Introduction: Navigating the Global Market for leather fabric texture

In an increasingly competitive global market, sourcing high-quality leather fabric texture can pose significant challenges for B2B buyers. With diverse applications ranging from luxury automotive interiors to high-end fashion and furniture, understanding the nuances of leather texture is crucial. This guide is designed to empower international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, including key markets such as Saudi Arabia and Brazil. By providing an in-depth exploration of various types of leather textures, their applications, and the intricacies of supplier vetting, we aim to facilitate informed purchasing decisions that align with your business needs.

Throughout this comprehensive guide, you will find insights into the different categories of leather fabric textures, including full grain, nubuck, and suede, along with their respective properties and uses. We will also address critical factors such as cost considerations, quality assessment, and sustainability practices, which are increasingly important in today’s eco-conscious marketplace. With this knowledge at your fingertips, you’ll be better equipped to navigate the complexities of sourcing leather textures, ensuring that your procurement strategies not only meet aesthetic and functional requirements but also resonate with the values of your target market. By the end of this guide, you will have a robust framework for making strategic decisions that enhance your competitive edge in the global leather fabric industry.

Table Of Contents

- Top 3 Leather Fabric Texture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather fabric texture

- Understanding leather fabric texture Types and Variations

- Key Industrial Applications of leather fabric texture

- 3 Common User Pain Points for ‘leather fabric texture’ & Their Solutions

- Strategic Material Selection Guide for leather fabric texture

- In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric texture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric texture’

- Comprehensive Cost and Pricing Analysis for leather fabric texture Sourcing

- Alternatives Analysis: Comparing leather fabric texture With Other Solutions

- Essential Technical Properties and Trade Terminology for leather fabric texture

- Navigating Market Dynamics and Sourcing Trends in the leather fabric texture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric texture

- Strategic Sourcing Conclusion and Outlook for leather fabric texture

- Important Disclaimer & Terms of Use

Understanding leather fabric texture Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains natural grain, durable, high-quality | Luxury goods, high-end furniture, automotive | Pros: Exceptional durability, develops patina; Cons: Higher cost, requires maintenance. |

| Top Grain Leather | Sanded surface for a smooth finish, less durable than full grain | Fashion accessories, upholstery, bags | Pros: More affordable, versatile; Cons: Less natural appearance, may not age as well. |

| Suede | Soft, napped finish, often made from the underside of the hide | Clothing, footwear, upholstery | Pros: Luxurious feel, good for fashion; Cons: Prone to staining, less durable. |

| Nubuck | Sanded top layer, velvety texture, more durable than suede | Footwear, upholstery, luxury items | Pros: Durable, soft texture; Cons: Requires special care, susceptible to water damage. |

| Faux Leather | Synthetic alternative to real leather, various textures | Cost-effective alternatives, fashion, upholstery | Pros: Animal-friendly, easy maintenance; Cons: Less breathable, may not last as long as genuine leather. |

What Are the Characteristics of Full Grain Leather and Its Suitability for B2B Buyers?

Full grain leather is recognized for its natural grain, which retains the hide’s unique characteristics. This type of leather is highly durable and ages beautifully, developing a rich patina over time. It is primarily used in luxury goods, high-end furniture, and automotive interiors, making it a preferred choice for businesses targeting premium markets. When considering full grain leather, buyers should note its higher cost and the need for regular maintenance to preserve its appearance and longevity.

How Does Top Grain Leather Differ and What Are Its Key B2B Applications?

Top grain leather is crafted by sanding the surface of the hide, resulting in a smooth finish that is less durable than full grain leather. It is commonly used in fashion accessories, upholstery, and bags, appealing to businesses looking for a balance between quality and affordability. Buyers should consider that while top grain leather is versatile and generally more affordable, it may lack the natural look and longevity associated with full grain options.

What Makes Suede a Popular Choice for Fashion and Upholstery?

Suede features a soft, napped finish created from the underside of the hide, offering a luxurious feel that is popular in clothing, footwear, and upholstery. Its aesthetic appeal makes it a sought-after material in fashion industries. However, buyers must be aware that suede is prone to staining and may not offer the same durability as other leather types, which could impact its long-term viability in high-traffic applications.

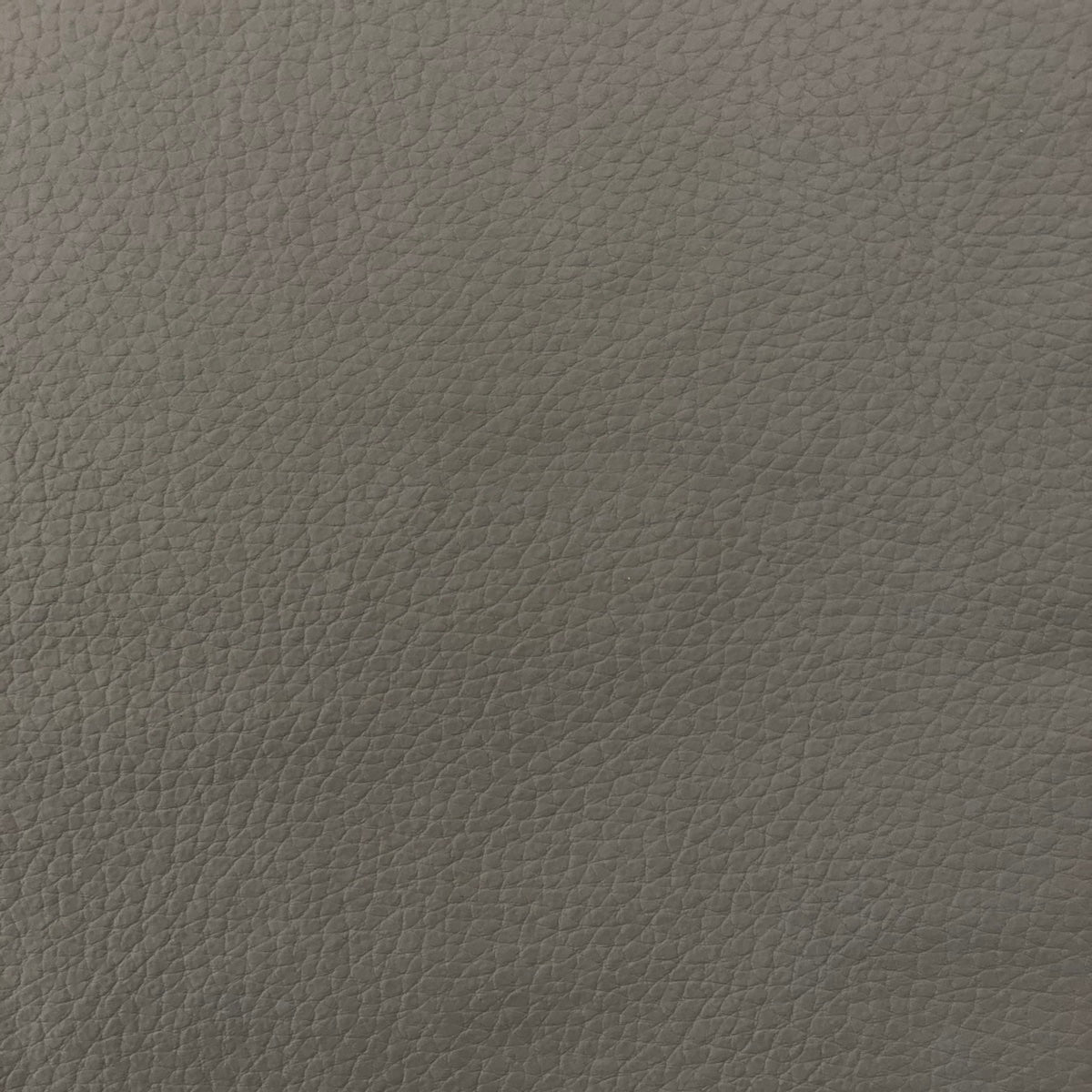

Illustrative image related to leather fabric texture

How Does Nubuck Compare to Other Leather Types in Terms of Durability?

Nubuck leather is similar to suede but is made from the outer layer of the hide, giving it a velvety texture and greater durability. It is often used in footwear, upholstery, and luxury items, appealing to businesses that prioritize both aesthetics and longevity. Buyers should consider the special care required for nubuck to prevent water damage and maintain its appearance, as this could influence the total cost of ownership.

Why Choose Faux Leather for Cost-Effective Solutions?

Faux leather, a synthetic alternative, offers a variety of textures and finishes, making it a popular choice for cost-effective solutions in fashion and upholstery. It provides an animal-friendly option that is easy to maintain and clean. While buyers appreciate the affordability and ethical considerations of faux leather, they should also be aware of its limitations in breathability and potential longevity compared to genuine leather.

Key Industrial Applications of leather fabric texture

| Industry/Sector | Specific Application of leather fabric texture | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for luxury vehicles | Enhances brand image and customer experience | Look for high durability and resistance to wear and tear |

| Fashion & Apparel | High-end clothing and accessories | Provides a premium feel and aesthetic appeal | Ensure compliance with ethical sourcing and sustainable practices |

| Furniture | Upholstered furniture and decor | Adds luxury and comfort, increasing perceived value | Consider customization options and color variety |

| Interior Design | Wall coverings and decorative elements | Creates a sophisticated ambiance | Assess texture variety and compatibility with design themes |

| Home Goods | Bags, wallets, and small leather goods | Offers durability and style, appealing to consumers | Focus on sourcing from reputable suppliers with quality assurance |

How is Leather Fabric Texture Used in the Automotive Sector?

In the automotive industry, leather fabric texture is primarily utilized for upholstery in luxury vehicles. The use of leather enhances the vehicle’s aesthetic appeal, providing a premium look and feel that can significantly elevate the brand image. Buyers in this sector often seek high durability and resistance to wear and tear, ensuring that the leather can withstand various environmental conditions while maintaining its luxurious appearance. Additionally, sourcing from suppliers who adhere to sustainable practices is increasingly important to align with consumer preferences.

What Role Does Leather Fabric Texture Play in Fashion and Apparel?

In the fashion and apparel sector, leather fabric texture is a staple for high-end clothing and accessories, such as jackets, bags, and shoes. The luxurious nature of leather not only enhances the aesthetic appeal but also adds a unique tactile experience that consumers value. B2B buyers in this industry must prioritize ethical sourcing and sustainable production methods to meet market demands. They should also consider the specific leather types, such as full-grain or suede, which can influence the final product’s quality and marketability.

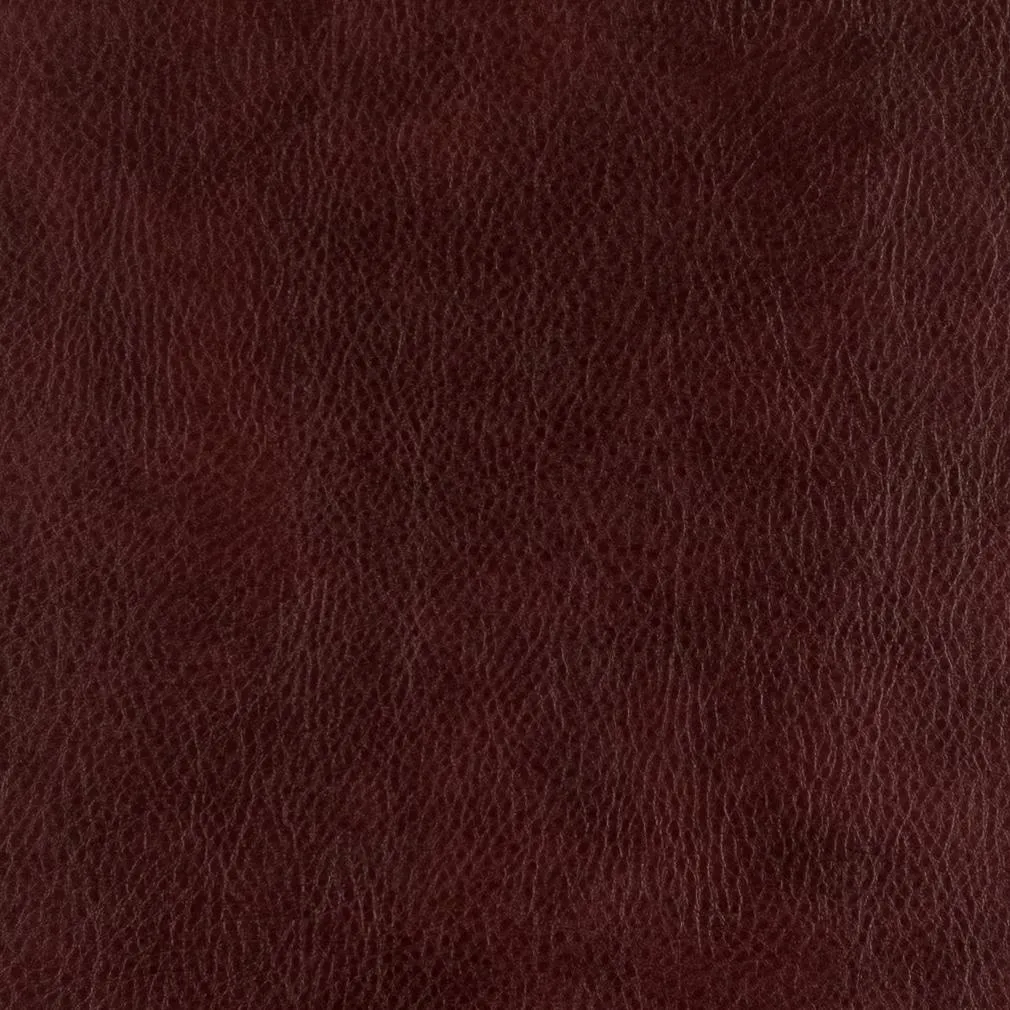

Illustrative image related to leather fabric texture

How is Leather Fabric Texture Integrated into Furniture Design?

Leather fabric texture is a sought-after material in the furniture industry, particularly for upholstered pieces like sofas and chairs. The addition of leather not only increases the comfort and luxury of furniture but also enhances its perceived value, making it a preferred choice for high-end interior designs. Buyers must consider customization options, such as color and texture variety, to meet diverse consumer preferences. Sourcing quality leather that meets durability standards is crucial to ensure longevity and customer satisfaction.

In What Ways Does Leather Fabric Texture Enhance Interior Design?

In interior design, leather fabric texture is often used for wall coverings and decorative elements, contributing to a sophisticated ambiance in residential and commercial spaces. The versatility of leather allows designers to create unique and luxurious environments that resonate with clients. B2B buyers should assess the variety of textures available, ensuring compatibility with their overall design themes. Additionally, they should consider the environmental impact of sourcing leather, opting for suppliers who prioritize sustainability.

How is Leather Fabric Texture Applied in Home Goods?

Leather fabric texture is widely used in the production of bags, wallets, and other small leather goods. These products are favored for their durability and stylish appearance, appealing to a wide range of consumers. B2B buyers in this sector should focus on sourcing from reputable suppliers who guarantee quality assurance, as well as exploring customization options to differentiate their offerings in a competitive market. Understanding the latest trends in color and texture can also help attract discerning customers.

3 Common User Pain Points for ‘leather fabric texture’ & Their Solutions

Scenario 1: Difficulty in Matching Leather Textures with Design Specifications

The Problem: B2B buyers often face challenges when trying to match specific leather textures with their design requirements. This issue is particularly prevalent in industries such as furniture manufacturing and automotive upholstery, where the aesthetic and tactile qualities of leather are crucial. Buyers may receive samples that do not meet their expectations in terms of color, finish, or texture consistency, leading to potential delays in production and increased costs. Additionally, variations in leather quality from different suppliers can complicate the sourcing process.

The Solution: To effectively address this issue, buyers should establish clear specifications for the desired leather texture, including color codes, grain patterns, and finishes. Collaborating with suppliers who offer a wide range of high-quality leather options can significantly reduce the risk of mismatches. Utilizing digital tools, such as color-matching software or virtual design platforms, can help visualize how different textures will look in the final product. Furthermore, requesting multiple samples from different suppliers and conducting side-by-side comparisons can provide a more accurate assessment of texture compatibility. Establishing a strong communication line with suppliers about expectations and quality standards is also essential.

Illustrative image related to leather fabric texture

Scenario 2: Concerns Over Leather Sustainability and Ethical Sourcing

The Problem: As global awareness of sustainability and ethical sourcing grows, B2B buyers are increasingly concerned about the environmental impact of leather production. This is particularly true for companies in Europe and North America, where consumers demand transparency in sourcing practices. Buyers may struggle to find suppliers who can guarantee that their leather is sourced from environmentally responsible tanneries or produced using humane practices. This concern can hinder their ability to meet consumer expectations and affect brand reputation.

The Solution: B2B buyers should prioritize partnerships with suppliers who are certified for sustainable and ethical practices, such as those with environmental management certifications (e.g., ISO 14001) or those that adhere to the Leather Working Group (LWG) standards. Conducting due diligence through supplier audits or requesting certifications can ensure that the leather is sourced responsibly. Additionally, buyers can explore alternatives to traditional leather, such as plant-based or synthetic leathers that offer similar aesthetics without the environmental footprint. Engaging in transparent dialogue with suppliers about their sourcing practices can also help buyers align their procurement strategies with sustainability goals.

Scenario 3: Managing the Cost of Quality Leather Textures

The Problem: The cost of high-quality leather textures can be a significant concern for B2B buyers, especially when budgets are tight or when competing with cheaper alternatives. This is particularly relevant for manufacturers in regions like South America and Africa, where price sensitivity is high. Buyers may be tempted to compromise on quality to meet budget constraints, which can lead to inferior products and long-term costs associated with replacements or repairs.

The Solution: To manage costs effectively while ensuring quality, buyers should adopt a strategic sourcing approach that includes bulk purchasing agreements or long-term contracts with suppliers. This can often lead to volume discounts and more favorable pricing terms. Additionally, investing in high-quality leather can prove cost-effective in the long run, as it typically offers better durability and longevity. Buyers should also consider the total cost of ownership (TCO) rather than just the initial purchase price. This includes evaluating factors such as maintenance costs, replacement frequency, and the overall customer satisfaction that high-quality leather can provide. Engaging in supplier relationship management to negotiate better terms and exploring alternative materials that offer a similar look and feel at a lower price point can also be beneficial strategies.

Strategic Material Selection Guide for leather fabric texture

When selecting leather fabric textures for various applications, it is essential to consider the specific materials available, their properties, advantages, disadvantages, and how they align with the needs of international B2B buyers. Here, we analyze four common leather materials: full-grain leather, top-grain leather, suede, and faux leather. Each material has unique characteristics that can significantly influence product performance and suitability for diverse markets, particularly in Africa, South America, the Middle East, and Europe.

Illustrative image related to leather fabric texture

What Are the Key Properties of Full-Grain Leather?

Full-grain leather is the highest quality leather available, made from the top layer of the hide, which retains its natural grain. This material is known for its durability, breathability, and ability to develop a rich patina over time. Full-grain leather can withstand significant wear and tear, making it ideal for high-end products such as luxury handbags, furniture, and automotive interiors. However, it is also sensitive to moisture and requires regular maintenance to preserve its appearance.

Pros: Exceptional durability, natural aesthetics, and breathability.

Cons: Higher cost, requires maintenance, and may not be suitable for all applications due to its sensitivity to moisture.

How Does Top-Grain Leather Compare to Full-Grain Leather?

Top-grain leather is slightly less durable than full-grain leather but is more affordable and easier to maintain. It is sanded and treated to remove imperfections, providing a more uniform appearance. This material is widely used in furniture, bags, and clothing. While it offers a good balance between quality and cost, it may not develop the same depth of character as full-grain leather over time.

Pros: More affordable than full-grain, easier to clean, and has a consistent look.

Cons: Less durable than full-grain, may not age as beautifully, and can be prone to scratches.

What Are the Benefits of Using Suede Leather?

Suede leather, made from the underside of animal hides, is soft and has a unique texture. It is often used in fashion items, upholstery, and accessories. Suede is known for its luxurious feel and aesthetic appeal, but it is less durable than other leather types and can be more susceptible to stains and water damage.

Pros: Soft texture, luxurious appearance, and lightweight.

Cons: Less durable, prone to staining, and requires special care for cleaning.

Why Choose Faux Leather for Cost-Effective Solutions?

Faux leather, or synthetic leather, is made from polyurethane or polyvinyl chloride (PVC). It mimics the appearance of real leather while being more affordable and often easier to clean. Faux leather is popular in various applications, including furniture, clothing, and accessories, especially in markets where ethical considerations regarding animal products are paramount.

Pros: Cost-effective, easy to clean, and available in various colors and textures.

Cons: Less durable than genuine leather, can wear out faster, and may not have the same aesthetic appeal as real leather.

Summary of Material Selection for Leather Fabric Textures

| Material | Typical Use Case for leather fabric texture | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end furniture, luxury bags | Exceptional durability | Requires maintenance, higher cost | High |

| Top-Grain Leather | Bags, clothing, furniture | More affordable than full-grain | Less durable, may not age as well | Medium |

| Suede | Fashion items, upholstery | Luxurious feel | Less durable, prone to staining | Medium |

| Faux Leather | Budget-friendly furniture, clothing | Cost-effective, easy to clean | Less durable, may lack authenticity | Low |

In conclusion, understanding the properties and applications of different leather fabric textures is crucial for B2B buyers. Each material offers unique advantages and disadvantages, influencing the final product’s performance and appeal. Buyers in diverse regions should consider local preferences, compliance with standards, and the specific demands of their markets when selecting leather materials.

In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric texture

What Are the Key Manufacturing Processes for Leather Fabric Texture?

Manufacturing leather fabric involves several stages that ensure the final product meets both aesthetic and functional requirements. Understanding these processes is crucial for B2B buyers looking for high-quality leather textures.

Material Preparation: What Raw Materials Are Used?

The first step in the leather manufacturing process is the preparation of raw materials, which primarily consist of animal hides. Common sources include cattle, goats, and sheep. The quality of the leather largely depends on the type and condition of the hides.

Illustrative image related to leather fabric texture

-

Sourcing: High-quality hides are sourced from reputable suppliers, often through partnerships with tanneries. Buyers should verify the origin of hides to ensure ethical sourcing practices.

-

Curing: To prevent decomposition, hides undergo curing, which involves salting or drying. This step is critical in preserving the material for subsequent processing.

-

Soaking and Cleaning: After curing, hides are soaked in water to rehydrate and clean them of impurities. This process prepares the hides for the tanning phase.

How Is Leather Fabric Formed and Processed?

Once the hides are prepared, the next stages involve various techniques to transform them into usable leather fabric.

-

Tanning: This process converts raw hides into leather through chemical or vegetable methods. Tanning not only preserves the hide but also enhances its durability and appearance.

-

Splitting: After tanning, hides may be split into layers to create different grades of leather. The top layer, known as full-grain leather, retains the natural texture and characteristics of the hide, while lower layers are often processed into suede or split leather.

-

Dyeing: Leather can be dyed to achieve specific colors and finishes. This stage often utilizes aniline dyes for a natural look or pigmented dyes for a more uniform appearance.

-

Finishing: The final step involves applying coatings or treatments to enhance texture, protect against wear, and improve water resistance. Techniques such as embossing or polishing may also be employed to achieve desired surface characteristics.

What Quality Assurance Measures Are Essential in Leather Manufacturing?

Quality assurance is crucial in ensuring that leather products meet international standards and customer expectations. Various checkpoints throughout the manufacturing process help maintain quality.

What International Standards Should Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards that govern leather manufacturing. The most notable include:

Illustrative image related to leather fabric texture

- ISO 9001: This standard outlines the criteria for a quality management system, emphasizing customer satisfaction and continuous improvement.

- CE Marking: Relevant for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: For leather used in specific applications, such as automotive or medical, adherence to American Petroleum Institute standards may be necessary.

How Are Quality Control Checkpoints Structured?

Quality control checkpoints are integral to maintaining product integrity throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): Inspects raw materials upon arrival, ensuring they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): Monitors processes during production, identifying defects or deviations in real-time, allowing for immediate corrective actions.

-

Final Quality Control (FQC): Conducted before shipment, this stage ensures that the finished leather meets the agreed-upon specifications and standards.

What Common Testing Methods Are Employed in Leather Quality Control?

To assess the quality of leather fabric, various testing methods are utilized:

- Physical Testing: Involves assessments of tensile strength, tear resistance, and abrasion resistance to ensure durability.

- Chemical Testing: Checks for harmful substances, such as heavy metals and azo dyes, ensuring compliance with health regulations.

- Visual Inspection: A thorough examination for surface defects, color uniformity, and overall aesthetic appeal.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is paramount.

-

Supplier Audits: Conducting on-site audits of potential suppliers provides insight into their manufacturing processes, quality control measures, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand testing methods, results, and any corrective actions taken in case of non-compliance.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of a supplier’s adherence to quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

Quality control can vary significantly based on regional standards and practices. B2B buyers should consider the following nuances:

- Local Regulations: Different countries have specific regulations concerning leather production, which may affect compliance and quality assurance practices.

- Cultural Expectations: Buyers from different regions may have varying expectations regarding leather quality and texture, necessitating clear communication with suppliers about specific requirements.

- Logistical Considerations: Understanding the logistics of transporting leather products, including potential impacts on quality during transit, is essential for maintaining product integrity.

Conclusion: The Importance of Rigorous Manufacturing and Quality Assurance in Leather Textiles

For B2B buyers, a thorough understanding of the manufacturing processes and quality assurance practices in leather fabric production is critical. By focusing on material preparation, forming techniques, and stringent quality control measures, buyers can ensure they source high-quality leather textures that meet their specific needs. Engaging in proactive verification of supplier practices will further enhance the likelihood of successful partnerships in the leather industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric texture’

Introduction

In the competitive landscape of B2B procurement, sourcing high-quality leather fabric textures is vital for businesses aiming to create luxurious products. This guide provides a structured checklist to ensure you make informed decisions while sourcing leather textures that meet your specific needs. From understanding the various types of leather to evaluating suppliers, each step is designed to help you navigate the procurement process efficiently.

Step 1: Define Your Technical Specifications

Before starting your procurement process, it’s essential to outline your technical specifications. This includes the type of leather (e.g., full grain, top grain, suede), desired texture (e.g., pebbled, smooth, distressed), and color palette. Clear specifications will help you communicate your requirements effectively to suppliers and ensure the leather meets your product standards.

Step 2: Research Different Leather Types and Textures

Understanding the variety of leather textures available can significantly influence your purchasing decisions. Leather can range from exotic types like crocodile and lizard to more common varieties like cowhide and lambskin. Familiarize yourself with the characteristics and applications of each type to choose the most suitable option for your product line.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Request detailed company profiles, product samples, and references from other buyers in similar industries or regions. Look for suppliers with a proven track record in quality and reliability, and ensure they can meet your volume requirements and delivery timelines.

- Check Certifications: Verify any industry certifications that ensure the quality and ethical sourcing of materials.

- Assess Production Capacity: Ensure the supplier can meet your demand without compromising quality.

Step 4: Request and Analyze Samples

Once you have identified potential suppliers, request samples of the leather textures you are interested in. Analyzing samples allows you to assess the quality, feel, and overall appearance of the leather. Pay attention to factors such as durability, color consistency, and texture variations.

- Conduct Tests: Consider performing tests for abrasion resistance and colorfastness to ensure the leather meets your performance standards.

- Evaluate Aesthetics: Ensure that the texture aligns with your brand’s aesthetic and the intended use of the product.

Step 5: Negotiate Terms and Pricing

After selecting a supplier and confirming the quality of the leather, it’s time to discuss pricing and contract terms. Negotiating favorable terms can lead to long-term savings and ensure a mutually beneficial relationship. Be clear about your budget constraints while also considering the value that quality leather adds to your products.

Step 6: Establish Quality Control Measures

Implementing quality control measures is critical to maintaining product standards. Discuss inspection processes with your supplier to ensure that all leather delivered meets your specifications. This can include pre-shipment inspections or third-party quality checks to avoid discrepancies.

Step 7: Monitor Supplier Performance

Once the procurement process is complete, continuously monitor your supplier’s performance. Establish metrics for evaluating delivery times, quality consistency, and responsiveness. Regular feedback and communication will help build a strong partnership and ensure that your leather fabric sourcing remains reliable and efficient.

By following this checklist, B2B buyers can confidently source leather fabric textures that enhance their products and meet market demands effectively.

Comprehensive Cost and Pricing Analysis for leather fabric texture Sourcing

What Are the Key Cost Components in Sourcing Leather Fabric Textures?

When sourcing leather fabric textures, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The type of leather used significantly affects the overall cost. High-quality leathers like full-grain or top-grain are more expensive than lower-grade options like split leather or synthetic alternatives. The source of the leather, whether domestically produced or imported, also plays a role.

-

Labor: The complexity of the leather treatment process, such as tanning, dyeing, and finishing, determines labor costs. Skilled artisans may command higher wages, particularly in regions with a rich tradition of leather craftsmanship.

-

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and equipment depreciation. The overhead can vary based on the operational efficiency of the manufacturing plant.

-

Tooling: Custom tooling for specific textures or patterns can add to costs. Buyers should consider whether they require standard textures or if custom designs are necessary, as this will influence tooling expenses.

-

Quality Control (QC): Ensuring the leather meets specific quality standards involves additional costs related to inspections and testing. Certifications, especially for international markets, can also lead to increased QC expenses.

-

Logistics: Transportation costs, including shipping and customs duties, can vary significantly based on the supplier’s location and the buyer’s destination. Incoterms will also dictate who bears the shipping costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding typical margins in the leather industry can help buyers negotiate effectively.

How Do Price Influencers Impact the Cost of Leather Fabric Textures?

Several factors can influence the pricing of leather fabric textures:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Ordering in larger quantities often leads to discounts, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Customized textures or finishes may lead to increased costs due to the need for specialized processes or materials. Buyers should weigh the benefits of customization against the potential cost increases.

-

Materials Quality and Certifications: Leather with specific certifications (e.g., eco-friendly, sustainable sourcing) may command higher prices. Buyers should assess whether these certifications add value to their purchase.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their brand and assurance of quality, while newer suppliers might offer competitive pricing to gain market entry.

-

Incoterms: The terms of shipping and delivery (Incoterms) can impact overall costs. Buyers should clarify responsibilities for shipping, insurance, and duties, as these can significantly alter the final price.

What Are Essential Negotiation Tips for B2B Buyers?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance their negotiation outcomes:

-

Understand Total Cost of Ownership (TCO): Look beyond the initial price and consider the TCO, which includes shipping, handling, and potential costs of defects or returns. This holistic view can justify a higher upfront cost if it leads to lower long-term expenses.

-

Leverage Relationships: Building strong relationships with suppliers can yield better pricing and terms. Regular communication and trust can lead to favorable outcomes during negotiations.

-

Be Informed on Market Trends: Keeping abreast of market trends, including price fluctuations due to supply chain issues or material shortages, can empower buyers during negotiations.

-

Explore Alternative Suppliers: Having multiple potential suppliers can provide leverage in negotiations. Buyers should explore different sources and compare offerings to find the best balance of quality and price.

-

Negotiate Payment Terms: Flexibility in payment terms can lead to better pricing. Buyers should explore options such as extended payment periods or discounts for upfront payments.

What Should International Buyers Consider When Sourcing Leather Fabric Textures?

International buyers should be aware of specific nuances when sourcing leather fabric textures:

-

Cultural Differences: Understand the cultural nuances of suppliers in different regions, as this can affect communication and negotiation styles.

-

Regulatory Compliance: Ensure compliance with import/export regulations, including customs duties and tariffs, which can impact overall costs.

-

Shipping Logistics: Factor in the logistics of international shipping, including potential delays and the reliability of shipping partners.

Disclaimer on Pricing Information

Prices for leather fabric textures can vary widely based on the factors discussed above. The information provided is indicative and should be verified through direct supplier engagement for accurate quotations tailored to specific needs.

Alternatives Analysis: Comparing leather fabric texture With Other Solutions

Exploring Alternative Solutions to Leather Fabric Texture

In the quest for high-quality materials in design and manufacturing, leather fabric texture stands out for its aesthetic appeal and durability. However, various alternatives can achieve similar functional and visual goals. This analysis compares leather fabric texture with two viable alternatives: Faux Leather and Textured Fabric. Each option presents unique benefits and drawbacks, making it crucial for B2B buyers to assess their specific requirements.

| Comparison Aspect | Leather Fabric Texture | Faux Leather | Textured Fabric |

|---|---|---|---|

| Performance | Durable, high-end finish | Less durable, but versatile | Varies widely; can be durable |

| Cost | Higher initial investment | Generally lower cost | Moderate, depending on material |

| Ease of Implementation | Requires skilled labor for best results | Easier to work with; more forgiving | Dependent on fabric type; generally easy |

| Maintenance | Requires special care | Easy to clean and maintain | Varies; some are machine washable |

| Best Use Case | Luxury applications, upholstery | Budget-friendly furniture, fashion | General upholstery, casual settings |

What Are the Pros and Cons of Faux Leather?

Faux leather, often made from polyurethane or polyvinyl chloride (PVC), offers a cost-effective alternative to genuine leather. Its major advantage is affordability, making it a popular choice for budget-conscious buyers. Faux leather is also easier to clean and maintain, as it can often be wiped down with a damp cloth. However, it may not provide the same level of durability or luxury feel as genuine leather, leading to wear and tear more quickly. This option is best suited for items like budget furniture and casual fashion accessories where high-end aesthetics are less critical.

How Does Textured Fabric Compare to Leather Fabric Texture?

Textured fabric encompasses a wide range of materials, including cotton, polyester, and blends that can be designed to mimic leather or provide unique visual appeal. The performance of textured fabrics can vary significantly based on the specific material used. While some types are durable and suitable for upholstery, others may not withstand heavy use. Textured fabrics often come at a moderate cost, making them accessible for a variety of applications. They can also be easier to clean, with many options being machine washable. However, they may lack the luxurious feel and longevity associated with leather fabric texture, making them less suitable for high-end applications.

How Can B2B Buyers Choose the Right Solution?

When selecting between leather fabric texture and its alternatives, B2B buyers should consider their specific application, budget, and desired aesthetic. For luxury items or environments where durability is paramount, genuine leather remains an excellent choice despite its higher cost. Conversely, for projects focused on cost-efficiency and ease of maintenance, faux leather or textured fabric may provide the best value. Assessing the intended use case, maintenance capabilities, and budget constraints will guide buyers toward the most suitable material for their needs. Ultimately, a well-informed choice can enhance product appeal while aligning with business objectives.

Essential Technical Properties and Trade Terminology for leather fabric texture

What Are the Key Technical Properties of Leather Fabric Texture for B2B Buyers?

Understanding the technical specifications of leather fabric textures is crucial for B2B buyers to make informed purchasing decisions. Here are several key properties to consider:

-

Material Grade

– Leather is categorized into various grades, such as full-grain, top-grain, genuine leather, and bonded leather. Each grade indicates the quality and durability of the material. Full-grain leather, for instance, retains the natural texture and imperfections, making it more durable and desirable for high-end products. Buyers must assess the intended use of the leather to select the appropriate grade, as this directly impacts product longevity and customer satisfaction. -

Thickness

– The thickness of leather is measured in ounces or millimeters and significantly influences its application. Thicker leather is often used in heavy-duty applications like furniture and automotive interiors, while thinner leather may be better suited for garments and accessories. Understanding the required thickness helps buyers ensure that the leather will perform adequately in its intended environment. -

Finish Type

– Leather can be finished in numerous ways, including aniline, semi-aniline, and pigmented finishes. Aniline finishes offer a natural look and feel, while pigmented finishes provide more color options and are more resistant to wear and stains. Buyers should consider the finish type based on aesthetic preferences and functional requirements, as this affects both appearance and maintenance. -

Tensile Strength

– This property refers to the leather’s ability to withstand stretching and pulling forces. It is crucial for applications that require durability and resistance to wear. A higher tensile strength indicates a more robust leather, which is vital for items subjected to frequent use, such as upholstery and luggage. Buyers must ensure that the tensile strength meets the demands of their specific applications. -

Water Resistance

– Some leather types are treated to be water-resistant, while others are not. This property is essential for products exposed to moisture, such as outdoor gear or automotive interiors. Understanding the level of water resistance helps buyers determine the suitability of leather for their intended application, minimizing the risk of damage over time.

What Trade Terminology Should B2B Buyers Know When Purchasing Leather Fabric Textures?

Familiarity with industry jargon is essential for effective communication and negotiation in the leather market. Here are several common terms that B2B buyers should be aware of:

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that manufactures products that are sold under another company’s brand name. In the leather industry, OEMs often produce leather goods for various brands. Understanding OEM relationships can help buyers navigate partnerships and ensure quality control. -

MOQ (Minimum Order Quantity)

– MOQ represents the smallest quantity of a product that a supplier is willing to sell. For leather fabrics, MOQs can vary widely based on the type, quality, and supplier. Knowing the MOQ is vital for buyers to align their purchasing strategy with their production needs and budget constraints. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers requesting pricing information and terms for specific products. In the leather industry, issuing an RFQ can help buyers compare quotes from multiple suppliers, ensuring they secure the best price and terms for their leather fabric needs. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is critical for B2B buyers to determine liability, shipping responsibilities, and cost allocation, ensuring smooth transactions across borders. -

Lead Time

– Lead time is the amount of time it takes for a supplier to fulfill an order after it has been placed. In the leather industry, lead times can vary based on factors such as customization and production capacity. Buyers should consider lead times in their planning to avoid delays in product availability.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing leather fabric textures, ensuring they meet their business needs effectively.

Navigating Market Dynamics and Sourcing Trends in the leather fabric texture Sector

What Are the Current Market Dynamics and Key Trends in the Leather Fabric Texture Sector?

The leather fabric texture market is experiencing robust growth, driven by several global factors. The rising demand for luxury goods, especially in emerging markets like Africa and South America, is fueling the need for high-quality leather textures in fashion, automotive, and furniture industries. Technological advancements in production techniques, including digital printing and improved tanning processes, are enabling manufacturers to offer a wider variety of textures and finishes. Additionally, the trend toward customization is gaining traction, with businesses seeking unique leather textures to differentiate their products in a competitive market.

International B2B buyers are increasingly prioritizing suppliers that utilize sustainable practices and innovative technologies. For instance, the integration of AI in supply chain management is enhancing sourcing efficiency, allowing buyers to quickly identify suitable suppliers and negotiate better terms. Furthermore, the demand for faux leather and alternative materials is on the rise, reflecting a shift in consumer preferences towards cruelty-free and environmentally friendly options. This trend is particularly pronounced in regions like Europe and the Middle East, where consumers are more environmentally conscious.

How Is Sustainability Shaping the Leather Fabric Texture Supply Chain?

Sustainability is becoming a crucial factor in the leather fabric texture sector, with increasing awareness of environmental impacts associated with traditional leather production. The tanning process, often involving harmful chemicals, poses risks not only to the environment but also to workers’ health. As a result, B2B buyers are gravitating towards suppliers that prioritize ethical sourcing and sustainable practices.

Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining importance in the procurement process. These certifications ensure that the leather is produced using environmentally friendly methods and that labor practices adhere to ethical standards. By sourcing leather textures that meet these certifications, businesses can enhance their brand reputation and appeal to a growing segment of eco-conscious consumers. Moreover, the use of plant-based tanning processes and recycled materials in production is becoming more prevalent, offering buyers innovative options that align with their sustainability goals.

How Has the Leather Fabric Texture Market Evolved Over Time?

The evolution of the leather fabric texture market reflects broader shifts in consumer behavior and technological advancements. Historically, leather was primarily sourced from livestock, with traditional tanning methods dominating the industry. However, the late 20th century saw a rise in synthetic materials, leading to the development of faux leather, which offered a more affordable and cruelty-free alternative.

Illustrative image related to leather fabric texture

In recent years, there has been a resurgence of interest in genuine leather, driven by its durability and luxury appeal. At the same time, advancements in technology have allowed for the creation of high-quality synthetic alternatives that mimic the look and feel of natural leather. This duality has led to a diverse market landscape, where both genuine and faux leather textures coexist, catering to varying consumer preferences and values. As the market continues to evolve, international B2B buyers must stay attuned to these trends to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric texture

-

1. How do I choose the right leather fabric texture for my project?

Selecting the appropriate leather fabric texture depends on the intended use and the aesthetic you aim to achieve. Consider factors like durability, softness, and the specific visual appeal you want, such as smooth, distressed, or embossed finishes. If you’re creating high-end products, opt for full-grain or top-grain leather, while for more budget-friendly options, faux or split leather may suffice. Additionally, sample swatches can help you evaluate the texture and color in relation to your project. -

2. What types of leather textures are available for B2B purchases?

The market offers a diverse range of leather textures, including full-grain, top-grain, suede, nubuck, and faux leather, each with distinct characteristics. Full-grain leather boasts durability and natural beauty, while suede offers a soft, luxurious touch. Faux leather can provide a cost-effective alternative with various finishes. Depending on your project needs—be it upholstery, fashion, or accessories—select the texture that aligns with your brand’s identity and customer expectations. -

3. How can I ensure the quality of leather fabric textures before buying?

To verify the quality of leather fabric textures, request samples from potential suppliers to assess the material firsthand. Look for certifications that indicate compliance with industry standards, such as ISO or environmental sustainability certifications. Additionally, consider supplier reviews and ratings from other B2B buyers. Establishing a trial order can also help you evaluate the product quality before committing to larger purchases. -

4. What are the minimum order quantities (MOQ) for leather fabric textures?

Minimum order quantities (MOQ) for leather fabric textures can vary significantly depending on the supplier and the type of leather. Typically, MOQs range from 50 to 500 meters or pieces. It’s essential to discuss your specific needs with the supplier to negotiate MOQs that align with your production capabilities. Some suppliers may offer flexibility for initial orders, especially if you’re establishing a long-term partnership. -

5. What payment terms should I expect when sourcing leather fabric textures internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, deposits (usually 30-50%), and balance payments upon delivery. Some suppliers may also offer net payment terms (e.g., net 30 or net 60 days) for established clients. Always clarify payment terms before placing an order, and consider using secure payment methods like letters of credit or escrow services to protect your interests in international transactions. -

6. How do I vet potential suppliers for leather fabric textures?

To vet potential suppliers, start by researching their business history, industry reputation, and customer reviews. Request references from past clients to gauge their reliability and product quality. It’s advisable to conduct on-site visits if possible or utilize third-party inspection services to assess manufacturing processes. Additionally, ensure the supplier adheres to ethical practices, including fair labor standards and environmental regulations. -

7. What logistics considerations should I keep in mind when importing leather fabric textures?

When importing leather fabric textures, consider shipping methods, transit times, and customs regulations specific to your country. Choose between air freight for faster delivery or sea freight for cost-effectiveness. Ensure that all necessary documentation, such as invoices and certificates of origin, is in order to avoid customs delays. It’s also beneficial to work with a logistics partner experienced in international trade to streamline the process. -

8. Can I customize leather fabric textures to meet my specific needs?

Many suppliers offer customization options for leather fabric textures, including color, finish, and even embossing patterns. Discuss your specific requirements with the supplier to determine the feasibility of customization and any associated costs. Keep in mind that custom orders may have longer lead times and higher MOQs, so plan accordingly to meet your project timelines.

Top 3 Leather Fabric Texture Manufacturers & Suppliers List

1. Pinterest – Designer Upholstery Fabrics

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Leather texture, Cream Leather Texture, Beige Leather Texture, Green Leather Texture, Brown Leather Texture, Gray Leather Texture, Orange Leather Texture, Smooth Leather Fabric Sample, Faux Leather Fabric, Vinyl Fabric, Upholstery Fabric, Designer Upholstery Fabric by the Yard, Textured Leather Material Samples, Seamless Leather Texture, Environmental Management System Zone High Performance Vinyl,…

2. Unsplash – Leather Texture Images

Domain: unsplash.com

Registered: 2013 (12 years)

Introduction: 1000+ Leather Texture Pictures | Download Free Images on Unsplash

3. Adobe Stock – Leather Texture Images

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Leather Texture Seamless Images – 149,683 Stock Photos, Vectors, and Videos available on Adobe Stock. Includes options for free trials to access images and videos. Various formats include images, videos, audio, templates, and 3D assets. License terms and regional options available.

Strategic Sourcing Conclusion and Outlook for leather fabric texture

As the global demand for leather fabric continues to rise, strategic sourcing emerges as a critical element for B2B buyers aiming to enhance their product offerings. By understanding the diverse range of leather textures—from classic cowhide to exotic finishes—buyers can cater to various market needs, ensuring their products stand out in competitive landscapes.

Investing in high-quality leather textures not only elevates the aesthetic appeal of products but also fosters brand loyalty among consumers who value craftsmanship and durability. For international buyers from regions such as Africa, South America, the Middle East, and Europe, establishing strong partnerships with reliable suppliers will facilitate access to premium materials that meet evolving consumer preferences.

Looking ahead, the leather fabric market is poised for innovation, driven by sustainable practices and technological advancements. B2B buyers are encouraged to stay informed about emerging trends and to leverage strategic sourcing as a means to secure a competitive edge. By prioritizing quality and sustainability in their sourcing strategies, businesses can position themselves for success in a dynamic marketplace. Embrace the opportunity to explore new textures and enhance your product line today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.