Introduction: Navigating the Global Market for makers leather supply

In today’s competitive landscape, sourcing quality makers leather supply presents a significant challenge for B2B buyers across various international markets, particularly in Africa, South America, the Middle East, and Europe. As businesses seek to create distinctive leather goods, understanding the nuances of sourcing—from material selection to supplier reliability—is crucial. This guide is designed to illuminate the complexities of the global leather supply chain, providing insights into the types of leather available, their diverse applications, and how to effectively vet suppliers to ensure quality and compliance.

Navigating this intricate market involves more than just selecting materials; it requires an understanding of cost structures, shipping logistics, and market trends. Each section of this guide addresses these critical factors, empowering you to make informed purchasing decisions that align with your business objectives. We delve into essential topics such as negotiating prices, understanding regional market dynamics, and the importance of sustainable sourcing practices.

By leveraging the knowledge contained within this guide, B2B buyers in regions like Nigeria and Vietnam can enhance their procurement strategies, optimize their supply chains, and ultimately deliver superior products to their customers. With comprehensive insights at your fingertips, you can confidently navigate the makers leather supply market and elevate your business to new heights.

Table Of Contents

- Top 3 Makers Leather Supply Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for makers leather supply

- Understanding makers leather supply Types and Variations

- Key Industrial Applications of makers leather supply

- 3 Common User Pain Points for ‘makers leather supply’ & Their Solutions

- Strategic Material Selection Guide for makers leather supply

- In-depth Look: Manufacturing Processes and Quality Assurance for makers leather supply

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘makers leather supply’

- Comprehensive Cost and Pricing Analysis for makers leather supply Sourcing

- Alternatives Analysis: Comparing makers leather supply With Other Solutions

- Essential Technical Properties and Trade Terminology for makers leather supply

- Navigating Market Dynamics and Sourcing Trends in the makers leather supply Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of makers leather supply

- Strategic Sourcing Conclusion and Outlook for makers leather supply

- Important Disclaimer & Terms of Use

Understanding makers leather supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable-Tanned Leather | Eco-friendly, rich texture, ages beautifully | High-end leather goods, accessories, upholstery | Pros: Sustainable, durable, aesthetic appeal. Cons: Longer processing time, may be pricier. |

| Chrome-Tanned Leather | Soft, flexible, water-resistant | Fashion items, bags, shoes, automotive interiors | Pros: Quick processing, versatile. Cons: Less eco-friendly, potential for chemical residues. |

| Exotic Leathers | Unique patterns, sourced from specialty animals | Luxury goods, high-fashion items | Pros: Distinctive, high market value. Cons: Ethical concerns, limited availability. |

| Tooling Patterns & Templates | Pre-designed patterns for crafting | Crafting, DIY projects, educational purposes | Pros: Time-saving, precision in design. Cons: May limit creativity, reliance on templates. |

| Leather Hardware & Tools | Essential tools and components for leatherwork | Manufacturing, bespoke leather goods production | Pros: Complements leather projects, enhances quality. Cons: Initial investment cost, requires learning curve. |

What Are the Key Characteristics of Vegetable-Tanned Leather for B2B Buyers?

Vegetable-tanned leather is characterized by its eco-friendly tanning process, which uses natural tannins from plant sources. This type of leather is known for its rich texture and ability to develop a unique patina over time, making it ideal for high-end leather goods, accessories, and upholstery. B2B buyers should consider the longer processing times associated with vegetable tanning, as well as the potential for higher costs due to its sustainable nature. However, its durability and aesthetic appeal often justify the investment for luxury brands.

How Does Chrome-Tanned Leather Compare for Different Applications?

Chrome-tanned leather is distinguished by its softness, flexibility, and water resistance, making it suitable for a wide range of applications, including fashion items, bags, shoes, and automotive interiors. The tanning process is quicker than vegetable tanning, which allows for faster production cycles. B2B buyers should be aware of its less eco-friendly reputation and the potential for chemical residues, which could affect marketability. However, its versatility and rapid availability often make it a favored choice among manufacturers.

Illustrative image related to makers leather supply

What Are the Unique Aspects of Exotic Leathers for Luxury Goods?

Exotic leathers, such as those sourced from snakes, crocodiles, or ostriches, offer unique patterns and textures that cater to the luxury market. These materials are often used in high-fashion items and luxury goods, providing a distinct edge in competitive markets. B2B buyers must consider the ethical implications of sourcing exotic leathers and the limited availability due to wildlife regulations. While they command high prices, the distinctive appeal and exclusivity can significantly enhance brand prestige.

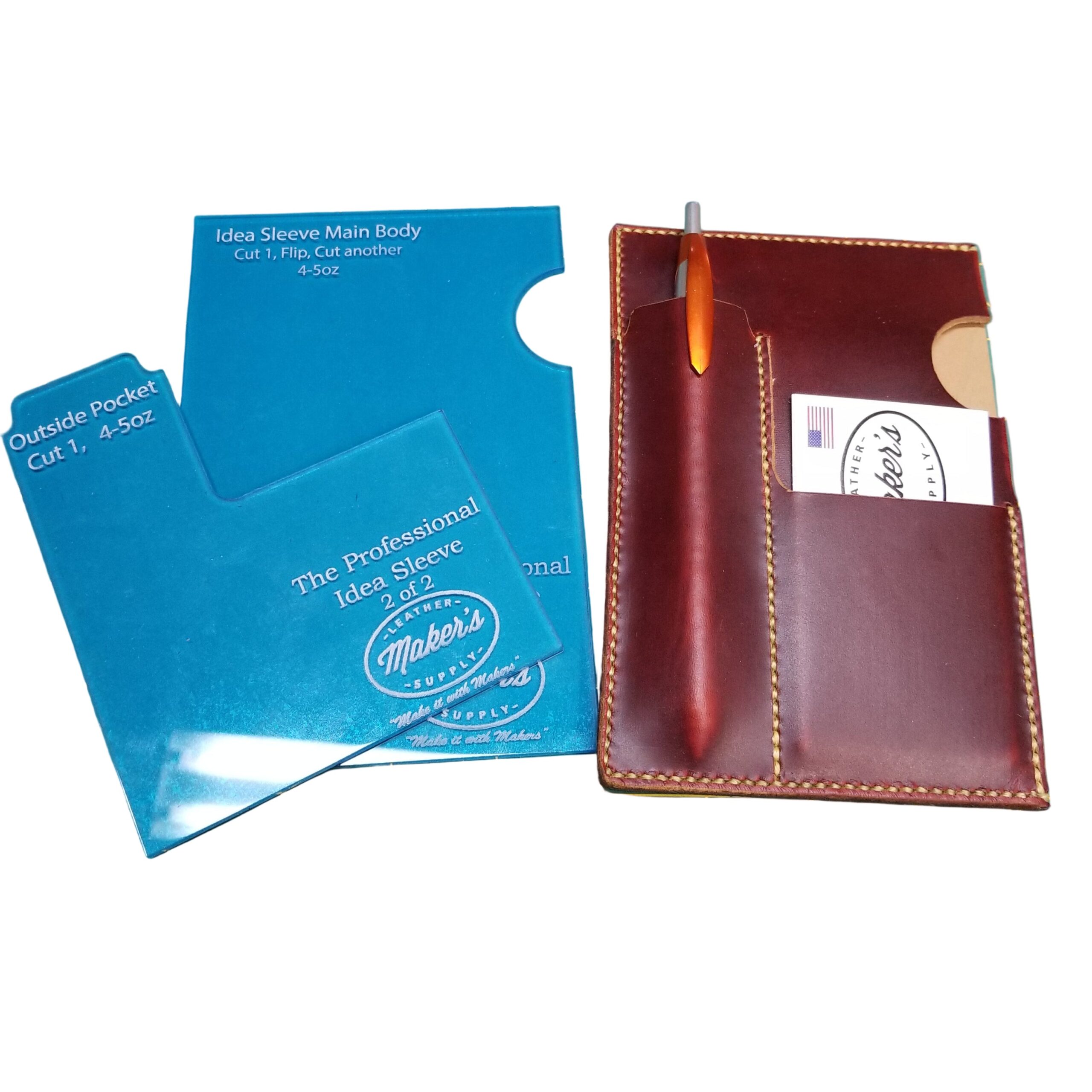

Why Are Tooling Patterns & Templates Important for Crafting?

Tooling patterns and templates are pre-designed guides that facilitate the crafting process, allowing makers to achieve precision in their designs. They are especially useful for DIY projects, educational purposes, and crafting classes. B2B buyers should evaluate the time-saving benefits of using these templates against the potential limitations on creativity. While they can streamline production, reliance on templates may hinder innovation and customization in bespoke projects.

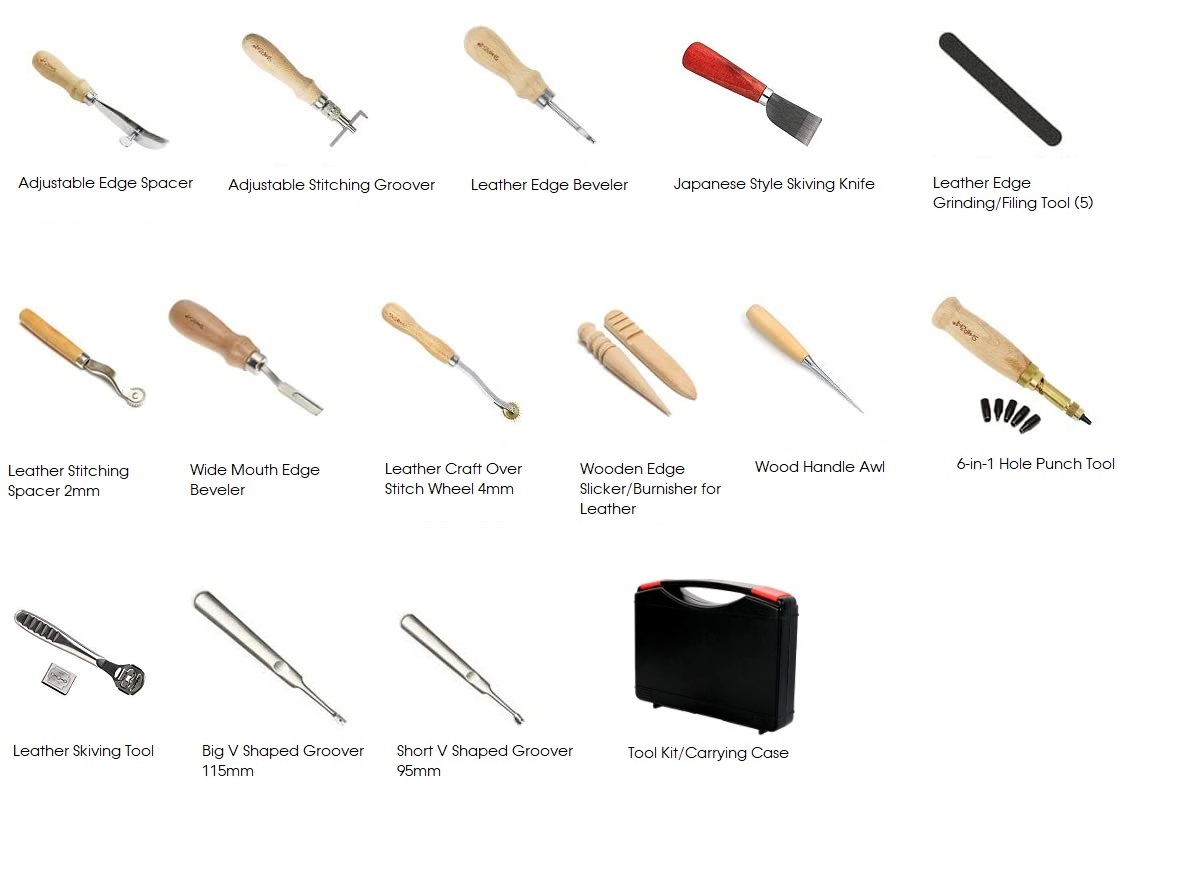

How Do Leather Hardware & Tools Enhance Leather Projects?

Leather hardware and tools are essential components that complement leather projects, ranging from stitching supplies to buckles and rivets. They play a critical role in the manufacturing and bespoke leather goods production processes. B2B buyers should consider the initial investment costs and the learning curve associated with using these tools. However, the quality and efficiency they bring to leatherwork can significantly enhance the final product, making them a worthwhile investment for serious makers.

Key Industrial Applications of makers leather supply

| Industry/Sector | Specific Application of makers leather supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom leather goods production, including bags and wallets | High-quality, bespoke products that enhance brand image | Sourcing premium leather, ensuring ethical practices, and evaluating supplier reliability |

| Automotive | Interior leather upholstery for vehicles | Improved aesthetic appeal and durability of interiors | Compliance with automotive standards and availability of specific leather types |

| Furniture Manufacturing | Upholstery for luxury furniture pieces | Enhanced product quality and customer satisfaction | Selection of suitable leather types and finishes, along with supplier lead times |

| Craft and DIY | Materials for hobbyists and small-scale artisans | Empowerment of local artisans and support for creativity | Availability of templates, tools, and patterns tailored for various skill levels |

| E-commerce and Retail | Online sales of leather crafting supplies | Access to a global market and increased sales potential | Efficient logistics, shipping options, and customer service support |

How is ‘makers leather supply’ utilized in the fashion and apparel industry?

In the fashion and apparel sector, makers leather supply is essential for producing custom leather goods like handbags, wallets, and belts. This application allows brands to offer high-quality, bespoke products that enhance their image and appeal to discerning customers. For international B2B buyers, especially from regions like Africa and South America, sourcing premium leather that meets ethical standards is crucial. Buyers must also evaluate supplier reliability to ensure consistent quality and timely deliveries.

What role does makers leather supply play in the automotive industry?

In the automotive industry, makers leather supply is predominantly used for interior upholstery, enhancing both the aesthetic appeal and durability of vehicle interiors. High-quality leather not only elevates the luxury feel of vehicles but also meets strict automotive standards. Buyers in the Middle East and Europe should consider specific leather types and finishes that comply with these standards while also ensuring that suppliers can deliver large quantities on time to meet production schedules.

Illustrative image related to makers leather supply

How does makers leather supply benefit furniture manufacturing?

Furniture manufacturers utilize makers leather supply for upholstery in luxury furniture pieces, allowing for enhanced quality and customer satisfaction. The tactile and visual appeal of leather contributes significantly to the perceived value of furniture items. For buyers in Europe and Africa, it is essential to select suitable leather types that align with design aesthetics and durability requirements while also considering supplier lead times to maintain production flow.

In what ways does makers leather supply support the craft and DIY sector?

In the craft and DIY sector, makers leather supply provides materials for hobbyists and small-scale artisans looking to create unique leather products. This application empowers local artisans and supports creativity, allowing for the production of custom items that reflect individual styles. International buyers, particularly from emerging markets like Vietnam, should focus on sourcing templates, tools, and patterns that cater to various skill levels, ensuring that they can effectively meet the needs of their customers.

How is makers leather supply transforming e-commerce and retail?

In the e-commerce and retail sectors, makers leather supply facilitates the online sale of leather crafting supplies, enabling businesses to reach a global market. This application increases sales potential and allows for the growth of niche markets. Buyers must consider efficient logistics and shipping options, as well as robust customer service support, to ensure a seamless purchasing experience for international customers.

3 Common User Pain Points for ‘makers leather supply’ & Their Solutions

Scenario 1: Sourcing Quality Leather Materials from Diverse Suppliers

The Problem: B2B buyers often struggle to find reliable sources for high-quality leather materials that meet specific project requirements. This issue is especially prevalent in regions like Africa and South America, where access to premium leather can be inconsistent. Buyers may encounter challenges with varying grades, ethical sourcing, and fluctuating prices, making it difficult to maintain quality standards for their products. Furthermore, the lack of clear communication regarding material specifications can lead to costly mistakes and project delays.

Illustrative image related to makers leather supply

The Solution: To effectively source quality leather, B2B buyers should establish relationships with reputable suppliers like Maker’s Leather Supply, known for their commitment to quality and transparency. Start by conducting thorough research on the types of leather available, such as vegetable-tanned or chrome-tanned options, and how these materials fit your product specifications. Utilize the supplier’s online resources, including detailed product descriptions, tutorials, and customer reviews to gain insight into the material’s performance. Additionally, consider requesting samples before making bulk purchases to ensure the leather meets your expectations. Engaging in direct communication with suppliers about your specific needs can also foster better partnerships and facilitate more reliable sourcing.

Scenario 2: Navigating Complex Tooling Techniques for Leather Crafting

The Problem: Many B2B buyers in the leather crafting industry face challenges when it comes to mastering tooling techniques. This is particularly true for companies that are new to leatherwork or are expanding their product lines. The intricacies of tooling can lead to frustration, wasted materials, and subpar finished products, ultimately affecting customer satisfaction and brand reputation. For instance, without proper guidance, a buyer might struggle with selecting the right tools or patterns, resulting in inconsistent results.

The Solution: To overcome this challenge, B2B buyers should leverage educational resources offered by Maker’s Leather Supply, such as online tutorials, how-to videos, and project patterns. These resources are invaluable for understanding different tooling methods and can significantly enhance the learning curve for new craftsmen. Buyers should also invest in high-quality tooling supplies and templates that simplify the process. By using pre-designed templates, businesses can reduce the time spent on design and focus on perfecting their techniques. Additionally, consider enrolling in online courses that delve into advanced tooling methods, providing hands-on experience that can elevate the quality of your products.

Scenario 3: Managing Inventory and Supply Chain Efficiency

The Problem: Inventory management is a critical concern for B2B buyers dealing with makers leather supply. Fluctuating demand and lead times for materials can lead to overstocking or stockouts, which in turn affects production schedules and profitability. Buyers often find themselves scrambling to align their supply with market demands, leading to inefficient use of capital and resources. This issue is exacerbated in regions with less reliable shipping and logistics networks, where delays can be detrimental to business operations.

The Solution: To improve inventory management, buyers should implement a robust inventory tracking system that integrates with their supply chain processes. Using data analytics tools to forecast demand can provide valuable insights into purchasing patterns, allowing for more strategic ordering of leather supplies. Partnering with Maker’s Leather Supply can also help streamline logistics; their commitment to fast shipping and reliable delivery can mitigate risks associated with supply chain disruptions. Establishing a minimum stock level for essential materials can further ensure that production is not hindered. Regularly reviewing inventory levels and supplier performance will enable businesses to adapt quickly to changes in demand, optimizing both costs and operations.

Strategic Material Selection Guide for makers leather supply

When selecting materials for makers leather supply, it is essential to understand the properties, advantages, disadvantages, and specific considerations that impact international B2B buyers. Here, we analyze four common materials used in leather crafting, providing insights that can guide purchasing decisions.

What Are the Key Properties of Vegetable-Tanned Leather?

Vegetable-tanned leather is a popular choice among leather artisans due to its eco-friendly tanning process. This type of leather is characterized by its firmness and ability to develop a rich patina over time. It typically has a temperature rating that can withstand moderate heat and pressure, making it suitable for various applications, including wallets, belts, and bags.

Illustrative image related to makers leather supply

Pros include its durability and ability to be dyed, carved, or embossed, which enhances its aesthetic appeal. However, the cons involve a longer manufacturing process and higher costs compared to chrome-tanned leather. International buyers should be aware of compliance with environmental regulations, particularly in regions like Europe where eco-friendly practices are emphasized.

How Does Chrome-Tanned Leather Compare in Terms of Performance?

Chrome-tanned leather is known for its softness and flexibility, making it ideal for products that require comfort, such as shoes and jackets. It is resistant to water and has a good temperature rating, allowing it to perform well in various climates.

について advantages of chrome-tanned leather include its quicker production time and lower cost, making it accessible for mass production. However, its disadvantages include a lesser ability to develop a patina and potential environmental concerns due to the chemicals used in tanning. Buyers from Africa and South America should consider local regulations regarding chemical use and disposal.

What Are the Benefits of Suede Leather for Specific Applications?

Suede leather, made from the underside of animal hides, offers a unique texture and aesthetic that is highly sought after in fashion and upholstery. It is lightweight and has a good temperature rating, making it suitable for garments and accessories.

について key advantage of suede is its luxurious feel and appearance, which can elevate the perceived value of products. However, it is less durable than full-grain leather and more susceptible to stains and moisture, which can be a significant limitation. Buyers in the Middle East should consider the climate’s impact on suede’s performance and maintenance requirements.

Illustrative image related to makers leather supply

Why Is Synthetic Leather Gaining Popularity Among International Buyers?

Synthetic leather, often made from polyurethane or PVC, is an increasingly popular alternative due to its affordability and versatility. It can mimic the look and feel of genuine leather while being resistant to moisture and easy to clean.

について advantages of synthetic leather include lower costs and a wide range of colors and textures. However, it may not offer the same durability or aesthetic appeal as natural leather, which could be a disadvantage for high-end products. Buyers from Europe may need to ensure that synthetic materials meet specific environmental standards, as there is a growing trend towards sustainable sourcing.

Summary Table of Material Selection for Makers Leather Supply

| 素材 | Typical Use Case for makers leather supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Wallets, belts, bags | Eco-friendly, develops patina | Longer manufacturing time, higher cost | 高い |

| Chrome-Tanned Leather | Shoes, jackets | Softness, quicker production | Lesser patina, environmental concerns | Medium |

| Suede Leather | Garments, accessories | Luxurious feel, lightweight | Less durable, moisture-sensitive | Medium |

| Synthetic Leather | Fashion items, upholstery | Affordable, versatile | Lower durability, may lack authenticity | 低い |

This material selection guide serves as a valuable resource for international B2B buyers, enabling informed decisions that align with market demands and compliance standards. Understanding the nuances of each material can significantly impact product quality and customer satisfaction in the leather supply industry.

In-depth Look: Manufacturing Processes and Quality Assurance for makers leather supply

What Are the Main Stages of Manufacturing for Maker’s Leather Supply?

The manufacturing process for Maker’s Leather Supply involves several critical stages, each designed to ensure that the final product meets the high standards expected by B2B buyers. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to makers leather supply

How is Material Prepared for Leather Products?

Material preparation is the first step in the manufacturing process. High-quality leather, often sourced from reputable tanneries, is selected based on specific project requirements. This stage involves cutting the leather into manageable pieces, ensuring that they meet the precise dimensions needed for the final product. Additionally, any necessary treatments—such as tanning or dyeing—are applied to enhance the leather’s durability and aesthetic appeal. For international buyers, understanding the origin of the leather and the treatment processes can provide insights into sustainability and compliance with environmental standards.

What Techniques Are Used in the Forming Stage?

The forming stage is where the prepared leather is shaped into the desired product forms. Techniques such as die cutting, laser cutting, and hand tooling are commonly employed. Die cutting is particularly efficient for large production runs, ensuring uniformity across products. In contrast, laser cutting allows for intricate designs and customization, catering to specific buyer needs. Hand tooling, often used for unique or artisanal items, adds a personal touch that can enhance product value. Buyers should inquire about the techniques used to ensure they align with their quality and design expectations.

How Are Leather Products Assembled?

Assembly is where the various components of the leather products come together. This stage typically involves stitching, gluing, and riveting. Skilled artisans or automated machinery may perform stitching, depending on the complexity and volume of the order. The choice of adhesives is also critical; high-quality contact cement is often used for durability. For B2B buyers, understanding the assembly methods is vital, as it directly impacts the strength and longevity of the final products.

What Finishing Processes Are Essential for Quality Leather Goods?

The finishing stage enhances the leather’s appearance and protects it from wear and tear. Techniques such as edge finishing, dyeing, and applying protective coatings are standard. Edge finishing not only improves aesthetics but also prevents fraying, a common issue in leather goods. Protective coatings can include waxes or sealants that provide moisture resistance, essential for products intended for diverse climates. Buyers should assess the finishing techniques used to ensure they meet their specific market demands, especially in regions with varying environmental conditions.

How is Quality Assurance Implemented in Leather Manufacturing?

Quality assurance (QA) is integral to ensuring that the products meet both international and industry-specific standards. Implementing a robust QA system helps manufacturers maintain consistency and reliability in their offerings.

What International Standards Should B2B Buyers Be Aware Of?

For international buyers, understanding relevant standards is crucial. ISO 9001 is a widely recognized standard that sets criteria for quality management systems. Compliance with ISO 9001 indicates that the manufacturer has a systematic approach to managing quality. Additionally, industry-specific certifications, such as CE marking for products sold in Europe, or API standards for certain technical applications, may also apply. Buyers should ensure their suppliers possess relevant certifications to guarantee compliance with international quality norms.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. Incoming Quality Control (IQC) assesses materials upon arrival, ensuring they meet specified quality standards. In-Process Quality Control (IPQC) monitors production at various stages, allowing for immediate corrective actions if deviations occur. Finally, Final Quality Control (FQC) involves a comprehensive inspection of the completed products before shipment. This multi-tiered approach ensures that any issues are identified and rectified early, minimizing the risk of defective products reaching the buyer.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for B2B buyers, especially when sourcing from international markets.

What Methods Can Buyers Use to Assess Supplier QC?

Buyers can utilize several methods to verify supplier quality control. Conducting audits is one of the most effective ways to assess a supplier’s practices. These audits can be scheduled or surprise visits, allowing buyers to observe the manufacturing processes firsthand. Additionally, requesting quality assurance reports from the supplier can provide insights into their QC practices, including the frequency of inspections and any corrective actions taken in the past.

Engaging third-party inspection services is another viable option. Independent inspectors can conduct thorough evaluations of the manufacturing facilities and processes, providing an unbiased report on quality compliance. This can be particularly valuable for buyers in regions like Africa and South America, where local regulations and standards may differ from international norms.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional differences in quality control practices is essential. Variability in local regulations, cultural standards, and market expectations can impact product quality.

How Can Buyers Navigate These Differences?

Buyers should familiarize themselves with the specific quality standards applicable in their target markets. Collaborating with local experts or industry associations can provide valuable insights into regional preferences and compliance requirements. Additionally, establishing clear communication with suppliers regarding quality expectations and standards can help mitigate misunderstandings and ensure product consistency.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for Maker’s Leather Supply is critical for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control practices, buyers can ensure they select reliable suppliers that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘makers leather supply’

In this guide, we will provide a comprehensive checklist designed for B2B buyers seeking to procure supplies from Maker’s Leather Supply. This step-by-step approach will help you streamline your sourcing process and ensure that you make informed decisions when selecting leather materials, tools, and accessories for your projects.

Step 1: Identify Your Project Requirements

Before diving into sourcing, clearly outline your project specifications. Determine the types of leather, tools, and additional supplies needed based on the products you intend to create. Understanding your requirements will help you focus your search and communicate effectively with suppliers.

- Consider project scope: Are you producing small items like wallets or larger pieces like bags?

- Specify material types: Different projects may require specific leather finishes or weights.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in the Maker’s Leather Supply sector. Use online platforms, industry directories, and trade shows to gather a list of reputable suppliers.

- Focus on reviews and ratings: Look for customer feedback and testimonials to gauge reliability.

- Check supplier portfolios: Examine previous work to ensure their capabilities align with your needs.

Step 3: Evaluate Supplier Credentials

Once you have a shortlist, assess the credentials of each supplier. This includes verifying their certifications and compliance with international quality standards.

- Request documentation: Ask for ISO certifications, quality control processes, and sustainability practices.

- Understand their supply chain: Ensure that the supplier sources materials ethically and sustainably.

Step 4: Request Samples

Before making a bulk purchase, request samples of leather and other materials. This step allows you to evaluate the quality and suitability of the products for your specific applications.

- Assess texture and durability: Check how the materials feel and perform under various conditions.

- Test compatibility: Make sure that the supplies work well with your tools and techniques.

Step 5: Compare Pricing and Terms

Analyze the pricing structures of your shortlisted suppliers. Look beyond just the unit price and consider factors like shipping costs, payment terms, and bulk order discounts.

Illustrative image related to makers leather supply

- Request detailed quotes: Ensure that all potential costs are included to avoid surprises later.

- Negotiate terms: Don’t hesitate to discuss terms that could benefit both parties, especially for long-term partnerships.

Step 6: Establish Communication Channels

Effective communication is essential for a successful sourcing relationship. Make sure you establish clear lines of communication with your chosen supplier.

- Set expectations: Discuss timelines, order processes, and points of contact.

- Use technology: Utilize platforms for real-time updates and tracking orders to enhance transparency.

Step 7: Finalize Your Order and Monitor Delivery

After selecting a supplier and negotiating terms, finalize your order. Keep track of the delivery process to ensure timely receipt of your supplies.

- Confirm delivery timelines: Make sure you have a clear understanding of when to expect your order.

- Inspect upon arrival: Check the materials against your order specifications to ensure accuracy and quality.

By following this practical sourcing checklist, B2B buyers can effectively navigate the complexities of procuring from Maker’s Leather Supply, ensuring a smooth and successful purchasing experience.

Comprehensive Cost and Pricing Analysis for makers leather supply Sourcing

When sourcing makers leather supply, a comprehensive understanding of the cost structure and pricing dynamics is crucial for B2B buyers. This section outlines the various cost components, price influencers, and actionable tips for international buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Makers Leather Supply?

Materials: The primary cost driver in leather supply is the quality of materials. High-quality leather varieties, such as Hermann Oak, can significantly impact the price. Buyers should consider the type of leather, its sourcing location, and its treatment processes when assessing material costs.

Illustrative image related to makers leather supply

Labor: Labor costs vary widely depending on the region of production. Skilled labor in Europe may command higher wages than in Africa or South America. Understanding local wage standards and labor practices is essential for accurate cost predictions.

Manufacturing Overhead: Overhead costs include expenses related to facilities, utilities, and administrative functions. These can vary by region and affect the overall pricing structure. Buyers should inquire about the supplier’s operational efficiencies and cost management strategies.

Tooling and Equipment: Custom tooling can add significant costs, especially for unique designs or patterns. Investing in templates and patterns may streamline production and reduce long-term costs, making it a vital consideration for buyers.

Quality Control (QC): Ensuring product quality incurs costs associated with inspections and testing. High-quality leather supply often involves rigorous QC processes, which may influence the final price. Buyers should assess the supplier’s QC protocols to ensure product consistency.

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as shipping distance, mode of transport, and customs duties can affect logistics costs. Buyers should explore Incoterms to clarify responsibilities and costs associated with transportation.

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. Understanding the typical margins in the leather supply industry can help buyers gauge the fairness of pricing.

What Influences Pricing in Makers Leather Supply?

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower unit prices. Buyers should negotiate MOQs to achieve cost efficiencies while ensuring they don’t overcommit to excess inventory.

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should clearly communicate their specifications to avoid unexpected charges and ensure that the supplier can meet their needs.

Material Quality and Certifications: Premium materials often come with certifications that assure buyers of their quality and sustainability. Such certifications may come at a premium, but they can enhance the product’s marketability.

Illustrative image related to makers leather supply

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of delivering quality products may command higher prices due to perceived reliability.

Incoterms: Understanding Incoterms is crucial for managing costs associated with shipping and logistics. Different terms dictate the responsibilities of buyers and sellers, affecting overall pricing.

How Can B2B Buyers Negotiate Effectively for Makers Leather Supply?

Negotiation Strategies: Effective negotiation requires clear communication about expectations and requirements. Buyers should be prepared to discuss volume commitments and inquire about pricing flexibility based on order size.

Illustrative image related to makers leather supply

Understanding Total Cost of Ownership (TCO): Beyond the initial purchase price, buyers should consider TCO, which includes shipping, handling, and potential returns. Evaluating TCO helps identify the most cost-effective suppliers.

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, tariffs, and import duties that can impact final costs. Establishing agreements in stable currencies and understanding local tax implications can mitigate risks.

Disclaimer for Indicative Prices: Prices in makers leather supply can vary significantly based on numerous factors outlined above. The prices mentioned are indicative and subject to change based on market conditions and supplier negotiations. Always request updated quotes before making purchasing decisions.

By understanding these components and influencers, B2B buyers can navigate the complexities of sourcing makers leather supply more effectively, ensuring that they achieve both quality and cost-efficiency in their procurement strategies.

Illustrative image related to makers leather supply

Alternatives Analysis: Comparing makers leather supply With Other Solutions

Exploring Alternative Solutions to Maker’s Leather Supply

In the realm of leather crafting and supply, it’s essential for B2B buyers to evaluate various options to determine the most suitable solution for their business needs. Maker’s Leather Supply offers a range of tools, templates, and materials specifically designed for leather crafting. However, other alternatives exist that may better serve specific requirements depending on factors such as performance, cost, and ease of implementation. Below is a comparative analysis of Maker’s Leather Supply alongside two viable alternatives: Tandy Leather and Leathercraft Tools.

| Comparison Aspect | Maker’s Leather Supply | Tandy Leather | Leathercraft Tools |

|---|---|---|---|

| Performance | High-quality, specialized templates and tools | Comprehensive range with proven reliability | Diverse tools, but less specialized |

| Cost | Moderate pricing, competitive with quality | Generally lower prices, but variable quality | Affordable tools, but quality varies widely |

| Ease of Implementation | User-friendly templates, tutorials available | Established resources and community support | Moderate learning curve for advanced tools |

| Maintenance | Low; tools are durable and reliable | Requires occasional maintenance; quality can vary | Varies; some tools may need regular upkeep |

| Best Use Case | Ideal for professional and hobbyist crafters | Suited for beginners and cost-conscious buyers | Good for budget projects and casual users |

What Are the Advantages and Disadvantages of Tandy Leather?

Tandy Leather is a longstanding supplier in the leather crafting industry, known for its extensive product range. One of its primary advantages is the affordability of its products, making it an attractive option for startups and smaller businesses. Tandy also provides a wealth of resources, including tutorials and community support, which can be invaluable for beginners. However, the quality of Tandy’s materials can be inconsistent, which may lead to challenges in high-stakes projects where precision is crucial.

How Does Leathercraft Tools Compare?

Leathercraft Tools offers a broad assortment of leather crafting supplies at competitive prices. Its affordability makes it an excellent choice for businesses operating on tight budgets. While the selection is diverse, the quality can vary significantly among different products. This inconsistency may pose risks for businesses that require high-quality materials for professional-grade outputs. Additionally, some of the more advanced tools may require a learning curve, which could slow down production for less experienced users.

How to Choose the Right Leather Supply Solution?

When selecting a leather supply solution, B2B buyers should assess their specific needs and priorities. Maker’s Leather Supply is highly recommended for professionals seeking specialized tools and high-quality results. In contrast, Tandy Leather may be ideal for those looking for budget-friendly options with extensive community support. Leathercraft Tools can serve businesses that prioritize affordability but may necessitate thorough research to ensure quality. By carefully considering these factors, buyers can make informed decisions that align with their operational goals and enhance their crafting capabilities.

Essential Technical Properties and Trade Terminology for makers leather supply

What Are the Key Technical Properties of Makers Leather Supply?

Understanding the technical properties of leather is crucial for B2B buyers in the makers leather supply industry. Here are some essential specifications that can impact your purchasing decisions:

-

Material Grade

Leather is categorized into various grades based on its quality and finish. Full-grain leather, for instance, is the highest quality, retaining the natural grain and imperfections, making it durable and aesthetically appealing. In contrast, corrected-grain leather has been sanded and treated to remove flaws. Knowing the material grade helps buyers assess the longevity and suitability of leather for their projects. -

Thickness (Oz or mm)

Leather thickness is measured in ounces (oz) or millimeters (mm). For example, 3 oz leather is approximately 1.2 mm thick. Thicker leather is generally used for heavy-duty applications like bags and belts, while thinner leather is ideal for smaller items like wallets. Understanding thickness allows buyers to select the right leather for specific applications, ensuring the final product meets quality expectations. -

Tolerance

Tolerance refers to the acceptable variation in dimensions of the leather pieces. Inconsistent tolerances can lead to issues in assembly and product quality. Specifying tolerances in your orders is essential for maintaining uniformity, particularly when producing large quantities of items where precision is critical. -

Finish Type

Leather finishes can vary from natural to coated. Natural finishes retain the leather’s inherent characteristics, while coated finishes provide additional protection against moisture and wear. Buyers should understand the finish type to ensure compatibility with their intended use, whether it’s for fashion, upholstery, or other applications. -

Colorfastness

This property measures the leather’s ability to retain its color when exposed to light, water, and friction. High colorfastness is vital for products that will undergo frequent handling or exposure to various environmental conditions. Buyers should prioritize colorfastness to ensure the longevity and visual appeal of their leather goods. -

通気性

Breathability refers to the leather’s ability to allow air circulation, which is particularly important for items like footwear and garments. Leather with good breathability helps prevent moisture buildup, enhancing comfort and durability. Understanding this property is essential for ensuring the end-user experience meets expectations.

What Are Common Trade Terms in the Makers Leather Supply Industry?

Familiarity with industry jargon is vital for effective communication and negotiation in the makers leather supply sector. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or products that are used in another company’s final product. For instance, a leather supplier may provide materials that a handbag manufacturer incorporates into its designs. Understanding OEM relationships can help buyers identify potential suppliers and partners in the production chain. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is a crucial consideration for buyers looking to manage inventory costs effectively. Knowing the MOQ can help businesses plan their orders and reduce excess inventory. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer solicits price quotes from suppliers for specific goods or services. Issuing an RFQ allows buyers to compare prices and terms from multiple suppliers, helping them make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers navigate the complexities of international shipping, ensuring compliance and minimizing risks. -

Lead Time

Lead time refers to the time it takes for a supplier to fulfill an order from the moment it is placed until it is delivered. Understanding lead times is essential for effective supply chain management, as it allows buyers to plan their production schedules accordingly. -

Tannage

Tannage is the process of treating animal hides to produce leather. Various tanning methods, such as vegetable or chrome tanning, can affect the leather’s properties, including durability and environmental impact. Buyers should be aware of the tanning processes to ensure they align with their sustainability goals and product requirements.

By grasping these technical properties and trade terms, B2B buyers in the makers leather supply industry can make more informed decisions, ultimately leading to better product quality and business success.

Navigating Market Dynamics and Sourcing Trends in the makers leather supply Sector

What Are the Current Market Dynamics and Key Trends in the Makers Leather Supply Sector?

The makers leather supply sector is witnessing a transformative phase influenced by several global drivers. Increased consumer interest in artisanal and bespoke products has propelled demand for high-quality leather goods. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly sourcing materials that emphasize craftsmanship and quality. The rise of e-commerce platforms has also made it easier for international buyers to access diverse suppliers, leading to more competitive pricing and a broader selection of products.

Emerging technologies are reshaping sourcing practices. For instance, the integration of digital tools for inventory management and supply chain optimization is becoming commonplace. Companies are leveraging data analytics to forecast trends and manage stock levels more efficiently. Furthermore, the adoption of virtual design tools and CAD software allows makers to prototype products quickly, reducing time-to-market.

Sustainability is another critical trend shaping the market dynamics. Buyers are now prioritizing suppliers who demonstrate environmental responsibility, leading to increased demand for eco-friendly leather alternatives and sustainable production methods. As more businesses recognize the importance of agility in their supply chains, collaborations between manufacturers and local artisans are becoming more prevalent, fostering innovation and cultural exchange.

How Can Sustainability and Ethical Sourcing Impact Your B2B Leather Supply Decisions?

The environmental impact of leather production is a significant concern for both consumers and businesses. Traditional tanning methods can lead to pollution and waste, prompting a shift towards more sustainable practices. Ethical sourcing is not just a trend; it has become a necessity in the B2B landscape. Buyers are increasingly scrutinizing their supply chains to ensure that their materials come from responsible sources that prioritize human rights and environmental stewardship.

Illustrative image related to makers leather supply

Sustainable leather options, such as vegetable-tanned leather and innovative materials like mushroom leather, are gaining traction. B2B buyers should look for suppliers that offer certifications such as the Leather Working Group (LWG) certification, which ensures environmentally responsible production practices. Additionally, sourcing materials from companies that adhere to fair trade principles can enhance brand reputation and appeal to eco-conscious consumers.

By prioritizing sustainability and ethical sourcing, businesses can not only mitigate risks associated with environmental regulations but also tap into a growing market segment that values transparency and responsibility. This proactive approach can lead to long-term partnerships with suppliers and a more resilient supply chain.

What Is the Evolution of the Makers Leather Supply Sector?

The makers leather supply sector has evolved significantly over the decades, transitioning from traditional craftsmanship to a more diversified and technology-driven landscape. Initially, leather production was dominated by small-scale artisans who utilized local materials and methods. However, the industrial revolution brought about mass production techniques that made leather goods more accessible but often compromised quality.

In recent years, there has been a resurgence of interest in artisanal leatherwork, fueled by consumer demand for unique, handcrafted items. This shift has prompted suppliers to adapt by offering a wider range of tools, templates, and materials that cater to both amateur and professional makers. The rise of online marketplaces has further enabled artisans to reach global audiences, fostering a collaborative environment where traditional techniques meet modern innovation.

As the sector continues to grow, it remains essential for B2B buyers to stay informed about market trends and sourcing practices, ensuring they can navigate the complexities of the global leather supply chain effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of makers leather supply

-

How do I select the right leather supply for my business needs?

Choosing the right leather supply depends on your specific requirements, including the type of products you manufacture, desired leather characteristics (such as texture and durability), and budget constraints. Start by assessing your target market’s preferences and the applications for which you need leather. Consider samples from various suppliers to evaluate quality and pricing. Additionally, engage with suppliers to understand their sourcing practices and whether they can meet your customization needs. -

What types of leather are best suited for various applications?

Different types of leather serve different purposes. For example, full-grain leather is ideal for high-quality bags and shoes due to its durability, while suede is often used for softer, fashion-oriented products. If you are creating items that require flexibility, such as wallets or belts, consider using top-grain leather. Research the specific needs of your end products and consult with suppliers to find the most suitable leather types. -

How can I ensure the quality of leather supplies from international suppliers?

To ensure quality, vet suppliers by requesting samples and checking their certifications. Look for suppliers with a strong reputation and positive reviews from other B2B buyers. Establish quality assurance protocols, including regular inspections and testing for colorfastness, grain consistency, and physical properties. Additionally, consider visiting the supplier’s facility if feasible to gain firsthand insight into their production processes. -

What are common payment terms for international leather supply transactions?

Payment terms can vary significantly based on the supplier’s policies and your negotiation. Common practices include upfront payments, letters of credit, or payment upon delivery. For first-time orders, suppliers may require a partial upfront payment to mitigate risk. Always clarify payment methods, currency preferences, and any associated fees before finalizing agreements to avoid misunderstandings. -

What is the minimum order quantity (MOQ) for leather supplies?

MOQs can differ widely among suppliers and are influenced by factors such as product type and customization options. Typically, MOQs for leather can range from a few hides to several hundred square feet. It’s crucial to discuss MOQs upfront to align with your production capacity and ensure you can meet your business needs without incurring excess inventory costs. -

How do I handle logistics for importing leather supplies?

Logistics for importing leather supplies require careful planning. Partner with a reliable freight forwarder who understands the complexities of international shipping, including customs clearance and duty regulations. Ensure you have all necessary documentation, such as invoices and certificates of origin. Consider shipping terms (Incoterms) that clarify who bears the costs and risks during transit to avoid unexpected expenses. -

Can I customize leather products according to my specifications?

Many suppliers offer customization options for leather products, including color, texture, and size. It’s advisable to discuss your specific requirements with potential suppliers early in the negotiation process. Some suppliers may have limitations on customization based on their manufacturing capabilities or MOQ, so it’s essential to confirm these details before placing an order. -

What are the best practices for sustainable sourcing of leather supplies?

Sustainable sourcing is increasingly important in the leather industry. To ensure ethical practices, look for suppliers that prioritize eco-friendly tanning processes and source leather from responsibly managed farms. Certifications such as the Leather Working Group (LWG) can indicate sustainable practices. Additionally, consider engaging in dialogue with suppliers about their sustainability initiatives and how they minimize environmental impact throughout their supply chain.

Top 3 Makers Leather Supply Manufacturers & Suppliers List

1. Makers Leather Supply – Essential Tools & Supplies

Domain: makersleathersupply.com

Registered: 2012 (13 years)

Introduction: Must Have Supplies: 1. Hermann Oak – Branded Natural Tooling & Carving Side – $225.00 (11 reviews) 2. Maker’s Breezy Clutch Purse/Wallet Acrylic Template Set – $34.95 (4 reviews) 3. Maker’s Contact Cement – $32.95 (25 reviews) 4. Maker’s Indelible Leather Marker – Precision Dye & Edge Finishing Pen – $6.95 (13 reviews) 5. MLS Double Sided Tape, 1/4″ (Small) – $14.95 (16 reviews)

2. Leather Craft Supply Store – Lessons & Materials

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Leather Craft Supply Store – Lessons & Materials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. DGS Saddlery – Maker’s Tooling Patterns

Domain: shop.dgsaddlery.com

Registered: 2004 (21 years)

Introduction: [{‘name’: “Maker’s Billfold and Billfold 2.0 Tooling Patterns DIGITAL”, ‘price’: ‘$15.00’}, {‘name’: “Maker’s Tally Book Pattern – DIGITAL”, ‘price’: ‘$15.00’}, {‘name’: “Maker’s Breezy Clutch Pattern DIGITAL”, ‘price’: ‘$20.00’}]

Strategic Sourcing Conclusion and Outlook for makers leather supply

In the evolving landscape of makers leather supply, strategic sourcing emerges as a pivotal approach for international B2B buyers. By prioritizing quality materials, innovative tools, and efficient supply chains, businesses can significantly enhance their production capabilities. Notably, the availability of specialized templates, kits, and hardware from reputable suppliers like Maker’s Leather Supply not only streamlines the crafting process but also reduces waste and increases profitability.

The importance of building strong partnerships with suppliers cannot be overstated, particularly in regions such as Africa, South America, the Middle East, and Europe. Establishing reliable connections fosters trust and ensures a steady flow of high-quality materials essential for creating superior leather goods. Furthermore, leveraging digital resources and tutorials can empower buyers to make informed decisions and enhance their craftsmanship.

As we look to the future, the demand for sustainable and ethically sourced leather products is set to rise. International buyers should stay ahead of this trend by integrating sustainability into their sourcing strategies. Now is the time to take action: connect with suppliers who align with your values and elevate your leather-making projects to new heights.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to makers leather supply

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.