Introduction: Navigating the Global Market for custom leather branding iron

Navigating the complexities of sourcing custom leather branding irons can be a daunting challenge for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and established economies in Europe like Germany and Brazil. With a plethora of options available—from electric to fire-heated branding tools—buyers face the critical task of ensuring they select the right type of branding iron that meets their specific needs and budget constraints. This guide serves as a comprehensive resource, delving into the various types of branding irons, their applications across different materials, and essential tips for effective branding on leather.

In addition to exploring product specifications and supplier vetting strategies, this guide will provide insights into pricing structures and the factors that influence costs, empowering buyers to make informed purchasing decisions. Whether you are looking to enhance your leather goods with customized branding or seeking to streamline your production process, understanding these elements is vital for maximizing your investment. By leveraging the information within this guide, B2B buyers can navigate the global market with confidence, ensuring they not only meet their branding needs but also elevate their product offerings in a competitive landscape.

Table Of Contents

- Top 6 Custom Leather Branding Iron Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather branding iron

- Understanding custom leather branding iron Types and Variations

- Key Industrial Applications of custom leather branding iron

- 3 Common User Pain Points for ‘custom leather branding iron’ & Their Solutions

- Strategic Material Selection Guide for custom leather branding iron

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather branding iron

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather branding iron’

- Comprehensive Cost and Pricing Analysis for custom leather branding iron Sourcing

- Alternatives Analysis: Comparing custom leather branding iron With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather branding iron

- Navigating Market Dynamics and Sourcing Trends in the custom leather branding iron Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather branding iron

- Strategic Sourcing Conclusion and Outlook for custom leather branding iron

- Important Disclaimer & Terms of Use

Understanding custom leather branding iron Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fire-Heated Branding Irons | Operate using heat from flames; portable; versatile | Small-scale leather goods production, crafts, and hobbyists | Pros: Cost-effective, easy to use; Cons: Limited heat control, slower branding process. |

| Electric Branding Irons | Digital temperature control; consistent heat; faster | High-volume branding, commercial leather goods production | Pros: Precise temperature settings, efficient; Cons: Higher initial investment, requires electricity. |

| Heavy Duty Branding Irons | Robust construction; ideal for thick leather materials | Industrial applications, heavy-duty leather goods | Pros: Durable, suitable for tough materials; Cons: Heavier, may require more handling effort. |

| Custom Curved Surface Branders | Designed for irregular surfaces; adaptable to various shapes | Branding sports equipment, bags, and other curved items | Pros: Versatile, effective on uneven surfaces; Cons: May require additional setup for use. |

| Custom Stamps with Heat Embossing | Combines branding with embossing; ideal for intricate designs | Premium leather products, high-end branding | Pros: Unique finish, adds value; Cons: More complex setup, potentially higher costs. |

What Are Fire-Heated Branding Irons and Their Applications?

Fire-heated branding irons are a traditional method for marking leather using flames. These irons are portable and cost-effective, making them suitable for small-scale production or hobbyist use. However, they offer limited heat control and a slower branding process compared to electric options. B2B buyers in regions with access to flame sources may find these irons ideal for crafts and artisanal leather goods, where branding speed is less critical.

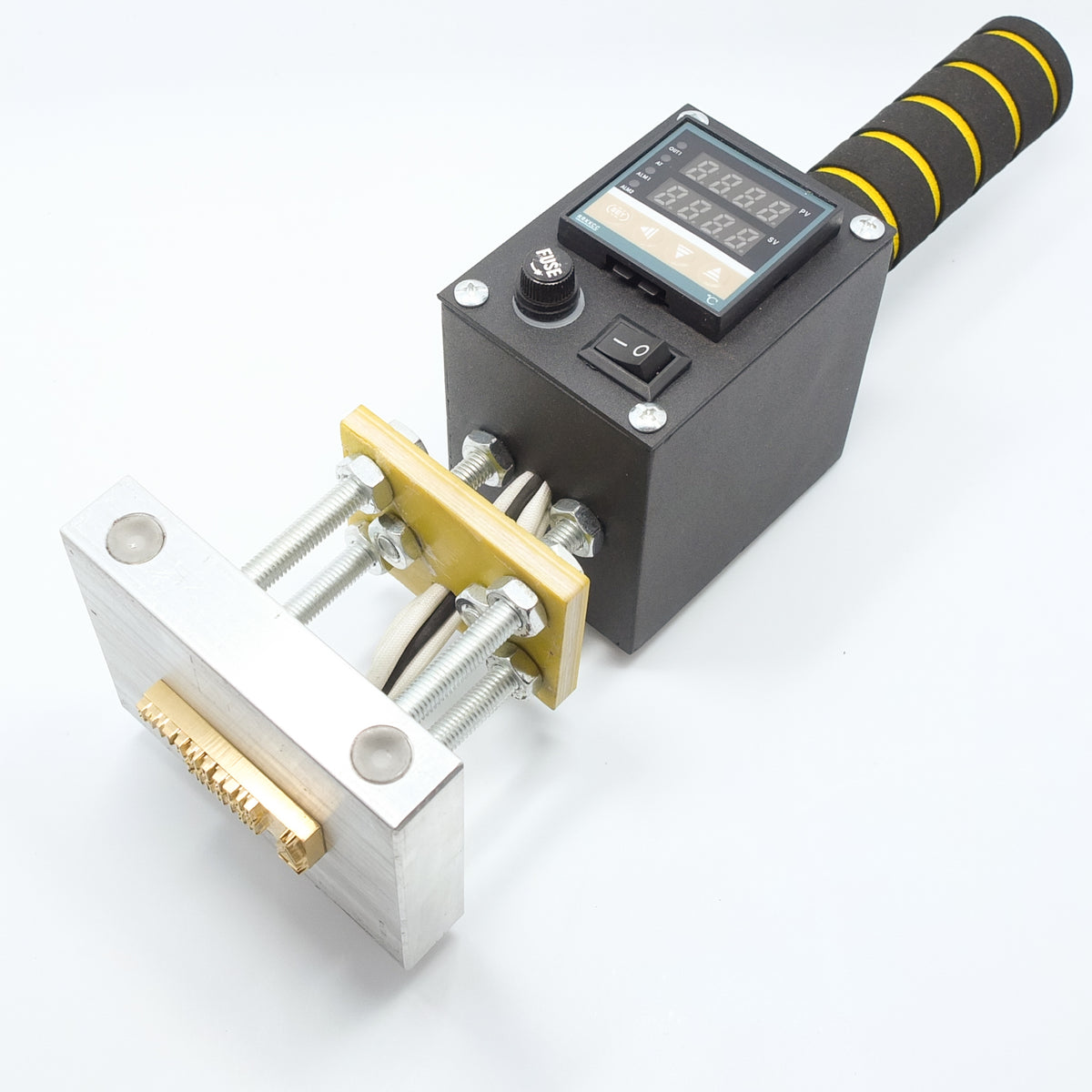

How Do Electric Branding Irons Enhance Efficiency?

Electric branding irons feature digital temperature control, allowing for consistent heat application, which is essential for high-volume branding operations. These tools are particularly advantageous for businesses that require precision and efficiency, such as commercial leather manufacturers. While the initial investment is higher, the ability to maintain optimal temperatures reduces the risk of inconsistent branding, making them a preferred choice for serious B2B buyers.

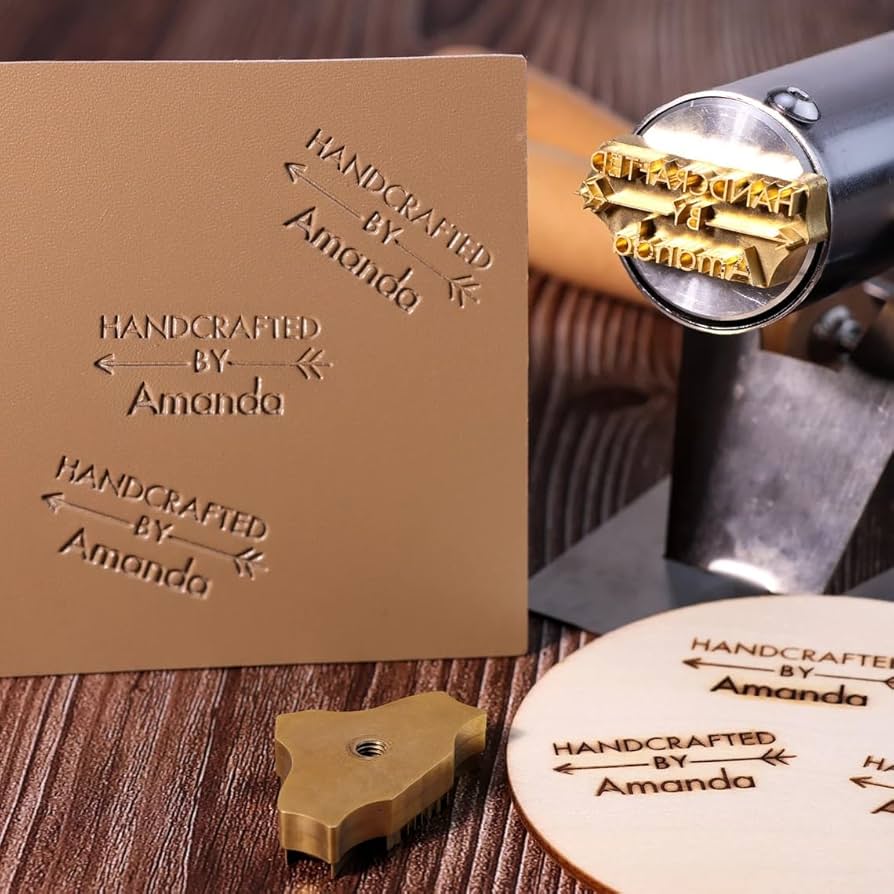

Illustrative image related to custom leather branding iron

Why Choose Heavy Duty Branding Irons for Industrial Needs?

Heavy-duty branding irons are built to withstand rigorous use and are ideal for branding thick leather materials. They are suitable for industrial applications where durability and strength are paramount. B2B buyers in sectors such as automotive or heavy-duty leather goods may prefer these irons despite their weight and handling requirements, as they ensure long-lasting marks on tough materials.

What Makes Custom Curved Surface Branders Unique?

Custom curved surface branders are specifically designed to brand irregular or rounded surfaces, such as sports equipment or bags. Their adaptability allows for effective branding on a variety of shapes, making them valuable for businesses that produce diverse products. While they may require additional setup, the versatility they offer can significantly enhance branding capabilities for specialized B2B applications.

How Do Custom Stamps with Heat Embossing Add Value?

Custom stamps that incorporate heat embossing techniques allow businesses to create intricate designs and unique finishes on leather products. This method is particularly appealing for premium leather goods where branding adds significant value. Although the setup can be more complex and the costs potentially higher, the distinctiveness and quality of the branding can lead to enhanced product appeal in competitive markets.

Key Industrial Applications of custom leather branding iron

| Industry/Sector | Specific Application of custom leather branding iron | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Leather Goods Manufacturing | Branding of handbags, wallets, and belts | Enhances brand visibility and product differentiation | Customization options, heat retention capabilities |

| Agriculture and Livestock | Branding livestock and equipment | Ensures ownership identification and reduces theft | Durability, ability to withstand outdoor conditions |

| Fashion and Apparel | Custom logos on clothing items | Adds a premium touch and personalizes products | Design intricacy, compatibility with fabric types |

| Furniture and Home Decor | Branding leather furniture pieces | Elevates perceived value and authenticity | Material compatibility, branding depth requirements |

| Crafts and Artisans | Custom branding for handmade leather goods | Creates unique, personalized items for consumers | Versatility for different surfaces, ease of use |

How is Custom Leather Branding Iron Used in Leather Goods Manufacturing?

In the leather goods manufacturing sector, custom leather branding irons are essential for marking products such as handbags, wallets, and belts with brand logos. This process not only enhances brand visibility but also helps differentiate products in a competitive market. For international buyers, particularly in regions like Europe and South America, sourcing branding irons that offer customization and superior heat retention is crucial. These features ensure consistent quality and reduce the need for frequent reheating, streamlining the production process.

Illustrative image related to custom leather branding iron

What Role Does Custom Leather Branding Iron Play in Agriculture and Livestock?

In agriculture, custom leather branding irons are used to mark livestock and equipment, providing a reliable method for ownership identification. This is particularly important in regions like Africa and the Middle East, where livestock theft can be a significant issue. The durability of the branding iron is a key consideration for buyers in these sectors, as it must withstand harsh outdoor conditions while maintaining effectiveness. A branding iron that can produce clear, long-lasting marks is invaluable for livestock management.

How Does Custom Leather Branding Iron Enhance Fashion and Apparel?

The fashion and apparel industry utilizes custom leather branding irons to imprint logos and designs on clothing items, adding a touch of premium quality and personalization. This branding method can significantly enhance the perceived value of products, making them more appealing to consumers. Buyers need to consider the intricacy of the design and ensure compatibility with various fabric types, as different materials may require specific heat settings for optimal results.

In What Ways Does Custom Leather Branding Iron Benefit Furniture and Home Decor?

In the furniture and home decor sector, custom leather branding irons are employed to brand leather furniture pieces, elevating their perceived value and authenticity. This branding technique can help artisans and manufacturers create unique selling propositions. Key sourcing considerations include ensuring the branding iron is compatible with the leather type and can achieve the desired branding depth without damaging the material, which is particularly important for high-end furniture markets in Europe.

Illustrative image related to custom leather branding iron

How is Custom Leather Branding Iron Used by Crafts and Artisans?

For crafts and artisans, custom leather branding irons are invaluable tools for creating unique, personalized leather goods. These branding irons allow for the marking of handmade items, which can significantly enhance their appeal to consumers looking for distinctive products. Sourcing versatile branding tools that can work on various surfaces and are easy to use is essential for artisans, especially those operating in international markets where craftsmanship and uniqueness are highly valued.

3 Common User Pain Points for ‘custom leather branding iron’ & Their Solutions

Scenario 1: Inconsistent Branding Quality Across Different Leather Types

The Problem: B2B buyers often encounter challenges when branding different types of leather. Each type—be it soft suede or thick full-grain leather—requires specific heat settings and branding techniques. A buyer may find that their branding iron does not produce a consistent quality of imprint, leading to dissatisfaction from their customers and potential financial losses. This inconsistency can stem from inadequate knowledge of heat settings or incorrect dwell times, making it crucial for buyers to understand how to adjust their branding process accordingly.

The Solution: To overcome this issue, buyers should invest in electric branding irons with adjustable temperature controls. These tools allow users to set the precise heat required for various leather types, ensuring that each branding mark is clear and consistent. Additionally, conducting small tests on scrap pieces of leather before starting production can help buyers determine the optimal temperature and dwell time for each specific leather type. Keeping a detailed log of these settings can serve as a valuable reference for future branding projects, enhancing efficiency and quality control.

Scenario 2: Long Lead Times and Delays in Custom Branding Iron Production

The Problem: International buyers, particularly in regions like Africa and South America, often face long lead times when ordering custom leather branding irons. These delays can disrupt production schedules and lead to missed deadlines, particularly if the branding iron is needed for a specific promotional event or product launch. Buyers may experience frustration if they are unaware of the production timelines and shipping logistics, which can vary significantly depending on the manufacturer.

The Solution: To mitigate this pain point, B2B buyers should prioritize working with manufacturers who provide transparent timelines and reliable shipping options. Requesting a detailed production schedule at the outset can help set clear expectations. Moreover, sourcing from suppliers who maintain a robust inventory of standard designs may allow for quicker turnaround times. Establishing strong communication with suppliers regarding shipping options and potential delays can also provide buyers with more control over their timelines, enabling them to plan more effectively.

Scenario 3: Difficulty in Achieving Precise Branding Designs

The Problem: Buyers often struggle to achieve the desired precision in their branding designs, especially when they require intricate logos or text. The challenge lies in ensuring that the branding iron accurately reproduces fine details, which can be critical for branding strategies. If the branding iron does not produce a clear imprint, it can lead to wasted materials and additional costs, frustrating buyers who are aiming for high-quality outputs.

The Solution: To enhance precision in branding designs, buyers should consider collaborating closely with manufacturers during the design phase. Providing high-resolution artwork and clear specifications can significantly improve the quality of the final product. Additionally, investing in branding irons with deeper engraving and higher relief can allow for more detailed impressions on leather. Conducting test runs with prototype branding irons can further help in evaluating the accuracy of designs before mass production, ultimately ensuring that the final branded products meet quality standards and customer expectations.

Strategic Material Selection Guide for custom leather branding iron

What Are the Key Materials for Custom Leather Branding Irons?

When selecting materials for custom leather branding irons, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials: brass, stainless steel, aluminum, and copper.

Brass: The Versatile Choice for Branding Irons

Brass is a popular choice for custom branding irons due to its excellent thermal conductivity and durability. It can withstand high temperatures, making it suitable for both electric and fire-heated branding methods. Brass also exhibits good corrosion resistance, which is essential for maintaining the integrity of the branding iron over time.

Illustrative image related to custom leather branding iron

Pros: Brass branding irons are durable and can produce clear, deep impressions on leather. They are relatively easy to manufacture and can be customized to intricate designs.

Cons: The primary drawback of brass is its cost, which can be higher than other materials. Additionally, it may tarnish over time if not properly maintained.

Impact on Application: Brass is compatible with various leather types, including soft and hard leather, making it versatile for different branding needs.

Considerations for International Buyers: Brass branding irons must comply with international standards, such as ASTM for material quality. Buyers from regions like Europe and the Middle East may prefer brass due to its traditional use in high-quality branding tools.

Stainless Steel: The Durable and Corrosion-Resistant Option

Stainless steel is another excellent material for custom leather branding irons, known for its strength and resistance to corrosion. It can endure high temperatures and is less prone to warping compared to softer metals.

Pros: The durability of stainless steel branding irons ensures a long lifespan, even under heavy use. They are also easy to clean and maintain, making them ideal for businesses with high branding volumes.

Cons: Stainless steel can be more challenging to machine and shape, potentially increasing manufacturing complexity and costs. Additionally, its thermal conductivity is lower than that of brass, which may affect branding efficiency.

Impact on Application: Stainless steel is suitable for branding on various leather types, but it may require higher temperatures for effective branding compared to brass.

Illustrative image related to custom leather branding iron

Considerations for International Buyers: Compliance with international standards for stainless steel quality is essential, especially for buyers in regions like Africa and South America, where material quality may vary.

Aluminum: The Lightweight and Cost-Effective Alternative

Aluminum branding irons are lightweight and cost-effective, making them an attractive option for businesses looking to minimize expenses. They are easy to handle and can be manufactured quickly.

Pros: The lightweight nature of aluminum allows for easier maneuverability during branding. It is also less expensive than brass or stainless steel, making it a budget-friendly choice for startups or small businesses.

Cons: However, aluminum is less durable and can warp under high heat, which may lead to inconsistent branding results. Its lower thermal conductivity means it may not retain heat as effectively as other materials.

Impact on Application: Aluminum is best suited for lighter branding tasks or softer leather types, as it may struggle with thicker materials.

Illustrative image related to custom leather branding iron

Considerations for International Buyers: Buyers should ensure that the aluminum used meets relevant international standards, as lower-quality aluminum can lead to poor performance.

Copper: The Traditional Material with Unique Properties

Copper branding irons are known for their excellent thermal conductivity, allowing for quick heating and effective branding. They can produce high-quality impressions on leather.

Pros: The ability of copper to heat quickly makes it suitable for high-speed branding operations. It also provides a unique aesthetic appeal due to its distinct color.

Cons: Copper is prone to oxidation and tarnishing, which can affect the quality of the branding over time. Additionally, it can be more expensive than aluminum.

Impact on Application: Copper branding irons work well on various leather types but may require frequent maintenance to ensure optimal performance.

Considerations for International Buyers: Compliance with international standards for copper quality is critical, especially in markets with strict regulations, such as Germany.

Summary Table of Material Selection for Custom Leather Branding Irons

| Material | Typical Use Case for custom leather branding iron | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Versatile branding on various leather types | Excellent thermal conductivity | Higher cost and potential tarnishing | High |

| Stainless Steel | Heavy-duty branding for high-volume applications | Durable and corrosion-resistant | More complex manufacturing | Medium |

| Aluminum | Lightweight branding for softer leather | Cost-effective and easy to handle | Less durable and lower heat retention | Low |

| Copper | Quick branding for high-speed operations | Rapid heating and aesthetic appeal | Prone to oxidation and higher cost | Medium |

This guide provides a comprehensive overview of the materials used in custom leather branding irons, enabling international B2B buyers to make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather branding iron

What Are the Key Stages in the Manufacturing Process of Custom Leather Branding Irons?

The manufacturing process of custom leather branding irons involves several critical stages, each contributing to the final quality and functionality of the product. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Typically Used?

The initial phase begins with selecting high-quality materials, typically brass or stainless steel, known for their durability and heat retention properties. Brass is often preferred for its excellent engraving capabilities, allowing for intricate designs that result in clearer branding marks. The raw materials undergo rigorous quality checks to ensure they meet specified standards before moving to the next stage.

Forming: How Are Branding Irons Shaped and Crafted?

In the forming stage, materials are shaped into the desired branding iron design. This may involve processes such as CNC machining, where computer-controlled tools precisely carve out the branding head based on the provided artwork or logo. This technique ensures high accuracy and consistency, crucial for producing multiple units with identical specifications. After forming, the branding heads are subjected to further quality assessments to confirm that they meet design tolerances.

Assembly: What Does the Assembly Process Entail?

Once the branding heads are formed, they are assembled with handles, which may be made from wood or heat-resistant materials. The assembly process often includes fitting electrical components for electric branding irons, such as heating elements and temperature control units. Each assembled unit is again inspected for functionality, ensuring that all parts are securely attached and operate as intended.

Finishing: What Final Touches Are Applied to Ensure Quality?

The final stage involves surface treatment and finishing. This may include polishing the branding head to remove any burrs or sharp edges, which can affect the branding quality. Some manufacturers apply a protective coating to prevent corrosion. Finishing processes not only enhance the aesthetics of the branding iron but also improve its longevity and effectiveness in branding.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is a crucial aspect of the manufacturing process, particularly for products like branding irons that require precision and reliability. A robust QA program ensures that each branding iron meets international and industry-specific standards.

What International Standards Should B2B Buyers Be Aware Of?

For manufacturers of custom leather branding irons, adherence to international standards such as ISO 9001 is essential. This certification indicates that the manufacturer has established a quality management system that meets global best practices. Additionally, region-specific certifications, such as CE marking in Europe, may be required to comply with safety and environmental regulations.

Illustrative image related to custom leather branding iron

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process. These checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Inspections are conducted during the manufacturing process to monitor adherence to design specifications and quality standards.

- Final Quality Control (FQC): Once the branding irons are fully assembled, a final inspection is performed to ensure they meet all quality criteria before shipping.

What Testing Methods Are Commonly Used?

Common testing methods for custom leather branding irons include:

- Heat Resistance Testing: Ensuring that the materials can withstand high temperatures without deforming or degrading.

- Branding Quality Testing: Conducting test brands on various leather types to evaluate the clarity and depth of the branding marks.

- Functional Testing: For electric branding irons, testing the heating elements and temperature controls for accuracy and reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure product reliability and compliance with local regulations.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality assurance reports from suppliers, including results from inspections and testing. These reports should outline the procedures followed during manufacturing and any certifications obtained. Regular audits conducted by third-party organizations can also provide an unbiased assessment of a supplier’s quality management systems.

How Can Third-Party Inspections Ensure Compliance?

Engaging third-party inspection services can provide additional assurance that products meet specified standards and regulations. These inspections can occur at various stages of production, offering insights into the supplier’s practices and adherence to quality standards. Buyers should consider incorporating this as part of their procurement process, especially when dealing with new or unverified suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of international quality control can be challenging. B2B buyers should be aware of regional differences in quality standards and certifications. For instance, while ISO 9001 is recognized globally, specific countries may have additional requirements that must be met to ensure product acceptance in local markets.

Illustrative image related to custom leather branding iron

How Can Buyers Build Strong Relationships with Suppliers?

Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations and requirements. Regular dialogue about quality control processes, combined with visits to manufacturing facilities, can help buyers gain confidence in their suppliers’ capabilities.

By understanding the manufacturing processes and quality assurance practices behind custom leather branding irons, B2B buyers can make well-informed decisions that align with their business needs and expectations, ultimately leading to successful partnerships and high-quality branding solutions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather branding iron’

In today’s competitive market, sourcing a custom leather branding iron is essential for businesses looking to enhance their brand identity and product differentiation. This guide outlines a practical checklist to streamline the procurement process, ensuring you select the right branding solution for your needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s crucial to clarify your requirements. Consider factors such as size, material, heating method (electric vs. fire-heated), and design intricacies. A well-defined specification will help suppliers provide accurate quotes and ensure the final product meets your branding needs.

Illustrative image related to custom leather branding iron

- Size Considerations: Determine the dimensions that will fit your branding requirements.

- Heating Method: Decide whether an electric or fire-heated iron best suits your production environment.

Step 2: Research Potential Suppliers

Identify potential suppliers who specialize in custom leather branding irons. Look for companies with a proven track record in the industry and positive reviews from other businesses. Researching suppliers thoroughly can prevent costly mistakes and ensure you partner with reliable manufacturers.

- Online Reviews: Check platforms like Google and LinkedIn for feedback.

- Industry Reputation: Investigate how long they have been in business and their presence in your target market.

Step 3: Evaluate Supplier Capabilities

Not all suppliers are created equal, so assess their manufacturing capabilities. Look for suppliers who offer customization options, quality materials, and advanced technology for production. A capable supplier can provide insights into design optimization and production efficiency.

- Customization Options: Verify if they can accommodate your specific design needs.

- Quality Assurance Processes: Understand their quality control measures to ensure consistency in product delivery.

Step 4: Request Samples

Before placing a bulk order, request samples of the branding irons. This step allows you to evaluate the quality, heat retention, and branding effectiveness on various leather types. Testing samples is vital for ensuring that the final product meets your expectations.

- Test Different Leathers: Brand on various leather samples to see how well the iron performs.

- Heat Retention: Check how long the iron maintains heat during the branding process.

Step 5: Verify Supplier Certifications

Ensure that your selected suppliers comply with relevant industry standards and certifications. This step is particularly important for international transactions, where compliance with local regulations can impact your business operations.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance standards.

- Safety Standards: Ensure compliance with safety regulations in your region.

Step 6: Discuss Pricing and Terms

Engage suppliers in discussions about pricing, payment terms, and delivery timelines. Transparency in these areas can help prevent misunderstandings and foster a smoother business relationship. Obtain detailed quotations that outline all costs involved, including shipping and handling.

Illustrative image related to custom leather branding iron

- Bulk Discounts: Inquire if they offer discounts for larger orders.

- Payment Flexibility: Discuss payment options that align with your cash flow needs.

Step 7: Establish a Communication Plan

Once you have chosen a supplier, establish a clear communication plan. Regular updates on production progress, shipping timelines, and any potential issues are crucial for maintaining a good working relationship. Clear communication helps address concerns promptly and ensures that expectations are met.

- Point of Contact: Designate a primary contact for seamless communication.

- Regular Check-ins: Schedule periodic updates to stay informed about the order status.

By following these steps, you can confidently navigate the sourcing process for custom leather branding irons, ensuring that you select a supplier who meets your business needs and enhances your branding efforts.

Comprehensive Cost and Pricing Analysis for custom leather branding iron Sourcing

What Are the Key Cost Components in Custom Leather Branding Iron Production?

When considering the sourcing of custom leather branding irons, understanding the cost structure is essential for effective budgeting and planning. The primary cost components include:

Illustrative image related to custom leather branding iron

-

Materials: The choice of materials significantly impacts costs. Common materials include brass and stainless steel for the branding head, while handles can be made from wood or plastic. Higher quality materials often lead to increased durability and performance, justifying a higher price.

-

Labor: Skilled labor is required for the design and production of custom branding irons. Labor costs can vary widely based on the region and the complexity of the design, especially when intricate details are involved.

-

Manufacturing Overhead: This includes costs associated with the facilities, utilities, and equipment used in production. Overhead can vary by supplier, particularly if they operate in regions with different labor laws or operational efficiencies.

-

Tooling: Custom designs may require unique tooling, which can represent a significant upfront cost. The tooling costs are amortized over the number of units produced, making it essential to consider the production volume when assessing overall costs.

-

Quality Control (QC): Ensuring that each branding iron meets quality standards incurs additional costs. This includes testing for heat retention and branding quality, which is crucial for maintaining customer satisfaction.

-

Logistics: Shipping and handling costs can add up, especially for international transactions. Factors such as distance, shipping method, and whether the goods are shipped via air or sea will influence overall logistics costs.

-

Margin: Suppliers will typically add a profit margin to their costs, which can vary based on market demand and competition.

What Price Influencers Should B2B Buyers Consider When Sourcing?

Several factors can influence the pricing of custom leather branding irons:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk often results in lower per-unit costs. Suppliers are more likely to offer discounts for larger orders, which can significantly reduce the total cost.

-

Specifications/Customization: Custom features, such as unique logos or designs, can increase the price. Buyers should clearly communicate their specifications to get accurate quotes.

-

Material Quality and Certifications: Higher quality materials and specific certifications can raise costs. Buyers should assess whether these certifications are necessary for their end-use applications.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can affect pricing. Established suppliers with a track record of quality may charge more but provide better reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the shipping costs and risks. This can influence the total landed cost of the products.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

B2B buyers should consider the following strategies to enhance their negotiation outcomes:

-

Research and Compare: Conduct thorough market research to understand the average pricing and quality levels across different suppliers. This knowledge can empower buyers during negotiations.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and more favorable terms. Suppliers may be more willing to negotiate with repeat customers.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the branding irons, including maintenance, durability, and potential replacement costs. A higher upfront investment in quality may lead to lower TCO.

-

Leverage Volume Discounts: If applicable, emphasize your willingness to place larger orders to negotiate better pricing.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be mindful of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can impact pricing, so it’s wise to lock in prices when favorable rates are available.

-

Import Duties and Taxes: Be aware of any import tariffs or taxes that may apply to custom branding irons, as these can significantly affect the total cost.

-

Cultural Differences: Negotiation styles and expectations can vary by region. Understanding these cultural nuances can facilitate smoother negotiations.

Disclaimer on Indicative Prices

Pricing for custom leather branding irons can vary widely based on the factors mentioned above. The prices referenced in this analysis are indicative and may not reflect the final costs incurred by buyers. Always consult with suppliers for precise quotes tailored to specific needs.

Alternatives Analysis: Comparing custom leather branding iron With Other Solutions

When considering branding solutions for leather, businesses often evaluate various methods to achieve high-quality results. The traditional custom leather branding iron is a popular choice, but alternatives such as electric branding tools and custom stamps offer unique benefits. This analysis compares these options to help international B2B buyers make informed decisions.

| Comparison Aspect | Custom Leather Branding Iron | Electric Branding Tool | Custom Leather Stamp |

|---|---|---|---|

| Performance | High-quality, durable marks | Consistent heat and precision | Clear impressions, less durable |

| Cost | Moderate ($89 – $300) | Higher ($148 – $458) | Lower ($68 – $148) |

| Ease of Implementation | Requires manual heating | Plug-and-play with temperature control | Simple to use, no heating required |

| Maintenance | Minimal; occasional cleaning | Needs calibration and upkeep | Low; mainly cleaning after use |

| Best Use Case | Large batches and detailed designs | High-volume branding, precision | Simple logos or text on flat surfaces |

What Are the Performance Differences Between Custom Leather Branding Irons and Electric Branding Tools?

Custom leather branding irons provide high-quality and durable marks on leather, making them ideal for intricate designs and detailed artwork. However, they require manual heating, which can lead to inconsistencies in heat application if not monitored closely. On the other hand, electric branding tools offer consistent heat and precision, making them suitable for high-volume branding tasks. They often include temperature control features, ensuring that the heat is maintained at optimal levels throughout the branding process.

How Does Cost Affect the Choice Between Custom Leather Branding Irons and Custom Leather Stamps?

The cost of custom leather branding irons typically ranges from $89 to $300, depending on the complexity and size of the branding head. Electric branding tools are generally more expensive, falling between $148 and $458, reflecting their advanced technology and features. In contrast, custom leather stamps are the most affordable option, ranging from $68 to $148. This lower price point makes stamps an attractive choice for businesses with limited budgets, although they may not provide the same level of durability or detail as branding irons.

Why Consider Ease of Implementation When Choosing a Branding Solution?

Ease of implementation is a critical factor for businesses aiming to streamline their production processes. Custom leather branding irons require manual heating, which can slow down production and require additional training for staff. Electric branding tools are designed for simplicity, often featuring plug-and-play functionality, allowing for quick setup and operation. Custom leather stamps, being a straightforward method, require no heating, making them easy to use right out of the box.

What Maintenance Considerations Should Businesses Keep in Mind?

Maintenance is essential for ensuring the longevity and effectiveness of branding tools. Custom leather branding irons require minimal maintenance, primarily consisting of cleaning the branding head after use. Electric branding tools, while efficient, may need calibration and regular upkeep to ensure consistent performance. Custom leather stamps generally have low maintenance needs, requiring only cleaning after use to maintain their impression quality.

How Can B2B Buyers Choose the Right Branding Solution for Their Needs?

When selecting a branding solution, B2B buyers should assess their specific needs, including budget constraints, the volume of branding required, and the desired level of detail in the branding. For businesses focused on high-volume production and precision, electric branding tools may be the best fit. Conversely, those looking for cost-effective solutions with good durability might prefer custom leather branding irons or stamps. By evaluating these factors, buyers can make informed choices that align with their operational goals and branding strategies.

Essential Technical Properties and Trade Terminology for custom leather branding iron

What Are the Essential Technical Properties of Custom Leather Branding Irons?

When considering the purchase of custom leather branding irons, understanding their technical properties is crucial for making informed decisions that align with your business needs. Here are some critical specifications:

Illustrative image related to custom leather branding iron

-

Material Grade

– Custom leather branding irons are typically made from high-quality brass or stainless steel. Brass is favored for its excellent heat retention and durability, while stainless steel offers resistance to corrosion and wear. The choice of material affects the longevity and performance of the branding iron, making it essential for buyers to select the right grade based on their branding needs. -

Heat Retention and Temperature Control

– Effective branding requires precise temperature control. High-quality branding irons are designed to retain heat effectively, allowing for consistent branding without frequent reheating. Electric branding irons often come with digital temperature controls, enabling users to adjust the heat based on the leather type, which can vary in heat tolerance. -

Branding Head Depth

– The depth of the branding head is important for achieving a clear, legible mark. A deeper engraving allows for better impressions on uneven or textured surfaces. This property is particularly relevant for businesses branding a variety of materials or those that require intricate designs. -

Dwell Time

– Dwell time refers to the duration the branding iron needs to be in contact with the leather to create a permanent mark. Different leather types require varying dwell times; softer leathers may need less time compared to thicker, firmer varieties. Understanding dwell time is critical for ensuring high-quality branding results, reducing the risk of damaging the leather. -

Size and Shape Options

– Custom branding irons are available in various sizes and shapes, tailored to specific branding needs. Whether you require a small logo or a larger design, selecting the appropriate size ensures that the branding iron fits your product and branding strategy effectively. -

Power Source

– Branding irons can be either fire-heated or electric. Fire-heated irons are portable and do not require electricity, making them suitable for outdoor settings. Electric branding irons, on the other hand, offer convenience and precision, often with adjustable temperature settings, making them ideal for high-volume branding operations.

Which Trade Terminology Should B2B Buyers Know for Custom Leather Branding Irons?

Understanding industry terminology is essential for effective communication and negotiation in the procurement process. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Knowing about OEMs can help buyers identify reliable suppliers for custom branding irons that meet their specific requirements. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity a supplier is willing to sell. This is crucial for buyers as it affects inventory management and cash flow. Understanding MOQ helps businesses plan their purchases and avoid overstock or stockouts. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. It is a fundamental step in the procurement process, allowing buyers to compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps in understanding shipping costs, risk management, and delivery responsibilities. -

Lead Time

– This refers to the time taken from placing an order to delivery. Understanding lead time is vital for businesses that rely on timely branding solutions, ensuring that they can meet their production schedules. -

Custom Design Specifications

– This term refers to the specific details and requirements for a custom branding iron, including size, shape, and design elements. Clear communication of these specifications is essential to ensure that the final product meets expectations.

By familiarizing yourself with these technical properties and trade terms, you can navigate the procurement of custom leather branding irons more effectively, ensuring that your branding needs are met with precision and quality.

Navigating Market Dynamics and Sourcing Trends in the custom leather branding iron Sector

What Are the Key Market Drivers and Trends in the Custom Leather Branding Iron Sector?

The global custom leather branding iron market is witnessing significant growth driven by the increasing demand for personalized leather goods across various sectors, including fashion, automotive, and furniture. Emerging markets in Africa and South America are particularly important, as they exhibit a growing interest in custom branding for local craftsmanship and artisanal products. The rise of e-commerce platforms has further propelled this trend, enabling international buyers to access a wide variety of branding solutions tailored to their specific needs.

Technological advancements are also reshaping the landscape. The introduction of electric branding irons with digital temperature control enhances precision and reduces the risk of damaging the leather, which is particularly appealing to B2B buyers focused on quality. Additionally, automated branding solutions, such as drill press-mounted branding irons, are becoming increasingly popular for high-volume production, offering efficiency and consistency. As sustainability becomes a priority, buyers are also seeking brands that utilize eco-friendly materials and processes, leading to a surge in demand for sustainably sourced leather.

How Is Sustainability Influencing the Sourcing of Custom Leather Branding Irons?

Environmental considerations are at the forefront of B2B procurement decisions, and the custom leather branding iron sector is no exception. The leather industry has faced scrutiny regarding its environmental impact, particularly concerning water usage, waste management, and chemical treatment processes. As a result, buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and sustainable practices.

Illustrative image related to custom leather branding iron

To align with these values, many manufacturers are adopting ‘green’ certifications and utilizing eco-friendly materials. This includes sourcing leather from tanneries that comply with environmental standards, such as the Leather Working Group (LWG) certification. Additionally, brands are exploring alternative materials, like vegetable-tanned leather, which is less harmful to the environment. For B2B buyers, partnering with suppliers that prioritize sustainability not only enhances brand reputation but also meets the growing consumer demand for responsible products.

What Is the Historical Context of Custom Leather Branding Irons for B2B Buyers?

The practice of branding leather dates back centuries, originally used by artisans to signify ownership or craftsmanship. Historically, branding irons were simple tools made from heated metal, primarily utilized in agriculture and leatherworking. As the demand for personalized goods grew, so did the sophistication of branding techniques.

In recent decades, advancements in technology have transformed the industry, introducing electric branding irons and customizable solutions that allow for intricate designs and logos. This evolution reflects broader trends in consumer preferences for unique, personalized products, which is particularly relevant for B2B buyers seeking to differentiate their offerings in a competitive marketplace. Understanding this historical context can help buyers appreciate the craftsmanship and technological innovation that underpin modern branding solutions.

Conclusion

Navigating the custom leather branding iron sector involves understanding the interplay of market dynamics, sustainability, and historical evolution. B2B buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, must stay informed about these trends to make strategic sourcing decisions that align with their business goals and consumer expectations. By prioritizing suppliers that embrace innovation and sustainability, businesses can enhance their brand identity while contributing to a more responsible leather industry.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather branding iron

-

How do I choose the right custom leather branding iron for my business needs?

When selecting a custom leather branding iron, consider the type of leather you will be branding, the size of the brand you need, and the level of detail in your design. Different irons, such as electric or fire-heated, can offer varying degrees of heat control and efficiency. Also, think about whether you need a standard design or a fully customized option. It’s essential to consult with suppliers about your specific branding requirements to ensure you choose an iron that meets your production needs. -

What is the typical lead time for ordering a custom leather branding iron?

Lead times can vary based on the supplier and the complexity of your design. Generally, expect a production time of 2-4 weeks for standard orders, while custom designs may take longer. It’s advisable to confirm the timeline during your initial discussions with suppliers. Additionally, consider shipping times, especially for international orders, as they can significantly impact your overall timeline. -

What are the minimum order quantities (MOQ) for custom leather branding irons?

Minimum order quantities can differ widely among suppliers, ranging from a single unit for custom branding to larger quantities for bulk orders. Many suppliers are flexible, especially for B2B buyers looking to establish long-term relationships. Always inquire about the MOQ upfront, as well as any potential discounts for larger orders, to better plan your budget and inventory. -

What payment terms should I expect when sourcing custom leather branding irons internationally?

Payment terms can vary, but common practices include partial upfront payment (typically 30-50%) with the balance due upon completion or delivery. Some suppliers may offer net payment terms, allowing you to pay within a specified period after receiving the goods. Always clarify payment methods accepted (e.g., wire transfer, credit card) and any associated fees. Establishing clear terms helps prevent misunderstandings and ensures a smooth transaction. -

How do I ensure the quality of the custom leather branding irons I order?

To ensure quality, work with reputable suppliers who provide samples or prototypes before full production. Request details about the materials used, production processes, and any quality assurance measures in place. Additionally, consider asking for customer references or reviews to gauge their reliability. For international orders, you might also want to explore third-party quality inspections before shipment. -

What should I consider regarding logistics and shipping for international orders of branding irons?

Logistics is crucial when sourcing internationally. Confirm the supplier’s shipping capabilities, including whether they can handle customs clearance and duties for your country. Discuss shipping options such as air or sea freight, considering cost and delivery time. It’s also wise to have a clear agreement on who bears the risk during transit and whether insurance is available for high-value shipments. -

Can I customize the design and size of my branding iron?

Yes, most suppliers offer customization options, allowing you to create a branding iron that fits your specific design and size requirements. You can typically submit your artwork, choose the dimensions, and specify any additional features you might need. Ensure that you provide clear specifications and communicate closely with the supplier during the design phase to achieve the desired results. -

What types of leather can be branded, and does heat level vary by material?

Different types of leather require varying heat levels for effective branding. Soft leather and suede generally need less heat compared to thicker, firmer leather. It’s essential to consult with your supplier for recommendations on the appropriate temperature settings for different leather types. They can provide guidance on dwell time and techniques to achieve clear, crisp branding marks without damaging the material.

Top 6 Custom Leather Branding Iron Manufacturers & Suppliers List

1. Branding Irons – Custom Branding Solutions

Domain: brandingirons.com

Registered: 1999 (26 years)

Introduction: Branding Irons for Leather – Family owned and operated for over 25 years. Made in the USA. Custom Branding Irons, Livestock Branding Irons, Curved Custom Branding Iron, Extra Large Custom Branding Irons, Custom Interchangeable Branding Irons, Light Duty Branding Irons, Heavy Duty Branding Irons, Basic Pre-Made Packages, Personalized Branding Irons, Food Branding Irons, Event Planning & Catering, S…

2. LW Leathers – Electric Branding Irons

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: Electric Branding Iron for leather stamping with custom leather stamp & Gold Foiling. Production lead time: 2-5 working days. Four types of electric branding irons available: 60W for vegetable tanned leather (stamps up to 4x4cm), 300W with digital control for stamps up to 6x6cm (works with chrome tanned and faux leather), 500W for larger stamps (up to 4×5 inch), and Electric Heating Arbor Press fo…

3. Gearheart Industry – Custom Leather Stamping Tools

Domain: gearheartindustry.com

Registered: 2013 (12 years)

Introduction: Custom Leather Stamping Tools, Made in the USA; Premium leatherworking tools for intricate designs and custom branding; Suitable for seasoned leatherworkers and beginners; Products include: Custom Leather Stamp ($119.00), Leather Stamp Handle ($21.00), SmartBrand Branding System (from $412.00), SmartBrand Drill Press Branding System (from $522.00), Extra Branding Iron Plates (from $65.00); Feature…

4. Brandnew – Custom Leather Branding Irons

Domain: brandnew.net

Registered: 1998 (27 years)

Introduction: Leather Branding Irons are fully customizable branding irons made with any artwork, logo, or text. They feature extra deep relief for branding leather and rough, uneven surfaces. Made from brass, the high relief ranges from 0.1″ to 0.15″ depending on specific artwork. Standard production time is 2 weeks plus shipping. Pricing starts at $106.28. Options include size (1″, 2″, or 3″ for length and wi…

5. Leather Branding Tools – Custom Logo Stamps

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Leather branding tool, custom logo stamps, 80 watt heating irons, sourced from Leatherstampmaker.com.

6. Custom Branding Iron – Key Product

Domain: custombrandshop.com

Registered: 2016 (9 years)

Introduction: This company, Custom Branding Iron – Key Product, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for custom leather branding iron

In today’s competitive landscape, the strategic sourcing of custom leather branding irons is vital for businesses looking to enhance their product offerings and brand identity. By investing in high-quality branding tools, companies can achieve consistent, professional results that elevate their craftsmanship and customer satisfaction. Key considerations include selecting the right type of branding iron—whether electric or fire-heated—and understanding the specific heat requirements for various leather types.

Illustrative image related to custom leather branding iron

Moreover, the ability to customize designs ensures that brands can maintain a unique presence in the market. With options ranging from simple initials to intricate logos, businesses can effectively communicate their identity through every product they offer.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe explore their options, the importance of establishing reliable partnerships with reputable suppliers cannot be overstated. Look for manufacturers that offer comprehensive support, including design assistance and technical expertise. Embrace the potential of custom leather branding irons to not only reinforce brand loyalty but also drive innovation in your product lines. Invest strategically today to secure a competitive edge for tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather branding iron