Introduction: Navigating the Global Market for how to make a leather sheath

In the competitive landscape of B2B sourcing, understanding how to make a leather sheath is essential for businesses aiming to provide high-quality products that stand out. With varying requirements across regions—from Africa to South America, the Middle East, and Europe—companies face the challenge of sourcing materials, identifying reliable suppliers, and ensuring the craftsmanship meets international standards. This comprehensive guide addresses these challenges by offering insights into the types of leather sheaths available, their applications across industries, and effective strategies for vetting suppliers.

By delving into the intricacies of leather crafting, this guide empowers international buyers to make informed purchasing decisions. It covers key factors such as cost analysis, material sourcing, and production techniques, enabling businesses to optimize their supply chains while ensuring quality and sustainability. Whether you are a retailer seeking to enhance your product line or a manufacturer looking to streamline operations, understanding the nuances of leather sheath production will give you a competitive edge.

As you navigate the global market, this guide serves as a vital resource, equipping you with the knowledge and tools necessary to meet your specific needs, ultimately driving growth and profitability in your business ventures.

Table Of Contents

- Top 4 How To Make A Leather Sheath Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather sheath

- Understanding how to make a leather sheath Types and Variations

- Key Industrial Applications of how to make a leather sheath

- 3 Common User Pain Points for ‘how to make a leather sheath’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather sheath

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather sheath

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather sheath’

- Comprehensive Cost and Pricing Analysis for how to make a leather sheath Sourcing

- Alternatives Analysis: Comparing how to make a leather sheath With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather sheath

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather sheath Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather sheath

- Strategic Sourcing Conclusion and Outlook for how to make a leather sheath

- Important Disclaimer & Terms of Use

Understanding how to make a leather sheath Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Knife Sheath | Typically hand-stitched, often made from vegetable-tanned leather. | Custom knife makers, artisanal shops. | Pros: Unique, durable, aesthetic appeal. Cons: Higher labor costs, longer production time. |

| Folding Knife Sheath | Designed for compact folding knives, often includes a belt clip. | Retailers of outdoor gear, camping supplies. | Pros: Convenient, space-saving design. Cons: Limited to specific knife shapes. |

| Tactical Sheath | Made from heavy-duty leather or synthetic materials, often with MOLLE compatibility. | Military, law enforcement, tactical gear suppliers. | Pros: Highly durable, functional for rugged use. Cons: May lack aesthetic appeal. |

| Decorative Sheath | Embellished with tooling, dyes, or inlays, often custom-made. | Artisans, gift shops, premium retailers. | Pros: High value, attractive to collectors. Cons: Higher production costs, niche market. |

| Minimalist Sheath | Simple design, often using a single piece of leather with minimal stitching. | Mass production, budget-friendly retailers. | Pros: Cost-effective, quick to produce. Cons: Limited protection, less durable. |

What are the Characteristics of a Traditional Knife Sheath?

Traditional knife sheaths are typically handcrafted from vegetable-tanned leather, offering a rustic and artisanal appeal. They are often hand-stitched for durability and can be customized to fit specific knife shapes. This type is particularly suitable for custom knife makers and artisanal shops looking to provide unique, high-quality products. B2B buyers should consider the labor costs and longer production times associated with this style, as well as the potential for high margins due to its craftsmanship.

How Does a Folding Knife Sheath Differ?

Folding knife sheaths are designed for compact folding knives and often include features like belt clips for easy carrying. This design is prevalent among retailers of outdoor gear and camping supplies, catering to consumers who prioritize portability. When purchasing, B2B buyers should consider the specific knife shapes that the sheath accommodates and the volume of demand for such products in their market, balancing convenience with functionality.

What Makes a Tactical Sheath Essential?

Tactical sheaths are built from heavy-duty leather or synthetic materials and are often designed to be compatible with MOLLE systems, making them ideal for military and law enforcement applications. B2B suppliers in the tactical gear industry should focus on the durability and functionality of these sheaths, as they are frequently used in rugged environments. Buyers should weigh the durability against aesthetic considerations, as tactical sheaths may not appeal to all consumer segments.

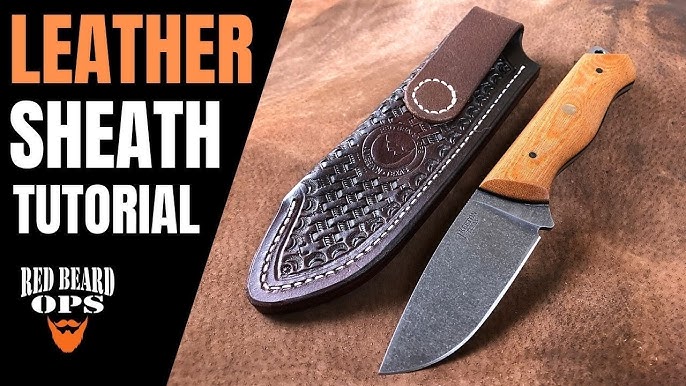

Illustrative image related to how to make a leather sheath

Why Choose a Decorative Sheath?

Decorative sheaths are characterized by their embellishments, such as tooling, dyes, or inlays, and are often custom-made for a more personalized touch. These sheaths are popular among artisans and gift shops, targeting consumers looking for unique and aesthetically pleasing items. B2B buyers should consider the higher production costs associated with decorative sheaths, as well as their appeal to niche markets, which can command premium pricing.

What are the Benefits of a Minimalist Sheath?

Minimalist sheaths focus on simplicity, often utilizing a single piece of leather with minimal stitching. This design is cost-effective and allows for quick production, making it suitable for mass production and budget-friendly retailers. B2B buyers should evaluate the trade-offs between cost and durability, as minimalist sheaths may offer less protection compared to more complex designs, potentially affecting customer satisfaction in certain markets.

Key Industrial Applications of how to make a leather sheath

| Industry/Sector | Specific Application of how to make a leather sheath | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Equipment | Custom knife sheaths for camping and hunting tools | Enhances product offering with bespoke accessories | Sourcing durable leather, ensuring weather resistance, and customization options. |

| Craftsmanship and Art | Artisan leather sheaths for handmade knives | Adds value through unique, handcrafted products | Access to high-quality leather, tools for precision crafting, and skilled artisans. |

| Military and Defense | Tactical sheaths for knives and multi-tools | Provides functional and durable gear for professionals | Compliance with military specifications, sourcing robust materials, and custom designs. |

| Fashion and Retail | Fashionable leather sheaths for knives as accessories | Expands product line with stylish offerings | Trends in leather fashion, sourcing aesthetic materials, and branding opportunities. |

| Culinary Equipment | Sheaths for culinary knives used by chefs | Protects investment in high-quality knives | Sourcing food-safe materials, ensuring proper hygiene standards, and customization for branding. |

How is ‘how to make a leather sheath’ utilized in the Outdoor Equipment sector?

In the outdoor equipment industry, leather sheaths are commonly crafted for knives used in camping and hunting. These sheaths not only protect the blade but also enhance the overall aesthetic of the tool. Businesses can benefit by offering customizable sheaths that meet specific customer preferences, such as size, color, and design. International buyers, particularly from regions with rich outdoor traditions, should consider sourcing high-quality, weather-resistant leather to ensure durability in various climates.

What role does artisan craftsmanship play in the creation of leather sheaths?

Artisan leather sheaths for handmade knives represent a significant application in the craftsmanship and art sector. These sheaths provide an opportunity for artisans to showcase their skills and creativity, resulting in unique products that appeal to niche markets. B2B buyers should focus on sourcing premium leather and precision tools to maintain high quality. Additionally, establishing connections with skilled artisans can lead to exclusive collaborations, enhancing brand value and market differentiation.

How do tactical sheaths serve the Military and Defense industry?

In the military and defense sector, tactical sheaths for knives and multi-tools are essential for operational efficiency. These sheaths must be durable and designed to withstand harsh conditions, ensuring that personnel have reliable access to their tools. Businesses must ensure compliance with military specifications when sourcing materials. Furthermore, customization options can provide units with personalized gear, fostering a sense of identity and pride among service members.

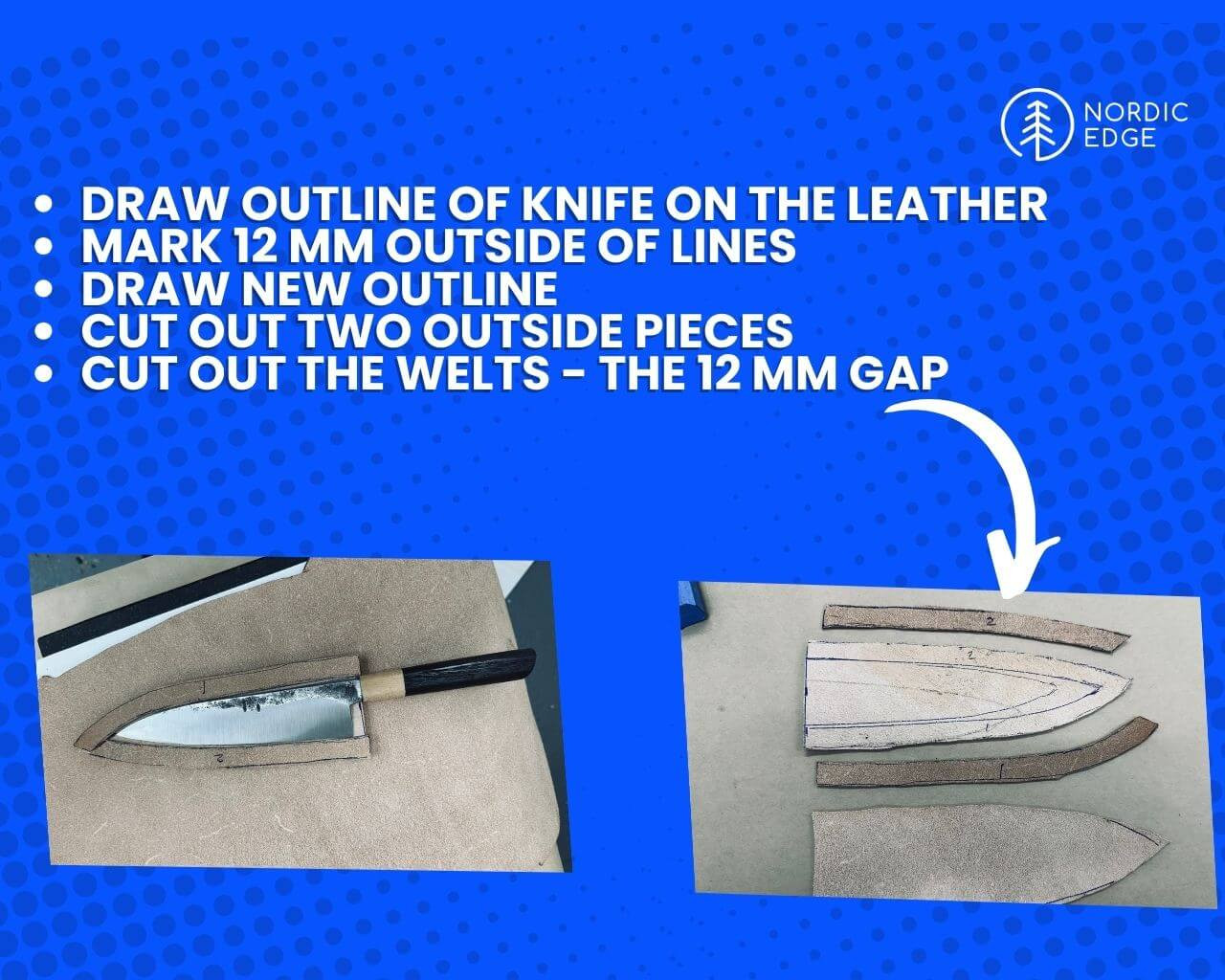

Illustrative image related to how to make a leather sheath

Why are fashionable leather sheaths important in the Fashion and Retail sector?

Fashionable leather sheaths for knives serve as unique accessories in the fashion and retail industry. These products can attract consumers looking for stylish yet functional items. By offering a range of designs, businesses can tap into current fashion trends, driving sales and brand loyalty. Sourcing aesthetically pleasing leather and staying updated with market trends are crucial for success in this competitive space, particularly for international buyers aiming to cater to diverse fashion tastes.

How do culinary knife sheaths contribute to the Culinary Equipment industry?

In the culinary equipment sector, sheaths for high-quality knives are vital for protecting chefs’ investments. These sheaths not only safeguard the blades but also contribute to the overall organization and presentation of culinary tools. B2B buyers should prioritize sourcing food-safe materials that meet hygiene standards, ensuring that their products are safe for professional kitchens. Customization options for branding can further enhance marketability, making these sheaths a valuable addition to culinary equipment offerings.

3 Common User Pain Points for ‘how to make a leather sheath’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Leather for Sheaths

The Problem: B2B buyers, especially those operating in regions with limited access to quality leather, often struggle to find reliable sources for materials. In Africa and South America, for example, local suppliers may not provide the variety or quality necessary for crafting durable leather sheaths. Additionally, buyers might face challenges with inconsistent quality, leading to potential delays in production and customer dissatisfaction.

The Solution: Establishing a network of trusted suppliers is essential. Buyers should consider attending industry trade shows and leather fairs to connect with manufacturers who specialize in high-quality leather. Utilizing platforms like Alibaba can also be beneficial for sourcing leather from international vendors. To ensure quality, buyers should request samples before placing large orders. Furthermore, collaborating with local artisans or tanneries can help in acquiring upcycled leather scraps, which not only supports local economies but also aligns with sustainable practices. Implementing a quality assurance protocol during the procurement process can help mitigate risks associated with subpar materials.

Scenario 2: Inefficient Leather Sheath Design Processes

The Problem: Many B2B buyers encounter challenges in designing leather sheaths that meet both functional and aesthetic requirements. This issue is particularly prevalent among new businesses that lack experience in leather crafting. A poorly designed sheath can result in product failures, such as blades slipping out or inadequate protection, which can damage the reputation of a brand.

Illustrative image related to how to make a leather sheath

The Solution: To enhance the design process, buyers should invest in comprehensive training for their design teams, focusing on both traditional and modern leatherworking techniques. Utilizing CAD software can facilitate precise designs and allow for adjustments before production. Additionally, creating prototypes using less expensive materials can help in visualizing and testing designs without committing to costly leather. Engaging customers in the design process through surveys or focus groups can also provide valuable feedback, ensuring that the final product meets market demands. Implementing an iterative design process that emphasizes testing and revision will lead to a more refined and successful leather sheath.

Scenario 3: Challenges with Leather Sheath Durability and Functionality

The Problem: Buyers frequently report issues with the durability and functionality of leather sheaths, particularly in harsh environments. For instance, sheaths used in outdoor or industrial applications may experience wear and tear much faster than anticipated, leading to increased replacement costs and customer complaints.

The Solution: To combat durability issues, buyers should focus on selecting the right type of leather and construction methods. Vegetable-tanned leather, known for its strength and longevity, is often a preferred choice for outdoor applications. Additionally, reinforcing key stress points with rivets or stitching can significantly enhance the lifespan of the sheath. Conducting thorough field testing before full-scale production can help identify potential weaknesses in the design. It is also advisable to incorporate care instructions for end-users, educating them on how to maintain their leather sheaths properly, which can extend the product’s life and improve customer satisfaction. Regularly reviewing and updating the design based on user feedback and performance data will ensure continuous improvement and reliability.

Strategic Material Selection Guide for how to make a leather sheath

When selecting materials for crafting leather sheaths, it is essential to consider various factors that impact performance, durability, and cost. Here, we analyze four common materials used in the production of leather sheaths, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to how to make a leather sheath

What Are the Key Properties of Vegetable-Tanned Leather for Sheath Production?

Vegetable-tanned leather is a popular choice for leather sheaths due to its natural tanning process, which utilizes plant-based tannins. This material offers excellent durability and a rich aesthetic appeal. It is resistant to wear and tear, making it suitable for long-term use. However, it may not perform well under extreme moisture conditions unless treated with additional waterproofing agents.

Pros: High durability, excellent aging characteristics, environmentally friendly.

Cons: Higher cost compared to synthetic options, potential for water absorption without treatment.

Impact on Application: Ideal for knives and tools that require a robust sheath but may need additional treatment for outdoor use.

Considerations for International Buyers: Compliance with environmental regulations is crucial, especially in regions with strict sustainability standards. Buyers should ensure that the leather meets local regulations like REACH in Europe.

How Does Synthetic Leather Compare in Terms of Performance and Cost?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to traditional leather. It is lightweight, easy to clean, and typically more resistant to water and stains. However, synthetic leather may not provide the same level of durability or aesthetic appeal as genuine leather.

Pros: Lower cost, water-resistant, easy maintenance.

Cons: Less durable than genuine leather, can degrade over time under UV exposure.

Impact on Application: Suitable for budget-friendly products or temporary use cases, but may not hold up under heavy-duty conditions.

Considerations for International Buyers: Ensure compliance with local regulations regarding synthetic materials, as some regions may have restrictions on PVC usage.

What Are the Advantages of Using Suede Leather for Sheath Applications?

Suede leather, known for its soft texture and flexibility, can be an excellent choice for sheaths that require a snug fit. It is typically made from the underside of the animal hide and offers good grip characteristics. However, suede is more susceptible to staining and may require additional care to maintain its appearance.

Pros: Soft texture, good grip, aesthetically pleasing.

Cons: Prone to staining, less durable than full-grain leather.

Impact on Application: Best suited for decorative sheaths or applications where comfort is prioritized over ruggedness.

Considerations for International Buyers: Suede may not meet the durability expectations in harsher climates, so buyers should assess local market needs.

Why Choose Full-Grain Leather for High-Performance Sheaths?

Full-grain leather is the highest quality leather available, known for its strength and natural grain. It ages beautifully and develops a unique patina over time, making it a favorite for premium products. While it is more expensive than other leather types, its durability and performance make it a worthwhile investment.

Pros: Exceptional durability, develops character over time, highly resistant to wear.

Cons: Higher cost, may require more care to maintain its appearance.

Impact on Application: Perfect for high-end knives and tools that demand a premium sheath.

Considerations for International Buyers: Buyers should look for certifications that ensure ethical sourcing and compliance with international leather standards.

Summary of Material Selection for Leather Sheath Production

| Material | Typical Use Case for how to make a leather sheath | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end knife sheaths | Environmentally friendly, durable | Higher cost, moisture absorption risk | High |

| Synthetic Leather | Budget-friendly sheaths | Water-resistant, easy to clean | Less durable, UV degradation | Low |

| Suede Leather | Decorative or comfort-focused sheaths | Soft texture, good grip | Prone to staining, less durable | Medium |

| Full-Grain Leather | Premium knife sheaths | Exceptional durability, develops character | Higher cost, requires maintenance | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions when sourcing materials for leather sheath production. Understanding the properties, advantages, and limitations of each material will help businesses align their product offerings with market demands and regulatory requirements.

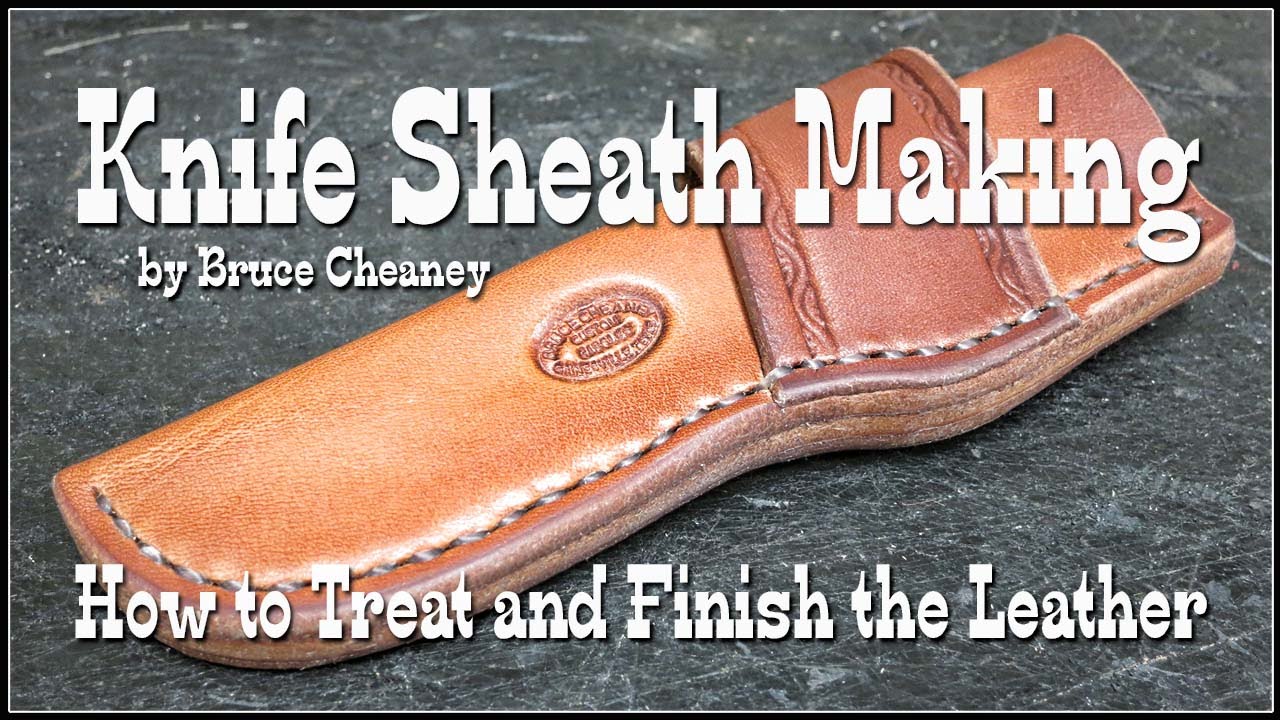

Illustrative image related to how to make a leather sheath

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather sheath

What Are the Main Stages in the Manufacturing Process of Leather Sheaths?

The manufacturing process of leather sheaths consists of several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets quality standards and customer expectations.

How Is Material Prepared for Leather Sheath Manufacturing?

Material preparation begins with the selection of high-quality leather, which can be sourced from various suppliers. This leather is often subjected to tanning processes to enhance its durability and aesthetics. For B2B buyers, understanding the source of leather is essential as it impacts the final product’s quality.

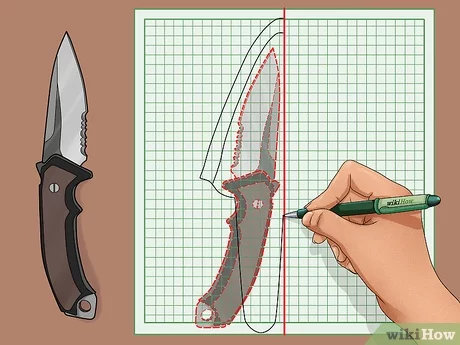

During this stage, leather is inspected for defects such as scratches, color inconsistencies, or thickness variations. Buyers should inquire about the supplier’s material sourcing practices and whether they comply with international standards. The preparation phase may also include cutting the leather into predetermined shapes using templates, which facilitates uniformity in the production process.

What Techniques Are Used in Forming Leather Sheaths?

Once the leather is prepared, the next step is forming. This involves shaping the leather pieces into the desired form of the sheath. Techniques such as molding, stitching, and burnishing edges are critical at this stage.

Illustrative image related to how to make a leather sheath

Molding can be performed using heat or moisture to create the necessary contours for a snug fit around the knife. Burnishing edges not only enhances the aesthetic appeal but also protects the leather from fraying. For B2B buyers, it’s important to know that the forming techniques can vary by manufacturer and may affect the longevity and usability of the sheath.

How Are Leather Sheaths Assembled?

Assembly is where the individual components come together. This process typically involves gluing, stitching, and attaching hardware such as snaps or rivets. The quality of the adhesive used is essential; using a specialized leather glue ensures a strong bond that withstands daily wear and tear.

Buyers should look for suppliers who use double-stitching techniques, as this adds strength to the seams. Furthermore, the assembly phase may include quality checks to ensure that all components fit correctly and that the sheath functions as intended.

Illustrative image related to how to make a leather sheath

What Finishing Techniques Are Commonly Applied to Leather Sheaths?

Finishing is the final stage of the manufacturing process and is crucial for aesthetic and functional purposes. This stage may include dyeing, polishing, and applying protective coatings. A quality finish not only enhances the appearance but also provides resistance to moisture and wear.

For international buyers, understanding the types of finishes used can help assess the durability and maintenance requirements of the sheath. Some manufacturers may offer customization options for finishes, which can be a significant selling point for B2B buyers looking to differentiate their product offerings.

What Quality Assurance Practices Should Be Followed in Leather Sheath Manufacturing?

Quality assurance (QA) is a vital aspect of the leather sheath manufacturing process. It ensures that the products meet both international and industry-specific standards.

Which International Standards Are Relevant for Leather Sheath Manufacturing?

ISO 9001 is the most recognized international standard for quality management systems. Manufacturers adhering to this standard demonstrate their commitment to consistent quality, which is crucial for B2B buyers. Additionally, certifications such as CE (Conformité Européenne) for products sold in the European market and API (American Petroleum Institute) standards for products used in specific industries can be important indicators of quality.

Illustrative image related to how to make a leather sheath

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, random checks are conducted to identify any deviations from quality standards.

- Final Quality Control (FQC): Once the product is completed, it undergoes a final inspection to verify its compliance with quality standards.

These checkpoints are critical for ensuring that defects are caught early, reducing waste and improving overall product quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should conduct thorough due diligence when selecting suppliers. This can include:

- Audits: Regular audits of manufacturing facilities can help ensure compliance with quality standards and identify areas for improvement.

- Quality Control Reports: Requesting detailed QC reports can provide insights into the manufacturing process and any issues that have been identified and resolved.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices.

Buyers from Africa, South America, the Middle East, and Europe should be particularly vigilant about QC nuances, as different regions may have varying regulations and standards.

What Common Testing Methods Are Used to Ensure Quality in Leather Sheath Manufacturing?

Common testing methods include:

- Physical Testing: This involves assessing the leather’s tensile strength, abrasion resistance, and flexibility. These tests help determine how well the leather will perform under stress.

- Chemical Testing: Testing for the presence of harmful substances ensures that the leather complies with environmental regulations, which is particularly important for international trade.

- Durability Testing: Simulating real-world conditions helps assess the longevity of the sheath, including exposure to moisture, heat, and physical wear.

By understanding these testing methods, B2B buyers can make informed decisions about their suppliers and the quality of the leather sheaths they intend to purchase.

Conclusion

In summary, the manufacturing processes and quality assurance practices for leather sheaths are complex and multifaceted. B2B buyers must pay close attention to the manufacturing stages, quality control checkpoints, and testing methods to ensure they are sourcing high-quality products that meet their specific needs. By leveraging this knowledge, international buyers can forge strong partnerships with suppliers that prioritize quality and reliability in their leather sheath offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather sheath’

Introduction

Creating a high-quality leather sheath requires a systematic approach to sourcing materials and tools. This guide outlines essential steps for B2B buyers to effectively procure the necessary components for crafting leather sheaths, ensuring quality, efficiency, and cost-effectiveness in production.

Illustrative image related to how to make a leather sheath

Step 1: Identify Required Materials

Begin by clearly defining the materials needed for making a leather sheath. This includes leather types (such as vegetable-tanned or chrome-tanned), thread, and fasteners.

– Leather: Choose based on durability and finish; consider sourcing from local tanneries for better pricing and quality assurance.

– Thread and Fasteners: Opt for high-strength nylon or polyester threads and reliable snap fasteners to ensure longevity and usability.

Step 2: Research and Select Suppliers

Conduct thorough research to identify potential suppliers who specialize in leather and leatherworking materials.

– Supplier Reputation: Look for suppliers with established reputations in the industry. Check reviews and testimonials from other businesses to gauge reliability.

– Local vs. International Suppliers: Depending on your location, evaluate the benefits of sourcing locally for easier logistics or internationally for broader options and potential cost savings.

Step 3: Evaluate Supplier Certifications

Before making commitments, verify that your chosen suppliers have the necessary certifications and compliance with industry standards.

– Quality Assurance: Certifications such as ISO 9001 ensure that suppliers adhere to quality management principles.

– Sustainability Practices: Consider suppliers who follow sustainable practices, which can enhance your brand’s reputation and appeal to environmentally-conscious consumers.

Step 4: Request Samples

Always request samples of materials before placing bulk orders. This allows you to evaluate the quality and suitability for your specific needs.

– Material Testing: Assess the leather’s texture, flexibility, and durability. For threads, check tensile strength and colorfastness.

– Prototype Creation: Use the samples to create a prototype sheath, helping to identify any potential issues before full-scale production.

Illustrative image related to how to make a leather sheath

Step 5: Negotiate Terms and Pricing

Once you have identified suitable suppliers, engage in negotiations regarding pricing, minimum order quantities, and delivery timelines.

– Bulk Discounts: Inquire about bulk pricing options which can significantly reduce costs for larger orders.

– Payment Terms: Discuss flexible payment options to align with your cash flow requirements.

Step 6: Establish a Quality Control Process

Implement a quality control process to ensure all incoming materials meet your specifications and standards.

– Inspection Criteria: Develop clear criteria for inspecting leather and other materials upon arrival.

– Feedback Loop: Maintain an open line of communication with suppliers to address any quality issues promptly.

Step 7: Plan for Logistics and Storage

Finally, consider logistics and storage solutions for your sourced materials.

– Shipping Options: Evaluate various shipping methods to find the most cost-effective and timely solutions.

– Storage Conditions: Ensure that you have appropriate storage facilities to protect leather and other materials from damage or degradation.

Illustrative image related to how to make a leather sheath

By following these steps, B2B buyers can efficiently procure the necessary materials and tools for making leather sheaths, ensuring a smooth production process and high-quality final products.

Comprehensive Cost and Pricing Analysis for how to make a leather sheath Sourcing

Understanding the cost structure and pricing for producing leather sheaths is essential for international B2B buyers. This analysis outlines the various cost components involved in the sourcing process, highlights the factors influencing prices, and provides actionable tips for buyers to optimize their procurement strategy.

What Are the Key Cost Components for Making Leather Sheaths?

-

Materials: The primary cost driver is the leather itself, which can vary significantly based on quality, type (e.g., vegetable-tanned, chrome-tanned), and source. Other materials include leather glue, fasteners, and any additional decorative elements. Buyers should consider sourcing leather from local suppliers to reduce costs, particularly in regions where leather production is prominent.

-

Labor: Labor costs can fluctuate based on the skill level of the artisans involved in crafting the sheaths. In regions with lower wage standards, such as parts of Africa or South America, labor costs may be significantly lower than in Europe or the Middle East. Understanding local labor markets can help buyers negotiate better pricing.

-

Manufacturing Overhead: This includes utilities, rent, and general operational expenses of the manufacturing facility. Overhead costs can be minimized by partnering with suppliers that have efficient production processes or utilizing shared manufacturing spaces.

-

Tooling: Initial investments in specialized tools, such as leather punches and sewing machines, can impact pricing. For smaller orders, suppliers may amortize these costs over a larger production run, which can benefit buyers with higher volume orders.

-

Quality Control (QC): Ensuring that products meet specific standards requires investment in quality assurance processes. Buyers should inquire about the QC measures implemented by suppliers, as this can affect both the final product’s quality and the overall cost.

-

Logistics: Transportation costs can vary widely based on distance, shipping methods, and Incoterms. Buyers should consider the total shipping costs in their budget, especially when importing from overseas suppliers.

-

Margin: Suppliers typically add a profit margin to cover their expenses and desired profit. Understanding industry standards for margins can help buyers assess if a supplier’s pricing is competitive.

How Do Price Influencers Affect Leather Sheath Sourcing?

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Buyers should evaluate their needs and consider bulk purchasing to negotiate better pricing.

-

Specifications and Customization: Custom designs or unique specifications can increase costs. Buyers should be clear about their requirements from the outset to avoid unexpected expenses.

-

Materials and Quality Certifications: Leather quality directly impacts pricing. Higher-quality leathers with certifications (e.g., eco-friendly or sustainable sourcing) may command higher prices. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can significantly influence pricing. Establishing long-term relationships with trusted suppliers can lead to better pricing and service.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is crucial. These terms dictate who is responsible for shipping costs, insurance, and risks, affecting overall pricing.

What Tips Can Buyers Use to Optimize Leather Sheath Sourcing?

-

Negotiate Effectively: Leverage volume discounts and long-term contracts to negotiate better terms. Building a relationship with suppliers can also lead to preferential pricing.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just upfront costs. Consider factors such as durability, maintenance, and potential returns when assessing price.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and local regulations that can affect pricing. Staying informed about market trends in leather can provide negotiation leverage.

-

Conduct Market Research: Understanding the pricing landscape in different regions can help buyers make informed decisions. Engaging with local industry groups or trade organizations can provide valuable insights.

In summary, a comprehensive understanding of the cost structure and pricing dynamics in leather sheath sourcing will empower international B2B buyers to make informed decisions, optimize their procurement strategies, and ultimately enhance their competitive edge in the market.

Illustrative image related to how to make a leather sheath

Alternatives Analysis: Comparing how to make a leather sheath With Other Solutions

Exploring Alternatives to Making a Leather Sheath

When considering the creation of a leather sheath, it is essential to evaluate alternative methods that may offer different advantages depending on your specific business needs. This analysis aims to compare the traditional leather crafting method with two viable alternatives: synthetic sheath production and 3D printing. Each method has unique characteristics that can influence a B2B buyer’s decision-making process.

Comparison Table

| Comparison Aspect | How To Make A Leather Sheath | Synthetic Sheath Production | 3D Printing |

|---|---|---|---|

| Performance | Durable and customizable; high-quality finish | Consistent quality; can be waterproof | Limited durability; suitable for low-stress applications |

| Cost | Moderate initial investment; variable based on materials | Generally lower cost for mass production | High initial setup cost; cost-effective for small batches |

| Ease of Implementation | Requires skill and tools; time-intensive | Simple once set up; relies on automated processes | Requires technical knowledge and access to 3D printers |

| Maintenance | Requires regular care to maintain leather quality | Low maintenance; durable against environmental factors | Minimal; however, may need replacements over time |

| Best Use Case | High-end, bespoke products; artisanal markets | Mass production for standard items; cost-sensitive markets | Prototyping; low-volume custom designs |

Detailed Breakdown of Alternatives

Synthetic Sheath Production

Synthetic materials, such as nylon or polyester, are often used in the production of sheaths. These materials are typically lighter, waterproof, and resistant to wear and tear, making them suitable for outdoor and rugged environments. The production process can be automated, allowing for rapid manufacturing and consistent quality. However, synthetic sheaths may lack the aesthetic appeal and tactile qualities that leather offers, which could be a disadvantage for businesses targeting premium markets.

3D Printing

3D printing technology has emerged as a novel method for creating sheath designs. This approach allows for high customization and rapid prototyping, making it ideal for businesses looking to test new designs without the commitment to large-scale production. However, the durability of 3D-printed materials can be a concern, particularly for applications requiring robust protection. Additionally, the initial investment in 3D printing technology and materials can be substantial, making it less accessible for businesses with limited budgets.

Illustrative image related to how to make a leather sheath

Conclusion: How to Choose the Right Solution for Your Business Needs

Selecting the right sheath-making solution depends on various factors, including the target market, production volume, and desired product characteristics. For businesses focusing on high-end or artisanal products, traditional leather crafting may provide the best combination of quality and customization. Conversely, companies looking for efficiency and lower costs might prefer synthetic sheath production, particularly for mass-market applications. Lastly, businesses aiming for innovation and customization may find 3D printing to be a compelling option, despite its initial costs. Ultimately, understanding the strengths and weaknesses of each method will enable B2B buyers to make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for how to make a leather sheath

What Are the Key Technical Properties for Making a Leather Sheath?

When producing leather sheaths, understanding specific technical properties is crucial for ensuring product quality and meeting customer expectations. Here are some essential specifications to consider:

-

Material Grade

The grade of leather used significantly affects the durability and aesthetic appeal of the sheath. Full-grain leather, known for its strength and natural grain patterns, is often preferred for high-quality sheaths. In contrast, corrected-grain leather may be used for more budget-friendly options. Selecting the right grade impacts customer satisfaction and repeat business. -

Thickness

Leather thickness is typically measured in ounces or millimeters. A common range for knife sheaths is 4-8 ounces (approximately 1.6-3.2 mm). Thicker leather offers better protection but may require more intricate crafting techniques. Understanding the ideal thickness for the intended use is essential to balance protection, weight, and ease of handling. -

Tolerance

Tolerance refers to the allowable variation in dimensions during production. For leather sheaths, maintaining tight tolerances is critical for ensuring that the knife fits securely and easily within the sheath. Poorly fitting sheaths can lead to customer dissatisfaction and increased returns, impacting profitability. -

Finish

The finish applied to the leather can affect both aesthetics and functionality. Common finishes include aniline, which highlights natural leather features, and polyurethane, which provides a more durable, water-resistant surface. Choosing the right finish is vital for targeting specific markets, such as outdoor enthusiasts or everyday users. -

Colorfastness

Colorfastness is the resistance of leather dye to fading or bleeding when exposed to moisture or light. This property is particularly important for sheaths that may be exposed to the elements. Ensuring high colorfastness can improve product longevity and customer satisfaction, especially in markets with varying climate conditions.

Which Trade Terms Should B2B Buyers Know When Sourcing Leather Sheaths?

Understanding industry jargon can significantly streamline communication between buyers and suppliers. Here are some common trade terms relevant to the leather sheath production:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce goods for other brands to sell under their own label. B2B buyers may work with OEMs to create custom-designed leather sheaths tailored to their brand specifications, allowing for unique product offerings without the need for extensive manufacturing capabilities. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory and avoid excess costs. Negotiating MOQs can lead to better pricing structures, especially for bulk orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price for specific goods or services. B2B buyers should prepare detailed RFQs that specify desired materials, dimensions, and quantities to receive accurate and competitive quotes from potential manufacturers. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for the delivery of goods under sales contracts. Familiarity with these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), can help buyers manage shipping costs and responsibilities effectively, ensuring a smoother procurement process. -

Lead Time

Lead time is the time taken from placing an order to receiving the product. Understanding lead times is essential for inventory planning and ensuring that products are available when needed, particularly for seasonal demands or promotional events.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, optimize their sourcing strategies, and ultimately enhance their product offerings in the competitive leather goods market.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather sheath Sector

What Are the Key Market Dynamics Driving the Leather Sheath Industry?

The leather sheath market is experiencing significant growth, driven by a surge in outdoor activities and the rising popularity of handmade crafts. B2B buyers in regions such as Africa, South America, the Middle East, and Europe are increasingly seeking high-quality leather products for various applications, including hunting, fishing, and culinary uses. The demand for customizable and artisanal leather sheaths is on the rise, reflecting a broader trend toward unique, personalized products that cater to individual preferences.

Emerging technologies, such as laser cutting and 3D modeling, are transforming traditional leather crafting methods, enabling manufacturers to create intricate designs efficiently. Additionally, advancements in e-commerce platforms are making it easier for international buyers to source leather sheaths directly from artisans and manufacturers worldwide. This digital shift is particularly significant for regions like Vietnam and Brazil, where local artisans can showcase their craftsmanship to a global audience.

Furthermore, the market dynamics are influenced by changing consumer preferences towards sustainable and ethically sourced materials. As buyers become more aware of the environmental impact of leather production, they are increasingly demanding transparency in the sourcing process. This shift presents opportunities for suppliers who can demonstrate their commitment to ethical practices and sustainable sourcing.

How Is Sustainability Shaping the Leather Sheath Supply Chain?

Sustainability has become a cornerstone of the leather sheath industry, influencing sourcing decisions for B2B buyers. The environmental impact of leather production, including land use, water consumption, and chemical usage, is prompting companies to seek out sustainable practices. Ethical sourcing is not just a trend; it is becoming a requirement for businesses aiming to build strong relationships with conscientious consumers.

Illustrative image related to how to make a leather sheath

The importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for suppliers who can provide certifications that guarantee the leather used is sourced responsibly, such as the Leather Working Group (LWG) certification. This certification ensures that tanneries follow best practices in environmental stewardship and social responsibility.

Moreover, the use of alternative materials and eco-friendly tanning processes is gaining traction. Innovations such as vegetable-tanned leather and synthetic options made from recycled materials are appealing to buyers who prioritize sustainability. By aligning with these trends, businesses can enhance their market appeal while contributing to environmental conservation.

What Is the Historical Context of Leather Sheath Production?

The art of leather crafting has a rich history, dating back thousands of years when early humans used animal hides for protection and utility. Leather sheaths were among the first functional items created, designed to safeguard tools and weapons. Over the centuries, leather production evolved with advancements in tanning techniques, allowing for more durable and versatile materials.

In the modern era, leather sheath production has seen a resurgence due to the growing interest in traditional crafting methods and artisanal goods. This revival is particularly relevant for B2B buyers who value craftsmanship and the unique qualities of handmade products. As the industry continues to evolve, understanding its historical context can provide valuable insights into current trends and consumer preferences, helping businesses to better cater to their clientele.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather sheath

-

How do I choose the right leather for making a sheath?

Choosing the right leather for a sheath depends on the intended use and desired aesthetics. Vegetable-tanned leather is popular for its durability and ability to mold, while chrome-tanned leather offers flexibility. Consider the thickness; around 8-10 oz. is ideal for a sturdy sheath. Additionally, source leather from reputable suppliers to ensure quality. Establish relationships with local tanneries or international suppliers who can provide consistent quality and supply, especially if you need bulk orders for production. -

What tools do I need to make a leather sheath?

Essential tools for making a leather sheath include a sharp utility knife or scalpel for cutting, leather punches for holes, a burnishing tool for smoothing edges, and leather glue or contact cement for assembly. A sewing kit with leather needles and strong thread is also necessary for stitching. If you’re producing at scale, consider investing in industrial tools to enhance efficiency. Always ensure your tools are of high quality to maintain consistent results. -

What is the minimum order quantity (MOQ) for leather sheaths from suppliers?

Minimum order quantities can vary significantly among suppliers, typically ranging from 50 to 500 units. When sourcing internationally, inquire about MOQs upfront to ensure they align with your production needs. Some suppliers may offer lower MOQs for customized items, while others might require larger orders for bulk pricing. Establishing a good relationship with your supplier can also lead to more flexible terms. -

How do I ensure the quality of leather sheaths from suppliers?

To ensure quality, conduct thorough supplier vetting by requesting samples before placing large orders. Assess the leather’s thickness, texture, and finish. Certifications or quality assurance processes can also indicate a supplier’s commitment to standards. Consider visiting the supplier’s facility if possible or using third-party inspection services to verify product quality before shipping, especially for international transactions. -

What customization options are available for leather sheaths?

Customization options for leather sheaths include size, color, and design features such as stitching patterns or additional compartments. Many suppliers offer options for embossing logos or personalizing sheaths to enhance brand visibility. When discussing customization, provide detailed specifications and examples to ensure the supplier understands your vision. Be prepared for potential costs associated with custom designs and minimum order requirements. -

What are typical payment terms for international leather sheath orders?

Payment terms can vary widely, but typical arrangements include a 30-50% deposit upon order confirmation and the balance due before shipment. Some suppliers may offer payment upon delivery or credit terms for established clients. Ensure you understand the currency exchange implications and any transaction fees involved. Using secure payment methods, such as letters of credit or escrow services, can mitigate risks in international transactions. -

How can I manage logistics when importing leather sheaths?

Managing logistics involves selecting reliable freight forwarders experienced in international shipping. Assess shipping options based on cost, speed, and reliability. Ensure all customs documentation is prepared to prevent delays. Consider the Incoterms (International Commercial Terms) to clarify responsibilities for shipping, insurance, and duties. Tracking shipments and maintaining communication with suppliers can also help streamline the logistics process. -

What are the best practices for maintaining leather sheaths?

To maintain leather sheaths, regularly clean them with a damp cloth and avoid prolonged exposure to moisture. Apply a leather conditioner periodically to keep the leather supple and prevent cracking. Store sheaths in a cool, dry place away from direct sunlight. Educate your customers about proper care to enhance the lifespan of the product, which can be a selling point when marketing your sheaths.

Top 4 How To Make A Leather Sheath Manufacturers & Suppliers List

1. Instructables – Leather Craft Essentials

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Leather Punches, Leather Glue, Leather Needle Set, Snap Fasteners, Utility Knife or Scalpel, Candle Wax, Thick Paper for Template, Optional Pulleys (cost about $4), Razor Blade (cost about $0.10 each).

2. Reddit – Leather Sheath Advice

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The user wants to make a leather sheath for a new knife received as a present. They have access to soft leather used for furniture, as their dad is an upholsterer, and are seeking advice on whether this material will be suitable for the sheath.

3. Self Reliance Outfitters – Leather Knife Sheaths

Domain: selfrelianceoutfitters.com

Registered: 2011 (14 years)

Introduction: Leather knife sheaths are the most reliable material for protecting and carrying knives. Quality leather offers toughness, stability, and structure, making it quieter than plastic or nylon. However, leather is vulnerable to rain and sunshine, which can wear it down over time. Making a leather knife sheath involves using easy-to-find materials, basic tools, and detailed instructions.

4. Art of Manliness – Leather Crafting Essentials

Domain: artofmanliness.com

Registered: 2007 (18 years)

Introduction: Materials and Tools: Leather (medium weight 5 to 6 ounces), Rotary cutter or X-Acto knife, Pencil, Cardboard from file folder, Rowel wheel, Fid, Groover tool, Waxed artificial sinew or thread, Leather-stitching needles, Pie pan of water, Spring clips, Saran wrap, Tape, Dishtowel.

Strategic Sourcing Conclusion and Outlook for how to make a leather sheath

The process of creating a leather sheath is not only a craft but also an opportunity for strategic sourcing that can enhance your business’s value proposition. By leveraging local resources, such as upcycled leather scraps and collaborating with local artisans, B2B buyers can significantly reduce production costs while supporting sustainable practices. This approach not only fosters community relationships but also aligns with global trends toward sustainability and ethical sourcing.

Furthermore, investing in quality tools and materials—such as specialized leather punches, glues, and fasteners—ensures the durability and aesthetic appeal of the final product. As international markets continue to grow, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for well-crafted leather goods is likely to increase.

In conclusion, as you explore the potential of leather sheath production, consider the benefits of strategic sourcing to enhance product quality and sustainability. Embrace innovation and craftsmanship to differentiate your offerings in the competitive global marketplace. Engage with local suppliers and artisans today to position your business for success tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how to make a leather sheath