Introduction: Navigating the Global Market for the leather factory sofa

In an increasingly interconnected world, sourcing high-quality leather factory sofas presents a unique challenge for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. As businesses strive to enhance their offerings, they must navigate a complex landscape of suppliers, materials, and pricing structures. This comprehensive guide is designed to empower decision-makers by providing insights into the various types of leather factory sofas available, their applications in different settings, and essential considerations for supplier vetting.

From understanding the nuances of leather grades to evaluating the craftsmanship that distinguishes high-end sofas from mass-produced options, this guide covers all critical aspects of the purchasing process. It also delves into cost considerations, enabling buyers to align their budgets with their quality expectations while maximizing value. Whether you are a furniture retailer in Nigeria seeking to expand your product line, an interior designer in Saudi Arabia looking for bespoke solutions, or a hotel owner in Europe aiming to furnish luxurious spaces, this resource equips you with the knowledge needed to make informed decisions.

By addressing key challenges and providing actionable insights, this guide serves as a strategic tool for international B2B buyers, ensuring that every investment in leather factory sofas enhances both their brand and customer satisfaction.

Table Of Contents

- Top 4 The Leather Factory Sofa Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for the leather factory sofa

- Understanding the leather factory sofa Types and Variations

- Key Industrial Applications of the leather factory sofa

- 3 Common User Pain Points for ‘the leather factory sofa’ & Their Solutions

- Strategic Material Selection Guide for the leather factory sofa

- In-depth Look: Manufacturing Processes and Quality Assurance for the leather factory sofa

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘the leather factory sofa’

- Comprehensive Cost and Pricing Analysis for the leather factory sofa Sourcing

- Alternatives Analysis: Comparing the leather factory sofa With Other Solutions

- Essential Technical Properties and Trade Terminology for the leather factory sofa

- Navigating Market Dynamics and Sourcing Trends in the the leather factory sofa Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of the leather factory sofa

- Strategic Sourcing Conclusion and Outlook for the leather factory sofa

- Important Disclaimer & Terms of Use

Understanding the leather factory sofa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather Sofa | Made from the top layer of hide; retains natural grain and markings. | Luxury hotels, high-end retailers | Pros: Durability, natural aesthetics. Cons: Higher cost, requires maintenance. |

| Top-Grain Leather Sofa | Second layer of hide, sanded to remove imperfections; more affordable than full-grain. | Offices, upscale residential | Pros: Good balance of quality and price. Cons: Less durable than full-grain. |

| Aniline-Dyed Leather Sofa | Colored with transparent dyes, showcasing natural textures. | Boutique stores, art galleries | Pros: Rich colors, luxurious feel. Cons: Prone to staining, requires careful upkeep. |

| Bonded Leather Sofa | Made from leather scraps bonded together; cost-effective option. | Budget hotels, student housing | Pros: Affordable, available in various styles. Cons: Less durable, may peel over time. |

| Reclining Leather Sofa | Features reclining mechanisms for enhanced comfort. | Home theaters, lounges | Pros: Increased comfort, ideal for relaxation. Cons: Mechanisms may require maintenance, bulkier design. |

What Are the Key Characteristics of Full-Grain Leather Sofas?

Full-grain leather sofas are crafted from the top layer of the hide, preserving the natural grain and markings. This type of leather is highly regarded for its durability and unique aesthetic, making it a popular choice for luxury hotels and high-end retailers. B2B buyers should consider the long-term investment aspect, as these sofas can withstand heavy use and age beautifully, though they come at a higher price point and require regular maintenance to keep them looking their best.

How Do Top-Grain Leather Sofas Compare to Full-Grain Options?

Top-grain leather sofas are made from the second layer of hide, sanded to remove imperfections, resulting in a more uniform appearance. This variation offers a balance between quality and affordability, making it suitable for upscale residential settings and offices. Buyers looking for a durable yet cost-effective solution will find top-grain leather a compelling option. However, it’s essential to note that while they are less expensive than full-grain, they may not last as long under heavy wear.

Why Choose Aniline-Dyed Leather Sofas for Boutique Environments?

Aniline-dyed leather sofas are colored using transparent dyes that allow the natural textures of the leather to shine through, providing a luxurious feel. These sofas are ideal for boutique stores and art galleries where aesthetics are paramount. While they offer rich colors and a high-end appearance, B2B buyers should be aware that aniline-dyed leather is more susceptible to staining and requires careful upkeep, which could impact long-term maintenance costs.

Illustrative image related to the leather factory sofa

What Are the Benefits of Bonded Leather Sofas for Budget-Conscious Buyers?

Bonded leather sofas are made from leather scraps that are bonded together, making them a cost-effective option for businesses such as budget hotels and student housing. They are available in various styles and can provide a leather-like appearance at a lower price. However, buyers should consider that bonded leather may not be as durable as other types and can peel over time, which could lead to additional replacement costs.

How Do Reclining Leather Sofas Enhance Comfort in Commercial Settings?

Reclining leather sofas are designed with mechanisms that allow for reclining, providing enhanced comfort and relaxation. These sofas are particularly suited for home theaters and lounges, where comfort is essential. While they offer a great way to improve customer experience, B2B buyers should consider the potential for mechanical issues and the bulkier design that may require more space.

Key Industrial Applications of the leather factory sofa

| Industry/Sector | Specific Application of the leather factory sofa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Lobby and lounge areas in hotels and resorts | Enhances guest experience and brand image | Durability, style options, and customization for branding needs |

| Corporate Offices | Reception areas and executive lounges | Creates a professional atmosphere and comfort for clients | Color and finish options to match corporate branding |

| Retail | Showrooms and display areas for high-end merchandise | Attracts customers and showcases products effectively | Design flexibility and customization to align with brand aesthetics |

| Real Estate | Staging homes for sale or rent | Increases appeal and perceived value of properties | Quality and style to match target market demographics |

| Health and Wellness | Waiting areas in clinics and wellness centers | Provides comfort and a calming environment for clients | Easy maintenance and durability to withstand high traffic |

How is the leather factory sofa used in the hospitality industry?

In the hospitality sector, leather factory sofas are commonly utilized in lobby and lounge areas of hotels and resorts. These sofas not only enhance the aesthetic appeal of the space but also contribute significantly to the overall guest experience. Buyers in this sector often seek durable, stylish options that can withstand heavy use while maintaining a luxurious appearance. Customization options are crucial for aligning the sofas with the hotel’s branding, ensuring that the furniture complements the overall design theme.

Illustrative image related to the leather factory sofa

What role does the leather factory sofa play in corporate offices?

Corporate offices frequently incorporate leather factory sofas into reception areas and executive lounges to create a welcoming and professional environment. These sofas provide comfort for clients and guests, facilitating a positive first impression. B2B buyers in this sector prioritize options that reflect their corporate identity, looking for specific colors and finishes that align with branding. The durability of leather is also a key consideration, as these spaces experience high foot traffic.

How does the leather factory sofa benefit retail environments?

In retail settings, leather factory sofas are often used in showrooms and display areas to attract customers. The elegant appearance of leather furniture can enhance the shopping experience, making products appear more appealing. Retailers benefit from customization options that allow the sofas to align with their brand aesthetics. Buyers should consider the ability to source unique designs that stand out in a competitive market while ensuring that the sofas are durable enough to handle frequent customer interaction.

Why are leather factory sofas important for real estate staging?

In the real estate industry, leather factory sofas are essential for staging homes for sale or rent. They help create an inviting atmosphere that can increase the appeal and perceived value of a property. Real estate professionals seek high-quality, stylish options that resonate with potential buyers’ tastes. Sourcing considerations include selecting pieces that can match the demographics of the target market, ensuring the furniture enhances the overall presentation of the home.

How do leather factory sofas contribute to health and wellness spaces?

In health and wellness settings, such as clinics and wellness centers, leather factory sofas are used in waiting areas to provide comfort and a calming environment for clients. The choice of durable, easy-to-maintain materials is critical, as these areas often see high traffic. B2B buyers in this sector should prioritize sofas that not only look appealing but also offer easy cleaning solutions to ensure hygiene standards are met, thereby fostering a welcoming atmosphere for visitors.

3 Common User Pain Points for ‘the leather factory sofa’ & Their Solutions

Scenario 1: Quality Assurance in Leather Sofa Sourcing

The Problem: B2B buyers often face challenges in ensuring the quality of leather sofas sourced from manufacturers, especially when purchasing in bulk for hotels, offices, or retail spaces. Concerns about durability, material authenticity, and the craftsmanship can lead to anxiety over whether the investment will meet the expected standards. Furthermore, international buyers might encounter issues with varying quality standards across different regions, making it difficult to maintain consistency.

The Solution: To address quality assurance, buyers should establish direct communication with manufacturers known for their craftsmanship, like those in the leather factory sector. It’s essential to request samples of the leather used, along with detailed specifications of the manufacturing processes. Engaging in thorough discussions about the sourcing of materials and the types of leather available (such as full-grain or top-grain) will enhance understanding. Additionally, visiting the production facility, if feasible, can provide first-hand insights into the quality control measures in place. Buyers should also seek warranties and guarantees on the products, which can serve as an extra layer of assurance regarding durability and craftsmanship.

Scenario 2: Customization and Design Flexibility Challenges

The Problem: Many B2B buyers struggle with the limited options available for customization when sourcing leather sofas. This is especially true for businesses looking to create a unique brand identity through their furniture choices, such as in hospitality or high-end retail environments. A lack of customization options can lead to dissatisfaction, as the furniture may not align with the desired aesthetic or functional requirements of the space.

The Solution: Buyers should leverage manufacturers that offer extensive customization capabilities. Before placing an order, it’s beneficial to inquire about the options for selecting leather types, colors, and designs that align with specific brand aesthetics. Engaging in a design consultation can also facilitate a more tailored approach. Many manufacturers provide configurators or design tools that allow buyers to visualize their selections in real-time. Collaborating with the manufacturer’s design team can lead to innovative solutions that meet both aesthetic and functional needs, ensuring that the final product enhances the overall brand experience.

Scenario 3: Logistics and Delivery Concerns for International Orders

The Problem: Logistics can be a significant pain point for B2B buyers, particularly when ordering leather sofas from international manufacturers. Buyers may encounter delays in shipping, unexpected customs issues, or higher-than-anticipated delivery costs. Such challenges can disrupt project timelines and impact overall customer satisfaction, especially in industries like hospitality where timely delivery is critical.

The Solution: To mitigate logistics issues, buyers should conduct thorough research on the shipping and delivery processes of potential manufacturers. It’s advisable to ask about their experience with international shipping and to inquire about average delivery times. Establishing a clear logistics plan that includes understanding the customs requirements for their specific region can also minimize delays. Buyers should consider working with freight forwarders who specialize in furniture to help navigate these complexities. Additionally, requesting a detailed shipping timeline and tracking information can provide transparency and allow for proactive management of any potential delays, ensuring that the delivery aligns with project schedules.

Strategic Material Selection Guide for the leather factory sofa

What Are the Key Materials Used in Leather Factory Sofas?

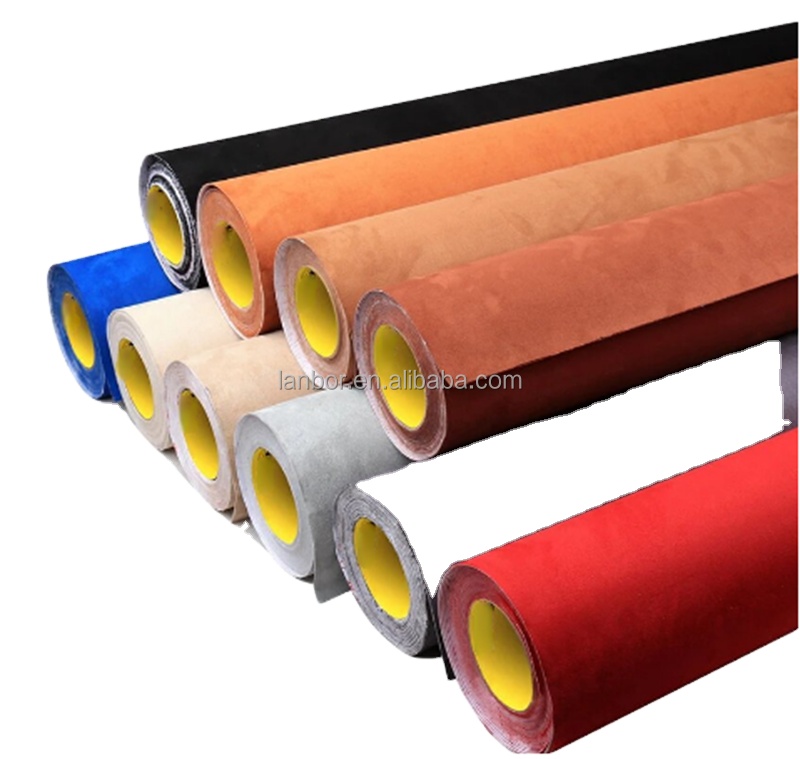

When selecting materials for leather factory sofas, it is crucial to consider their properties, advantages, disadvantages, and the specific needs of international B2B buyers. The following analysis focuses on four common materials used in the production of leather sofas: aniline leather, pigmented leather, bonded leather, and synthetic leather.

How Does Aniline Leather Perform in Leather Factory Sofas?

Aniline leather is made from high-quality hides that are dyed with soluble dyes, preserving the natural grain and texture. This type of leather is known for its luxurious feel and breathability, making it an excellent choice for high-end sofas.

Pros: Aniline leather is soft, supple, and develops a beautiful patina over time, enhancing its aesthetic appeal. It is also highly breathable, which contributes to comfort during use.

Illustrative image related to the leather factory sofa

Cons: The primary drawback of aniline leather is its vulnerability to stains and fading from sunlight, which can limit its suitability for environments with heavy use or direct sunlight exposure. Additionally, it tends to be more expensive than other leather types.

Impact on Application: Aniline leather is best suited for upscale markets and buyers looking for premium products. Its natural characteristics may appeal to consumers in Europe and the Middle East, where luxury and craftsmanship are highly valued.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the climate when selecting aniline leather, as high humidity can affect its longevity. Compliance with international leather standards, such as those set by ASTM, is also essential for ensuring quality.

What Are the Benefits of Pigmented Leather in Leather Sofas?

Pigmented leather is treated with a protective coating that enhances durability and resistance to stains and fading. This makes it a popular choice for families and commercial settings.

Pros: The durability of pigmented leather is one of its strongest advantages. It is easy to clean and maintain, making it suitable for high-traffic areas. Additionally, it is available in a wide range of colors and finishes.

Cons: While pigmented leather is robust, it may lack the natural feel and breathability of aniline leather. The protective coating can sometimes give it a less authentic appearance.

Impact on Application: Pigmented leather is ideal for environments where durability and ease of maintenance are priorities, such as hotels and restaurants. Its versatility makes it appealing to buyers across various markets.

Considerations for International Buyers: Buyers should ensure that the pigmented leather complies with local regulations regarding chemical treatments and environmental standards, particularly in the Middle East and Europe.

How Does Bonded Leather Compare in Terms of Cost and Performance?

Bonded leather is made from leftover leather scraps that are bonded together with polyurethane. It is often marketed as a cost-effective alternative to genuine leather.

Pros: The primary advantage of bonded leather is its affordability, making it accessible for budget-conscious buyers. It also offers a leather-like appearance while being easier to maintain than genuine leather.

Cons: Bonded leather is less durable than aniline or pigmented leather and may wear out more quickly. It is also less breathable, which can affect comfort.

Impact on Application: Bonded leather is suitable for entry-level products and can appeal to buyers in regions where cost is a significant factor, such as in parts of Africa and South America.

Considerations for International Buyers: Buyers should be aware of the quality variations in bonded leather and ensure compliance with standards that ensure the absence of harmful chemicals.

What Role Does Synthetic Leather Play in Leather Sofa Manufacturing?

Synthetic leather, often made from polyurethane or PVC, mimics the look and feel of genuine leather while being entirely man-made.

Pros: Synthetic leather is highly durable, water-resistant, and easy to clean. It is also available in a wide variety of colors and textures, appealing to diverse consumer preferences.

Cons: Despite its many advantages, synthetic leather may not provide the same luxurious feel as genuine leather. Additionally, it can be less breathable, which may affect comfort in warmer climates.

Impact on Application: Synthetic leather is often used in budget-friendly products and is suitable for various applications, including commercial settings where durability is essential.

Considerations for International Buyers: Buyers should consider local preferences for sustainability, as synthetic leather may not align with eco-friendly practices in some markets, particularly in Europe.

Summary Table of Material Selection for Leather Factory Sofas

| Material | Typical Use Case for the leather factory sofa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aniline Leather | High-end residential and luxury markets | Luxurious feel and breathability | Vulnerable to stains and fading | High |

| Pigmented Leather | Commercial settings and family use | Durable and easy to maintain | Less authentic appearance | Medium |

| Bonded Leather | Entry-level products and budget markets | Affordable and leather-like look | Less durable and wears out quickly | Low |

| Synthetic Leather | Budget-friendly and commercial applications | Highly durable and easy to clean | Less luxurious feel and breathability | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, ensuring informed decisions that align with market demands and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for the leather factory sofa

What Are the Main Stages in the Manufacturing Process of a Leather Factory Sofa?

The manufacturing process of a leather factory sofa typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers looking to ensure that their suppliers adhere to high-quality production standards.

Illustrative image related to the leather factory sofa

How Is Material Prepared for Leather Sofa Production?

The first step in manufacturing is the preparation of materials. High-quality leather is sourced from reputable suppliers, often from countries known for their leather production, such as Italy, Brazil, and Argentina. This leather undergoes an extensive selection process to ensure it meets specific criteria, including texture, durability, and color.

Once selected, the leather is treated and dyed using environmentally friendly processes to maintain its integrity and appearance. This treatment not only enhances the leather’s aesthetic qualities but also ensures its longevity. Additionally, wood frames, which form the structural backbone of the sofa, are sourced from sustainably managed forests, ensuring compliance with international environmental standards.

What Techniques Are Used in Forming Leather Sofas?

In the forming stage, the leather is cut to precise dimensions based on the design specifications. Computerized cutting machines are often employed to enhance accuracy and minimize waste. Following the cutting process, the leather pieces are shaped and molded over the wooden frame. This involves techniques such as upholstery, where layers of padding and cushioning materials are added to provide comfort.

Illustrative image related to the leather factory sofa

Advanced techniques like steam bending may be used for certain wooden components to achieve specific curves and shapes, enhancing both functionality and aesthetic appeal. Each piece is meticulously crafted to ensure that it fits perfectly, maintaining the overall design integrity of the sofa.

What Is Involved in the Assembly of Leather Sofas?

During assembly, all components of the sofa come together. Skilled craftsmen or assemblers use specialized tools and techniques to join the leather to the frame securely. Reinforced stitching and high-quality adhesives are used to ensure that the seams can withstand wear and tear over time.

Quality furniture manufacturers often implement a modular design approach, allowing for easier assembly and disassembly, which can be beneficial for international shipping. This modularity also aids in repairs and replacements, enhancing the product’s lifecycle.

How Is the Finishing Process Conducted for Leather Sofas?

The final stage is finishing, where the sofa undergoes various treatments to ensure it is both visually appealing and durable. This may include applying protective coatings that resist stains, scratches, and UV damage. The finishing process is critical as it contributes significantly to the sofa’s longevity and ease of maintenance.

Quality assurance checks are integral during the finishing stage to ensure that every piece meets the desired specifications. This includes inspecting color consistency, surface quality, and overall craftsmanship.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance in leather sofa manufacturing is paramount, especially for international buyers. Compliance with international standards such as ISO 9001, which focuses on quality management systems, is essential. This standard ensures that manufacturers adhere to consistent quality throughout their production processes.

In addition to ISO certifications, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for materials may also apply. These certifications provide an assurance of safety, quality, and environmental responsibility.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is a critical aspect of the manufacturing process and typically involves multiple checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival. Leather is checked for defects, and wood is evaluated for structural integrity.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are conducted to ensure that each stage of production adheres to quality standards. This includes monitoring stitching techniques, assembly integrity, and finishing quality.

-

Final Quality Control (FQC): Once the sofa is completed, it undergoes a final inspection. This includes a thorough examination of the finished product for defects in stitching, leather quality, and overall aesthetic appeal.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying supplier quality control is crucial to ensure that products meet their standards. Here are some actionable steps:

-

Request Documentation: Buyers should ask for quality assurance documentation, including compliance certificates and inspection reports. This transparency is vital in establishing trust.

-

Conduct Audits: Periodic audits of the supplier’s manufacturing facilities can provide deeper insights into their production processes and quality control measures.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s compliance with quality standards. This is particularly important when dealing with suppliers from different regions, as local practices and standards may vary.

-

Assess Product Samples: Before placing large orders, request samples of the products. This not only helps in assessing the quality but also allows buyers to evaluate the supplier’s responsiveness and flexibility in meeting specific requirements.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, may face unique challenges in quality assurance. Understanding local market regulations, import/export compliance, and customs requirements is crucial.

Moreover, cultural differences in business practices can influence expectations regarding quality and service. Building strong relationships with suppliers through clear communication and mutual understanding can help mitigate these challenges.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers of leather factory sofas. By focusing on these aspects, buyers can ensure that they partner with reliable suppliers who prioritize quality and craftsmanship, ultimately leading to successful business outcomes.

Illustrative image related to the leather factory sofa

Practical Sourcing Guide: A Step-by-Step Checklist for ‘the leather factory sofa’

Introduction

This sourcing guide is designed for international B2B buyers looking to procure leather factory sofas. By following this step-by-step checklist, you can ensure that your purchasing process is efficient, cost-effective, and aligned with your business needs. This guide emphasizes critical considerations that will lead to informed decision-making and successful sourcing outcomes.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications of the leather factory sofa you wish to procure. This includes dimensions, styles, leather grades, and customization options. Having a detailed specification sheet ensures that potential suppliers understand your requirements, minimizing the risk of miscommunication and ensuring that the final product meets your expectations.

Step 2: Research and Identify Potential Suppliers

Conduct comprehensive research to identify reputable suppliers specializing in leather factory sofas. Look for suppliers with a strong track record in your target markets—Africa, South America, the Middle East, and Europe. Key factors to consider include:

– Experience: Suppliers with significant industry experience are likely to offer higher quality products.

– Local Presence: A local supplier can help mitigate import challenges and provide better customer support.

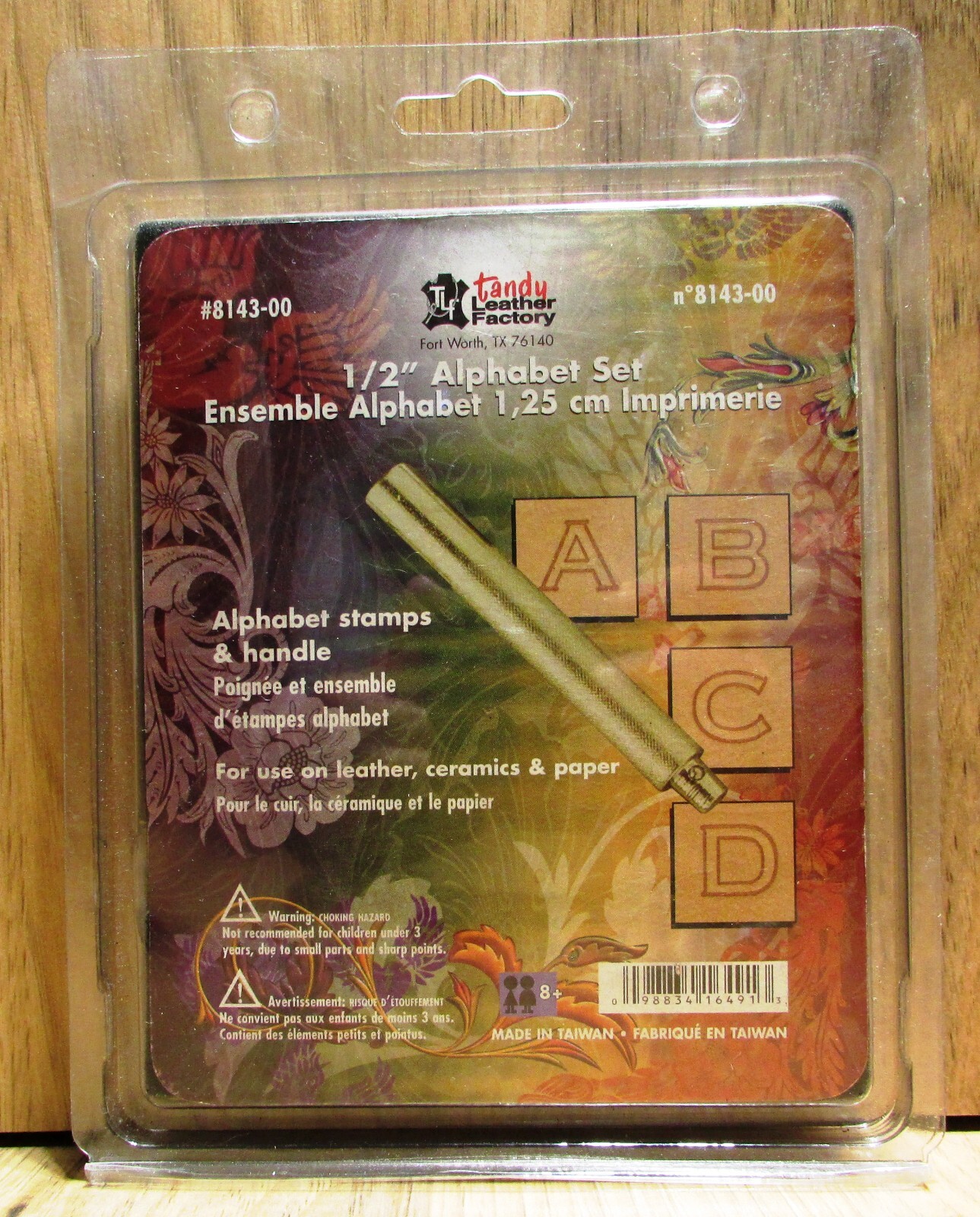

Step 3: Evaluate Supplier Certifications and Compliance

Before making a purchase, verify that suppliers possess relevant certifications and comply with industry standards. This step is crucial for ensuring product quality and sustainability. Look for certifications such as:

– ISO Certification: Indicates adherence to international quality management standards.

– Environmental Compliance: Suppliers should demonstrate responsible sourcing and manufacturing practices.

Illustrative image related to the leather factory sofa

Step 4: Request Product Samples

Request samples of the leather and sofa constructions from shortlisted suppliers. Evaluating samples allows you to assess the quality of materials and craftsmanship firsthand. Pay attention to:

– Leather Texture and Finish: Ensure the quality aligns with your brand’s standards.

– Construction Quality: Check for durability in stitching and frame materials.

Step 5: Review Pricing and Payment Terms

Compare pricing structures from different suppliers to ensure you are getting a competitive deal. Additionally, understand the payment terms offered by each supplier. Look for:

– Volume Discounts: Suppliers may offer discounts for bulk orders, which can significantly reduce costs.

– Payment Flexibility: Consider suppliers who provide financing options or flexible payment plans, especially for larger orders.

Step 6: Assess Delivery and Logistics Capabilities

Confirm that the supplier can meet your delivery requirements. Efficient logistics are critical to ensuring timely availability of products. Key considerations include:

– Delivery Times: Understand lead times and factor them into your project schedules.

– Shipping Options: Assess whether the supplier can accommodate different shipping methods to suit your needs.

Illustrative image related to the leather factory sofa

Step 7: Establish a Long-term Relationship

Once you’ve made your selection, focus on establishing a long-term relationship with the supplier. Ongoing partnerships can lead to better pricing, priority service, and customized solutions. Regular communication and feedback will enhance collaboration and foster trust, ensuring that future orders meet your evolving business needs.

By following these steps, you can streamline your sourcing process for leather factory sofas and ensure that your procurement aligns with your business objectives.

Comprehensive Cost and Pricing Analysis for the leather factory sofa Sourcing

What Are the Key Cost Components in Leather Sofa Manufacturing?

The cost structure for leather factory sofas encompasses several critical components that international B2B buyers must understand to make informed sourcing decisions.

-

Materials: The primary cost driver is the quality of leather used. Premium grades such as aniline and full-grain leather sourced from reputable regions like Italy, Sweden, and Brazil significantly impact pricing. Additionally, other materials like wood for frames, cushioning, and upholstery fabrics contribute to overall costs.

-

Labor: Skilled labor is essential for crafting high-quality leather sofas. The labor cost can vary based on the region of production, with countries offering lower wage rates potentially reducing costs. However, investing in skilled artisans ensures superior craftsmanship and durability, which can justify higher upfront expenses.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, and equipment maintenance. Efficient production processes can help mitigate these costs, but they must be factored into the overall pricing.

-

Tooling: Initial setup costs for molds and specialized equipment can be significant, especially for custom designs. Buyers should inquire about tooling fees, particularly if they plan to order unique specifications.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the final product meets industry standards and buyer expectations. While this adds to the overall cost, it protects buyers from potential defects and enhances customer satisfaction.

-

Logistics: Shipping costs can vary widely based on the destination, shipping method, and Incoterms. Buyers from Africa, South America, the Middle East, and Europe should consider these factors when calculating total costs.

-

Margin: Manufacturers typically add a margin to cover profit and reinvestment. Understanding the markup can help buyers assess whether they are getting a fair deal.

How Do Price Influencers Affect Leather Sofa Sourcing?

Several factors can influence the price of leather sofas, impacting the overall sourcing strategy for B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often yield better pricing. Buyers should negotiate terms that align with their procurement strategies, especially if they anticipate ongoing needs.

-

Specifications and Customization: Custom designs and specific material choices can increase costs. Buyers should evaluate whether customization is essential or if standard models can meet their needs.

-

Quality Certifications: Products certified for sustainability or quality assurance may carry a premium but can enhance brand reputation and customer trust, especially in markets that prioritize eco-friendliness.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role. Established manufacturers may command higher prices due to their brand equity and proven track record.

-

Incoterms: Understanding the terms of shipment and delivery is vital. Different Incoterms can shift responsibilities and costs between buyer and seller, affecting the total landed cost.

What Are the Best Buyer Tips for Leather Sofa Sourcing?

-

Negotiate Wisely: Always negotiate terms with suppliers. Leverage volume discounts and explore flexible payment options to improve cash flow.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, durability, and potential repair costs. A higher initial investment in quality leather can lead to lower TCO over time.

-

Understand Pricing Nuances for International Transactions: When sourcing from different regions, be aware of currency fluctuations, import duties, and tariffs that can impact overall costs.

-

Research and Compare Suppliers: Conduct thorough market research to identify multiple suppliers. Comparing quotes and understanding their cost structures can reveal significant savings opportunities.

-

Assess Shipping Logistics: Work with logistics experts to determine the most cost-effective shipping methods and routes, ensuring that delivery timelines align with business needs.

Disclaimer on Indicative Prices

Prices for leather factory sofas can vary significantly based on the aforementioned factors. Buyers should seek detailed quotes from multiple suppliers to obtain the most accurate pricing tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing the leather factory sofa With Other Solutions

When considering the best seating solutions for commercial or residential spaces, it’s essential to explore various options available in the market. This analysis compares ‘The Leather Factory Sofa’ with alternative seating solutions, focusing on their performance, cost, ease of implementation, maintenance, and best use cases. By evaluating these aspects, B2B buyers can make informed decisions based on their specific requirements.

| Comparison Aspect | The Leather Factory Sofa | Alternative 1: Custom Leather Furniture | Alternative 2: Fabric Sofa |

|---|---|---|---|

| Performance | High durability and luxury feel | Exceptional craftsmanship with personalization | Moderate durability, various styles available |

| Cost | Approx. $2,400 | Starting from $3,000, varies based on customization | Generally ranges from $500 to $2,000 |

| Ease of Implementation | Requires lead time for custom orders | Customization may extend delivery time | Readily available in stores, minimal wait time |

| Maintenance | Easy to clean, long-lasting | Requires similar care as leather | Varies based on fabric; some may stain easily |

| Best Use Case | Ideal for luxury settings, high-end clientele | Perfect for tailored spaces where aesthetics matter | Suitable for budget-conscious buyers or casual settings |

What Are the Advantages of Custom Leather Furniture Compared to The Leather Factory Sofa?

Custom leather furniture offers a unique advantage in terms of personalization. Buyers can select styles, colors, and leather grades that align with their brand’s aesthetics or personal preferences. While the initial investment may be higher, the quality often justifies the price, especially for businesses looking to create a lasting impression. However, the customization process can lead to longer lead times, which may not suit urgent needs.

How Does a Fabric Sofa Compare to The Leather Factory Sofa?

Fabric sofas present a more budget-friendly option, appealing to a wider range of consumers. They come in numerous styles, colors, and textures, allowing for flexibility in design. However, they may not provide the same level of durability or luxury as leather options. Maintenance can also be more challenging, as some fabrics are prone to staining and may require professional cleaning. Fabric sofas are best suited for casual environments or temporary solutions.

Illustrative image related to the leather factory sofa

Conclusion: Which Seating Solution Should B2B Buyers Choose?

Choosing the right seating solution ultimately depends on the specific needs of the buyer. For businesses that prioritize luxury and long-term investment, ‘The Leather Factory Sofa’ stands out for its durability and aesthetic appeal. Conversely, if customization and unique design are crucial, exploring custom leather options may be beneficial. On the other hand, for budget-conscious buyers or those seeking quick, versatile solutions, fabric sofas provide an adequate alternative. By carefully weighing these factors, B2B buyers can select a solution that aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for the leather factory sofa

What Are the Key Technical Properties of Leather Factory Sofas?

Understanding the technical properties of leather factory sofas is crucial for B2B buyers seeking durable and high-quality products. Here are several essential specifications to consider:

1. Material Grade

The grade of leather is a primary factor influencing the quality and price of a sofa. Common classifications include full-grain, top-grain, and bonded leather. Full-grain leather is the highest quality, retaining the natural texture and durability, while bonded leather is a more affordable option made from scraps. For B2B buyers, selecting the appropriate grade can impact customer satisfaction and return rates.

2. Frame Construction

The frame’s construction material, often hardwood or engineered wood, determines the sofa’s durability and stability. A solid hardwood frame is typically more resilient, while engineered wood can offer cost savings but may not last as long. Understanding frame construction is vital for buyers aiming to provide long-lasting furniture solutions.

3. Cushioning and Support

Foam density and type (e.g., high-resiliency foam, memory foam) significantly affect comfort and longevity. High-density foam offers better support and resists sagging over time. Buyers should evaluate these properties to ensure the product meets end-user comfort expectations, which can enhance brand reputation and reduce warranty claims.

Illustrative image related to the leather factory sofa

4. Stitching and Upholstery

Quality stitching not only enhances aesthetic appeal but also reinforces the sofa’s durability. Double-stitched seams are often a hallmark of high-quality craftsmanship. B2B buyers should prioritize suppliers who demonstrate rigorous quality control in their upholstery processes to minimize defects and returns.

5. Weight Capacity and Dimensions

Understanding the weight capacity and overall dimensions is crucial for ensuring that the sofa fits both the intended space and the expected usage. Different models may have varying weight tolerances, which can affect their suitability for commercial environments. Buyers should confirm these specifications to avoid future issues with product performance.

6. Warranty and Service

A comprehensive warranty covering frame, stitching, and upholstery can signal a manufacturer’s confidence in their product. Warranties are essential for B2B buyers, as they provide assurance of quality and support in case of defects. Understanding warranty details can influence purchasing decisions and long-term supplier relationships.

What Are Common Trade Terms Used in the Leather Furniture Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are key trade terms relevant to leather factory sofas:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products based on specifications provided by another company. In the leather sofa industry, an OEM may manufacture sofas for a retailer under that retailer’s brand. Understanding OEM relationships can help buyers navigate supplier options and negotiate better terms.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and cash flow. Knowing the MOQ helps buyers align their purchasing strategies with their sales forecasts.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. For buyers, using RFQs can streamline the procurement process, ensuring that all suppliers provide comparable quotes, which aids in making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping contracts. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) helps buyers understand their obligations and costs, which is critical for budgeting and logistics planning.

5. Lead Time

Lead time refers to the duration from the order placement to the delivery of the product. This term is essential for B2B buyers who must plan inventory and manage customer expectations. Understanding lead times can help buyers align their operational needs with supplier capabilities.

6. Upholstery Grade

Upholstery grade refers to the classification of fabric or leather based on its durability and intended use. This classification helps buyers select materials appropriate for specific environments, such as residential versus commercial use, ensuring that the product meets the necessary performance standards.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select leather factory sofas that meet both quality standards and market demands.

Navigating Market Dynamics and Sourcing Trends in the the leather factory sofa Sector

What Are the Key Market Trends Influencing the Leather Factory Sofa Sector?

The leather factory sofa market is experiencing a dynamic shift influenced by several global drivers. Increased urbanization and rising disposable incomes in regions like Africa, South America, the Middle East, and Europe are contributing to heightened demand for premium furniture. International B2B buyers are increasingly seeking high-quality, customizable leather sofas that reflect both style and functionality. The trend towards personalization is significant, with buyers looking for tailored solutions that meet specific aesthetic and spatial requirements.

Illustrative image related to the leather factory sofa

Additionally, technological advancements in manufacturing processes have streamlined operations, enabling manufacturers to produce higher-quality sofas at competitive prices. Automation and digital tools, such as virtual design consultations, are becoming commonplace in the sourcing process, allowing buyers to visualize their purchases before making commitments. Sustainability is also a critical concern, with buyers favoring suppliers that adhere to eco-friendly practices. This trend is especially pronounced in the Middle East and Europe, where consumers are more conscious of environmental impacts.

How Are Sustainability and Ethical Sourcing Impacting the Leather Factory Sofa Market?

Sustainability and ethical sourcing are becoming integral aspects of the leather factory sofa sector, driven by growing consumer awareness regarding environmental and social issues. The leather industry has faced scrutiny over its environmental impact, particularly in terms of deforestation and pollution associated with tanning processes. As a result, buyers are increasingly prioritizing suppliers who utilize environmentally friendly materials and sustainable practices.

Certifications such as the Leather Working Group (LWG) and other green certifications signal compliance with high environmental standards and ethical labor practices. Buyers should seek out manufacturers that source leather from certified tanneries that employ responsible practices. These certifications not only enhance brand reputation but also appeal to eco-conscious consumers, particularly in regions like Europe and North America. Additionally, the use of recycled materials and innovative, sustainable production techniques can significantly reduce the carbon footprint of leather sofas, making them more attractive to international B2B buyers.

How Has the Leather Factory Sofa Sector Evolved Over Time?

The leather factory sofa sector has undergone significant evolution over the past few decades, transitioning from a niche market for luxury buyers to a more accessible option for a broader audience. Initially, leather sofas were primarily associated with high-end furniture, often viewed as a status symbol. However, advancements in manufacturing technology and increased competition have allowed for a wider variety of styles, prices, and customization options.

In recent years, the rise of online shopping and direct-to-consumer sales has further transformed the landscape, enabling buyers from diverse regions to access a global market. This evolution has led to a more informed customer base that values quality, sustainability, and customization. As the market continues to mature, businesses must adapt to these changing preferences while maintaining high standards in craftsmanship and ethical sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of the leather factory sofa

-

How do I ensure the quality of leather factory sofas when sourcing internationally?

To ensure quality when sourcing leather factory sofas, it is crucial to conduct thorough supplier vetting. Request samples of the leather and finished products to assess craftsmanship and material quality. Additionally, review certifications for leather grades, and inquire about the manufacturing process. Establishing direct communication with the supplier can provide insights into their quality control measures and production standards. Consider visiting the factory if feasible, or engage third-party inspection services to verify quality before shipment. -

What customization options are available for leather factory sofas?

Customization options for leather factory sofas typically include choosing the leather type, color, and design style. Many manufacturers offer extensive selections, allowing buyers to select from various grades and finishes of leather. Buyers can also customize dimensions, configurations (like sectional or modular designs), and additional features such as recliners or integrated storage. Before placing an order, discuss your specific requirements with the supplier to ensure they can accommodate your preferences within their production capabilities. -

What are the minimum order quantities (MOQs) for leather factory sofas?

Minimum order quantities (MOQs) for leather factory sofas can vary widely based on the manufacturer and the complexity of the customization. Generally, MOQs can range from a single unit for standard designs to larger quantities for custom pieces. It’s advisable to clarify the MOQ with potential suppliers during initial discussions. If your order does not meet the MOQ, inquire about the possibility of combining orders with other buyers or exploring stock items that may be available for immediate purchase. -

What payment terms should I expect when sourcing leather factory sofas?

Payment terms for sourcing leather factory sofas often include a deposit upfront, commonly around 30-50% of the total order value, with the balance due before shipment. Some suppliers may offer financing options or flexible payment plans. Always confirm the terms in writing to avoid misunderstandings. Additionally, consider using secure payment methods such as letters of credit or escrow services to mitigate risk, especially for large international transactions. -

What logistics considerations should I keep in mind when importing leather factory sofas?

When importing leather factory sofas, logistics considerations include shipping methods, costs, and delivery timelines. Determine whether air or sea freight is more suitable based on your budget and urgency. Be aware of customs regulations in your country, including import duties and tariffs. Collaborating with a freight forwarder can help streamline the process, ensuring compliance with local regulations and efficient delivery to your location. -

How do I evaluate potential suppliers for leather factory sofas?

Evaluating potential suppliers involves assessing their reputation, experience, and product offerings. Research online reviews and testimonials from other B2B buyers. Request references and case studies to understand their capacity to meet your needs. Additionally, inquire about their manufacturing processes, quality control measures, and lead times. A reliable supplier should be transparent about their operations and willing to provide information that supports their credibility. -

What warranty options should I look for when purchasing leather factory sofas?

When purchasing leather factory sofas, it’s essential to review warranty options carefully. A reputable manufacturer should offer a warranty that covers the frame, stitching, and leather quality for a significant period, often ranging from several years to a lifetime. Ensure that the warranty includes provisions for wear and tear, as well as potential defects. Understanding the terms and conditions of the warranty will help you assess the long-term value of your investment. -

How can I ensure compliance with international trade regulations when sourcing leather factory sofas?

To ensure compliance with international trade regulations, familiarize yourself with the import/export laws applicable to your country and the supplier’s location. This includes understanding tariffs, trade agreements, and product safety standards. Working with a customs broker can facilitate compliance and help navigate the complexities of international shipping. Additionally, ensure all documentation, including invoices and certificates of origin, is accurate and complete to avoid delays at customs.

Top 4 The Leather Factory Sofa Manufacturers & Suppliers List

1. Leathersofa – Alexandria Sectional

Domain: leathersofaco.com

Registered: 2004 (21 years)

Introduction: [{‘name’: ‘Alexandria Sectional (Left Arm Loveseat + Left Arm Right Chaise Sofa)’, ‘base_leather’: ‘Sooner Golden Tan’, ‘price’: ‘$9,200.00’, ‘description’: ‘Few designs offer a more perfect balance of style and comfort than the Alexandria. This contemporary off the floor silhouette features a beautifully sculpted frame and soft…’, ‘features’: ‘Left Arm Loveseat + Left Arm Right Chaise Sofa’}, {…

2. The Leather Factory – Leather Couch & Love-seat

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, The Leather Factory – Leather Couch & Love-seat, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

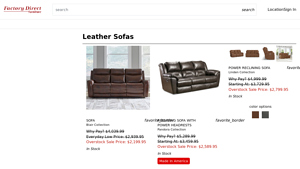

3. Factory Direct Furniture – Blair Collection Sofa

Domain: fdfonline.com

Registered: 2009 (16 years)

Introduction: Leather Sofas available in Hutchinson, Glencoe, Litchfield, McLeod County, Meeker County from Factory Direct Furniture. Key products include:

1. Blair Collection Sofa – Everyday Low Price: $2,939.95, Overstock Sale Price: $2,199.95, In Stock.

2. Pandora Collection Reclining Sofa with Power Headrests – Starting At: $3,459.95, Overstock Sale Price: $2,589.95, In Stock, Made In America.

3. Linden Co…

4. American Leather – Comfort Sleeper

Domain: americanleather.com

Registered: 1997 (28 years)

Introduction: American Leather offers handcrafted furniture made in the USA, including a variety of collections such as Accent Chairs, Beds and Headboards, Comfort Sleeper, Motion Furniture, and more. Key products include the Comfort Sleeper available in 14 styles with over 500 upholstery options, Comfort Air with power or manual options, and various recliners and stationary furniture. The company emphasizes cu…

Strategic Sourcing Conclusion and Outlook for the leather factory sofa

As the global demand for high-quality leather factory sofas continues to rise, strategic sourcing becomes an essential component for B2B buyers aiming to enhance their product offerings. Understanding the nuances of leather types, craftsmanship, and customization options allows buyers to make informed decisions that align with their market needs. Key takeaways include the importance of building strong relationships with reputable manufacturers, assessing the sustainability practices of suppliers, and leveraging customization capabilities to meet diverse customer preferences.

Investing in leather factory sofas not only elevates the aesthetic appeal of any space but also ensures durability and comfort that end-users desire. For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, establishing partnerships with manufacturers who prioritize quality and customer service can significantly impact business success.

Illustrative image related to the leather factory sofa

Looking ahead, the landscape of leather furniture is poised for innovation, and buyers are encouraged to stay ahead of trends by exploring new materials and designs. Engage with suppliers who demonstrate a commitment to excellence and sustainability, and take proactive steps to secure your position in this competitive market. Now is the time to transform your sourcing strategy and elevate your offerings to meet the demands of discerning customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to the leather factory sofa

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.