Introduction: Navigating the Global Market for oil stain on leather

In the competitive landscape of leather goods, addressing the challenge of oil stains on leather is essential for maintaining product integrity and customer satisfaction. B2B buyers in regions such as Africa, South America, the Middle East, and Europe (including Germany and Vietnam) face the critical task of sourcing high-quality leather products that resist or can be treated for oil stains effectively. This comprehensive guide delves into the various types of leather, the specific applications of oil stain removal techniques, and the importance of vetting suppliers to ensure they provide durable and stain-resistant materials.

By exploring innovative solutions and industry best practices, this guide equips international buyers with the knowledge necessary to make informed purchasing decisions. It highlights key factors such as cost considerations, environmental impacts, and the effectiveness of various stain removal methods. Additionally, the guide provides insights into potential partnerships with suppliers who prioritize quality and sustainability, ensuring that buyers not only meet their immediate needs but also contribute to long-term brand reputation and customer loyalty.

Whether you’re looking to enhance the durability of leather products or seeking effective ways to tackle oil stains, this guide serves as your essential resource, empowering you to navigate the global market with confidence.

Table Of Contents

- Top 3 Oil Stain On Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for oil stain on leather

- Understanding oil stain on leather Types and Variations

- Key Industrial Applications of oil stain on leather

- 3 Common User Pain Points for ‘oil stain on leather’ & Their Solutions

- Strategic Material Selection Guide for oil stain on leather

- In-depth Look: Manufacturing Processes and Quality Assurance for oil stain on leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘oil stain on leather’

- Comprehensive Cost and Pricing Analysis for oil stain on leather Sourcing

- Alternatives Analysis: Comparing oil stain on leather With Other Solutions

- Essential Technical Properties and Trade Terminology for oil stain on leather

- Navigating Market Dynamics and Sourcing Trends in the oil stain on leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of oil stain on leather

- Strategic Sourcing Conclusion and Outlook for oil stain on leather

- Important Disclaimer & Terms of Use

Understanding oil stain on leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Oil Stains | Often caused by contact with cooking oils or lotions; typically easy to spot. | Fashion accessories, upholstery. | Pros: Easier to clean; Cons: May require frequent maintenance. |

| Deep Penetrating Oil Stains | Absorbed deeply into the leather, often from oils or greases; harder to remove. | Industrial leather goods, workwear. | Pros: Durable; Cons: Difficult to treat and may require professional cleaning. |

| Wax-Based Stains | Result from waxy substances like candles; can leave a residue. | High-end leather goods, art pieces. | Pros: Unique aesthetic; Cons: Requires specific cleaning agents. |

| Grease Stains | Typically from mechanical oils or food; can create a slippery texture. | Automotive upholstery, work uniforms. | Pros: Resilient to wear; Cons: Challenging to remove without damaging leather. |

| Chemical Stains | Caused by harsh cleaning agents or solvents; can discolor leather. | Specialty leather products, industrial applications. | Pros: Strong performance; Cons: Risk of permanent damage if not treated correctly. |

What Are the Characteristics of Surface Oil Stains on Leather?

Surface oil stains are primarily characterized by their visibility on the leather’s exterior. These stains are typically caused by contact with oils from cooking, lotions, or skin products. They are relatively easy to identify and often can be removed with basic household cleaning products. For B2B buyers in the fashion accessory and upholstery industries, understanding that these stains can be managed through regular maintenance is crucial. Buyers should consider the ease of cleaning and the potential need for protective treatments to ensure longevity.

How Do Deep Penetrating Oil Stains Affect Leather Products?

Deep penetrating oil stains occur when oils seep into the leather fibers, making them more difficult to remove. This type of stain is common in industrial leather goods and workwear, where exposure to oils and greases is frequent. For B2B buyers, the durability of leather products with deep stains can be a selling point, but they should also be aware of the challenges associated with cleaning. Investing in professional cleaning services may be necessary, which could impact overall maintenance costs.

What Makes Wax-Based Stains Unique?

Wax-based stains are typically a result of contact with candles or waxy substances. These stains can leave a residue that affects the leather’s appearance and texture. In high-end leather goods and art pieces, buyers may appreciate the unique aesthetic that wax can provide. However, cleaning these stains requires specific agents to avoid damaging the leather. B2B buyers should weigh the aesthetic appeal against the potential for increased maintenance.

Why Are Grease Stains Particularly Challenging?

Grease stains, often originating from mechanical oils or food, can create a slippery texture on leather surfaces. They are particularly prevalent in automotive upholstery and work uniforms. While these products are designed for resilience and durability, the challenge lies in removing grease stains without damaging the leather. B2B buyers in relevant industries should consider the balance between durability and ease of maintenance when selecting leather materials.

How Do Chemical Stains Impact Leather Quality?

Chemical stains arise from exposure to harsh cleaning agents or solvents, leading to discoloration and potential damage. These stains can be particularly problematic in specialty leather products and industrial applications where strong cleaning agents are common. For B2B buyers, understanding the risks associated with chemical stains is vital. They should prioritize sourcing high-quality leather that can withstand cleaning processes, while also considering the long-term implications of chemical exposure on product integrity.

Key Industrial Applications of oil stain on leather

| Industry/Sector | Specific Application of Oil Stain on Leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Leather upholstery in vehicles | Enhances the aesthetic appeal and durability of interiors | Sourcing high-quality leather that is resistant to staining and easy to clean. Consider local suppliers for reduced shipping costs. |

| Fashion & Apparel | Leather garments and accessories | Provides a luxurious look while ensuring longevity and wear resistance | Ensure the leather has appropriate treatments for stain resistance and durability. Verify ethical sourcing practices. |

| Furniture & Upholstery | Leather furniture pieces | Increases the value of furniture through premium materials and finishes | Look for suppliers offering treated leather that resists stains while maintaining comfort and style. Prioritize suppliers with a strong reputation for quality. |

| Industrial Equipment | Leather protective gear and workwear | Enhances worker safety and comfort in harsh environments | Focus on sourcing leather that meets industry safety standards and offers resistance to oil and other contaminants. Check for certifications. |

| Leather Goods Manufacturing | Production of bags and wallets | Offers a competitive edge through high-quality, stain-resistant products | Source leather that can withstand daily wear and tear, while also being easy to clean. Consider suppliers with a reliable track record in quality assurance. |

How is Oil Stain on Leather Utilized in the Automotive Industry?

In the automotive sector, oil stain on leather is often a concern for vehicle manufacturers and upholstery suppliers. Leather upholstery is favored for its luxury and comfort, but it requires careful maintenance to avoid stains from oils and other substances. By sourcing high-quality, treated leather that is stain-resistant, businesses can enhance the aesthetic appeal and longevity of vehicle interiors. This not only improves customer satisfaction but also reduces the need for costly replacements or repairs.

What Role Does Oil Stain on Leather Play in Fashion and Apparel?

In the fashion and apparel industry, oil stain on leather is a critical consideration for designers and manufacturers. Leather garments and accessories provide a sophisticated look, but they are susceptible to staining, which can detract from their value. By selecting leather that undergoes specific treatments to resist stains, businesses can ensure their products maintain their luxurious appearance over time. This enhances brand reputation and customer loyalty, particularly among consumers in Europe and other fashion-centric markets.

How is Oil Stain on Leather Important for Furniture and Upholstery?

Furniture manufacturers and upholstery specialists utilize leather for its durability and aesthetic appeal. However, oil stains can be a significant issue, impacting the overall quality and appearance of leather furniture. By sourcing leather that has been treated for stain resistance, businesses can offer products that are both beautiful and functional. This not only increases the value of the furniture but also appeals to consumers looking for longevity and easy maintenance in their home furnishings.

Why is Oil Stain on Leather Relevant in Industrial Equipment?

In industries requiring protective gear, oil stain on leather is a fundamental consideration. Leather workwear and protective gear must withstand harsh conditions while providing comfort to workers. By sourcing leather that is resistant to oil and other contaminants, businesses can enhance safety and durability in the workplace. This is particularly crucial for sectors like construction and manufacturing, where worker safety is paramount.

How Does Oil Stain on Leather Affect Leather Goods Manufacturing?

For manufacturers of leather goods such as bags and wallets, oil stain resistance is essential to maintain product quality and customer satisfaction. Leather that can withstand daily wear while being easy to clean provides a competitive advantage. By focusing on high-quality, treated leather, manufacturers can ensure their products meet consumer expectations for durability and style, thereby enhancing brand loyalty and marketability in diverse regions, including Africa and South America.

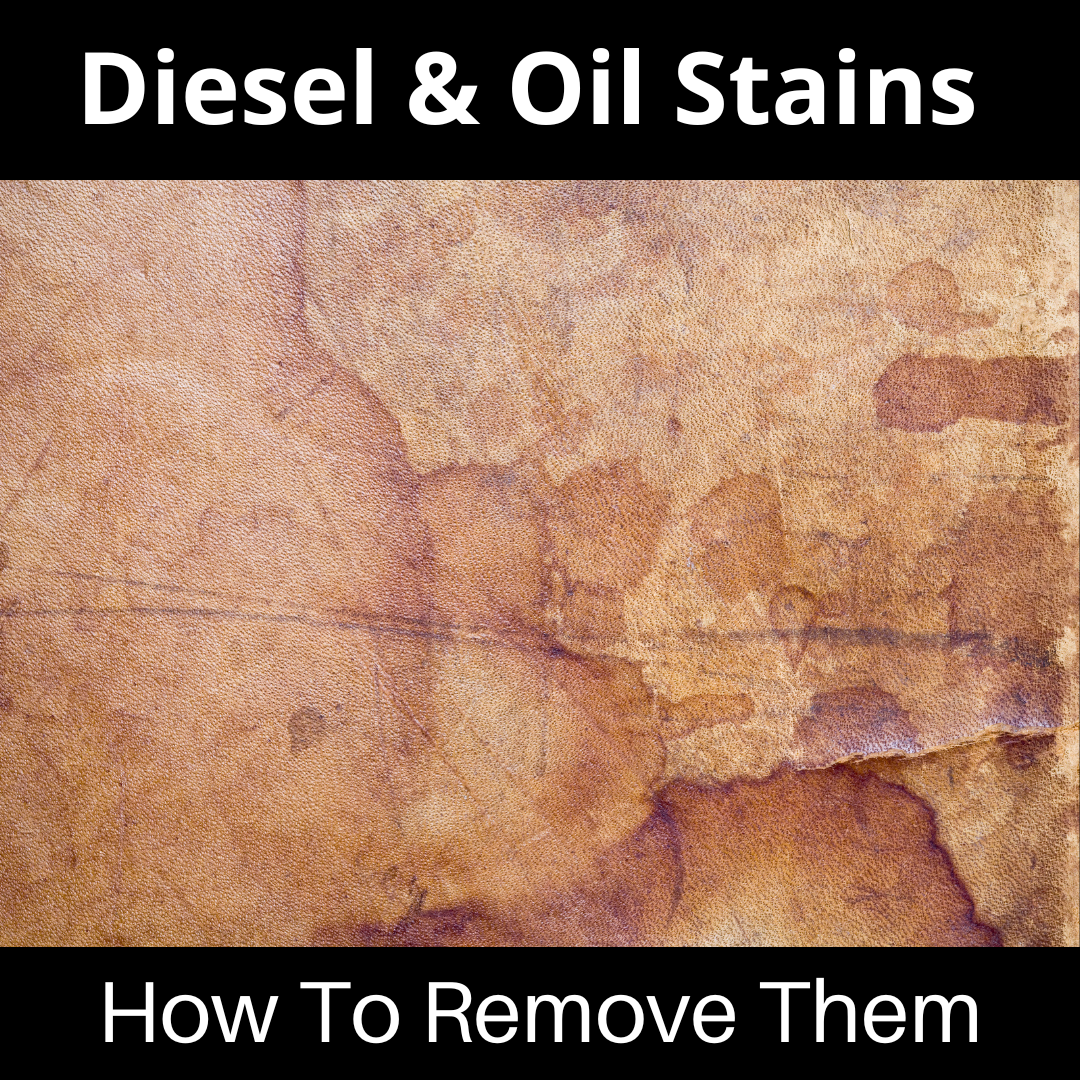

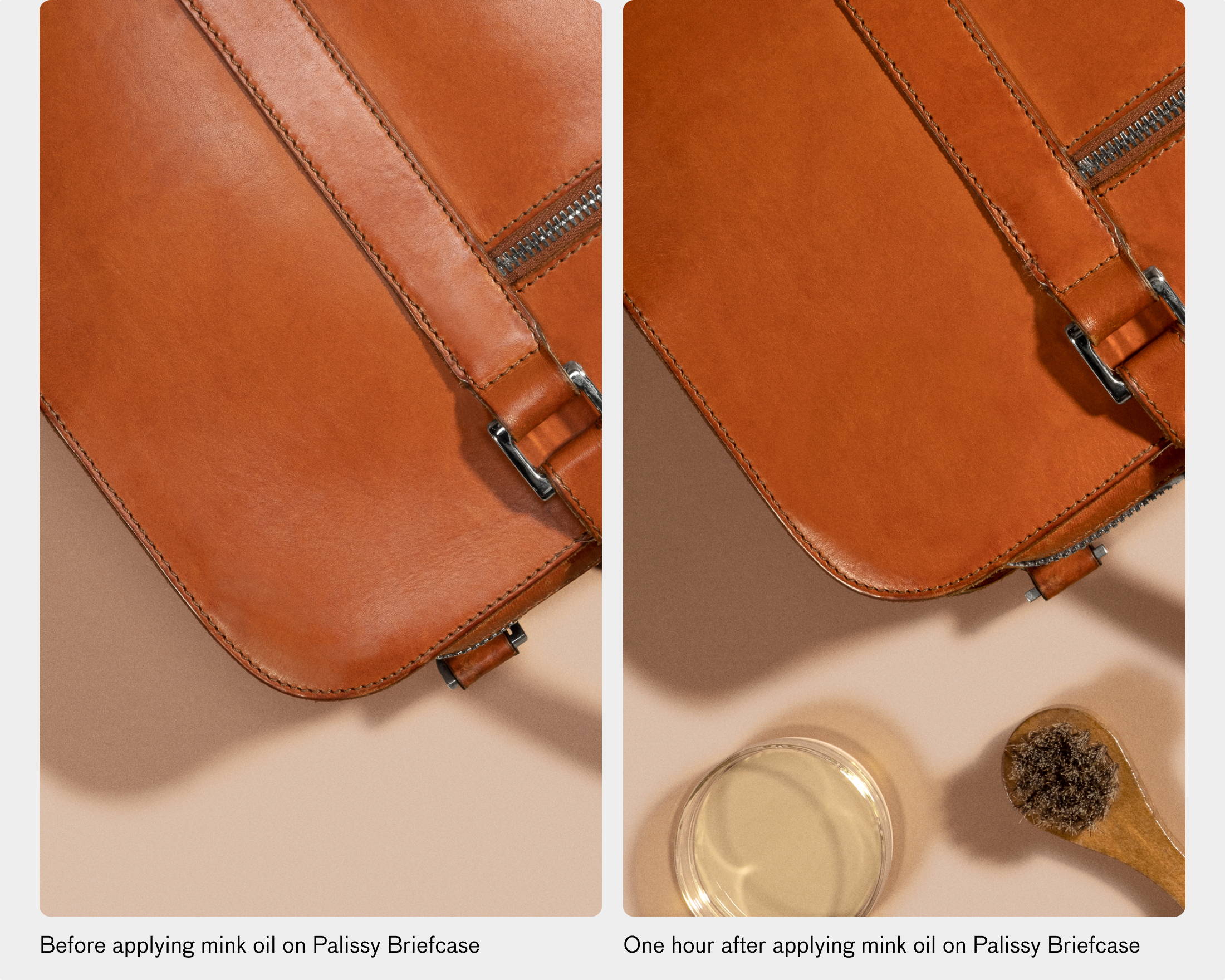

Illustrative image related to oil stain on leather

3 Common User Pain Points for ‘oil stain on leather’ & Their Solutions

Scenario 1: Difficulty in Stain Removal from High-End Leather Goods

The Problem: Many B2B buyers, particularly those in the luxury leather goods sector, face the challenge of oil stains on high-end leather products such as handbags, shoes, and upholstery. These items are often made from delicate materials that require special care. A single oil stain can significantly diminish the product’s value, leading to customer dissatisfaction and potential loss of reputation. Buyers are often unsure about the appropriate cleaning methods that won’t damage the leather’s finish or texture, adding to their frustration.

The Solution: To effectively remove oil stains without compromising the integrity of high-end leather, buyers should source specialized leather cleaning products designed for delicate materials. Look for solutions that contain natural ingredients like beeswax or lanolin, which can lift the stain without harsh chemicals. For immediate action, sprinkle cornstarch or talcum powder onto the stain to absorb the oil, allowing it to sit for several hours. Afterward, gently brush away the powder and apply a small amount of the specialized cleaner with a soft cloth. This method not only helps remove the stain but also nourishes the leather, maintaining its quality and extending its lifespan.

Scenario 2: Inconsistent Results with DIY Cleaning Methods

The Problem: Many businesses attempt to tackle oil stains on leather using DIY methods, often resulting in inconsistent outcomes. Common household products such as vinegar or baking soda may not yield the desired results and can even worsen the stain or discolor the leather. This inconsistency creates uncertainty and can lead to increased costs when items must be replaced or professionally cleaned. B2B buyers need a reliable approach that ensures consistent and effective stain removal every time.

The Solution: To achieve uniform results, businesses should invest in professional-grade leather care kits that include both cleaning and conditioning products specifically formulated for oil stains. These kits often come with step-by-step instructions tailored to different leather types, ensuring that even less experienced staff can perform effective cleaning. Additionally, regular training sessions on leather care can help staff understand the best practices for maintaining leather products, reducing the reliance on trial and error. By adopting a structured approach, companies can ensure that their leather goods are treated consistently, preserving their quality and aesthetic appeal.

Scenario 3: Impact of Environmental Factors on Leather Care

The Problem: For B2B buyers operating in regions with high humidity or extreme temperatures, maintaining leather can be particularly challenging. Oil stains not only occur more frequently in these conditions but can also set more deeply into the leather, making them harder to remove. Businesses are often concerned about the long-term effects of environmental factors on their leather inventory, fearing damage that could lead to significant financial losses.

The Solution: To combat the effects of harsh environmental conditions, businesses should consider sourcing leather products treated with water and stain-resistant finishes. Additionally, implementing controlled storage environments, such as climate-controlled warehouses, can help mitigate damage from humidity and temperature fluctuations. Regularly conditioning leather with appropriate treatments can also create a protective barrier against oil stains and other contaminants. By proactively addressing these environmental challenges, businesses can safeguard their leather investments and reduce the frequency of costly cleaning or replacement.

Strategic Material Selection Guide for oil stain on leather

What Materials Are Most Effective for Addressing Oil Stains on Leather?

When dealing with oil stains on leather, the choice of materials for cleaning and treatment is crucial. Here, we analyze several common materials that are effective in addressing oil stains, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to oil stain on leather

1. Absorbent Powders (e.g., Talcum Powder, Cornstarch)

Key Properties: Absorbent powders are designed to soak up oil and moisture, making them effective for initial stain treatment. They do not react chemically with leather, preserving the integrity of the material.

Pros & Cons: These powders are cost-effective and easy to apply. However, they may require multiple applications for complete stain removal, which can be time-consuming. Their effectiveness can also vary based on the type of leather and the age of the stain.

Impact on Application: Absorbent powders work best on fresh stains. For older stains, they may not be as effective, necessitating additional cleaning agents.

Considerations for International Buyers: Compliance with local regulations regarding chemical use is essential. In regions like Europe and Germany, buyers should ensure that products meet safety standards such as REACH.

2. Leather Conditioners with Natural Oils

Key Properties: These conditioners often contain oils like mink or neatsfoot oil, which can penetrate the leather and help lift oil stains while also conditioning the leather to prevent future damage.

Illustrative image related to oil stain on leather

Pros & Cons: They enhance the leather’s appearance and longevity but can be more expensive than basic cleaning solutions. Additionally, improper application can lead to a greasy residue if too much product is used.

Impact on Application: Conditioners are beneficial for maintaining leather’s suppleness and preventing cracking, which can be a concern in dry climates prevalent in Africa and the Middle East.

Considerations for International Buyers: Buyers should look for products that comply with local leather care standards, such as ASTM in the U.S. or DIN in Europe, ensuring they are suitable for their specific leather types.

3. Solvent-Based Cleaners

Key Properties: These cleaners typically contain solvents like isopropyl alcohol or mineral spirits, which can effectively break down oil stains.

Pros & Cons: Solvent-based cleaners are powerful and can remove tough stains quickly. However, they may risk damaging the leather if not used correctly, making them less suitable for delicate leathers.

Illustrative image related to oil stain on leather

Impact on Application: They are particularly effective for commercial applications where heavy-duty cleaning is required, such as in upholstery or leather goods manufacturing.

Considerations for International Buyers: Compliance with VOC regulations is critical, especially in regions with strict environmental laws. Buyers in Europe, for example, must ensure that products meet EU regulations regarding chemical safety.

4. Biodegradable Cleaning Solutions

Key Properties: These solutions are formulated with natural ingredients that are effective for cleaning without harsh chemicals, making them environmentally friendly.

Pros & Cons: They are safer for both users and the environment, appealing to eco-conscious consumers. However, they may not be as effective on stubborn oil stains compared to traditional solvents.

Impact on Application: Biodegradable cleaners are suitable for a wide range of leather products and are particularly appealing in markets that prioritize sustainability.

Considerations for International Buyers: Buyers should verify that these products meet local environmental regulations and standards. In regions like South America, where eco-friendly products are gaining traction, this can be a significant selling point.

Summary Table of Material Selection for Oil Stains on Leather

| Material | Typical Use Case for oil stain on leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Absorbent Powders | Initial treatment for fresh stains | Cost-effective and easy to apply | May require multiple applications | Low |

| Leather Conditioners with Oils | Maintenance and stain prevention | Enhances leather appearance | Can leave a greasy residue | Med |

| Solvent-Based Cleaners | Heavy-duty cleaning in commercial settings | Quick and effective stain removal | Risk of damage to delicate leather | High |

| Biodegradable Cleaning Solutions | General cleaning for eco-conscious users | Environmentally friendly | May be less effective on tough stains | Med |

This strategic material selection guide provides B2B buyers with actionable insights into the best materials for addressing oil stains on leather, considering performance, cost, and regulatory compliance across different international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for oil stain on leather

What Are the Key Stages in the Manufacturing Process of Leather Products Affected by Oil Stains?

The manufacturing of leather products, particularly those that may encounter oil stains, involves several critical stages. Each stage is designed to enhance the quality and durability of the final product while considering the potential for oil exposure.

Material Preparation: How Is Leather Processed Before Use?

The first stage is material preparation, where raw hides are selected based on quality. This selection process considers factors such as thickness, texture, and absence of blemishes. The hides undergo tanning, a chemical process that stabilizes the proteins in the leather, making it more resistant to damage and deterioration. Vegetable tanning and chrome tanning are two common methods, each offering unique properties that can influence the leather’s susceptibility to stains.

During this phase, oils may be intentionally added to enhance the leather’s suppleness and resistance to moisture. However, careful consideration is needed to ensure that these oils do not contribute to staining issues later.

Forming: What Techniques Are Used to Shape Leather Products?

The forming stage involves cutting the leather into specific shapes for various products, such as bags, shoes, or upholstery. Techniques such as die-cutting or hand-cutting are employed, depending on the complexity of the design. Precision is crucial, as any irregularities in the cut can lead to weak points in the finished product, potentially exacerbating oil stain issues.

During this stage, manufacturers may also apply treatments that enhance the leather’s protective qualities against oils and stains. This includes applying surface coatings that repel liquids, thereby reducing the likelihood of oil absorption.

Assembly: How Are Leather Products Constructed?

In the assembly phase, the cut leather pieces are stitched together using specialized machinery or hand-stitching techniques. This stage requires meticulous attention to detail to ensure that seams are tight and secure, as poorly constructed seams can allow oils to penetrate the leather.

Manufacturers often utilize high-quality threads that are resistant to oil degradation. This choice not only enhances the product’s durability but also contributes to its overall aesthetic appeal.

Finishing: What Are the Final Steps to Ensure Quality?

The finishing stage is critical for enhancing the leather’s appearance and functionality. This includes processes such as dyeing, polishing, and applying protective coatings. These finishes can provide an additional barrier against oil stains, helping to maintain the leather’s integrity over time.

Quality finishes are essential for products that are likely to encounter oils, as they can significantly influence how easily stains can be removed. A well-finished leather product will have a uniform appearance and improved resistance to environmental factors.

What Quality Assurance Measures Are Implemented in Leather Manufacturing?

Quality assurance is vital in the leather industry, especially for B2B buyers concerned about the long-term durability of products exposed to oil. Several international standards and industry-specific regulations guide the quality assurance processes.

Illustrative image related to oil stain on leather

Which International Standards Are Relevant for Leather Manufacturing?

One of the most recognized international standards is ISO 9001, which outlines a framework for quality management systems. Compliance with ISO 9001 ensures that manufacturers maintain consistent quality across all stages of production, from material selection to finishing.

Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, especially for products intended for specific markets or uses. These certifications indicate that the products meet stringent safety and quality requirements.

What Are the Critical Checkpoints in the Quality Control Process?

Quality control (QC) checkpoints are implemented throughout the manufacturing process to ensure that products meet established standards. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. It ensures that only high-quality hides are processed.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC involves monitoring production processes to catch any defects early on. This includes inspecting cuts, stitching, and finishes.

-

Final Quality Control (FQC): The final inspection before products are shipped ensures that they meet all specifications. This includes checking for any signs of oil stains or other defects.

What Common Testing Methods Are Used to Ensure Quality?

Manufacturers employ various testing methods to assess the quality of leather products. Common tests include:

-

Water Resistance Testing: Determines how well the leather repels water and oils.

-

Flexural Testing: Assesses the leather’s durability under repeated bending, which is critical for items like bags and footwear.

-

Color Fastness Testing: Evaluates how well the dye holds up against environmental factors like light and water, which can also affect oil stain visibility.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential to ensure product reliability.

Illustrative image related to oil stain on leather

What Methods Can Be Used to Assess Supplier Quality?

-

Audits: Conducting on-site audits allows buyers to directly assess the manufacturing processes, quality control measures, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC procedures and the outcomes of recent inspections.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality practices.

-

Certifications and Documentation: Buyers should request documentation proving compliance with relevant international standards and certifications. This can include ISO certificates, CE markings, and any other industry-specific credentials.

What Are the Specific QC Nuances for International B2B Buyers?

International buyers face unique challenges related to quality assurance, particularly when sourcing from diverse markets. Understanding local regulations, cultural practices, and manufacturing standards is crucial.

How Do Cultural Differences Impact Quality Expectations?

Cultural differences can influence manufacturing practices and quality expectations. For instance, the emphasis on craftsmanship may vary significantly between regions. Buyers should ensure that their suppliers understand and meet the quality standards expected in their target markets.

What Should Buyers Consider Regarding Shipping and Handling?

Finally, B2B buyers must consider how shipping and handling can impact quality. Leather products are sensitive to environmental conditions, and improper handling can lead to damage, including oil stains. Suppliers should be able to demonstrate their capability in maintaining product integrity during transportation.

By understanding the manufacturing processes and quality assurance measures involved in leather production, international B2B buyers can make informed decisions that ensure the longevity and quality of their leather products, particularly those at risk of oil stains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oil stain on leather’

In the realm of leather goods, oil stains can pose significant challenges, impacting product aesthetics and longevity. This guide provides a practical sourcing checklist for B2B buyers seeking effective solutions to address oil stains on leather products. By following these steps, you can ensure that your procurement process leads to high-quality outcomes.

Step 1: Identify the Types of Leather Affected

Understanding the specific types of leather you are dealing with is crucial. Different leather types, such as full-grain, top-grain, and suede, react differently to oil stains. Knowing the material allows for tailored cleaning methods and product recommendations, reducing the risk of damage during cleaning.

Step 2: Research Effective Cleaning Solutions

Before purchasing, investigate cleaning solutions that are specifically formulated for leather. Look for products containing natural ingredients that effectively break down oil without harming the leather’s finish. Key details to consider include:

– Biodegradable options: These are better for the environment and often safer for leather.

– pH balance: Ensure the product maintains the leather’s natural pH to prevent drying or cracking.

Step 3: Evaluate Supplier Reputation

Thoroughly vet potential suppliers of leather cleaning solutions. Look for companies with a solid reputation in the leather care industry. Request testimonials, case studies, and references from other businesses in your region to gauge supplier reliability and product effectiveness.

Step 4: Verify Product Safety and Compliance

Ensure that the cleaning products comply with international safety standards. Look for certifications such as ISO or specific eco-labels that indicate the product is safe for use on leather. This step is vital to avoid potential liability issues and to ensure the safety of your employees handling the products.

Step 5: Assess Cost-Effectiveness

Analyze the pricing of various cleaning solutions while considering their efficacy. A higher initial investment in a quality product can yield long-term savings by reducing the frequency of required applications and prolonging the life of your leather goods. Be sure to compare bulk purchasing options for better rates.

Step 6: Request Sample Products

Before making a large purchase, request samples of the cleaning solutions. Testing these products on small, inconspicuous areas of leather can help assess their effectiveness without risking damage to the entire item. This step allows you to make informed decisions based on firsthand experience.

Illustrative image related to oil stain on leather

Step 7: Establish a Cleaning Protocol

Once you have selected the appropriate products, develop a comprehensive cleaning protocol tailored to your specific leather types. This should include:

– Frequency of cleaning: Establish how often items should be treated based on usage.

– Application methods: Provide clear instructions on how to apply the cleaning solutions effectively.

By following this checklist, B2B buyers can navigate the complexities of procuring solutions for oil stains on leather, ensuring quality, safety, and effectiveness in their operations.

Comprehensive Cost and Pricing Analysis for oil stain on leather Sourcing

What Are the Key Cost Components for Sourcing Solutions for Oil Stains on Leather?

When sourcing products or services for treating oil stains on leather, understanding the cost structure is essential. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of cleaning solutions, conditioners, and protective treatments varies based on the quality and type of ingredients used. High-quality, eco-friendly products may come at a premium.

-

Labor: Labor costs encompass the wages for skilled workers involved in the production and application processes. In regions with higher wage standards, such as parts of Europe, labor costs will significantly impact the overall pricing.

-

Manufacturing Overhead: This includes expenses such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these costs, ultimately affecting the final price.

-

Tooling: The initial investment in tools and machinery necessary for production can be substantial. Suppliers that have already invested in modern, efficient tooling can offer more competitive prices.

-

Quality Control (QC): Ensuring that products meet required standards is vital. The costs associated with QC processes can vary, influencing overall pricing.

-

Logistics: Shipping and handling costs can be significant, especially for international buyers. Factors such as distance, shipping method, and customs duties will influence logistics costs.

-

Margin: Supplier profit margins vary, often depending on market competition and the perceived value of the product.

How Do Price Influencers Affect Sourcing Decisions for Oil Stain Solutions?

Several price influencers can significantly impact sourcing decisions for oil stain solutions on leather.

-

Volume/MOQ: Buyers should consider minimum order quantities (MOQs) and the benefits of bulk purchasing. Larger orders typically reduce per-unit costs and can improve negotiation leverage.

-

Specifications/Customization: Custom formulations tailored to specific leather types or stain challenges may incur additional costs. Buyers should weigh the benefits of customized solutions against standard options.

-

Materials: The choice of materials directly affects pricing. For instance, natural, biodegradable products may be more expensive but can appeal to environmentally conscious markets.

-

Quality/Certifications: Products that meet international quality standards or have certifications (e.g., eco-labels) often command higher prices. Buyers should assess the value of these certifications in relation to their target market.

-

Supplier Factors: Reliability, reputation, and historical performance of suppliers can influence pricing. Established suppliers may charge a premium, but their reliability can lead to cost savings in the long run.

-

Incoterms: Understanding shipping terms (Incoterms) is crucial for international transactions. These terms dictate responsibilities for shipping costs, risks, and insurance, affecting the total landed cost.

What Negotiation Strategies Can Buyers Employ for Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, employing effective negotiation strategies is vital for cost-efficiency.

Illustrative image related to oil stain on leather

-

Focus on Total Cost of Ownership (TCO): Rather than merely negotiating the price, consider the total cost, including shipping, customs, and potential warranty claims. A lower upfront cost might lead to higher overall expenses.

-

Leverage Volume Discounts: Consolidate orders to maximize volume discounts. Suppliers are often more willing to negotiate on price when larger quantities are involved.

-

Evaluate Payment Terms: Flexible payment terms can improve cash flow. Negotiate for extended payment periods, which can ease financial pressure.

-

Build Long-term Relationships: Establishing long-term relationships with suppliers can lead to better pricing, preferential treatment, and improved service.

What Pricing Nuances Should International Buyers Consider?

International buyers must navigate various pricing nuances when sourcing oil stain solutions for leather.

-

Currency Fluctuations: Currency volatility can impact pricing, especially for long-term contracts. Consider hedging options to mitigate risks.

-

Cultural Differences in Negotiation: Understand the cultural context of suppliers from different regions. Negotiation styles can vary widely, influencing the approach to price discussions.

-

Regulatory Compliance: Ensure that all products meet local regulations in your market, as non-compliance can lead to additional costs and delays.

Disclaimer on Indicative Prices

Prices for oil stain solutions can vary widely based on the factors discussed above. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing oil stain on leather With Other Solutions

Introduction to Alternative Solutions for Oil Stains on Leather

Oil stains on leather can be particularly challenging for businesses that rely on leather goods, whether in manufacturing, retail, or maintenance services. Understanding alternative solutions for treating these stains is crucial for maintaining the quality and longevity of leather products. This section explores various methods and products that can effectively remove oil stains, comparing their performance, cost, ease of implementation, and maintenance requirements.

Comparison Table of Oil Stain Removal Solutions

| Comparison Aspect | Oil Stain On Leather | Cornstarch or Talcum Powder | Leather Cleaner Products |

|---|---|---|---|

| Performance | Moderate effectiveness; may require multiple applications | High absorption capability; effective for fresh stains | High effectiveness; designed specifically for leather care |

| Cost | Low cost if using household items | Very low cost; typically found in kitchens | Moderate cost; varies by brand and formulation |

| Ease of Implementation | Requires blotting and time to work | Simple application; leave for several hours | Easy to use; often spray or wipe application |

| Maintenance | Minimal; occasional reapplication needed | Minimal; only needed for fresh stains | Moderate; may require regular use for best results |

| Best Use Case | Suitable for minor, fresh stains | Best for fresh spills; not ideal for old stains | Ideal for all types of stains, including old and set-in oil |

Detailed Breakdown of Alternatives

Cornstarch or Talcum Powder

Cornstarch or talcum powder is an effective household alternative for treating fresh oil stains on leather. When applied directly to the stain, these powders absorb the oil, helping to lift the stain from the leather surface. The primary advantage of this method is its low cost and simplicity—users can apply it easily without the need for extensive cleaning tools. However, its effectiveness diminishes significantly with older stains, and it may require several applications to achieve desired results.

Illustrative image related to oil stain on leather

Leather Cleaner Products

Commercial leather cleaners are specifically formulated to address oil stains and other types of dirt on leather. These products often contain a combination of solvents and conditioners that not only clean but also nourish the leather, helping maintain its suppleness and shine. The primary benefits include high effectiveness and ease of use, as many are designed for quick application. However, costs can vary, and consistent use may be necessary to prevent future stains, leading to higher long-term expenses.

Conclusion: How to Choose the Right Solution for Oil Stains on Leather

When selecting an oil stain removal solution for leather, B2B buyers must consider several factors, including the type of leather, the age and severity of the stain, and their budget. For fresh stains, household items like cornstarch or talcum powder can be an effective and economical choice. In contrast, for older or more stubborn stains, investing in a quality leather cleaner may yield better results and ensure the longevity of the leather product. Understanding these alternatives allows buyers to make informed decisions that align with their operational needs and customer expectations.

Essential Technical Properties and Trade Terminology for oil stain on leather

What Are the Key Technical Properties of Oil Stains on Leather?

Understanding the technical properties of oil stains on leather is crucial for B2B buyers, particularly those involved in leather goods manufacturing and maintenance. Here are several critical specifications to consider:

-

Material Grade

Material grade refers to the quality of the leather, which directly affects its susceptibility to oil stains. High-grade leather, such as full-grain or top-grain, tends to have better resistance due to its dense fiber structure. Buyers should prioritize sourcing high-grade leather to minimize the risk of oil stains, ensuring longevity and durability in their products. -

Absorbency Level

The absorbency of leather indicates how much liquid it can hold before it starts to show stains. This is particularly important for buyers in regions with high humidity or for products intended for outdoor use. Understanding the absorbency level helps in selecting appropriate leather types that can withstand specific environmental conditions, thus reducing the frequency of oil stain incidents. -

Finish Type

The finish on leather plays a significant role in its stain resistance. Aniline leather, for example, is more porous and susceptible to stains, while pigmented leather offers better protection. B2B buyers should consider the intended use of leather products when selecting finishes, as this will influence maintenance practices and longevity. -

Tannery Treatment

The treatment process of leather, including vegetable tanning or chrome tanning, can affect its reaction to oil stains. Vegetable-tanned leather, while more eco-friendly, may require more careful handling to prevent stains. Buyers should inquire about the tannery treatment when sourcing leather to ensure it meets their specific requirements for durability and stain resistance. -

Thickness

The thickness of the leather can impact its overall durability and stain resistance. Thicker leather tends to withstand wear and tear better and may offer more protection against oil penetration. Understanding the thickness specifications can help B2B buyers choose the right leather for their products, balancing aesthetics and functionality. -

Color Fastness

Color fastness refers to the leather’s ability to retain its color when exposed to various conditions, including oil stains. This property is vital for products where appearance is critical. Buyers should seek suppliers who provide information on color fastness tests, ensuring that their leather goods maintain their visual appeal over time.

What Are Common Trade Terms Relevant to Oil Stains on Leather?

Familiarity with industry jargon can facilitate smoother communication between suppliers and buyers. Here are some common trade terms to understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products based on the specifications provided by another company. In the leather industry, OEMs may produce leather goods tailored to specific client needs. Understanding OEM relationships can help buyers negotiate better terms and ensure quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For leather goods, this can significantly impact inventory management and cash flow. Buyers should negotiate MOQs that align with their production schedules and demand forecasts to optimize their purchasing strategy. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to obtain price estimates for specific products or services. In the context of leather goods, an RFQ helps buyers compare prices and negotiate terms effectively. Understanding how to prepare a comprehensive RFQ can lead to better purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to ensure clarity in logistics and reduce potential disputes over responsibilities. -

Lead Time

Lead time is the duration between placing an order and receiving the product. For leather goods, understanding lead times is crucial for inventory planning and fulfilling customer orders. Buyers should always inquire about lead times when negotiating contracts to ensure they can meet market demands. -

Quality Assurance (QA)

QA refers to the processes and procedures put in place to ensure that products meet specified quality standards. For leather goods, effective QA can help mitigate issues related to oil stains and other damages. B2B buyers should prioritize suppliers with robust QA processes to maintain product integrity and customer satisfaction.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance their sourcing strategies and improve product quality in the leather market.

Navigating Market Dynamics and Sourcing Trends in the oil stain on leather Sector

What Are the Key Market Dynamics and Trends Affecting Oil Stains on Leather?

The global leather market continues to evolve, driven by a mix of traditional craftsmanship and modern technological advancements. For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding market dynamics is crucial. A significant trend is the increasing demand for high-quality leather goods, which often face challenges such as oil stains. As consumers become more discerning about product longevity and aesthetics, suppliers are adapting by investing in innovative treatments and coatings that resist stains.

Emerging technologies in leather processing, such as nanotechnology, are enhancing the durability and stain resistance of leather products. This is particularly pertinent for manufacturers and distributors targeting premium markets. Additionally, the rise of e-commerce platforms is reshaping sourcing strategies, enabling international buyers to access a broader range of products and suppliers. Companies are increasingly leveraging digital tools for inventory management and logistics, improving efficiency in the supply chain.

Furthermore, the impact of global trade policies and economic fluctuations cannot be overlooked. Tariffs and regulations can affect sourcing costs and product availability, necessitating strategic planning from B2B buyers. Understanding local market conditions, such as consumer preferences and economic stability, is vital for successful sourcing and sales strategies.

Illustrative image related to oil stain on leather

How Does Sustainability and Ethical Sourcing Impact the Oil Stain on Leather Sector?

Sustainability is becoming a cornerstone of business practices within the leather industry. B2B buyers are increasingly prioritizing suppliers that adhere to ethical sourcing standards and environmentally friendly practices. The environmental impact of leather production, particularly in relation to chemical treatments used in stain removal and prevention, is under scrutiny. Buyers are now more inclined to seek out products that utilize ‘green’ certifications, such as the Leather Working Group’s certification, which ensures responsible sourcing and processing of leather.

The demand for sustainable alternatives is also influencing the formulation of cleaning products and treatments for oil stains. Companies that offer biodegradable or less toxic cleaning solutions are gaining a competitive edge. Buyers should consider partnering with suppliers who provide transparency about their supply chain and sourcing practices, as this can enhance brand reputation and customer loyalty.

Moreover, the shift towards circular economies is prompting manufacturers to explore ways to recycle and repurpose leather goods. This approach not only reduces waste but also addresses consumer concerns regarding sustainability. By investing in ethical sourcing and environmentally friendly practices, B2B buyers can align their offerings with the growing consumer demand for sustainable products.

What Is the Historical Context of the Oil Stain on Leather Sector?

The history of leather as a material dates back thousands of years, with its use evolving alongside human civilization. Traditionally, leather was valued for its durability and versatility, used in everything from clothing to tools. As industrialization progressed, the leather industry saw significant advancements in tanning and processing techniques, which improved the quality and lifespan of leather goods.

However, with these advancements came challenges, notably the susceptibility of leather to various stains, including oil. The introduction of chemical treatments in the mid-20th century provided solutions for stain resistance, but often at the cost of environmental sustainability. Today, the industry is witnessing a resurgence in artisanal methods that prioritize both quality and eco-friendliness, reflecting a broader cultural shift towards valuing craftsmanship and sustainability.

This historical context is essential for B2B buyers as it underscores the importance of balancing traditional practices with modern innovations. Understanding this evolution can aid businesses in making informed sourcing decisions that resonate with contemporary consumer values.

Frequently Asked Questions (FAQs) for B2B Buyers of oil stain on leather

-

How do I solve oil stains on leather?

To effectively address oil stains on leather, it’s crucial to act quickly. Blot the stain gently with a clean cloth to absorb excess oil. Then, apply a small amount of cornstarch or talcum powder directly onto the stain, allowing it to sit for several hours or overnight to absorb the oil. Afterward, brush off the powder and check if the stain persists. If necessary, repeat the process or consider using a specialized leather cleaner designed for oil stains, ensuring it’s compatible with your leather type. -

What is the best method for removing oil stains from leather?

The most effective method for removing oil stains from leather involves a combination of blotting and absorbent powders. Cornstarch or talcum powder works well to draw out the oil. For deeper stains, a solution of mild soap and water can be used for spot cleaning, but it’s essential to test it on an inconspicuous area first. Following cleaning, conditioning the leather is recommended to restore moisture and prevent cracking. -

What products should I use for cleaning oil stains on leather?

When selecting products for cleaning oil stains from leather, opt for gentle, non-abrasive cleaners specifically formulated for leather. Look for absorbent powders like cornstarch or talcum powder for initial treatment. Additionally, specialized leather cleaning solutions that target oil stains can be effective. Always ensure that any product used is safe for the specific type of leather to avoid damage. -

How can I prevent oil stains on leather items?

To prevent oil stains on leather, consider applying a protective leather conditioner that contains water and stain repellent properties. Avoid placing oily items directly on leather surfaces, and be cautious when handling food or cosmetics near leather products. Regular cleaning and conditioning can also help maintain the integrity of the leather, making it less susceptible to stains. -

What are the minimum order quantities (MOQs) for leather care products?

Minimum order quantities for leather care products can vary significantly among suppliers, typically ranging from 100 to 500 units. It’s advisable to inquire directly with potential suppliers for their specific MOQs, as this can influence your purchasing strategy. Additionally, consider negotiating terms if you require smaller quantities, especially when testing new products. -

How do I vet suppliers for leather care products?

To vet suppliers for leather care products, assess their industry reputation through customer reviews and testimonials. Verify their certifications, compliance with international quality standards, and the authenticity of their products. Request samples of their products to evaluate quality, and ensure they provide clear information regarding their sourcing and production practices. -

What are the payment terms typically offered by suppliers?

Payment terms can vary widely among suppliers but commonly include options such as upfront payment, net 30, or net 60 days. Some suppliers may offer discounts for early payments or bulk orders. It’s essential to clarify these terms before finalizing any agreements, ensuring they align with your cash flow and budgeting practices. -

How do logistics and shipping affect the procurement of leather care products?

Logistics and shipping play a crucial role in the timely procurement of leather care products. Considerations include shipping times, costs, and customs regulations, which can differ by region. It’s important to work with suppliers who have reliable logistics partners and can provide transparent shipping timelines. Additionally, understanding import duties and taxes for your region can help you budget effectively and avoid unexpected costs.

Top 3 Oil Stain On Leather Manufacturers & Suppliers List

1. Reddit – Leather Care Essentials

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Saddle Soap: Used to clean leather and draw out oils. 2. Mink Oil: Recommended for conditioning and protecting leather after cleaning. 3. Sno-Seal: A waterproofing wax preferred for shoes exposed to water or snow. 4. Fiebings Weather Proof Wax: Suggested for enhancing the appearance of leather boots. 5. Neatsfoot Oil: Another option for conditioning leather after cleaning. 6. Oil Absorbing Shee…

2. Leather Repair Company – Premium Leather Cleaners & Conditioners

Domain: leatherrepaircompany.com

Registered: 2007 (18 years)

Introduction: LRC1 Leather Cleaner – for pigmented leather; LRC2 Luxury Leather Cleaner – for fine Nappa leather; LRC7 Aniline Leather Cleaner – for aniline leather; LRC52 Suede & Nubuck Leather Cleaner – for suede and nubuck; Natural leather conditioner protection cream; Suede and nubuck protection spray.

3. The Leather Colour Doctor – Leather Dyes & Care Products

Domain: theleathercolourdoctor.co.uk

Registered: 2017 (8 years)

Introduction: Leather Dyes: Leather Shoe Dyes, Leather Jacket Dyes, Leather Sofa Dyes, Leather Dye Kits, Car Leather Dyes (BMW, Audi, Porsche, Jaguar, Bentley, Mercedes, Ford, Lexus, Alfa Romeo, Maserati, Land Rover, Aston Martin); Leather Care: Leather Waxes & Balms, Leather Conditioner, Leather Protection Cream, Leather Cleaner, Leather Degreaser, Spew Remover; Fabric Dyes: Suede Dye, Suede Cleaner, Convertib…

Strategic Sourcing Conclusion and Outlook for oil stain on leather

What Are the Key Insights for B2B Buyers on Oil Stains in Leather?

In conclusion, addressing oil stains on leather is vital for maintaining product quality and customer satisfaction. B2B buyers must prioritize strategic sourcing of leather care solutions that not only effectively remove stains but also enhance the longevity of leather products. Leveraging insights from leading manufacturers and cleaning experts can empower businesses to choose the right cleaning agents and techniques tailored to various leather types, ultimately safeguarding their investments.

Furthermore, understanding the unique challenges of different markets—such as humidity levels in Africa or the climatic conditions in Europe and South America—can influence sourcing decisions. As international buyers seek to enhance their product offerings, incorporating high-quality leather maintenance products will not only benefit end-users but also strengthen brand loyalty and reputation.

Looking ahead, we encourage you to explore partnerships with reputable suppliers who specialize in leather care solutions. By integrating effective oil stain removal strategies into your sourcing processes, you can enhance your product value and position your brand as a leader in leather quality and care. Engage with your suppliers today to ensure that your leather goods remain pristine and appealing to customers across diverse markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to oil stain on leather

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.