcomes.

Alternatives Analysis: Comparing pvc garments With Other Solutions

Understanding Alternatives in the Context of PVC Garments

In the ever-evolving landscape of fashion and industrial applications, PVC garments have carved a niche due to their unique properties. However, international B2B buyers may find it beneficial to explore alternatives that offer similar functionalities. This analysis delves into a comparative overview of PVC garments against alternative solutions, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to pvc garments

Comparison Table of PVC Garments and Alternatives

| Comparison Aspect | PVC Garments | Polyurethane (PU) Coated Fabrics | Neoprene Fabric |

|---|---|---|---|

| Performance | Durable, water-resistant, aesthetic appeal | Flexible, breathable, good durability | Excellent insulation, durable |

| Cost | Moderate to high | Moderate | High |

| Ease of Implementation | Easy to manufacture | Requires specific techniques | More complex due to thickness |

| Maintenance | Simple care, resistant to stains | Requires careful cleaning | Hand wash recommended |

| Best Use Case | Fashion, cosplay, protective wear | Activewear, fashion applications | Wetsuits, thermal wear |

What Are the Advantages and Disadvantages of Polyurethane (PU) Coated Fabrics?

Polyurethane-coated fabrics serve as a flexible alternative to PVC garments. They are known for their breathability and comfort, making them ideal for activewear and fashion applications. PU offers a similar level of durability but is often lighter than PVC, enhancing wearability. However, they may not provide the same level of aesthetic appeal and shine that PVC garments are known for. Additionally, PU fabrics can be more expensive due to the manufacturing processes involved, impacting cost-effectiveness for bulk purchases.

How Does Neoprene Fabric Compare to PVC Garments?

Neoprene fabric is another viable alternative, particularly recognized for its excellent insulation properties. Commonly used in wetsuits and thermal wear, neoprene offers durability and flexibility, making it suitable for extreme conditions. Its thickness can provide substantial warmth, which is beneficial in colder environments. However, neoprene’s complexity in manufacturing can lead to higher costs and more challenging implementation processes, which may not suit all B2B buyers looking for straightforward solutions.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When deciding between PVC garments and alternative solutions like PU-coated fabrics or neoprene, B2B buyers should consider their specific application needs and budget constraints. While PVC offers unique aesthetic qualities and ease of maintenance, alternatives may provide enhanced comfort, breathability, or thermal insulation. Evaluating the intended use case, cost implications, and maintenance requirements will help buyers identify the most suitable option for their business. This strategic approach ensures that the chosen material aligns with both operational goals and customer expectations, fostering successful outcomes in diverse markets.

Essential Technical Properties and Trade Terminology for pvc garments

What Are the Key Technical Properties of PVC Garments?

Understanding the technical properties of PVC garments is essential for B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality and composition of the PVC used in garments. Higher grades typically provide better durability, flexibility, and resistance to environmental factors. For B2B buyers, selecting the right material grade ensures the garments meet performance requirements and customer expectations.

2. Tolerance Levels

Tolerance levels indicate the permissible variations in the dimensions and properties of PVC garments. This is crucial for ensuring consistency in manufacturing and fit. For buyers, understanding tolerance helps in assessing whether the products will meet their specifications, reducing the risk of returns and dissatisfaction.

3. Thickness

Thickness is a critical property that affects the garment’s durability, appearance, and comfort. Thicker PVC materials generally offer better protection and longevity, while thinner options may be more flexible and lightweight. Buyers should evaluate thickness based on the intended use of the garments, whether for fashion, protection, or performance.

Illustrative image related to pvc garments

4. Surface Finish

The surface finish of PVC garments can vary from glossy to matte, and this characteristic influences both aesthetics and functionality. A glossy finish might be preferred for fashion items, while a matte finish can be more suitable for industrial applications. Understanding the surface finish helps buyers align their selections with market trends and consumer preferences.

5. UV Resistance

UV resistance is the ability of PVC garments to withstand prolonged exposure to sunlight without degrading. This property is particularly important for outdoor applications or garments intended for sunny climates. Buyers should prioritize UV resistance to ensure the longevity and reliability of their products, especially in regions like Africa and the Middle East.

6. Water Resistance

Water resistance denotes the garment’s ability to repel water, which is vital for protective clothing used in wet environments. Buyers in sectors such as hospitality, healthcare, and outdoor recreation should assess water resistance to ensure their garments provide adequate protection.

What Are Common Trade Terminology and Jargon in the PVC Garment Industry?

Familiarizing yourself with industry-specific terminology can enhance communication and negotiation in B2B transactions. Here are several key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are marketed under another company’s brand. In the context of PVC garments, this means that a manufacturer can create custom designs or products for brands looking to expand their offerings. Understanding OEM relationships can help buyers identify potential partners for private-label products.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to produce or sell in a single order. This term is crucial for B2B buyers as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their sales forecasts and storage capabilities.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers to request pricing and terms for specific products. In the PVC garment industry, sending an RFQ helps streamline the procurement process and allows buyers to compare quotes effectively. Crafting a precise RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is particularly relevant for buyers sourcing PVC garments from different regions. Understanding Incoterms can prevent misunderstandings and ensure smooth transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. In the PVC garment industry, lead times can vary significantly based on production schedules, material availability, and shipping conditions. Buyers should factor lead time into their planning to maintain inventory levels and meet customer demand.

6. Sustainability Certifications

Sustainability certifications indicate that a product meets specific environmental standards. In the PVC garment industry, certifications can enhance brand reputation and appeal to eco-conscious consumers. Buyers should consider sustainability certifications as part of their sourcing strategy to align with market trends and consumer preferences.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions that enhance their procurement processes and meet market demands effectively.

Navigating Market Dynamics and Sourcing Trends in the pvc garments Sector

What Are the Current Market Dynamics and Key Trends in the PVC Garments Sector?

The PVC garments sector is experiencing a dynamic transformation influenced by various global drivers. Notably, the rising demand for fashionable yet functional apparel is propelling the market forward. International buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly investing in PVC garments, attracted by their versatility and unique aesthetic appeal. This surge is supported by the rapid evolution of e-commerce platforms, which facilitate seamless sourcing and distribution processes. B2B tech trends, such as AI-driven inventory management systems and digital fabric printing, are enhancing operational efficiencies, allowing businesses to respond promptly to market trends.

Emerging markets, particularly in Africa and South America, are witnessing a growing acceptance of PVC garments as fashion staples. The Middle East, with its thriving fashion industry, is also becoming a significant player in the PVC sector. Key trends include the integration of holographic and glow-in-the-dark elements, catering to niche markets such as cosplay and nightlife. As European markets, particularly Germany, emphasize sustainability, buyers are increasingly prioritizing suppliers who can provide eco-friendly PVC options without compromising style.

How Is Sustainability Shaping the Sourcing Strategies for PVC Garments?

Sustainability is becoming a crucial consideration for B2B buyers in the PVC garments sector. The environmental impact of PVC production, primarily its contribution to plastic pollution and greenhouse gas emissions, is prompting businesses to seek more ethical sourcing solutions. Buyers are encouraged to collaborate with manufacturers who prioritize sustainable practices, such as using recycled materials and adopting eco-friendly production methods.

Ethical supply chains are increasingly important, as consumers demand transparency about the origins of their products. Certifications such as Global Recycled Standard (GRS) and Oeko-Tex Standard 100 are becoming essential for suppliers to demonstrate their commitment to sustainability. By sourcing PVC garments that meet these standards, B2B buyers can enhance their brand reputation and appeal to environmentally-conscious consumers. Furthermore, incorporating sustainable PVC options can reduce waste and foster a circular economy, offering long-term benefits for both businesses and the planet.

What Is the Historical Context of PVC Garments in the B2B Landscape?

The PVC garments sector has evolved significantly since its inception in the mid-20th century. Initially popularized in the fashion industry for its affordability and versatility, PVC began to be associated with avant-garde styles and subcultures. Over the decades, advancements in technology have improved the quality and variety of PVC fabrics, making them suitable for diverse applications beyond fashion, including functional wear and protective clothing.

In recent years, the PVC garments market has seen a resurgence, driven by a blend of nostalgia and innovation. B2B buyers are increasingly recognizing the potential of PVC as a material that combines fashion-forward design with practicality. This evolution reflects broader trends in the textile industry, where traditional materials are being reimagined to meet contemporary consumer demands. As the market continues to evolve, understanding its historical context can provide valuable insights for strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc garments

-

How can I identify reliable suppliers for PVC garments?

To identify reliable suppliers for PVC garments, start by conducting thorough research online. Look for manufacturers with a strong online presence, including certifications and customer testimonials. Utilize platforms like Alibaba, Global Sources, or industry-specific directories. Additionally, request samples to assess product quality and engage in direct communication to gauge responsiveness and professionalism. Networking through trade shows or industry events can also provide insights into reputable suppliers. -

What are the typical minimum order quantities (MOQs) for PVC garments?

Minimum order quantities (MOQs) for PVC garments can vary widely depending on the supplier and the complexity of the garments. Generally, MOQs can range from 100 to 1,000 units. However, some suppliers may offer lower MOQs for sample orders or introductory projects. It’s crucial to discuss MOQs upfront during negotiations to align with your purchasing capacity and market demands. -

What customization options are available for PVC garments?

Customization options for PVC garments often include fabric colors, textures, styles, and sizes. Many suppliers allow buyers to submit their designs for tailored production. Some may also offer additional features like branding, logos, or unique patterns. When seeking customization, provide detailed specifications and consider sample production to ensure the final product meets your expectations. -

What payment terms should I expect when sourcing PVC garments internationally?

Payment terms can vary significantly among suppliers, but common practices include a 30% deposit before production and the remaining 70% upon shipment. Some suppliers may offer letters of credit or escrow services for larger orders. Always clarify payment methods, including options like bank transfers or online payment platforms, to ensure security and ease of transactions. -

What quality assurance measures should I implement when sourcing PVC garments?

Implementing quality assurance measures is essential to ensure product reliability. Start by conducting pre-production meetings to establish quality standards. Request detailed product specifications and conduct in-factory inspections during production. Utilizing third-party quality control services can also help assess product quality before shipment. Always specify penalties for non-compliance in your contracts to protect your interests. -

What are the key logistics considerations for importing PVC garments?

When importing PVC garments, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Evaluate whether to use air or sea freight based on urgency and budget. Ensure compliance with international shipping regulations, including necessary documentation like commercial invoices and packing lists. Collaborating with a reliable freight forwarder can streamline the process and mitigate potential delays. -

How do I handle potential issues with PVC garment suppliers?

Handling issues with suppliers requires clear communication and a proactive approach. If a problem arises, document all relevant details and reach out to the supplier promptly. Maintain a professional tone and seek resolution through dialogue, whether that involves product replacements, refunds, or adjustments. Establishing a solid relationship beforehand can facilitate smoother conflict resolution. -

What are the environmental considerations for sourcing PVC garments?

As awareness of sustainability grows, it’s essential to consider the environmental impact of PVC garments. Look for suppliers who adhere to eco-friendly manufacturing practices, such as using recyclable materials or reducing harmful chemicals. Request information about their sustainability certifications and initiatives. Collaborating with environmentally conscious suppliers can enhance your brand’s reputation and align with consumer preferences.

Top 2 Pvc Garments Manufacturers & Suppliers List

1. Fabric Wholesale Direct – PVC Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – PVC Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Corset Story – Premium Corsets

Domain: corset-story.com

Registered: 2010 (15 years)

Introduction: Product Type: corset top, corset with shoulder straps, overbust corset top, underbust corset, waspie corset; Colour: Black, Brown, Gold, Purple, Red, Silver; Comfort Rating: 6, 7, 8, 9; Corset Features: cord lacing, hip gores, ribbon lacing, shoulder straps, steel busk, swing hook, zip; Disguise Rating: 1 to 10; Product Stock State: In Stock, Pre Order; Length: longline, petite, regular; Achievabl…

Strategic Sourcing Conclusion and Outlook for pvc garments

In the evolving landscape of PVC garments, strategic sourcing emerges as a critical component for international B2B buyers seeking competitive advantage. By prioritizing high-quality materials and reliable suppliers, businesses can enhance their product offerings while ensuring compliance with regional regulations and sustainability standards. This approach not only mitigates risks associated with supply chain disruptions but also fosters innovation in design and functionality.

For buyers in Africa, South America, the Middle East, and Europe, understanding market trends and consumer preferences is essential. The demand for diverse PVC applications—from fashion-forward garments to protective wear—indicates a robust market potential. Collaborating with manufacturers that offer customization and responsiveness to trends can significantly boost market penetration.

As we look ahead, the PVC garment sector is poised for growth driven by technological advancements and a shift towards eco-friendly practices. Buyers are encouraged to engage in long-term partnerships with suppliers that share their vision for sustainability and innovation. By investing in strategic sourcing now, businesses can position themselves as leaders in the global market for PVC garments, ready to capitalize on emerging opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.